Abstract

Oxidative stability of cold-pressed plum (Prunus domestica) kernel oil (PKO), and apricot (Prunus armeniaca) kernel oil (AKO) were evaluated under thermal-oxidation and photo-oxidation conditions. Changes in peroxide value (PV), conjugated dienes (K232), and levels of volatile compounds in the cold-pressed oils were monitored during storage for 12 days under oxidation conditions. Under thermal oxidation conditions, PV values of PKO reached the maximum value (63.8 meq O2/kg) after 12 days of storage, while PV values of AKO reached the maximum value (54.5 meq O2/kg) after 10 days of storage. K232 values exhibited similar behavior under accelerated oxidation conditions, wherein the highest K232 values were 12.38 and 10.91 for PKO and AKO at the 12th and the 10th day of storage, respectively. Under photo-oxidation conditions, both values recorded similar behavior. At the end of storage (12th day), PV values reached 117.5 and 67.62 meq O2/kg for PKO and AKO, respectively. Similarly, the maximum K232 values were 5.72 and 4.56 for PKO and AKO, respectively. Hexanal, and E-2-heptenal recorded the values of 149.2 and 41.83 × 106 AU for the PKO after 12 days of storage under thermal oxidation conditions, while hexanal, and E-2-heptenal reach up to 199.2 and 58.88 × 106 AU for the AKO after only 10 days of storage. At the end of 12 days of storage under photo-oxidation of PKO and AKO, the aldehydes were detected as the most identified chemical group (especially hexanal, and E-2-heptenal) in the photo-oxidized PKO and AKO.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, there is an increasing interest on the efficient utilization of agro-industrial by-products. The improper disposal of fruits, vegetables and crops by-products generates pollution problems and a significant loss of biomass that might be used to obtain value-added compounds [1]. Agro-industrial wastes (i.e., olive pomace, and grape pomace) are a promising raw material for oil production due to their low costs and might be a good alternative for edible oils [2,3,4]. Non-traditional fats and oils have gained attention due to their useful and health-promoting traits [5,6,7,8,9].

Plums (family Rosaceae) are grown in different Turkish regions [10]. Plums belong to the genus Prunus spp. are among the popular processed fruits, with the global production in 2014 reaching 11.2 million tons. In this respect, Turkey is a major plums producer worldwide [11]. During fruit processing tones of fruit pits (agro-industrial by-products) are generated. As the world production of plums continues to rise, utilization of fruit pits will be of importance for the industry and environment [9, 12].

Using the stone fruits (i.e., plum and apricot) as a raw material, the Turkish food industry produces significant amounts of preserved fruits, and juices. Plum (Prunus domestica) and apricot (Prunus armeniaca), are characterized by high contents of oil, fiber, and phenolics with health-promoting effects [1, 13, 14]. Kernels of apricot and plum are produced as by-products in a significant amount from food industry. Kernels, located inside of the fruit pits, could be considered as a non-traditional source of lipidic bioactive compounds [15,16,17,18].

Plum kernels are a good source of oil which can yield over 50% [9], with a high level of oleic acid, and a moderate level of linoleic acid. Plum kernel oil (PKO) contains high amounts of sterols and tocols with beneficial traits [19]. Apricot kernels, after removing the stone, are used as roasted, salted tidbit and appetizers [14, 20]. Apricot kernel is a rich source of oil, fiber, and protein [14, 16, 21]. Apricot kernels are used for oil production. Fatty acids are the main constituents (91.5–91.8%) of apricot kernel oil (AKO), including oleic (58.3–73.4%) and linoleic (18.8–31.7%) acid [22].

PKO aroma is rich in benzaldehyde and benzyl alcohol compounds [23]. Benzaldehyde, 2-methyl-propanal, 2-methyl-butyl aldehyde, furfural, nonanal, methylpyrazine, 2,5-dimethyl-pyrazine, methoxy pyrazine, and 3-ethyl-2,5-dimethyl-pyrazine were the major volatile compounds that contribute to AKO aroma [24]. PKO and AKO could be used in cosmetics and personal care products. Besides, PKO and AKO could be used in the food products such as salad dressing and for desert flavoring [25].

Fruit kernel oils contain high levels of bioactive compounds including tocols [9, 26], and phenolic compounds [27] which contribute to the stability of the oils. Fruits kernel oils exhibited a strong resistant towards oxidation under the ambient temperature [28], wherein AKO showed high stability under moderate and high temperatures [29]. Recent studies on the stability of oils and fats highlighted the importance of studying lipids stability under thermal and photo-oxidation conditions [30, 31].

Studies on the oxidative stability of cold-pressed PKO and AKO under accelerated oxidative conditions and photo-oxidation conditions have not been carried out up to now. The aim of this work was to investigate the oxidative stability and changes in the volatile compounds of cold-pressed AKO and PKO under thermal and photo-oxidative conditions. The results may open a new and feasible area for the applications of PKO and AKO in the industrial and technological fields.

Materials and methods

Cold-pressed AKO and PKO were obtained from a local cold pressing factory (Oneva cold pressing, Istanbul, Turkey). High purity chemicals and solvents were commercially provided and used without further purification.

Fatty acid composition of AKO and PKO

Fatty acid methyl esters (FAME) were prepared according to IUPAC [32]. The gas chromatograph (GC) analysis of FAME was performed using a Shimadzu GC-2010 gas chromatograph equipped with a fused capillary DB-23 fused-silica capillary column (60 m, 0.25 mm i.d., 0.25 μm film thickness, Agilent J&W, USA). Helium with a flow rate of 0.70 mL/min was used as a carrier gas. The column temperature was adjusted to be isothermal at 190 °C for 95 min whereas the injector and detector temperatures were 230 and 240 °C, respectively. FAME were quantified as percentages of the total FAME peak areas and identified by the comparison of retention times with the reference standards.

Thermal oxidation of AKO and PKO

Three grams of oil samples were accurately weighed and placed into a 20-mL brown headspace auto sampler vial capped with a Teflon-lined septum. The oxidation was carried out in a forced-draft air oven at 60 °C. Peroxide value (PV), conjugated diene (K232) and volatile compounds released from oil samples were analyzed at the end of every twin-day up to the end of 12th day of storage under accelerated thermal oxidation conditions.

Photo-oxidation of AKO and PKO

Oil samples (3 g) were precisely poured into 20-mL clear headspace auto sampler vial capped with a Teflon-lined septum, and placed in a lightbox (Test 742, Turkey) equipped with cool white fluorescent lights. The fluorescent radiation intensity was about 3000 lx. Levels of PV, K232, and volatile compounds in oil samples were measured every 24 h wherein the storage under photo-oxidation conditions was lasted for 12 days.

Monitoring oxidation parameters

Peroxide values (PV) of the oils were determined iodometrically according to AOCS Cd 8-53 method [33]. The oils were analyzed for conjugated diene (K232) according to AOCS Cd 18-90 method [33].

Analyses of volatile compounds by SPME-GC/MS

Two grams of oil sample were attentively placed in 20 mL headspace screw-top vial and allowed to equilibrate for 15 min at the constant temperature (35 °C). The headspace of samples was extracted for 45 min at 35 °C with the aid of a CTC Combi PAL (CTC Analytics AG, Zwingen, Switzerland) auto sampler with 75 μm carboxen/polydimethylsiloxane (CAR/PDMS) solid phase micro extraction (SPME) fiber. Volatile compounds were directly desorbed by inserting the fiber for 10 min into the injection port of GC maintained at the constant temperature (250 °C). Analyses of volatile compounds were performed by means of an Agilent model 7890 Series (Agilent Technologies, Santa Clara, CA, USA) GC in combination with a CTC Combi PAL autosampler and an Agilent 5975 N (Agilent Technologies, Santa Clara, CA, USA) mass selective detector. The compounds were separated in a capillary column of DB-624 (30 m length × 0.25 mm ID × 1.4 μm film thickness, Agilent Technologies, Santa Clara, CA, USA) with the following temperature program: hold for 5 min at 40 °C; 3 °C/min up to 110 °C; 4 °C/min up to 150 °C; 10 °C/min up to 210 °C and hold for 12 min. The temperatures of the injection port, ion source, quadrupole, and interface were set to be 250, 230, 150, and 240 °C, respectively. Mass spectra were recorded in full scan mode at the electron impact of 70 eV with the scan range from m/z 41 to 400.

Identification of compounds was detected by comparing mass spectra and Kovats index (KI) with the authentic standards and published data, as well as by comparing their mass spectra with the mass spectrometry library of Nist05 (National Institute of Standards and Technology, Gaithersburg MD, USA) and Wiley7.0 (Wiley, NY, USA). The parameters of KI were calculated using the series of n-hydrocarbons (C4 to C20). High purity chemicals (hexanal, limonene, p-cymene, and nonanal) were purchased from Sigma-Aldrich (St Louis, MO, USA).

Results and discussion

Fatty acid composition of PKO and AKO

Fatty acid composition of edible oils varies among plant species and the occurrence of unusual fatty acids can be used for the differentiation of plant families [34]. Fatty acid composition of PKO and AKO is shown in Table 1. It is visible from the table that oleic acid (C18:1) was the most abundant fatty acid in both oils and accounted for 75.4 and 68.7% of the total fatty acids in PKO and AKO, respectively. Linoleic acid (C18:2) was the second main fatty acid in both oils and accounted for 15.9 and 23.9% of the total fatty acids in PKO and AKO, respectively. Regarding saturated fatty acids (SFA), palmitic acid (C16:0) was the main SFA in both oils and accounted for 5.83 and 5.12% of the total identified fatty acids in PKO and AKO, respectively. The fatty acid profile of PKO and AKO is found to be in similar with those reported in the literature [35]. These results are in good agreement with the fatty acid composition for several Prunus kernels described in the literature [26, 36]. Matthaeus and Ozcan [19] found the similar results for PKO and AKO, wherein C18:1, C18:2 and C16:0 levels were 63.9–78.5%; 9.7–26.9%, and 5.4–7.3% in PKO, and 62.3–71.6%; 18.7–28.0%, and 4.9–5.7% in AKO, respectively. Oleic (62.0–70.6%), linoleic (20.5–27.7%), palmitic (5.0–7.79%) and linolenic (0.4–1.42%) acids were present in major quantity of AKO [37]. In another study, the major fatty acids detected in AKO were oleic (62.3–80.9%), linoleic (13.1–30.3%) and palmitic (3.35–5.93%) acids [21]. Recently, palmitic, oleic and linoleic acids were determined as major fatty acids in AKO [14].

The fatty acid composition of PKA and AKO is highly favorable for human nutrition. High oleic-linoleic oils are of interest because of their stability and nutritional properties. Clinical trials reported that high oleic oils showed significant reductions in total cholesterol (TC), LDL-cholesterol, triacylglycerols, TC:HDL-cholesterol and increased HDL-cholesterol. High oleic oils have favorable impacts on plasma lipid risk factors and coronary heart disease risk [38]. Linoleic acid is considered as one of the most important polyunsaturated fatty acids (PUFA) in human nutrition due to its preventive impacts for heart diseases [14, 38].

Effect of thermal-oxidation on the stability of PKO and AKO

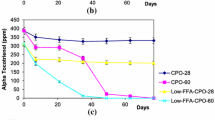

Changes in PV of PKO and AKO during the oven test at 60 °C were given in Fig. 1. The results indicated that PV tends to increase with the increasing of the storage time. At the end of 12th day of storage under the thermal oxidation condition, the PV of AKO and PKO were reached up to 24.41 and 63.82 meq O2/kg, respectively. The increment in PV for PKO was noted to be higher when compared to that of AKO. Individual headspace vials were used during the experiment; hence the volatile compounds were kept in the vials. Durmaz et al. [29] studied the roasting effect on oxidative stability of AKO at 70 °C and showed that PV increased up to 80 meq O2/kg oil at the end of 22 days of storage. There were no significant differences in the levels of PV with the result reported for n-hexane-extracted PKO that stored up to 7 days at 60 °C [39].

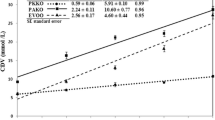

K232 values determined in the oil samples during thermal oxidation are shown in Fig. 2. After 8 days of storage under accelerated oxidation condition, K232 values of PKO was increased rapidly in comparison with AKO. After 10 days, K232 values of AKO exhibited an increase in comparison with PKO. However, at the end of storage period (12 days), K232 value of PKO was increased over the K232 value of AKO. The similar changes in the K232 values were recorded in soybean oil during storage under thermal condition [40]. This may be attributed to the fact that the fluctuations in the K232 value stem from the conjugated dienes appeared at the beginning stage of oxidation so that the dienes prone to degrade into smaller ones due to the unstable nature.

A total of 19 compounds were identified in the fresh PKO before thermal oxidation (Table 2). The identified compounds in PKO consisted of 6 aldehydes (hexanal, heptanal, E-2-heptenal, benzaldehyde, octanal, and nonanal), 4 terpenes (α-thujene, α-pinene, β-pinene, and p-cymene), 3 hydrocarbons (ethylbenzene, p-xylene, and 2,2,4,6,6-pentamethylheptane), 2 alcohols (1-pentanol, and benzyl alcohol), 2 acids (pentanoic acid, and hexanoic acid), 1 ester (isoamyl acetate), 1 furan (2-penthylfuran). Benzaldehyde with the range of 48.82 × 106 AU was the major compound of volatiles in the fresh PKO. Hexanal was the second major compound accounted for 18.32 × 106 AU in PKO. The major compounds detected in the fresh PKO were in agreement with results reported by Nunes et al. [41] and Pino et al. [42]. It is to be emphasized that the branched hydrocarbon (2,2,4,6,6-pentamethylheptane) previously found among the volatiles of Iberian pig lipids [43] is identified for the first time in PKO.

Throughout the thermal oxidation of PKO, the volatile compounds including 2 hydrocarbons (octane and nonane), 3 ketones (2-heptanone, 2-octanone, and 3-octen-2-one), 8 aldehydes (2-hexenal, 2,4-heptadienal, 2-octenal, 2,4-nonadienal isomers, 2-decenal, E,Z-2,4-decadienal, and E,E-2,4-decadienal) and 2 acids (octanoic, and nonanoic) were released constantly. Most of these compounds previously mentioned were appeared after 6 days of storage under thermal oxidation conditions. Of those compounds, 2-heptanone was first appeared as a volatile oxidation compound. E,Z-2,4-decadienal, and E,E-2,4-decadienal became apparent towards the end of storage. 2,4-decadienal was a decomposition product from heat-oxidized linoleate [44]. E,Z-2,4-decadienal, and E,E-2,4-decadienal were detected in high values upon frying of Pinus halepensis seed oil [45]. Among the compounds resulted from the thermal oxidation of PKO during storage at 60 °C, octane being released after 6 days of storage, wherein the level of octane reached the value of 70.82 AU at the 10th day of storage. Hexanal is resulted from the auto-oxidation of linoleic acid [46]. According to the experimental findings, a significant (p < 0.05) increase in the total amount of hexanal was observed during the thermal oxidation. After 6 days, there was a sharp increase in hexanal level from the initial average value of 18.32 × 106 area units to 154.86 × 106 area units in PKO.

E-2-heptenal is another major volatile compound stemming from the oxidation process of PKO due to the decomposition product of linoleate hydroperoxides [47]. In the current work, the level of E-2-heptenal compound was found to augment sharply with the increase in the thermal condition period for PKO (especially between the 4th day and the 6th day of storage). Our experimental results agree with the results of Gómez-Alonso et al. [48] who reported that hexanal and E-2-heptenal were determined as the major volatile oxidation compounds in the purified olive oil with high oleic acid content.

The volatile compounds measured in AKO during thermal oxidation are shown in Table 3. A total of nine volatile compounds were identified in the AKO before treatment. The major volatile compound found in the headspace of AKO was benzaldehyde, and hexanal was the second most common volatile compound. Benzaldehyde, exhibiting a very strong almond aroma, was found in a level of 58.40 × 106 AU in the AKO [49]. As for the hexanal contribution to the apricot aroma, the amount of volatile compound was observed to be 47.80 × 106 AU. The major volatile compounds of AKO found in this study were also reported in the apricot oil [24] and the volatile compounds have already been assigned in the apricots [50]. The content of volatile oxidation compounds was found to be in the highest level in the oxidized AKO after 10 days of storage. After 10 days of storage, hexanal with the value of 199.28 × 106 AU was the dominant volatile component in the AKO. E-2-heptenal with the value of 58.88 × 106 AU was found to be the second most volatile component in AKO. Further, 2-heptanone, heptanal, pentanoic acid, 2-penthylfuran, octanal, hexanoic acid, 3-octen-2-one and nonanal were detected, and those volatile compounds release increased up to their high values after the 10 days of storage. On the other hand, the volatile oxidation compounds of 1-pentanol, 2-hexenal, pentanoic acid, 1-octen-3-ol, 2-octanone, 2,4-heptadienal, 2-octenal, octanoic acid, 2,4-nonadienal, 2-decenal, and 2,4-decadienal were only detected after 10 days of storage under thermal conditions. The volatiles of hexanal and octane accounted for 4.1 × 103 AU in the olive oil after 8 days of storage at 60 °C [51].

Effect of photo-oxidation on the stability of PKO and AKO

Changes in the levels of PV of PKO and AKO upon photo-oxidation is shown in Fig. 3. It is clear from the figure that PV of oil samples were sharply increased. At the end of 12 days of storage, PV of AKO and PKO reached up to 67.62 and 117.5 meq O2/kg, respectively. During the storage time, the increase in PV value of PKO was higher than that of AKO. It could be noted that the impact of light irradiation on the increment of PV of AKO and PKO is higher that of the thermal oxidation. Jung et al. [52] reported that the increasing rate of PV for soybean oil stored under light irradiation conditions was slightly greater than that of soybean oil stored under thermal conditions (60 °C). This difference is related to the photosensitizers, namely the chlorophylls, that act as photosensitizer in photosynthesis of carbohydrates in plants and transfer the energy absorbed from light into the triplet oxygen that resulted in the formation of reactive radicals such as singlet oxygen [53]. Bianchi et al. [54] determined the influences of different light wavelengths with varied irradiation powers on the chlorophyll of soybean oil and reported a rapid increment in PV values of soybean oil with the decrement in the wavelength.

The K232 values for both AKO and PKO exhibited a linear increase during photo-oxidation (Fig. 4). In this respect, K232 values in PKO and AKO increased from 1.93 and 1.86 (fresh oils) to 5.72 and 4.75 after 12 days of storage, respectively. It is noteworthy that the increase rate in K232 of PKO was higher as compared to AKO during the storage in the existence of light irradiation. The similar increase was observed for PV belonging to both oils. The increment in conjugated diene values was found to be higher in the soybean oil exposed to the sunlight than that of soybean oil stored at the dark [55].

Among the volatile oxidation products in PKO, hexanal and E-2-heptenal amounts were increased with the prolonged storage time under photo-oxidation conditions (Table 4). The level of hexanal reached 48.95 × 106 AU, while the level of E-2-heptenal increased up to 20.13 × 106 AU at the end of storage. E-2-heptenal is an important volatile aldehyde induced during linoleic acid oxidation wherein the odor threshold of this compound is very low with 0.001 mg/kg [31]. The other volatile components including 1-octene, octane and 1-octen-3-ol were detected after 10 days of storage. The release of nonanoic acid was detected only at the end of storage period. Lee and Min [56] reported that E-2-heptenal, 1-octen-3-ol, and octanoic acid were measured in a linoleic acid model stored under light irradiation. Other research group reported that E-2-heptenal was detected to be more abundant in olive oil exposed to light irradiation [57].

Hexanal, 1-octene, and E-2-heptenal were the major volatile oxidation compounds detected in AKO stored under the light irradiation conditions (Table 5). Changes in hexanal, and E-2-heptenal levels were noticed to be close to each other for both oils until the tenth day of storage. After 12 days of storage, the amounts of hexanal, and E-2-heptenal sharply increased up to 100.01 × 106 and 11.57 × 106 AU, respectively. Interestingly, 1-octene (11.94 × 106 AU) was detected only at 12th day of storage. Similarly, 1-octen-3-ol, 2,4-heptadienal, and 2-octenal were determined at the end of storage. On the other hand, 2-heptanone, heptanal, 2-octanone, octanal, hexanoic acid, and nonanal levels were observed to be increased regularly during the experimental process.

Conclusion

The results of the present study provide important information on the volatile oxidation products produced in cold-pressed AKO and PKO during thermal and photo-oxidation. The increments in K232 and PV values of PKO were higher than those in AKO. In fact, light irradiation conditions resulted in more PV and K232 values than the thermal oxidation did. PV values of PKO reached the maximum value after 12 days of storage, while PV values of AKO reached the maximum value after 10 days of storage under thermal oxidation condition. K232 values exhibited the similar behavior under accelerated thermal oxidation condition. Under the photo-oxidation conditions, both PV and K232 values recorded similar behavior. There were no literature reports on the effects of thermal and photo-oxidation conditions on the volatile oxidation compounds of cold-pressed AKO and PKO, therefore, no comparison could be done with the literatures. The current study pointed out that hexanal and E-2-heptenal released during thermal-oxidation and photo-oxidation could be considered as good indicators for PKO and AKO stability.

Abbreviations

- AKO:

-

Cold-pressed apricot kernel oil

- PKO:

-

Cold-pressed plum kernel oil

- PV:

-

Peroxide value

- K232 :

-

Conjugated diene

- IUPAC:

-

International Union of Pure and Applied Chemistry

- GC:

-

Gas chromatography

- FAME:

-

Fatty acid methyl esters

- SPME:

-

Solid phase micro extraction

- KI:

-

Kovats index

References

Dulf FV, Vodnar DC, Socaciu C (2016) Effects of solid-state fermentation with two filamentous fungi on the total phenolic contents, flavonoids, antioxidant activities and lipid fractions of plum fruit (Prunus domestica L.) by-products. Food Chem 209:27–36

Özdikicierler O, Yemişçioğlu F, Gümüşkesen AS (2016) Effects of process parameters on 3-MCPD and glycidyl ester formation during steam distillation of olive oil and olive pomace oil. Eur Food Res Technol 242:805–813

Aguilar T, Loyola C, de Bruijn J, Bustamante L, Vergara C, von Baer D, Mardones C, Serra I (2016) Effect of thermomaceration and enzymatic maceration on phenolic compounds of grape must enriched by grape pomace vine leaves and canes. Eur Food Res Technol 242:1149–1158

Hammouda IB, Zribi A, Ben Mansour A, Matthäus B, Bouaziz M (2017) Effect of deep-frying on 3-MCPD esters and glycidyl esters contents and quality control of refined olive pomace oil blended with refined palm oil. Eur Food Res Technol. doi:10.1007/s00217-016-2836-4 (in press)

Górnaś P, Rudzińska M, Raczyk M, Mišina I, Soliven A, Lācis G, Segliņa D (2016) Impact of species and variety on concentrations of minor lipophilic bioactive compounds in oils recovered from plum kernels. J Agric Food Chem 64:898–905

Ramadan MF, Amer MMA, Awad A (2008) Coriander (Coriandrum sativum L.) seed oil improves plasma lipid profile in rats fed diet containing cholesterol. Eur Food Res Technol 227:1173–1182

Ramadan MF, Asker MMS, Tadros M (2012) Antiradical and antimicrobial properties of cold-pressed black cumin and cumin oils. Eur Food Res Technol 234:833–844

Ramadan MF (2013) Healthy blends of high linoleic sunflower oil with selected cold pressed oils: functionality, stability and antioxidative characteristics. Ind Crop Prod 43:65–72

Górnaś P, Mišina I, Grāvīte I, Lācis G, Radenkovs V, Olšteine A, Seglina D, Kaufmane E, Rubauskis E (2015) Composition of tocochromanols in the kernels recovered from plum pits: the impact of the varieties and species on the potential utility value for industrial application. Eur Food Res Technol 241:513–520

Özcan M (2000) Composition of some apricot (Prunus armeniaca) kernels grown in Turkey. Acta Aliment 29:289–293

FAOSTAT (2017) FAO Statistical Database. http://www.fao.org/faostat/ar/#data/QC. Accessed 24 March 2017

Kostic MD, Velickovic AV, Jokovic NM, Stamenkovic OS, Veljkovic VB (2016) Optimization and kinetic modeling of esterification of the oil obtained from waste plum stones as a pretreatment step in biodiesel production. Waste Manag 48:619–629

Sójka M, Kołodziejczyk K, Milala J, Abadias M, Viñas I, Guyot S, Baron A (2015) Composition and properties of the polyphenolic extracts obtained from industrial plum pomaces. J Funct Foods 12:168–178

Matthaus B, Özcan MM, Al Juhaimi F (2016) Fatty acid composition and tocopherol content of the kernel oil from apricot varieties (Hasanbey, Hacihaliloglu, Kabaasi and Soganci) collected at different harvest times. Eur Food Res Technol 242:221–226

Ramadan MF, Mӧrsel J-T (2004) Oxidative stability of black cumin (Nigella sativa L.), coriander (Coriandrum sativum L.) and niger (Guizotia abyssinica Cass.) upon stripping. Eur J Lipid Sci Technol 106:35–43

Ramadan MF, Zayed R, Abozid M, Asker MMS (2011) Apricot and pumpkin oils reduce plasma cholesterol and triacylglycerol concentrations in rats fed a high-fat diet. Grasas Aceites 62:443–452

Hassanien MMM, Abdel-Razek AG, Rudzińska M, Siger A, Ratusz K, Przybylski R (2014) Phytochemical contents and oxidative stability of oils from non-traditional sources. Eur J Lipid Sci Technol 116:1563–1571

Rudzińska M, Górnaś P, Raczyk M, Soliven A (2017) Sterols and squalene in apricot (Prunus armeniaca L.) kernel oils: the variety as a key factor. Nat Prod Res 31:84–88

Matthaus B, Özcan MM (2009) Fatty acids and tocopherol contents of some Prunus spp. Kernel oil. J Food Lipids 16:187–199

Asma BM, Kan T, Birhanli O (2007) Characterization of promising apricot (Prunus armeniaca L.) genetic resources in Malatya, Turkey. Genet Resour Crop Evol 54:205–212

Manzoor M, Anwar F, Ashraf M, Alkharfy KM (2012) Physicochemical characteristics of seed oils extracted from different apricot (Prunus armeniaca L.) varieties from Pakistan. Grasas Aceites 63:193–201

Tian H, Yan H, Tan S, Zhan P, Mao X, Wang P, Wang Z (2016) Apricot kernel oil ameliorates cyclophosphamide-associated immunosuppression in rats. Lipids 51:931–939

Pićurić-Jovanović K, Milovanović M (1993) Analysis of volatile compounds in almond and plum kernel oils. J Am Oil Chem Soc 70:1101–1104

Zhou B, Wang Y, Kang J, Zhong H, Prenzler PD (2016) The quality and volatile-profile changes of Longwangmo apricot (Prunus armeniaca L.) kernel oil prepared by different oil-producing processes. Eur J Lipid Sci Technol 118:236–243

Wittenberg MM (2013) The essential good food guide: the complete resource for buying and using whole grains and specialty flours, heirloom fruit and vegetables, meat and poultry, seafood, and more. Random House, LLC

Femenia A, Chen YC, Mulet A, Canellas J (1995) Chemical composition of bitter and sweet apricot kernels. J Agric Food Chem 43:356–361

Khallouki F, Haubner R, Erben G, Ulrich CM, Owen RW (2012) Phytochemical composition and antioxidant capacity of various botanical parts of the fruits of Prunus domestica L. from the Lorraine region of Europe. Food Chem 133:697–706

Sharma PC, Kamboj P, Sharma R, Raj D (2006) Storage behaviour of stone fruit kernel oils in different packages. J Food Sci Technol 43:297–300

Durmaz G, Karabulut İ, Topçu A, Asiltürk M, Kutlu T (2010) Roasting-related changes in oxidative stability and antioxidant capacity of apricot kernel oil. J Am Oil Chem Soc 87:401–409

Özkan G, Kiralan M, Karacabey E, Çalik G, Özdemir N, Tat T, Bayrak A, Ramadan MF (2016) Effect of hazelnut roasting on the oil properties and stability under thermal and photooxidation. Eur Food Res Technol 242:2011–2019

Kiralan M, Ramadan MF (2016) Volatile oxidation compounds and stability of safflower, sesame and canola cold-pressed oils as affected by thermal and microwave treatments. J Oleo Sci 65:825–833

IUPAC (1987) Standard methods for the analysis of oils, fats and derivatives: International Union of Pure and Applied Chemistry (IUPAC) Method 2.301, Report of IUPAC Working Group WG 2/87Blackwell Scientific Publications, Palo Alto, CA, USA

AOCS (1997) In: Firestone D (ed) Official methods and recommended practices of the american oil chemists’ society, 4th edn. American Oil Chemists’ Society, Champaign

Aitzetmüller K (1993) Capillary GLC fatty acid fingerprints of seed lipids-a tool in plant chemotaxonomy. J High Res Chromatogr 16:488–490

Turan S, Topcu A, Karabulut I, Vural H, Hayaloglu AA (2007) Fatty acid, triacylglycerol, phytosterol, and tocopherol variations in kernel oil of Malatya apricots from Turkey. J Agric Food Chem 55:10787–10794

Özcan MM, Unver A, Erkan E, Arslan D (2011) Characteristics of some almond kernel and oils. Sci Hort 127:330–333

Gupta A, Sharma PC, Tilakratne BMKS, Verma AK (2012) Studies on physico-chemical characteristics and fatty acid composition of wild apricot (Prunus armeniaca Linn.) kernel oil. Ind J Nat Prod Res 3:366–370

Huth PJ, Fulgoni VL, Larson BT (2015) A systematic review of high-oleic vegetable oil substitutions for other fats and oils on cardiovascular disease risk factors: implications for novel high-oleic soybean oils. Adv Nutr 6:674–693

Picuric-Jovanovic K, Vrbaski Z, Milovanovic M (1999) Influence of the aqueous-enzymatic method on the oxidative stability of plum kernel oil. Lipid/Fett 101:109–112

Dastgerdi GF, Goli SAH, Kadivar MA (2016) A new antioxidant active film based on HDPE and peppermint essential oil for packaging soybean oil. J Am Oil Chem Soc 93:657–664

Nunes C, Coimbra MA, Saraiva J, Rocha SM (2008) Study of the volatile components of a candied plum and estimation of their contribution to the aroma. Food Chem 111:897–905

Pino JA, Quijano CE (2012) Study of the volatile compounds from plum (Prunus domestica L. cv. horvin) and estimation of their contribution to the fruit aroma. Ciencia e Tecnologia de Alimentos 32:76–83

Narváez-Rivas M, Pablos F, Jurado JM, León-Camacho M (2011) Authentication of fattening diet of Iberian pigs according to their volatile compounds profile from raw subcutaneous fat. Anal Bioanal Chem 399:2115–2122

Frankel EN, Selke E, Neff WE, Miyashita K (1992) Autoxidation of polyunsaturated triacylglycerols. IV. Volatile decomposition products from triacylglycerols containing linoleate and linolenate. Lipids 27:442–446

Dhibi M, Flamini G, Issaoui M, Hammami M (2012) Volatile compounds and oxidative stability of Pinus halepensis Mill. seed oil under heating conditions. Inter J Food Sci Technol 47:1158–1164

Frankel E, Hu ML, Tappel A (1989) Rapid headspace gas chromatography of hexanal as a measure of lipid peroxidation in biological samples. Lipids 24:976–981

Frankel EN (1985) Chemistry of autoxidation: mechanism, products and flavor significance. In: Min DB, Smouse TH (eds) Flavor chemistry of fats and oils. AOCS, Champaign, pp 1–37

Gómez-Alonso S, Salvador MD, Fregapane G (2004) Evolution of the oxidation process in olive oil triacylglycerol under accelerated storage conditions (40–60 °C). J Am Oil Chem Soc 81:177–184

Guichard E, Souty M (1988) Comparison of the relative quantities of aroma compounds found in fresh apricot (Prunus armeniaca) from six different varieties. Zeitschrift für Lebensmittel-Untersuchung und Forschung 186:301–307

Gokbulut I, Karabulut I (2012) SPME-GC-MS detection of volatile compounds in apricot varieties. Food Chem 132:1098–1102

Snyder JM, Frankel EN, Selke E (1985) Capillary gas chromatographic analyses of headspace volatiles from vegetable oils. J Am Oil Chem Soc 62:1675–1679

Jung MY, Choi DS, Oh CH, Yoon SH (2015) Autoxidation and photooxidation of triacylglycerols containing conjugated linoleic acids. Food Sci Biotechnol 24:1987–1994

Choe E, Min DB (2006) Chemistry and reactions of reactive oxygen species in foods. Crit Rev Food Sci Nutr 46:1–22

Bianchi LM, Duncan SE, Webster JB, Neilson AP, O’Keefe SF (2015) Contribution of chlorophyll to photooxidation of soybean oil at specific visible wavelengths of light. J Food Sci 80:C252–C261

Anwar F, Shahid Chatha SA, Ijaz Hussain A (2007) Assessment of oxidative deterioration of soybean oil at ambient and sunlight storage. Grasas Aceites 58:390–395

Lee J, Min DB (2010) Analysis of volatile compounds from chlorophyll photosensitized linoleic acid by headspace solid-phase microextraction (HS-SPME). Food Sci Biotechnol 19:611–616

Kanavouras A, Hernandez-Münoz P, Coutelieris F, Selke S (2004) Oxidation-derived flavor compounds as quality indicators for packaged olive oil. J Am Oil Chem Soc 81:251–257

Acknowledgements

Authors thank Mr. Süha ERSOY (Oneva cold pressing, Istanbul, Turkey) for supplying cold-pressed oils.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Kiralan, M., Kayahan, M., Kiralan, S.S. et al. Effect of thermal and photo oxidation on the stability of cold-pressed plum and apricot kernel oils. Eur Food Res Technol 244, 31–42 (2018). https://doi.org/10.1007/s00217-017-2932-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2932-0