Abstract

Ground vibration is one of the major hazards produced by rock-blasting operation. The accurate prediction of vibration is necessary for designing controlled blasting parameters. The existing vibration predictors consider maximum explosive charge weight per delay and distance as the parameters responsible for ground vibration. These predictors are based on the assumption that the geometrical parameters of the blast will be constant for a site. However, the mining sites with bigger production targets have varying geometrical parameters to suit the excavator utility. Accordingly, the other blast design parameters will also have an impact on ground vibration intensity. A principal component analysis is a dimension reduction technique. This technique along with multivariate logarithmic regression has been used in this paper to predict the ground vibration. The technique has classified the blast design parameters into four principal components. The regression with the scores from these principal components has been carried out. The evaluation of the model performance of predictors along with the existing empirical predictors has been carried out using R2 and RMSE values. The evaluation suggests that the predictor with logarithmic regression followed by principal component analysis gives better performance with respect to the existing empirical predictors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Drilling- and blasting-based rock excavation technique is dominantly used in mining and civil construction excavations. This technique comes with many safety and environmental hazards. The major hazards due to blasting are ground vibration, flyrock, air overpressure, noise, dust, etc. The minimization of these hazards is necessary from both safety and productivity perspectives. The higher magnitude of blast-induced hazard can cause improper utilization of explosive energy. It has been reported by various researchers that the maximum utility of explosive energy for rock breakage is in the range of 20–30%. The remaining energy gets devastated in the form of different hazards [6, 8, 29, 36].

The ground vibration from blasting is a major environmental hazard, which may cause stability threats to the nearby structures and nuisance to the habitants. The intensity of ground vibration at a location is measured by peak particle velocity (PPV) and associated frequency. PPV has impacts on controllable blast design parameters and some uncontrollable parameters. The rock mass parameters, geological parameters, presence of discontinuities, etc. are considered uncontrollable parameters influencing PPV. Researchers around the globe have made attempts using different techniques to assess the impact of these controllable and uncontrollable parameters on PPV. The empirical predictor models such as USBM predictors [11], Ambraseys and Hendron [3] model, Langefors and Kihlstrom [27] model, Ghosh and Daemen [12] model, Pal Roy [35] model, etc. have been developed over the years. The empirical models determine site constants for the experimental blast faces. These site constants are specific to the site and are dependent on the vibration propagating media. Himanshu et al. [20] developed a multivariate empirical predictor for a coal mining site. The predictor consisted of other parameters such as hole diameter, number of blast holes, total explosive charge, and distance. Roy et al. [38] have investigated the impact of the total explosive charge on PPV. The scaled distance up to which there is a dependency of total explosive charge on PPV has been given in this study. Khandelwal and Singh [24] considered hole geometry including its diameter and depth along with burden, spacing, bench height, stemming length, total charge, powder factor, etc. as the parameters influencing PPV. Ainalis et al. [2] also considered free face, confinement, coupling of explosive, decking, and charge length as the parameters influencing PPV.

Various researchers have used statistical algorithms such as neural network, genetic algorithms, colony optimisation algorithm, random decision tree, particle swarm optimisation, and support vector machine for the assessment of parameters influencing PPV [1, 13, 17, 25, 31, 41, 42, 44, 46]. These statistical algorithms predict PPV on the basis of analysis of data for the trial blasts conducted at the site. The summary of statistical algorithms used for the prediction of PPV and air overpressure (AOp) is given in Table 1. Rezaeineshat et al. [37] predicted PPV using artificial neural network. The authors found that ‘maximum explosive charge weight per delay (MCPD)’ and ‘distance of the blast face from vibration monitoring point (D)’ are most influencing parameters and burden, spacing, and rock quality designation are least influencing parameter for PPV. Nguyen et al. [34] using different machine learning algorithms found that the elevation between blast site and vibration monitoring station is another important parameter influencing PPV along with charging parameters and distance. Additionally, researchers have also used the numerical simulation–based approach for prediction of PPV and damages from the blasting operation [2, 18, 19, 21, 26, 28].

Principal component analysis–based classification and logarithmic regression technique has been used in this paper for the prediction of blast-induced ground vibration. The technique consists of representing data in a lower dimensional space. The technique is useful in identifying the linked parameters. The most and least influencing parameters have also been identified using this technique. Researchers, viz., Dehgani and Ataee-Pour [10], Zhongya and Xiaoguang [45], and Shida et al. [39], have used PCA-based and other dimension reduction techniques for the prediction of blast-induced ground vibration.

1.1 Details of Study Site and Experimental Blasts

The study site was a coal mine located in the Singrauli coalfield, Madhya Pradesh, India. The mine is broadly divided into two parts: the easternmost part is known as Moher sub-basin and the western part is known as Moher main basin. The mining block during the experimental trial was situated in the Moher sub-basin which is a broad basinal structure with uneven undulations on its limbs. An overview of the working benches of the mine is shown in Fig. 1.

Experimental trials were undertaken at different working benches of the mine. The mine consists of shovel and dumper excavators. The benches of the mine have been developed considering the optimum utility of these excavators. Deeper benches of 40–55 m have been developed for the optimum utility of the dragline. Shovel benches were having a height of 20–25 m. The data were recorded for thirty-two experimental blasts. Table 2 summarises the blast design parameters used for shovel benches and dragline benches during trial blasts.

1.2 Prediction of Ground Vibration Using Empirical Models

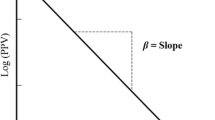

Different empirical predictors have been proposed over the years for the prediction of PPV. The most popular predictor among these is the US Bureau of Mines (USBM) predictor equation proposed by Duvall and Petkof [11]. The predictor relates PPV with square root scaled distance. Ambraseys and Hendron [3] proposed a cube root scaled distance-based predictor. Pal Roy [35] included a joint parameter as a dominant parameter along with maximum charge weight per delay (MCPD) and distance. The performance of some of the empirical model has been assessed in this study using the data collected at the experimental sites. The empirical models used for comparison are shown in Table 3.

The recorded PPV data along with blast design parameters were grouped together. The statistical analysis was carried out to compute site constants under different empirical models. The regression plots to establish the USBM predictor, Langefors and Kihlstrom predictor, and Ambraseys and Hendron predictor are shown in Fig. 2. Site constants for Ghosh and Daemen predictor have been evaluated using multivariate statistical analysis. The summary of empirical models for the study site is shown in Table 4.

1.3 Methodology for Classification of Parameters Using Principal Component Analysis.

Principle component analysis (PCA) is a dimension reduction technique. This technique is mainly used for representing data in the lower dimension space. Data in lower dimensional space reduces the complexity of the model. At first, the parameters to be classified are identified for this purpose. The data are normalised before analysis. A matrix is formed using the data set of these parameters. Suppose there are ‘m’ parameters to be classified with a total of ‘n’ data set. Then a matrix ‘A’ of n × m will be formed. In the next step, covariance matrix ‘C’ of the matrix ‘A’ is computed as – C = ATA. Here, AT represents the transpose of matrix ‘A’. Matrix ‘C’ will be the symmetric matrix of m × m. In the next step, the eigenvalues corresponding to this covariance matrix are computed using the relation shown in Eq. 1.

where ‘I’ is the identity matrix.

λ = λ1, λ2, λ3, λm.

λ1, λ2, λ3 represents Eigen values.

Eigenvectors corresponding to each eigenvalues are calculated as per Eq. 2. These eigenvectors are known as principal components (PCs). Each component is compared with the respective eigenvalues to assess the variance of data in that component. The plot of PCs with the respective eigenvalue is known as the scree plot. Variance of the principal components is evaluated as per Eq. 3. The principal component corresponding to λ1 will have the highest variance of data as compared to other PCs.

where [0] is m × 1 null matrix.

[X] is eigenvector of m × 1.

The data sets are further projected along the corresponding principal component using Eq. 4. The projected data is known as the factor score.

This technique of classification and subsequent regression has been used for the prediction of PPV in this study. The purpose of principal component analysis in the study is to classify the parameters influencing PPV in different sets. Eight input blast design parameters influencing PPV have been taken for this purpose. The parameters include hole diameter (⏀), numbers of blast holes (N), burden (B), spacing (S), column length of explosive charge (L), MCPD (Q), total explosive charge in a blasting round (Qt), and distance of blast face from vibration monitoring point (D). The methodology used in the study is shown in the flow chart in Fig. 3. Initially, the optimum number of principal components is selected based on the scree plot to accommodate the maximum information from the data set. Factor scores are extracted along the selected number of PCs. After that, the regression analysis is performed between the extracted scores and PPV. The correlation coefficient of the regression analysis is determined. The number of PCs is further increased and scores are again extracted if the correlation coefficient is less than 0.9. After achieving a correlation coefficient of more than 0.9, data are classified based on the rotated component matrix. The Kaiser-Varimax rotation is applied to the component matrix of PCs to get a rotated component matrix. The rotation uses a mathematical algorithm that is based on the principle of maximizing the sum of the squares of the loadings. The factor loadings with high and low values are maximised and those of mid-value are minimised under this rotation [43]. Finally, the most dominant parameters along each PC are classified based on the rotated component matrix. This results in the classification of parameters influencing PPV.

1.4 Classification of Data Using Principal Component Analysis and Prediction of Ground Vibration.

Initially, the exploratory analysis has been carried out to identify the parameters influencing PPV. The PCA of all the input parameters has been done along with PPV. The result shows the extraction of two PCs with a cumulative variance of more than 80%. The scree plot of PCs is shown in Fig. 4. The parameters have been plotted along the extracted components. The component plot for exploratory analysis is shown in Fig. 5. The plot shows a significant distinction between PPV and other parameters. The distinction between distance and other blast design parameters can also be seen in this plot. It can be drawn from this plot that there is an interrelationship among blast design parameters that affect the magnitude of PPV. The classification of this interdependency is necessary for the accurate prediction of PPV.

The PCA has been carried out among all the input parameters influencing PPV. The scree plot of PCA is shown in Fig. 6. It can be seen in the scree plot that the plot becomes linear after 4th component. Eigenvalue matrix of the components is shown in Table 5. The table shows that the variance of eigenvalues of 1st, 2nd, 3rd, 4th, 5th, 6th, 7th, and 8th components are 72%, 83%, 90%, 95%, 97%, 99%, 99%, and 100% respectively. The first component alone has a very high variance to represent the data. Accordingly, the score for a single PC was extracted and regression analysis was carried out. The regression shows a correlation coefficient of 0.19. So, the score was further extracted with an increasing number of PCs. The regression analysis with two and three scores has correlation coefficients of 0.319 and 0.757 respectively. Four PCs have variance of more than 95%. The scores were extracted for four PCs. The regression analysis with four extracted scores and PPV shows a correlation coefficient of 0.931. Hence, the classification of data along four PCs has been accepted.

The rotated component matrix with four PCs is shown in Table 6. The comparison of component scores of each parameter shows that PC1 contains ⏀, B, and S parameters. The parameters of PC1 can be termed geometrical parameters. PC2 contains L and Q parameters. PC3 contains N and Qt parameters. The parameters of PC2 and PC3 can be termed charging parameters. PC4 contains D as the dominant parameter. The scores along all the four PCs have been extracted. The logarithmic regression analysis has been carried out between extracted scores and PPV. The relationship between PCs and PPV has been established based on the regression output. The relationship is shown in Eq. 5.

The study of powers of PCs in this equation reveals that the dependency of PPV on PCs is in order of PC4 > PC2 > PC1 > PC3. The higher dependency of PPV on PC4 (i.e. distance) and PC2 (i.e. MCPD and column length of the explosive charge) is in the same line with the conclusions of other researchers who considered Q and D as the most dominant parameters influencing PPV. Holmberg and Persson (1978) have also considered Column length of explosive charge as a dominant factor influencing PPV. The predicted magnitude of PPV was determined using Eq. 5. The comparison between the measured and predicted values of PPV is shown in Fig. 7.

1.5 Evaluation of Models’ Performance.

The performance of empirical predictors and PPV prediction using PCs has been evaluated. The evaluation has been done by computing R2 and root mean square error (RMSE) values. The computation of RMSE has been done on the basis of the relation shown in Eq. 6

The computed values of R2 and RMSE for different predictors are shown in Table 7. The analysis of the computed values reveals that USBM and Ghosh and Daemen predictors are the best empirical predictors. The prediction comprising of regression analysis followed by PCA shows better R2 values than all the empirical predictors. RMSE value for PPV prediction using this method is also significantly low. Hence, predictions using this classification and regression technique are more accurate.

2 Conclusions

The accurate prediction of blast-induced ground vibration is the main challenge in designing controlled blasting parameters for rock excavation. The identification of the impact of different parameters on vibration intensity is also important. The regression analysis followed by principal component analysis–based data classification can be a useful tool to identify the parameters and predict PPV. This paper has used this technique for the classification of eight input parameters influencing PPV. The dimension reduction of parameters has been carried out for this purpose using PCA. The appropriate numbers of principal components have been initially selected by assessment of the variance of data in different principal components. The original data has been projected along the required number of principal components to extract the factor score. The regression analysis has been done by taking the factor scores of PCs as input and PPV as output. The regression with four PCs gives a correlation coefficient of more than 0.9. Accordingly, the data has been classified into four PCs. The comparison of component scores of each parameter shows that PC1 contains geometrical parameters such as hole diameter, burden, and spacing. PC2 contains MCPD and column length of the explosive charge. PC3 contains number of blast holes and total explosive charge in a blasting round. PC4 contains the distance of the blasting face from the monitoring point. The relationship between these PCs and PPV has been established using logarithmic regression analysis. The comparison of coefficients of PCs reveals that the dependency of PPV on PCs are in order of PC4 > PC2 > PC1 > PC3. The performance of the vibration prediction model using regression analysis followed by PCA has been compared with the existing empirical predictors. This prediction technique gives better predictions than the existing empirical predictors. Hence, the prediction technique can be used for a more accurate prediction of PPV at a rock excavation site having large variations in blast design parameters. The technique used in the paper may be applied for the prediction of ground vibration for sites similar to the study site. The technique can also be used in the future for the assessment of the impact of other input parameters such as rock mass properties and joint conditions on PPV.

References

Agrawal H, Mishra AK (2020) An innovative technique of simplified signature hole analysis for prediction of blast-induced ground vibration of multi-hole/production blast: an empirical analysis. Nat Hazards 100:111–132. https://doi.org/10.1007/s11069-019-03801-2

Ainalis D, Kaufmann O, Tshibangu JP, Verlinden O, Kouroussis G (2017) Modelling the source of blasting for the numerical simulation of blast-induced ground vibrations: a review. Rock Mech Rock Eng 50(1):171–193. https://doi.org/10.1007/s00603-016-1101-2

Ambraseys NR, Hendron AJ (1968) Dynamic behaviour of rock masses. In rock mechanics in engineering practices, Wley

Amiri M, Bakhshandeh Amnieh H, Hasanipanah M, Mohammad Khanli L (2016) A new combination of artificial neural network and K-nearest neighbors models to predict blast-induced ground vibration and air-overpressure. Eng Comp 32(4):631–644. https://doi.org/10.1007/s00366-016-0442-5

Armaghani DJ, Momeni E, Abad SVANK, Khandelwal M (2015) Feasibility of ANFIS model for prediction of ground vibrations resulting from quarry blasting. Environ Earth Sci 74(4):2845–2860. https://doi.org/10.1007/s12665-015-4305-y

Arthur CK, Temeng VA, Ziggah YY (2019) Soft computing-based technique as a predictive tool to estimate blast-induced ground vibration. J Sustain Min 18(4):287–296. https://doi.org/10.1016/j.jsm.2019.10.001

Azimi Y, Khoshrou SH, Osanloo M (2019) Prediction of blast induced ground vibration (BIGV) of quarry mining using hybrid genetic algorithm optimized artificial neural network. Meas J Int Meas Confederation 147:106874. https://doi.org/10.1016/j.measurement.2019.106874

Bakhtavar E, Abdollahisharif J, Ahmadi M (2017) Reduction of the undesirable bench-blasting consequences with emphasis on ground vibration using a developed multi-objective stochastic programming. Int J Min Reclam Environ 31(5):333–345. https://doi.org/10.1080/17480930.2016.1158964

Bayat P, Monjezi M, Rezakhah M, Armaghani DJ (2020) Artificial neural network and firefly algorithm for estimation and minimization of ground vibration induced by blasting in a mine. Nat Resour Res 29(6):4121–4132. https://doi.org/10.1007/s11053-020-09697-1

Dehgani H, Ataee-pour M (2011) Development of a model to predict peak particle velocity in a blasting operation. Int J Rock Mech Min Sci 48(1):51–58. https://doi.org/10.1016/j.ijrmms.2010.08.005

Duvall, W. I., Petkof, B. (1959). Spherical propagation of explosion generated strain pulses in rock. USBM RI 5483

Ghosh, A., Daemen, J. K. (1983). A simple new blast vibration predictor. Proc. 24th US Symp. Rock Mechanics, 151–161

Gorai AK, Himanshu VK, Santi C (2021) Development of ANN-based universal predictor for prediction of blast-induced vibration indicators and its performance comparison with existing empirical models. Min Metall Explor 38:2021–2036. https://doi.org/10.1007/s42461-021-00449-0

Hajihassani M, Jahed Armaghani D, Marto A, Tonnizam Mohamad E (2015) Vibrations au sol prédiction dans quarry dynamitage à travers un réseau neural artificiel optimisé par une concurrence impérialiste algorithme. Bull Eng Geol Env 74(3):873–886. https://doi.org/10.1007/s10064-014-0657-x

Hajihassani M, Jahed Armaghani D, Monjezi M, Mohamad ET, Marto A (2015) Blast-induced air and ground vibration prediction: a particle swarm optimization-based artificial neural network approach. Environ Earth Sci 74(4):2799–2817. https://doi.org/10.1007/s12665-015-4274-1

Harandizadeh H, Armaghani DJ (2021) Prediction of air-overpressure induced by blasting using an ANFIS-PNN model optimized by GA. Appl Soft Comp 99(xxxx), 106904 https://doi.org/10.1016/j.asoc.2020.106904

Hasanipanah M, Monjezi M, Shahnazar A, Jahed Armaghani D, Farazmand A (2015) Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 75:289–297. https://doi.org/10.1016/j.measurement.2015.07.019

Himanshu VK, Mishra AK, Vishwakarma AK, Roy MP, Singh PK (2022) Explicit dynamics based numerical simulation approach for assessment of impact of relief hole on blast induced deformation pattern in an underground face blast. Geomech Geophys Geo-Energy Geo-Res 8:19. https://doi.org/10.1007/s40948-021-00327-5

Himanshu VK, Mishra AK, Roy MP, Vishwakarma AK, Singh PK (2021) Numerical simulation based approach for assessment of blast induced deformation pattern in slot raise excavation. Int J Rock Mech Min Sci 144:104816. https://doi.org/10.1016/j.ijrmms.2021.104816

Himanshu VK, Roy MP, Mishra AK, Paswan RK, Panda D, Singh PK (2018) Multivariate statistical analysis approach for prediction of blast-induced ground vibration. Arab J Geosci 11(16):460. https://doi.org/10.1007/s12517-018-3796-8

Himanshu, V. K., Roy, M. P. (2017). Prediction of blast induced vibration using numerical simulation. Chapter in Edited book entitled Sustainable Mining Practices (ISBN10 8184876041) 219–227

Holmberg R, P. P. (1978). The Swedish approach to contour blasting. Proceedings of. 4th Annual Conference on Explosives and Blasting Research, International Society of Explosives Engineers, 113–127

Khandelwal M, Kumar DL, Yellishetty M (2011) Application of soft computing to predict blast-induced ground vibration. Eng Comput 27(2):117–125. https://doi.org/10.1007/s00366-009-0157-y

Khandelwal M, Singh TN (2009) Prediction of blast-induced ground vibration using artificial neural network. Int J Rock Mech Min Sci 46(7):1214–1222. https://doi.org/10.1016/j.ijrmms.2009.03.004

Kumar S, Choudhary BS, Mishra AK (2022) Modelling the effects of ground vibrations on the surface due to blasting in underground coal mines. Nat Hazards. https://doi.org/10.1007/s11069-021-04948-7

Kumar S, Mishra AK, Choudhary BS, Sinha RK, Deepak D, Agrawal H (2020) Prediction of ground vibration induced due to single hole blast using explicit dynamics. Min Metall Explor 37:733–741. https://doi.org/10.1007/s42461-019-00162-z

Langefors U, Kihlstrom B (1963) The modern technique of rock blasting. Wiley

Li, X., Huang, J., Luo, Y., Dong, Q., Li, Y., Wan, Y., Liu, T. (2017). Numerical simulation of blast vibration and crack forming effect of rock-anchored beam excavation in deep underground caverns. Shock and Vibration, Volume 2017, Article ID 1812080. https://doi.org/10.1155/2017/1812080.

Mohammadi Azizabadi HR, Mansouri H, Fouché O (2014) Coupling of two methods, waveform superposition and numerical, to model blast vibration effect on slope stability in jointed rock masses. Comput Geotech 61:42–49. https://doi.org/10.1016/j.compgeo.2014.04.008

Mokfi T, Shahnazar A, Bakhshayeshi I, Derakhsh AM, Tabrizi O (2018) Proposing of a new soft computing-based model to predict peak particle velocity induced by blasting. Eng Comput 34(4):881–888. https://doi.org/10.1007/s00366-018-0578-6

Monjezi M, Ahmadi M, Sheikhan M, Bahrami A, Salimi AR (2010) Predicting blast-induced ground vibration using various types of neural networks. Soil Dyn Earthq Eng 30(11):1233–1236. https://doi.org/10.1016/j.soildyn.2010.05.005

Nguyen H, Bui XN (2019) Predicting blast-induced air overpressure: a robust artificial intelligence system based on artificial neural networks and random forest. Nat Resour Res 28(3):893–907. https://doi.org/10.1007/s11053-018-9424-1

Nguyen H, Bui XN (2020) Soft computing models for predicting blast-induced air over-pressure: a novel artificial intelligence approach. Appl Soft Comput J 92:106292. https://doi.org/10.1016/j.asoc.2020.106292

Nguyen H, Drebenstedt C, Bui XN, Bui DT (2020) Prediction of blast-induced ground vibration in an open-pit mine by a novel hybrid model based on clustering and artificial neural network. Nat Resour Res 29(2):691–709. https://doi.org/10.1007/s11053-019-09470-z

Pal Roy P (1991) Vibration control in an opencast mine based on improved blast vibration predictors. Min Sci Technol 12(2):157–165. https://doi.org/10.1016/0167-9031(91)91642-U

Rajabi AM, Vafaee A (2020) Prediction of blast-induced ground vibration using empirical models and artificial neural network (Bakhtiari Dam access tunnel, as a case study). JVC/J Vib Control 26(7–8):520–531. https://doi.org/10.1177/1077546319889844

Rezaeineshat A, Monjezi M, Mehrdanesh A, Khandelwal M. (2020). Optimization of blasting design in open pit limestone mines with the aim of reducing ground vibration using robust techniques. Geomech Geophys Geo-Energy Geo-Res 6(2 https://doi.org/10.1007/s40948-020-00164-y

Roy MP, Mishra AK, Agrawal H, Singh PK (2020) Blast vibration dependence on total explosives weight in open-pit blasting. Arab J Geosci 13(13):531. https://doi.org/10.1007/s12517-020-05560-y

Shida X, Tianxiao C, Jiaqi L, Chenrui Z, Zhiyang C (2021) Blasting vibration control using an improved artificial neural network in the Ashele Copper Mine. Shock and Vibration (2021)https://doi.org/10.1155/2021/9949858

Taheri K, Hasanipanah M, Golzar SB, Majid MZA (2017) A hybrid artificial bee colony algorithm-artificial neural network for forecasting the blast-produced ground vibration. Eng Comput 33(3):689–700. https://doi.org/10.1007/s00366-016-0497-3

Tian E, Zhang J, Soltani Tehrani M, Surendar A, Ibatova AZ (2019) Development of GA-based models for simulating the ground vibration in mine blasting. Eng Comput 35(3):849–855. https://doi.org/10.1007/s00366-018-0635-1

Verma AK, Singh TN (2011) Intelligent systems for ground vibration measurement: a comparative study. Eng Comput 27(3):225–233. https://doi.org/10.1007/s00366-010-0193-7

Zeller RA (2005) Measurement Error, Issues and Solutions (K. B. T.-E. of S. M. Kempf-Leonard (ed.); pp. 665–676) Elsevier https://doi.org/10.1016/B0-12-369398-5/00109-2

Zhang X, Nguyen H, Bui X-N, Tran Q-H, Nguyen D-A, Bui DT, Moayedi H (2020) Novel soft computing model for predicting blast-induced ground vibration in open-pit mines based on particle swarm optimization and XGBoost. Nat Resour Res 29(2):711–721. https://doi.org/10.1007/s11053-019-09492-7

Zhongya Z, Xiaoguang J (2018) prediction of peak velocity of blasting vibration based on artificial neural network optimized by dimensionality reduction of FA-MIV. Math Prob Eng 2018 Article ID 8473547 12 pages 2018 https://doi.org/10.1155/2018/8473547

Zhou J, Li C, Koopialipoor M, Jahed Armaghani D, Thai Pham B (2021) Development of a new methodology for estimating the amount of PPV in surface mines based on prediction and probabilistic models (GEP-MC). Int J Min Reclam Environ 35(1):48–68. https://doi.org/10.1080/17480930.2020.1734151

Acknowledgements

The authors would like to thank the management of M/s Reliance Sasan Power Limited for necessary support during the experimental trials.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

•PCA is a useful data classification technique and can be used for ground vibration prediction.

•PCA with logarithmic regression gives a more accurate prediction than existing empirical predictors.

•The principal component comprising MCPD, distance, and column length of explosive charge has maximum influence on PPV.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Himanshu, V.K., Mishra, A.K., Vishwakarma, A.K. et al. Prediction of Blast-Induced Ground Vibration Using Principal Component Analysis–Based Classification and Logarithmic Regression Technique. Mining, Metallurgy & Exploration 39, 2065–2074 (2022). https://doi.org/10.1007/s42461-022-00659-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00659-0