Abstract

The availability of a rapidly increasing number of genome sequences of basidiomycete fungi has resulted in a strongly growing interest in basidiomycete genes and enzymes, in particularly those related to plant biomass degradation. The arsenal of enzymes produced by basidiomycete fungi differs markedly from those produced by ascomycete fungi, and the properties of the enzymes are also different. Most basidiomycetes do not have efficient transformation systems and large scale enzyme production in basidiomycetes is challenging. Therefore, heterologous production in ascomycete hosts is often the approach of choice, but there are still many challenges in producing these enzymes. Factors hampering heterologous expression of basidiomycete genes in ascomycetes include differences in the gene content such as in codon usage bias, and intron structure and size. In addition, basidiomycete enzymes are often considered foreign by the ascomycete production systems and therefore targets for their proteolytic systems, reducing the production yields.

In this chapter we provide the state of the art of expression of basidiomycete genes involved in plant biomass degradation and the production of the corresponding enzymes. Both homologous and heterologous expression is addressed and an overview of successful studies including the production yield is presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Basidiomycetes

- Heterologous expression

- Homologous expression

- Plant biomass degradation

- Pichia

- Biotechnology

1 Introduction

The necessity to move towards a bio-based economy creates many challenges for industry and academia. Industries dedicated to supplying the population with food, feed, detergents, textile and other products collaborate with researchers to develop efficient biotechnological tools. This includes the development of optimal enzyme sets to convert plant biomass into valuable products. Recently there has been a strong increase in the demand of these enzymes due to their growing biotechnological significance (Harris et al. 2014).

Fungi play an important role in plant biomass degradation; therefore improving the production of fungal enzymes is of great interest for biotechnology. Fungal enzymes have been mainly studied in saprobic ascomycetes, and much less extensively in basidiomycetes. This is largely caused by the better manageability of ascomycetes in industrial fermentations and the availability of transformation systems for many ascomycetes, while these aspects are still a major challenge in basidiomycetes. Despite this, basidiomycetes form a promising source of novel enzymes with different biochemical properties than ascomycete enzymes.

Plant biomass consists mainly of polysaccharides, proteins and lignin (Pauly and Keegstra 2010). Ascomycete enzyme systems focus largely on the polysaccharide fraction but they rarely modify the aromatic lignin polymer, due to the absence of lignin-modifying peroxidases in their genomes (Floudas et al. 2012). They do produce laccases, which have been implicated to potentially modify lignin (Xie et al. 2014). In contrast, basidiomycetes include the most efficient lignin decomposers, but they also degrade polysaccharides. The lignin-modifying enzymes of basidiomycetes are of fundamental importance for efficient bioconversion of plant residues that are rich in lignin, such as wheat straw. They are therefore highly relevant for various biotechnological applications, for example pulp and paper, and textile industries, bioremediation, and the production of biofuels and biochemicals (Jolivalt et al. 2005; Raghukumar et al. 2008). With respect to plant biomass degradation, basidiomycetes are classifi ed either as white-rot, brown-rot or litter-decomposing fungi. White- and brown-rot refer to the appearance of wood after fungal decomposition. Brown-rot fungi efficiently degrade wood polysaccharides but are only slightly capable of modifying lignin, resulting in a brownish residue of partly decayed wood. In contrast, white-rot fungi are able to decompose all wood polymers, including lignin, resulting in a white residue, consisting mainly of cellulose (Lee et al. 2014; Ruiz-Dueñas et al. 2013; Rytioja et al. 2014).

1.1 Plant Polysaccharide Degrading Enzymes

Cellulose is the most abundant polysaccharide in plant biomass. This polymer gives rigidity to the plant cell wall and is formed by chains of β-1,4-linked d-glucose molecules that create linear crystalline structures (microfibrils) and less crystalline, amorphous regions (Kolpak and Blackwell 1976).

Several types of hemicelluloses are present in plant biomass: xyloglucan, xylan, mannan, glucomannan, and β-1,3/1,4-glucans. They are named after the monosaccharides that form their backbone (de Vries and Visser 2001). In addition, they contain various branches consisting of monomers and short oligomers.

Pectin is a heteropolysaccharide mainly composed of three principal structures (Caffal and Mohnen 2009). The simplest one is homogalacturonan, a galacturonic acid based linear polysaccharide. Xylogalacturonan is modified form of homogalacturonan in that it contains xylose branches. Rhamnogalacturonan I has a backbone of alternating galacturonic acid and rhamnose residues, with arabinan and (arabino-)galactan side chains attached to the rhamnose residues.

Each plant polysaccharide degrading fungus has a specific set of carbohydrate-active enzymes involved in the degradation of the backbone and branching structures (Culleton et al. 2013; van den Brink and de Vries 2011). The different enzymes involved in this process with their CAZy family (Lombard et al. 2014), EC number and substrate are listed in Table 1. While some enzymes act only on a single polysaccharide (e.g. cellobiohydrolase on cellulose), others are involved in the degradation of several polysaccharides (e.g. β-galactosidase for xylan, pectin, xyloglucan and galactomannan). An overview of the available knowledge on plant polysaccharide degrading enzymes from basidiomycetes was recently presented (Rytioja et al. 2014).

1.2 Lignin-Modifying Enzymes

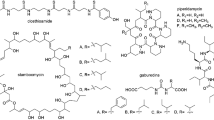

Lignin is a complex heterogenous aromatic polymer that is among the most abundant natural materials on earth (Martinez et al. 2004). Lignin is present in all layers of woody cell walls and is composed of three monomers: coniferyl alcohol, sinapyl alcohol and p-coumaryl alcohol. Plant laccases and peroxidases polymerize these monomers to guaiacyl-, syringyl- and hydroxyphenyl-type of lignin subunits (Higuchi 2006). The most common linkage between the subunits is a β-aryl-ether linkage (Adler 1977), but other linkages also occur (Brunow et al. 1998). The structure and composition of lignin varies significantly depending on the plant species (Martínez et al. 2008; Ralph et al. 2004). Lignin is an undesirable component e.g. in the conversion of wood into pulp and paper and remova1 of lignin is a major step in the paper making process (Campbell and Sederoff 1996). White-rot basidiomycetes are studied due to their efficient and complete degradation of woody plant cell walls (Ruiz-Dueñas et al. 2008). In contrast to other fungi and bacteria they are capable of mineralising lignin to carbon dioxide and water by producing extracellular, oxidative lignin-modifying enzymes. These include class II heme-containing peroxidases (AA2 in CAZy database), i.e. manganese peroxidases (MnPs), lignin peroxidases (LiPs) and versatile peroxidases (VPs), which catalyse H2O2-dependent unspecific reactions (Table 1) (Mäkelä et al. 2014). Various phenolic compounds are oxidised to organic radicals via the action of MnPs, while LiPs are able to oxidise non-phenolic lignin substructures. VP is a hybrid type of peroxidase combining the activities of both MnP and LiP (Kamitsuji et al. 2005; Ruiz-Dueñas et al. 2001).

Fungal laccases (AA1_1 in CAZy database) belong to the widely distributed family of multicopper oxidases and participate in many processes from fungal morphogenesis to melanin synthesis (Giardina et al. 2010; Kües and Rühl 2011). Laccases catalyse the oxidation of phenolic compounds and aromatic amines coupled to the reduction of molecular oxygen to water (Giardina et al. 2010). In the presence of small molecular weight mediator molecules laccases can also oxidise non-phenolic compounds. Although the role of laccases in lignin degradation is still debatable, they are usually regarded as lignin-modifying enzymes (Lundell et al. 2010). Laccases can be used in various biotechnological processes. For example the white-rot fungus Trametes pubescens is considered an excellent producer of industrial laccases (Galhaup et al. 2002). Applications of laccases include bleaching of textiles (Vinod 2001) and wood pulp (Widsten and Kandelbauer 2008), clearing of fruit juice, beer and wine (Minussi et al. 2002), biosensors (Kulys and Vidziunaite 2003), hair dyes, degradation of plastics and decontamination of soils (Kunamneni et al. 2008).

Despite the huge biotechnological potential of fungal lignin-modifying enzymes, the production of both laccases and peroxidases to levels required by industry using homologous and heterologous expression remains a challenge and has been the topic of numerous research projects.

2 Homologous and Heterologous Expression of Basidiomycete Genes in Basidiomycetes

Overexpression of genes in basidiomycetes is less commonly performed than in ascomycetes. This is largely due to the availability of transformation systems for many ascomycetes, while only a relatively small number of basidiomycetes can be transformed. A well-developed transformation system based on auxotrophic mutants was generated for the white-rot fungus Phanerochaete chrysosporium that is the best studied basidiomycete with respect to plant biomass degradation (Mayfield et al. 1994). Transformation systems are also being developed for other basidiomycete species and significant progress has been made (e.g. Burns et al. 2005, 2006; Eastwood et al. 2008; Salame et al. 2012; Sharma and Kuhad 2010; Shi et al. 2012; Wang et al. 2008), but their efficiency is still significantly less than those of ascomycetes.

2.1 Homologous Expression

Homologous transformation of plant cell wall degradation related genes is limited to a small number of basidiomycete species and this involves mainly genes related to lignin degradation. The advantage of homologous overexpression is that the genes do not need to be modified to accommodate optimal codon usage or gene structure as is sometimes the case for heterologous overexpression (Kajita et al. 2004). Homologous expression in basidiomycetes has been reported for several genes (Irie et al. 2001; Li et al. 2000; Ma et al. 2003; Mayfield et al. 1994; Sollewijn Gelpke et al. 1999), and some examples are discussed in more detail below and listed in Table 2.

Laccases have been overproduced in some basidiomycete species. The genome of the white-rot fungus Trametes (Coriolus) versicolor contains several laccases but the highest secretion level was observed for laccase III (CVL3, Kajita et al. 2004). Improved production of this enzyme was achieved by transformation using a chimeric gene for laccase III under glyceraldehyde-3-phosphate dehydrogenase (GPD) promoter of T. versicolor and hygromycin B phosphotransferase (hph) gene that encodes resistance to phleomycin and hygromycin B as a selection marker. In addition, a further improvement was made by the addition of copper (II) sulphate to the growth medium (Kajita et al. 2004).

Overexpression of laccase genes in the white-rot species Polyporus brumalis resulted in a three to fourfold increase in laccase activity (Ryu et al. 2008 b). In this case, transformants were generated using the restriction enzyme mediated integration (REMI) method (Leem et al. 1999) and using hygromycin resistance selection. The lcc1 gene of the coprophilic fungus Coprinopsis cinerea has been homologously expressed using different homologous and heterologous promoters. The highest activity of one of the C. cinerea transformants was reached under control of gpd II promoter from the litter-decomposing fungus Agaricus bisporus and with addition of copper to the medium (Kilaru et al. 2006).

The production of a laccase of the white-rot fungus Pycnoporus cinnabarinus was significantly increased by overexpression under control of its own promoter, and Schizophyllum commune GPD and hydrophobin (SC3) promoters (Alves et al. 2004). The maximum levels (4660 nkat mL−1) are the highest reported so far, highlighting the potential of this species for enzyme production.

As mentioned above, P. chrysosporium has been the most extensively studied white-rot basidiomycete and a transformation system for this fungus was already developed many years ago (Mayfield et al. 1994). The P. chrysosporium genome does not have laccase encoding genes, but this species produces a number of lignin-modifying heme peroxidases (Martinez et al. 2004).

Homologous production of lignin peroxidase (LiPH8) of P. chrysosporium has been successful (Sollewijn Gelpke et al. 1999). LiPs are major extracellular components of the lignin-degrading system of P. chrysosporium, but there are still open questions about their mechanisms of action, like the presumptive role of veratryl alcohol as a mediator in LiP-catalysed reactions.

Another species of the genus Phanerochaete, Phanerochaete sordida, exhibits greater ligninolytic selectivity during growth on beech wood than either P. chrysosporium or T. versicolor, and produces two LiPs (YK-LiP1 and YK-LiP2) under manganese-deficient conditions. Cloning and homologous expression of the YK-LiP1 and YK-LiP2 encoding genes in P. sordida YK-624 were carried out to obtain higher levels of these enzymes allowing characterization of the recombinant protein (Sugiura et al. 2009).

A manganese peroxidase (MnP3) from the white-rot fungus Pleutorus ostreatus was also homologously overproduced using a drug-resistant selection marker. This marker was based on a nucleotide substitution in P. ostreatus sdi1, encoding an iron sulfur protein that confers dominant resistance to the fungicide carboxin (Honda et al. 2000). The recombinant mnp3 was expressed under control of the P. ostreatus sdi1 promoter and terminator (Irie et al. 2001).

Due to the lower transformation efficiency of (filamentous) basidiomycetes compared to ascomycetes, relatively few studies have been reported on gene disruption of plant biomass degradation related genes in basidiomycetes. However, a homologous gene-replacement system was developed for P. ostreatus (Salame et al. 2012). This highlighted the limitations of homologous recombination in basidiomycetes due to the low frequency (2.3 %) of site-specific recombination of DNA integration and the low transformation efficiency using protoplast-mediated transformation.

2.2 Heterologous Expression in Other Basidiomycetes

Because of the limited number of easily transformable basidiomycete species only few basidiomycete genes encoding plant biomass degrading enzymes have been heterologously expressed in other basidiomycetes (Table 3). One example is the expression of a MnP encoding gene from the white-rot fungus Dichomitus squalens in P. chrysosporium. Most (82 %) of the transformants exhibited MnP activity and further analysis demonstrated that the recombinant protein was fully functional (Li et al. 2001)

Glucuronoyl esterases are suggested to break the linkage between lignin and xylan through glucuronic acid. Two genes (ge1 and ge2) from P. chrysosporium encoding these enzymes were successfully expressed in P. cinnabarinus under control of the S. commune GPD promoter and in S. commune under control of the S. commune SC3 promoter to produce the recombinant protein (Duranová et al. 2009). The highest glucoronoyl esterase activity was found in the transformants of ge2 in S. commune.

3 Heterologous Expression of Basidiomycete Genes in Ascomycetes

3.1 Expression in Yeasts

Pichia pastoris and Saccharomyces cerevisiae are the most commonly used yeast hosts for heterologous expression of plant biomass modifying enzyme encoding genes from basidiomycetes. This is because of the various production strains and vectors that are available for these species. In few cases, Kluyveromyces lactis, Pichia methanolica and Yarrowia lipolytica have been employed as hosts for the production of basidiomycete plant biomass modifying enzymes. K. lactis, S. cerevisiae and Y. lipolytica are generally regarded as safe (GRAS) organisms, which is beneficial when producing food or medical related proteins. The methylotrophic yeasts P. pastoris and P. methanolica both have two alcohol oxidase (AOX, AUG) encoding genes and can utilize methanol as a sole carbon source (Cregg et al. 1989; Raymond et al. 1998). The strong and regulated AOX (or AUG) promoter regions of these yeasts are widely employed for the heterologous expression of recombinant proteins.

In contrast to the other eukaryotic heterologous protein production systems, the yeast systems are fast and inexpensive ways to achieve recombinant proteins. One of the main advantages is also the availability of a wide variety of well-developed tools for genetic manipulation of yeasts. In addition, unicellular yeasts are easy to cultivate in bioreactors, unlike filamentous fungi. Yeasts can be cultivated on a comparatively simple and inexpensive medium at a relatively fast growth rate (Daly and Hearn 2005). As eukaryotic organisms , yeasts are more suitable for the production of eukaryotic proteins than bacteria, since yeasts are able to perform several post-translational modifications, which are often crucial for the biochemical properties of the target proteins. These include e.g. phosphorylation, glycosylation, formation of disulfide bonds and proteolytic processing of the signal sequence (Cregg et al. 2000; Gasser et al. 2008; Huang et al. 2012).

Although yeasts are able to perform these modifications, the patterns of O- and N-linked sugar units added to the synthesized proteins by yeasts differ from those of other eukaryotes (Berends et al. 2009; Cereghino and Cregg 2000; Gasser et al. 2008; Gellissen et al. 2005; Hamilton and Gerngross 2007; Herscovics and Orlean 1993). This can be a drawback when using yeasts as production hosts since the different glycosylation patterns may alter the folding of the recombinant protein and by that change its biochemical and functional properties (Berends et al. 2009; Bohlin et al. 2006; Hamilton and Gerngross 2007; Herscovics and Orlean 1993). The O-linked glycosylation of the proteins produced by yeasts consist only of mannose subunits. In contrast, higher eukaryotes, including basidiomycete fungi, add also other O-linked sugar units, such as galactose, N-acetylgalactosamine and N-acetylglucosamine, to the proteins (Lengeler et al. 2008). Yeasts may also attach excess N-linked mannose subunits to the recombinant proteins (Fig. 1) (Berends et al. 2009; Hamilton and Gerngross 2007; Herscovics and Orlean 1993). Especially, S. cerevisiae is known to hyperglycosylate secreted proteins (Mattanovich et al. 2009).

Yeast can produce intracellular recombinant proteins or secrete proteins out of the cells (Macauley-Patrick et al. 2005). However, secretion of the recombinant proteins is usually preferred, since targeting of the recombinant protein into the yeast eukaryotic secretory pathway is necessary especially when the recombinant protein requires post-translational modifications. Yeasts also secrete relatively low levels of native proteins, thus simplifying the recovery and purification of the target protein from the extracellular culture medium (Cregg et al. 2000; Huang et al. 2011a).

3.1.1 Yeast Expression Systems Used for the Heterologous Production of Plant Biomass Modifying Enzymes from Basidiomycetes

3.1.1.1 Recombinant Protein Production in Saccharomyces Cerevisiae

Multiple S. cerevisiae strains (such as CEN.PK2-1C, CEN.PK113-17A, W303-1A, INVSc1, Y294, BJ5465 and BJ3505) have been used for the heterologous expression of basidiomycete plant cell wall modifying enzymes (Table 4). From these strains, BJ5465 and BJ3505 are protease deficient, thus making the recombinant proteins less susceptible to degradation by extracellular proteases. All the previously mentioned S. cerevisiae strains are auxotrophic mutants which are unable to synthetize uracil or uridine, indispensable compounds for ribonucleic acids, or one of the essential amino acids tryptophan or leucine. These features have been exploited as selection markers in the S. cerevisiae expression vectors (Table 5). Most of the vectors applied for the expression of the basidiomycete lignocellulose modifying genes contain the ura3 gene enabling the uracil auxotrophic strain to grow on a medium that lacks uracil or uridine.

The S. cerevisiae expression vectors employ both constitutive and inducible promoter regions of the yeast. The constitutive promoters applied are alcohol dehydrogenase I (ADH1) and phosphoglycerate kinase (PGK) (Derynck et al. 1983; Hitzeman et al. 1981; Romanos et al. 1992). These promotes are active in the presence of glucose and the genes cloned downstream of them are then expressed. The inducible promoters include galactokinase (GAL1), UDP galactose-4-epimerase (GAL10), alcohol dehydrogenase II (ADH2) and copper-metallothionein (CUP1) (Butt et al. 1984; Johnston and Davis 1984; Mascorro-Gallardo et al. 1996; Romanos et al. 1992; West et al. 1984). The GAL1 and GAL10 promoters are activated by galactose and repressed by glucose. The expression of ADH2 promoter is activated by a non-fermentable carbon source such as ethanol or glycerol, whereas the addition of Cu2+ ions activates the expression of CUP1 promoter region.

3.1.1.2 Recombinant Protein Production in Pichia Pastoris

All P. pastoris strains are derivatives of the wild type strain Y-11430 from Northern Regional Research Laboratories (NRRL, Peoria, IL, USA). Both wild type and auxotrophic strains of P. pastoris have been applied for the production of lignocellulose converting basidiomycete enzymes (Table 4). X-33 is a wild type strain, whereas GS115, KM71 and SMD1168 have a mutated histidinol dehydrogenase (his4) gene and are unable to grow without histidine supplementation. In addition, SMD1168 and SMAD1168H are protease deficient strains that lack protease A activity, thus often improving the yield of recombinant proteins. The strains KM71 and KM71H contain a mutated AOX1 promoter. The remaining AOX2 promoter is weaker and therefore the cells exhibit a slower growth rate with decreased consumption of toxic methanol (Chiruvolu et al. 1997; Cregg et al. 1989). The his4 gene of P. pastoris and a gene encoding resistance against the antibiotic zeocin have been employed as selection markers in the expression vectors (Table 5). In these vectors, alcohol oxidase (AOX) and glyceraldehyde-3-phosphate dehydrogenase (GAP) promoter regions of P. pastoris are used. The AOX1 promoter is induced when methanol is used as the sole carbon source (Cregg et al. 1989) while the constitutive GAP promoter is active in the presence of glucose (Waterham et al. 1997). P. pastoris vectors pPIC3.5, pHIL-D2, pPICZ and pGAPZ use the native signal sequence of the heterologously produced protein for the secretion, whereas in the vectors pPIC9, pPICZα and pGAPZα the signal sequence of S. cerevisiae mating type α-factor is included (Cregg and Higgins 1995).

Compared to other yeasts, P. pastoris is capable of growing at higher cell density (OD600 500) therefore often resulting in elevated yield of recombinant protein (Cereghino and Cregg 2000; Jahic et al. 2002). In fact, the amount of the target protein can be up to 30 % of all the extracellular proteins secreted by P. pastoris (Cregg and Higgins 1995; Gellissen 2000).

3.1.1.3 Other Recombinant Protein Production Systems

K. lactis, P. methanolica and Y. lipolytica are yeast species more rarely applied for the production of plant biomass modifying proteins from basidiomycetes. K. lactis CMK5 strain is a uracil auxotroph and possess only one functional alcohol dehydrogenase (KlADH) encoding gene (Table 4) (Saliola et al. 1999). K. lactis expression vectors include the inducible KlADH4 promoter region (Table 5), which is activated in the presence of ethanol (Saliola et al. 1991). In K. lactis expression vectors, ura3 and a gene encoding antibiotic resistance against geneticin are used as selection markers (Van Ooyen et al. 2006).

The P. methanolica PMAD11 and PMAD16 strains are adenine auxotrophic mutants. In addition, PMAD16 strain is protease deficient. In the P. methanolica expression vector, the ade2 gene from S. cerevisiae has been used to complement adenine auxotrophy in the host strain (Table 5) (Raymond et al. 1998). Similarly with P. pastoris, the methanol inducible promoter region of alcohol oxidase (AUG) has been applied for the production of recombinant proteins in P. methanolica (Raymond et al. 1998). The pMETα vector utilizes the signal sequence of S. cerevisiae mating type α-factor for the secretion of the recombinant protein.

The protease deficient and leucine auxotrophic strain of Y. lipolytica , Polg, has been used for the production of recombinant plant cell wall degrading enzymes from basidiomycetes (Table 4) (Madzak et al. 2004). The expression vectors pINA1267 and pINA1296 both contain the inducible leucine promoter region (pLEU2) of Y. lipolytica which is activated by the presence of leucine precursors (Table 5) (Madzak et al. 2000, 2004). These vectors complement leu2 deficiency providing a wild type phenotype. Recombinant proteins are secreted by employing the signal sequence of extracellular protease (XPR2) of Y. lipolytica (Madzak et al. 2000).

3.1.2 Examples of Recombinant Proteins Involved in Plant Biomass Degradation Produced in Yeasts

Biochemically active plant biomass modifying enzymes including hydrolases, oxidases and lyases from various basidiomycete species has been successfully produced in S. cerevisiae and P. pastoris (Table 6). Most of these enzymes originate from wood-decaying white-rot fungal species. Recently, the P. pastoris expression system has gained an increasing interest when compared to S. cerevisiae and other yeast systems.

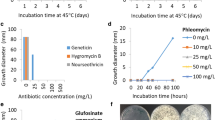

Laccases (AA1_1) are the most commonly produced basidiomycete lignin modifying enzymes in yeasts (Table 6). From lignin modifying oxidoreductases, the highest activity levels, up to 7200 U/L, have been achieved with laccase from the saprobic fungus Cyathus bulleri produced in P. pastoris (Garg et al. 2012). The highest protein yield, up to 340 mg/L, has been reported when laccase of the white-rot fungus Trametes trogii has been produced in P. pastoris (Colao et al. 2009). Laccase production in P. pastoris has been significantly optimized. Supplementation of copper ions and lowered growth temperature (15–25 °C) has resulted in increased laccase activity (Cassland and Jönsson 1999; Hildén et al. 2013; Liu et al. 2003; O’Callaghan et al. 2002). While copper ions are indispensable for laccase activity by forming the enzyme catalytic site (Baldrian 2006), lower temperature may prevent denaturation and aggregation of the native proteins which decreases the need for protein folding mechanisms resulting in higher and more efficient secretion capacity (Dragosits et al. 2009). In addition, improved production of two laccase isoenzymes of Coprinus comatus has been obtained by using an N-terminal fusion of 10 amino acids from a Volvariella volvacea xylanase (Gu et al. 2014).

Different class II heme peroxidases (AA2), lignin peroxidases (LiPs), manganese peroxidases (MnPs) and versatile peroxidases (VPs) have been produced in S. cerevisiae and P. pastoris (Garcia-Ruiz et al. 2012; Gu et al. 2003; Jiang et al. 2008; Ryu et al. 2008a; Wang and Wen 2009). The highest production level, 21 mg/L, has been described for the white-rot fungus Pleurotus eryngii VP produced in S. cerevisiae (Garcia-Ruiz et al. 2012). Recombinant production of class II heme peroxidases has been challenging in yeasts (Conesa et al. 2002). However, they have been produced successfully in Escherichia coli and Aspergillus species (Conesa et al. 2002; Fernández-Fueyo et al. 2012, see 3.2.1). The main obstacle in producing recombinant class II heme peroxidases is the availability and incorporation of iron-containing heme as the prosthetic group (Franken et al. 2011; Gu et al. 2003). While the production of heme peroxidases increased by supplementation of hemoglobin or hemin to the medium (Conesa et al. 2000; Gu et al. 2003), the mechanism of heme uptake is poorly understood. Better knowledge of the heme biosynthetic pathway and its regulation is needed to overcome the limiting effect of heme.

The production of active oxalate metabolizing enzymes, oxalate decarboxylase (ODC) and oxalate oxidase (OXO), from the white-rot fungi Dichomitus squalens (Sietiö et al. 2015) and Ceriporiopsis subvermispora (Moomaw et al. 2013; Moussatche et al. 2011), respectively, has been successful in P. pastoris (Table 6). In wood-decaying fungi these enzymes have been associated with the regulation of intra- and extracellular concentrations of oxalic acid, which is one of the key components in biological decomposition of wood. The production level of C. subvermispora OXO was 4 mg/L (Moussatche et al. 2011).

In addition to the lignin modifying oxidoreductases, plant cell wall polysaccharide degrading enzymes of basidiomycetes have been produced in S. cerevisiae and P. pastoris. The production of cellulose hydrolysing enzymes such as cellobiohydrolase I (GH7), cellobiohydrolase II (GH6), endoglucanases (GH5, GH45) and β-glucosidase (GH1) have been described (Table 6). From those, the highest yield (100 mg/L) was obtained for endoglucanase from the straw-degrading basidiomycete V. volvacea produced in P. pastoris (Ding et al. 2002). Oxidative cellobiose dehydrogenases (CDH; AA3 and AA8) have been produced only in P. pastoris (Bey et al. 2011; Stapleton et al. 2004; Yoshida et al. 2001), and the highest yield (350 mg/L) was achieved for CDH from the white-rot fungus P. cinnabarinus (Bey et al. 2011).

Some hemicellulose degrading enzymes, such as β-mannanase (GH5), endo-β-1,4-xylanase (GH10), β-galactanase (GH43), arabinanase (GH43), an enzyme possessing both xylosidase and arabinofuranosidase activities (GH43), and acetyl xylan esterase (CE1) have also been produced in yeasts (Table 6). The best production level, up to 440 mg/L, in P. pastoris has been reported for a β-mannanase from the plant pathogen Armillariella tabescens (Wang et al. 2009).

3.2 Expression in Filamentous Ascomycetes

The limitations of overexpression of genes in basidiomycetes has stimulated attempts to heterologously express basidiomycete genes in filamentous ascomycetes, in particular those species used in industry, due to their high secretion capacity and good fermentation properties. However, production levels of basidiomycete enzymes in these ascomycetes are often very low. In this section we will provide examples of successful expression and the production levels that were reached.

Many yeasts and filamentous fungi have been used as hosts to develop different heterologous protein production systems for basidiomycete enzymes (Hoshida et al. 2005). Particular emphasis has been on lignin-modifying enzymes, as they are largely absent in ascomycete fungi. However, most lignin-modifying enzymes are generally difficult to overproduce heterologously in an active form (Hoshida et al. 2005). Heterologous production of active lignin-modifying peroxidases has been reported in several species (Eibes et al. 2009; Montiel-González et al. 2009; Stewart et al. 1996), but in no cases the levels have been satisfactory enough taking into account the amount of enzyme required for its biotechnological application. One of the reasons of this setback is factors related to the hemoprotein nature of the peroxidases.

3.2.1 Heterologous Expression in Aspergillus and Penicillium

Aspergillus niger is a well-known fungal host that produces high levels of recombinant enzymes for many industrial applications. It is therefore not surprising that it has also been used for the expression of basidiomycete genes.

The enzyme that has received the most attention for heterologous production in ascomycetes is laccase, due to its potential in a variety of industrial applications (Kunamneni et al. 2008). While overall expression of basidiomycete laccases in Aspergillus and Penicillium is regularly successful, the production levels vary strongly (Table 3). Expression of a laccase from P. cinnabarinus in P. pastoris resulted in a protein that differed in some biochemical properties (e.g. molecular mass, isoelectric point, optimal temperature and pH) from the native enzyme (Otterbein et al. 2000). However, expression of this laccase in A. niger demonstrated highly similar properties to the native enzyme, suggesting that A. niger is a more suitable production host for this enzyme (Record et al. 2002). When comparing the production of the P. cinnabarinus laccase in A. niger and Aspergillus oryzae, higher protein yields were obtained for A. oryzae (Sigoillot et al. 2004). While the biochemical properties were similar between the native and the recombinant enzymes, the recombinant enzymes had a higher K m value than the native enzyme. Also, in the presence of a redox mediator, 1-hydroxybenzotriazole, both the native enzyme and the recombinant enzyme produced in A. niger were able to delignify Kraft pulp almost to 75 %, while no delignification was observed with the A. oryzae produced enzyme (Sigoillot et al. 2004). Other basidiomycete laccases were also expressed in A. niger, such as one from P. eryngii (pel3), although the activity level obtained was low (Rodríguez et al. 2008). The best result was obtained when the native signal peptide was replaced by the signal peptide from A. niger glucoamylase and a protease deficient A. niger strain was used, suggesting that the native signal sequence was not well recognized and/or processed by A. niger. Expression in a low-protease producing A. niger strain also resulted in high production levels for a laccase from P. ostreatus and a variant thereof that was obtained through directed evolution (Macellaro et al. 2014). Using a low protease strain was also beneficial for the production of a laccase from S. commune. Several ascomycete strains were tested in this study, but the best production was achieved with Aspergillus sojae 1860, which has low extracellular protease levels (Hatamoto et al. 1999). These results indicate that ascomycete proteases can significantly reduce the production of basidiomycete enzymes.

The fermentation approach also affects the production of laccases, as was demonstrated for the production of a T. versicolor laccase in A. niger. Solid state fermentation resulted in a much higher yield of laccase than submerged fermentation (Téllez-Jurado et al. 2006). In a different study, expression of two laccase genes from T. versicolor in A. niger under control of the gpdA promoter demonstrated much higher yield compared to expression of these genes in P. pastoris (Bohlin et al. 2006), confirming the high potential of A. niger for industrial enzyme production, while P. pastoris is more suitable for academic studies.

A Trametes villosa laccase (lcc1) was successfully expressed in another industrial Aspergillus species, A. oryzae and the properties of the recombinant enzyme were the same as those of the native enzyme (Yaver and Golightly 1996). This demonstrates that while there are differences in the glycosylation patterns of ascomycetes and basidiomycetes (Berends et al. 2009), these do not necessarily affect the biochemical properties of the heterologously produced enzymes. A. oryzae was also used for the heterologous production of a laccase from the white-rot fungus Pycnoporus coccineus using the maltose inducible promoter of α-amylase encoding amyB gene (Taka promoter) (Hoshida et al. 2005). The activity of this laccase was highly copper-dependent, even if the expression of the gene under control of the amyB promoter was not. When three laccase genes from the plant pathogenic basidiomycete Rhizoctonia solani were expressed in A. oryzae under control of the Taka amylase promoter, good production levels were only obtained for two of the enzymes (Wahleithner et al. 1996). For the third gene an initial activity level could be detected, but this disappeared in time, suggesting that this enzyme was not stable in A. oryzae cultures.

Penicillium is a sister genus of Aspergillus and species of this genus are more commonly used for the production of secondary metabolites than of enzymes. However, heterologous production of a laccase from Trametes hirsuta in Penicillium canescens resulted in a high level of secreted protein (Abianova et al. 2010), indicating that species of this genus could be good alternatives for Aspergillus species with respect to enzyme production.

Heterologous expression of genes encoding lignin-modifying peroxidases from P. chrysosporium has been performed in several Aspergilli (Cortés-Espinosa et al. 2011). Stewart et al. (1996) were able to successfully produce active MnP and LiP from P. chrysosporium in A. oryzae under control of the Taka amylase promoter. To achieve this hemin was added to the culture medium. The same mnp containing expression vector was also introduced in A. niger where active protein was similarly detected when the culture medium contained hemoglobin (Cortés-Espinosa et al. 2011). However, the best A. niger transformant had less activity than the native P. chrysosporium strain.

The importance of temperature during bioreactor cultivation for the improvement of the recombinant proteins was demonstrated in a recent study using a versatile peroxidase from Pleurotus eryngii. The production of this enzyme in A. nidulans and A. niger was performed under different temperatures and the highest activity was obtained at 19 °C, which is significantly below the optimum growth temperature for A. niger (Eibes et al. 2009). Also in these cultures, hemin was added to the media.

Production levels of the flavoenzyme aryl-alcohol oxidase (AAO), also involved in lignin degradation, in P. eryngii are quite low and unsuitable for industrial applications. Heterologous production of the P. eryngii AAO encoding gene in A. nidulans was performed using the strong inducible alcohol dehydrogenase promoter (alcA). The recombinant protein had the same molecular mass and isoelectric point as the native protein, suggesting no significant modifications. In addition, the production of the recombinant enzyme was 10–50 times higher than in the original fungus, indicating that this strategy is highly promising for obtaining industrially relevant levels of lignin-related enzymes (Varela et al. 2001).

Cellobiose dehydrogenases (CDHs) are produced by many plant biomass degrading and phytopathogenic fungi, but the function of these enzymes are not fully deciphered. A putative cdh gene from Coprinopsis cinerea as well as one from the ascomycete Podospora anserina were successfully expressed in A. niger to enable comparison of their enzymatic properties (Turbe-Doan et al. 2013). Interestingly a much higher activity was observed for the transformant carrying the C. cinerea cdh and taking into account the specific activity of the enzymes, a fivefold higher enzyme production was observed for the basidiomycete protein (Turbe-Doan et al. 2013).

In many studies, the main purpose of heterologous expression of the gene is to allow the detailed characterization of the enzyme, since the production level in the original species is too low or the purification is too complicated to obtain sufficient amounts of pure enzyme. This was the case for the CDH described above, but for instance also for the heterologous expression of a cellobiohydrolase gene (cbh1) from the plant pathogen Athelia rolfsii (synonym Corticium rolfsii) in A. oryzae under control of the phosphoglycerate kinase promoter pgkA (Yasokawa et al. 2003). The same motivation resulted in the expression of the UeBgl3A gene encoding a β-glucosidase from the plant pathogen Ustilago esculenta, in A. oryzae under control of the amyB promoter (Nakajima et al. 2012). The production levels are highly variable though (Table 3), and reflect the problems associated with the heterologous production of basidiomycete proteins in ascomycetes. While some are produced at high levels, others result in only minor amounts of protein that is barely sufficient for extensive characterization.

The major pyranose dehydrogenase (PDH) from the litter-decomposing fungus Agaricus meleagris was heterologously expressed in A. nidulans and A. niger under control of the glucoamylase promoter of the respective species (Pisanelli et al. 2010). Two versions were introduced in A. nidulans, one with its native signal sequence and one with the signal sequence of the A. nidulans glucoamylase, with the native signal sequence resulting in the highest extracellular activity. This is the opposite results as that obtained for the P. eryngii laccase (pel3, see above), where the glucoamylase signal peptide improved the production of the enzyme (Rodríguez et al. 2008). Introduction of this modified version of PDH in A. niger resulted in yields that were 10 times lower than those obtained for the best A. nidulans transformant (Pisanelli et al. 2010). As expression of P. eryngii pel3 was also performed in A. niger, this could imply that A. nidulans is more capable to processing basidiomycete signal peptides.

Expression of a P. cinnabarinus glucuronoyl esterase encoding gene was attempted in A. niger and Aspergillus vadensis under control of the A. niger glucoamylase promoter (Duranová et al. 2009). Activity was only detected in transformants of A. vadensis, although 10–20-fold lower than in transformants of S. commune and P. cinnabarinus (see 2.2). The better result for A. vadensis compared to A. niger could be due to the very low extracellular protease production in A. vadensis and the absence of acidification of the medium (de Vries et al. 2004), which may be the main reasons why no active protein was detected in A. niger transformants.

3.2.2 Heterologous Expression in Trichoderma reesei

Trichoderma reesei is with Aspergillus the most commonly used fungus for industrial production of heterologous and homologous proteins, in particular cellulases. Some successful examples of heterologous production of basidiomycete enzymes in T. reesei have been reported (Table 3). One example is the expression of a laccase gene (lacA) from Trametes sp. The gene was placed under control of the strong and constitutive gpdA promoter from A. nidulans and its native signal peptide was replaced by the signal peptide of T. reesei cellobiohydrolase I (CBHI). The production levels obtained for this construct were higher than those of most other studies (Zhang et al. 2012).

Dong et al. (2012) obtained a 28.6-fold higher production of a P. ostreatus laccase by producing it heterologously in T. reesei. The gene was codon optimized for T. reesei and expressed under control of the cbh1 promoter. When this promoter and species was used for the heterologous production of a Phlebia radiata laccase, three additional isoforms were detected, suggesting variable phosphorylation or glycosylation of the recombinant enzyme (Saloheimo and Niku-Paavola 1991). Fusion of heterologous proteins of interest to homologous proteins of the expression host can improve the production of the target protein. To test this, a native form of a laccase from an ascomycete fungus Melanocarpus albomyces and one fused to a hydrophobin were expressed in T. reesei under control of the cbh1 promoter (Macellaro et al. 2014). In this case, the fusion protein was accumulating intracellularly, likely due to the difficulties in secretion, and higher production of the native form was observed.

3.2.3 Promoters Used for Heterologous Expression of Basidiomycete Genes in Ascomycetes

The promoters used for expression of heterologous genes in filamentous ascomycetes can be divided in constitutive and inducible promoters, but all originate from genes that are highly expressed in the intended hosts. The constitutive promoters have the advantage that they result in high expression under most culture conditions, allowing more flexibility in the enzyme production. In contrast, inducible promoters require specific inducing conditions, but often result in higher enzyme production than the constitutive promoters. In addition, inducible promoters can be used for production of proteins that have a negative effect on the production hosts. In such a case, the production strain can initially be grown under non-inducing conditions and when sufficient growth has occurred the inducer can be added to result in a short period of high protein production.

Both types of promoters have been used for heterologous expression of basidiomycete genes encoding plant biomass degrading enzymes (Table 7). The most commonly used inducible promoters are the glucoamylase promoter from A. niger (Conesa et al. 2000) and the Taka amylase promoter from A. oryzae (Stewart et al. 1996), which both respond to the presence of maltose or starch. The most commonly used constitutive promoter is the glyceraldehyde-3-phosphate dehydrogenase (gpdA) promoter from A. nidulans (Punt and van den Hondel 1992), although this promoter has also been used from other species. Recently, a new set of constitutive promoters from A. niger and A. vadensis were tested for enzyme production, resulting in several with a higher production levels than gpdA (Culleton et al. 2014), but these have not yet been tested for the expression of basidiomycete genes.

4 Heterologous Expression in Zygomycetes

Only one example of heterologous expression of basidiomycete genes in zygomycetes has been described (Montiel-González et al. 2009) (Table 3). Amylomyces rouxii was used as a cell factory for heterologous expression of a LiP and a MnP encoding genes from P. chrysosporium under control of the Taka amylase promoter of A. oryzae. A. rouxii is an efficient degrader of organopollutants such as pentachlorophenol (PCP) through its ability to produce phenoloxidases. As no heme peroxidases were found in cultures of this fungus, the introduction of heterologous peroxidases was believed to further improve its ability to degrade PCP, which was confirmed in this study. Interestingly, no exogenous heme or hemoglobin was added to the media to ensure active forms of the heme-containing lignin-modifying peroxidases, as has been used in filamentous ascomycetes.

5 Conclusions and Outlook

Homologous and heterologous overexpression of basidiomycete genes is a challenging research field. The low number of transformable basidiomycete species strongly limits the options for homologous overexpression, as well as heterologous expression in basidiomycete hosts. Development of better transformation systems for a larger number of basidiomycetes will be required to develop them as an enzyme production platform.

In contrast, ascomycete expression systems are well established and cover both yeasts and filamentous fungi as described in this chapter. However, the levels of basidiomycete enzymes produced in these systems are often much lower than those of ascomycete enzymes. No systematic studies into the reasons behind this have been performed, but it is likely that differences in basidiomycete and ascomycete gene models (basidiomycete genes often have more introns with less conserved start and stop sequences) or sensitivity to ascomycete proteases contribute to this. A better understanding of the factors affecting the production of basidiomycete enzymes in ascomycete hosts is required to reach the levels that are suitable for industrial applications.

References

Abianova AR, Chulkin AM, Vavilova EA, et al. A heterologous production of the Trametes hirsuta laccase in the fungus Penicillium canescens. Prikl Biokhim Mikrobiol. 2010;46:342–7.

Adler E. Lignin chemistry—past, present and future. Wood Sci Technol. 1977;11:169–218.

Alves AM, Record E, Lomascolo A, et al. Highly efficient production of laccase by the basidiomycete Pycnoporus cinnabarinus. Appl Environ Microbiol. 2004;70:6379–84.

Autore F, Del Vecchio C, Fraternali F, et al. Molecular determinants of peculiar properties of a Pleurotus ostreatus laccase: Analysis by site-directed mutagenesis. Enzyme Microb Technol. 2009;45:507–13.

Baldrian P. Fungal laccases—occurrence and properties. FEMS Microbiol Rev. 2006;30:215–42.

Bao S, Teng Z, Ding S. Heterologous expression and characterization of a novel laccase isoenzyme with dyes decolorization potential from Coprinus comatus. Mol Biol Rep. 2013;40:1927–36.

Berends E, Ohm RA, De Jong JF, et al. Genomic and biochemical analysis of N glycosylation in the mushroom-forming basidiomycete Schizophyllum commune. Appl Environ Microbiol. 2009;75:4648–52.

Bey M, Berrin J, Poidevin L, et al. Heterologous expression of Pycnoporus cinnabarinus cellobiose dehydrogenase in Pichia pastoris and involvement in saccharification processes. Microb Cell Fact. 2011;10:113–27.

Bleve G, Lezzi C, Mita G, et al. Molecular cloning and heterologous expression of a laccase gene from Pleurotus eryngii in free and immobilized Saccharomyces cerevisiae cells. Appl Microbiol Biotechnol. 2008;79:731–41.

Bleve G, Lezzi C, Spagnolo S, et al. Role of the C-terminus of Pleurotus eryngii Ery4 laccase in determining enzyme structure, catalytic properties and stability. Protein Eng Des Sel. 2013;26:1–13.

Bohlin C, Jönsson LJ, Roth R, et al. Heterologous expression of Trametes versicolor laccase in Pichia pastoris and Aspergillus niger. Appl Biochem Biotechnol. 2006;129:195–214.

Brown MA, Zhao Z, Mauk A. Expression and characterization of a recombinant multi-copper oxidase: laccase IV from Trametes versicolor. Inorg Chim Acta. 2002;331:232–8.

Brunow G, Lundquist K, Gellerstedt G. Lignin. In: Sjöström E, Alén R, editors. Analytical methods in wood chemistry, pulping, and papermaking. Berlin: Springer; 1998. p. 77–124.

Burns C, Gregory KE, Kirby M, et al. Efficient GFP expression in the mushrooms Agaricus bisporus and Coprinus cinereus requires introns. Fungal Genet Biol. 2005;42:191–9.

Burns C, Leach KM, Elliott TJ, et al. Evaluation of agrobacterium-mediated transformation of Agaricus bisporus using a range of promoters linked to hygromycin resistance. Mol Biotechnol. 2006;32:129–38.

Butt TR, Sternberg EJ, Gorman JA, et al. Copper metallothionein of yeast, structure of the gene, and regulation of expression. Proc Natl Acad Sci U S A. 1984;81:3332–6.

Caffal KH, Mohnen D. The structure, function, and biosynthesis of plant cell wall pectic polysaccharides. Carbohydr Res. 2009;344:1879–900.

Camattari A, Bianchi MM, Branduardi P, et al. Induction by hypoxia of heterologous-protein production with the KIPDC1 promoter in yeasts. Appl Environ Microbiol. 2007;73:922–9.

Campbell MM, Sederoff RR. Variation in lignin content and composition (Mechanisms of control and implications for the genetic improvement of plants). Plant Physiol. 1996;110:3–13.

Cassland P, Jönsson LJ. Characterization of a gene encoding Trametes versicolor laccase A and improved heterologous expression in Saccharomyces cerevisiae by decreased cultivation temperature. Appl Microbiol Biotechnol. 1999;52:393–400.

Cereghino JL, Cregg JM. Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol Rev. 2000;24:45–66.

Chiruvolu V, Cregg JM, Meagher MM. Recombinant protein production in an alcohol oxidase-defective strain of Pichia pastoris in fedbatch fermentations. Enzyme Microb Technol. 1997;21:277–83.

Christensen T, Woeldike H, Boel E, et al. High-level expression of recombinant genes in Aspergillus oryzae. Biotechnol. 1988;6:1419–22.

Colao MC, Lupino S, Garzillo AM, et al. Heterologous expression of lcc1 gene from Trametes trogii in Pichia pastoris and characterization of the recombinant enzyme. Microb Cell Fact. 2006;5:1–11.

Colao MC, Caporale C, Silvestri F, et al. Modeling the 3-D structure of a recombinant laccase from Trametes trogii active at a pH close to neutrality. Protein J. 2009;28:375–83.

Conesa A, van den Hondel CA, Punt PJ. Studies on the production of fungal peroxidases in Aspergillus niger. Appl Environ Microbiol. 2000;667:3016–23.

Conesa A, Punt PJ, van den Hondel CAMJJ. Fungal peroxidases: molecular aspects and applications. J Biotechnol. 2002;93:143–58.

Cortés-Espinosa DV, Absalón ÁE, Sanchez N, et al. Heterologous expression of manganese peroxidase in Aspergillus niger and its effect on phenanthrene removal from soil. J Mol Microbiol Biotechnol. 2011;21:120–9.

Coutinho PM, Anderson M, Kolenova K, et al. Post-genomic insights into the plant polysaccharide degradation potential of Aspergillus nidulans and comparison to Aspergillus niger and Aspergillus oryzae. Fungal Genet Biol. 2009;46:S161–9.

Cregg JM, Higgins DR. Production of foreign proteins in the yeast Pichia pastoris. Can J Bot. 1995;73:S891–7.

Cregg JM, Madden KR, Barringer KJ, et al. Functional characterization of the two alcohol oxidase genes from the yeast Pichia pastoris. Mol Cell Biol. 1989;9:1316–23.

Cregg JM, Cereghino JL, Shi J, et al. Recombinant protein expression in Pichia pastoris. Appl Biochem Biotechnol. 2000;16:23–52.

Culleton H, McKie V, de Vries RP. Physiological and molecular aspects of the degradation of plant polysaccharides by fungi: what have we learned from Aspergillus? Biotechnol J. 2013;8:884–94.

Culleton H, Bouzid O, McKie V, et al. New promoters to improve heterologous protein production in Aspergillus vadensis. Curr Biotechnol. 2014;3(3):244–51.

Cusano AM, Mekmouche Y, Meglecz E, et al. Plasticity of laccase generated by homeologous recombination in yeast. FEBS J. 2009;276:5471–80.

Daly R, Hearn MTW. Expression of heterologous proteins in Pichia pastoris: a useful experimental tool in protein engineering and production. J Mol Recognit. 2005;18:119–38.

de Vries RP, Visser J. Aspergillus enzymes involved in degradation of plant cell wall polysaccharides. Microbiol Mol Biol Rev. 2001;65:497–522.

de Vries RP, Burgers K, van de Vondervoort PJI, et al. A new black Aspergillus species, A. vadensis, is a promising host for homologous and heterologous protein production. Appl Environ Microbiol. 2004;70:3954–9.

Derynck R, Singh A, Goeddel DV. Expression of the human interferon-γ cDNA in yeast. Nucleic Acids Res. 1983;11:1819–37.

Ding S, Ge W, Buswell JA. Secretion, purification and characterisation of a recombinant Volvariella volvacea endoglucanase expressed in the yeast Pichia pastoris. Enzyme Microb Technol. 2002;31:621–6.

Dong X, Qin L, Tao Y, et al. Overexpression and characterization of a laccase gene from Pleurotus ostreatus in Trichoderma reesei. Acta Microbiol Sin. 2012;52:850–6.

Dragosits M, Stadlmann J, Albiol J, et al. The effect of temperature on the proteome of recombinant Pichia pastoris. J Proteome Res. 2009;8:1380–92.

Duranová M, Spániková S, Wösten HA, et al. Two glucuronoyl esterases of Phanerochaete chrysosporium. Arch Microbiol. 2009;191:133–40.

Eastwood DC, Challen MP, Zhang C, et al. Hairpin-mediated down-regulation of the urea cycle enzyme argininosuccinate lyase in Agaricus bisporus. Mycol Res. 2008;112:708–16.

Eibes GM, Lú-Chau TA, Ruiz-Dueñas F, et al. Effect of culture temperature on the heterologous expression of Pleurotus eryngii versatile peroxidase in Aspergillus hosts. Bioprocess Biosyst Eng. 2009;32:129–34.

Faraco V, Ercole C, Festa G, et al. Heterologous expression of heterodimeric laccase from Pleurotus ostreatus in Kluyveromyces lactis. Appl Microbiol Biotechnol. 2008;77:1329–35.

Fernández-Cañón JM, Peñalva MA. Overexpression of two penicillin structural genes in Aspergillus nidulans. Mol Gen Genet. 1995;246:110.

Fernández-Fueyo E, Ruiz-Dueñas FJ, Miki Y, et al. Lignin-degrading peroxidases from genome of selective ligninolytic fungus Ceriporiopsis subvermispora. J Biol Chem. 2012;287:16903–16.

Festa G, Autore F, Fraternali F, et al. Development of new laccases by directed evolution: Functional and computational analyses. Proteins. 2008;72:25–34.

Floudas D, Binder M, Riley R, et al. The paleozoic origin of enzymatic lignin decomposition reconstructed from 31 fungal genomes. Science. 2012;336:1715–9.

Franken ACW, Lokman BC, Ram AFJ, et al. Heme biosynthesis and its regulation: towards understanding and improvement of heme biosynthesis in filamentous fungi. Appl Microbiol Biotechnol. 2011;91:447–60.

Galhaup C, Wagner H, Hinterstoisser B, et al. Increased production of laccase by the wood-degrading basidiomycete Trametes pubescens. Enzyme Microbial Technol. 2002;30:529–36.

Garcia-Ruiz E, Gonzalez-Perez D, Ruiz-Dueñas F, et al. Directed evolution of a temperature-, peroxide- and alkaline pH-tolerant versatile peroxidase. Biochem J. 2012;441:487–98.

Garg N, Bieler N, Kenzom T, et al. Cloning, sequence analysis, expression of Cyathus bulleri laccase in Pichia pastoris and characterization of recombinant laccase. BMC Biotechnol. 2012;12:75.

Gasser B, Saloheimo M, Rinas U, et al. Protein folding and conformational stress in microbial cells producing recombinant proteins: a host comparative overview. Microb Cell Fact. 2008;7:11–28.

Gellissen G. Heterologous protein production in methylotrophic yeasts. Appl Microbiol Biotechnol. 2000;54:741–50.

Gellissen G, Kunze G, Gaillardin C, et al. New yeast expression platforms based on methylotrophic Hansenula polymorpha and Pichia pastoris and on dimorphic Arxula adeninivorans and Yarrowia lipolytica—A comparison. FEMS Yeast Res. 2005;5:1079–96.

Gelo-Pujic M, Kim H, Butlin NG, et al. Electrochemical studies of a truncated laccase produced in Pichia pastoris. Appl Environ Microbiol. 1999;65:5515–7.

Giardina P, Faraco V, Pezzella C, et al. Laccases: a never-ending story. Cell Mol Life Sci. 2010;67:369–85.

Gu L, Lajoie C, Kelly C. Expression of a Phanerochaete chrysosporium manganese peroxidase gene in the yeast Pichia pastoris. Biotechnol Prog. 2003;19:1403–9.

Gu C, Zheng F, Long L, et al. Engineering the expression and characterization of two novel laccase isoenzymes from Coprinus comatus in Pichia pastoris by fusing an additional ten amino acids tag at N-terminus. PLoS One. 2014;9, e93912.

Guo M, Lu F, Pu J, et al. Molecular cloning of the cDNA encoding laccase from Trametes versicolor and heterologous expression in Pichia methanolica. Appl Microbiol Biotechnol. 2005;69:178–83.

Guo M, Lu F, Du L, et al. Optimization of the expression of a laccase gene from Trametes versicolor in Pichia methanolica. Appl Microbiol Biotechnol. 2006;71:848–52.

Guo M, Lu F, Liu M, et al. Purification of recombinant laccase from Trametes versicolor in Pichia methanolica and its use for the decolorization of anthraquinone dye. Biotechnol Lett. 2008;30:2091–6.

Hamilton SR, Gerngross TU. Glycosylation engineering in yeast: the advent of fully humanized yeast. Curr Opin Biotechnol. 2007;18:387–92.

Harris PV, Xu F, Kreel NE, et al. New enzyme insights drive advances in commercial ethanol production. Curr Opin Chem Biol. 2014;19:162–70.

Hatamoto O, Watarai T, Kikuchi M, et al. Cloning and sequencing of the gene encoding tannase and a structural study of the tannase subunit from Aspergillus oryzae. Gene. 1996;175:215–21.

Hatamoto O, Sekine H, Nakano E, et al. Cloning and expression of a cDNA encoding the laccase from Schizophyllum commune. Biosci Biotechnol Biochem. 1999;63:58–64.

Herscovics A, Orlean P. Glycoprotein biosynthesis in yeast. FASEB J. 1993;7:540–50.

Herter S, Mikolasch A, Michalik D, et al. C–N coupling of 3-methylcatechol with primary amines using native and recombinant laccases from Trametes versicolor and Pycnoporus cinnabarinus. Tetrahedron. 2011;67:9311–21.

Higuchi T. Look back over the studies of lignin biochemistry. J Wood Sci. 2006;52:2–8.

Hildén K, Mäkelä MR, Lundell T, et al. Heterologous expression and structural characterization of two low pH laccases from a biopulping white-rot fungus Physisporinus rivulosus. Appl Microbiol Biotechnol. 2013;97:1589–99.

Hill JE, Myers AM, Koerner TJ, et al. Yeast/E. coli shuttle vectors with multiple unique restriction sites. Yeast. 1986;2:163–7.

Hitzeman RA, Hagie FE, Levine HL, et al. Expression of a human gene for interferon in yeast. Nature. 1981;293:717–22.

Honda Y, Matsuyama T, Irie T, et al. Carboxin resistance transformation of the homobasidiomycete fungus Pleurotus ostreatus. Curr Genet. 2000;37:209–12.

Hong YZ, Xiao Y, Zhou H, et al. Expression of a laccase cDNA from Trametes sp. AH28-2 in Pichia pastoris and mutagenesis of transformants by nitrogen ion implantation. FEMS Microbiol Lett. 2006;258:96–101.

Hong Y, Zhou H, Tu X, et al. Cloning of a laccase gene from a novel basidiomycete Trametes sp. 420 and its heterologous expression in Pichia pastoris. Curr Microbiol. 2007;54:260–5.

Hoshida H, Nakao M, Kanazawa H, et al. Isolation of five laccase gene sequences from the white-rot fungus Trametes sanguinea by PCR, and cloning, characterization and expression of the laccase cDNA in yeasts. J Biosci Bioeng. 2001;92:372–80.

Hoshida H, Fujita T, Murata K, et al. Copper-dependent production of a Pycnoporus coccineus extracellular laccase in Aspergillus oryzae and Saccharomyces cerevisiae. Biosci Biotechnol Biochem. 2005;69:1090–7.

Hu MR, Chao Y, Zhang G, et al. Molecular evolution of Fome lignosus laccase by ethyl methane sulfonate-based random mutagenesis in vitro. Biomol Eng. 2007;24:619–24.

Huang Jr C, Damasceno LM, Anderson KA, et al. A proteomic analysis of the Pichia pastoris secretome in methanol-induced cultures. Appl Microbiol Biotechnol. 2011a;90:235–47.

Huang SJ, Liu ZM, Huang XL, et al. Molecular cloning and characterization of a novel laccase gene from a white-rot fungus Polyporus grammocephalus TR16 and expression in Pichia pastoris. Lett Appl Microbiol. 2011b;52:290–7.

Huang C, Lin H, Yang X. Industrial production of recombinant therapeutics in Escherichia coli and its recent advancements. J Ind Microbiol Biotechnol. 2012;39:383–99.

Huy ND, Kim SW, Park SM. Heterologous expression of endo-1,4-beta-xylanaseC from Phanerochaete chrysosporium in Pichia pastoris. J Biosci Bioeng. 2011;111:654–7.

Huy ND, Thayumanavan P, Kwon T, et al. Characterization of a recombinant bifunctional xylosidase/arabinofuranosidase from Phanerochaete chrysosporium. J Biosci Bioeng. 2013a;116:152–9.

Huy ND, Thiyagarajan S, Choi Y, et al. Cloning and characterization of a thermostable endo-arabinanase from Phanerochaete chrysosporium and its synergistic action with endo-xylanase. Bioprocess Biosyst Eng. 2013b;36:677–85.

Huy ND, Thiyagarajan S, Kim D, et al. Cloning and characterization of a novel bifunctional acetyl xylan esterase with carbohydrate binding module from Phanerochaete chrysosporium. J Biosci Bioeng. 2013c;115:507–13.

Igarashi K, Ishida T, Hori C, et al. Characterization of an endoglucanase belonging to a new subfamily of glycoside hydrolase family 45 of the basidiomycete Phanerochaete chrysosporium. Antimicrob Agents Chemother. 2008;74:5628–34.

Irie T, Honda Y, Watanabe T, et al. Homologous expression of recombinant manganese peroxidase genes in ligninolytic fungus Pleurotus ostreatus. Appl Microbiol Biotechnol. 2001;55:566–70.

Jahic M, Rotticci-Mulder J, Martinelle M, et al. Modeling of growth and energy metabolism of Pichia pastoris producing a fusion protein. Bioprocess Biosyst Eng. 2002;24:385–93.

Jiang F, Kongsaeree P, Schilke K, et al. Effects of pH and temperature on recombinant manganese peroxidase production and stability. Appl Biochem Biotechnol. 2008;146:15–27.

Johnston M, Davis RW. Sequences that regulate the divergent GAL1-GAL10 promoter in Saccharomyces cerevisiae. Mol Cell Biol. 1984;4:1440.

Jolivalt C, Madzak C, Brault A, et al. Expression of laccase IIIb from the white-rot fungus Trametes versicolor in the yeast Yarrowia lipolytica for environmental applications. Appl Microbiol Biotechnol. 2005;66:450–6.

Jönsson LJ, Saloheimo M, Penttilä M. Laccase from the white-rot fungus Trametes versicolor: cDNA cloning of lcc1 and expression in Pichia pastoris. Curr Genet. 1997;32:425–30.

Joo SS, Ryu IW, Park JK, et al. Molecular cloning and expression of a laccase from Ganoderma lucidum, and its antioxidative properties. Mol Cells. 2008;25:112–8.

Kajita S, Sugawara S, Miyazaki Y, et al. Overproduction of recombinant laccase using a homologous expression system in Coriolus versicolor. Appl Microbiol Biotechnol. 2004;66:194–9.

Kamitsuji H, Watanabe T, Honda Y, et al. Direct oxidation of polymeric substrates by multifunctional manganese peroxidase isoenzyme from Pleurotus ostreatus without redox mediators. Biochem J. 2005;386:387–93.

Kawai R, Yoshida M, Tani T, et al. Production and characterization of recombinant Phanerochaete chrysosporium β-glucosidase in the methylotrophic yeast Pichia pastoris. Biosci Biotechnol Biochem. 2003;67:1–7.

Kiiskinen L-L, Kruus K, Bailey M, et al. Expression of Melanocarpus albomyces laccase in Trichoderma reesei and characterization of the purified enzyme. Microbiology. 2004;150:3065–74.

Kilaru S, Hoegger PJ, Majcherczyk A, et al. Expression of laccase gene lcc1 in Coprinopsis cinerea under control of various basidiomycetous promoters. Appl Microbiol Biotechnol. 2006;71:200–10.

Kim HM, Lee YG, Patel DH, et al. Characteristics of bifunctional acidic endoglucanase (Cel5B) from Gloeophyllum trabeum. J Ind Microbiol Biotechnol. 2012;39:1081–9.

Klonowska A, Gaudin C, Asso M, et al. LAC3, a new low redox potential laccase from Trametes sp. strain C30 obtained as a recombinant protein in yeast. Enzyme Microb Technol. 2005;36:34–41.

Kojima Y, Tsukuda Y, Kawai Y, et al. Cloning, sequence analysis, and expression of ligninolytic phenoloxidase genes of the white-rot basidiomycete Coriolus hirsutus. J Biol Chem. 1990;265:15224–30.

Kolpak FJ, Blackwell J. Determination of the structure of cellulose II. Macromolecules. 1976;9:273–8.

Kotake T, Kitazawa K, Takata R, et al. Molecular cloning and expression in Pichia pastoris of a Irpex lacteus exo-β-(1 → 3)-galactanase gene. Biosci Biotechnol Biochem. 2009;73:2303–9.

Kües U, Rühl M. Multiple multi-copper oxidase gene families in Basidiomycetes—what for? Curr Genomics. 2011;12:72–94.

Kulys J, Vidziunaite R. Amperometric biosensors based on recombinant laccases for phenols determination. Biosens Bioelectron. 2003;18:319–25.

Kunamneni A, Plou FJ, Ballesteros A, et al. Laccases and their applications: a patent review. Recent Pat Biotechnol. 2008;2:10–24.

Lee H, Jang Y, Choi YS, et al. Biotechnological procedures to select white rot fungi for the degradation of PAHs. J Microbiol Methods. 2014;97:56–62.

Leem Y, Kim S, Ross I, et al. Transformation and laccase mutant isolation in Coprinus congregatus by restriction enzyme-mediated integration. FEMS Microbiol Lett. 1999;172:35–40.

Lengeler KB, Tielker D, Ernst JF. Protein-O-mannosyltransferases in virulence and development. Cell Mol Life Sci. 2008;65:528–44.

Li B, Rotsaert FA, Gold MH, et al. Homologous expression of recombinant cellobiose dehydrogenase in Phanerochaete chrysosporium. Biochem Biophys Res Commun. 2000;270:141–6.

Li D, Heather L, Youngs L, et al. Heterologous expression of a thermostable manganese peroxidase from Dichomitus squalens in Phanerochaete chrysosporium. Arch Biochem Biophys. 2001;385:348–56.

Li JF, Hong YZ, Xiao YZ, et al. High production of laccase B from Trametes sp. in Pichia pastoris. World J Microbiol Biotechnol. 2007;23:741–5.

Lin Y, Zhang Z, Tian Y, et al. Purification and characterization of a novel laccase from Coprinus cinereus and decolorization of different chemically dyes. Mol Biol Rep. 2013;40:1487–94.

Liu W, Chao Y, Liu S, et al. Molecular cloning and characterization of a laccase gene from the basidiomycete Fome lignosus and expression in Pichia pastoris. Appl Microbiol Biotechnol. 2003;63:174–81.

Lombard V, Golaconda Ramulu H, Drula E, et al. The carbohydrate-active enzymes database (CAZy) in 2013. Nucleic Acids Res. 2014;42:D490–5.

Lu L, Zhao M, Liang SC, et al. Production and synthetic dyes decolourization capacity of a recombinant laccase from Pichia pastoris. J Appl Microbiol. 2009;107:1149–56.

Lundell TK, Mäkelä MR, Hildén K. Lignin-modifying enzymes in filamentous basidiomycetes—ecological, functional and phylogenetic review. J Basic Microbiol. 2010;50:5–20.

Ma B, Mayfield MB, Gold MH. Homologous expression of Phanerochaete chrysosporium manganese peroxidase, using bialaphos resistance as a dominant selectable marker. Curr Genet. 2003;43:407–14.

Macauley-Patrick S, Fazenda ML, McNeil B, et al. Heterologous protein production using the Pichia pastoris expression system. Yeast. 2005;22:249–70.

Macellaro G, Baratto MC, Piscitelli A, et al. Effective mutations in a high redox potential laccase from Pleurotus ostreatus. Appl Microbiol Biotechnol. 2014;98:49494961.

Madzak C, Treton B, Blanchin-Roland S. Strong hybrid promoters and integrative expression/secretion vectors for quasi-constitutive expression of heterologous proteins in the yeast Yarrowia lipolytica. J Mol Microbiol Biotechnol. 2000;2:207–16.

Madzak C, Gaillardin C, Beckerich J. Heterologous protein expression and secretion in the non-conventional yeast Yarrowia lipolytica: a review. J Biotechnol. 2004;109:63–81.

Madzak C, Otterbein L, Chamkha M, et al. Heterologous production of a laccase from the basidiomycete Pycnoporus cinnabarinus in the dimorphic yeast Yarrowia lipolytica. FEMS Yeast Res. 2005;5:635–46.

Madzak C, Mimmi M, Caminade E, et al. Shifting the optimal pH of activity for a laccase from the fungus Trametes versicolor by structure-based mutagenesis. Protein Eng Des Sel. 2006;19:77–84.

Mäkelä MR, Hildén KS, de Vries RP. Degradation and modification of plant biomass by fungi. In: Nowrousian M, editor. Mycota, Fungal genomics, vol. 13. 2nd ed. Berlin: Springer; 2014. p. 175–208.

Martinez D, Larrondo LF, Putnam N, et al. Genome sequence of the lignocellulose degrading fungus Phanerochaete chrysosporium strain RP78. Nat Biotechnol. 2004;22:695–700.

Martínez AT, Rencoret J, Marques G, et al. Monolignol acylation and lignin structure in some nonwoody plants: a 2D NMR study. Phytochemistry. 2008;69:2831–43.

Mascorro-Gallardo JO, Covarrubias AA, Gaxiola R. Construction of a CUP1 promoter-based vector to modulate gene expression in Saccharomyces cerevisiae. Gene. 1996;172:169–70.

Mattanovich D, Graf A, Stadlmann J, et al. Genome, secretome and glucose transport highlight unique features of the protein production host Pichia pastoris. Microb Cell Fact. 2009;8:29–41.

Mayfield MB, Kishi K, Alic M, et al. Homologous expression of recombinant manganese peroxidase in Phanerochaete chrysosporium. Appl Environ Microbiol. 1994;60:4303–9.

Minussi R, Pastore GM, Duran N. Potential applications of laccase in the food industry. Trends Food Sci Technol. 2002;13:205–16.

Montiel-González AM, Fernández FJ, Keer N, et al. Increased PCP removal by Amylomyces rouxii transformants with heterologous Phanerochaete chrysosporium peroxidases supplementing their natural degradative pathway. Appl Microbiol Biotechnol. 2009;84:335–40.

Moomaw EM, Hoffer E, Moussatche P, et al. Kinetic and spectroscopic studies of bicupin oxalate oxidase and putative active site mutants. PLoS One. 2013;8, e57933.

Moussatche P, Angerhofer A, Imaram W, et al. Characterization of Ceriporiopsis subvermispora bicubin oxalate oxidase expressed in Pichia pastoris. Arch Biochem Biophys. 2011;509:100–7.

Nakajima M, Yamashita T, Takahashi M, et al. Identification, cloning, and characterization of β-glucosidase from Ustilago esculenta. Appl Microbiol Biotechnol. 2012;93:1989–98.

Necochea R. Phylogenetic and biochemical characterisation of a recombinant laccase from Trametes versicolor. FEMS Microbiol Lett. 2005;244:235–41.

Nikolaev IV, Epishin SM, Zakharova ES, et al. Molecular cloning of a secreted beta-galactosidase gene from the filamentous fungus Penicillium canescens. Mol Biol (Moscow). 1992;26:869–75.

Nishibori N, Masaki K, Tsuchioka H, et al. Comparison of laccase production levels in Pichia pastoris and Cryptococcus sp. S-2. J Biosci Bioeng. 2013;115:394–9.

O’Callaghan J, O’Brien MM, McClean K, et al. Optimisation of the expression of a Trametes versicolor laccase gene in Pichia pastoris. J Ind Microbiol Biotechnol. 2002;29:55–9.

Ogawa M, Kitamoto K, Gomi K et al. DDBJ Accession No. D28484. 1994.

Otterbein L, Record E, Longhi S, et al. Molecular cloning of the cDNA encoding laccase from Pycnoporus cinnabarinus I-937 and expression in Pichia pastoris. Eur J Biochem. 2000;267:1619–25.

Pauly M, Keegstra K. Plant cell wall polymers as precursors for biofuels. Curr Opin Plant Biol. 2010;13:305–12.

Pezzella C, Autore F, Giardina P, et al. The Pleurotus ostreatus laccase multi-gene family: isolation and heterologous expression of new family members. Curr Genet. 2009;55:45–57.

Pisanelli I, Kujawa M, Gschnitzer D, et al. Heterologous expression of an Agaricus meleagris pyranose dehydrogenase-encoding gene in Aspergillus spp. and characterization of the recombinant enzyme. Appl Microbiol Biotechnol. 2010;86:599–606.

Piscitelli A, Giardina P, Mazzoni C, et al. Recombinant expression of Pleurotus ostreatus laccases in Kluyveromyces lactis and Saccharomyces cerevisiae. Appl Microbiol Biotechnol. 2005;69:428–39.

Punt PJ, van den Hondel CAAJJ. Transformation of a filamentous fungi based on hygromycin B and phleomycin resistance markers. Methods Enzymol. 1992;216:447–57.

Raghukumar C, D’Souza-Ticlo D, Verma AK. Treatment of colored effluents with lignin-degrading enzymes: an emerging role of marine-derived fungi. Crit Rev Microbiol. 2008;34:189–206.

Ralph J, Lundquist K, Brunow G, et al. Lignins: natural polymers from oxidativecoupling of 4-hydroxyphenylpropanoids. Phytochem Rev. 2004;3:29–60.

Ranieri D, Colao MC, Ruzzi M, et al. Optimization of recombinant fungal laccase production with strains of the yeast Kluyveromyces lactis from the pyruvate decarboxylase promoter. FEMS Yeast Res. 2009;9:892–902.

Raymond CK, Bukowski T, Holderman SD, et al. Development of the methylotrophic yeast Pichia methanolica for the expression of the 65 kilodalton isoform of human glutamate decarboxylase. Yeast. 1998;14:11–23.

Record E, Punt PJ, Chamkha M, et al. Expression of the Pycnoporus cinnabarinus laccase gene in Aspergillus niger and characterization of the recombinant enzyme. Eur J Biochem. 2002;269:602–9.

Rodríguez E, Ruiz-Dueñas FJ, Kooistra R, et al. Isolation of two laccase genes from the white-rot fungus Pleurotus eryngii and heterologous expression of the pel3 encoded protein. J Biotechnol. 2008;134:9–19.

Romanos MA, Scorer CA, Clare JJ. Foreign gene expression in yeast: A review. Yeast. 1992;8:423–88.

Ruiz-Dueñas FJ, Camarero S, Pérez-Boada M, et al. A new versatile peroxidase from Pleurotus. Biochem Soc Trans. 2001;29:116–22.

Ruiz-Dueñas FJ, Morales M, García E, et al. Substrate oxidation sites in versatile peroxidase and other basidiomycete peroxidases. J Exp Bot. 2008;60:441–52.

Ruiz-Dueñas FJ, Lundell T, Floudas D, et al. Lignin-degrading peroxidases in Polyporales: an evolutionary survey based on 10 sequenced genomes. Mycologia. 2013;105:1428–44.

Rytioja J, Yuzon J, Hildén KS, et al. Plant polysaccharide degrading enzymes from basidiomycetes. Microbiol Mol Biol Rev. 2014;78:614–49.

Ryu K, Kang JH, Wang L, et al. Expression in yeast of secreted lignin peroxidase with improved 2,4-dichlorophenol degradability by DNA shuffling. J Biotechnol. 2008a;135:241–6.

Ryu SH, Lee AY, Kim M. Molecular characteristics of two laccases from the basidiomycete fungus Polyporus brumalis. J Microbiol. 2008b;46:62–9.

Saito K, Kurose S, Tsujino Y, et al. Electrochemical characterization of a unique, “neutral” laccase from Flammulina velutipes. J Biosci Bioeng. 2013;115:159–67.

Salame TM, Knop D, Tal D, et al. Predominance of a versatile-peroxidase-encoding gene, mnp4, as demonstrated by gene replacement via a gene targeting system for Pleurotus ostreatus. Appl Environ Microbiol. 2012;78:5341–52.

Salinas A, Vega M, Lienqueo ME, et al. Cloning of novel cellulases from cellulolytic fungi: Heterologous expression of a family 5 glycoside hydrolase from Trametes versicolor in Pichia pastoris. Enzyme Microb Technol. 2011;49:485–91.

Saliola M, Gonnella R, Mazzoni C, et al. Two genes encoding putative mitochondrial alcohol dehydrogenases are present in the yeast Kluyveromyces lactis. Yeast. 1991;7:391–400.

Saliola M, Mazzoni C, Solimando N, et al. Use of the KlADH4 promoter for ethanol-dependent production of recombinant human serum albumin in Kluyveromyces lactis. Appl Environ Microbiol. 1999;65:53–60.

Saloheimo M, Niku-Paavola ML. Heterologous production of a ligninolytic enzyme: expression of the Phlebia radiata laccase gene in Trichoderma reesei. Nat Biotechnol. 1991;9:987–90.

Saloheimo M, Niku-Paavola ML, Knowles JK. A lignin peroxidase-encoding cDNA from the white-rot fungus Phlebia radiata: characterization and expression in Trichoderma reesei. Gene. 1989;85:343–51.

Sharma KK, Kuhad RC. Genetic transformation of lignin degrading fungi facilitated by Agrobacterium tumefaciens. BMC Biotechnol. 2010;14:10–67.

Shi L, Fang X, Li M, et al. Development of a simple and efficient transformation system for the basidiomycetous medicinal fungus Ganoderma lucidum. World J Microbiol Biotechnol. 2012;28:283–91.

Sietiö O-M, Mäkelä MR, Hildén K. Biochemical characterization of recombinant oxalate decarboxylases of the white rot fungus Dichomitus squalens. Curr Biotechnol. 2015.

Sigoillot C, Record E, Belle V, et al. Natural and recombinant fungal laccases for paper pulp bleaching. Appl Microbiol Biotechnol. 2004;64:346–52.

Sietiö O-M, Mäkelä MR, Hildén K. Biochemical characterization of recombinant oxalate decarboxylases of the white rot fungus Dichomitus squalens. Curr Biotechnol. In press.

Soden DM, O’Callaghan J, Dobson ADW. Molecular cloning of a laccase isozyme gene from Pleurotus sajor-caju and expression in the heterologous Pichia pastoris host. Microbiology. 2002;148:4003–14.

Sollewijn Gelpke MD, Mayfield-Gambill M, Lin Cereghino GP, et al. Homologous expression of recombinant lignin peroxidase in Phanerochaete chrysosporium. Appl Environ Microbiol. 1999;65:1670–4.