Abstract

Steam distillation was applied to lampante olive oil and olive pomace oil in a laboratory-scale steam distillation equipment, and effects of process parameters (temperature, pressure and stripping steam) were determined and modeled on bound 3-MCPD and glycidyl ester formation. Levels of process parameters were optimized to minimize bound 3-MCPD and glycidyl ester formation using response surface methodology. According to the results of the study, olive pomace oil has a significant content (4.1 mg/kg) of bound 3-MCPD prior to steam distillation. Results showed that temperature of the steam distillation was highly effective on bound 3-MCPD and glycidyl ester formation. Interaction between stripping steam rate and temperature was statistically significant for glycidyl ester formation. Effects of process parameters were visualized by using perturbation plots. Perturbation plots showed that stripping steam rate was possibly effective not only on glycidyl ester formation, but also on bound 3-MCPD formation in the case of steam distillation carried out at wide-ranged process conditions. According to the optimization results, optimum steam distillation temperature is 230 °C, water flow rate is 1.2 ml/min, and pressure is 4 mbar for olive oil, and temperature is 230 °C, water flow rate is 1 ml/min, and pressure is 2 mbar for olive pomace oil to minimize the bound 3-MCPD and glycidyl ester formation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Refining of edible oils is applied to remove or reduce the unwanted compounds such as oxidation products, free fatty acids (FFA), phospholipids and other contaminants. Deodorization is the last step of the chemical refining, whereas steam distillation is the final of physical refining process where the oil temperature can increase above 240 °C and undesired side reactions occur forming some unwanted substances [1].

3-Monochloropropane-1,2-diol (3-MCPD) is a well-known process contaminant of which esterified forms of 3-MCPD can be found in oils and fat products and free forms can be found in several processed food products [2, 3]. According to the formation pathway of the 3-MCPD, glycidyl esters and acyloxonium ions are formed from fatty acid (FFA), monoglyceride (MAG) and diglycerides (DAG) as a result of high temperature. The presence of chlorine ion causes 3-MCPD formation which is a chloropropanol substance [3–6]. The European Commission Scientific Committee on Food defined the tolerable daily intake (TDI) of 2 mg free 3-MCPD/kg body weight [7]. In vegetable oils and fats, different concentrations of bound 3-MCPD and glycidyl esters have been frequently reported in many studies [3, 5, 8–11]. 3-MCPD esters and glycidyl esters are mainly formed due to high-temperature applications during refining of oils, especially steam distillation step [6, 12].

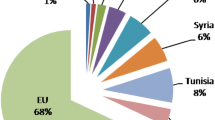

Olive oil is a very important fruit oil, especially for Mediterranean countries. Refined olive oil and olive pomace oil have large consumption volumes in many countries. Refined olive oils are used as cooking oil because of the high-temperature resistance against oxidation reactions due to their high monounsaturated fatty acid content [1]. Also in many European countries, refined olive oil is sold as virgin olive oil/refined olive oil mixture (20:80) and these oils are used in restaurants as salad oils. Refined olive pomace oil is produced using excessive thermal applications (generally higher than 200 °C) such as drying of pomace and is a good cooking and frying oil due to same reasons and sold for household usage in local markets. According to the Codex Alimentarius, olive oils have a FFA content higher than 3.3 % (in oleic acid) defined as “lampante olive oil” and have to be refined [13]. General refining method for olive oils and olive pomace oils is physical refining. Lampante olive oil has significant amount of MAG and DAG which are known as precursors of 3-MCPD and glycidyl esters [5, 11]. Therefore, these oils are susceptible to bound 3-MCPD and glycidyl ester formation during refining. Studies have shown that most of the bound 3-MCPD and glycidyl ester formation occurs during last step of refining which is known as steam distillation. During steam distillation, water and steam can further hydrolyze triglycerides to MAG and DAG. Studies have shown that MAG and DAG may form acyloxonium ion and glycidyl esters under acidic conditions and the nucleophilic reaction of chloride ions to the acyloxonium ion will lead to the formation of 3-MCPD esters [4]. Bound 3-MCPD and glycidyl ester formation during olive oil or olive pomace oil refining has not been investigated, although there are some studies about determination of bound 3-MCPD levels in olive oils [3, 14, 15].

Although there are some studies investigating the bound 3-MCPD formation mechanism during steam distillation step of oil refining [6, 9, 16–19], in many of them, oil sample was deodorized without stripping steam or vacuum except three studies [6, 10, 18]. In these studies, pilot-scale deodorizers with pressure and temperature control were used to deodorize palm oil with stripping steam. Most studies were focused on palm oil, since palm oil has a very large market share in oil and fat production market throughout the world. Moreover, palm oil is a fruit oil. Fruit oils are more susceptible to hydrolysis reaction, since fruit oil is exposed to water longer than seed oil, and this increases the chance of MAG and DAG formation which are precursors of bound 3-MCPD and glycidyl esters [1].

Response surface methodology (RSM) is a statistical technique for designing experiments, building models, evaluating the effect of factors and searching optimum conditions for desirable responses. The optimization procedure involved systematic formulations design to minimize the number of experiments and analyze the response surfaces in order to realize the effect of causal factors and to obtain the appropriate formulations with target goals as well as the acceptable component region as process control conditions in practical preparation [20, 21].

The recent study focused on determination and the modeling of the effect of process parameters on bound 3-MCPD and glycidyl ester formation during steam distillation of olive oil and olive pomace oil. Optimum steam distillation temperature, pressure levels and stripping steam rate were determined and verified using response surface methodology (RSM) where minimum bound 3-MCPD and glycidyl esters were formed. This study also puts forward and discusses the recent situation of bound 3-MCPD and glycidyl ester content in olive pomace oil prior to steam distillation which has not been investigated in any study before.

Materials and methods

Materials

Olive oil and olive pomace oil samples were purchased from a local refining plant in Izmir, Turkey. Lampante olive oil was obtained from a local olive oil factory using a two-phase decanting system with nonthermal methods. After extraction, lampante olive oil was degummed and bleached.

Olive pomace oil sample was degummed, alkaline neutralized, bleached and taken before steam distillation step. Olive oil and olive pomace oil samples were stored under −40 ± 2 °C until steam distillation runs.

Methods

Application of steam distillation

Steam distillation runs were carried out using a laboratory-scale distillation equipment made of glass as shown in Fig. 1. Eventually, system pressure was decreased according to the experimental design using a high-power vacuum pump (LVS 105 T-10 EF, ILMVAC GmbH, Germany). Temperature of the oil in reaction flask was increased and maintained at a desired level using a programmable interface controller, since stripping steam was produced by applying water with a constant flow rate in a heated round-bottom flask, expressed as water flow rate (ml/min) in this study. Water vaporized on heated glass surface and transferred into oil sample through a perforated glass tube. Boiling effect was achieved by introducing the steam into heated oil with the help of vacuum. Distillation vapor condensed into a glass cooler with the help of tap water and collected as solid phase in a glass flask that was placed in an ice bath.

In refineries, duration of steam distillation is regulated depending on initial chemical properties of crude oil as well as temperature, stripping steam amount and vacuum applied in steam distillation process. Likewise in our study, the duration of steam distillation runs was determined as the minimum essential distillation time to refine oil samples until FFA content and peroxide value decreased to 0.5 % and 0 meq O2/kg oil, respectively, which are commercial refining goals for refined oils [1]. Olive oil and olive pomace oil were steam-distilled at different temperatures in pre-runs, and minimum distillation durations were determined as 30 min for 260 °C, 60 min for 245 °C and 90 min for 230 °C for our distillation equipment.

Free fatty acid (FFA) content

FFA content of olive oil and olive pomace oil samples was determined using AOCS Official Method Ca 5a-40 [22].

Total MAG and DAG content

Total MAG and DAG of oil samples were determined using AOCS Official Method Cd 11c-93. This method determines glyceride mixtures by solid–liquid adsorption chromatography, using silica gel as the adsorbent [23].

Bound 3-MCPD and glycidyl ester analysis

Quantitative determination of 3-MCPD (esters) and glycidyl esters (bound glycidol) was done by using DGF Standard Method C-VI 18 (10). According to this method, 1,2-bis-palmitoyl-3-chloropropanediol-d5 standard (TRC Inc, Canada) and sodium hydroxide (Merck) solution were added and reaction stopped using sodium chloride solution. After this step, isohexane (Merck) extraction was applied to remove undesired nonpolar compounds. The sample was extracted with diethyl ether (Merck) and ethyl acetate (Merck) mixture, derivatized using phenylboronic acid (Sigma-Aldrich), dried under nitrogen gas and dissolved in isooctane (Merck) prior to GC–MS (Thermo Scientific, USA) injection. Same procedure was repeated by using sodium bromide solution instead of sodium chloride solution to avoid 3-MCPD formation from glycidyl esters during analysis. The quantitative difference between these two repeats was multiplied with transformation factor, and this value represented the glycidyl ester content of the sample [24]. The detection limit was found as 0.25 mg/kg bound 3-MCPD and 0.1 mg/kg glycidyl ester.

Experimental design and statistical analysis

Experimental plan including 17 experiments was developed by using Box–Behnken design for three independent variables with three levels according to RSM. Upper and lower limits of these three independent variables of steam distillation process were determined as given in Table 1. Detailed information about RSM can be found elsewhere [25]. Design Expert ® for Windows version 7.0 (Stat-Ease, Inc., Minneapolis, MN, USA) was used for statistical evaluation and modeling with a second-order polynomial equation to determine the coefficients of the response model as well as their standard errors and significance.

Response models are shown in Eq. 1.

where Y is the predicted response, β 0, β i , β ii and β ij are the regression coefficients for the intercept and the linear, quadratic and interaction coefficients, respectively, X i and X j are independent variables and k is the number of independent variables. Models were refined and insignificant coefficients were eliminated using back-substitution method.

Numerical optimization was applied to determine optimum temperature, water flow rate and pressure levels of steam distillation. Predicted values were validated by repeating the steam distillation operations at optimum conditions for both olive oil and olive pomace oil [25].

Results and discussion

Chemical compositions of olive oil an olive pomace oil

FFA content, MAG content, DAG content and bound 3-MCPD and glycidyl ester contents of olive oil and olive pomace oil were determined, and results are given in Table 2.

Lampante olive oil was degummed and bleached, while olive pomace oil was degummed, neutralized and bleached. These oil samples of FFA, MAG, DAG, bound 3-MCPD and glycidyl ester contents are given in Table 2, obtained before steam distillation step of refining. According to the results given in Table 2, there was a significant difference between FFA content of olive oil (10.1 ± 0.3 %) and olive pomace oil (0.8 ± 0.1 %) sample. This difference was directly related to the chemical neutralization applied to the olive pomace oil.

MAG and DAG content increased as a result of hydrolysis reaction. During this reaction, triglycerides are degraded into FFA, MAG and DAG. Since these substances are known as precursors of bound 3-MCPD, their higher levels were expected to increase bound 3-MCPD and glycidyl ester formation during steam distillation runs. The significant difference between MAG and DAG contents of olive oil and olive pomace oil was related to the preliminary operations (degumming, chemical neutralization, bleaching) applied to olive pomace oil that possibly decreased MAG and DAG to a degree [1].

Since olive oil was produced with nonthermal applications, 3-MCPD or glycidyl esters were not detected in our olive oil sample. Similarly, previous studies indicated that bound 3-MCPD was not detected in olive oils [15, 26]. On the other hand, some studies were reported 0.1–0.7 mg/kg bound 3-MCPD in olive oils [3, 9]. This result showed that olive oil (virgin or lampante) is safer regarding the presence of bound 3-MCPD and glycidyl ester when compared with crude palm oil. A previous work indicated that crude palm oil might contain 5.5 mg/kg bound 3-MCPD [10]. Another study indicated that palm oils that were used for industrial purposes in Brazil contain 1.05–2.95 mg/kg bound 3-MCPD [15]. Although bound 3-MCPD and glycidyl esters were not detected in olive oil, olive pomace oil has 4.17 mg/kg of bound 3-MCPD and 0.3 mg/kg of glycidyl esters in our study. This significant difference possibly resulted from excessive heat application to dry olive pomace before oil extraction. During pomace drying process, temperature of the olive pomace can reach approximately 300–400 °C [27]. This high temperature can cause glycidyl ester and bound 3-MCPD formation according to the formation pathway. Similar results were reported in another survey study in olive oil and pomace oil mixtures obtained from Spain and Portugal with relatively higher bound 3-MCPD contents [15].

Results of experimental design and modeling

Formation of bound 3-MCPD and glycidyl esters during steam distillation runs is given in Table 3. Since there were bound 3-MCPD and glycidyl ester contents in olive pomace oil before steam distillation runs, initial values were subtracted from results to obtain absolute 3-MCPD and glycidyl ester content formation during steam distillation runs.

According to the results given in Table 3, significantly higher amounts of bound 3-MCPD and glycidyl ester were formed during steam distillation of olive oil than olive pomace oil. This was an expected result since the precursor (MAG and DAG) content of olive oil was higher than olive pomace oil prior to steam distillation runs. Effect of precursor amount in oils on bound 3-MCPD was also discussed in many previous studies. A previous study reported that as the precursor amount reduced during degumming and bleaching operations with the application of water- and acid-activated clay, less bound 3-MCPD was observed after heat treatments at deodorization temperatures [18, 28]. Also heat application to model oils containing MAG, DAG and triglycerides proved that glycidyl esters and bound 3-MCPD can be formed at considerable amounts. Low levels of heat application could result in glycidyl esters and bound 3-MCPD formation with the presence of chlorine ion, especially in model oils containing only MAG and DAG [17].

Temperature was found significantly effective on bound 3-MCPD and glycidyl ester formation during steam distillation of olive oil and olive pomace oil. Also interaction between temperature and water flow rate is significant for glycidyl ester formation in olive oil.

Models were developed using backward substitution method after adding quadratic terms to the model equations. Although water flow rate and pressure were not effective for bound 3-MCPD formation during steam distillation of olive oil and olive pomace oil, these terms are main independent variables of the study and re-added to the equations to maintain logical expression capability of the models. Since interaction between temperature and water flow rate was significant for glycidyl ester formation in olive oils, water flow rate term was re-added to the equation to maintain model hierarchy. There were no sufficient data to develop a model for glycidyl ester formation during steam distillation of olive pomace oil. Mathematical models derived from the results of the bound 3-MCPD and glycidyl esters content are given in Table 4. Contour graph that was drawn using these models is shown in Fig. 2.

According to Table 4, p values of all model models were significant and lack of fit values were insignificant at a significance level (α) of 0.05. Adequate precision values (7.728, 8.932 and 6.323 for Model 1, Model 2 and Model 3, respectively) were higher than “4,” which shows models have adequate signals and reasonable for this experimental design [25, 29].

According to the contour graphs shown in Fig. 2, as the temperature increased, bound 3-MCPD and glycidyl ester formation were also increased during steam distillation operations. This effect can be explained through the formation pathway of the bound 3-MCPD since glycidyl esters are formed with the provocation of high temperature, which is a well-known information. Another study indicated that increasing temperature over 230 °C causes significant glycidyl ester formation, whereas increase in 3-MCPD formation was not statistically important [6]. Results of recent study showed that formation of both bound 3-MCPD and glycidyl esters is significantly increased in oil samples as the temperature increased 230–260 °C. In a previous study at which olive oil samples were kept at 230 and 260 °C for 8 h, results showed that bound 3-MCPD content rapidly increased for 1 h at 260 °C and started to decrease continuously at further thermal treatment. Bound 3-MCPD levels were decreased continuously during a thermal treatment at 230 °C for 8 h [3]. Since the duration of steam distillation runs was 30 min for 260 °C and 90 min for 230 °C, the results of the previous study obviously in agreement with our results explain the increasing effect of temperature on bound 3-MCPD formation during steam distillation of olive oils and olive pomace oils in our study.

Although water flow rate seems effective on bound 3-MCPD formation in olive oil and olive pomace oil, this effect was not statistically significant. Interaction between temperature and water flow rate for glycidyl ester formation in olive oils during steam distillation can be observed from contour graphs in Fig. 2. Due to this interaction, at low water flow rates (up to 1.5 ml/min according to the graph) temperature was effective on glycidyl ester formation. Effect of temperature on glycidyl ester formation in olive oil was not significant at a water flow rate of 2.0 ml/min in the current study. As water flow rate increased, more stripping steam introduced to heated oil medium. As the stripping steam rate increased, the mass transfer rate of distillation vapor from oil to cooler increases, and this situation possibly leads to rapid stripping of MAG and DAG from oil medium, decreasing the glycidyl ester formation [1]. Also similar results were discussed in a previous study that focused on 3-MCPD ester formation during a model frying operation using frying oils with different sodium chloride and water content. Researchers indicated that as frying temperature increased, water evaporates rapidly and leaves oil medium faster resulting reduced production of MAG and DAG which are known as precursors of 3-MCPD. Thus, decrease in precursor formation decreased the glycidyl ester and bound 3-MCPD formation during frying [30]. In our study, similar effect of water flow rate was not observed for bound 3-MCPD formation, since bound 3-MCPD formation depends not only on glycidyl ester amount but also on the presence of chlorine ion in oil [31].

Visualization of variable effects using perturbation plots

In response to surface designs, the perturbation plot shows how the response changes as each factor moves from the chosen reference point, with all other factors held constant at the reference value. In other words, the variable having the highest slope in perturbation curve is the most effective variable for the given response in current variable limits [32, 33]. Also if the upper and lower limits of the variables were enlarged and different equipments were used for same samples and conditions in another study, insignificant variables having the highest slope have a possibility to become significant. This information can be used for predicting effective variables at off-limit conditions. Also perturbation plots are useful for predicting the possible effective variables at scale-up situations [29]. Perturbation plots of the models are shown in Fig. 3.

In all perturbation plots, temperature, water flow rate and pressure were kept at 245 °C, 2 ml/min and 3 mbar, respectively. According to the perturbation plots shown in Fig. 3, the slope of the temperature curve is highest among other variables in every plot showing its superior effect on formation of bound 3-MCPD and glycidyl esters as mentioned before. Glycidyl ester formation was also affected from water flow rate. Although effect of pressure was not statistically important for glycidyl ester formation in olive oils, perturbation plot showed that this factor has a possibility of becoming significant at off-limit conditions. Likewise, water flow rate has a greater slope than pressure for bound 3-MCPD formation in olive oils and olive pomace oils.

Optimization and optimum point verification of the steam distillation parameters

Numerical optimization was applied to steam distillation parameters. Goals of optimization were to minimize bound 3-MCPD and glycidyl ester formation with same importance level in olive oil and olive pomace oil.

According to the optimization results given in Table 5, model predicted 4.5 mg/kg bound 3-MCPD at a temperature 230 °C, water flow rate 1.2 ml/min and pressure 4 mbar for olive oil. During verification experiments at optimum conditions, 5.1 mg/kg bound 3-MCPD was formed with a difference of 11 % from the predicted value in olive oil. In olive pomace oil, model predicted 1.7 mg/kg bound 3-MCPD formation during steam distillation at temperature 230 °C, water flow rate 1 ml/min and pressure 2 mbar. Verification experiments showed that 1.9 mg/kg bound 3-MCPD was formed during steam distillation of olive pomace oil at optimum point with a difference of 9.5 %.

Difference between predicted and experimental bound 3-MCPD levels is 11 and 9.5 % for olive oil and olive pomace oil, respectively. Average difference values lower than 15 % show that the optimization can be considered valid and model can be acceptable as in our study [25]. Moreover, desirability factors of numerical optimizations are relatively high values (0.85 and 0.95 for olive oil and olive pomace oil, respectively). Desirability factors between 1 and 0.8 are considered as “very good” and show that numerical optimization model highly meets the goals of the optimization [34].

Conclusion

Refined olive oil and olive pomace oil have large consumption volumes in many countries. These oils are susceptible to bound 3-MCPD and glycidyl ester formation during steam distillation. Olive oil has higher amount of MAG and DAG which are known as precursors than olive pomace oil. This difference is due to the alkaline neutralization applied to olive pomace oil at very beginning of refining operation. As a result of this difference, relatively less bound 3-MCPD and glycidyl ester were formed in olive pomace oil than olive oil. This result has put forward the importance of precursor content of the oil for bound 3-MCPD formation, and further studies about reducing bound 3-MCPD and glycidyl ester formation in final products should focus on reducing the precursor content of the oil at earlier stages of refining.

Bound 3-MCPD and glycidyl esters were not detected in olive oils prior to steam distillation, since olive oil production consists of nonthermal applications. Results of this study also showed that during production of olive pomace oil, bound 3-MCPD and glycidyl ester can be formed due to high drying temperatures applied to pomace before oil extraction. Additional heat applications increased total bound 3-MCPD amount up to 10.9 mg/kg after steam distillation in olive pomace oil. This situation showed that olive pomace oil is highly susceptible to containing bound 3-MCPD and glycidyl esters. Statistical analysis and modeling of bound 3-MCPD and glycidyl ester results of steam-distilled samples showed that temperature has a promoting effect on those contaminants. Moreover, this promoting effect was not significant for glycidyl ester formation at high stripping steam rates in olive oils during distillation.

Numerical optimization of the process parameters and validation results showed that developed models and optimization is a useful tool for minimizing and predicting bound 3-MCPD and glycidyl ester formation during steam distillation process.

References

Shahidi F (2005) Bailey’s industrial oil and fat products, 6th edn. Wiley, Hoboken, NJ

Velísek J, Davídek J, Kubelka V et al (1980) New chlorine-containing organic compounds in protein hydrolysates. J Agric Food Chem 28:1142–1144

Zelinková Z, Svejkovská B, Velísek J, Dolezal M (2006) Fatty acid esters of 3-chloropropane-1,2-diol in edible oils. Food Addit Contam 23:1290–1298. doi:10.1080/02652030600887628

Hamlet CG, Asuncion L, Velíšek J et al (2011) Formation and occurrence of esters of 3-chloropropane-1,2-diol (3-CPD) in foods: what we know and what we assume. Eur J Lipid Sci Technol 113:279–303. doi:10.1002/ejlt.201000480

Craft BD, Nagy K, Seefelder W et al (2012) Glycidyl esters in refined palm (Elaeis guineensis) oil and related fractions. Part II: practical recommendations for effective mitigation. Food Chem 132:73–79. doi:10.1016/j.foodchem.2011.10.034

Hrncirik K, van Duijn G (2011) An initial study on the formation of 3-MCPD esters during oil refining. Eur J Lipid Sci Technol 113:374–379. doi:10.1002/ejlt.201000317

SCF (2001) Opinion of the scientific committee on food on 3-monochloropropane-1,2-diol (3-MCPD). Updating the opinion of 1994. 1:1–5. doi:10.1111/1467-8608.00251

Kuhlmann J (2011) Determination of bound 2,3-epoxy-1-propanol (glycidol) and bound monochloropropanediol (MCPD) in refined oils. Eur J Lipid Sci Technol 113:335–344. doi:10.1002/ejlt.201000313

Franke K, Strijowski U, Fleck G, Pudel F (2009) Influence of chemical refining process and oil type on bound 3-chloro-1,2-propanediol contents in palm oil and rapeseed oil. LWT Food Sci Technol 42:1751–1754. doi:10.1016/j.lwt.2009.05.021

Pudel F, Benecke P, Fehling P et al (2011) On the necessity of edible oil refining and possible sources of 3-MCPD and glycidyl esters. Eur J Lipid Sci Technol 113:368–373. doi:10.1002/ejlt.201000460

Craft BD, Nagy K (2012) Mitigation of MCPD-ester and glycidyl-ester levels during the production of refined palm oil. Lipid Technol 24:155–157. doi:10.1002/lite.201200207

Lacoste F (2014) Undesirable substances in vegetable oils: Anything to declare? Ocl 21:A103. doi:10.1051/ocl/2013060

Anonymous (1981) Codex standard for olive oils and olive pomace oils. Codex Alimentarius, p 8

Chung SWC, Chan BTP, Chung HY et al (2013) Occurrence of bound 3-monochloropropan-1,2-diol content in commonly consumed foods in Hong Kong analysed by enzymatic hydrolysis and GC–MS detection. Food Addit Contam A Chem Anal Control Expo Risk Assess 30:1248–1254. doi:10.1080/19440049.2013.800996

Arisseto AP, Marcolino PFC, Vicente E (2014) Determination of 3-monochloropropane-1,2-diol fatty acid esters in Brazilian vegetable oils and fats by an in-house validated method. Food Addit Contam A 31:1385–1392. doi:10.1080/19440049.2014.926400

Ermacora A, Hrncirik K (2014) Influence of oil composition on the formation of fatty acid esters of 2-chloropropane-1,3-diol (2-MCPD) and 3-chloropropane-1,2-diol (3-MCPD) under conditions simulating oil refining. Food Chem 161:383–389. doi:10.1016/j.foodchem.2014.03.130

Shimizu M, Vosmann K, Matthäus B (2012) Generation of 3-monochloro-1,2-propanediol and related materials from tri-, di-, and monoolein at deodorization temperature. Eur J Lipid Sci Technol 114:1268–1273. doi:10.1002/ejlt.201200078

Zulkurnain M, Lai OM, Latip RA et al (2012) The effects of physical refining on the formation of 3-monochloropropane-1,2-diol esters in relation to palm oil minor components. Food Chem 135:799–805. doi:10.1016/j.foodchem.2012.04.144

Ermacora A, Hrncirik K (2014) Study on the thermal degradation of 3-MCPD esters in model systems simulating deodorization of vegetable oils. Food Chem 150:158–163. doi:10.1016/j.foodchem.2013.10.063

Deshmukh RK, Naik JB (2015) Optimization of sustained release aceclofenac microspheres using response surface methodology. Mater Sci Eng C 48:197–204. doi:10.1016/j.msec.2014.12.008

Silbir S, Dagbagli S, Yegin S et al (2014) Levan production by Zymomonas mobilis in batch and continuous fermentation systems. Carbohydr Polym 99:454–461. doi:10.1016/j.carbpol.2013.08.031

AOCS (2014) AOCS official method Ca 5a-40 free fatty acids. In: Official methods and recommended practices of the AOCS, 6th edn. American Oil Chemists’ Society

AOCS (2014) AOCS official method Cd 11c-93 mono–, di–, and triglycerides by silica gel chromatography. In: Official methods and recommended practices of the AOCS, 6th edn. American Oil Chemists’ Society

Standard DGF, Section M, C-vi F (2011) DGF standard methods section C—fats C-VI 18 (10), vol 18

Myers RH, Montgomery DC, Anderson-Cook CM (2011) Response surface methodology: process and product optimization using designed experiments, 3rd edn. Wiley, New York

Karasek L, Wenzl T, Ulberth F (2011) Determination of 3-MCPD esters in edible oil—methods of analysis and comparability of results. Eur J Lipid Sci Technol 113:1433–1442. doi:10.1002/ejlt.201100035

Sánchez Moral P, Ruiz Méndez MV (2006) Production of pomace olive oil. Grasas Aceites 57:47–55. doi:10.3989/gya.2006.v57.i1.21

Zulkurnain M, Lai OM, Tan SC et al (2013) Optimization of palm oil physical refining process for reduction of 3-monochloropropane-1,2-diol (3-MCPD) ester formation. J Agric Food Chem 61:3341–3349. doi:10.1021/jf4009185

Stat-Ease (2015) Design-expert for windows manual. 15

Zhou H, Jin Q, Wang X, Xu X (2014) Effects of temperature and water content on the formation of 3-chloropropane-1,2-diol fatty acid esters in palm oil under conditions simulating deep fat frying. Eur Food Res Technol 238:495–501. doi:10.1007/s00217-013-2126-3

Hamlet CG, Sadd PA, Crews C et al (2002) Occurrence of 3-chloro-propane-1,2-diol (3-MCPD) and related compounds in foods: a review. Food Addit Contam 19:619–631. doi:10.1080/02652030210132391

Chen Q, Bi J, Zhou Y et al (2014) Multi-objective optimization of spray drying of jujube (Zizyphus jujuba Miller) powder using response surface methodology. Food Bioprocess Technol 7:1807–1818. doi:10.1007/s11947-013-1171-z

Akdeniz Bilge (2012) Use of factorial experimental design for analyzing the effect of storage conditions on color quality of sun-dried tomatoes. Sci Res Essays 7:477–489. doi:10.5897/SRE11.1372

Lazic ZR (2004) Design of experiments in chemical engineering: a practical guide. Wiley-VCH, Strauss GmbH, Mörlenbach

Acknowledgments

The authors wish to thank the Scientific and Technological Research Council of Turkey (TUBITAK) for financially supporting this study under Project Number 113O483.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Özdikicierler, O., Yemişçioğlu, F. & Saygın Gümüşkesen, A. Effects of process parameters on 3-MCPD and glycidyl ester formation during steam distillation of olive oil and olive pomace oil. Eur Food Res Technol 242, 805–813 (2016). https://doi.org/10.1007/s00217-015-2587-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-015-2587-7