Abstract

The economic viability of enzyme-assisted aqueous extraction processing (EAEP) of soybeans depends on properties and potential applications of all fractions (skim and insolubles as well as oil). EAEP oil contained lower free fatty acid, phosphorus, and tocopherol contents, similar unsaponifiable matter levels, and higher degrees of oxidation (peroxide and p-anisidine values) than hexane-extracted oil. The phospholipid profile of EAEP fractions was mainly composed of phosphatidic acid, followed by phosphatidylcholine, phosphatidylinositol, and phosphatidylethanolamine. Most of phospholipids were present in the skim, except for phosphatidic acid, which was the major phospholipid in the cream fraction. Skim and cream contained 55 and 3 % of the soluble carbohydrates in the original extruded flakes, respectively. Soluble carbohydrates of the skim were mainly composed of stachyose (5.8 ± 0.8 mg/mL) and sucrose (9.9 ± 0.8 mg/mL), which were hydrolyzed into glucose, galactose, and fructose after addition of α-galactosidase. Skim and cream peptides contained <20 kDa MW molecules. About 71 % of the skim peptides were <20 kDa MW, with 49 % being <1.35 kDa MW, 22 % being 17–1.35 kDa MW, and 29 % being 44–670 kDa MW. Skim protein and carbohydrate contents make this fraction suitable for replacing water in ethanol fermentations, thereby improving the fermentation rate/production and the nutritional quality of distiller’s dried grains with solubles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Safety and health concerns regarding the use of hexane in soybean crushing plants have caused a resurgence of interest in using a more environmentally friendly extraction technology to extract oil and protein from oil-bearing seeds [1–5]. The enzyme-assisted aqueous extraction process (EAEP) achieves simultaneous extraction of oil and protein from soybeans, which are fractionated into cream (oil-rich fraction), skim (protein- and sugar-rich fraction), and insolubles (cellulose-rich fraction). These fractions can be converted into edible oil, biofuel, and protein ingredients for food and feed [5].

The most advanced strategy of EAEP of soybeans is integrated, countercurrent, two-stage EAEP [5, 6]. This process strategy integrates the two main steps of the countercurrent EAEP of extruded soybean flakes, two-stages of countercurrent extraction and cream demulsification by recycling the enzyme used to demulsify the cream into the two extraction stages. The enzyme is used three times throughout the process. We demonstrated proof-of-concept for integrated, countercurrent, two-stage EAEP of soybeans with reduced enzyme usage on the pilot-plant scale (75 kg of soybeans) achieving improved skim-cream separation when using equipment similar to that used by the industry [5]. Better fraction separation achieved at pilot-plant scale produced less cream, reducing the amount of enzyme needed to demulsify the cream and thus reduced the amount of enzyme recycled into the extraction. Higher oil (98 vs. 96 %) and protein (96.5 vs. 89 %) extraction yields, better oil distribution among the fractions as evidenced by lower oil content in the skim (19 vs. 32 %), higher oil content in the cream (79 vs. 64 %), and cream with lower stability towards demulsification (91.6 vs. 81.2 % demulsification efficiency) were achieved compared with results obtained on laboratory scale [6], thereby improving overall free oil recovery from 64 to 79 % [5, 6].

Although we successfully demonstrated proof-of-concept on pilot-plant scale [5], complete characterization of all fractions produced (protein- and sugar-rich skim, free oil from cream demulsification, and cellulose-rich insolubles) is necessary to identify high-value uses for these fractions and to maximize economic viability of EAEP. The objectives of the present study were to: (1) evaluate the effects of the pilot-plant, integrated, countercurrent, two-stage EAEP on oil quality and compare it to the quality of hexane-extracted soybean oil, (2) determine the phospholipid profile and distribution in all fractions, and (3) determine the carbohydrate and protein contents/profiles of the skim and cream fractions. These data will help assess potential applications/benefits of the fractions obtained.

Materials and Methods

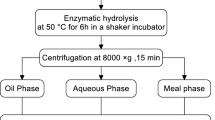

Pilot-Plant Scale, Integrated, Countercurrent, Two-Stage, EAEP of Soybeans

Soybeans (variety 92M91-N201-Pioneer, a DuPont Business, Johnston, IA, USA) were flaked and extruded at 90 rpm screw speed and 100 °C prior to EAEP, where three fractions (cream, the oil-rich emulsion; skim, the protein- and sugar-rich fraction; and insolubles, the cellulose-rich fraction) were produced. Integrated, countercurrent, two-stage EAEP was performed in the pilot-plant facilities of the Center for Crops Utilization Research, Iowa State University (Ames, IA, USA), according to procedures developed by de Moura et al. [5].

Each trial was composed of two countercurrent extraction stages and one cream demulsification step. Protex 6L (Genencor Division of Danisco, Rochester, NY, USA), a bacterial alkaline endoprotease derived from a strain of Bacillus licheniformis, was used in both extraction stages and cream demulsification. The enzyme used for demulsifying the cream to obtain free oil was recycled upstream into the second extraction stage and then into the first extraction stage. No fresh enzyme was added during the extraction after the second trial; all enzyme came into the extraction process only through the demulsification step. Extractions were performed at a 1:6 solids-to-liquid ratio, pH 9.0, and 50 °C with stirring for 1 h at 35 rpm. Cream demulsification was performed by adjusting the slurry to pH 9.0 before adding 2.5 % (weight of enzyme preparation to weight of flakes) Protex 6L and stirring for 1.5 h at 180 rpm and 65 °C (the enzyme is stable at this temperature). Only samples of skim, cream, and insolubles produced with steady-state extraction [5] were analyzed.

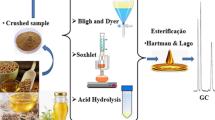

Hexane-Extracted Soybean Oil

Eight 115-g batches of full-fat soybean flakes (0.25 mm thickness, ~10 % moisture content) were extracted with hexane for 6 h by using a Soxhlet apparatus (AOAC method 963.15) [7]. After extraction, the eight extracts were combined into four samples (in order to produce a sufficient amount of oil for all analyses) and the solvent was removed by rotary evaporating at 85 °C.

Oil Quality Analyses

Oil samples from four extraction batches (at steady-state extraction) from the pilot-plant, integrated, countercurrent, two-stage EAEP of soybeans [5] and four samples of hexane-extracted oil were analyzed for phosphorus (AOCS Ca 12-55) [8], unsaponifiable matter (AOCS Ca 6a-40) [8], p-anisidine value (AOCS Cd 18-90) [8], peroxide value (AOCS Cd 8-53) [8], and free fatty acid content (modified AOCS Ca 5a-40 by Rukunudin et al. [9]).

Fatty acid methyl esters (FAME) of oil samples were prepared by adding 3 mL methanol containing 3 % (by vol) sulfuric acid to 30 mg of oil (moisture and solvent free) [10]. The mixture was heated at 60 °C for 2 days. The resulting FAME was extracted with 2 mL hexane and washed with 10 mL distilled water. 1 μL of FAME in hexane was injected into an HP 5890 Series II gas chromatograph (Hewlett–Packard, Palo Alto, CA, USA) equipped with a SPB-2330 fused silica column (15 m × 0.25 mm and 0.20 μm film thickness) (Supelco, Bellefonte, PA, USA). The injector and flame ionization detector were set at 230 °C, and the oven temperature was programmed at 10 °C/min from 100 to 220 °C. The column flow rate was 5 mL/min and the split ratio was 24:1 [10].

Oil samples were also analyzed for tocopherols by using high-performance liquid chromatography (HPLC) with a UV detector at 280 nm according to the methods of Guzman and Murphy [11]. The HPLC system (Beckman System Gold, Miami, FL, USA) consisted of a 250 × 4.6 mm Ultra sphere Si column, a 126 pump module, a 508 auto sampler, and a 168 PDA detector. The mobile phase was 1 % 2-propanol in hexane at 2 mL/min flow rate. Twenty-microliter samples were injected. Peaks were identified based on retention times of standards (α-, γ-, and δ-tocopherols). Tocopherol concentrations were determined by using standard curves for each tocopherol.

Phospholipid Analyses

Phospholipids were extracted from extruded flakes (~50 g, as is), insolubles (~65 g, freeze-dried), and skim fractions (~140 g, freeze-dried). Methanol (200 mL) and chloroform (400 mL) were added to each material, and the mixture was homogenized for 4 min with an Ultra-Turrax T25 homogenizer (Ika Works, Wilmington, NC, USA) at 9,500 rpm. The mixture was then stirred for 2 h at room temperature before vacuum filtering. The residue recovered from Buchner funnel filtration was mixed with fresh methanol (200 mL) and chloroform (400 mL) for a second extraction at room temperature for 4 h. The filtrates from the two extractions were combined and the solvent was removed with a rotary evaporator at 40 °C. The crude oil was then subjected to a Folch wash with chloroform/methanol/0.74 % aqueous solution of KCl (8:4:3 by vol) [12]. The crude oil was measured gravimetrically after removing the residual solvent in a vacuum oven at 22 °C and then stored at −26 °C until analyzed. The crude oil from the cream (~34 g, freeze-dried) was obtained according to the procedure described above except that only one solvent extraction was performed.

The phospholipids were concentrated by using solvent partitioning with hexane and 87 % ethanol following a procedure adapted from Galanos and Kapoulas [13]. Hexane (100 mL) and 87 % of ethanol (100 mL) were mixed and equilibrated in a separator funnel. The upper hexane phase and lower ethanol phase were collected as solvents A and B, respectively. Crude oil (~10 g) was dissolved in 45 mL of solvent A and 15 mL of solvent B in a 200-mL separator funnel. After 5 min for phase equilibration, the lower ethanol phase was collected. Fresh solvent B (15 mL) was added to the upper phase. Then a second ethanol phase was collected after phase equilibration and combined with the first. The extraction was repeated 10 times and the pooled ethanol extracts were mixed with chloroform (130 mL) and 0.1 N K-EDTA (111 mL, pH 7). The chloroform phase was then collected and dried with sodium sulfate. The concentrated oil freed of solvent was stored at −26 °C.

Concentrated polar lipids (~100 mg) and triphenyl phosphate (TPP, ~10 mg, solid) were dissolved in chloroform-d (1 mL), methanol (1 mL), and Cs-EDTA (1 mL, 0.2 N, pH 8.5). After vigorous shaking, the sample was centrifuged and the lower phase was transferred to a 5-mm NMR tube (Kimble/Kontes, Vineland, NJ, USA). The 31P-NMR spectra were obtained by using a Varian VXR 400 spectrometer (Varian, Inc., Palo Alto, CA, USA) with a Bruker Magnet (BrukerBioSpin, Billerica, MA, USA) operating at 162 MHz. Samples were analyzed with an inverse gated decoupling pulse sequence to suppress any nuclear overhauser effect [14]. The NMR spectroscopic scan conditions were set as: probe temperature 29 °C, pulse width 22 μs, sweep width 9,718 Hz, acquisition time 1.2 s, relaxation delay 10 s, and number of scans 256. The chemical shifts were reported relative to TPP (δ−17.8). The relative distribution of phospholipids was expressed in mole percent related to the sum of all phospholipids that were detected by 31P NMR. The data processing was completed with MestReNova software (Mestrelab Research SL, Santiago de Compostela, Spain). The chemical shifts of various phospholipid classes were determined by comparing with previously reported spectra [15]. The phospholipid content in the oil extracted from each sample was calculated as follows: phospholipid content (%) = 100[(phospholipids (g) in the concentrated oil)/(starting oil (g) in the solvent fractionation)].

Carbohydrate Profile and α-Galactosidase Treatment of Skim

Ash contents of EAEP skims were determined by heating samples in a muffle furnace at 550 °C for approximately 30 h [8]. Carbohydrate content was determined by differences from oil, protein, moisture [5], and ash contents.

The soluble carbohydrate profiles of skims were determined by HPLC [16]. Aliquots of skims were placed in microcentrifuge tubes, vortexed for 30 s, and then centrifuged at 13,500×g for 10 min. The liquid phases, 20-μL injections, were run on an Aminex HPX-87P column (Biorad, Hercules, CA, USA) at 85 °C with 18 MQ water mobile phase and 0.6 mL/min flow rate. Peaks were detected by using an RI detector at 35 °C. Peaks were identified based on retention times of standards (galactose, glucose, stachyose, raffinose, fructose, sucrose, xylose, mannose, and arabinose). Sugar concentrations were determined by using standard curves for each sugar. Skims from seven different extraction batches were analyzed.

Fifteen kg of skim was adjusted to pH 6 with 2 N HCL and α-galactosidase (Bio-Cat, Inc., Troy, VA, USA) was added to achieve 0.25 % (w/w, wet basis) concentration. The skim was incubated at 40 °C for 30 min at 54 rpm in a 265-L jacketed stainless-steel tank reactor. Skim samples were spray-dried at 180 °C inlet and 95 °C outlet temperatures, ~70 % atomizer speed (10,000 rpm) (APV Crepaco Inc., Attleboro Falls, MA, USA) and stored at 4 °C until analyzed.

SDS-PAGE Protein Profile Analysis

Peptide profiles of freeze-dried skims and cream samples (not subjected to α-galactosidase treatment) were determined by SDS-PAGE on 4–20 % polyacrylamide gels (Mini-PROTEAN TGX, Bio-Rad, Hercules, CA, USA). A pre-stained SDS-PAGE standard broad-range MW marker (6.8–198.5 kDa, Bio-Rad, Hercules, CA, USA) was used. Each sample was diluted to ~2.3 mg/0.5 mL protein concentration in 2× sample buffer (urea-SDS-PAGE), and loaded into the gel well by using 10-μL aliquots, loading ~45 μg of protein of marker and protein extract and 20-μL aliquots loading ~90 μg of protein of skim and cream fractions. After destaining, the gels were scanned with an Amersham Pharmacia Biotech Image Scanner (Piscatawa, NJ, USA). Freeze-dried samples of skims and creams from two different extractions were analyzed.

Size-Exclusion Chromatography of Skim Peptides

Aliquots of skims (not subjected to α-galactosidase treatment) were centrifuged at 13,500×g for 10 min in microtubes [17]. The liquid phases (20-μL injections) were run on a Bio-Sil SEC column (300 × 7.8 mm analytical column, 80 × 7.8 mm guard column, Biorad, Hercules, CA, USA) at ambient temperature with a mobile phase composed of 0.05 M NaH2PO4, 0.05 M Na2HPO4, and 0.15 M NaCl (pH 6.8) at 1.0 mL/min flow rate. Peaks were detected by using a UV detector at 280 nm. Peak MW ranges were based on retention times of standards (thyroglobulin, bovine gamma globulin, chick ovalbumin, equine myoglobin, and vitamin B12). Skim fractions from seven different extractions were analyzed.

Statistical Analyses

The data were analyzed by using Analysis of Variance (ANOVA) with mixed models from the SAS system (version 8.2, SAS Institute, Inc., Cary, NC, USA). Means were compared by using F-protected contrasts and the level of significance was set at P < 0.05.

Results and Discussion

Effects of Extraction Parameters on Oil Quality and Fatty Acid Composition

Crude soybean oil and degummed soybean oil have phospholipid contents ranging from 1–3 % (317–950 ppm phosphorus) and 0.32–0.64 % (100–200 ppm phosphorus), respectively [18]. Soybean oil phospholipids are composed of hydratable phospholipids (HP) that hydrate and swell when coming into contact with free water to form gums (lecithin), and non-hydratable phospholipids (NHP) that will not form gums and precipitate from the oil after centrifugation [18, 19]. The aqueous medium during EAEP (at 50 °C for two extraction stages and at 65 °C during cream demulsification) hydrated the majority of the HP present in the crude oil (Table 1), with phospholipid contents being significantly lower when using EAEP than when using hexane extraction. EAEP-extracted and hexane-extracted oils contained 0.37 and 1.51 % (125 and 505 ppm) phospholipids, respectively.

EAEP-extracted oil was partially degummed soybean oil (<200 ppm) due to its very low phospholipid content (125 ppm) and, thus, was suitable for physical refining. Our results agree with previous findings of Jung et al. [20] in which phosphorus content of EAEP-extracted oil from single-stage extraction EAEP (pH 9.0, 1 h, 0.5 % Protex 6L) and enzyme-catalyzed cream demulsification (pH 9.0, 1.5 h, 2.5 % Protex 6L) was much lower than hexane-extracted oil, 54 vs. 240 ppm, respectively. Higher phospholipid contents of oils obtained from the pilot-plant, integrated, countercurrent, two-stage EAEP (our results) compared with those from single-stage EAEP [20] (125 vs. 54 ppm) may be due to the differences in processing conditions, storage times of the soybeans and extruded flakes prior to extraction, and extraction conditions.

NHP (phospholipids not removed by water degumming) consists of phosphatidic acids produced by phospholipase D conversion of phosphatidylethanolamine, phosphatidylcholine, and/or phosphatidylinositol. The formation of NHP in crude oil is affected by the combination of cell wall disruption when processing the beans, phospholipase D activity, moisture of the beans/flakes/extruded flakes entering extraction, and heat applied prior to or during extraction [19, 21, 22]. Similar low phosphorus contents were obtained when extracting corn germ oil by EAEP (0.02 % phospholipids) in comparison with industrial procedures such as screw-pressed crude corn oil (1.40 % phospholipids) and degummed oil (0.14 % phospholipids) [23].

There were no significant differences (P < 0.05) in unsaponifiable values (sterols, pigments, hydrocarbons) for both EAEP- and hexane-extracted oils, 0.75 vs. 0.55 %, respectively, which was in agreement with previous findings reported for oil from single-stage EAEP [20], 0.38 vs. 0.30, respectively.

The FFA content, a measure of hydrolytic degradation during seed storage and oil extraction, of EAEP-extracted oil (0.1 %) was significantly lower than that of hexane-extracted oil (0.24 %), likely due to the rapid inactivation of lipases during extrusion preparation for EAEP. The FFA content of the oil from the pilot-plant, integrated, countercurrent, two-stage EAEP (0.1 %) was lower than that of oil from single-stage EAEP (0.25 %) [20].

Peroxide value (2.31 vs. 0.60 mequiv/kg), a measure of primary oxidation products, and p-anisidine value (8.56 vs. 1.88), a measure of secondary oxidation products, were significantly higher for EAEP-extracted oil than for hexane-extracted oil. Higher oxidation values for EAEP-extracted oil than for hexane-extracted oil were not expected. Perhaps some lipoxygenase action occurred before extrusion. Higher oxidation values for EAEP-extracted oil may also be related with its low phosphorus content. Oxidation stabilities of extruded-expelled oil (75 ppm phosphorus and 1.73 mequiv/kg PV) and of hexane-extracted oil (277 ppm phosphorus and 0.96 mequiv/kg PV) were reported by Wang and Johnson [24]. Phospholipid provides some resistance to oxidation. Although no lipoxygenase (MW 102) was observed in SDS PAGE of skims and creams (see Fig. 4), likely being inactivated when extruding soybean flakes at 100 °C, some enzyme activity may have been present after flaking but before extruding. The initial moisture of the flakes was increased from 7–9 to 14 % before extruding, which may have favored enzyme action. Reducing processing time between unit operations (flaking, moistening, and extruding) would minimize lipoxygenase action before extruding thereby minimizing lipid hydroperoxide formation.

In order to compare the oxidative state of the oil from the pilot-plant, integrated, two-stage, countercurrent EAEP to oil extracted by employing single-stage EAEP [20], the combination of the past history of the oil (p-anisidine value, AV) and present state (peroxide value, PV) was used to calculate the TOTOX value = 2 PV + AV, of both oils. TOTOX values for oil samples from the two processes were 13.2 and 10.3, respectively, indicating that oil from two-stage EAEP had more oxidation than did single-stage EAEP oil, indicating increasing extraction stages increased oxidation. In general, the pilot-plant, integrated, countercurrent, two-stage EAEP produced better quality oil (in terms of phospholipids and FFA) but with higher oxidation values when compared with hexane-extracted oil. Perhaps this was due to having residual lipoxygenase activity or low phospholipids content (which acts as antioxidants) even though EAEP conditions were milder than those used for hexane extraction.

Fatty acid compositions of hexane- and EAEP-extracted oils are shown in Table 2. Although some fatty acids were statistically different between the two processes, the differences were not of practical importance.

Concentrations of α-,γ-,and δ-tocopherols of EAEP and solvent-extracted oils are presented in Table 3. No α- and δ-tocopherols were detected in both EAEP and solvent-extracted oils. EAEP oil had a significantly (P < 0.05) lower γ-tocopherol content (637 vs. 2,140 mg/kg than hexane-extracted oil. Total tocopherol concentration was significantly lower (P < 0.05) for the EAEP oil than for hexane-extracted oil. EAEP-extracted oils from sunflower and canola had higher total tocopherol contents than when not using enzyme, probably a consequence of hydrolysis of the cell walls by enzymes, which may have improved tocopherol release during extraction [25, 26]. An opposite trend was observed in the present work. The lower total tocopherol content of the EAEP oil than hexane-extracted oil was consistent with the higher oxidation values of EAEP oil, which may have contained degraded tocopherol.

Phospholipids Profiles of EAEP Fractions

The primary soybean oil phospholipids are phosphatidylcholine, phosphatidylethanolamine, and phosphatidylinositol, accounting for 55.3, 26.3, and 18.4 % of the total phospholipids in soybean oil, respectively [27]. The phospholipid compositions of extruded flakes and fractions produced in pilot-plant, integrated, two-stage, countercurrent EAEP of soybeans (skim, cream, and insolubles) are shown in Fig. 1. The major phospholipids present in the extruded flakes (starting material) were phosphatidylcholine (18 mol%), phosphatidylinositol (20 mol%), phosphatidylethanolamine (10 mol%), and phosphatidic acid (48 mol%). Comparing our results with those of Yao and Jung [15], the extruded flakes used in our experiment contained lower amounts of phosphatidylcholine (18 vs. 43 mol%) and phosphatidylethanolamine (10 vs. 21 mol%), and higher amounts of phosphatidylinositol (20 vs. 17 mol%) and phosphatidic acid (48 vs. 10 mol%). This profile indicated polar lipid degradation.

Phospholipid composition of skim from the pilot-plant, integrated, countercurrent, two-stage EAEP of soybeans. PC Phosphatidylcholine, PI phosphatidylinositol, PE phosphatidylethanolamine, PA phosphatidic acid, LPC lysophosphatidylcholine, PS phosphatidylserine, APE n-acyl phosphatidylethanolamine, DPG diphosphatidylglycerol, PG phosphatidylglycerol, LPE lysophosphatidylethanolamine, LPA lysophosphatidic acid

Differences in the phospholipid profile were probably related to differences in soybean varieties being used and/or differences in processing variables, which affected phospholipase D activity. Our results indicated conversion of phosphatidylcholine and phosphatidylethanolamine to phosphatidic acid by phospholipase D action. Knowing that moisture, heat, cell wall rupture, and storage time affect phospholipase D activity [19], we believe that the time between flaking and increasing moisture content of the flakes to 14 % prior to extruding the flakes likely allowed phospholipase D activity. Our material (1,400 kg soybeans) was processed over about a 2-month period and the storage time between flaking, increasing the flakes moisture, and the period between flaking and extruding varied from 1 to 2 weeks.

The phospholipid profiles of all fractions, including the extruded flakes, show that phosphatidic acid is the major component of each fraction, followed by phosphatidylcholine, phosphatidylinositol, and phosphatidylethanolamine. The highest phosphatidic acid content (64 mol%) was for the cream fraction (oil-rich emulsion). Phosphatidic acid strongly adsorbs to proteins thus increasing emulsion stability [28, 29]. Minor components, such as phosphatidylserine (PS), n-acyl phosphatidylethanolamine (APE), di phosphatidylglycerol (DPG), phosphatidylglycerol (PG), lyso phosphatidylethanolamine (LPE), and lysophosphatidic acid (LPA), were also present.

The phospholipid distribution among the fractions (Fig. 2) shows that the majority of the phospholipids were present in the skim fraction, followed by cream, and a small amount remaining in the insolubles. PA was the exception, with the majority being present in the cream fraction, followed by skim and insolubles. Higher phospholipid content in the skim fraction would explain the difficulty in improving oil recovery from the skim fraction, which accounted for approximately 20 % of soybean oil [5].

Carbohydrate Profile and α-Galactosidase Treatment of Skim

EAEP fraction characterization is essential for identifying uses to determine the economic feasibility of EAEP by using the fractions in high-value applications. Since most oil is recovered as free oil from the cream (oil-rich emulsion), characterizing and finding value for the skim fraction remains a challenge to commercializing EAEP. Our starting material (dehulled, extruded flakes) contained approximately 35.6 % protein, 20.7 % lipid, 11.6 % moisture [5], 27.6 % carbohydrates, and 4.4 % ash, while the average composition of whole soybeans is approximately 35 % protein, 17 % oil, 31 % carbohydrate, and 4.4 % ash [30]. The carbohydrate contents of EAEP fractions were 2.45 ± 0.18 % in skim, 1.86 ± 0.61 % in cream, and 11.6 ± 0.35 % in insolubles (wet-basis). Figure 3 shows the carbohydrate distribution among cream, skim, and insoluble fractions. Approximately 58 % of the carbohydrates in extruded soybean flakes were extracted during two-stage, countercurrent EAEP of soybeans, with 3 and 55 % present in cream and skim fractions, respectively. Since protein (60 % db) and carbohydrates (22 % db) are the two major components of the skim fraction [5], compositions and/or functionalities of both provide insight to appropriate uses for this fraction as food or feed.

Total nonstructural carbohydrates (mono-, disaccharides, oligosaccharides, and starch) make up to 50 % of the total soybean carbohydrates and are mainly composed of sucrose (31–57 mg/g, db) followed by the oligosaccharides stachyose (31–41 mg/g, db) and raffinose (5–7.5 mg/g, db) [31, 32]. Skim fractions contained 5.8 ± 0.8 mg/mL stachyose and 9.9 ± 0.8 mg/mL sucrose, representing approximately 55 % of the total carbohydrates in the extruded flakes. Considering 100 % soluble carbohydrate extraction and the use of a 1:6 solids-to-liquid ratio, our current results are in agreement with those previously reported for skim from single-stage EAEP using 1:10 solids-to-liquid ratio in which ~3.8 mg/mL stachyose in soybeans was reported [3]. While low-MW sugars and storage polysaccharides (starch) are readily utilized by non-ruminants, oligosaccharides require hydrolysis (α-galactosidase) to be digested [31]. The HPLC soluble carbohydrate profile (Fig. 4) showed two major peaks corresponding to stachyose and sucrose before α-galactosidase hydrolysis. The HPLC profile after α-galactosidase hydrolysis showed the conversion of the two peaks of stachyose (tetrasaccharide of two galactoses, one glucose, and one fructose) and sucrose into glucose, galactose, and fructose. The carbohydrate concentrations after α-galactosidase hydrolysis are shown in Table 4. Total disappearances of the 5.5 % stachyose and 11.1 % sucrose were accompanied with the appearance of 33 % glucose, 4.8 % galactose, and 7.3 % fructose. While raffinose detection after α-galactosidase hydrolysis was possible, the same was not possible before α-galactosidase hydrolysis, in which raffinose was likely co-eluted with stachyose.

Peptide Profiles of Skim and Cream Fractions

The peptide profiles of skim and cream from the pilot-plant, integrated, countercurrent, two-stage EAEP of soybeans are shown in Fig. 5. SDS-PAGE gels showed similar peptide profiles for the skim and cream fractions with both having peptides with <53.9 kDa MW, and the majority of peptides having <20 kDa MW. These results were in agreement with the MW profiles of skims from a similar process (countercurrent, two-stage extraction, but without enzyme recycling) [33] in which most of skim peptides were <20 kDa MW. The skim peptide profile (Fig. 6) indicated that 71 % of the skim peptides had MWs <20 kDa, 49 % had MWs <1.35 kDa, 22 % had MWs from 17 to 1.35 kDa, and 29 % had MWs from 44 to 670 kDa. Our results indicated that the skim produced by pilot-plant, integrated, countercurrent, two-stage EAEP had slightly larger peptides than the skim produced in lab-scale, countercurrent, two-stage EAEP [33], in which 81 % of skim peptides had MW <20 kDa.

SDS-PAGE of skim and cream fractions from pilot-plant, integrated, countercurrent, two-stage EAEP of soybeans, Skims and creams from two extraction batches from the pilot-plant, integrated, two-stage countercurrent, two-stage EAEP of soybeans. Protein Extract: Protein extract from countercurrent, two-stage EAEP of air-desolventized, hexane-defatted soybean flakes without using protease in either extraction stage

Conclusions

EAEP of soybeans produced degummed oil with low phosphorus content, which may have contributed to reduced oxidative stability of the oil. EAEP oil had much lower free fatty acid content and similar unsaponifiable value and fatty acid composition as hexane- extracted oil. Thus, refining losses should be much less with EAEP oil than with conventional, hexane-extracted oil but, because oxidative stability is lower, oxidation prevention measures need to be employed. Phosphatidic acid was the major phospholipid in all EAEP fractions, being mostly present in the cream fraction, likely due to its excellent emulsification properties. Skim carbohydrates were composed of stachyose and sucrose, representing approximately 55 % of total carbohydrates in the extruded flakes. α-galactosidase treatment was effective in hydrolyzing flatulence-producing oligosaccharides to fermentable sugars. Soluble hydrolyzed peptides and carbohydrate content make skim suitable to produce protein concentrates for food/feed applications and to slurry corn-based ethanol production, improving fermentation rate and nutritional quality of distillers dried grains with soluble.

References

Jung S, de Moura JMLN, Campbell KC, Johnson LA (2011) Enzyme-assisted aqueous extraction of oilseeds. In: Lebovka N, Vorobiev E, Chemat F (eds) Enhancing Extraction Processes in the food industry. Food Engineering Series, Taylor & Francis LLC, Boca Raton, FL

Campbell K, Glatz CE, Johnson LA, Jung S, de Moura JMLN, Kapchie V, Murphy PA (2011) Advances in aqueous extraction processing of soybeans. J Am Oil ChemSoc 88:449–465

de Moura JMLN, Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson LA (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

de Moura JMLN, Johnson LA (2009) Two-stage countercurrent enzyme-assisted aqueous extraction processing of oil and protein from soybeans. J Am Oil Chem Soc 86:283–289

de Moura JMLN, Maurer D, Jung S, Johnson LA (2011) Pilot-plant proof-of-concept for integrated, countercurrent, two-stage, enzyme-assisted aqueous extraction of soybeans. J Am Oil Chem Soc 88:1649–1658

de Moura JMLN, Maurer D, Jung S, Johnson LA (2011) Integrated countercurrent two-stage extraction and cream de-emulsification in enzyme-assisted aqueous extraction of soybeans. J Am Oil Chem Soc 88:1045–1051

AOAC (2005) Official Methods of Analysis, 18th ed., Gaithersburg

AOCS (1992) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Washington

Rukunudin IH, White PJ, Bern CJ, Bailey TB (1998) A modified method for determining free fatty acids from small soybean oil sample sizes. J Am Oil Chem Soc 75:563–568

Yao L, Wang T (2011) Physical and textural properties of biorenewable waxes containing partial acylglycerides. J Am Oil Chem Soc 89:155–166

Guzman GJ, Murphy PA (1986) Tocopherols of soybean seeds and soybean curd (tofu). J Agric Food Chem 34:791–795

Folch J, Lees M, Sloane GHS (1957) A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226:497–509

Galanos DS, Kapoulas VM (1961) Isolation of polar lipids from triglyceride mixtures. J Lipid Res 3:134–137

Diehl BWK (2002) 31P-NMR in phospholipid analysis. Lipid Technol 14:62–65

Yao L, Jung S (2010) 31P NMR phospholipid profiling of soybean emulsion recovered from aqueous extraction. J Agric Food Chem 58:4866–4872

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2006) Determination of sugar, byproducts, and degradation products in liquid fraction process samples. Laboratory analytical procedure. Issue Date 12/8/06. NREL/TP-510-42623

Jung S, Mahfuz A, Maurer D (2009) Structure, protein interactions and in vitro protease accessibility of extruded and pressurized full-fat soybean flakes. J Am Oil Chem Soc 86:475–483

Gupta MK (2007) Basic oil chemistry. In: Gupta MK (ed) Practical guide to vegetable oil processing. AOCS Press, Urbana

List RG, Mounts TL, Lanser AC, Holloway RK (1990) Effect of moisture, microwave heating, and live steam treatment on phospholipase D activity in soybeans and soy flakes. J Am Oil Chem Soc 67:867–871

Jung S, Maurer D, Johnson LA (2009) Factors affecting emulsion stability and quality of oil recovered from enzyme-assisted aqueous extraction of soybeans. Bioresour Technol 100:5340–5347

List RG, Mounts TL, Lanser AC (1992) Factors promoting the formation of non hydratable soybean phosphatides. J Am Oil Chem Soc 69:443–445

List RG, Mounts TL (1993) Origin of the non hydratable soybean phosphatides: whole beans or extraction? J Am Oil Chem Soc 70:639–641

Bocevska M, Karlovic D, Turkulov J, Pericin D (1993) Quality of corn germ oil obtained by aqueous enzymatic extraction. J Am Oil Chem Soc 70:1273–1277

Wang T, Johnson LA (2001) Survey of soybean oil and meal qualities produced by different processes. J Am Oil Chem Soc 78:311–318

Latif S, Diosady LL, Anwar F (2008) Enzyme-assisted aqueous extraction of oil and protein from canola (Brassica napus L.) seeds. Eur J Lipid Sci Tech 110:887–892

Latif S, Anwar F (2009) Effect of aqueous enzymatic processes on sunflower oil quality. J Am Oil Chem Soc 86:393–400

Wang T, Hammond EG, Fehr WR (1997) Phospholipid fatty acid composition and stereospecific distribution of soybeans with a wide range of fatty acid composition. J Am Oil Chem Soc 74:1587–1594

Malmsten M (1995) Protein adsorption at phospholipids surface. J Colloid Interface Sci 172:106–115

Rubino JT (1990) The influence of charged lipids on the flocculation and coalescence of oil-in-water emulsions: I Kinetic assessment of emulsion stability. J Parenter Sci Technol 44:210–215

Liu K (1999) Soybeans: chemistry, technology, and utilization. Aspen Publishers, Inc., Gaithersburg

Middelbos IS, Fahey GC (2008) Soybean carbohydrates. In: Johnson LA, White PJ, Galloway R (eds) Soybeans: chemistry, production processing, and utilization. AOCS Press, Urbana, pp 269–296

Grieshop CM, Kadzer CT, Clapper GM, Flickinger EA, Bauer LL, Frazier RL, Fahey GC (2003) Chemical and nutritional characteristics of United States soybeans and soybean meals. J Agric Food Chem 51:7684–7691

de Moura JMLN, Hernandez-Ledesma B, Almeida NM, Hsieh CC, de Lumen BO, Johnson LA (2011) Lunasin and Bowman-Birk protease inhibitor concentrations of protein extracts from enzyme-assisted aqueous extraction of soybeans. J Agric Food Chem 59:6940–6946

Acknowledgments

This work was supported by funds provided by the U.S. Department of Agriculture, Cooperative State Research, Education, and Extension Service, Grant #2009-34432-20057.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

de Moura Bell, J.M.L.N., Maurer, D., Yao, L. et al. Characteristics of Oil and Skim in Enzyme-Assisted Aqueous Extraction of Soybeans. J Am Oil Chem Soc 90, 1079–1088 (2013). https://doi.org/10.1007/s11746-013-2248-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-013-2248-6