Abstract

An electrochemical sensor for H2O2 was developed based on electrochemically deposited Prussian blue (PB) nanoparticles doped poly(3,4-ethylenedioxythiophene) (PEDOT). The PEDOT/PB composite was composed of PEDOT wrapped PB nanoparticles, where the conducting polymer PEDOT not only protected the PB particles to warrant high stability, but also connected them to enhance the electron transfer. Owing to the excellent conductivity of PEDOT and unique electrocatalytic activity of PB, the PEDOT/PB modified electrode exhibited good catalytic activity toward the electrochemical reduction of H2O2, and was used for the detection of H2O2 in concentrations ranging from 0.5 to 839 μM, with a detection limit of 0.16 μM. Moreover, the sensor also demonstrated excellent reproducibility, selectivity and long-term stability, showing great promise for the fabrication of electrochemical sensors and H2O2 related biosensors.

An electrochemical non-enzymatic sensor for hydrogen peroxide with excellent stability was developed. It is based on conducting polymer PEDOT doped with Prussian blue nanoparticles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many previous works have focused on the development of enzyme-based H2O2 sensors, which may be restricted in practical application owing to the limited lifetimes, high costs, low stability and denaturation of enzymes. An effective way to overcome these disadvantages is to develop non-enzymatic sensors for H2O2 detection. Various materials have been used for the fabrication of sensors, including metal [1–6], polypyrrole [7], MoS2 [8], carbon nanotubes [9] and materials with enzyme-like activities, such as Prussian blue (PB) [10].

PB, an “artificial enzyme peroxidase”, has been widely used as an electron transfer mediator for the construction of oxidase-based electrochemical biosensors due to its excellent reversible redox properties and good catalytic property [11–13]. However, the immobilization of electron-shuttling mediators on the interfaces of electrode faces several challenges, which is particularly true for soluble mediators with low molecular weight, because they can easily diffuse away from the electrode surface into the surrounding solution, leading to poor response performance. Nanoparticles, with increased size and molecular weights, can well address this problem owing to their unique chemical and physical properties [14, 15]. As a result of their extended surfaces, the improved activities of nanoparticles make them promising candidates for sensing and catalysis. Up to now, the synthesis and properties of PB nanoparticles have been well established [16, 17]. PB nanoparticles with improved stability have been widely used in the electrochemical sensor field due to their large surface-to-volume ratio and enhanced electrochemical properties [18, 19]. However, it is still a challenge for researchers to find suitable strategies for PB immobilization, without sacrificing its activity.

Conducting polymers have also been extensively used in the development of sensors because of their good electrical, optical and electrocatalytic properties [20]. Among various conducting polymers, poly(3, 4-ethylenedioxythiophene) (PEDOT) has been considered as the most promising one due to its outstanding stability and conductivity [21, 22]. Kulesza’ group has fabricated a structured film composed of a layer of compact chemically formed PB and a layer of electrodeposited PEDOT (the PB based inner layer was cover by PEDOT) to develop an enzyme-based biosensor for H2O2 detection [23]. In this work, pre-synthesized PB nanoparticles were electrodeposited together with PEDOT onto an electrode surface to form a homogeneous nanocomposite of PEDOT/PB in a single step. The prepared PEDOT/PB nanocomposite, with PB nanoparticles protected by a thin layer of highly conductive PEDOT, possessed a grape-like microstructure with a large surface area. The deposited PEDOT/PB exhibited excellent stability and catalytic activity, and it was directly used for the development of a non-enzymatic electrochemical H2O2 sensor.

Experimental

Reagents

3,4-ethylenedioxythiophene (EDOT), ascorbic acid (AA), uric acid (UA), and dopamine (DA) were purchased from Aladin Ltd. (Shanghai, China) (http://www.aladdin-e.com/). Acetone was purchased from Yantai Sanhe Chemical Reagent Co., China (http://11365509.czvv.com/). All reagents were of analytical grade and used as received. Millipore water from a Milli-Q water purifying system was used throughout all experiments.

Apparatus

Electrochemical experiments were carried out with the CHI760D electrochemical workstation (CH Instruments, Shanghai, China) (http://www.chinstr.com/), using a conventional three-electrode system with the platinum wire as the counter electrode, Ag/AgCl (3 M KCl) as the reference electrode and the glassy carbon electrode (GCE, diameter 3.0 mm) or modified GCE as the working electrode. The surface morphologies and microstructures of the modified electrodes were examined using a field emission scanning electron microscopy (SEM) instrument (JSM-7500F, Hitachi High-Technology Co., Japan), with an acceleration voltage of 5.0 kV. X-Ray photoelectron spectroscopy (XPS) analysis was conducted using an AXIS Ultra spectrometer with a high-performance Al monochromatic source operated at 15 kV. Transmission electron microscopy (TEM) was performed at a JEOL2010F transmission electron microscope at 20 kV.

Synthesis of PB nanoparticles

PB nanoparticles were synthesized via a facile one-step method according to the previous report [24]. 100 mL of 1.0 mM K3[Fe(CN)6] was added dropwise into an aqueous solution of 1.0 mM FeCl2 solution (100 mL) under vigorous stirring condition. The color of the solution gradually changed to dark blue, indicating that PB nanoparticles were formed. Then 400 mL of acetone was added into the above-mentioned reaction mixture to precipitate the nanoparticles. The resultant precipitate was separated by centrifugation at 9000 rpm (with a centrifugational force of 12,829 g) for 30 min and further cleaned using acetone repeatedly for three times.

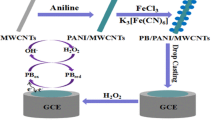

Fabrication of PB doped PEDOT modified electrodes

PEDOT/PB nanocomposite films were electrochemically deposited onto GCE surfaces from a solution of 2.0 mL water containing 2.0 mg mL−1 PB nanoparticles and 0.02 M EDOT, using a constant potential of 1.0 V for 50 s. GCEs modified with the PEDOT/PB nanocomposite were denoted as PEDOT/PB/GCE. For comparison, GCE modified with PEDOT polymerized in a solution containing 2.0 mg mL−1 K3[Fe(CN)6] and 0.02 M EDOT was prepared similarly (denoted as PEDOT/K3[Fe(CN)6]/GCE); PB nanoparticles modified GCE was prepared by drop-coating 2.0 mg mL−1 PB nanoparticles solution (10 μL) onto the electrode surface and dried in air (denoted as PB/GCE). Cyclic voltammograms (CVs) were recorded at a scan rate of 100 mV s−1. For the electrochemical detection of H2O2, different concentrations of H2O2 were added to the stirring N2-saturated phosphate buffered saline (PBS, 0.2 M, containing 0.9% NaCl) and the generated current was recorded using amperometric i-t curve technique with an applied potential of 0.0 V.

Results and discussion

Choice of materials

PEDOT has been considered to be one of the most promising conducting polymers due to its outstanding stability and conductivity. PB nanoparticles have been widely used owing to its excellent reversible redox properties and good catalytic property. However, the electrochemical stability of PB is unsatisfactory in many cases. Herein, PB nanoparticles were coated with electrodeposited PEDOT through a simple electropolymerization process, in order to improve the stability of PB and at the same time keep its electrochemical activity. The stability of the PEDOT/PB/GCE was tested in PBS (0.2 M, pH 5.7) using CV between −0.2 V and 0.6 V for 50 cycles (Fig. 1a). The PEDOT/PB/GCE shows excellent stability with slight decrease in currents of the redox peaks even after 50 CV cycles. For comparison, PEDOT/K3[Fe(CN)6]/GCE (Fig. 1c) and PB/GCE (Fig. 1b) were fabricated, respectively, and tested their stabilities under the same condition. In sharp contrast, significant decrease in currents was observed for the redox peaks of both the PEDOT/K3[Fe(CN)6]/FCE and the PB/GCE after 50 cycles. The peak current of the PB/GCE decreased significantly and it retained only 23.3% of its initial peak current after 50 cycles (Fig. 1d). The PEDOT/PB modified electrode was able to retain 82.3% of its initial value after 50 cycles, while the PEDOT/K3[Fe(CN)6] just retained 2.0%. This result clearly shows improved stability of the PEDOT/PB nanocomposite, verifying effective protection of PB with the conducting polymer PEDOT.

Characterization of PB nanoparticles and the PB doped PEDOT nanocomposite

TEM images of the PB nanoparticles are shown in Fig. 2a. The PB nanoparticles are well-dispersed and show an average diameter of approximately 40 nm. Figure 2b shows the SEM images of the PEDOT/PB nanocomposite/GCE. The PEDOT/PB film shows a grape-like microstructure, possessing a porous structure in the nanoscale with an enlarged surface area. The diameter of the PEDOT/PB particles was about 60–100 nm, which is significantly larger than that of the PB nanoparticles. As PB nanoparticals were the only dopant for the electrochemical polymerization of PEDOT, this unique grape-like microstructure might be formed through the wrapping of PB by a thin layer of PEDOT. That was, the PEDOT was polymerized around the PB nanoparticles, which connect different PB nanoparticles and protect the PB nanoparticles as a covering shell.

As shown in Fig. 2c, C 1 s, N 1 s, O 1 s, S 2p and Fe 2p core-level photoemission spectra all appeared on the XPS spectrum. Judging from the Fe 2p pattern of the PEDOT/PB nanocomposite shown in Fig. 2d, it can be revealed that the levels of Fe 2p3/2 and Fe 2p1/2 located at 711.6 eV and 722.7 eV, respectively, which came from the Fe3+ of PB nanoparticles. Moreover, an additional XPS peak at 708.6 eV can be attributed to the Fe 2p3/2 of [Fe(CN)6]4−, which was consistent with the previous literature [25].

Figure 3 shows the electrochemical impedance spectroscopy (EIS) Nyquist plots of different electrodes recorded in 5.0 mM [Fe(CN)6 4−/3-] solution containing 0.1 M KCl. The semicircle portion of the plot corresponds to the charge transfer process, with the diameter of the semicircle equivalent to the charge transfer resistance (Rct) [26], while the linear portion reflects the diffusion limited process at the electrode interface. Clearly, with the electrochemical deposition of PEDOT/PB on the GCE, the PEDOT/PB/GCE (curve a) shows a much lower Rct than that of the bare GCE (curve b). This result may be ascribed to the fact that the electrodeposited nanocomposite film is conductive and provides an increased effective surface on the electrode.

Electrochemical response to hydrogen peroxide

The electrochemical behavior of the PEDOT/PB/GCE was investigated by cyclic voltammograms. As shown in Fig. 4 curve a1, the PEDOT/PB/GCE exhibited a pair of well-defined redox peaks, corresponding to the reversible conversion of PB to Prussian white [18, 27]. In the presence of H2O2, the cathodic peak current of the PEDOT/PB/GCE is increased and the anodic peak current decreased (curve a2), indicating excellent catalytic property of the PEDOT/PB to the reduction of H2O2. However, for the bare GCE and the GCE modified with PEDOT doped with an inert macromolecule, poly(sodium-p-styrenesulfonate) (PSS), they show no obvious redox peaks in PBS (Fig. 4, curves c1 and b1), owing to the lack of redox probe like PB. After the addition of H2O2, there was no response for the GCE and the PEDOT/PSS/GCE (curves c2 and b2). Therefore, it can be concluded that the PEDOT/PB/GCE had high catalytic activity toward the reduction of H2O2, which might be ascribed to the effective incorporation of PB nanoparticles in the conductive PEDOT film.

Detection of hydrogen peroxide

In order to optimize conditions for the detection of H2O2, the influence of the deposition time of the PEDOT/PB nanocomposite and the effect of pH of the electrolyte were investigated (Fig. S1 and S2, Supporting Information). It was found that the PEDOT/PB/GCE exhibited the maximum response when the deposition time was 50 s and the pH was 4.0, respectively. The effect of the applied potential on the sensor response was also studied with different potentials ranging from −0.1 to 0.3 V (Fig. S3, Supporting Information). Clearly, the response current increased with an increase in the potential from −0.1 V to 0.0 V and then decreased in the potential from 0.0 V to 0.3 V. Therefore, a deposition time of 50 s, a pH of 4.0 and an applied potential of 0.0 V were selected as the optimum condition for the following measurements.

Figure 5 shows the amperometric i-t curve of the PEDOT/PB/GCE with successive addition of varying concentrations of H2O2. It can be observed that the PEDOT/PB/GCE exhibited a quick response to the injection of H2O2, and the steady-state current can be achieved within 5 s. Moreover, the calibration curve reveals a linear range of 0.5–839 μM (R2 = 0.9981). The limit of detection (LOD) of the H2O2 sensor was calculated to be 0.16 μM (S/N = 3). Compared with other PB modified electrodes for H2O2 [28–32] (Table 1), the PEDOT/PB/GCE sensor shows satisfying sensitivity and lower operation potential. The good sensitivity might be ascribed to the unique property of the PEDOT/PB nanocomposite. Firstly, the PEDOT/PB possessed a grape-like microstructure with large surface area for easy diffusion of H2O2 molecules. Secondly, PB nanoparticles in the nanocomposite retained good catalytic activity as an artificial enzyme for H2O2. Finally, the highly conductive PEDOT bridged PB nanoparticles effectively accelerate the electron transfer. In addition, the operation potential of 0.0 V allowed the sensor to be able to free from interferences of many electroactive molecules.

Amperometric responses of PEDOT/PB/GCE toward the successive additions of H2O2 into stirring 0.2 M PBS (pH 4.0). The working potential was 0.0 V, and the H2O2 concentrations added were 0.5, 0.8, 1.0, 2.0, 5.0, 10.0, 20.0, 30.0, 30.0, 50.0, 50.0, 70.0, 70.0, 100.0, 100.0 and 150.0 μM in sequence, and the rest additions were all 150.0 μM. Inset left, magnified portion of the amperometric response curve of the sensor. Inset right, the linear calibration curve of the H2O2 sensor

A highly selective response to the analyte over potentially competing species is another requirement for an application in real sample test. The selectivity of the PEDOT/PB/GCE to H2O2 over potentially interfering substances such DA, AA, and UA was shown in Fig. 6. The sensor shows a clear response toward the addition of H2O2, while the successive addition of DA, AA and UA with a much higher concentration gives no significant response. The effects of lactose, Mg and Ca ions have also been tested, and they generated no electrochemical response at the applied low potential of 0.0 V. The above results indicate excellent selectivity of the sensor toward H2O2.

The reproducibility of the prepared H2O2 sensor was also investigated. Five PEDOT/PB modified electrodes prepared independently were used to detect 10 μM H2O2, and the relative standard deviation (RSD) of these sensor responses was 4.5%, indicating excellent reproducibility. The stability of the sensor was also tested by measuring its current response to H2O2 every a few days over a month. The sensor current response decreased by about 2.8% after the first week and 9.2% after 30 days when stored at room temperature. The satisfying reproducibility and stability, in addition to the excellent sensitivity and selectivity, makes the PEDOT/PB based sensor highly attractive for practical applications.

Small quantities of hydrogen peroxide were added to milk in order to prevent its spoilage or extend its longevity. This strategy was effective to control the microbial growth that leads to milk spoilage [33]. To investigate the feasibility of the fabricated H2O2 sensor in practical application, the standard addition method was carried out to detect H2O2 in milk. Milk samples were firstly diluted 100 times with 0.2 M PBS (pH 5.7) contains 0.9% (0.15 M) NaCl. Then 10 mL of the diluted milk samples was added into a small electrochemical cell and standard concentration of H2O2 was spiked into the samples. As shown in Table 2, the recoveries ranged from 98.0% to 102.7%, and the RSD was between 2.4–3.8%, indicating acceptable sensing performance.

Conclusions

A H2O2 electrochemical sensor was fabricated based on the electrodeposited conducting polymer PEDOT doped with PB nanoparticles. Owing to the protection and connection with highly conductive PEDOT, PB nanoparticles were very stable. The PEDOT/PB based sensor, with an interface suitable for H2O2 diffusion and a conductive substrate favorable for electron transfer, exhibited a good sensitivity. The operation potential of 0.0 V for this electrochemical sensor warrants excellent selectivity even in the presence of other electroactive molecules. Considering its simple preparation method, excellent stability and electrochemical catalytic activity, the PEDOT/PB nanocomposite may become a promising material for constructing electrochemical sensors and biosensors associated with the assay of hydrogen peroxide. To further simplify the sensor fabrication, efforts may be made to obtained PEDOT/PB nanocomposite in one step without the pre-synthesis of PB nanoparticles.

References

Li Y, Zheng J, Sheng Q, Wang B (2015) Synthesis of Ag@AgCl nanoboxes, and their application to electrochemical sensing of hydrogen peroxide at very low potential. Microchim Acta 182(1–2):61–68

Yang Y, Fu R, Yuan J, Wu S, Zhang J, Wang H (2015) Highly sensitive hydrogen peroxide sensor based on a glassy carbon electrode modified with platinum nanoparticles on carbon nanofiber heterostructures. Microchim Acta 182(13–14):2241–2249

Ming L, Peng T, Tu Y (2016) Multiple enhancement of luminol electrochemiluminescence using electrodes functionalized with titania nanotubes and platinum black: ultrasensitive determination of hydrogen peroxide, resveratrol, and dopamine. Microchim Acta 183(1):305–310

Yang Z, Qi C, Zheng X, Zheng J (2016) Sensing hydrogen peroxide with a glassy carbon electrode modified with silver nanoparticles, AlOOH and reduced graphene oxide. Microchim Acta 183(3):1131–1136

Mei L, Zhang P, Chen J, Chen D, Quan Y, Gu N, Cui R (2016) Non-enzymatic sensing of glucose and hydrogen peroxide using a glassy carbon electrode modified with a nanocomposite consisting of nanoporous copper, carbon black and nafion. Microchim Acta 183(4):1359–1365

Wu Q, Sheng Q, Zheng J (2016) Nonenzymatic amperometric sensing of hydrogen peroxide using a glassy carbon electrode modified with a sandwich-structured nanocomposite consisting of silver nanoparticles, Co3O4 and reduced graphene oxide. Microchim Acta 183(6):1943–1951

Baghayeri M, Zare EN, Lakouraj MM (2015) Monitoring of hydrogen peroxide using a glassy carbon electrode modified with hemoglobin and a polypyrrole-based nanocomposite. Microchim Acta 182(3–4):771–779

Lin Y, Chen X, Lin Y, Zhou Q, Tang D (2015) Non-enzymatic sensing of hydrogen peroxide using a glassy carbon electrode modified with a nanocomposite made from carbon nanotubes and molybdenum disulfide. Microchim Acta 182(9–10):1803–1809

Shi L, Niu X, Liu T, Zhao H, Lan M (2015) Electrocatalytic sensing of hydrogen peroxide using a screen printed carbon electrode modified with nitrogen-doped graphene nanoribbons. Microchim Acta 182(15–16):2485–2493

Yang J, Lin M, Cho M, Lee Y (2015) Determination of hydrogen peroxide using a Prussian blue modified macroporous gold electrode. Microchim Acta 182(5–6):1089–1094

Ricci F, Palleschi G (2005) Sensor and biosensor preparation, optimisation and applications of Prussian blue modified electrodes. Biosens Bioelectron 21(3):389–407

Mokrushina AV, Heim M, Karyakina EE, Kuhn A, Karyakin AA (2013) Enhanced hydrogen peroxide sensing based on Prussian blue modified macroporous microelectrodes. Electrochem Commun 29:78–80

Kong B, Selomulya C, Zheng G, Zhao D (2015) New faces of porous Prussian blue: interfacial assembly of integrated hetero-structures for sensing applications. Chem Soc Rev 44(22):7997–8018

Zanfrognini B, Zanardi C, Terzi F, Ääritalo T, Viinikanoja A, Lukkari J, Seeber R (2011) Layer-by-layer deposition of a polythiophene/Au nanoparticles multilayer with effective electrochemical properties. J Solid State Electr 15(11–12):2395–2400

Sau TK, Rogach AL, Jäckel F, Klar TA, Feldmann J (2010) Properties and applications of colloidal nonspherical noble metal nanoparticles. Adv Mater 22(16):1805–1825

Hornok V, Dékány I (2007) Synthesis and stabilization of Prussian blue nanoparticles and application for sensors. Interf Sci 309(1):176–182

Fiorito PA, Gonçales VR, Ponzio EA, de Torresi SIC (2005) Synthesis, characterization and immobilization of Prussian blue nanoparticles. A potential tool for biosensing devices. Chem Commun 3:366–368

Haghighi B, Hamidi H, Gorton L (2010) Electrochemical behavior and application of Prussian blue nanoparticle modified graphite electrode. Sensors Actuators B Chem 147(1):270–276

Li N, He B, Xu S, Yuan J, Miao J, Niu L, Song J (2012) In site formation and growth of Prussian blue nanoparticles anchored to multiwalled carbon nanotubes with poly (4-vinylpyridine) linker by layer-by-layer assembly. Mater Chem Phys 133(2):726–734

Lange U, Roznyatovskaya NV, Mirsky VM (2008) Conducting polymers in chemical sensors and arrays. Anal Chim Acta 614(1):1–26

Bhandari S, Deepa M, Srivastava AK, Joshi AG, Kant R (2009) Poly (3, 4-ethylenedioxythiophene)-multiwalled carbon nanotube composite films: structure-directed amplified electrochromic response and improved redox activity. J Phys Chem B 113(28):9416–9428

Sundari PA, Manisankar P (2011) Development of ultrasensitive surfactants doped poly (3, 4-ethylenedioxythiophene)/multiwalled carbon nanotube sensor for the detection of pyrethroids and an organochlorine pesticide. J Appl Electrochem 41(1):29–37

Ernst A, Makowski O, Kowalewska B, Miecznikowski K, Kulesza PJ (2007) Hybrid bioelectrocatalyst for hydrogen peroxide reduction: immobilization of enzyme within organic-inorganic film of structured Prussian blue and PEDOT. Bioelectrochemistry 71(1):23–28

Zhang Q, Zhang L, Li J (2007) “Green” synthesis of size controllable Prussian blue nanoparticles stabilized by soluble starch. Nanotechnol 7(12):4557–4561

Cao L, Liu Y, Zhang B, Lu L (2010) In situ controllable growth of Prussian blue nanocubes on reduced graphene oxide: facile synthesis and their application as enhanced nanoelectrocatalyst for H2O2 reduction. ACS Appl Mater Interfaces 2(8):2339–2346

Xu M, Luo X, Davis JJ (2013) The label free picomolar detection of insulin in blood serum. Biosens Bioelectron 39(1):21–25

Karyakin AA (2001) Prussian blue and its analogues: electrochemistry and analytical applications. Electroanalysis 13(10):813–819

Zhang Y, Sun X, Zhu L, Shen H, Jia N (2011) Electrochemical sensing based on graphene oxide/Prussian blue hybrid film modified electrode. Electrochim Acta 56:1239–1245

Ghaderi S, Mehrgardi MA (2014) Prussian blue-modified nanoporous gold film electrode foramperometric determination of hydrogen peroxide. Bioelectrochemistry 98:64–69

Zhang Y, Luo H, Li N (2011) Hydrogen peroxide sensor based on Prussian blue electrodeposited on (3-mercaptopropyl)-trimethoxysilane polymer-modified gold electrode. Bioprocess Biosyst Eng 34:215–221

Gong H, Sun M, Fan R (2013) Qian L (2013) one-step preparation of a composite consisting of grapheme oxide, Prussian blue and chitosan for electrochemical sensing of hydrogen peroxide. Microchim Acta 180:295–301

Li Y, Liu X, Zeng X, Liu Y, Liu X, Wei W, Luo S (2009) Nonenzymatic hydrogen peroxide sensor based on a Prussian blue-modified carbon ionic liquid electrode. Microchim Acta 165:393–398

Saha BK, Ali MY, Chakraborty M, Islam Z, Hira AK (2003) Study on the preservation of raw milk with hydrogen peroxide (H2O2) for rural dairy farmers. Pak J Nutr 2:36–42

Acknowledgements

This research is supported by the National Natural Science Foundation of China (21275087, 21422504), the Natural Science Foundation of Shandong Province of China (JQ201406), and the Taishan Scholar Program of Shandong Province of China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOC 132 kb)

Rights and permissions

About this article

Cite this article

Wang, J., Wang, Y., Cui, M. et al. Enzymeless voltammetric hydrogen peroxide sensor based on the use of PEDOT doped with Prussian Blue nanoparticles. Microchim Acta 184, 483–489 (2017). https://doi.org/10.1007/s00604-016-2025-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-016-2025-y