Abstract

Tropical peat soils present higher ash content than those generated at temperate climate areas. Therefore, this study evaluated the characteristics of a Brazilian organic soil (OS), commercialized as peat, as well as its capacity in removing Cr(VI) from contaminated waters. The OS is composed of 35.5 wt% of organic matter and 56 wt% of inorganic fraction (ash), which is formed by minerals and phytoliths rich in silica (29.2 wt%) and alumina (23.6 wt%). The Cr(VI) removal tests were carried out in batch and column systems using OS and solutions of Cr(VI) prepared with distilled water and groundwater. Batch tests revealed that the organic substances in the OS caused the reduction of Cr(VI) to Cr(III), with an efficiency depending on solution pH. At pH 5.0 the Cr(VI) removal was 0.45 mg g−1 in 24 h; whereas at pH 2.0, this removal increased to 1.10 mg g−1. Since this redox reaction is very slow, the removal of Cr(VI) at pH 5.0 increased to around 2 mg g−1 after 5 days. The removal of Cr(VI) was more effective in the column tests than in the batch test due to the greater solid/solution ratio, and their half-lives were 4.4 and 26.2 h, respectively. Chemical analysis indicated that Cr(VI) was reduced by the humic substances of OS, followed by the precipitation and/or adsorption of Cr(III) into the organic and inorganic components, as anatase. The presence of Cr(III) increased the stability of anatase structure, avoiding its transformation into rutile, even after being heated at 800 °C/2 h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Peatland forms in terrestrial wetland ecosystems where the production of organic matter exceeds its decomposition and a net accumulation results (Page et al. 2006). According to standards of the American Society for Testing and Materials (ASTM 2014), peat contains < 25% dry weight inorganic material (ash). These inorganic components of peat include minerals from the substrate and suspended detritus or precipitated from solutions, and also elements absorbed by plants, known as phytoliths (Cameron et al. 1989).

There are many differences between temperate and tropical deposits of peat, such as structure, texture and composition, with features depending on the vegetation type, hydrology regime, bedrock composition, geomorphology etc. (Cameron et al. 1989). However, the classification used for tropical peat deposits is the same as those developed in humid temperate regions (Wüst et al. 2003).

In the tropical areas, peat soil is formed from woody plant debris under high-rainfall and high-temperature conditions, while in temperate and boreal regions, peat originates mainly from mosses and herbs (Chimner and Ewel 2005). These plants can contribute to the biogenic ash content of peat, incorporating up to 10% inorganic material as phytoliths (Wüst et al. 2003). Therefore, peat chemical composition is very complex and is commonly formed by bitumens, humic substances, carbohydrates and lignin (Brown et al. 2000).

Being a low-cost material, this organic rich material has been used in the remediation of soils and waters contaminated by heavy metals. Several studies have demonstrated the ability of peat to remove heavy metals in solution, such as Cu2+ (Gardea-Torresdey et al. 1996), Ni2+ (Janaki et al. 2015) and Pb2+ (Zehra et al. 2015). According to Crist et al. (1996) metal uptake on peat is an ion exchange process at acidic sites formed from the humification process, such as humic (HA) and fulvic acids (FA).

The effectiveness of peat organic carbon in reducing the anionic species of Cr(VI) into cation species of Cr(III) was also analyzed in various studies (Zhilin et al. 2004; Henryk et al. 2016; Priyantha et al. 2016). This redox properties are improved by the presence of FA and HA (Mak and Lo 2011).

The rate of Cr(VI) reduction by FA and HA can be affected by the presence of other redox active solutes in the system, as ferric iron (Wittbrodt and Palmer 1996). These authors verified that FA substances reduce Fe(III) in solution faster than HA and, then, Fe(II) reduces Cr(VI) relatively rapid. Thus, the presence of ferric iron (even in a small amount) increases the rate of Cr(VI) reduction.

The trivalent form of chromium is stable and, at low concentrations, is considered an essential element for human nutrition. However, any concentration of Cr(VI) is toxic and carcinogenic to humans. Furthermore, due to its anionic form—as dichromate (Cr2O72−) and chromate (Cr2O42−) for example—, Cr(VI) is poorly adsorbed by the soil components, being very mobile and therefore, an important groundwater contaminant (Sharma et al. 2012). According to USEPA (2017), the current drinking water standard for total chromium is 0.1 mg L−1 (including hexavalent chromium). Because of uncertainties in the toxicological database of chromium, the guidelines for drinking-water quality stablished by WHO (2017) states the provisional value for total chromium of 0.05 mg L−1.

Usually, the remediation of groundwater contaminated with Cr(VI) is based on ex-situ technologies, in which the groundwater is pumped and treated by chemical reactions to promote the reduction of hexavalent species to the trivalent form, followed by its precipitation using basic solutions (Mulligan et al. 2001). One option among the in-situ remediation technologies are the permeable reactive barriers (PRB), which are hollow trenches filled with a permeable reactive material, chosen according to the contaminant species (USEPA 1989).

Different PRB filler material, such as zeolites, siderite, pyrite, zero-valent iron and chitosan have been tested in the remediation of aquifers contaminated by heavy metals (Blowes et al. 1997, 2000; Thiruvenkatachari et al. 2008; Zhang et al. 2012; Zengguang et al. 2013; Wilkin et al. 2005, 2014; Liu et al. 2015). Among these materials, zero-valent iron has been revealed as a potential reducing agent of Cr(VI) when used in coarse granular form.

Studies using peat for Cr(VI) removal are scarce and most of them used peat samples originated in the boreal or humid temperate regions. Therefore, the main objective of this study was to evaluate the characteristics and the capacity of a tropical (Brazilian) peat in the removal of hexavalent chromium from the contaminated waters. This study should also subsidize the application of peat as low-cost material in PRBs used for remediation of groundwater contaminated with Cr(VI).

Materials and methods

Organic soil characterization

Samples of organic soil (OS), which is commercialized as peat to be used in the agriculture, were collected in deposits of São Luiz do Paraitinga (São Paulo state, Brazil). These samples were dried at 50 °C for 48 h and homogenized using the elongated pile method (Góes et al. 2004).

Total carbon (C), hydrogen (H), nitrogen (N) and sulfur (S) of OS was determined in CHNS 2400/Perkin Elmer equipment at Núcleo de Instrumentação para Pesquisa e Ensino of Universidade Federal de São Paulo (NIPE/UNIFESP). The OS organic matter content was calculated multiplying the carbon content (wt%) by the conversion factor of 1.724 (proposed by Kiehl 1979).

The OS inorganic content (ash) was calculated from the loss on ignition (LOI) value subtracted of 100 wt% sample. The LOI was obtained by igniting the oven-dried sample in a muffle furnace at 1050 °C for 1 h at Laboratório de Caracterização Tecnológica of Universidade de São Paulo (LCT/USP). Then, the OS ash chemical composition was analyzed by X-ray fluorescence (Axios Advanced/Panalytical) at LCT/USP.

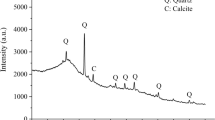

The mineralogical composition of OS was determined by X-ray diffraction (XRD) using a Bruker D8 Advance diffractometer at NIPE/UNIFESP. This analysis used CuKα radiation (40 kV, 40 mA), angular range (2θ) from 3° to 70°, with pitch 0.020° and counting time of 1.0 s/step.

The particle size distribution was determined by a low angle laser light scattering technique in aqueous dispersant in the Malven Mastersize equipment.

The cation exchange capacity (CEC) was analyzed by the method proposed by Hesse (1971). First, the sample was saturated with sodium acetate solution (1 mol L−1) at pH 7.0, and then by ammonium acetate (1 mol L−1) at pH 7.0. The concentration of sodium displaced by ammonium was then determined by the flame spectrophotometer (DM-62/Digimed).

The anion exchange capacity (AEC) analysis was based on the method of Wada and Okamura (1977). Each sample was saturated with potassium phosphate solution (1 mol L−1) at pH 7.0 and, subsequently, by ammonium chloride (1 mol L−1) at pH 7.0. The phosphate content in the solution was then determined on the HI 83215 photometer (Hanna Instruments).

The point of zero charge (PZC) was determined by the method proposed by Camargo et al. (2009) to verify the predominance of positive (pH < PZC) or negative charges (pH > PZC) in the surface of the OS, providing anion or cation adsorption, respectively (Alleoni et al. 2009). In this method 4.0 g of OS were put into 13 flasks where, in seven of them, 0–3 mL of 0.1 mol L−1 HCl was added. In the six other flasks, 0.5–3.0 mL of 0.1 mol L−1 NaOH was added. In all flasks 0.5 mL of 0.01 mol L−1 CaCl2 (background electrolyte) and distilled water were put to complete a volume of 20 mL. All the flasks were agitated on a horizontal shaker for 4 days at 25 °C. Then the final pH values were recorded. The difference between initial and final pH values (∆pH) was plotted against initial pH values and the PZC value was identified at the pH when ∆pH was zero.

The thermal behavior of the OS was analyzed by burning under controlled temperature in the equipment DTG 60H of Shimadzu at NIPE/UNIFESP. A heating rate of 10 °C s−1 and a temperature range of 25–1500 °C were used in an inert atmosphere of nitrogen.

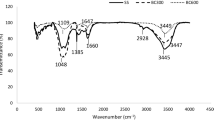

Fourier transform infrared spectroscopic analysis (FTIR) was also used to allow the identification of functional groups, such as carboxylic acids, amines, amides, hydroxyls and aliphatic and aromatic structures (Stevenson 1994). Measurements were made in the NIPE/UNIFESP on the Shimadzu spectrophotometer model IRP restige-21, using the percentage absorption mode, prepared on dry KBr pellets with a resolution of 4 cm−1, accumulation of 50 spectra (scans) and spectral range of 400–4000 cm−1.

Groundwater chemical composition

To simulate the removal in contaminated waters, groundwater was collected from a monitoring well located at the Diadema district (São Paulo state, Brazil). The values of pH, Eh and electrical conductivity (EC) were determined on site using a probe coupled to a field measurements equipment (DM-PV/Digimed and DMCM010/Digimed).

The main chemical composition of groundwater was determined by inductively coupled plasma—atomic emission spectrometry (ICP-OES) in the equipment of Spectro Arcos and ion chromatography (ICS-Dionex 90) in the NIPE/UNIFESP.

Cr(VI) removal tests

Batch tests

Stock solutions of 500 mg L−1 of Cr(VI) were prepared by dissolving K2Cr2O7 of analytical grade to deionized water (DW) and also to groundwater (GW).

All reactors were prepared in 50 mL conical flasks (falcon tubes) with 1.0 g of OS suspended in 50 mL solution. Reactors were setup with 200 mg L−1 of Cr(VI) to study the effect of contact time (1–6 days) and 50 mg L−1 to study the effect of solution pH (2.0–6.0), adjusted with 0.1 mol L−1 of HCl or NaOH, remaining in contact for 24 h. To observe the effect of Cr(VI) concentration in the adsorption capacity, tests were performed using Cr(VI) solutions ranging from 50.0 to 300 mg L−1 for 24 h.

The flasks were stirred and, after the period of each test, were centrifuged/filtered and then the filtrates were analyzed for the remaining Cr(VI) concentration with UV–Vis spectrophotometer (Genesys 20/Thermo Scientific), based on the method 7196 of USEPA (1991). All experiments were performed and replicated at room temperature (25 °C), and the average values are reported in the data analysis.

Total concentration of Cr was measured by inductively coupled plasma-atomic emission spectrometry (ICP-OES) (Spectro/Arcos). The concentrations of Cr(III) were obtained by subtracting the values of total Cr by Cr(VI). The rate of removal (Qe) of Cr(VI) (mg g−1) was determined by Eq. (1).

where, C0 (mg L−1) is the initial Cr(VI) concentration, Ce (mg L−1) is the final concentration, V (L) is the volume of the solution and m (g) is the mass of OS.

After these tests, the OS samples were analyzed by XRD to identify the formation of new mineralogical solid phases with chromium. This analysis was performed on the Bruker D8 Advance diffractometer, using CuKα radiation (40 kV, 40 mA), angular range (2θ) from 3° to 70°, with pitch 0.020° and counting time of 1.0 s/step. The functional groups responsible for ion adsorption was determined by FTIR analysis in the Shimadzu spectrophotometer model IRP restige-21, using the percentage absorption mod with a resolution of 4 cm−1, accumulation of 50 spectra (scans) and spectral range of 400–4000 cm−1.

Fixed bed column test

Column tests were performed using an acrylic pipe 4 cm ID and 15 cm long, to simulate Cr(VI) contaminated water flow through the reactive material, simulating a PRB. The column was wet-packed with 106 g of OS, with particle size between 0.4 and 1.0 mm. Before the Cr(VI) solution was injected, the column was washed with deionized water with upward flow for 24 h. Then, the Cr(VI) solution of 200 mg L−1 prepared with groundwater sample (stored in a 3 L bottle) was pumped upward at a constant flow rate of 0.666 mL min−1 using a peristaltic pump (Watson Marlow/120U) for 1800 min (30 h), until the concentration of Cr(VI) did not increase significantly (variation up to 8.17%).

To determine the Cr(VI) concentration by UV–Vis spectrophotometry (Genesys 20/Thermo Scientific), about 4 mL of solution were collected in column outlet every 40 min for 30 h (1800 min) in a Falcon tube. The pH and Eh in the column outlet were also monitored during the test, using a pHmeter (210 MPA/MS TECNOPON). After the test, the OS sample used in the column was dried, homogenized and analyzed by ICP-OES (Spectro/Arcos) to determine the total chromium fixed in OS.

The breakthrough curve obtained in the column test was simulated using the one direction flow and transport model Analytic 1 (Schwartz and Zhang 2003). The transport equation (Eq. 2) used by this model considers advection, dispersion, retardation (based on a linear sorption isotherm) and first-order decay kinetics (Genutchen and Alves 1982):

where \(U=\sqrt {v_{x}^{2}+4\lambda {D_x}}\); λ is the reaction rate constant; Dx—longitudinal dispersion coefficient, defined as αLvx + τDm (αL is dispersity, τ is the tortuosity of the medium, and Dm is the molecular diffusion coefficient for chromium, equal to 0,00001 cm2 min−1) (Genutchen and Alves 1982); and, Rf is the retardation factor.

The mass balance was obtained considering the total mass injected [Cr(total)input] was either removed by the OS [Cr(total)removed] or left the system in the column effluent [Cr(total)output] (Eq. 3). The total mass leaving the system was calculated integrating the breakthrough curve (C × t). In addition, the mass of Cr in the column effluent was considered to be as the sum of Cr(VI) + Cr(III) (Eq. 4).

Results and discussion

Characterization of OS

The OS sample has 20.6 wt% C, 2.83 wt% H, 0.39 wt% N and < 0.3 wt% S. Considering the conversion factor to organic matter (OM) equal to 1.724 (Kiehl 1979), OS has a content of 35.5 wt% OM.

The N/C ratio of OS is low (0.016) due to the loss of nitrogen of the precursor organic matter (nitrification) by the diagenetic and maturation processes (Dević 2015). From the LOI value (43.9 wt%, Table 1) the ash content of OS was determined as being 56.1 wt%, which is composed of the mineral phases and the inorganic components incorporated by plants (phytoliths). The high LOI value is due the volatilization of the organic matter and hydroxyl groups of the minerals present in OS composition.

These results differ significantly from the temperate peat samples, where the OM content is higher and the ash content lower. For example, the Romania sphagnum peat contents of total organic matter and ash are, respectively, 84–85 and 4.85% (Balan et al. 2008). The ash of the peat profiles from two heterogeneous ombrotrophic bogs in Latvia range between 0.30 and 6.10% and the C concentrations range from 40 to 55% (Klavins et al. 2013).

In tropical peatlands the accumulation rates are faster than in most temperate and boreal peatlands (Chimner and Ewel 2005). So, these deposits can be up to 20 m thick (Page et al. 2006). Therefore, as Joosten (2016) has observed to the tropical peatlands from Java (which has up to 49% ash), these characteristics may indicate that OS must have been derived from geogenous peatlands. The geogenous peatlands have limited distribution, being confined to the edges of coastal lagoons, the banks and flood zones of rivers, and the margins of upland lakes; thus, the water that fed these deposits had been in contact with the mineral bedrock and soils (Page et al. 2006).

According to US Soil Taxonomy (USDA 1999) the organic deposits with ash content > 25% are classified as clayey sapric. However Wüst et al. (2003) proposed a new classification for organic soils developed at tropical condition, where soils with 40–55% ash (LOI = 45–60%) and > 18% C are defined as peat with very high ash. Therefore, despite having 20.6% C, the OS sample must be considered as a muck, since it contains 56.0% ash (1% ash more to be considered as a peat).

The chemical analysis of the inorganic fraction of OS reveals the predominance of silica and alumina in the ash fraction composition (Table 1).

The main minerals present in OS are muscovite (KAl2(Si3Al)O10(OH,F)2), kaolinite (Al2Si2O5(OH)4), quartz (SiO2), gibbsite (AlOH3), illite ((K,H3O)(Al,Mg,Fe)2(Si,Al)4O10[(OH)2,(H2O)]), anatase (TiO2) and 2:1-clay minerals (vermiculite, montmorillonite, chloride) (Fig. 1).

The grain size of OS sample is composed of 0.25% of clay, 7.80% of silt and 91.95% of sand, thus it has a sandy texture. The PZC of OS sample (3.6) indicates that in solutions with pH > 3.6 the cationic exchange prevails. In agreement, the result of CEC analysis of OS (537.0 mmolc kg−1) was higher than AEC (73.89 mmolc kg−1), since they were conducted in solutions at pH 7.0.

The values of pHPCZ (3.7) and CEC (570.0 mmolc kg−1) of the sphagnum peat from Romania (Balan et al. 2008) are similar to those determined for the OS sample. Therefore, although the ash and OM contents of tropical and temperate peats are different, their PCZ and CEC properties are very similar.

The thermogravimetric (TG) curve of the OS (Fig. 2) indicated a total mass loss of 46.5% and corroborated with the LOI value of this sample (43.9%). By the analysis of the derivative of the thermogravimetric curve (DTG), a loss of mass (about 9.0%) occurred at temperature range of 25–200 °C, corresponding to the dehydration process. Another mass loss (about 4%) occurred from 200 to 300 °C due to the dehydroxylation (OH−) of minerals such as gibbsite and degradation of aliphatic structures of humic acids (Schnitzer 1972). In the temperature range between 350 and 600 °C, the kaolinite and organic matter decomposition caused the mass loss of 15.0%, corroborating the findings from Miyazawa et al. (2000). Finally, in the temperature range of 600–1200 °C there was a mass loss of 18.5%, attributed to the degradation of aromatic structures (Schnitzer 1972).

The differential thermal analysis (DTA) of OS revealed the main endothermic peaks at 73.8, 246.25 and 480.7 °C, which are related to the loss of water and OH−, and dehydroxylation of kaolinite and gibbsite, respectively. According to Benites et al. (2003) the decomposition of the aliphatic structures of the humic acids occurs at 250–280 °C, and of the aromatic structures at > 400 °C. The peak around 570.0 °C should be the phase transformation of anatase to rutile (Huang et al. 1997), and the peaks > 1000 °C corresponds to the transformation of metakaolinite into mullite (3Al2O3.2SiO2) (Chen and Lan 2000).

Groundwater chemical composition

The concentrations of the main ionic components of the groundwater used in this study are listed in Table 2. The pH was 5.0 and the main ions detected were Cl− and Na+. This sample was not previously contaminated with of Cr(VI) or Cr (III).

Tests of Cr(VI) removal

Batch tests

Effect of the Cr(VI) concentration in solution

The mass of Cr(VI) removed from solutions prepared with both deionized water (DW) and groundwater (GW) increased as the initial concentration was raised above 150 mg L−1 (Fig. 3). This behavior indicate that high concentrations of dichromate (Cr2O72−) in solutions with relative low pH (4.1 and 5.0 for the DW and GW, respectively) promote the organic material oxidation and consequently the reduction of Cr(VI) to Cr(III) (Eq. 5) (Machado et al. 2011). For DW, the removal rate increased when the initial concentration decreased from 100 to 50 mg L−1. This was unexpected and could be a result of higher uncertainty in Cr(VI) quantification at lower values.

The amount of Cr(VI) removed by OS in solutions prepared with DW was higher (0.5–4.7 mg g−1) than in those prepared with GW (0.4–1.7 mg g−1). The lower removal in GW could be caused by complexation of ions originally present in groundwater on the peat reaction sites, decreasing the Cr(VI) reduction efficiency (Banks et al. 2006).

The analysis of the final solutions of the tests conducted with DW with 50 and 200 mg L−1 of Cr(VI) indicated the presence of Cr(VI) (respectively, 7.3 and 34.6 mg L−1) and the absence of Cr(III). The absence of Cr(III) in solution indicates that it was adsorbed/complexed into the OS coumpounds or/and precipitated as a solid. The Cr mass removed from solution by these processes was estimated as the difference between the total Cr concentration in the initial solution and the Cr(VI) concentration at the end of the test.

To verify if Cr(III) was associated with the organic and inorganic components of the OS, the FTIR analyses were made in samples of OS in natura and that exposed to 200 mg L−1 Cr(VI) (Fig. 4). The main functional groups detected in the FTIR spectra analyses are described in Table 3.

Comparing the OS in natura with the sample mixed with 200 mg L−1 Cr(VI) in batch test, both FTIR spectra are very similar. However, the absorption peaks at 3690 and 3618 cm− 1 are more evident in the latter. These peaks are attributed to the functional groups of O–H of kaolinite and gibbsite structures (Russel 1987), and to OH of alcohols and/or phenols and/or carboxylic acids (Krumins et al. 2012) and can indicate the Cr(III) adsorption in the structures of inorganic and organic components of OS.

Upon reaction with Cr(VI), the peak at 1614 cm−1, attributed to aromatic C=C stretching, became a little more broad because the oxidation of phenolic groups could lead to the formation of quinone with C=O groups, exhibiting a strong absorption at 1614 cm−1 (Huang et al. 2012). In addition, the complexation of redox product of Cr(III) on residual carboxyl groups could shift the absorption peak of 1614 cm−1 (Haberhauer et al. 2000, Hsu et al. 2010).

Effect of contact time

The efficiency of Cr(VI) removal by the OS increased with the contact time in solutions prepared with DW and GW (Fig. 5).

As observed in the previous tests, the removal of Cr(VI) was more efficient with DW than with GW in a period of 1 day. However, for contact times greater than 1 day, the Cr(VI) removal by peat increased significantly in solutions prepared with GW. The maximum removal occurred at 5 days (2.0 mg g−1 in DW and 2.2 mg g−1 in GW), consistent with previous studies which indicated that the chemical reduction of Cr(VI) by organic substances is very slow, and, depending on pH, it can take weeks (Wittbrodt and Palmer 1996; Gu and Chen 2003).

To verify the content of chromium retained in OS, the sample taken from the batch test of 3 days was analyzed by XRF, which results indicated that 1 g of peat retained 1.4 mg of Cr. This value is close to that obtained based on the aqueous phase analysis in the batch test, where 1 g of OS removed 1.6 mg of Cr(VI). Therefore, the Cr retained by OS components must be as trivalent cation, since the pH of the solution (5.5) was above the PZC value of the OS (3.6), which favored the cation adsorption. Zhilin et al. (2004) also observed that peat humic substances were able to reduce Cr(VI) at pH 5.4, on account of the irreversible oxidation of carbohydrate units.

Effect of pH

This test was performed only with DW solutions and, as was expected, the decrease in pH increased the efficiency of Cr(VI) removal from solutions, since its redox reaction is more favorable in acidic environments (Fig. 6). Thus, it is noticed that as the pH increases, the removal efficiency decreases from 95% to almost 25%. The higher removal rate of Cr(VI) was observed in pH 2.0 solution, where 1.06 mg of Cr(VI) was removed by 1 g of OS.

Many authors also observed that the reduction of Cr(VI) occurs more efficiently in acid solutions (Sharma and Forster 1993; Gu and Chen 2003; Ulmanu et al. 2008). For example, the maximum removal rate of Cr(VI) by a horticultural peat containing 20% of ash was about 9–10 mg g−1 in solution with pH 3.5 (Ulmanu et al. 2008), while the removal rate of the sphagnum peat from Romania was 13.05 mg g−1 in pH 1.0 (Balan et al. 2012). Since both removal rates are greater than the OS from this study in acid conditions, likely the low carbon and high ash content of OS impacted the removal efficiency of Cr(VI).

When reducing agents (as organic matter) were absent in acidic solutions, the hexavalent species of Cr (HCrO4− e CrO4−2) could only be removed by adsorption (Barlett and James 1988). In this case, some minerals as gibbsite and goethite, which surface charge is dependent on the solution pH, may retain Cr(VI) (Ajouyed et al. 2010). However, since the studied sample (OS) is rich in organic matter, this reducing agent promote the reduction of Cr(VI) and the adsorption/complexation, or even the precipitation of Cr(III), depending on solution pH.

According to Olazabal et al. (1997) at pH 1.5–3.5, chromate ions affect the solubility of iron, inducing the formation of precipitates chromate/iron, as FeOHCrO4 (between pH 1.5 and 2.5), FeOHCrO4.2Fe(OH)3 (pH 2.5–3.5) and Fe(OH)3 (at pH greater than 3.5). However, XRD analyses performed in samples treated with Cr(VI) solutions with pH 2.0 and 6.0 did not indicate the presence of these phases. Since commonly these precipitates are amorphous and therefore not identifiable by XRD, these samples were heated at 800 °C for 2 h to promote the formation of any crystalline oxides associated with Cr(III), as Cr2O3 and (Cr,Fe)2O3 (Music et al. 1999).

However, the XRD patterns of OS treated with Cr(VI) solutions with pH 2.0 and 6.0 and subjected to the heating process did not indicate the presence of any crystalline phases of iron chromium oxide, probably because the precipitate phases remained amorphous. The main identified phases are anatase, muscovite, silica (β-quartz), β-tridymite and mullite (Fig. 7).

The anatase peaks are present in both samples, mainly in pH 2.0. Normally, anatase transforms into rutile at temperature range of 600–700 °C (Nolan et al. 2009). Bellifa et al. (2014) verified that the chromium incorporated in the anatase delays its transformation to the more stable phase of rutile even at 800 °C, so it is possible that the presence of Cr(III) in the anatase structure affected this transformation. The capacity of anatase in reducing or adsorbing Cr(VI) was not very known. Liu et al. (2014) showed that TiO2 has high photocatalytic activity due its excellent chemical and optical properties and can be used in form of nanotubes as adsorbents for removal of heavy metals.

Despite being submitted to high temperature (800 °C) muscovite remained in the samples, probably due to its high temperature resistance. The presence of β-tridymite indicate that the silica (in form of β-quartz) is converting into this high temperature polymorph, while mullite is the product of decomposition of kaolinite.

Fixed bed column test

The concentration of Cr(VI) in the solution collected at the end of the column remained below detection limit until approximately 400 min (~ 2 pore volumes) (Fig. 8a).

This retention was greater than observed for a medium containing siderite (FeCO3), but less than for a medium with pyrite (FeS2), Fe chips and Fe fillings (Blowes et al. 1997). However, the flow velocity (~ 430 m year−1) was at least one order of magnitude higher in our study, which can lead to lower removal due to the limited time for diffusion (Blowes et al. 1997). In the range of 400–800 min, the concentration of Cr(VI) in the treated solution reached up to 60% of the initial concentration, and approximately at 1200 min it stabilized at around 80% of the initial concentration of Cr(VI).

In the first 300 min, the Eh values decreased from 25 to − 75 mV, and then in the next hour increased to 150 mV. From that point, these values oscillated between 100 and 200 mV. The pH values, in the first 200 min, increased from 5.0 to 6.5. In the range of 200–500 min, the pH decreased to about 5.5 and after 500 min remained around 5.5. The changes observed at the initial 300 min are due to the replacement of distilled water by the Cr(VI) solution.

The breakthrough curve could be simulated relatively well using the Analytic 1 software (Fig. 8b) (Schwartz and Zhang 2003). This simulation was based on a linear adsorption model and a first-order reaction, being, therefore, a simplification of the reduction and complexation reactions between OS and Cr(VI) in solution (Palmer and Plus 1994). From the data obtained in the batch and column tests, the value of the reaction constant (λ) for Cr(VI) removal in contact with the organic soil was determined. The batch test showed a reaction constant of 0.64 day−1 and the column test a value of 3.74 day−1.

The higher value in the column test is probably due to the increased contact between the OS and the Cr(VI) solution, since the ratio solids/solution was greater in the column tests. The half-life time, corresponding to the time required to halve Cr(VI) mass in the reaction between the organic soil and the metal, was calculated for both the batch and column tests applying t1/2 = ln 2/λ. The value was almost six times higher in the batch study (26.2 h) than that of the column (4.4 h), also due to the lower proportion of contact surface per volume of solution.

Another parameter that shows the chemical interaction between organic soil and Cr(VI) in solution is the retardation factor (R), the ratio of water velocity to contaminant velocity. The value found for R was 3.9, based on the simulation in the Analytic1 model. A retardation of 3.9 can be considered a high value when compared to other literary studies, such as that of Yolcubal and Akyol (2007) who determined R of 1.07, in a column filled with limestone with a porosity of 0.59, using initial concentrations of 200 mg L−1 Cr(VI) in solution.

The total mass of Cr injected into the column was equal to 239.76 mg Cr(VI), and the mass recovered in the column effluent was 104.45 mg of Cr(VI). The data obtained in the ICP-OES analysis showed the amount of total chromium retained in this material and revealed that each gram of OS was able to retain 1.26 mg of total chromium, totaling 133.56 mg Cr removed in the column OS.

Based on a mass balance analysis (Eq. 3), the difference between the total Cr input and the sum of the masses of total Cr and Cr(VI) determined at the column output and removed by the OS corresponds to 1.75 mg, only 0.73% of the total Cr mass injected, indicating that all of the Cr is accounted for. The small difference may be due to some imprecision in the analyses for Cr determination. The proportion of Cr mass retained per mass of OS (1.26 mg g−1) is very similar to the value obtained in the batch test with groundwater, where 1.6 mg of Cr(VI) was retained per gram of OS in solution with 200 mg L−1 Cr(VI). The retained mass probably is in the form of Cr(III), due to the ability of organic matter to promote the reduction of Cr(VI) to (III) and the constituents of the OS in immobilizing it.

In order to promote the increase of Cr(VI) reduction capacity, OS could be modified adding Fe(III) in the system. According to Mak and Lo (2011), the reduction of Cr(VI) by both fulvic acids and humic acids of natural organic matter increases when Fe(III) is added. The humic substances transform Fe(III) into Fe(II), which in turn reduces Cr(VI) to Cr(III). Wu et al. (2017) also enhanced the removal performance of chitosan by Fe(III) pretreatment. The Fe(OOO)-cross-linked chitosan beads synthesized by these authors presented a high adsorption capacity of Cr(VI) (166.3 mg g−1) under ambient temperature and pH 6.0.

Conclusions

The ash content (56 wt%) of the studied organic soil (OS) is high, as it was expected for tropical peat soils. Its organic carbon content was only 20.5 wt%, which corresponds to 35.5 wt% of organic matter. Therefore, OS is considered as a muck and not as a really peat. The main inorganic components of OS are silica and alumina, and its main mineral constituents are kaolinite, gibbsite, muscovite, quartz and anatase.

Despite of the high ash content, the organic substances of OS had the capacity to remove approximately 2 mg g−1 of Cr(VI), depending on test conditions. This process involved the reduction of Cr(VI) by the humic substances of OS, followed by precipitation and/or adsorption/complexation of Cr(III) by organic and inorganic components.

In 24 h, the greatest rate of Cr(VI) removal was observed in solutions with pH 2.0 (1.1 mg g−1), since the reduction of Cr(VI) to Cr(III) by organic compounds consumes hydrogen. An increased Cr(VI) removal (around 2.0 mg g−1) was also observed at original groundwater pH (around 5.0), however it took a longer period, of 5 days.

The column tests simulating the use of the OS as permeable reactive barrier fillers to treat groundwater contaminated with Cr(VI) also presented a high removal capacity of Cr(VI) (1.3 mg g−1) as obtained in batch tests (1.6 mg g−1). The advantage of this system is that its half-life (4.4 h) is almost six times smaller than that batch test (26.2 h), due to the higher proportion of contact surface per volume of solution. Therefore, the use of OS in the permeable reactive barriers can be effective to promote the removal of Cr(VI), even at original groundwater pH.

The presence of reducing agents as humic substances in OS induced chromium reduction, instead of anion exchange. The Cr(III) association with mineral phases was confirmed by the presence of anatase in samples submitted at heating at 800 °C/2 h.

Further investigations could reveal if the addition of Fe(III) in the system increases the performance of OS in the reduction of Cr(VI) to Cr(III).

References

Ajouyed O, Hurel C, Ammari M et al (2010) Sorption of Cr(VI) onto natural iron and aluminum (oxy)hydroxides: effects of pH, ionic strength and initial concentration. J Hazard Mater 174:616–622. https://doi.org/10.1016/j.jhazmat.2009.09.096

Alleoni LRF, Mello JWV, Rocha WSD (2009) Eletroquímica, adsorção e troca iônica do solo. In: SBCS (ed) Química e mineralogia do solo—Parte II—Aplicações. Minas Gerais, Viçosa

ASTM (2014) D 653—14: soil, rock, and contained fluids. ASTM, West Conshohocken

Balan C, Bilba D, Macoveanu M (2008) Removal of cadmium (II) from aqueous solutions by sphagnum moss peat: equilibrium study. Env Eng Manag J 7:17–23

Balan C, Volf I, Bulai P, Bilba D, Macoveanu M (2012) Removal of Cr(VI) form aqueous environment using peat moss: equilibrium study. Env Eng Manag J 11:21–28

Banks MK, Schwab AP, Henderson C (2006) Leaching and reduction of chromium in soil as affected by soil organic content and plants. Chemosphere 62:255–264. https://doi.org/10.1016/j.chemosphere.2005.05.020

Barlett RJ, James BR (1988) Mobility and bioavailability of chromium in soils. In: Nriagu JO, Nierboer E (eds) Chromium in the natural environment. Wiley, New York, pp 267–304

Bellifa A, Pirault-Roy L, Kappenstein C, Choukchou-Braham A (2014) Study of effect of chromium on titanium dioxide phase transformation. Bull Mater Sci 37(3):669–677

Benites VM, Madar B, Machado PLOA (2003) Extração e fracionamento quantitativo de substâncias húmicas do solo: um procedimento simplificado de baixo custo. Comun Técnico 16:1–7

Blowes DW, Ptacek CJ, Jambor JL (1997) In-situ remediation of Cr(VI)-contaminated groundwater using permeable reactive walls: laboratory studies. Environ Sci Technol 31:3348–3357. https://doi.org/10.1021/es960844b

Blowes DW, Ptacek CJ, Benner SG et al (2000) Treatment of inorganic contaminants using permeable reactive barriers. J Contam Hydrol 45:123–137. https://doi.org/10.1016/S0169-7722(00)00122-4

Brown P, Gill S, Allen SJ (2000) Metal removal from wastewater using peat. Water Res 34:3907–3916. https://doi.org/10.1016/S0043-1354(00)00152-4

Cameron CC, Esterle JS, Palmer CA (1989) The geology, botany and chemistry of selected peat-forming environments from temperate and tropical latitudes. Int J Coal Geol 12:105–156. https://doi.org/10.1016/0166-5162(89)90049-9

Camargo AO, Moniz AC, Jorge JA, Valadares JMAS (2009) Métodos de análise química, mineralógica e física de solos do Instituto Agronômico de Campinas - Boletim técnico 106. Instituto Agronômico do Estado de São Paulo, Campinas

Chen CY, Lan GS (2000) Preparation of mullite by the reaction sintering of kaolinite\rand alumina. J Eur Ceram Soc 20:2519–2525

Chimner RA, Ewel KC (2005) A tropical freshwater wetland: II. production, decomposition, and peat formation. Wetl Ecol Manag 13:671–684. https://doi.org/10.1007/s11273-005-0965-9

Crist RH, Martin JR, Choniko J, Crist DR (1996) Uptake of metals on peat moss: an ion exchange process. Environ Sci Technol 30:2456–2461

Dević G (2015) An assessment of the chemical characteristics of early diagenetic processes in a geologically well-defined brown coal basin. Energy Sources Part A Recover Util Environ Eff 37:2559–2566. https://doi.org/10.1080/15567036.2012.724147

Gardea-Torresdey JL, Tang L, Salvador JM (1996) Copper adsorption by esterified and unesterified fractions of sphagnum peat moss and its different humic substances. J Hazard Mater 48:191–206

Genutchen MT van, Alves WJ (1982) Analytical solutions of the one-dimensional convective dispersive solute transport equation, Boletim Té. US Department of Agriculture

Góes MA, Luz AB, Possa MV (2004) Amostragem. In: Luz AB, Sampaio J, Almeida SLM (eds) Tratamento de minérios, 4°. CETEM, Rio de Janeiro, pp 18–50

Gu B, Chen J (2003) Enhanced microbial reduction of Cr(VI) and U(VI) by different natural organic matter fractions. Geochim Cosmochim Acta 67:3575–3582. https://doi.org/10.1016/S0016-7037(03)00162-5

Haberhauer G, Feigl B, Gerzabek MH, Cerri C (2000) FT-IR Spectroscopy of organic matter in tropical soils: changes induced through deforestation. Appl Spectrosc 54(2):221–224

Henryk K, Jarosław C, Witold Ż (2016) Peat and coconut fiber as biofilters for chromium adsorption from contaminated wastewaters. Environ Sci Pollut Res 23:527–534. https://doi.org/10.1007/s11356-015-5285-x

Hesse PR (1971) A textbook of soil chemical analysis. Chemical Publishing Co., New York

Hsu TC, Guo GL, Chen WH, Hwang WS (2010) Effect of dilute acid pretreatment of rice straw on structural properties and enzymatic hydrolysis. Bioresour Technol 101:4907–4913. https://doi.org/10.1016/j.biortech.2009.10.009

Huang PJ, Chang H, Yeh CT, Tsai CW (1997) Phase transformation of TiO2 monitored by thermo-Raman spectroscopy with TGA/DTA. Thermochim Acta 297:85–92. https://doi.org/10.1016/S0040-6031(97)00168-8

Huang SW, Chiang PN, Liu JC et al (2012) Chromate reduction on humic acid derived from a peat soil—exploration of the activated sites on HAs for chromate removal. Chemosphere 87:587–594. https://doi.org/10.1016/j.chemosphere.2012.01.010

Janaki V, Kamala-Kannan S, Shanthi K (2015) Significance of Indian peat moss for the removal of Ni(II) ions from aqueous solution. Environ Earth Sci 74:5351–5357. https://doi.org/10.1007/s12665-015-4547-8

Joosten H (2016) Changing paradigms in the history of tropical peatlands research. In: Osaki M, Tsuji N (eds) Tropical peatland ecosystems. Springer, Tokyo, pp 33–48

Kiehl EJ (1979) Manual de Edafologia—relações solo-planta. Ceres, São Paulo

Klavins M, Purmalis O, Rodinov V (2013) Peat humic acid properties and factors influencing their variability in a temperate bog ecosystem. Estonian J Ecol 62(1):35–52. https://doi.org/10.3176/eco.2013.1.04

Krumins J, Klavins M, Seglins V (2012) Comparative study of peat composition by using FT-IR spectroscopy. Mater Sci Appl Chem 26:106–114

Liu W, Ni J, Yin X (2014) Synergy of photocatalysis and adsorption for simultaneous removal of Cr(VI) and Cr(III) with TiO2 and titanate nanotubes. Water Res 53:12–25. https://doi.org/10.1016/j.watres.2013.12.043

Liu Y, Mou H, Chen L et al (2015) Cr(VI)-contaminated groundwater remediation with simulated permeable reactive barrier (PRB) filled with natural pyrite as reactive material: environmental factors and effectiveness. J Hazard Mater 298:83–90. https://doi.org/10.1016/j.jhazmat.2015.05.007

Machado JMC, Oliveira LMCPE, Kamogawa MY (2011) Reciclagem do crômio de resíduos químicos provenientes da determinação de carbono oxidável em fertilizantes orgânicos. Quim Nova 34:131–134

Mak MSH, Lo IMC (2011) Influences of redox transformation, metal complexation and aggregation of fulvic acid and humic acid on Cr(VI) and As(V) removal by zero-valent iron. Chemosphere 84:234–240. https://doi.org/10.1016/j.chemosphere.2011.04.024

Miyazawa M, Pavan MA, Oliveira EL de et al (2000) Gravimetric determination of soil organic matter. Braz Arch Biol Technol 43:475–478. https://doi.org/10.1590/S1516-89132000000500005

Mulligan CN, Yong RN, Gibbs BF (2001) Remediation technologies for metal-contaminated soils and groundwater: an evaluation. Eng Geol 60:193–207. https://doi.org/10.1016/S0013-7952(00)00101-0

Music S, Maljkovic M, Popovic S, Trojko R (1999) Formation of chromia from amorphous chromium hydroxide. Croat Chem Acta 72:789–802

Nolan NT, Seery MK, Pillai SC (2009) Spectroscopic investigation of the anatase-to-rutile transformation of sol–gel-synthesized TiO2 photocatalysts. J Phys Chem C 113:16151–16157. https://doi.org/10.1021/jp904358g

Olazabal MA, Nikolaidis NP, Suib SA, Madariaga JM (1997) Precipitation equilibria of the chromium(VI)/iron(III) system and spectrospcopic characterization of the precipitates. Environ Sci Technol 31:2898–2902. https://doi.org/10.1021/es9700865

Page SE, Rieley JO, Wüst R (2006) Lowland tropical peatlands of Southeast Asia. In: Martini IP, Cortizas AM, Chesworth W (eds) Peatlands: evolution and records of environmenal and climate changes. Elsevier, Amsterdam, pp 145–172

Palmer CD, Plus RW (1994) Natural attenuation of hexavalent chromium in groundwater and soils. USEPA, Washington, DC

Priyantha N, Lim LBL, Wickramasooriya S (2016) Adsorption behaviour of Cr(VI) by Muthurajawela peat. Desalin Water Treat 57:16592–16600. https://doi.org/10.1080/19443994.2015.1081835

Russel JD (1987) Infrared methods. In: Wilson MJ (ed) A handbook of determinative methods in clay mineralogy. Blackie & Sons, London, pp 133–173

Schnitzer M (1972) Chemical, spectroscopic, and thermal methods for the classification and characterization of humic substances. In: Povoledo D, Golterman HL (eds) Proceedings of international meeting on humic substances. PUDOC, Wageningen, pp 293–310

Schwartz FW, Zhang H (2003) Fundamentals of groundwater. Wiley, New York

Sharma DC, Forster CF (1993) Removal of hexavalent chromium using sphagnum moss peat. Water Res 7:1201–1208

Sharma P, Bihari V, Agarwal SK et al (2012) Groundwater contaminated with hexavalent chromium [Cr (VI)]: a health survey and clinical examination of community inhabitants (Kanpur, India). PLoS One 7:3–9. https://doi.org/10.1371/journal.pone.0047877

Stevenson FJ (1994) Humus chemistry: genesis, composition, and reaction. Wiley, New York

Thiruvenkatachari R, Vigneswaran S, Naidu R (2008) Permeable reactive barrier for groundwater remediation. J Ind Eng Chem 14:145–156. https://doi.org/10.1016/j.jiec.2007.10.001

Ulmanu M, Anger I, Fernández Y et al (2008) Batch chromium(VI), cadmium(II) and lead(II) removal from aqueous solutions by horticultural peat. Water Air Soil Pollut 194:209–216. https://doi.org/10.1007/s11270-008-9709-9

USDA (United States Department of Agriculture) (1999) Soil taxonomy, 2nd edn. USDA, Washington, DC

USEPA (United States Environmental Protection Agency) (1989) Evaluation of groundwater extraction remedies. EPA Office of Emergency and Remedial Responses, Washington, DC

USEPA (United States Environmental Protection Agency) (1991) EPA method 2186—determination of dissolved hexavalent chromium in drinking water, groundwater and industrial wastewater effluents by ion chromatography. United States Environmental Protection Agency, Washington, DC

USEPA (United States Environmental Protection Agency) (2017) Chromium in drinking water. https://www.epa.gov/dwstandardsregulations/chromium-drinking-water. Accessed 24 Apr 2017

Wada K and Okamura Y (1977) Measurements of exchange capacities and hydrolysis as means of characterizing cation and anion retentions by soils. Proceedings of the international seminar on soil environment and fertility management in intensive agriculture, Tokyo-Japan, pp 811–815

WHO (World Health Organization) (2017) Guidelines for drinking-water quality, 4th edn. World Health Organization, Geneva

Wilkin RT, Su C, Ford RG, Paul CJ (2005) Chromium-removal processes during groundwater remediation by a zerovalent iron permeable reactive barrier. Environ Sci Technol 39:4599–4605. https://doi.org/10.1021/es050157x

Wilkin RT, Acree SD, Ross RR et al (2014) Fifteen-year assessment of a permeable reactive barrier for treatment of chromate and trichloroethylene in groundwater. Sci Total Environ 468–469:186–194. https://doi.org/10.1016/j.scitotenv.2013.08.056

Wittbrodt PR, Palmer CD (1996) Reduction of Cr (VI) by soil humic acids. Eur J Soil Sci 47:151–162

Wu Y, Zhang Y, Qian J, Xin X, Hu S, Zhang S, Wei J (2017) An exploratory study on low-concentration hexavalent chromium adsorption by Fe (III)-cross-linked chitosan beads. R Soc Open Sci 4:170905. https://doi.org/10.1098/rsos.170905

Wüst RAJ, Bustin RM, Lavkulich LM (2003) New classification systems for tropical organic-rich deposits based on studies of the Tasek Bera Basin, Malaysia. Catena 53:133–163. https://doi.org/10.1016/S0341-8162(03)00022-5

Yolcubal I, Akyol NH (2007) Retention and transport of hexavalent chromium in calcareous karst soils. Turk J Earth Sci 16:363–379

Zehra T, Lim LBL, Priyantha N (2015) Removal behavior of peat collected from Brunei Darussalam for Pb(II) ions from aqueous solution: equilibrium isotherm, thermodynamics, kinetics and regeneration studies. Environ Earth Sci 74:2541–2551. https://doi.org/10.1007/s12665-015-4273-2

Zengguang X, Yanqing W, Hui X (2013) Optimization of a PRB structure with modified chitosan restoring Cr(VI)-contaminated groundwater. Environ Earth Sci 68:2189–2197. https://doi.org/10.1007/s12665-012-1902-x

Zhang J, Xu Y, Li W et al (2012) Enhanced remediation of Cr(VI)-contaminated soil by incorporating a calcined-hydrotalcite-based permeable reactive barrier with electrokinetics. J Hazard Mater 239–240:128–134. https://doi.org/10.1016/j.jhazmat.2012.08.039

Zhilin DM, Schmitt-Kopplin P, Perminova IV (2004) Reduction of Cr(VI) by peat and coal humic substances. Environ Chem Lett 2:141–145. https://doi.org/10.1007/s10311-004-0085-4

Acknowledgements

The authors would like to acknowledge Prof. Dr. José Guilherme Franchi for the donation of the peat samples from São Luiz do Paraitinga (SP) and the anonymous referees for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

dos Santos, M.M.A., Shinzato, M.C. & de Freitas, J.G. Characterization and evaluation of a tropical peat for the removal of Cr(VI) from solution. Environ Earth Sci 77, 515 (2018). https://doi.org/10.1007/s12665-018-7703-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-018-7703-0