Abstract

This comprehensive review aims to explore and elucidate the pivotal role of biotechnology in biofuel production, specifically focusing on its contribution to enhancing sustainability, efficiency, and productivity in the energy sector. By examining various biotechnological approaches like genetic engineering, metabolic engineering, and synthetic biology, it seeks to provide insights into effectively harnessing biofuel generation processes, including the integration of machine learning and life cycle assessment for microalgae cultivation and harvesting. Additionally, it sheds light on the multifaceted implications surrounding biofuel production and consumption, addressing technological, ethical, social, and economic considerations. Through critical analysis of the advantages and challenges associated with biotechnology-driven biofuel development, it offers a balanced perspective on the true potential of biofuels as a viable, sustainable, and equitable energy source for the future. This examination provides a holistic analysis of the symbiotic relationship between biotechnology and biofuels, highlighting how advancements in biotechnological techniques can pave the way for a more sustainable and resilient energy future. By addressing both the promises and limitations of biotechnology in this context, it aims to contribute to informed decision-making and policy formulation to drive the transition toward a cleaner and more equitable energy paradigm.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Biotechnology has emerged as a pivotal tool in developing sustainable solutions for a renewable energy future, focusing primarily on the advancement of biofuels. Utilization of biomass, which includes wood, charcoal, and agricultural residues, has been used in various applications, such as cooking, heating, and the generation of both biofuels and electricity. Through appropriate processing, biomass can be converted into solid forms such as wood pellets or biochar, which, when burned, contribute to energy production [1]. Furthermore, biomass serves as a precursor for liquid products such as bio-oils, such as biodiesel, offering a sustainable substitute for conventional crude oil [2]. Moreover, the potential of biomass extends to the production of biogas, including methane or syngas, further diversifying the range of viable bioenergy resources [3].

The use of biofuels has gained significant attention in recent years due to growing concerns about climate change, energy security, and sustainability [4]. Biofuels have several advantages over conventional fossil fuels, including lower greenhouse gas emissions, reduced dependence on foreign oil, and improved rural economies [5]. Biofuels are also more sustainable, as they are derived from renewable sources and can be produced locally, reducing the need for long-distance fuel transportation [6]. In addition, biofuels can be used in existing infrastructure without significant modifications, making them a practical alternative to fossil fuels.

Biotechnology-based approaches such as genetic engineering, metabolic engineering, and synthetic biology have been used to enhance the productivity and efficiency of biofuel generation processes. These technologies enable the development of high-yield, low-cost, and sustainable biofuel generation systems. For example, genetic engineering has been used to modify plant genes to increase their oil content [7, 8], while metabolic engineering has been used to optimize ethanol production of ethanol from various feedstocks [9]. Synthetic biology has been used to design and construct new biological systems for the production of biofuels [10]. Enzymes [11, 12], fermentation [13, 14] and algae [15, 16] are promising sources of biofuels due to their high yield and versatility. Enzymes can break down complex carbohydrates in plants and other feedstocks into simpler sugars that can be fermented into biofuels. Some fermentative microorganisms, such as yeast or bacteria, are being used industrially to convert sugars into biofuels, such as ethanol [17]. Algae can produce high yields of oil, which can be converted to biofuels. Biotechnology also enables the design and operation of biorefineries, leading to more efficient and sustainable operations [8]. Biorefineries are facilities that convert biomass into a variety of value-added products, including biofuels and chemicals. Biorefineries can help reduce waste and enhance the overall sustainability of the biofuel generation process.

However, biofuel production and consumption pose complex ethical, social and economic implications, which require careful consideration to promote sustainable and equitable economic growth while mitigating the effects of climate change. For example, there are concerns about the impact of biofuel production on land use, food security, and biodiversity. Additionally, the economics of biofuel production can be challenging, with high capital costs and uncertain returns on investment. The present review aims to provide a comprehensive understanding of recent advances in biotechnology and biofuel research, specifically focusing on the development of sustainable solutions for a future of renewable energy. The objective is to explore the role of biotechnology in addressing the technical, economic, and environmental challenges associated with biofuel production.

2 Types of biofuels

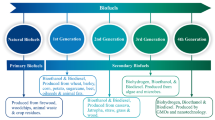

Biofuels are renewable energy sources derived from organic matter such as plants, algae, and waste materials, making them a promising alternative to conventional fossil fuels [18]. They are considered a promising alternative to fossil fuels because of their lower carbon emissions and sustainable production methods. There are four categories of biofuels based on the type of raw materials used in their production (Fig. 1), which are classified as first-generation, second-generation, third-generation and fourth-generation biofuels [5, 19].

2.1 First-generation biofuels

First-generation biofuels are derived from food crops such as corn, sugarcane and soybeans [5]. They are produced through conventional technologies, such as fermentation or transesterification, to convert plant materials into ethanol, biodiesel, or vegetable oil. While first-generation biofuels can help reduce greenhouse gas emissions, they have been held responsible for causing land use changes, deforestation, and competition for food crops (Table 1).

2.2 Second-generation biofuels

Second-generation biofuels are produced from non-food biomass, such as agricultural and forest residues, energy crops and municipal waste [4]. They are produced using advanced technologies, such as gasification, pyrolysis, and hydrothermal liquefaction, to convert biomass into liquid fuels, such as bioethanol, biodiesel or biogas [5]. Second-generation biofuels are more sustainable than first-generation biofuels, as they do not compete with food crops and can use waste materials as feedstock. Second-generation biofuels face challenges such as complex processing due to lignocellulosic feedstocks, which leads to higher production costs and technical hurdles [20]. Developing infrastructure and supply chains for dispersed biomass can be difficult, and commercial-scale production requires significant investment and market stability. Additionally, improperly managed feedstock production can pose environmental risks, such as change in land use, water usage, and biodiversity loss [21].

2.3 Third-generation biofuels

Third-generation biofuels are produced from algae or other microorganisms [4, 15]. They are grown in ponds or photobioreactors and can produce large amounts of oil or biomass per unit area. Third-generation biofuels are seen as promising due to their high productivity, low land use, and ability to grow in non-arable land [22]. However, they are still in the early stages of development and their commercial viability has yet to be established.

2.4 Fourth-generation biofuels

Fourth-generation biofuels are produced using synthetic biology and genetic engineering techniques [23]. Biofuels undergo processing by using genetically modified algae (GM), as well as photobiological solar and electrofuels [24, 25]. They have the potential to be more efficient and cost-effective than other biofuels, as they can be designed to produce specific types of fuel with higher energy densities [23]. However, there are concerns about the potential risks associated with genetically modified organisms and the environmental impacts of large-scale production.

3 Enzyme production: a key factor in biofuel generation

Enzymes are essential for the production of biofuels, as they catalyze the chemical reactions required to break down organic materials into simpler compounds that can be used to produce biofuels [26]. Enzymes used in biofuel generation include cellulases, amylases, and lipases [27]. Enzymes also improve the efficiency of biofuel generation by reducing the energy required to convert organic materials into biofuels. The widely used method for enzyme production is microbial fermentation, where microorganisms such as bacteria or yeast are grown in large-scale fermentation tanks under controlled conditions [16]. Microorganisms consume organic material, such as sugars or starch, and produce enzymes as waste products [28]. The enzymes are then harvested and purified for biofuel generation (Fig. S1).

Microbial fermentation is a cost-effective and scalable process [29], which can also be optimized by genetic engineering, to produce enzymes with specific properties or improved efficiency [30]. However, the production of enzymes through microbial fermentation may be limited by the availability of suitable microorganisms and the requirement for specific growth conditions [31]. Enzymes also facilitate the use of renewable organic materials, including agricultural waste and non-food crops, as biofuel feedstocks [32], thereby reducing dependence on non-renewable resources such as fossil fuels. Ultimately, the use of enzymes in the generation of biofuels drives us toward a more sustainable and environmentally friendly energy future and helps contribute to a more secure and sustainable energy system.

4 Role of fermentation in the generation of biofuels

Fermentation is a key process in producing biofuels from various sources, such as sugars, starch, and cellulose. During fermentation, microorganisms, such as bacteria [13], yeast [17], or fungi [33], convert the raw materials into biofuels, such as ethanol or butanol. For example, fermentation transforms sugars obtained from corn, sugarcane, or other biomass into ethanol. This process involves the combination of yeast with water and sugar, where yeast consumes sugar and generates ethanol and carbon dioxide as byproducts [17]. Similarly, when producing biofuels from lignocellulosic biomass, fermentation is used to break down complex sugars in biomass into simpler sugars that can be converted into biofuels [34]. This process involves using enzymes or microorganisms to break down the cellulose and hemicellulose in the biomass into sugars, which are then fermented into biofuels. Fermentation thus enables the conversion of biomass into usable fuels that can help reduce dependence on fossil fuels and mitigate the impact of greenhouse gas emissions on the environment.

4.1 Fermentation process

The fermentation process for the generation of biofuels is a complex and multistep process that requires careful attention to detail at each stage to ensure maximum efficiency and productivity. This process can occur under anaerobic or aerobic conditions, depending on the microorganism and the type of substrate used. During fermentation, microorganisms such as yeast or bacteria consume carbohydrates or other organic compounds and produce energy and waste products such as ethanol, butanol, or methane. A schematic representation of the fermentation process for biofuel generation is represented in Fig. 2, which typically involves the following steps.

4.1.1 Feedstock preparation

The initial stage of the process involves the preparation of the feedstock, which is selected based on the specific biofuel being produced. Feedstocks with an abundant sugar or starch content, such as corn, sugarcane, or other biomass sources, are utilized for bioethanol production. However, when working with lignocellulosic biomass such as wood chips or agricultural residues, the feedstock requires pretreatment to break down complex sugars into simpler forms that can be effectively fermented [34].

4.1.2 Fermentation

Once the feedstock is prepared, it is mixed with water and yeast or other microorganisms to initiate the fermentation process [35]. During fermentation, the microorganisms consume the sugars in the feedstock and convert them into ethanol or other organic compounds. The temperature and pH of the fermentation process are critical [31] as they can affect the efficiency and productivity of the process.

4.1.3 Distillation and purification

After fermentation, the resulting biofuel solution is distilled to separate the biofuel from the water and other impurities. Among the different liquid phase separation techniques, membrane processes have been reported as a major technology for process intensification in biomolecule separation and purification. These processes are recognized for their robustness, energy efficiency, and environmentally friendly nature, aligning with sustainability goals. Among these, membrane distillation (MD) is attracting significant interest, which employs hydrophobic microporous membranes and utilizes temperature differences to facilitate the vapour pressure-driven separation of volatile compounds from nonvolatile ones. There are four primary configurations of MD modules: Direct-Contact Membrane Distillation (DCMD) [36], Air-Gap Membrane Distillation (AGMD) [37], Vacuum Membrane Distillation (VMD) [38], and Sweeping Gas Membrane Distillation (SGMD) [39]. These configurations differ in how they condense vaporized molecules on the permeate side. DCMD employs a condensing fluid directly in contact with the membrane, while AGMD uses an air gap and cold plate for condensation. The VMD and SGMD involve transporting vaporized molecules outside the module via a vacuum pump or inert gas flow for subsequent condensation. Loulergue et al. [37] conducted a study assessing AGMD for the extraction of ethanol from algal-based fermentation broths. The AGMD process effectively achieved the concentration of ethanol in the permeate while retaining glycerol, sugar, and salts. The study highlighted the potential to optimize process productivity and selectivity by carefully selecting operational parameters.

4.1.4 Blending and distribution

Biofuel preparation for distribution and use incorporates a crucial process called blending. The process involves merging the biofuel with additional compounds to amplify specific attributes to meet precise standards before becoming a viable transportation fuel. A frequently adjusted attribute during blending is the octane rating of biofuels [40]. The octane rating measures the resistance of a fuel to engine knocking, which is an undesirable phenomenon in internal combustion engines. The mixing of biofuels with higher-octane compounds such as dimethylfuran, 2-methylfuran, prenol, 2-methyl-2-butene, and ethanol has been reported to improve the octane rating of the mixture, resulting in better engine performance and reduced risk of engine knocking [41]. The mixture is also used to modify the oxygen content of biofuels, which contributes to improved combustion efficiency and reduced emissions [42]. Following the blending procedures, the biofuel transforms into a customized product that meets performance, emissions, and compatibility suitable for vehicle and machinery deployment [43].

4.2 Types of biofuels produced using fermentation

Fermentation produces a wide range of biofuels, from ethanol and butanol to biogas and methane. The choice of biofuel produced depends on several factors, including the availability of feedstock, the type of microorganisms used, and the desired end-use of the biofuel. Some of the most commonly produced biofuels through fermentation are discussed below:

4.2.1 Bioethanol

Bioethanol is a widely produced renewable fuel on a global scale and is predominantly utilized as a fuel additive to gasoline. It is usually produced through the fermentation of sugars or starches obtained from feedstocks such as corn, sugarcane, or other biomass sources. Microorganisms such as yeast (eg. Saccharomyces cerevisiae) [44] and bacteria (e.g., Zymomonas mobilis) [45] are typically used in the fermentation process.

4.2.2 Butanol

Butanol is another type of biofuel that can be produced through fermentation. It has several advantages over bioethanol, including its higher energy content and compatibility with the existing gasoline infrastructure. Butanol can be produced by fermentation of sugars, starch, or lignocellulosic biomass. Different bacterial species, such as Clostridium acetobutylicum [46], Clostridium beijerinckii [47], and Butyribacterium methylotrophicum [48] can be used in the fermentation process.

4.2.3 Biogas

Biogas is a mixture of gases, primarily methane and carbon dioxide, produced through anaerobic digestion of organic matter, such as animal waste, food waste, or sewage [49]. Microorganisms, such as methanogenic archaea [50], and bacteria, such as Bacteroidetes and Firmicutes [51], are typically involved in the fermentation process.

4.2.4 Biodiesel

Biodiesel is usually produced through a chemical process called transesterification [14], which involves reacting vegetable oils or animal fats with alcohol, such as methanol or ethanol, in the presence of a catalyst. However, biodiesel can also be produced by fermenting lipids, such as algae or other microorganisms [15]. Yeasts, such as Rhodotorula glutinis [52] and Lipomyces starkeyi [53] are commonly used in fermentation.

4.2.5 Methane

Methane can be produced through the anaerobic digestion of organic matter. It is commonly referred to as biogas and can be used as a fuel for electricity or heat production [54]. Methane-producing microorganisms, such as Methanosarcina acetivorans [55] and Methanobacterium thermaggregans [56], are typically used for the production of methane as biofuel.

5 Exploring the potential of algae in biofuel generation

Macroalgae, with their high carbohydrate content, hold promise as a potential source for biofuel production. In addition, algae have a high lipid content, making them ideal for the production of biodiesel, with some species of algae containing up to 80% lipids by weight [57]. Algae can also absorb carbon dioxide from the atmosphere, mitigate greenhouse gas emissions, and absorb up to five times more carbon dioxide than other biofuel crops, reducing the carbon footprint of biofuels [8]. Macroalgae can also grow in various environments, including saltwater, freshwater, and wastewater, making them an attractive source of biofuels, including biodiesel, bioethanol, and biogas. A list of macroalgae used in biofuel production and yield is represented in Table 2. However, the use of marine macroalgae faces a significant challenge due to their robust hydrocolloid cell walls. Therefore, pretreatment is essential to break down these hydrocolloid-protected cellular structures and convert carbohydrates into suitable sugars for bioethanol production [58].

5.1 Production methods

Microalgae are a promising feedstock for biodiesel production, as they can be grown quickly and have high lipid content [59]. In addition, algae can be grown on non-agricultural land and can even use wastewater as a nutrient source [60], making them a more sustainable and environmentally friendly option for biofuel production. The process of producing biofuels from microalgae involves three main steps: algae cultivation, harvesting, and conversion (Fig. 3A). Algae can be grown in open ponds or closed photobioreactors, and once they have reached maturity, they need to be harvested using methods such as centrifugation, filtration, or flocculation. The harvested algae can then be converted to biofuels using various methods, such as pyrolysis, hydrothermal liquefaction or transesterification (Fig. 3B). Each of these steps has its advantages and disadvantages in terms of cost, efficiency, and yield. The various approaches that can be used to produce biofuels from algae are as follows.

5.1.1 Direct oil extraction

Direct oil extraction involves the mechanical or chemical extraction of oils from biomass or organic material [16, 61]. Mechanical methods of oil extraction from algae include sonication, high-pressure homogenization, and centrifugation. Chemical methods include solvent extraction using non-hexane solvents such as ethanol or supercritical carbon dioxide. In a study by Jeyakumar et al. [2], the Soxhlet extraction method was demonstrated, which involved mixing dried and ground biomass with distilled water and subjecting it to sonication. The extraction process involves the use of a Soxhlet apparatus with powdered algae placed in a filter paper thimble. A mixture of chloroform and methanol (2:1) solvent is used, which evaporates, condenses and drips back into the solid material chamber, accumulating warm solvents. This cyclic process is repeated over several hours. The dissolved compounds are then filtered, and distillation separates the crude algal lipids from the solvents. The non-soluble solid is discarded, while the remaining biomass, rich in carbohydrates, can be used as a biofertilizer or recycled for bioethanol production [62]. The oils obtained by direct extraction of oil from algae typically have a high energy density, making them an attractive option for use as biofuels.

5.1.2 Transesterification

Transesterification is a process that is used to convert lipids or oils from algae into biodiesel. In this process, the lipids or oils in algae are mixed with an alcohol, usually methanol, along with a catalyst such as sodium hydroxide (NaOH), potassium hydroxide (KOH), or enzymes. This mixture undergoes a reaction that produces fatty acid methyl esters (FAMEs) or biodiesel and glycerin as a byproduct [59, 63]. However, when the microalgal oil contains a significant level of free fatty acids, alkaline catalysts like NaOH and KOH are unsuitable for biodiesel production because of their tendency to produce soap. In such situations, acid catalysts such as sulfuric acid (H2SO4) and hydrochloric acid (HCl) are used [64]. Enzymes have also been used successfully in the conversion of microalgal oils to biodiesel. Li et al. [65] achieved a biodiesel conversion yield of 98% using immobilized lipase from Candidiasis sp. for oils extracted from C. protothecoides. In another study, Lai et al. [66] examined the catalytic efficiency of two immobilized lipases, namely Penicillium expansum lipase and Candida antarctica lipase B, to synthesize biodiesel from microalgal oil.

Advanced approaches to direct transesterification include microwave or ultrasound to enhance the mass transfer rates and reduce reaction times. Microwave-assisted transesterification utilizes quick redirection of microwave-absorbing methanol molecules, resulting in rapid heating throughout the sample [67]. Ultrasound disrupts the oil-alcohol phase boundary by generating cavitation bubbles, which improves the extraction of oil from cells and enhances the transesterification process [68]. Supercritical conditions and the application of surfactants have also been explored to increase conversion yields [69].

5.1.3 Pyrolysis

Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. It involves heating biomass, such as wood, crop residues or waste materials, at high temperatures (typically between 400 and 600 °C) to break it into three main products: bio-oil, biochar and gases. During pyrolysis, the biomass undergoes chemical and physical changes. The absence of oxygen prevents complete combustion, resulting in the production of bio-oil, which is a liquid mixture of various organic compounds. Biochar, a solid residue rich in carbon, is also generated during the process. Gases such as methane, carbon dioxide, and carbon monoxide are also released as by-products.

The specific mode of pyrolysis (e.g., slow, fast, or flash) and the operating parameters, such as the heating rate, temperature, residence time, and particle size, determine the type and quantity of the products obtained. Slow pyrolysis at lower temperatures for longer heating times produces more biochar, while fast and flash pyrolysis at higher temperatures for a shorter time yields higher amounts of bio-oil [2]. Fast pyrolysis has proven effective in producing concentrated fuel oils and recovering biofuels with medium to low calorific power [70]. The decomposition temperatures vary for different components of biomass. Hemicelluloses decompose between 190 and 350 °C, cellulose between 240 and 400 °C, and lignin over a broader temperature range [71]. Algal biomass is advantageous for pyrolysis due to its high lipid content, ranging from 20 to 50% of dry cell weight and reaching up to 80% under specific conditions. This abundant lipid content in the biomass of lignocellulosic algae contributes to a greater bio-oil yield than other traditional biomass [72]. Depending on the type of reactor used, the process can be carried out using different heating methods, such as microwave [73], fluidized bed [74], or entrained flow [70].

Pyrolysis offers several advantages as a biomass conversion process. It allows the production of valuable bio-oil, which can be further processed into fuels or chemicals. The biochar produced during pyrolysis can be used as a soil amendment or as a carbon sequestration. Additionally, the gases released during pyrolysis can be used as a source of energy. The bio-oil produced can be improved through hydrodeoxygenation or catalytic cracking to improve its quality [75]. One significant advantage of pyrolysis is the conversion of solid materials into gases and vapours that are convenient to handle, transport, and store. This is also considered a sustainable and green method of biomass use, as it can reduce greenhouse gas emissions and provide an alternative to fossil fuels [58].

5.1.4 Hydrothermal liquefaction

Hydrothermal liquefaction (HTL) is a thermochemical conversion process that uses hot and pressurized water to convert solid biomass, such as microalgae into biofuels [76]. HTL involves reactions like hydrolysis, dehydration, decarboxylation and repolymerization, resulting in the formation of water-soluble compounds and eventually water-insoluble biofuels [77]. Gu et al. [78] reported that the composition of microalgae, including their protein, lipid and carbohydrate content, affects the yield, quality, and composition of the bio-oil produced by HTL. In a similar study, Koley et al. [79] reported that high-protein microalgae are more suitable for the synthesizing of bio-oil, while lipids and carbohydrates can also be converted to bio-oil through the HTL process. The HTL temperature range of 250 to 375 °C is generally considered suitable for the production of high-yield bio-oil from microalgae [80].

Pretreatment processes and catalysts can enhance the yield and quality of bio-oil obtained through HTL [81]. Catalysts, such as noble metals, transition metals, solid acids, and zeolites, play a crucial role in the conversion of bio-oil into long-chain hydrocarbons by facilitating deoxygenation and hydrogenation reactions [77]. The selection of catalysts depends on their ability to break C-O bonds and promote specific reactions. Thus, HTL shows promise as a commercial process for microalgae bio-oil production, but further research is needed to optimize the process and improve efficiency.

5.1.5 Supercritical water gasification

Supercritical water gasification (SCWG) involves subjecting biomass to high temperatures and pressures, transforming water into a supercritical state with unique solvent properties [82]. In this state, water efficiently breaks down organic matter, including microalgae, into simpler compounds such as gases (primarily hydrogen and methane) and liquid hydrocarbons. SCWG offers advantages such as high efficiency, minimal by-products, feedstock flexibility, and the ability to recover energy through clean gas products [83]. However, the process requires high-pressure and high-temperature conditions, resulting in increased capital and operating costs, and requires durable materials and equipment that can withstand harsh operating conditions [84].

5.1.6 Fermentation

The anaerobic fermentation process can be used to produce algae ethanol, which is an attractive feedstock option for ethanol production due to its high carbohydrate content and rapid growth rate [60]. The first step involves the breakdown of carbohydrates into simple sugars, which can be accomplished using acid or enzymatic hydrolysis. The resulting sugars can then be fermented by microorganisms, such as yeast, bacteria, or fungi, to produce ethanol [4]. The process can also be optimized by adjusting the pH, temperature, or nutrient levels to improve the yield and quality of ethanol [16]. Solid residues left after fermentation can be used for various purposes, such as a source of protein for animal feed or as a soil amendment. Algal fermentation for ethanol production has been explored as a potential alternative to traditional feedstocks such as sugarcane and corn.

5.1.7 Anaerobic digestion

Anaerobic digestion is a natural process that occurs in an oxygen-free environment and involves various archaea and microorganisms. It consists of four essential stages: hydrolysis, acetogenesis, methanogenesis, and acetogenesis, which break down macromolecules into simpler units, particularly during the hydrolysis phase [1]. This breakdown process enables the conversion of organic matter into biogas, primarily composed of methane (CH4) and carbon dioxide (CO2) [85]. Anaerobic digestion is widely recognized as a valuable approach to harnessing the energy potential of biowastes. It has been used successfully in the treatment of various waste streams, including municipal solid waste, domestic wastewater, agricultural residues, and industrial wastewater [86]. Furthermore, research has shown that microalgae can be utilized to produce high-quality biodiesel through aerobic digestion of livestock wastewater [87]. The biomass of algae can be digested in large tanks under controlled conditions for several days. After digestion, the remaining solid digestate can be used as a fertilizer, while the released biogas can be used as fuel for the generation of heat and/or electricity generation [88]. The process can be enhanced by adding other organic waste streams to algae, such as animal manure or food waste, to increase biogas production. Additionally, the process can be combined with other methods, such as microbial electrolysis or microbial fuel cells, to produce electricity or hydrogen [89]. Anaerobic digestion is considered an energy-efficient and environmentally friendly way to produce biogas and valuable by-products from algae.

6 Biotechnology in the design and optimization of biorefineries

Biorefineries aim to convert biomass into a variety of products, including fuels, chemicals, and materials [90]. Biotechnology plays a crucial role in the design and operation of biorefineries. It enables the optimization of microbial strains, the development of novel enzymes, and the manipulation of metabolic pathways to improve product yields and reduce costs (Fig. 4).

6.1 Microbial strain development

Microorganisms are essential in biorefinery for converting biomass into valuable products. The development of microbial strains is a multistep process that involves the identification, selection, and modification of microorganisms for the efficient conversion of biomass into target products [83]. It involves screening microorganisms for desirable traits, such as high product yields and tolerance to harsh conditions. Once suitable microorganisms are identified, genetic engineering techniques can be used to optimize their genetic makeup and enhance their overall performance. Researchers have developed consortiums consisting of the yeast Scheffersomyces stipitis and the bacterium Zymomonas mobilis to enhance ethanol production from lignocellulosic biomass. By maintaining an inoculation ratio of 1:3 between S. stipitis and Z. mobilis, the consortium achieved a 5.52% increase in xylose consumption and a 6.52% higher ethanol titer compared to Z. mobilis alone. Furthermore, inserting metabolic genes for xylose into the genome of Z. mobilis improved xylose consumption and ethanol titer by 15.36% and 6.81%, respectively [91]. In another study, Tran et al. [92] demonstrated that engineered Saccharomyces cerevisiae can co-produce ethanol and polyhydroxybutyrate (PHB) from lignocellulosic biomass. The strain was modified to ferment both glucose and xylose and also to synthesize PHB, a biodegradable polymer. This yeast accumulated PHB at a content of 64 mg/g of dry cell weight while maintaining a high ethanol yield of 0.43 g of ethanol/g of sugar. A comprehensive studies on microbial metabolic pathway engineering for biofuels production is represented in Table 3.

6.2 Enzyme development

Genetic engineering enables the modification of microorganisms to enhance or introduce the production of various enzymes and other bioactive compounds that are not naturally produced in significant amounts by these organisms [93, 94]. This method involves transferring genes responsible for enzyme production from one organism to another, expanding the potential for biofuel generation and increasing the yield from natural producers (Fig. S2). In a study by Quayson et al. [95], a recombinant Fusarium heterosporum lipase from Aspergillus oryzae was used to combine degumming and transesterification in a single step with a 1:1 molar ratio of crude palm oil (CPO) to biodiesel. This approach achieved a high biodiesel yield of 98.8% while improving catalytic activity and allowing reuse of immobilized lipase in nine consecutive batches. Researchers optimized enzyme and pretreatment strategies to reduce the energy consumption of lignocellulosic biorefining for biofuels. Through directed evolution, You et al. [96] developed a dominant mutant M137E/N269G of Bispora sp. MEY-1 XYL10C_ΔN with high catalytic efficiency (970 mL/s mg) and specific activity (2090 U/mg) at 37 °C, as well as improved thermostability (T50 increased by 5 °C). In another study, Wang et al. [97] overexpressed an indigenous xylanase (XynB) encoded by the CA_P0053 gene in Clostridium acetobutylicum, resulting in an 88-fold increase in extracellular xylanase activity. This highly soluble and fully secreted xylanase enabled the production of 4.03 g/L of butanol from hemicellulose.

6.3 Metabolic pathway engineering

The engineering of metabolic pathways allows for the optimization of metabolic flux within cells to enhance the production of desired products. This is achievable through various genetic engineering techniques, such as gene silencing, insertion, or modification [8, 9]. Novak et al. [98] successfully established isobutanol production in Escherichia coli on a chemically defined medium by building a plasmid library and screening for a robust E. coli W strain with high isobutanol yields. The study also employed a combination of different aeration strategies, strain improvement, and pulsed fed-batch to optimize the production process, achieving 20 g/L of isobutanol using cheese whey as raw material. Studies have demonstrated the potential of advanced biofuels such as butanol, isobutanol, fatty acid, and isoprenoid derivatives due to their energy dense properties and compatibility with existing infrastructure. Through metabolic engineering, the microbial synthesis of these biofuels can be improved using strategies such as protein engineering and in silico approaches [99]. In another study, Meliawati et al. [100] investigated isobutanol production in Paenibacillus polymyxa using CRISPR-Cas9-based genome editing, resulting in successful isobutanol production under microaerobic conditions. Furthermore, metabolic pathway engineering has been applied to optimize lipid production in microalgae for biodiesel production [101].

6.4 Process optimization

Optimizing biorefinery processes involves adjusting various parameters such as temperature, pH, and nutrient concentrations [102], as well as integrating different unit operations, including fermentation, separation, and purification [28, 31]. The biotechnological intervention relies on computational models and simulation software to design and optimize processes [103] and monitor and control the production process in real time using sensors and automation systems [104]. Studies have shown that optimizing feed rates in fed-batch fermentations can lead to significant improvements in yields. Real-time monitoring and control using sensors and automation systems allow for precise management of conditions such as dissolved oxygen levels and nutrient availability [105, 106]. Studies have demonstrated the potential of Lactiplantibacillus casei E1 as a biocatalyst in bioethanol production, using cane molasses as substrate. The bacterium was fermented anaerobically at 37 °C for 36 h in molasses with a controlled pH of 6.0, resulting in an ethanol yield of 13.77 g/L and a carbohydrate utilization rate of 78.60% [107]. Controlled environmental factors, including the optimal pH level, allowed the strain to rapidly ferment sugars such as glucose and fructose into ethanol. Additionally, the use of artificial intelligence algorithms such as active learning, semi-supervised learning, and metalearning can optimize microalgae cultivation, system design, and supply chain management [108].

7 Machine learning and life cycle assessment for microalgae cultivation and harvesting

Machine learning and life cycle assessment (LCA) play crucial roles in optimizing biofuel production and minimizing environmental impacts across various types of biofuels, such as those derived from corn, sugarcane, cellulosic materials, and waste products. In corn ethanol production, LCA evaluates greenhouse gas emissions, energy balance, and water usage, revealing a significant reduction in emissions, approximately 40–50% compared to gasoline [109]. The life cycle assessment study in South-Central Brazil evaluated different scenarios for expanding ethanol production, including increasing sugarcane cultivation area, increasing yields, and adopting precision agriculture (PA) technologies such as fertilizer management and systematization. The study found that without yield gains, 4.5 million acres of expanded sugarcane cultivation would be needed. Increasing the average yield from 76.2 to 122.4 Mg ha− 1 could reduce production costs by 26% and greenhouse gas emissions by 14% [110]. In another study, the LCA study evaluated the environmental performance of the ethanol produced from cassava pulp and its use as a transport fuel [111]. The study indicated that the most favorable scenario is an ethanol factory that substitutes biogas for fuel oil to produce steam and allocates cassava pulp based on its economic value. The use of ethanol-based fuel in vehicles demonstrated a lower impact of climate change compared to gasoline, with reductions in greenhouse gas emissions of 6%, 10% and 48% for mixtures of 10%, 20% and 85% ethanol with gasoline, respectively. The reduction in fossil depletion was also significant at 14%, 19%, and 59% for the same mixtures. The lower blends of ethanol and gasoline showed slightly different impacts in terms of terrestrial acidification (TA), human toxicity (HT), and photochemical oxidation formation (POF) compared to gasoline. However, higher blends of ethanol led to increased negative impacts in freshwater eutrophication, TA, HT, and POF [111].

In waste-to-biofuel processes, LCA assesses the conversion of municipal solid waste or agricultural residues into biofuels, reducing waste and emissions while producing valuable biofuels. These processes can achieve greenhouse gas reductions of up to 80% compared to conventional fossil fuels [112, 113]. In another study, Moradiya, Marathe [114] conducted a LCA to evaluate the cultivation and harvesting processes of marine microalgae in the Indian context. The findings revealed that microalgae-based technology could mitigate approximately 1.28 kg CO2 eq./kg of algae produced. Among the various environmental impacts assessed, marine aquatic ecotoxicity potential (MAETP) was identified as the most significant, with a value of 612 kg 1,4-dichlorobenzene (DCB) eq./kg of algae. The study highlighted that the source of electricity played a significant role in contributing to MAETP. Furthermore, the results indicated that higher productivity and lower feed concentration correlated with greater mitigation of CO2.

Machine learning (ML) can improve feedstock production efficiency by analyzing data on soil health, weather patterns, and nutrient levels, contributing to yield increases of up to 10–20% [115]. ML is also gaining popularity in bioenergy and biorefinary for its ability to optimize processes. del Rio‐Chanona et al. [116] developed a deep learning model based on a convolutional neural network (CNN) that optimized a photobioreactor and microalgal production, significantly reducing time compared to traditional simulation calculations. Mujtaba et al. [117] combined an extreme learning machine (ELM) and a cuckoo search algorithm to predict optimal biodiesel yield, achieving an error margin of less than 0.26% between predicted and experimental values. In microbial metabolic production processes, ML focuses on maximizing the yield of desired products. ML models can guide different production scales, from gene-annotated strain planning to modify metabolic pathways to optimizing fermentation parameters for improved metabolite production [115, 118]. Furthermore, the ML and decision tree models successfully identified specific combinations of microalgae cultivation parameters that led to high biomass production, efficient nitrogen removal, and effective phosphorus removal for each microalgae class [119]. These advances offer exciting opportunities to advance microalgae-based technologies and drive the transition towards a more environmentally conscious and sustainable future.

8 Challenges in biofuel generation

8.1 Feedstock availability and cost

The availability and cost of feedstock pose significant challenges in biofuel generation, affecting the stability and sustainability of production chains [120, 121].. The availability of feedstock can be influenced by geographic location, seasonal changes, and competing uses such as food production, leading to fluctuations in the supply of crops, forest residues, and waste materials. Corn supply for ethanol production in the United States has been reported to fluctuate with weather patterns and demand for corn as a food source [122]. Seasonal variability in crop yields can disrupt consistent feedstock supply, making it difficult to scale up biofuel production to meet rising demand. Feedstock costs can also vary significantly due to market conditions and competition from other industries. Corn prices can vary widely from around $3.50 to $5.30 per bushel, affecting the profitability of corn ethanol production [123]. Additionally, transporting feedstocks can be expensive, especially for bulky materials like straw or wood chips that require long-distance hauling. According to the report, biofuels are likely to account for 27% of the world’s liquid transportation fuel supply by 2050 [124].

8.2 Impact on land use and food security

The impact of biofuel generation on land use and food security presents significant challenges that can undermine the environmental and social benefits of biofuels. Biofuel production often requires large areas of land, which can compete with food production for the same resources such as land, water, and nutrients [14, 125]. This competition can contribute to deforestation and soil degradation, particularly when natural habitats are cleared to make way for biofuel crops. Lima et al. [126] reported that the the expansion of sugarcane fields for ethanol production in Brazil has been linked to deforestation in the Amazon rainforest and Cerrado region, leading to a significant loss of biodiversity and carbon storage. This change in land use not only impacts local ecosystems but also displaces indigenous and local farming communities. Furthermore, the diversion of crops such as corn or soybeans from food to fuel production can lead to increased food prices and reduced availability, exacerbating food insecurity in some regions. During the 2007–2008 global food crisis, increased demand for biofuel crops contributed to increased food prices, affecting millions of people worldwide [127].

8.3 Energy and greenhouse balance

The balance of energy and greenhouse gas (GHG) from biofuels is a complex and critical aspect of evaluating their overall environmental impact. The entire production chain, from feedstock cultivation to biofuel processing, transportation and distribution, can affect net energy return and carbon emissions associated with biofuels [128].

A study comparing bioethanol production from corn in the US and sugarcane in Brazil found notable differences in their environmental impacts. US corn bioethanol has a smaller water footprint, requiring 541 L of water per liter of bioethanol, compared to Brazilian sugarcane bioethanol, which requires 1115 L of water per liter of bioethanol. However, Brazilian sugarcane bioethanol boasts a superior energy balance of 17.7 MJ/L of bioethanol and a smaller carbon footprint of 38.5 g CO2e/MJ, whereas US corn bioethanol has an energy balance of 11.2 MJ/L and a carbon footprint of 44.9 g CO2e/MJ. These regional differences highlight the need to consider local water resources, net energy production, and mitigation of climate change mitigation in biofuel production [129]. In another study in the Tokachi region of Hokkaido, northern Japan, the energy balance of a crop rotation of winter wheat, sugar beet, adzuki beans, and potatoes was assessed. Tractor operations, transportation, and grain drying consumed 6.09 and 11.50 GJ/ha/year in fossil fuels for adzuki beans and winter wheat, respectively. Energy use from materials such as chemical fertilizers ranged from 11.01 to 24.38 GJ GJ/ha/year. Energy output/input ratios varied between crops: 6.72 for winter wheat, 10.50 for sugar beet, 2.03 for adzuki bean, and 6.70 for potato [130]. The study reported that sugar beet had the highest energy efficiency and net energy gain, but bioethanol production from sugar beet could face lower energy output/input ratios due to high transformation energy requirements. Advanced biofuels derived from waste feedstocks, algae, or lignocellulosic materials can demonstrate more favorable energy balances and lower GHG emissions due to the utilization of non-food sources and innovative, energy-efficient processing methods [131, 132]. These biofuels often have higher energy returns on investment and smaller carbon footprints, as they utilize waste products or non-edible parts of plants.

Although biofuels have the potential to reduce fossil fuel consumption and reduce greenhouse gas emissions, their production can have unintended consequences that undermine these benefits. A major challenge is the indirect change in land use (ILUC) associated with the expansion of biofuels, which can lead to the conversion of natural habitats into agricultural land for the production of biofuel feedstock production [133]. This conversion can result in increased carbon emissions, loss of biodiversity, and disruption of ecosystems. Another challenge lies in the energy inputs required for biofuel production, including cultivation, harvesting, processing, and transportation. The energy-intensive nature of these stages, especially when coupled with the use of chemical fertilizers and pesticides, can offset the energy gains from biofuels. Studies have reported that certain crops such as corn, wheat, sugarcane, and sugar beet may have a higher energy balance, but their production processes often involve significant energy expenditures [134]. Furthermore, the use of fertilizers and pesticides in the cultivation of biofuel feedstock can lead to environmental degradation such as water pollution, soil degradation, and increased sediment loads [135]. These impacts not only affect local ecosystems, but also contribute to a higher carbon footprint.

8.4 Technical challenges

The generation of biofuels presents various technical challenges that can affect efficiency and cost-effectiveness. One major challenge is the variability of feedstocks, such as corn, sugarcane, or cellulosic materials, each of which has different chemical compositions and moisture levels, affecting the consistency of production processes [8, 136]. Lignocellulosic feedstocks, such as agricultural residues, require complex pretreatment processes such as steam explosion or acid hydrolysis to break down structural components before fermentation can occur [137]. Optimizing enzymes for specific feedstocks is another technical hurdle, as it requires advanced protein engineering techniques to enhance catalytic activity and specificity [138]. Furthermore, fermentation parameters such as pH, temperature, moisture content, aeration, etc. The levels of biofuels must be maintained at an optimal level to produce high yields while maintaining the viability of the microbial strains. Scaling up production from laboratory to industrial scales introduces additional challenges, such as maintaining efficient heat and mass transfer in larger equipment [139].

8.5 Policy and market conditions

The policy and market conditions present significant challenges to the generation of biofuels, which impact both production and distribution. Biofuel generation is influenced by various policy and market factors, such as subsidies, taxes, trade restrictions and consumer demand [140, 141]. Previous studies have indicated that a sudden reduction in ethanol tax credits in the US in 2012 led to uncertainty in the corn ethanol market [142]. In another study, researchers have raised concerns about the global impact of US biofuel production on land use, suggesting that US biofuel policies may drive land use changes in countries such as Malaysia and Indonesia [143]. These policies have been associated with claims of deforestation in Malaysia and Indonesia, although the US does not use palm oil for biodiesel production and imports only a small portion of the global supply (around 2.2% in 2017) for food uses [144, 145]. Sajid in 2020 [146] revealed that the COVID-19 pandemic significantly impacted the biomass supply chain of a US biofuel company, with an 85.01% chance of collecting low quality biomass during the pandemic. This risk decreased to 54.23% with the development of vaccines and partial reopenings of businesses. Low quality biomass increased the preprocessing cost of biomass feedstock by 84.60% during the pandemic. Furthermore, fuel prices fell to 89% of their regular levels due to lockdowns and decreased demand for fossil fuels [146]. Market conditions such as fluctuating oil prices also influence consumer demand for biofuels [147]. When oil prices are low, biofuels may struggle to compete economically with conventional fossil fuels, reducing their market share. Storage and transportation pose additional challenges, as biofuels such as ethanol are more susceptible to contamination and water absorption, which can lead to quality degradation [148]. Therefore, consistent policy support and clear market signals are essential to foster a stable and sustainable biofuel industry.

9 Navigating the ethical, social and economic implications of biofuel generation and consumption

Biofuel production and consumption have significant ethical, social, and economic implications that must be carefully considered. Although biofuels offer many potential benefits, such as reducing carbon emissions and promoting energy security, there are concerns about their impact on food security, land use, and social equity.

9.1 Ethical implications

The production of biofuels raises ethical concerns related to the use of resources and the distribution of benefits and harms. For example, using land and water resources to produce biofuels can come at the expense of food production, potentially exacerbating global hunger and poverty [149]. The expansion of croplands for biofuel production has been reported to often result in deforestation and habitat destruction, threatening biodiversity, and releasing stored carbon [150]. Intensive agricultural practices can degrade soil quality and cause erosion, while the use of pesticides and fertilizers can contaminate water sources [151]. Additionally, large-scale biofuel production can also displace local communities from their land, disrupting their livelihoods and traditional practices [152].

9.2 Social implications

The social implications of the production and consumption of biofuels are also significant. Biofuels can create economic opportunities in rural areas, promoting job creation and income generation [153, 154]. However, there are concerns about the potential of biofuels to exacerbate social inequality, particularly if the benefits of biofuel generation are not equitably distributed [155]. Furthermore, the use of crops for the production of biofuels may lead to higher food prices, which can disproportionately impact vulnerable populations [156].

9.3 Economic implications

Biofuel production and consumption have significant economic implications, both positive and negative. On the positive side, biofuels can reduce dependence on foreign oil and promote the growth of domestic industries [15]. Furthermore, corn bioethanol can contribute positively to food security by producing byproducts such as corn distiller oil and distillers grains [157]. Corn distillers oil is a food-grade oil that can be used in food manufacturing, while distillers grains are a high-protein animal feed, which can support the livestock industry. These by-products create a more efficient use of resources by allowing the production of both fuel and food-related products from the same raw materials. This integrated approach to biofuel production supports the agricultural sector and can improve overall food security. Biofuels can also generate revenue for farmers and rural communities, supporting local economies [153]. However, there are also concerns about the economic viability of biofuels, particularly in the face of fluctuating oil prices and uncertain government policies [140]. Moreover, there is a risk that biofuels could lead to the displacement of other important industries, such as food production.

10 Opportunities associated with the development and commercialization of biofuels

The development and commercialization of biofuels offer significant opportunities for economic, social, and environmental advancement (Fig. 5). One of the most compelling benefits of biofuels is their potential to reduce carbon emissions and mitigate the effects of climate change. The use of biofuels instead of traditional fossil fuels can significantly reduce greenhouse gas emissions, which is essential for achieving global climate goals [18, 93]. Furthermore, the production of biofuels can increase energy security by reducing dependence on foreign oil and diversifying our energy sources. Hoang et al. [158] emphasize the potential of rice bran oil-based biodiesel as a renewable alternative to petrodiesel. The study suggests that a blend of 20% rice bran oil biodiesel and 80% petrodiesel offers the best techno-economic composition for existing diesel engines, striking a balance between environmental benefits and cost-effectiveness. In another study, Hoang [159] describes the catalytic production process of 2-methylfuran from biomass, specifically through furfural, highlighting its viability as a green solution. Although 2-methylfuran exhibits properties similar to those of fossil fuels and can be derived from renewable biomass sources, further research is needed to explore aspects such as engine durability, material compatibility, and tribology behaviors. These investigations will be crucial in determining the long-term viability of 2-methylfuran and its practical implementation as a biofuel.

In addition to these environmental and energy security benefits, the development of biofuels also presents economic opportunities. The production of biofuels can create new revenue streams for local farmers and businesses, particularly in rural areas where agricultural feedstocks can be grown [160]. This can help revitalize rural economies and create new jobs [161, 162]. Furthermore, the development of biofuels requires innovation in biotechnology, agronomy, and engineering [163], leading to technological advancements that can be applied in other industries [8]. This can drive further economic growth and job creation, particularly in high-tech sectors. Countries like India and Nigeria are experiencing overproduction of sugarcane, which can disrupt market balance and reduce the profitability of farmers. In response, governments in these regions are encouraging farmers to shift to bioethanol production as a way to utilize excess sugarcane [164, 165]. This transition not only helps stabilize the sugar market but also supports the production of renewable fuels, aligning with global efforts to reduce dependence on fossil fuels and promote sustainable energy sources.

Finally, the development of biofuels can also promote international cooperation and partnerships, leading to increased opportunities for trade and investment opportunities between countries [166]. Biofuels are a global commodity and their production can help create new markets for agricultural products and foster international collaboration on sustainable development goals. By capitalizing on these opportunities, it is possible to accelerate the transition to a more sustainable and low-carbon economy [154] while also creating new economic and social opportunities for people around the world.

11 Conclusions

Integrating biotechnology into biofuel production offers substantial potential to achieve sustainable and equitable energy solutions. The use of techniques such as enzymatic catalysis, fermentation, and innovative algae-based systems presents tangible pathways to biofuel production with benefits such as sustainability, increased yields, and versatile applications. Biotechnology also extends beyond refining processes, involving the orchestration of biorefineries by designing innovative microbial strains, specialized enzymes, and optimized metabolic pathways. This synthesis improves yields and streamlines costs, significantly contributing to the overall economic feasibility of biofuel production. Additionally, the integration of machine learning into biofuel production processes holds promise for enhancing efficiency, predicting optimal conditions, and optimizing resource utilization. Despite these advances, a comprehensive evaluation of the ethical, social, and economic dimensions related to biofuel production remains crucial. Collaborative participation among diverse stakeholders is pivotal in directing biofuel production toward harmonious integration within broader renewable energy frameworks. By carefully addressing these complex issues and continually improving biotechnology-based solutions, it is possible to create a future centered on sustainable energy practices that exceed conventional limitations.

Data availability

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

References

Hoang AT, Goldfarb JL, Foley AM, Lichtfouse E, Kumar M, Xiao L, et al. Production of biochar from crop residues and its application for anaerobic digestion. Bioresour Technol. 2022;363:127970.

Jeyakumar N, Hoang AT, Nižetić S, Balasubramanian D, Kamaraj S, Pandian PL, et al. Experimental investigation on simultaneous production of bioethanol and biodiesel from macro-algae. Fuel. 2022;329:125362.

Chai WS, Bao Y, Jin P, Tang G, Zhou L. A review on ammonia, ammonia-hydrogen and ammonia-methane fuels. Renew Sustain Energy Rev. 2021;147:111254.

Mahapatra S, Kumar D, Singh B, Sachan PK. Biofuels and their sources of production: a review on cleaner sustainable alternative against conventional fuel, in the framework of the food and energy nexus. Energy Nexus. 2021;4:100036.

Jeswani HK, Chilvers A, Azapagic A. Environmental sustainability of biofuels: a review. Proc R Soc A. 2020;476(2243):20200351.

Mathiesen BV, Lund H, Connolly D, Wenzel H, Østergaard PA, Möller B, et al. Smart energy systems for coherent 100% renewable energy and transport solutions. Appl Energy. 2015;145:139–54.

Singh P, Fnu K, Encarnação T. Genetic modification: a gateway to stimulate the industrial production of biofuels. In: Encarnação T, Pais AC, editors. Marine organisms: a solution to environmental pollution?: uses in bioremediation and in biorefinery. Berlin: Springer; 2023. p. 237–60.

Yaashikaa P, Devi MK, Kumar PS. Algal biofuels: technological perspective on cultivation, fuel extraction and engineering genetic pathway for enhancing productivity. Fuel. 2022;320:123814.

Nisar A, Khan S, Hameed M, Nisar A, Ahmad H, Mehmood SA. Bio-conversion of CO2 into biofuels and other value-added chemicals via metabolic engineering. Microbiol Res. 2021;251:126813.

Sandhya D, Jogam P, Narnoliya LK, Srivastava A, Jadaun JS. Sustainable production of biofuels through synthetic biology approach. In: Kuila A, Mukhopadhyay M, editors. Biorefinery production technologies for chemicals and energy. Hoboken: Wiley; 2020. p. 289–312.

Punia H, Tokas J, Malik A, Kumar N. Enzymes as nanoadditives: a promising alternative for biofuel production. In: Kumar RP, Bharathiraja B, editors. Nanomaterials. Amsterdam: Elsevier; 2021. p. 631–62.

Minteer SD, Liaw BY, Cooney MJ. Enzyme-based biofuel cells. Curr Opin Biotechnol. 2007;18(3):228–34.

Mihajlovski K, Buntić A, Milić M, Rajilić-Stojanović M, Dimitrijević-Branković S. From agricultural waste to biofuel: enzymatic potential of a bacterial isolate Streptomyces fulvissimus CKS7 for bioethanol production. Waste Biomass Valor. 2021;12:165–74.

Nayab R, Imran M, Ramzan M, Tariq M, Taj MB, Akhtar MN, et al. Sustainable biodiesel production via catalytic and non-catalytic transesterification of feedstock materials—a review. Fuel. 2022;328:125254.

Ullah K, Ahmad M, Sharma VK, Lu P, Harvey A, Zafar M, et al. Assessing the potential of algal biomass opportunities for bioenergy industry: a review. Fuel. 2015;143:414–23.

Khan MI, Shin JH, Kim JD. The promising future of microalgae: current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb Cell Fact. 2018;17(1):1–21.

Sudhakar M, Merlyn R, Arunkumar K, Perumal K. Characterization, pretreatment and saccharification of spent seaweed biomass for bioethanol production using baker’s yeast. Biomass Bioenerg. 2016;90:148–54.

Deora PS, Verma Y, Muhal RA, Goswami C, Singh T. Biofuels: an alternative to conventional fuel and energy source. Mater Today Proc. 2022;48:1178–84.

Paul PEV, Sangeetha V, Deepika RG. Emerging trends in the industrial production of chemical products by microorganisms. In: Buddolla V, editor. Recent developments in applied microbiology and biochemistry. Amsterdam: Elsevier; 2019. p. 107–25.

Balan V. Current challenges in commercially producing biofuels from lignocellulosic biomass. Int Sch Res Notices. 2014;2014: 463074.

Holland R, Eigenbrod F, Muggeridge A, Brown G, Clarke D, Taylor G. A synthesis of the ecosystem services impact of second generation bioenergy crop production. Renew Sustain Energy Rev. 2015;46:30–40.

Veza I, Hoang AT, Abbas MM, Tamaldin N, Idris M, Djamari DW, et al. Microalgae and macroalgae for third-generation bioethanol production. In: Soccol CR, Amarante Guimarães Pereira G, Dussap CG, de Souza Vandenberghe LP, editors., et al., Liquid biofuels: bioethanol. Berlin: Springer; 2022. p. 301–31.

Abdullah B, Muhammad SAFS, Shokravi Z, Ismail S, Kassim KA, Mahmood AN, et al. Fourth generation biofuel: a review on risks and mitigation strategies. Renew Sustain Energy Rev. 2019;107:37–50.

Bhowmik D, Chetri S, Enerijiofi KE, Naha A, Kanungo TD, Shah MP, et al. Multitudinous approaches, challenges and opportunities of bioelectrochemical systems in conversion of waste to energy from wastewater treatment plants. Clean Circ Bioecon. 2023;4:100040.

Naha A, Antony S, Nath S, Sharma D, Mishra A, Biju DT, et al. A hypothetical model of multi-layered cost-effective wastewater treatment plant integrating microbial fuel cell and nanofiltration technology: a comprehensive review on wastewater treatment and sustainable remediation. Environ Pollut. 2023;323:121274.

Ummalyma SB, Bhaskar T. Recent advances in the role of biocatalyst in biofuel cells and its application: an overview. Biotechnol Genet Eng Rev. 2023. https://doi.org/10.1080/02648725.2023.2197715.

Kumar B, Verma P. Application of hydrolytic enzymes in biorefinery and its future prospects. In: Srivastava N, Srivastava M, Mishra PK, Gupta VK, editors. Microbial strategies for techno-economic biofuel production. Berlin: Springer; 2020. p. 59–83.

Asunis F, De Gioannis G, Isipato M, Muntoni A, Polettini A, Pomi R, et al. Control of fermentation duration and pH to orient biochemicals and biofuels production from cheese whey. Biores Technol. 2019;289:121722.

Baicha Z, Salar-García M, Ortiz-Martínez V, Hernández-Fernández F, De los Ríos A, Labjar N, et al. A critical review on microalgae as an alternative source for bioenergy production: a promising low cost substrate for microbial fuel cells. Fuel Process Technol. 2016;154:104–16.

De Paula RG, Antoniêto ACC, Ribeiro LFC, Srivastava N, O’Donovan A, Mishra P, et al. Engineered microbial host selection for value-added bioproducts from lignocellulose. Biotechnol Adv. 2019;37(6):107347.

Liu C, Luo G, Wang W, He Y, Zhang R, Liu G. The effects of pH and temperature on the acetate production and microbial community compositions by syngas fermentation. Fuel. 2018;224:537–44.

Rastogi M, Shrivastava S. Recent advances in second generation bioethanol production: an insight to pretreatment, saccharification and fermentation processes. Renew Sustain Energy Rev. 2017;80:330–40.

Ranganathan A, Smith OP, Youssef NH, Struchtemeyer CG, Atiyeh HK, Elshahed MS. Utilizing anaerobic fungi for two-stage sugar extraction and biofuel production from lignocellulosic biomass. Front Microbiol. 2017;8:635.

Huang K, Won W, Barnett KJ, Brentzel ZJ, Alonso DM, Huber GW, et al. Improving economics of lignocellulosic biofuels: an integrated strategy for coproducing 1, 5-pentanediol and ethanol. Appl Energy. 2018;213:585–94.

Kostas ET, White DA, Du C, Cook DJ. Selection of yeast strains for bioethanol production from UK seaweeds. J Appl Phycol. 2016;28:1427–41.

Fujii Y, Kigoshi S, Iwatani H, Aoyama M. Selectivity and characteristics of direct contact membrane distillation type experiment. I. Permeability and selectivity through dried hydrophobic fine porous membranes. J Membr Sci. 1992;72(1):53–72.

Loulergue P, Balannec B, Fouchard-Le Graët L, Cabrol A, Sayed W, Djelal H, et al. Air-gap membrane distillation for the separation of bioethanol from algal-based fermentation broth. Sep Purif Technol. 2019;213:255–63.

Izquierdo-Gil MA, Jonsson G. Factors affecting flux and ethanol separation performance in vacuum membrane distillation (VMD). J Membr Sci. 2003;214(1):113–30.

Shirazi MMA, Kargari A, Tabatabaei M. Sweeping gas membrane distillation (SGMD) as an alternative for integration of bioethanol processing: study on a commercial membrane and operating parameters. Chem Eng Commun. 2015;202(4):457–66.

Qian Y, Zhu L, Wang Y, Lu X. Recent progress in the development of biofuel 2, 5-dimethylfuran. Renew Sustain Energy Rev. 2015;41:633–46.

Fioroni GM, Rahimi MJ, Westbrook CK, Wagnon SW, Pitz WJ, Kim S, et al. Chemical kinetic basis of synergistic blending for research octane number. Fuel. 2022;307:121865.

Imtenan S, Masjuki H, Varman M, Kalam M, Arbab M, Sajjad H, et al. Impact of oxygenated additives to palm and jatropha biodiesel blends in the context of performance and emissions characteristics of a light-duty diesel engine. Energy Convers Manag. 2014;83:149–58.

Govindaraju R, Chen S-S, Wang L-P, Chang H-M, Pasawan M. Significance of membrane applications for high-quality biodiesel and byproduct (glycerol) in biofuel industries. Curr Pollut Rep. 2021;7:128–45.

Sun L, Jin YS. Xylose assimilation for the efficient production of biofuels and chemicals by engineered Saccharomyces cerevisiae. Biotechnol J. 2021;16(4):2000142.

Xia J, Yang Y, Liu C-G, Yang S, Bai F-W. Engineering Zymomonas mobilis for robust cellulosic ethanol production. Trends Biotechnol. 2019;37(9):960–72.

Raganati F, Olivieri G, Götz P, Marzocchella A, Salatino P. Butanol production from hexoses and pentoses by fermentation of Clostridium acetobutylicum. Anaerobe. 2015;34:146–55.

Maiti S, Sarma SJ, Brar SK, Le Bihan Y, Drogui P, Buelna G, et al. Agro-industrial wastes as feedstock for sustainable bio-production of butanol by Clostridium beijerinckii. Food Bioprod Process. 2016;98:217–26.

Humphreys JR, Hebdon SD, Rohrer H, Magnusson L, Urban C, Chen Y-P, et al. Establishing Butyribacterium methylotrophicum as a platform organism for the production of biocommodities from liquid C1 metabolites. Appl Environ Microbiol. 2022;88(6):e02393-e2421.

Surendra K, Takara D, Hashimoto AG, Khanal SK. Biogas as a sustainable energy source for developing countries: opportunities and challenges. Renew Sustain Energy Rev. 2014;31:846–59.

Bernat K, Zielińska M, Cydzik-Kwiatkowska A, Wojnowska-Baryła I. Biogas production from different size fractions separated from solid waste and the accompanying changes in the community structure of methanogenic Archaea. Biochem Eng J. 2015;100:30–40.

Kampmann K, Ratering S, Kramer I, Schmidt M, Zerr W, Schnell S. Unexpected stability of Bacteroidetes and Firmicutes communities in laboratory biogas reactors fed with different defined substrates. Appl Environ Microbiol. 2012;78(7):2106–19.

Kuan I-C, Kao W-C, Chen C-L, Yu C-Y. Microbial biodiesel production by direct transesterification of Rhodotorula glutinis biomass. Energies. 2018;11(5):1036.

Martani F, Maestroni L, Torchio M, Ami D, Natalello A, Lotti M, et al. Conversion of sugar beet residues into lipids by Lipomyces starkeyi for biodiesel production. Microb Cell Fact. 2020;19(1):1–13.

Xia A, Cheng J, Murphy JD. Innovation in biological production and upgrading of methane and hydrogen for use as gaseous transport biofuel. Biotechnol Adv. 2016;34(5):451–72.

Nazem-Bokaee H, Gopalakrishnan S, Ferry JG, Wood TK, Maranas CD. Assessing methanotrophy and carbon fixation for biofuel production by Methanosarcina acetivorans. Microb Cell Fact. 2016;15:1–13.

Mauerhofer L-M, Reischl B, Schmider T, Schupp B, Nagy K, Pappenreiter P, et al. Physiology and methane productivity of Methanobacterium thermaggregans. Appl Microbiol Biotechnol. 2018;102:7643–56.

El Maghraby DM, Fakhry EM. Lipid content and fatty acid composition of Mediterranean macro-algae as dynamic factors for biodiesel production. Oceanologia. 2015;57(1):86–92.

Sathya AB, Thirunavukkarasu A, Nithya R, Nandan A, Sakthishobana K, Kola AK, et al. Microalgal biofuel production: potential challenges and prospective research. Fuel. 2023;332:126199.

Mota GF, de Sousa IG, de Oliveira ALB, Cavalcante ALG, da Silva MK, Cavalcante FTT, et al. Biodiesel production from microalgae using lipase-based catalysts: current challenges and prospects. Algal Res. 2022;62:102616.

Chaudhary L, Pradhan P, Soni N, Singh P, Tiwari A. Algae as a feedstock for bioethanol production: new entrance in biofuel world. Int J Chem Technol Res. 2014;6:1381–9.

Onumaegbu C, Mooney J, Alaswad A, Olabi A. Pre-treatment methods for production of biofuel from microalgae biomass. Renew Sustain Energy Rev. 2018;93:16–26.

Abomohra AE-F, Eladel H, El-Esawi M, Wang S, Wang Q, He Z, et al. Effect of lipid-free microalgal biomass and waste glycerol on growth and lipid production of Scenedesmus obliquus: innovative waste recycling for extraordinary lipid production. Bioresour Technol. 2018;249:992–9.

Ghasemi Y, Rasoul-Amini S, Naseri A, Montazeri-Najafabady N, Mobasher M, Dabbagh F. Microalgae biofuel potentials. Appl Biochem Microbiol. 2012;48:126–44.

Park J-Y, Park MS, Lee Y-C, Yang J-W. Advances in direct transesterification of algal oils from wet biomass. Biores Technol. 2015;184:267–75.

Li X, Xu H, Wu Q. Large-scale biodiesel production from microalga Chlorella protothecoides through heterotrophic cultivation in bioreactors. Biotechnol Bioeng. 2007;98(4):764–71.

Lai J-Q, Hu Z-L, Wang P-W, Yang Z. Enzymatic production of microalgal biodiesel in ionic liquid [BMIm][PF6]. Fuel. 2012;95:329–33.

Patil PD, Gude VG, Mannarswamy A, Cooke P, Munson-McGee S, Nirmalakhandan N, et al. Optimization of microwave-assisted transesterification of dry algal biomass using response surface methodology. Biores Technol. 2011;102(2):1399–405.

Sivaramakrishnan R, Incharoensakdi A. Direct transesterification of Botryococcus sp. catalysed by immobilized lipase: ultrasound treatment can reduce reaction time with high yield of methyl ester. Fuel. 2017;191:363–70.

Huang W-C, Kim J-D. Cationic surfactant-based method for simultaneous harvesting and cell disruption of a microalgal biomass. Biores Technol. 2013;149:579–81.

Dhyani V, Bhaskar T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew Energy. 2018;129:695–716.

Guran S. Sustainable waste-to-energy technologies: gasification and pyrolysis. In: Trabold TA, Babbitt CW, editors. Sustainable food waste-to-energy systems. Amsterdam: Elsevier; 2018. p. 141–58.

Escalante J, Chen W-H, Tabatabaei M, Hoang AT, Kwon EE, Lin KYA, et al. Pyrolysis of lignocellulosic, algal, plastic, and other biomass wastes for biofuel production and circular bioeconomy: a review of thermogravimetric analysis (TGA) approach. Renew Sustain Energy Rev. 2022;169:112914.

Zhang Y, Cui Y, Liu S, Fan L, Zhou N, Peng P, et al. Fast microwave-assisted pyrolysis of wastes for biofuels production—a review. Biores Technol. 2020;297:122480.

Madhu P, Neethi Manickam I, Kanagasabapathy H. Production and upgradation of cotton shell pyrolytic oil for biofuel from flash pyrolysis by fluidized bed reactor. Proc Natl Acad Sci India Sect A. 2015;85:457–62.

Lahijani P, Mohammadi M, Mohamed AR, Ismail F, Lee KT, Amini G. Upgrading biomass-derived pyrolysis bio-oil to bio-jet fuel through catalytic cracking and hydrodeoxygenation: a review of recent progress. Energy Convers Manage. 2022;268:115956.

Ni J, Qian L, Wang Y, Zhang B, Gu H, Hu Y, et al. A review on fast hydrothermal liquefaction of biomass. Fuel. 2022;327:125135.

Ağbulut Ü, Sirohi R, Lichtfouse E, Chen W-H, Len C, Show PL, et al. Microalgae bio-oil production through pyrolysis and hydrothermal liquefaction: mechanism and characteristics. Bioresour Technol. 2023;376:128860.

Gu X, Martinez-Fernandez J, Pang N, Fu X, Chen S. Recent development of hydrothermal liquefaction for algal biorefinery. Renew Sustain Energy Rev. 2020;121:109707.

Koley S, Khadase MS, Mathimani T, Raheman H, Mallick N. Catalytic and non-catalytic hydrothermal processing of Scenedesmus obliquus biomass for bio-crude production—a sustainable energy perspective. Energy Convers Manag. 2018;163:111–21.

Akaberi S, Gusbeth C, Silve A, Senthilnathan DS, Navarro-López E, Molina-Grima E, et al. Effect of pulsed electric field treatment on enzymatic hydrolysis of proteins of Scenedesmus almeriensis. Algal Res. 2019;43:101656.

Zhang C, Wang C, Cao G, Chen W-H, Ho S-H. Comparison and characterization of property variation of microalgal biomass with non-oxidative and oxidative torrefaction. Fuel. 2019;246:375–85.

Kruse A. Supercritical water gasification. Biofuels Bioprod Biorefin. 2008;2(5):415–37.

Saxena S, Saxena S. Strategies of strain improvement of industrial microbes: classical and recombinant DNA technology in improving the characteristics of industrially relevant microbes. In: Applied microbiology. 2015. p. 155–71.

Chen J, Liang J, Xu Z, Jiaqiang E. Assessment of supercritical water gasification process for combustible gas production from thermodynamic, environmental and techno-economic perspectives: a review. Energy Convers Manage. 2020;226:113497.

Amin FR, Khalid H, El-Mashad HM, Chen C, Liu G, Zhang R. Functions of bacteria and archaea participating in the bioconversion of organic waste for methane production. Sci Total Environ. 2021;763:143007.

Wang G, Li Y, Sheng L, Xing Y, Liu G, Yao G, et al. A review on facilitating bio-wastes degradation and energy recovery efficiencies in anaerobic digestion systems with biochar amendment. Biores Technol. 2020;314:123777.

Li G, Zhang J, Li H, Hu R, Yao X, Liu Y, et al. Towards high-quality biodiesel production from microalgae using original and anaerobically-digested livestock wastewater. Chemosphere. 2021;273:128578.

Montingelli M, Tedesco S, Olabi A. Biogas production from algal biomass: a review. Renew Sustain Energy Rev. 2015;43:961–72.

Arun S, Sinharoy A, Pakshirajan K, Lens PN. Algae based microbial fuel cells for wastewater treatment and recovery of value-added products. Renew Sustain Energy Rev. 2020;132:110041.

Cherubini F. The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Convers Manage. 2010;51(7):1412–21.

Sun L, Wu B, Zhang Z, Yan J, Liu P, Song C, et al. Cellulosic ethanol production by consortia of Scheffersomyces stipitis and engineered Zymomonas mobilis. Biotechnol Biofuels. 2021;14:1–13.

Tran PHN, Jung JH, Ko JK, Gong G, Um Y, Lee S-M. Co-production of ethanol and polyhydroxybutyrate from lignocellulosic biomass using an engineered Saccharomyces cerevisiae. Renew Energy. 2023;212:601–11.

Rafeeq H, Afsheen N, Rafique S, Arshad A, Intisar M, Hussain A, et al. Genetically engineered microorganisms for environmental remediation. Chemosphere. 2023;310:136751.