Abstract

A sol–gel derived renewable biosensor was prepared by entrapping hemoglobin (Hb) in a mesoporous carbon ceramic electrode (MCCE) in order to study the direct electron transfer of Hb and to fabricate a sensitive biosensor for hydrogen peroxide (H2O2). The Hb in the MCCE retained its original structure and still displayed good electrochemical activity in showing a pair of well-defined redox peaks as a result of direct electron transfer between Hb and the electrode surface. The MCCE possesses good biocompatibility, renewability, uniformity, and is well suited for immobilization of enzymes. The immobilized Hb was found to display good electrocatalytic activity for the reduction of H2O2, and this resulted in the design of an amperometric biosensor working at −0.3 V and capable of sensing H2O2 with a detection limit of 0.4 μM (at a S/N of 3). The catalytic reduction current is proportional to the concentration of H2O2 in the 1.0 to 220.0 μM range. This work demonstrates MCCE to be a well suited and easily accessible substrate for engineering biosensors with various kinds of potential applications.

Electroreduction of hydrogen peroxide with a mesoporous carbon ceramic electrode containing immobilized hemoglobin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays amperometric biosensors, due to their good selectivity and high sensitivity, have attracted much attention; meanwhile, the improvement of the assistant matrix for the immobilization of the enzymes or proteins is the basic purpose of the amperometric biosensing researches. Unfortunately, the designed biosensors show lower stability and durability because of aloofness of the proteins and enzymes or conformational change; therefore, finding an appropriate matrix for immobilization of redox centers is important for obtaining their direct electrochemical reaction and keeping their bioactivities [1]. In this context, immobilization of proteins and enzymes on/in the three-dimensional matrices is a promising direction which results in rapid advances in biosensing researches. Recently, various three-dimensional matrices were tested for immobilization of proteins or enzymes and then were used for the fabrication of electrochemical biosensors [2, 3]. On the other hand, mesoporous materials have become a common choice when selecting immobilization support due to some unique advantages such as high specific surface area, well-ordered pore structure, narrow pore size distribution, mechanical and chemical resistance [4–6]. Therefore, they are promising materials for the loading of biomolecules. Among them mesoporous carbon (MC), due to a large number of mesopores, well-defined pore size, flexible framework composition and good biocompatibility, attracted much attention [7, 8]. Also, contrary to most porous silica-based materials such as SBA-15 [9] and zeolite [5] that are electronic semiconductors, MC is intrinsic conductor. Hence, MC may have more interests and potential advantages for many advanced applications than other porous materials [10–12]. Despite such potential capability of MC, there are a few reports on the immobilization of biomolecules such as hemoglobin (Hb) on/in the MC [13] and its application as an enzymatic sensor for H2O2 determination.

Hb, a tetrameric protein that consists of four polypeptide chains, contains a heme group which acts as the active center to store and carry oxygen in the blood cells and is a perfect component for the investigation of electron transfer performance of proteins and correspondingly for the development of biosensors [5, 9]. Electrocatalytic activity of Hb toward hydrogen peroxide (H2O2) reduction was demonstrated in the previous reported literatures [2, 3, 5, 9, 13–16]. To our best knowledge, there isn’t any report about the direct electrochemistry of heme protein immobilized in mesoporous carbon ceramic electrode (MCCE) as a renewable modified electrode and utilized to construct Hb entrapped mesoporous carbon ceramic electrode (Hb/MCCE) biosensor.

In this work, we entrapped the Hb into the MC sol–gel matrices as a novel and renewable MC ceramic electrode: Hb/MCCE. The constructed biosensor displayed fast electron transfer and prominent catalytic ability toward H2O2 reduction with wide linear range and low detection limit. On the other hand, because of good stability, ease of fabrication, renewability and special catalytic properties, MCCE can be used as an artificial medium which suggests that this substrate has an extensive range of potential uses in biosensor developing. These arresting properties of the MC combined with the benefits of sol–gel process mainly propose that the sol–gel derived MC materials are much more valuable for electrochemical studies than the conventional carbon ceramic electrode (CCE) (which is in the same family). Therefore, this work opens a new way to broaden the applications of MCCE in electrochemical biosensors.

Experimental

Chemicals and apparatus

Hb was purchased from sigma chemical Co. (USA) and MC was prepared via silica mesoporous as a template and glucose as carbon source. All of the other chemicals were of analytical grade and were used without additional purification. All of the solutions were prepared with distillated water. Pure nitrogen gas (N2) was applied for the elimination of oxygen from solutions to prevent the conceivable oxygen reaction throughout the experiments.

AUTOLAB PGSTAT-100 (potentiostat/galvanostat) (www.metrohm-autolab.com) is equipped with a three-electrode system, Hb/MCCE, a platinum wire electrode and a silver/silver chloride (satd. KCl) electrode (Ag/AgCl) (Azar Electrode Co., Iran) respectively as working, counter and reference electrodes, and was used to complete the electrochemical experiments. The morphological and structural characterizations of the Hb/MCCE were specified by field emission scanning electron microscopy (FE-SEM) on a JSM-6700 F (JEOL Ltd., Japan) (www.jeolusa.com/) device and the JEM-1200 EX/S transmission electron microscopy (TEM).

Preparation of Hb/MCCE

Mesoporous silica was fabricated by the described process [17]. The fabricated mesoporous silica was used as the MC template in the synthesizing procedure (Electronic Supplementary Material, ESM). For the preparation of Hb/MCCE, first 50 mg of Hb was dissolved in the 5.0 mL cold water (4 °C) and then it was mixed with 200 mg of MC at 4 °C while it was stirring for about 5 hours. The combination was left to dry in desiccator at 4 °C for about 48 h. Silica sol was prepared according to the following process: 0.30 mL of methanol, 0.15 mL of methyltrimethoxysilane and 10 μL of HCl (11 M) were mixed. This mixture was sonicated about 0.5 h and stored at room temperature for 24 h, after which Hb-impregnated MC was added and the obtained combination was shaken for 1 min at 4 °C. A 5-mm length of a Teflon tube (3–4 mm i.d.) was filled with the sol–gel Hb/MC mixture and dried for a week at 4 °C. The CCE and Hb/CCE were also prepared in the same way as above, except that the carbon powder was used instead of MC.

Results and discussion

Characteristics of MC and MCCE surface

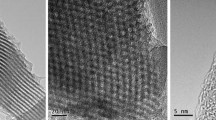

The characteristic FE-SEM images of the prepared MC with low (Fig. 1a) and high magnification (Fig. 1b) are shown in Fig. 1. Figure 1a demonstrates the uniform structure with approximately equal sizes for the fabricated MC particles. The high magnification displays that the MC consists of small spherical units with the particle sizes ranging from 20 to 50 nm (Fig. 1b). Furthermore the examination was accomplished by TEM. Figure 1 also shows the TEM images of synthesized MC in this work (Fig. 1c and d). These images show the separate pores with three dimensional unified channel organizations. The fabricated MC reveals a pore diameter of about 2–5 nm with the wall thickness of around 5 nm. The obtained results show that the resulted MC can be applied as a suitable matrix for enmeshment of biological compounds in biosensor development.

Moreover, the surface images of fabricated MCCE with low (Fig. 1e) and high (Fig. 1f) magnification are also shown in Fig. 1. The morphology of MCCE surface is gritty with a three-dimensional and porous arrangement. This proves that MC materials are surrounded by the jagged network of the sol–gel prepared electrode and formed a porous medium which creates a fitting matrix for capturing hemoproteins or enzymes.

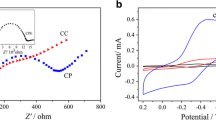

Direct electrochemistry of Hb/MCCE

The direct electrochemistry of Hb in the fabricated Hb/MCCE was studied by cyclic voltammetry. Curve a in Fig. 2 illustrates the cyclic voltammogram of the Hb/MCCE in 0.1 M, pH 7.0, N2-saturated phosphate buffer solution at the scan rate of 100 mV/s. The Hb/MCCE showed a couple of well-defined and quasi-reversible redox peaks at −0.236 V (Epc) and −0.085 V (Epa) with a peak-to-peak separation of about 150 mV. This represents the characteristic of heme Fe(III)/Fe(II) redox couples of Hb [3, 6, 18, 19] which indicated that the direct electron transfer of Hb with MCCE had taken place and MCCE can realize the direct electrochemistry of Hb. On the other hand, in order to compare the electron transfer of Hb in the MCCE with CCE (which is in the same family), direct electrochemistry of Hb trapped into CCE (Hb/CCE) was explored using cyclic voltammetry in N2-saturated 0.1 M phosphate buffer solution (pH 7.0). According to Fig. 2 curve b, no redox peak was perceived for the Hb/CCE. This phenomenon reveals that direct electron transfer between Hb and MCCE was greatly enhanced and MCCE could provide a favorable 3D material for the proteins and could play an important role in improving the electron exchange, due to its good biocompatibility, large surface, large number of mesopores, and high conductivity. In other words, it can be concluded that the MCCE has an immense effect on the kinetics of electrode reaction and produces a satisfactory environment for the Hb to transfer electron in the prepared electrode and provides a favorable nanoenvironment to avoid denaturation of Hb molecules [20, 21]. Additionally, as it can be seen in Fig. 2 curve a, the shape of the anodic to cathodic peaks are approximately symmetric, and the reduction and oxidation peak heights are similar. These behaviors suggest that all of the electroactive HbFe (III) centers on the electrode surface are transformed to HbFe (II) in the sweep forward to negative potential and vice versa.

To further investigate the characteristics of Hb at the Hb/MCCE electrode, the effect of the varying scan rate on the peak current was investigated. The cyclic voltammograms of Hb/MCCE at various scan rates were shown in Fig. 3. The peak current and also the separation of peak to peak increase with the increasing scan rate. The anodic and cathodic currents (Ipa and Ipc) of the immobilized Hb are linearly proportional to the scan rate (Ipa = 0.4941ν −11.896, R2 = 9968 and Ipc = 0.4847ν +9.799, R2 = 9976, respectively) in the range of 20 to 300 mVs−1 and this indicates a characteristic surface-controlled electrode procedure [5, 22]. According to Laviron’s equations [23], the potentials of the anodic and cathodic peaks were linearly reliant on the scan rates (ν) logarithm with the slopes of 2.3RT/ (1-α) nF and −2.3RT/αnF, correspondingly (Fig. S1, ESM). The value of the electron transfer coefficient (α) was estimated to be 0.57 and the rate constant (ks) of heterogeneous electron transference was calculated with the following equation [23]:

where α is the coefficient of charge transfer, ν is the scan rate, ΔEp is the separation of anodic to cathodic peak potential, n is the electron transfer number and the F, R and T symbols have their ordinary meanings. From the Eq. (1), ks was estimated to be 1.05 s−1. This value is much larger than those reported for the Hb immobilized on the other materials: AuNPs (0.490 s−1) [24], Hb/C60-MWCNT (0.39 s−1) [25], CNT powder (0.0620 s−1) [26], macroporous gold (0.950 s−1) [27], Fe3O4@AuNPs (1.03 s−1) [22], PSMAC/MWCNTs (0.84 s−1) [28], nano CaCO3 (0.75 s−1) [29], SnO2 (0.53 s−1) [30], TiO2 (0.137 s−1) [31], and WO3 (0.97 s−1) [32]. Such results indicate that the MCCE provides a suitable nanoenvironment for increasing the electron transfer rate of Hb.

Finally, the effect of pH on the Ep of anodic and cathodic waves was examined and a slope of about −60 mV/pH was obtained for both of them (Fig. S2, ESM).

Electrocatalytic reduction of H2O2 at the Hb/MCCE

Proteins and enzymes with heme group such as Hb, cytochrome c, horseradish peroxidase and myoglobin have high ability in reducing H2O2 electrocatalytically [2, 3, 5, 13]. So to explore the activity of Hb at the Hb/MCCE, its performance to the H2O2 reduction was deliberated. Fig. 4 exhibits the cyclic voltammograms of the Hb/MCCE in 0.1 M phosphate buffer solution (pH 7.0) and in the absence (a) and presence (b-e) of H2O2. The comparison of curve a and curves b to e reveals that after H2O2 addition, the reduction peak current growth goes along with decrease in the oxidation peak current. These behaviors show that the catalytic H2O2 reduction really develops from the Hb captured on/in the MC-silica network. The obtained results show that the immobilized Hb in the MC matrix reserved its bioactivity on/in the electrode and exhibited admirable electrocatalytic performance toward the H2O2 reduction. The common reaction for H2O2 reduction by Hb can be stated as following [26]:

Corresponding to the above equations, the added H2O2 upsurges the heme group oxidation form in the vicinity of the modified electrode, causing to amplifying the reduction current and vanishing the anodic current. On the other hand, as it might be expected, insignificant response to H2O2 was originated for the Hb/CCE (data not shown here).

Amperometric detection of H2O2 at the Hb/MCCE

The capability of the obtained biosensor was examined by challenging the Hb/MCCE with H2O2 increasing concentrations. The amperometric trial was performed in a stirred cell containing 0.1 M phosphate buffer solution (pH 7.0) in the optimized working electrode potential of −0.3 V. Figure 5 shows the cathodic current responses of the Hb/MCCE to frequent additions of H2O2 concentrations. The reaction happening at the Hb/MCCE very rapidly reaches a dynamic steadiness upon each addition of the H2O2, producing a steady-state current signal within 5–10 s. As exhibited in inset A of Fig. 5, the obtained linear range is around 1.0 to 220.0 μM (R2 = 0.994), and the detection limit is estimated to be 0.4 μM (S/N = 3). The apparent Michaelis-Menten constant (KM) which gives an indication of the enzyme-substrate kinetics and provides a way to compare the concerned H2O2 sensor with others can be calculated from the Lineweaver-Burk equation [34] (1/Iss = KM/ImaxC + 1/Imax), where ISS is the steady-state current after the addition of substrate, C is the bulk concentration of the H2O2, and Imax is the maximum current measured under saturated substrate conditions. The KM for the Hb/MCCE was estimated to be 0.125 mM (Fig. S3, ESM), which is smaller than those of Hb in sodium alginate-MWCNTs composite film of 0.533 mM [34] and Hb in silica sol–gel film of 0.898 mM [35]. This indicates that Hb entrapped in the Hb/MCCE exhibits a high affinity and catalytic activity to H2O2. Moreover with the purpose to demonstrate the applicability of the obtained biosensor for real sample analysis, 10, 50, 100 and 200 μM H2O2 were added into rain water samples, respectively. The average recovery of the biosensor was 98.1 %, 96.3 %, 101.5 % and 102.0 % (n = 5), respectively. The mean value of average recovery, 99.48 %, indicates that the potential practical application of Hb/MCCE biosensor for H2O2 in real samples.

Amperometric responses of Hb/MCCE to stepwise addition of H2O2 (1.0 to 220 μM) in 0.1 M phosphate buffer solution (pH 7.0) under the conditions of −0.30 V constant potential and rotation speed is 1000 rpm. Plot of amperometric current vs. H2O2 concentration, inset (a). Current-time curves for the Hb/MCCE exposed to 0.02 mM H2O2 and Glu, AA, UA, Dp, SA, 0.1 mM each compound and finally 0.02 mM H2O2, inset (b)

Finally the response of the resultant Hb/MCCE to the usual interfering species such as salicylic acid (SA), glucose (Glu), ascorbic acid (AA), uric acid (UA), dopamine (Dp) and salicylic acid (SA) was similarly estimated under the optimized condition (−0.3 V and pH 7.0). This perfect biosensor showed no response to 0.1 mM of each of these compounds (inset B of Fig. 5). The capability of the fabricated biosensor applied in this work was compared with some other reported immobilized Hb biosensors (Table S1, ESM). This comparison discloses that our planned biosensor exhibits efficient performance for H2O2 determination.

The Hb/MCCE stability, repeatability, reproducibility and renewability

The stability of the biosensor was investigated over about 2 weeks with the storing of Hb/MCCE in 0.1 M phosphate buffer solution (pH 7.0) at 4 °C. The biosensor reserved 95 % of its initial activity after 2 weeks. The biosensor repeatability and reproducibility were estimated [36, 37] in the presence of 5.0 μM of H2O2 in 0.1 M phosphate buffer solution (pH 7.0) via 5 repetitive tests and 5 separate modified electrodes were prepared in the same way for amperometric detection of H2O2 in the optimal operating conditions. The relative standard deviation (RSD) was 2.4 % for 5 consecutive evaluations and 3.5 % for 5 separate biosensors, respectively. In order to study the renewability of the individual Hb/MCCE, its responses were verified in the presence of 5.0 μM of H2O2 in 0.1 M phosphate buffer solution (pH 7.0) after each polish. The R.S.D. value of the measured anodic peak currents for five-time polish and use was about 3.8 %, which reveals very good polishing procedure. Therefore, the Hb/MCCE was stable in the storing condition just as the stability of the conventional graphite or glassy carbon electrodes, but its surface could be refreshed by polishing. These results show that the Hb/MCCE is a stable, repeatable, reproducible and renewable modified electrode which can be used in the H2O2 biosensing.

Conclusion

This study has effectively established a capable H2O2 biosensor based on Hb entrapped in the MCCE via a simple and effective immobilization method. Direct electrochemistry investigation of Hb/MCCE demonstrated high electron transfer for Hb stabilized on/in the MCCE. The prepared Hb/MCCE biosensor successfully sensed H2O2 with short response time, long linear range and low limit of detection. The obtained biosensor indicates actual high sensitivity, long-term stability, excellent repeatability, reproducibility and renewability. The present biosensor could detect H2O2 in a linear range of 1.0 to 220.0 μM and the detection limit was found around 0.4 μM (S/N = 3). The optimistic consequences obtained in this research demonstrate that the MC-silica network is an admirable matrix for protein and enzyme entrapment, introducing a new way for the progression of high-performance electrochemical biosensors. On the other hand, the main advantage of this biosensor is its facile and fast preparation in one polishing stage. In sum, the biosensor planned in this research is very promising in the recognition of H2O2 because of the advantages of low cost, easy preparation, high sensitivity, fast response and renewability.

References

Putzbach W, Ronkainen NJ (2013) Immobilization techniques in the fabrication of nanomaterial-based electrochemical biosensors: a review. Sensors 13:4811

Wang Y-H, Yu C-M, Pan Z-Q, Wang Y-F, Guo J-W, Gu H-Y (2013) A gold electrode modified with hemoglobin and the chitosan@Fe3O4 nanocomposite particles for direct electrochemistry of hydrogen peroxide. Microchim Acta 180:659

Qing Xie X, Chen HL, Yang W (2012) Direct electrochemistry and electrocatalysis of hemoglobin immobilized on an interlaced Co(OH)2 nanosheet-based three-dimensional macroporous film. Sens Actuators B Chem 168:277

Zhou J, Huang H, Xuan J, Zhang J, Zhu JJ (2010) Quantum dots electrochemical aptasensor based on three-dimensionally ordered macroporous gold film for the detection of ATP. Biosens Bioelectron 26:834

Ren L, Dong J, Cheng X, Xu J, Hu P (2013) Hydrogen peroxide biosensor based on direct electrochemistry of hemoglobin immobilized on gold nanoparticles in a hierarchically porous zeolite. Microchim Acta 180:1333

Wang Y, Bian X, Liao L, Zhu J, Guo K, Kong J, Liu B (2012) Electrochemistry and biosensing activity of cytochrome c immobilized on a mesoporous interface assembled from carbon nanospheres. Microchim Acta 178:277

Liu B, Lu L, Hua E, Jiang S, Xie G (2012) Detection of the human prostate-specific antigen using an aptasensor with gold nanoparticles encapsulated by graphitized mesoporous carbon. Microchim Acta 178:163

Wang Y, You C, Zhang S, Kong J, Marty J-L, Zhao D, Liu B (2009) Electrocatalytic oxidation of NADH at mesoporous carbon modified electrodes. Microchim Acta 167:75

Xian YZ, Xian Y, Zhou LH, Wu FH, Jin LT (2007) Encapsulation hemoglobin in ordered mesoporous silicas: influence factors for immobilization and bioelectrochemistry. Electrochem Commun 9:142

Qureshi A, Kang WP, Davidson JL, Gurbuz Y (2009) Review on carbon-derived, solid-state, micro and nano sensors for electrochemical sensing applications. Diamond Relat Mater 18:1401

Ndamanisha JC, Guo LP (2012) Ordered mesoporous carbon for electrochemical sensing: a review. Anal Chim Acta 747:19

Lee CH, Lin TC, Mou CY (2009) Mesoporous materials for encapsulating enzymes. Nano Today 4:165

Feng J-J, Xu J-J, Chen H-Y (2007) Direct electron transfer and electrocatalysis of hemoglobin adsorbed on mesoporous carbon through layer-by-layer assembly. Biosen Bioelectron 22:1618

Baghayeri M, Nazarzadeh Zare E, Hasanzadeh R (2014) Facile synthesis of PSMA-g-3ABA/MWCNTs nanocomposite as a substrate for hemoglobin immobilization: application to catalysis of H2O2. Mater Sci Eng C 39:213

Baghayeri M, Nazarzadeh Zare E, Mansour Lakouraj M (2014) Novel superparamagnetic PFu@Fe3O4 conductive nanocomposite as a suitable host for hemoglobin immobilization. Sens Actuators B 202:1200

Zhang L, Han G, Liu Y, Tang J, Tang W (2014) Immobilizing haemoglobin on gold/graphene–chitosan nanocomposite as efficient hydrogen peroxide biosensor. Sens Actuat B Chem 197:164

Jeevan CAA (2005) Indian Patent application no. 780/Del/2005

Pan Z-Q, Fan H, Shi C-G, Bao N, Yu C-M, Gu H-Y (2011) Direct electrochemistry of hemoglobin immobilized on CdS: Mn nanoparticles. Microchim Acta 173:277

Fan H, Pan Z-Q, Gu H-Y (2010) The self-assembly, characterization and application of hemoglobin immobilized on Fe3O4@Pt core-shell nanoparticles. Microchim Acta 168:239

Li J, Tang J, Zhou L, Han X, Liu H (2012) Direct electrochemistry and electrocatalysis of hemoglobin immobilized on polyacrylamide-P123 film modified glassy carbon electrode. Bioelectrochem 86:60

Sugimoto Y, Kitazumi Y, Tsujimura S, Shirai O, Yamamoto M, Kano K (2015) Electrostatic interaction between an enzyme and electrodes in the electric double layer examined in a view of direct electron transfer-type bioelectrocatalysis. Biosen Bioelectron 63:138

Liu Y, Han T, Chen C, Bao N, Yu C-M, Gu H-Y (2011) A novel platform of hemoglobin on core-shell structurally Fe3O4@Au nanoparticles and its direct electrochemistry. Electrochim Acta 56: 3238

Laviron E (1979) General expression of the linear potential sweep voltammogram in the case of diffusionless electrochemical systems. J Electroanal Chem 101:19

Gu HY, Yu AM, Chen HY (2001) Direct electron transfer and characterization of hemoglobin immobilized on a Au colloid-cysteamine-modified gold electrode. J Electroanal Chem 516:119

Zhang H, Fan LZ, Yang SH (2006) Significantly accelerated direct electron-transfer kinetics of hemoglobin in a C60-MWCNT nanocomposite film. Chem Eur J 12:7161

Wang Y, Guo R, Xi J (2009) Comparative studies of interactions of hemoglobin with single-chain and with gemini surfactants. Colloid Interface Sci 331:470

Wang Y, Chen X, Zhu JJ (2009) Fabrication of a novel hydrogen peroxide biosensor based on the AuNPs-C@SiO2 composite. Electrochem Commun 11:323

Baghayeri M, Nazarzadeh Zare E, Namadchian M (2013) Direct electrochemistry and electrocatalysis of hemoglobin immobilized on biocompatible poly(styrene-alternative-maleic acid)/functionalized multi-wall carbon nanotubes blends. Sens Actuators B Chem 188:227

Sun W, Gao R, Jiao K (2007) Electrochemistry and electrocatalysis of hemoglobin in nafion/nano-CaCO3 film on a new ionic liquid BPPF6 modified carbon paste electrode. J Phys Chem B 111:4560

Topoglidis E, Astuti Y, Duriaux F, Grätzel M, Durrant JR (2003) Direct electrochemistry and nitric oxide interaction of heme proteins adsorbed on nanocrystalline Tin oxide electrodes. Langmuir 19:6894

Li QW, Luo GA, Feng J (2001) Direct electron transfer for heme proteins assembled on nanocrystalline TiO2 film. Electroanalysis 13:359

Feng JJ, Xu JJ, Chen HY (2006) Direct electron transfer and electrocatalysis of hemoglobin adsorbed onto electrodeposited mesoporous tungsten oxide. Electrochem Commun 8:77

Kamin RA, Wilson GS (1980) Rotating ring-disk enzyme electrode for biocatalysis kinetic studies and characterization of the immobilized enzyme layer. Anal Chem 52:1198

Zhao HY, Zheng W, Meng ZX, Zhou HM, Xu XX, Li Z, Zheng YF (2009) Bioelectrochemistry of hemoglobin immobilized on a sodium alginate-multiwall carbon nanotubes composite film. Biosens Bioelectron 24:2352

Wang QL, Lu GX, Yang BJ (2004) Hydrogen peroxide biosensor based on direct electrochemistry of hemoglobin immobilized on carbon paste electrode by a silica sol–gel film. Sens Actuators B 99:50

Baghayeri M, Nazarzadeh Zare E, Lakouraj MM (2014) A simple hydrogen peroxide biosensor based on a novel electro-magnetic poly(p-phenylenediamine)@Fe3O4 nanocomposite. Biosens Bioelectron 55:259

Ucan D, Ekiz Kanik F, Karatas Y, Toppare L (2014) Synthesis and characterization of a novel polyphosphazene and its application to biosensor in combination with a conducting polymer. Sens Actuators B Chem 201:545

Acknowledgment

The authors are grateful to the Azarbaijan Shahid Madani University Research Office (Grant No. 214/d/10802), Tabriz, Iran for financial support.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 275 kb)

Rights and permissions

About this article

Cite this article

Habibi, B., Jahanbakhshi, M. Direct electrochemistry of hemoglobin in a renewable mesoporous carbon ceramic electrode: a new kind of hydrogen peroxide biosensor. Microchim Acta 182, 957–963 (2015). https://doi.org/10.1007/s00604-014-1403-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-014-1403-6