Abstract

Putative arabinanase (PcARA) was cloned from cDNA of Phanerochaete chrysosporium. The gene sequencing indicated that PcARA consisted of 939 nucleotides that encodes for 312 amino acid arabinanase-polypeptide chain, including a signal peptide of 19 amino acids. Three-dimensional homology indicated that this enzyme is a five-bladed β-propeller, belonging to glycosidase family 43 and its secondary structure is consisted of 24 β-sheets. The PcARA-cDNA was expressed in Pichia pastoris using pPICZαC. SDS-PAGE of purified arabinanase showed a single band of 33 kDa that is very close to theoretical molecular mass of 33.9 kDa calculated by its amino acid content. Recombinant arabinanase (rPcARA) exhibited maximum activity at pH and temperature of 5.0 and 60 °C, respectively. End-product analysis of debranched arabinan hydrolysis by thin-layer chromatography indicated that rPcARA acted as endo-type. The synergistic action of rPcARA with recombinant xylanase resulted in 72 and 9.3 % release of total soluble sugar of arabinoxylan and NaOH-pretreated barley straw, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Arabinose, a five carbons sugar, is found in hemicelluloses sources, such as arabinoxylan, arabinogalactan and arabinan, and is considered as a second most abundant hemicelluloses sugar after xylose. Arabinose constitutes up to 8 and 9 % of total dry biomass of brewery’s spent grain and wheat bran, respectively [1–3]. To release arabinose sugar from hemicelluloses substances by complete degradation, different hydrolases are required. α-l-arabinanases (EC 3.2.1.99) including endo- and exo-types, cleave the backbone of main chain arabinan, releasing arabinose or short arabino-oligosaccharides while α-l-arabinofuranosidases (EC 3.2.1.55) act on the side group non-reducing α-l-arabinofuranoside residues [4]. According to the classification listed in the carbohydrate active enzyme database (http://www.cazy.org/), arabinanases belong to glycosidase family 43. Three-dimensional crystal structure analysis of arabinanases showed secondary structure of enzyme was composed of five-bladed β-propeller fold. Multiple-sequence alignment of arabianases reveals three conserved blocks in catalytic domain. Block I and II are Asp residuals as general base and acid, where Glu of block III is pK a modular of active site. The substrate-biding residuals are also found to be hyperconserved in this family [5–7].

In recent years, the utilization of hemicellulosic sugars is essential for efficient conversion of lignocellulosic materials to fuel ethanol and other value-added fermentation products. Therefore, hemicellulose-degrading enzymes, including xylanase and arabinanases, hold great promise in saccharifying various pretreated agricultural and forestry residues to fermentable sugars. For instance, approximately 90 % of the total arabinose is released from sugar beet pulp by arabinanolytic enzymes of Penicillium chrysogenum [8]. Then, this sugar can be utilized to produce ethanol or organic compounds, such as 2,3-butanediol by some microorganisms [9, 10]. Moreover, arabinanolytic enzymes also have several other biotechnological applications such as improvement wine flavors, pulp treatment, juice clarification, production of important medicinal [11].

Phanerochaete chrysosporium is known to have ability to completely degrade plant cell walls by releasing complex lignin, cellulose, hemicelluloses degrading enzymes. Although many studies have been reported for ligninase and cellulase, there is limitation of knowledge in hemicellulases system of this fungus except xylanase. Consequently, the property and function of arabinanase have not been characterized. P. chrysosporium genome sequence showed at least a putative endo-arabinase. Moreover, protein that corresponds to putative endo-arabinanase is found in the matrix extracellular protein when P. chrysosporium is cultured using lignocellulosic biomass or in the xylan-supplemented medium [12–14]. The aim of this study is to clone, express and characterize the putative endo-arabinanase from P. chrysosporium (PcARA). The synergistic actions with recombinant xylanase on biomass degradation were also investigated.

Materials and methods

Strains, plasmids and medium cultures

The white rot fungus P. chrysosporium BKM-F-1767 was obtained from the Korean Collection for Type Culture and maintained in medium as described by Tien [15]. Escherichia coli Top10 was cultured in LB agar medium containing 50 μg ml−1 ampicillin with IPTG and X-Gal, for general cloning, and a low-salt LB medium containing 25 μg ml−1 Zeocin for PcARA genes constructed with the expression vectors. The heterologous expression hosts GS115 (his4) was supplied by Invitrogen (Carlsbad, CA, USA). Stock cultures were prepared by an overnight incubation in YPD agar medium (1 % yeast extract, 2 % peptone, 2 % dextrose, and 1.5 % agar) at 30 °C. Recombinant endo-arabinanase (rPcARA) expression was carried out by inoculating recombinant P. pastoris in YP medium (1 % yeast extract, and 2 % peptone) containing 1 % methanol.

The pGEM-T Easy Vector (Promega, Madison, WI, USA) was ligated with the PcARA polymerase chain reaction (PCR) products for gene sequencing. The vectors pPICZC and pPICZαC (Invitrogen) were used for expression in P. pastoris. The expression of inserts in both vectors is controlled by the methanol-inducible AOX1 promoter. pPICZα possesses the α-secretion factor from Saccharomyces cerevisiae, whereas pPICZ does not contain a secretion signal.

Total cDNA synthesis

Total mRNA was extracted from P. chrysosporium using the Oligotex mRNA Mini kit (Qiagen, Valencia, CA, USA). Total cDNA was synthesized using the SMARTer PCR cDNA Synthesis kit following the manufacturer’s recommendation (Clontech, Mountain View, CA, USA).

Construction and transformation of the recombinant plasmid

The nucleotide sequence of the putative PcARA was obtained from the P. chrysosporium genome database of the DOE Joint Genome Institute website at http://www.genome.jgi-psf.org/Phchr1/Phchr1.home.html as predicted by Wymelenberg [16]. This sequence was used to design the primers. The cDNA of PcARA including the signal peptide was amplified by PCR using the forward 5′-CTCGAGATGTGGACCTCCATCGTTT-3′ and reverse 5′-TACGTACACGACAATTGGCCACCCA-3′ primers. The following conditions were employed for PCR amplification: 94 °C for 1 min, 94 °C for 30 s, 60 °C for 30 s, and 72 °C for 2 min (for 30 cycles) with Pfu DNA polymerase. The PCR products were A-tailed by Taq DNA polymerase at 72 °C for 30 min and cloned to pGEM-T Easy Vector. Transformants carrying the interested size PCR product were screened by colony PCR with the specific primers mentioned above. Three recombinant plasmids were randomly isolated and sequenced. The PcARA gene was excised using XhoI and SnaBI, then separated and purified on a 0.8 % agarose gel. The purified PcARA gene was inserted into the pPICZC vector, resulting in pPICZC-PcARA. PCR amplification of the PcARAα cDNA into the pGEM-T Easy Vector was performed for cloning into pPICZαC, using the forward primer 5′-ATCGATGCAGCCAAACCCAGGGAGA-3′ and the reverse primer 5′-TCTAGAACGACAATTGGCCACCCAG-3′. The forward primer did not contain a P. chrysosporium PcARA secretion signal within the amplified region, as the S. cerevisiae α-secretion signal is presented in pPICZαC. The PCR conditions employed were same as previously described for PcARA cDNA. The resulting PCR product, PcARAα, was cloned into the pGEM-T Easy Vector, excised using ClaI and XbaI, purified on an agarose gel, and inserted into pPICZαC, which resulted in pPICZαC-PcARAα. After transformation into E. coli and isolation of the plasmid DNA, the presence of the inserts was determined both by PCR and restriction enzyme digestion followed by agarose-gel electrophoresis. A sequence analysis was performed on pPICZC-PcARA and pPICZαC-PcARAα using AOX1 primer as manufacture’s recommendation.

To transform the yeast strain, 10 μg of plasmid was linearized using PmeI and transformed into P. pastoris using an electroporation method, as recommended by the manufacturer (Bio-Rad, Hercules, CA, USA). Transformed cells were selected on YPD agar plates containing 100 μg ml−1 zeocin and 1 M sorbitol at 30 °C, until a colony was observed (2–3 days). Recombinant P. pastoris was confirmed by PCR using AOX1 primers.

Expression and production of recombinant PcARA (rPcARA)

The rPcARA secretion ability of twenty positive P. pastoris transformants were quantified by dot blot analysis as described by Vasu et al. [17]. The highest secreted P. pastoris transformants was grown in 5 ml YPD medium overnight at 30 °C and 200 rpm. Then, 5 ml cultures were transferred to 50 ml of fresh YP medium containing 1 % glycerol in a shaking incubator at 30 °C and 150 rpm for overnight. The cell pellets were harvested by centrifugation at 2000 rpm for 5 min, and the cell pellet was resuspended in 10 ml YP medium. Then, the suspensions were added slowly to 90 ml of fresh YP medium until an optical density of 1 was reached. Finally, fresh YP medium was added to make up the final volume to 100 ml. To induce rPcARA, 1 ml of 100 % methanol was added every 24 h to a final concentration of 1 %, for 7 days of culture at 25 °C. One milliliter of cultivation fluid was collected every 24 h and centrifuged for 5 min at 15,000 rpm, after which enzyme activity was measured.

Enzyme purification

To purify rPcARA, cell-free supernatants on the second day of culture were collected by centrifugation at 2,000 rpm for 5 min and filtered through 0.45-μm filters. In total, 90 ml of filtered supernatant was mixed with 10 ml of 10× binding buffer (20 mM sodium phosphate, 0.5 M NaCl, and 20 mM imidazole; pH 7.4). The mixture was applied to a Ni2+ his-tag column (Histrap-GE Healthcare, Picataway, NJ, USA) using the ÄKTA fast protein liquid chromatography purification system. Protein was eluted with an elution buffer (20 mM sodium phosphate, 0.5 M NaCl and 500 mM imidazole; pH 7.4), and collected into 15 ml conical tubes. All fractions containing purified enzyme were dialyzed with cellulose dialysis tubing membrane (Sigma, St. Louis, MO, USA) in distilled water to remove salt and imidazole at 4 °C overnight. Molecular mass of purified rPcARA was determined by SDS-PAGE as standard procedure by Sambrook et al. [18].

Enzyme assay

Arabianase activity was assayed by measuring the production of reducing-sugar ends, from debranched arabinan (Megazyme, Bray, Co. Wicklow, Ireland) with 3,5-dinitrosalicylic acid (DNSA). One hundred microliters of 1 % debranched arabinan in 100 mM sodium phosphate buffer were mixed with 200 μl of 50 mM sodium phosphate pH 7 at 50 °C. The reaction was started by adding 100 μl of supernatant and incubating the mixture for 10 min at 50 °C. The amount of released reducing sugar was determined at 540 nm wavelength using a TCC-240A UV spectrophotometer (Shimadzu, Kyoto, Japan). A standard curve was built using l-arabinose as a substrate, and the absorbance was converted into moles of reducing sugars released. One unit of arabinanase activity was defined as the release of 1 μmol min−1 of arabinose.

Effect of pH, temperature, metal ions on arabinanase activity

The effect of pH on rPcARA was determined by assaying for enzyme activity at 50 °C with different pH values of 3.0–6.0 using 50 mM sodium acetate and 7.0–8.0 using 50 mM sodium phosphate buffer. The optimal temperature was investigated in the range of 30–80 °C at the optimal pH.

The effect of metal ions (Mn2+, K+, Ca2+, Co2+, Fe2+, Fe3+, Cu2+, Mg2+, Zn2+, and Ni2+) on rPcARA activity was investigated to further characterize the enzyme. rPcARA was examined in the presence of 5 mM each of metal ion at the optimal pH and temperature. The residual activity was compared with enzyme activity in non-metal reaction.

Substrate specificity and thin-layer chromatography analysis of debranched arabinan hydrolysis

The substrate specificities of rPcARA were investigated using sugar beet arabinan, wheat arabinoxylan (Megazyme, Bray, Co. Wicklow, Ireland), birchwood xylan and p-nitrophenyl-α-l-arabinofuranoside (Sigma, St. Louis, MO, USA). The hydrolysis reactions of sugar beet arabinan, wheat arabinoxylan and birchwood xylan were carried out similar to the procedure of debrached arabinan assay, whereas p-nitrophenyl α-l-arabinofuranoside degradation was studied at 37 °C, pH 5 for 10 min and released 4-nitrophenol was measured by spectrometer using 410 nm wavelength.

Hydrolysis product of debranched arabinan was analyzed on thin layer chromatography (TLC) using chloroform/acetic acid/H2O (6:7:1) as mobile phase. Reaction products were visualized by spraying sulfuric acid/ethanol (5:95, v/v) containing 1 mg ml−1 of oricnol, following the baking at 110 °C for 5 min. l-Arabinose, 1,5-α-l-arabinobiose, 1,5-α-l-arabinotriose, 1,5-α-l-arabinopentaose, 1,5-α-l-arabinosehexaose (Megazyme, Bray, Co. Wicklow, Ireland) were used as standard.

Synergistic action with xylanase

The degradation of arabinoxylan and NaOH-pretreated barley by rPcARA and xylanase C (rPcXynC) were tested. The barley straw was treated using 3 M sodium hydroxide in 50 litter container under pressure of 5 kg cm−2 for 60 min at 150 °C. The sample was washed three times with equally volume water. The solid phase was harvested for further study. A mixture of purified rPcARA and rPcXynC of 0.3 and 0.5 U, respectively, were incubated with 1 mg arabinan in 400 μl of 50 mM sodium acetate, pH 5, 60 °C for 10 min. To investigate the biomass degradation using rPcARA and rPcXynC mixture, one hundred milligram of NaOH-pretreated barley straw were incubated with 10 U of each of the purified enzymes. The reaction was carried out in 5 ml of 50 mM sodium acetate, pH 5, at 60 °C for 16 h. The hydrolysis was terminated by boiling for 10 min to inactivate the enzymes. Total sugar releasing was estimated using DNSA methods as described above.

Results and discussion

Cloning and sequence analysis of PcARA

The predicted nucleotide sequence of putative endo-arabinanase P. chrysosporium strain RP78 was used as a template to design primer for gene amplification from total cDNA constructed. The PCR amplicon was perfectly matched with expected size of the predicted ARA gene of P. chrysosporium RP78, and hence, it was named PcARA. The nucleotide sequence of this cDNA product has 939 nucleotides, encoding for 312 amino acids. Comparison to putative endo-arabinanase P. chrysosporium strain RP78 indicated that both shared 91 % nucleotide similarity, whereas the deduced amino acid alignment showed 90 % identity. The full-length cDNA nucleotide sequence of PcARA in this study was deposited in GenBank (accession no. JQ838072).

A secretion peptide containing 19 amino acids was identified using the signal peptide detection tool available at http://www.cbs.dtu.dk/services/SignalP/. PcARA revealed a striking level of identity to other ARAs from Penicillium chrysogenum (41 %), A. niger (40 %), A. aculeatus (42 %), Bacillus thermodenitrificans (40 %) and Cellvibrio japonicus (35 %). As shown in Fig. 1, three amino acids Asp34, Asp151 and Glu203 residues are conserved among ARAs. These amino acids have been implicated in the catalytic function of arabinanase in glycoside hydrolase family 43 [5, 6]. Moreover, nine conserved residues that are essential for substrate recognition in GH43 arabinanases, are found on PcARA [7]. Although the important amino acid residues of PcARA showed high conservation, the less similarity to other ARAs suggest PcARA is a novel arabinanase member in glycoside hydrolase family 43. Three dimension homology to C. japonicus α-l-arabinanase (PDB code 1GYD), B. thermodenitrificans endo-1,5-α-l-arabinanase (PDB code 1W7L) using Phyre sever indicated that PcARA is a five-bladed β-propeller glycosidase and its secondary structure is consisted of 24 β-sheets [19]. No fungal carbohydrate binding domain was found, whereas one potential N-glycosylation site (Asn–Ser–Thr) was identified in the PcARA sequence (Fig. 1).

The deduced amino acid sequence alignment of P. chrysosporium endo-arabinanase (PcARA) and other ARAs from Penicillium chrysogenum (BAD89094), A. niger (AAA32682), A. aculeatus (AAG27441), and Cellvibrio japonicus (CAA71485) using ClustalW2 tool. Identical amino acids are written in black letters. The Asp33, Asp151 and Glu203 conserved catalytic residues of arabinanases are showed as closed inverted triangles. Conserved residues that are essential for substrate recognition in GH43 arabinanases are marked by closed circles. The N-glycosylation site (Asn–Xaa–Ser/Thr) is boxed

Expression and purification of rPcARA

The methylotrophic yeast P. pastoris is a useful system to express milligram-to-gram quantities of proteins for both basic laboratory research and industrial purposes. P. pastoris has a low specificity requirement for secretion signal sequence recognition; thus, many recombinant proteins might be expressed in P. pastoris using the native secretion signal peptide. Moreover, the glycosylation system of P. pastoris is less efficient than that of other heterologous expression systems such as Saccharomyces cerevisiae; therefore, it secretes a native recombinant protein or a less hyperglycosylated form [20, 21]. In this study, we expressed rPcARA in P. pastoris GS115 strain using both the native P. chrysosporium PcARA intrinsic and α-factor secretion signals. The results showed that recombinant P. pastoris strains did not produce rPcARA in induction medium when constructed with the intrinsic secretion signal by both enzymatic assay and Western blot analysis (data not shown).

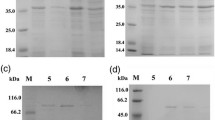

Enzymatic assay indicated the production of a PcARA by P. pastoris was achieved after 1 day induction. Enzyme accumulation increased dramatically until day 4 and reached a maximum of 1,660 U l−1. rPcARA was purified from a cell-free supernatant and its biochemical properties were studied. The result indicated rPcARA has specific activity on debrached arabinan of 204 U mg−1, whereas the K m and V max values were 4.3 mg ml−1 and 400 U mg−1, respectively. In comparison to others ARAs, rPcARA displays higher specific activity. For example arabinanases from P. chrysogenum, C. saccharolyticus have specific activity of 18.8 and 12 U mg−1, respectively [8, 22]. To our knowledge, only specific activity of arabinanase from B. subtilis is higher than that of rPcARA, however, the expression level is very low and the recombinant enzyme locates itself in periplasmic place [23]. The molecular mass of purified rPcARA was determined by SDS-PAGE. The results showed a single band around 33 kDa (Fig. 2). This size is very close to theoretical molecular mass of 33.9 kDa by calculating by the number of amino acids present in rPcARA sequence.

Effect of temperature, pH and metal ions on rPcARA activity

To determine the effect of temperature, 0.3 U of purified rPcARA was incubated with debrached araninan as described above. The enzyme assay showed that rPcARA exhibited its highest activity at 60 °C (Fig. 3a). Enzyme activity decreased rapidly when the reaction temperature was above 60 °C, and lost most of activity at 80 °C. The optimal temperature of rPcARA indicates rPcARA is thermostable enzyme and accordance to other thermostable arabinanases of A. aculeatus, P. chrysogenum, B. subtilis, and C. saccharolyticus, where optimal temperature are from 50 to 75 °C [8, 22–24].

The same amount of purified enzyme was also used to study the optimum pH for rPcARA activity. rPcARA reached maximum activity at pH 5.0, which decreased rapidly when the pH was below 5.0 or above 6.0 (Fig. 3b). The optimal pH for rPcARA was in accordance with the ARAs of P. chrysogenum, B. subtilis [8, 23], whereas the optimal pH of ARAs from C. saccharolyticus and A. aculeatus are observed at 6.5 and 5.5, respectively [22, 24].

Our results showed that most of the metal ions tested had an inhibitory effect on rPcARA activity (Fig. 4). Cu2+ strongly inhibited rPcARA activity. Zn2+, Ca2+ reduced rPcARA activity below 50 % when compared to the control. Hong [22] reported that Zn2+, Ca2+, and Cu2+ inhibited arabinanase activity but Mn2+, Co2+, Fe2+, Ba2+, Mg2+, and Ni2+ enhanced enzyme activity. Interesting, Ca2+ may play an important role in the catalytic domain of G. stearothermophilus arabianase since one calcium ion was found on this enzyme structure but rPcARA was inhibited by this ion [7].

Substrate specific and mode of action of rPcARA

Arabinanase activity of rPcARA was tested on debranched arabinan, sugar beet arabinan, arabinoxylan, and birchwood xylan. The results indicated that rPcARA displayed high activity toward debranched arabinan, but the specific activity on sugar beet arabinan and arabinoxylan were lower, whereas enzyme did not hydrolyze birchwood xylan (Table 1). Arabinanases from C. saccharolyticus and B. subtilis showed activity for both debranched arabinan and sugar beet arabinan substrates but did not act toward arabinoxylan [22, 25]. The lower specific activity for sugar beet arabinan and arabinoxylan might be explained due to the inhibition by the 1,2-α- and 1,3-α-l-arabinofuranosyl side chains linked to a 1,5-α-l-arabinfurabosyl backbone [26]. Arabinofuranosidase activity was not found on rPcARA as similar to other ARAs [22, 25].

The hydrolysis products of debranched arabinan by rPcARA were visualized on TLC. As evident from Fig. 5, rPcARA released arabinose, arabinobiose, and arabinotriose sugars. This result indicated that rPcARA is an endo-arabinanase that the major end-products are arabinobiose and arabinotriose. However, there are reported the major end-products of debranched arabinan hydrolysis of arabinanases from P. chrysogenum and Pseudomonas fluorescens are arabinotriose [8, 27]. These suggest that the mode of action of rPcARA is different to other ARAs reported.

Thin layer chromatography (TLC) analysis of reaction product by recombinant arabinanase (rPcARA). Reaction was carried out at 60 °C for 10 min, following incubation 100 °C for 5 min. Lane 1 arabinose, Lane 2 arabinobiose, Lane 3 arabinotriose, Lane 4 arabinopentaose, Lane 5 arabinohexaose, Lane 6 debranched arabinan, Lane 7 debranched arabinan hydrolysis product by rPcARA, Lane 8 Arabinooligomer mixture

Synergistic action with xylanase

We previously reported the expression and characterization of recombinant xylanase C from P. chrysosporium. This enzyme had optimum pH and temperature of 5.0 and 70 °C, respectively that is very closely to rPcARA [28]. In this study, we have investigated the synergistic action of both enzymes on degradation of commercial wheat arabinoxylan and NaOH-pretreated barley straw. Wheat arabinoxylan is composed of 37 % of arabinose and 61 % of xylose, thus in the present study a mixture of rPcARA and rPcXynC at ratio (3:5) was employed for the degradation of wheat arabinxylan. rPcXynC released 0.66 mg sugar, while rPcARA produced only 0.01 mg sugar of total 1 mg substrate used. However, the 3:5 ratio of rPcARA and rPcXynC increased sugar products up to 0.72 mg (Fig. 6a). The results indicated rPcXynC has high specific activity on wheat arabinoxylan, but the rPcARA specific activity is lower than that of its activity on debranched arabinan. This difference may be due to the effect of side groups linked on wheat arabinoxylan, where they inhibited rPcARA only. Moreover, it seems rPcXynC cleaves the β-1,4 backbone of xylooliosaccharide of arabinoxylan, and, consequently, not only xylose residues but also arabinose sugars were released. The combination of both enzyme showed increasing efficiency on arabinoxylan degradation. This demonstrates that both enzyme supported each other, resulting in enhancement of specific activity. There has been reported indicating the wheat arabinoxylan could be degraded by enzyme cocktail containing β-xylosidase, xylanase and α-l-arabinofuranosidase but no report on the synergistic action using arabinanase and xylanase [29].

Soluble sugar production following hydrolysis by the combination of rPcARA and rPcXynC on a commercial arabinoxylan and b NaOH-pretreated barley straw. Control biomass without enzyme incubation, 1 biomass incubated with rPcARA, 2 biomass incubated with rPcXynC, 3 biomass incubated with rPcARA and rPcXynC mixture. The hydrolysis reaction of arabinoxylan was carried out for 10 min, 60 °C in 400 μl 50 mM sodium acetate pH 5 containing 1 mg substance using 0.3 and 0.5 U of rPcARA and rPcXyn, respectively. One hundred mg of NaOH-pretreated barley straw was incubated with 10 U of each enzyme in 5 ml of 50 mM sodium acetate pH following 16 h at 60 °C. Total soluble sugar was measured by DNSA method

The previous study demonstrated the optimum pretreatment process of barley straw using sodium hydroxide was 3 M hydroxide under pressure of 5 kg cm−2 for 60 min at 150 °C (data unpublished). The lignin content of NaOH-pretreated barley straw decreased from 22.7 to 11.79 %, glucose increased from 40.07 to 61.52 %, while hemicelluloses sugars was equivalent of 19.34 %. The degradation efficiency of NaOH-pretreated barley straw is showed in Fig. 6b. Enzymatic hydrolysis by rPcARA was found to be 1.023 mg, while 8.729 mg was produced by rPcXynC. The combination of both rPcARA and rPcXynC improved the sugar production up to 9.376 mg. The role of xylanase on the degradation of barley straw has been demonstrated. The presence of xylanase not only enhanced xylose production but also improved the accessibility of cellulose to cellulases in the mixture containing by cellulose, β-glucosidase and endoxylanase [30]. Similarly in the present study, rPcXynC showed greater ability to hydrolyze pretreated barley straw. Moreover, a synergy of rPcARA and rPcXynC improved products yield.

The main compositions of barley straw are glucans, xylans and arabinans which account for 37.1, 21.3 and 3.8 % of dry weight, respectively [30]. Xylose and arabinose are represented of 15 and 4.0 %, respectively, in this plant as similar to this study [3]. However, the synergistic action of xylanase and arabinanase has not yet studied on barley straw saccharification. Our study indicated that synergistic action of rPcARA and rPcXynC resulted in total soluble sugars of 9.37 % presented hemicelluloses. Thus, these enzymes were efficient for saccharification processing of this material and could be potential candidate for other lignocelluloses biomass saccharification by enzymatic.

Although P. chrysosporium has been reported for improving up to 42.3 % of total sugar yield on rice straw [31], most of studies demonstrated that this fungus had little or no effect on improvement on enzymatic hydrolysis because of consuming large amount of readily accessible carbohydrates by itself, therefore, the remaining carbohydrates might be less digestible and thus resistant to the subsequent hydrolysis [32]. Moreover, the biomass saccharification processing by this fungus consumes more incubation time and it may secrete substances, which are harmful for other microorganisms. Consequently, it may require other processes such as neutralization and separation if using biomass saccharification products by this fungus as carbon sources for fermentation. Thus, the isolated enzyme in the present study would be a great potential to replace fungal saccharification.

Herein, we first reported the characterization and application of rPcARA and its application in biomass saccharification in synergistic action with rPcXynC. rPcARA shows high specific activity towards linear α-1,5-l-arabinan substance than that of most reported arabinanase. Moreover, rPcARA displays maximum activity at high temperature, suggesting it as a thermostable enzyme. On other hand, sugar production yield from biomass sources are increased in the presence of rPcARA and rPcXynC, creating the capable utilization of these enzymes on biomass degradation. Although rPcARA may play an important role in arabinan and biomass hydrolysis, however, this enzyme is strongly inhibited by arabinofuranoside groups that frequently present in natural plant structure. Thus, α-l-arabinofuranosidase that removes arabinofuranoside group may be required in order to completely degrade anabinan and hemicelluloses sources as well. Therefore, the interaction among these enzymes should be further topic of research.

References

Scheller HV, Ulvskov P (2010) Hemicelluloses. Annu Rev Plant Biol 61:263–289

Ebringerová A, Hromádková Z, Heinze T (2005) Hemicellulose. Adv Polym Sci 186:1–67

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Łukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101(13):4775–4800

Shallom D, Shoham Y (2003) Microbial hemicellulases. Curr Opin Microbiol 6(3):219–228

Nurizzo D, Turkenburg JP, Charnock SJ, Roberts SM, Dodson EJ, McKie VA, Taylor EJ, Gilbert HJ, Davies GJ (2002) Cellvibrio japonicus alpha-l-arabinanase 43A has a novel five-blade beta-propeller fold. Nat Struct Biol 9(9):665–668

Pons T, Naumoff DG, Martínez-Fleites C, Hernández L (2004) Three acidic residues are at the active site of a beta-propeller architecture in glycoside hydrolase families 32, 43, 62, and 68. Proteins 54(3):424–432

Alhassid A, Ben-David A, Tabachnikov O, Libster D, Naveh E, Zolotnitsky G, Shoham Y, Shoham G (2009) Crystal structure of an inverting GH 43 1,5-alpha-l-arabinanase from Geobacillus stearothermophilus complexed with its substrate. Biochem J 422(1):73–82

Sakamoto T, Inui M, Yasui K, Tokuda S, Akiyoshi M, Kobori Y, Nakaniwa T, Tada T (2012) Biochemical characterization and gene expression of two endo-arabinanases from Penicillium chrysogenum 31B. Appl Microbiol Biotechnol 93(3):1087–1096

Saha BC, Bothast RJ (1999) Production of 2,3-butanediol by newly isolated Enterobacter cloacae. Appl Microbiol Biotechnol 52(3):321–326

Chandel AK, Chandrasekhar G, Radhika K, Ravinder R, Ravindra P (2011) Bioconversion of pentose sugars into ethanol: a review and future directions. Biotechnol Mol Biol Rev 6(1):008–020

Seiboth B, Metz B (2011) Fungal arabinan and l-arabinose metabolism. Appl Microbiol Biotechnol 89(6):1665–1673

Martinez D, Larrondo LF, Putnam N, Gelpke MD, Huang K, Chapman J, Helfenbein KG, Ramaiya P, Detter J-C, Larimer F, Coutinho PM, Henrissat B, Berka R, Cullen D, Rokhsar D (2004) Genome sequence of the lignocellulose degrading fungus Phanerochaete chrysosporium strain RP78. Nat Biotechnol 22(6):695–700

Hori C, Igarashi K, Katayama A, Samejima M (2011) Effects of xylan and starch on secretome of the basidiomycete Phanerochaete chrysosporium grown on cellulose. FEMS Microbiol Lett 321(1):14–23

Adav SS, Ravindran A, Sze SK (2012) Quantitative proteomic analysis of lignocellulolytic enzymes by Phanerochaete chrysosporium on different lignocellulosic biomass. J Proteomics 75(5):1493–1504

Tien M, Kirk TK (1988) Lignin peroxidase of Phanerochaete chrysosporium. Methods Enzymol 161:238–249

Wymelenberg AV, Sabat G, Martinez D, Rajangam AS, Teeri TT, Gaskell J, Kersten PJ, Cullen D (2005) The Phaenerochaete chrysosporium secretom: database predictions and initial mass spectrometry peptide identifications in cellulose-grown medium. J Biotechnol 118:17–34

Vasu P, Bauer S, Savary BJ (2012) Cloning and expression of hemicellulases from Aspergillus nidulans in Pichia pastoris. In: Lorence A (ed) Recombinant gene expression: reviews and protocols, vol 824. Methods in Molecular Biology, 3rd edn. Humana Press, New York, pp 433–450

Sambrook S, Russell DW (2003) Molecular cloning: a laboratory manual, 3rd edn. Cold Spring Harbor, New York

Kelley LA, Sternberg MJ (2009) Protein structure prediction on the Web: a case study using the Phyre server. Nat Protoc 4(3):363–371

Daly R, Hearn MT (2005) Expression of heterologous proteins in Pichia pastoris: a useful experimental tool in protein engineering and production. J Mol Recognit 18:119–138

Grinna LS, Tschopp JF (1989) Size distribution and general structural features of N-linked oligosaccharides from the methylotrophic yeast. Yeast 5(2):107–115

Hong MR, Park CS, Oh DK (2009) Characterization of a thermostable endo-1,5-alpha-l-arabinanase from Caldicellulorsiruptor saccharolyticus. Biotechnol Lett 31(9):1439–1443

Leal TF, de Sá-Nogueira I (2004) Purification, characterization and functional analysis of an endo-arabinanase (AbnA) from Bacillus subtilis. FEMS Microbiol Lett 241(1):41–48

Skjøt M, Kauppinen S, Kofod LV, Fuglsang C, Pauly M, Dalbøge H, Andersen LN (2001) Functional cloning of an endo-arabinanase from Aspergillus aculeatus and its heterologous expression in A. oryzae and tobacco. Mol Genet Genomics 265(5):913–921

Inácio JM, de Sá-Nogueira I (2008) Characterization of abn2 (yxiA), encoding a Bacillus subtilis GH43 arabinanase, Abn2, and its role in arabino-polysaccharide degradation. J Bacteriol 190(12):4272–4280

Goddard-Borger ED, Carapito R, Jeltsch JM, Phalip V, Stick RV, Varrot A (2011) α-l-Arabinofuranosylated pyrrolidines as arabinanase inhibitors. Chem Commun 47(34):9684–9686

McKie VA, Black GW, Millward-Sadler SJ, Hazlewood GP, Laurie JI, Gilbert HJ (1997) Arabinanase A from Pseudomonas fluorescens subsp. cellulosa exhibits both an endo- and an exo- mode of action. Biochem J 232(Pt 2):547–555

Huy ND, Kim SW, Park SM (2011) Heterologous expression of endo-1,4-beta-xylanase C from Phanerochaete chrysosporium in Pichia pastoris. J Biosci Bioeng 111(6):654–657

Sørensen HR, Pedersen S, Jørgensen CT, Meyer AS (2007) Enzymatic hydrolysis of wheat arabinoxylan by a recombinant minimal enzyme cocktail containing beta-xylosidase and novel endo-1,4-beta-xylanase and alpha-l-arabinofuranosidase activities. Biotechnol Prog 23(1):100–107

García-Aparicio MP, Ballesteros M, Manzanares P, Ballesteros I, González A, Negro MJ (2007) Xylanase contribution to the efficiency of cellulose enzymatic hydrolysis of barley straw. Appl Biochem Biotechnol 137–140(1–12):353–365

Bak JS, Ko JK, Choi IG, Park YC, Seo JH, Kim KH (2009) Fungal pretreatment of lignocellulose by Phanerochaete chrysosporium to produce ethanol from rice straw. Biotechnol Bioeng 104(3):471–482

Wan C, Li Y (2012) Fungal pretreatment of lignocellulosic biomass. Biotechnol Adv 30(6):1447–1457

Acknowledgments

This research was supported by Technology Development Program for Agriculture and Forestry, Ministry for Food, Agriculture, Forestry and Fisheries, Republic of Korea. In partly, this research was also supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2010-0015666). We thank the Research Institute of Bioindustry at Chonbuk National University for kindly providing the facilities for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huy, N.D., Thiyagarajan, S., Choi, YE. et al. Cloning and characterization of a thermostable endo-arabinanase from Phanerochaete chrysosporium and its synergistic action with endo-xylanase. Bioprocess Biosyst Eng 36, 677–685 (2013). https://doi.org/10.1007/s00449-013-0891-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-0891-9