Abstract

The oxidation of vegetable oils is generally treated as an apparent first order kinetic reaction. This study investigated the deterioration of crude palm oil (CPO), refined canola oil (RCO) and their blend (CPO:RCO 1:1 w/w) during 20 h of successive deep-fat frying at 170, 180 and 190 °C. Kinetics of changes in oil quality indices, namely, free fatty acid (FFA), peroxide value (PV), anisidine value (p-AV), total polar compounds (TPC) and color index (CI) were monitored. The results showed that FFA and PV accumulation followed the kinetic first order model, while p-AV, TPC and CI followed the kinetic zero order model. The concentration and deterioration rate constants k, increased with increasing temperatures. This effect of temperature was modeled by the Arrhenius equation. The results showed that PV had the least activation energies E a (kJ/mol) values of 5.4 ± 1 (RCO), 6.6 ± 0.7 (CPO) and 11.4 ± 1 (blend). The highest E a requirement was exhibited by FFA with a range of 31.7 ± 3–76.5 ± 7 kJ/mol for the three oils. The overall E a values showed that the stability of the blend was superior and not just intermediate of CPO and RCO. The correlation of the other oil quality indices with TPC indicated a positive linear correlation. The p-AV displayed the strongest correlation, with mean correlation coefficient r s of 0.998 ± 0.00, 0.994 ± 0.00 and 0.999 ± 0.00 for CPO, RCO and blend, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The thermostability of frying oils during deep fat frying is most desirable. This depends on factors such as the type of oil and its composition, the frying procedure and the type of food being fried [1]. Other conditions that affect the rate of thermal degradation of oils include the presence of pro-oxidants (such as water, oxygen, salt, iron and cupper) and anti-oxidants (natural and synthetic) [2]. The mechanism of thermal oxidation mainly comes from free radical mediated breakages of the unsaturated sites of the triacylglycerol (TAG) [3, 4]. Oil degradation reactions that occur during deep-fat frying are hydrolysis, oxidation, isomerization and polymerization [5]. Frying oil degradation results in the generation of free fatty acids, small molecular weight alcohols, aldehydes, ketone, lactone and hydrocarbons [4]. Other compounds that have been identified in degraded oils include polymerized diacylglycerols, monoacylglycerols, oligomeric, cyclic, and epoxy compounds [6] as well as trans fats and volatile short-chain aldehyde compounds such as acrolein [7]. Some of these degradation products affect the quality of the fried products and can be potentially harmful to the consumers’ health [8]. It is necessary that any frying oil be reasonably stable to thermoxidation during extended exposure to the high temperatures (150–190 °C) used in frying different kinds of foods. Chemical indicators such as the free fatty acid (FFA %), peroxide value (PV), para-anisidine value (p-AV), and total polar compounds (TPC) are used in monitoring frying fats and oils. The TPC and polymeric triacylglycerols are among the most reliable frying oil degradation indicators used in regulations by many countries [8, 9]. In the year 2000, the DGF (German Society for Fat Research) recommended a TPC level of <24 % for used frying oils as TPC levels above 19 % result in fried products with poor sensory characteristics [10].

Palm oil has a near equal composition of saturated and unsaturated fatty acids, moderate amounts of linoleic acid and trace amount of linolenic acid [11]. Crude palm oil (CPO), also known as virgin palm oil, contains high levels of beneficial phytonutrients such as β-carotene, tocopherols and tocotrienols. These antioxidants make the oil less prone to oxidation and deterioration. CPO has a long history of direct use in cooking and food preparations in tropical Africa, Southeast Asia, and South America. The oil is readily available and is used as a major component of some processed foods or as a minor ingredient in a variety of food products [11]. Canola oil is commonly utilized in cooking and frying. It is very rich in oleic acid and is among the vegetable oils with a very low concentration of saturated fatty acids [12]. These characteristics make canola oil perform poorly during prolonged frying [13, 14]. Natural antioxidants of frying oils are lost during the refining process, some natural and synthetic antioxidants such as tocopherol, butylated hydroxytoluene (BHT), and butylated hydroxyanisole (BHA) are always added into the frying oil in order to slow down the oxidation process and especially reduce the formation and accumulation of TPC [1, 12]. Frying operators sometimes blend polyunsaturated oils with a more saturated or monounsaturated oil as a cost effective way of reducing the amounts of linolenic and linoleic acids in the frying medium and thus increasing its thermostability [15, 16]. In addition to controlling oil oxidation, blending can be used to attain better sensory properties in fried foods [17].

The maximum ‘fry life’ of oils, the various chemical reactions and the extent of thermooxidative degradation during deep-fat frying has continued to engage the attention of researchers [18–20]. Frying oils differ in their rate of deterioration and formation of breakdown products [2]. Mathematical models and kinetic studies of food quality changes during thermal processes is very important in estimating the performance and suitability of the applied thermal treatment. This ensures the selection of optimum processing variables. The controllable variables in deep fat frying are the oil type, the frying temperature and the frying time [21]. Furthermore, the oil’s chemical composition, the proportion of unsaturated fatty acids, the presence of pro- or anti- oxidant compounds and the initial oxidative state of the oil needs to be controlled. According to Van Boekel [22], the oxidation of vegetable oils can generally be treated as an apparent first order reaction. The need for further studies to determine if each individual oil quality index follows this apparent order during actual frying still exists. The knowledge of the kinetics of quality indices (like the FFA, PV, p-AV, TPC, and color index (CI)) changes in palm oil, canola oil and blend will make it possible to predict the threshold reject point due to safety or quality reasons. The application of kinetics will make it possible to design frying procedures that can maintain the quality of the oils studied for a reasonable time and produce fried products with minimal undesirable breakdown products, enhanced sensory characteristics and elimination of potential hazards. Some studies on repeated heating of blind oil samples, deep-fat frying of model systems and the presence of food in the frying oil reported that while polar and polymerization products are generated as a result of oil breakdown, the presence of food and some metals in the oil significantly increased the concentration of these breakdown products [23–25]. However, the conditions encountered in actual frying are different from heating blind oil samples and model systems. Refined vegetable oils mostly used in frying have significantly low amounts of natural phytonutrients and antioxidants. However, unrefined virgin oils are rich in various kinds of beneficial phytonutrients and antioxidants [26]. Therefore the need still exists to investigate the potentials of virgin oils for deep-fat frying and fried products enrichment. The objectives of this work are to evaluate the kinetics driving the deterioration of crude palm oil (CPO), refined canola oil (RCO) and a binary blend (CPO: RCO 1:1 w/w) during deep-fat frying of potato strips using established kinetic equations and to compare the deterioration rates of the oils’ determined quality indices based on their activation energies. The strength of the relationships between these quality indices of oil deterioration will also be investigated.

Materials and Methods

Materials

Crude palm oil (CPO) was obtained from a local palm oil mill in Abia State, Nigeria. The CPO production and packaging were supervised by a qualified industry-based oil chemist. The fresh CPO was filled into dark high-density polyethylene (HDPE) barrels. The bulk CPO cargo in wooden crates was transported by air within 2 weeks of production. The refined canola oil (RCO) (labelled as containing BHA, BHT and dimethyl polysiloxane (DMPS)) was obtained from Titan Oils Inc. Montréal, Canada. A binary blend was formulated by mixing and vortexing CPO and RCO (1:1 w/w) to a homogenous blend. The oils were kept in a dark cool place. Russets potatoes were purchased from a local grocery shop. All chemicals and solvents used were of analytical grade and obtained from Fisher Scientific, Fair Lawn, NJ, USA.

Frying and Oil Sampling Procedures

About 4.5 L of CPO, RCO and blend were heated from an initial temperature of 23 °C to the chosen frying temperature for 2 h in a batch electric fryer (D24527DZ DeLonghi Inc. USA). The frying temperatures used were 170, 180 and 190 °C for 5 h per day. These temperatures are commonly used for commercial and industrial deep-fat frying operations. Successive batches of 100 ± 2.0 g potato strips (≈10 cm long and 1.2 cm thick) were deep-fat fried for 10 min. The interval between frying the batches was 30 min. The frying procedure was repeated 3 more consecutive days, to give a total heating and frying time of 20 h. Each oil sample and frying temperature was treated the same way. A K-type thermocouple interfaced with Hotmux data logger was used to monitor the oil temperature during the frying process. The end of each 5-h frying cycle was followed by cooling to room temperature, then aliquots of the fried and fresh (unused) oil samples (250 mL) were drained into HDPE dark amber bottles and kept frozen at −20 °C until analyzed. Frying was done without oil replacement, however the oil in the fryer was kept in a dark cold place and filtered at the beginning of each successive frying day to remove solid debris.

Analytical Procedure

Before each analysis, the frozen oil samples were allowed to revert to their liquid state by briefly holding in warm water at 50 °C.

Physicochemical Analysis of the Oil Samples

The AOCS Official Method Ca 5a-40 was used to determine the free fatty acid (FFA) expressed as percentage (%) of oleic acid; the AOCS Method Ja 8-87 was used to determine the peroxide value (PV) expressed as milliequivalents of oxygen per kilogram of oil (mequiv O2/kg); the AOCS Method Tg 1-64 was used to determine the iodine value (IV) expressed as grams of iodine absorbed per 100 g of oil (g/100 g) [27]. The overall color change related to the degradation processes in the oil samples was measured as color index (CI) following the AOCS Method Cc 13c-50 [27]. The anisidine value (p-AV) was determined using the ISO Method 6885 [28]. The method described by Schulte [29] was followed to estimate the total polar compounds (TPC).

Kinetic Data Analysis

Oil deterioration was based on the accumulation of FFA, PV, p-AV, TPC and CI. The reaction kinetics were analyzed as described by Van Boekel [22]. Firstly, the most suitable kinetic reaction order model for each quality index data were established by pre-fitting the experimental data with different kinetic models. The kinetic model that gave the coefficient of determination R2 closest to 1 was chosen as the reaction order kinetics for the particular index.

As reported by Hindra and Baik [21], a model for the rate of food quality changes that degrade by accumulation in concentration with time is shown in Eq. (1).

(P = food property (in this case, FFA, PV, p-AV, TPC and CI), dp/dt = rate of deterioration, k = deterioration rate constant (time−1); [P] = concentration and n = apparent order of reaction).

If P 0 = initial value and P t = value at any time t; integrating and rearranging Eq. (1) give Eqs. (2, 3) for zero- and first-order reactions respectively:

Taking natural logarithm of Eq. (3) and rearranging, gives the linearized form (Eq. 4):

The effect of temperature on the k was described by the Arrhenius equation:

(k = deterioration rate constant; A = frequency factor (h−1); E a = activation energy (kJ mol−1); R = universal gas constant (0.008314 kJ mol−1 K−1) and T = absolute temperature (K)).

In order to reduce the correlation between A and E a, a reference temperature T ref was chosen. The T ref was the mean of the temperatures T studied [22]. The Arrhenius equation was then reformulated:

(A r = reparametrized frequency factor (h−1)).

The predicted data were obtained by substituting for k in Eqs. (2) and (4) using Eq. (6):

Statistical Analysis

All the experiments and measurements were performed in triplicate. The significant effects of factors were assessed by analysis of variance (ANOVA) and the differences between mean values of parameters were evaluated by Tukey’s LSD test (α = 0.05). The kinetic parameters were estimated by non-linear regression of the kinetic equations and the quality indices were also correlated (Statistical Analysis System (SAS) version 9.4). Model discrimination was based on pseudo-R 2 values and the correlation coefficient r. The validity of the kinetic models for each oil quality index was verified by the mean relative percentage deviation P (%) between experimental and calculated values [30], using Eq. (9).

(C ex = experimental concentration; C pr = predicted concentration and N = number of experimental data points. A model is considered acceptable if P values are below 10 %).

Results and Discussion

Free Fatty Acid (FFA) Variations

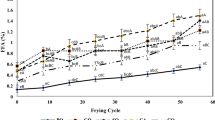

The initial free fatty acid (FFA) content expressed as % oleic acid and the acid value (AV) of the oil samples are shown in Table 1. The AV was 8.26 ± 1.00 mg KOH/g for CPO, 0.54 ± 0.06 mg KOH/g for RCO and 4.20 ± 0.28 mg KOH/g for the blend. These values are within the AV range of 0.60, 4.00 and 10.00 mg KOH/g recommended for refined oils, cold pressed/virgin oils and virgin palm oils respectively by the CODEX commission [31]. Our earlier characterization study showed that the amount of FFA in CPO was higher than RCO because it was not refined [32]. As shown in Fig. 1, the FFA of the oils significantly (P ˂ 0.05) increased with frying temperature and time. The maximum percentage changes in FFA over the temperature range studied were 1.59, 2.21 and 1.09 % for CPO, RCO and blend, respectively. RCO showed the most noticeable FFA deterioration despite its initial low levels. This can be attributed to the polyunsaturated nature of the oil which made it exhibit a greater degree of sensitivity to the moisture released by the potato strips. These observations are in line with literature reports on RCO [14, 33, 34]. The increase in FFA of the blend samples was not an intermediate between the observed increases in CPO and RCO. This is due to slower hydrolytic degradation in the blends, possibly because of alteration of the triacylglycerol composition and reduction in polyunsaturated C18 fatty acids [1, 16].

Results for free fatty acid (FFA) accumulation vs time on a natural log scale. Experimental data corresponds to unfilled diamonds at 170 °C, open squares at 180 °C and open triangles at 190 °C. Lines represent the first order fit: continuous lines for Crude Palm Oil, dashed lines for Refined Canola Oil and dotted lines for the Blend (1:1 w/w)

Figure 1 also shows the results of the kinetic study of the FFA accumulation. It can be seen that FFA concentration increased with time and became more rapid at higher temperatures. This was also reflected by the increase in deterioration rate constants k with temperature (Table 2). The first-order kinetic model was adequate in describing the FFA accumulation in CPO, RCO and blend. This was evidenced by the values of the regression coefficient R2 and the percentage deviation P also shown in Table 2. The Pr > F values which correspond to the p-values [35] were less than 0.05 which indicated that the model was statistically significant and robust as a predictor of changes in FFA during deep-fat frying.

The activation energies E a obtained from the non-linear regression of the Arrhenius equation at α = 0.05 is presented in Table 3. The high pseudo-R 2 values were evidence of the goodness of fit of the model. The E a (kJ/mol) values obtained were 76.5 ± 7, 31.7 ± 3 and 39.6 ± 3 for CPO, RCO and blend, respectively. The E a for RCO was the most significantly low. These results are in accordance with findings, that hydrolytic reactions that breaks the ester bonds of the TAG requires high activation energy [36]. Moisture attacks more readily the ester linkage of short and unsaturated fatty acids because they are more soluble in water than long and saturated fatty acids, releasing FFA, glycerol, di- and mono-acylglycerols. Also, RCO with higher amounts of unsaturated C18 fatty acids is more amenable to hydrolysis [5, 36].

Peroxide Value (PV) Variations

The initial PV values (mequiv O2/kg) of CPO, RCO and blend were 1.18 ± 0.12, 0.43 ± 0.11 and 0.78 ± 0.14, respectively (Table 1). These values are within the range of guidelines which recommended the initial PV of ≤2 mequiv O2/kg for good quality vegetable oil and discard level PV of 10 mequiv O2/kg [10] and up to 15 mequiv O2/kg for cold pressed and virgin oils [31]. There was no evidence of advanced auto-oxidation in the three oils as their initial PV were within the recommended range.

The kinetic study of the changes in hydroperoxides was expressed relative to the initial mean value of the unused oil on a natural log scale (Fig. 2). The PV values progressively increased with studied frying time and temperature in the three oils. Though RCO showed an accelerated rate of PV formation especially at 190 °C reaching up to 4.87 %, it did not reach the oil reject points specified by the DGF (German Society for Fat Research) [10] and the Codex Alimentarius Commission (CAC) [31]. A similar result was obtained by Tiwari, Tiwari and Toliwal [16] while frying potato chips at 180 °C in palm oil, sesame oil and a palm-sesame oil blend. This trend was also reported for unrefined pollock oil [37] and choibá oil containing antioxidants from Rosmarinus officinalis [38]. The first-order kinetic model gave a good fit in describing the changes in the PV of the oil samples as shown by the high R 2 and low P of the model (Table 2). The Pr > F values were 0.0033, 0.0052 and 0.0058 for CPO, RCO and blend respectively. These values gave further proof that the models for predicting changes in PV of the oil samples were statistically significant (P < 0.05). The same order of reaction for lipid peroxidation was reported by Piedrahita, Penaloza, Cogollo and Rojano [38] for choibá fruit oil and Sathivel, Huang and Prinyawiwatkul [37] for Pollock oil.

Results for peroxide value (PV) accumulation vs time on a natural log scale. Experimental data corresponds to unfilled diamonds at 170 °C, open squares at 180 °C and open triangles at 190 °C. Lines represent the first order fit: continuous lines for Crude Palm Oil, dashed lines for Refined Canola Oil and dotted lines for the Blend (1:1 w/w)

The Arrhenius equation was used to describe the temperature dependence of k of the oil samples. Non-linear regressions were performed, and the values obtained for the E a and the pseudo-R 2 are shown in Table 3. The resulting E a values (kJ/mol) were 6.6 ± 0.7, 5.4 ± 1 and 11.4 ± 1 for CPO, RCO and blend, respectively. The E a values for PV are in line with earlier findings that the E a required for the formation and accumulation of lipid peroxides and hydroperoxides is very low since peroxyl radicals’ formation and decomposition take place simultaneously during thermal processing of oils [36]. Low E a values implies that the reaction takes place very quickly as the buildup of aldehydes and carbonyls soon dominates [2]. The very low E a values obtained for the PV of the RCO can be attributed to the presence of more double bonds that led to greater spontaneous reaction between carbon-centered lipid radicals and molecular oxygen. Another polyunsaturated oil, choibá fruit oil, was reported to have shown PV E a range of 4.6–7.4 kJ/mol by Piedrahita, Penaloza, Cogollo and Rojano [38]. The blend oil sample had the highest PV E a. This confirmed that the rate of formation of peroxide radicals in the blend was slowest. This can be attributed to the combined effect of reduced double bond strength as saturation level increased and synergistic radical scavenging activity of both natural and synthetic antioxidants [17, 39].

Anisidine Value (p-AV) Variations

The p-AV test is one of the most common tests for monitoring oil thermostability because the aldehydes formed during secondary oxidation and the non-volatile portion of the carbonyls linger in the frying oil [2, 20]. As seen from Table 1, the initial p-AV for CPO, RCO and blend were 2.87 ± 0.07, 2.42 ± 0.01 and 3.88 ± 0.01, respectively. This variation in the p-AV of the fresh oil samples was not significant and could be due to inherent experimental errors within the chemical analysis method. Laguerre, Lecomte and Villeneuve [36], observed that as a result of autoxidation, some non-volatile aldehydes can be present in unused oils. However, the initial p-AV obtained were below 10 units in the three oil samples, indicating near absence of secondary oxidation [18]. In the oil samples, the p-AV increased as the frying temperature and time increased. In this study, RCO showed 41 % higher p-AV than the CPO and 5–18 % higher than the blend. The highest values observed in RCO can be due to higher proportions of linolenic and linoleic acids in the oil. These unsaturated C18 fatty acids decompose more readily after initial oxidation and yield more aldehydes, particularly 2-alkenals and 2, 4-dienals [1, 40].

The changes in p-AV of the oil samples as a function of time at different temperatures are shown in Fig. 3. The anisidine values significantly (P < 0.05) increased with increased time and temperature. The observed trend correlated with the iodine value (IV) of the oils, 54.82 ± 0.15 g/100 g (CPO), 101.27 ± 0.41 g/100 g (RCO) and 85.41 ± 0.83 g/100 g (blend) shown in Table 1. The CPO with the least number of double bonds showed the lowest reactivity of radicals and formation of secondary breakdown products. A similar trend has been reported for different lipid media by some researchers [3, 19, 36]. The deterioration rates k with respect to p-AV were well fitted by the zero-order kinetic model. This is evidenced by the values for Pr > F, R 2 and P at different temperatures shown in Table 2. Some workers have also used zero-order kinetic model to satisfactorily fit the increase in p-AV in lipids and blends of oils [13].

Results for anisidine value (AV) accumulation vs time. Experimental data corresponds to unfilled diamonds at 170 °C, unfilled squares at 180 °C and unfilled triangles at 190 °C. Lines represent the zero order fit: continuous lines for Crude Palm Oil, dashed lines for Refined Canola Oil and dotted lines for the Blend (1:1 w/w)

Non-linear regression analysis showed that k for p-AV, which is temperature dependent, was also well described by the Arrhenius equation. The results obtained are presented in Table 3. The result showed that the order of E a for p-AV is RCO < CPO < Blend (8.3 ± 0.7 < 14.1 ± 0.8 < 26.4 ± 2 kJ/mol). The E a results confirmed that RCO was most susceptible to secondary oxidation than CPO and blend. This is due to the presence of high concentration of polyunsaturated fatty acids in RCO [14]. The altered TAG composition of the blend resulted in reduction in level of unsaturation, intermediate IV and reduced rate of aldehyde accumulation. The reduced accumulation of aldehydes in the blend oil sample could be due to the presence of both natural and synthetic antioxidants. This antioxidant synergism likely inhibited rapid evolution and accumulation of the aldehydes [15, 36].

Total Polar Compounds (TPC) Variation

The percentage TPC is the commonly authorized criterion for the appraisal of deterioration of fats and oils during frying [10]. Theoretically, fresh oils are non-polar. However, the reported levels of TPC (%) in fresh oils ranged between 2.77 and 3.98 in hazelnut, corn, soybean and olive oils [41]; 2.40–2.80 in sunflower oil, tigernut oil and blend (1:1) of sunflower/tigernut oil [42]; 4.80–8.00 in soybean oil, beef tallow, shortening and double fractionated palm oil [43]; and 6.20 in extra virgin olive oil [44]. The initial TPC (%) values of the three oils used in this frying study were 5.83 ± 0.40, 6.10 ± 0.44, and 5.63 ± 0.61 for the CPO, RCO and blend respectively (Table 1). These TPC values mean that the oils have not been adversely altered by autoxidation. The recommended range of TPC in unused oils is 0.4–6.4 % [42, 45]. As oil breakdown progresses, polymerization products with polarity greater than the native TAGs are increasingly formed [2, 6]. The level of TPC in the three oil samples significantly (P < 0.05) increased linearly with frying time and temperature as shown in Fig. 4. This trend agrees with literature reports [3, 18, 41–44]. TPC accumulation in CPO, RCO and blend was well fitted by the zero-order kinetic model. This is also shown by the values for, R 2 and P at different temperatures reported in Table 2. The table also show that the Pr > F values range from 0.0130 to 0.0320 in the three oils which gave evidence of the significance (P < 0.05) of the models. The zero-order model was also used to estimate the theoretical frying hours until TPC reached the critical 25 % level in the seed oil of Moringa stenopetala [46]. In this study, the type of oil significantly (P < 0.05) influenced the accumulation of TPC during frying. The highest rates of TPC accumulation were observed in the RCO. This is because among the three oils, RCO has the highest linolenic acid content whose breakdown and further polymerization is a critical factor that affects the formation of polar compounds in frying oils [47, 48]. RCO fatty acids had higher rate of secondary oxidation and polymerization reactions. It was only RCO at 190 °C and 20 h frying that exceeded the 25 % TPC discard limit endorsed by the German Society for Fat Science.

Results for Total Polar Compounds (TPC) accumulation vs time. Experimental data corresponds to unfilled diamonds at 170 °C, open squares at 180 °C and open triangles at 190 °C. Lines represent the zero order fit: continuous lines for Crude Palm Oil, dashed lines for Refined Canola Oil and dotted lines for the Blend (1:1 w/w)

Table 3 shows E a and pseudo-R 2 obtained from the non-linear regression of the Arrhenius equation. The E a values were 30.8 ± 4 kJ/mol, 26.8 ± 3 kJ/mol and 45.8 ± 7 kJ/mol for CPO, RCO and blend, respectively. The E a for RCO was expectedly the lowest since it is the oil sample that was the most unsaturated. As seen from the IV of the three oils (Table 1), RCO had 45.87 and 35.82 % greater degree of unsaturation than CPO and the blend respectively. The blend had the highest TPC E a. Blending canola and palm oils at a 1:1 ratio affected the fatty acid composition and significantly altered the triacylglycerol (TAG) composition. These can hugely affect the frying performance of the blend [1]. In addition, antioxidant synergism and altered chemical composition contributed to reduce the rate of formation of oxidized TAG, oligomers and new polymeric compounds [2]. Based on TPC values in a work that used synthetic antioxidants, Farhoosh [49] reported that an oil medium that had a mix of TBHQ and α-tocopherol lasted up to 44 h of frying. In this work, frying with progressively reduced oil level in the fryer may have increased the relative formation of polar compounds especially at higher frying temperatures and time [24, 50]. However, maximum reject point based on TPC was largely not exceeded and the result is similar to the report of Omar, Nor-Nazuha, Nor-Dalilah and Sahri [51] that the TPC contents in standard palm olein and palm-based shortening were 19.60 and 15.3 % respectively after 40 h of frying potato chips at 180 °C.

Variations in Color Index (CI)

The composition of the oil, the accumulation of highly conjugated oxidation products, the formation of polymers in frying oil, reactions between glucose and glycine, the oil’s in situ pigments and the leached pigments from the fried products are involved in oil color changes during frying [1]. Color index (CI) is a measure of the totality of the degradation products that led to oil darkening [8, 18]. The initial CI values as presented in Table 1 showed the following values, 92.07 ± 0.70 (CPO), 2.38 ± 0.40 (RCO) and 42.37 ± 0.60. There were significant (P < 0.05) changes in the CI of CPO and blend as frying temperature and time changed. CI changes in RCO was not significant. The darkening of CPO and the blend was not necessarily an indication of instant deterioration. The darkening of the CPO based oils can be due to the degradation of β-carotene, transformation of phenols and tocotrienols and an increase in UV absorbance of polymerized acylglycerols [18]. After heating induced lightening of the oils, the CI began to increase with an increase in frying time and temperature. The increase in CI, was modeled with a zero-order kinetic equation (Fig. 5). The goodness of fit of the model was shown by the high R 2 for the three temperatures and low Pr > F as well as low P values (Table 2). The zero-order model was also proposed for color changes in corn and canola oils (in CIELAB color space) during frying by Wenstrup, Plans and Rodriguez-Saona [52].

Results for color index (CI) vs time. Experimental data corresponds to unfilled diamonds at 170 °C, open squares at 180 °C and open triangles at 190 °C. Lines represent the zero order fit: continuous lines for Crude Palm Oil, dashed lines for Refined Canola Oil and dotted lines for the Blend (1:1 w/w)

The E a and pseudo-R 2 results obtained from the non-linear regression of the Arrhenius equation is shown in Table 3. The high pseudo-R 2 gave evidence of the goodness of fit. The E a (kJ/mol) values obtained were 7.0 ± 2 (CPO), 2.5 ± 0.4 (RCO) and 11.2 ± 2 (blend). The E a for RCO was most significantly low. Most publications on frying color kinetics are focused on the fried products and not the frying oil. The reported E a are based on color parameters such as lightness, redness, yellowness and total color change ratios. The E a from such evaluations ranges from 71.95 to 174.55 kJ/mol at temperatures between 170 and 190 °C for different products [21]. This result showed that it takes far less E a for the colors of the frying oils to undergo changes. Though the frying temperature has a greater effect on the color of fried products than the oil type [5], it is also necessary to monitor the color of the frying oil as the fried products likely pick up some of the pigments and nutrients responsible for the oil color, especially at the early stages of frying.

Correlation Between TPC and Other Quality Indices Measured

By regulation, TPC is used to establish oil deterioration [10]. The method of assessment of TPC is laborious and time consuming and so efforts were made to correlate the strength of the relationships between TPC and the other quality indices. The Spearman’s correlation coefficient r s values obtained are presented in Table 4. In the three oils, at all the temperatures, TPC showed a strong positive linear correlation with the other quality indices (α = 0.05). The order of magnitude of correlation was p-AV > FFA > CI > PV. This trend agrees with the oil quality indices correlation results reported by Houhoula, Oreopoulou and Tzia [3]. The TPC’s significant positive correlation to the other degradation parameters is not unexpected since TPC is a measure of the totality of the non-volatile oil decomposition compounds such as thermal scission products, hydroperoxides, aldehydes, polymerized TAG, DAG, MAG, acids, alcohols, ketones and epoxides present in the frying oil [6]. The relatively lower correlation with PV (r s range = 0.9374–0.9900) and higher correlation with p-AV (r s range = 0.9933–0.9989) could be attributed to the ease with which hydroperoxides decompose to form more stable carbonyls, alcohols and aldehydes. The p-AV analysis targets secondary oxidation products that are retained in the oil and subsequently undergo polymerization reactions as frying time and temperature increased. The p-AV, FFA and CI could be used for the estimation of deterioration of CPO, RCO and blend (1:1 w/w) in deep-fat frying operation.

Conclusion

This work has provided kinetic information on the deterioration in quality indices of CPO, RCO and blend (CPO:RPO 1:1 w/w) during deep-fat frying. The study showed that first-order kinetic model adequately predicted changes in FFA and PV; while zero-order kinetic model fittingly predicted changes in p-AV, TPC and CI. The rate of changes in the quality indices of the oils and the activation energies were well described by the Arrhenius equation. The study showed that activation energy E a was least for PV and highest for FFA. The quality of the blend oil sample (CPO: RCO 1:1 w/w) was not just additive of the qualities of CPO and RCO. The blend had its own character and was more stable than CPO and RCO. This can be attributed to the dilution effect of blending which weakened any pro-oxidant likely present in CPO and induced lag in the oxidation of the blend during frying. The blend oil sample had altered fatty acid and TAG composition as shown by the IV of the fresh oil blend that affected the rate of deterioration. The blend oil sample also benefitted from the combined effect of reduced double bond strength as saturation level increased and synergistic radical scavenging activity of both natural and synthetic antioxidants present in CPO and RCO. TPC had a significant linear positive correlation with the other oil quality indices especially p-AV.

References

Aladedunye FA (2015) Curbing thermo-oxidative degradation of frying oils: current knowledge and challenges. Eur J Lipid Sci Technol 117:1867–1881

Aniołowska M, Kita A (2016) The effect of frying on glycidyl esters content in palm oil. Food Chem 203:95–103

Houhoula DP, Oreopoulou V, Tzia C (2003) The effect of process time and temperature on the accumulation of polar compounds in cottonseed oil during deep-fat frying. J Sci Food Agric 83:314–319

Zhang Q, Saleh ASM, Chen J, Shen Q (2012) Chemical alterations taken place during deep-fat frying based on certain reaction products: a review. Chem Phys Lipids 165:662–681

Choe E, Min D (2007) Chemistry of deep-fat frying oils. J Food Sci 72:R77–R86

Sebastian A, Ghazani SM, Marangoni AG (2014) Quality and safety of frying oils used in restaurants. Food Res Int 64:420–423

Wang Y, Hui T, Zhang YW, Liu B, Wang FL, Li JK, Cui BW, Guo XY, Peng ZQ (2015) Effects of frying conditions on the formation of heterocyclic amines and trans fatty acids in grass carp (Ctenopharyngodon idellus). Food Chem 167:251–257

Firestone D (2007) Regulation of frying fat and oil. In: Erickson MD (ed) Deep frying: Chemistry, nutrition, and practical applications. AOCS Press, Urbana IL USA, pp 373–387

Stier RF (2013) Ensuring the health and safety of fried foods. Eur J Lipid Sci Technol 115:956–964

DGF (German Society for Fat Research) (2000) Proceedings of the 3rd international symposium of deep-fat frying—final recommendations. Eur J Lipid Sci Technol 102:594–595

Mba OI, Dumont M-J, Ngadi M (2015) Palm oil: processing, characterization and utilization in the food industry—a review. Food Biosci 10:26–41

Aachary AA, Chen Y, Eskin N, Thiyam-Hollander U (2014) Crude canolol and canola distillate extracts improve the stability of refined canola oil during deep-fat frying. Eur J Lipid Sci Technol 116:1467–1476

Farhoosh R, Kenari RE, Poorazrang H (2009) Frying stability of canola oil blended with palm olein, and corn oils. J Am Oil Chem Soc 86:71–76

Aladedunye FA, Przybylski R (2012) Frying performance of canola oil triacylglycerides as affected by vegetable oils minor components. J Am Oil Chem Soc 89:41–53

Alireza S, Tan CP, Hamed M, Man YBC (2010) Effect of vegetable-based oil blends on physicochemical properties of oils during deep-fat frying. Am J Food Technol 5(310):323

Tiwari M, Tiwari K, Toliwal S (2014) Studies on thermal stability of palm-sesame oil blends during deep fat frying. J Sci Ind Res 73:153–156

Ramadan MF (2013) Healthy blends of high linoleic sunflower oil with selected cold pressed oils: functionality, stability and antioxidative characteristics, Industrial Crops and Products 43:65-72. Eur J Lipid Sci Technol 43:65–72

Petersen KD, Jahreis G, Busch-Stockfisch M, Fritsche J (2013) Chemical and sensory assessment of deep-frying oil alternatives for the processing of French fries. Eur J Lipid Sci Technol 115:935–945

Aladedunye F, Przybylski R (2014) Performance of palm olein and modified rapeseed, sunflower, and soybean oils in intermittent deep-frying. Eur J Lipid Sci Technol 116:144–152

Abdulkarim SM, Long K, Lai OM, Muhammad SKS, Ghazali HM (2007) Frying quality and stability of high-oleic Moringa oleifera seed oil in comparison with other vegetable oils. Food Chem 105:1382–1389

Hindra F, Baik O-D (2006) Kinetics of quality changes during food frying. Crit Rev Food Sci Nutr 46:239–258

Van Boekel MAJS (2008) Kinetic modeling of food quality: a critical review. Comp Rev Food Sci Food Safety 7:144–158

Kalogianni EP, Karastogiannidou C, Karapantsios TD (2010) Effect of potato presence on the degradation of extra virgin olive oil during frying. Int J Food Sci Technol 45:765–775

Kalogianni EP, Karastogiannidou C, Karapantsios TD (2009) Effect of the presence and absence of potatoes under repeated frying conditions on the composition of palm oil. J Am Oil Chem Soc 86:561–571

Lioumbas JS, Ampatzidis C, Karapantsios TD (2012) Effect of potato deep-fat frying conditions on temperature dependence of olive oil and palm oil viscosity. J Food Eng 113:217–225

Fine F, Brochet C, Gaud M, Carre P, Simon N, Ramli F, Joffre F (2016) Micronutrients in vegetable oils: the impact of crushing and refining processes on vitamins and antioxidants in sunflower, rapeseed, and soybean oils. Eur J Lipid Sci Technol 118:680–697

Firestone D (2009) Official methods and recommended practices of the American Oil Chemists’ Society, 6th edn. AOCS Press, Champaign, IL

ISO (2006) Animal and vegetable fats and oils—determination of anisidine value (Method 6885) International Organization for Standardization, Geneva, Switzerland 1–7

Schulte E (2004) Economical micromethod for determination of polar components in frying fats. Eur J Lipid Sci Technol 106:772–776

Kaymak-Ertekin F, Gedik A (2005) Kinetic modelling of quality deterioration in onions during drying and storage. J Food Eng 68:443–453

Codex Alimentarius Commission (CAC) (1999) Codex Standard For Named Vegetable Oils

Mba O, Adewale P, Dumont M-J, Ngadi M (2014) Application of near-infrared spectroscopy to characterize binary blends of palm and canola oils. Ind Crops Prod 61:472–478

Azmil Haizam Ahmad T, Siew Wai L (2008) Quality assessment of palm products upon prolonged heat treatment. J Oleo Sci 57:639–648

Xu T-T, Li J, Fan Y-W, Zheng T-W, Deng Z-Y (2014) Comparison of oxidative stability among edible oils under continuous frying conditions. Int J Food Prop 18:1478–1490

Meier L (2014) Statistical and Numerical Methods for Chemical Engineers:12–19

Laguerre M, Lecomte J, Villeneuve P (2007) Evaluation of the ability of antioxidants to counteract lipid oxidation: existing methods, new trends and challenges. Prog Lipid Res 46:244–282

Sathivel S, Huang J, Prinyawiwatkul W (2008) Thermal properties and applications of the Arrhenius equation for evaluating viscosity and oxidation rates of unrefined pollock oil. J Food Eng 84:187–193

Piedrahita AM, Penaloza J, Cogollo A, Rojano BA (2015) Kinetic Study of the oxidative degradation of Choiba oil (Dipteryx oleifera Benth.) with addition of Rosemary extract (Rosmarinus officinalis L.). Food Nutr Sci 6:466–479

Goburdhun D, Jhurree B (1995) Effect of deep-fat frying on fat oxidation in soybean oil. Int J Food Sci Nutr 46:363–371

Tompkins C, Perkins EG (2000) Frying performance of low-linolenic acid soybean oil. J Am Oil Chem Soc 77:223–229

Karakaya S, Şimşek Ş (2011) Changes in total polar compounds, peroxide value, total phenols and antioxidant activity of various oils used in deep fat frying. J Am Oil Chem Soc 88:1361–1366

Ali RFM, El-Anany AM (2012) Physicochemical studies on sunflower oil blended with cold pressed tiger nut oil, during deep frying process. Food Proc Technol 3:1–8

Gil B, Cho YJ, Yoon SH (2004) Rapid determination of polar compounds in frying fats and oils using image analysis. LWT Food Science and Technology 37:657–661

Benedito J, Mulet A, Velasco J, Dobarganes MC (2002) Ultrasonic assessment of oil quality during frying. J Agric Food Chem 50:4531–4536

Lumley ID (1988) Polar compounds in heated oils. Ellis Horwood Ltd, Chichester

Lalas S, Gortzi O, Tsaknis J (2006) Frying stability of Moringa stenopetala seed oil. Plant Foods Hum Nutr 61:93–102

Xu XQ, Tran VH, Palmer M, White K, Salisbury P (1999) Chemical and physical analyses and sensory evaluation of six deep-frying oils. J Am Oil Chem Soc 76:1091–1099

Chen W-A, Chiu CP, Cheng W-C, Hsu C-K, Kuo M-I (2013) Total polar compounds and acid values of repeatedly used frying oils measured by standard and rapid methods. J Food Drug Anal 21:58–65

Farhoosh R (2011) Effect of antioxidants on the stability of canola oil during deep frying. World Conference on Oilseed Processing, Fats and Oils Processing, Biofuels and Applications, Hilton Izmir, Izmir, Turkey

Aladedunye F, Przybylski R (2009) Degradation and nutritional quality changes of oil during frying. J Am Oil Chem Soc 86:149–156

Omar MN, Nor-Nazuha MN, Nor-Dalilah MN, Sahri MM (2010) Frying performance of palm-based solid frying shortening. Pak J Biol Sci 13:298–302

Wenstrup MJ, Plans M, Rodriguez-Saona LE (2014) Effect of a novel induction food- processing device in improving frying oil quality. Int J Food Sci Technol 49:2223–2229

Acknowledgments

The authors acknowledge the Natural Science and Engineering Research Council (NSERC) of Canada for their financial support. The Tertiary Education Trust Fund (TETFUND), Abuja Nigeria is acknowledged for the scholarship provided to Mr. Ogan Mba. Finally, the Abia State University (ABSU), Uturu Nigeria is acknowledged for the leave of absence extended to Ogan Mba.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

About this article

Cite this article

Mba, O.I., Dumont, MJ. & Ngadi, M. Deterioration Kinetics of Crude Palm Oil, Canola Oil and Blend During Repeated Deep-Fat Frying. J Am Oil Chem Soc 93, 1243–1253 (2016). https://doi.org/10.1007/s11746-016-2872-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2872-z