Abstract

Fresh-cut sweet potatoes are popular among consumers for their freshness and convenience. However, rapid browning and oxidative damage under stress significantly degrade their storage quality. This study aims to evaluate the effects of citric acid (CA) treatment on maintaining the quality of fresh-cut sweet potatoes during storage and to explore the underlying mechanisms. Fresh-cut sweet potatoes were immersed in 1% (w/v) CA for 10 min, with water treatment as the control (CK), and stored at 4 °C for 8 d. Physicochemical parameters were evaluated every 2 d. After 8 d of storage, CA-treated samples exhibited significantly lower total colony count (3.34 lg CFU g−1), soluble sugar content (1.52%), and lignin content (2.62 OD280 g−1) compared to the CK group (P < 0.05), and better maintained color values. Additionally, CA treatment inhibited the increase in browning-related enzyme activities (phenylalanine deaminase, polyphenol oxidase, peroxidase) and the accumulation of browning products (total phenolics, soluble quinones), resulting in a browning index 8.15% lower than the CK group at the end of storage. The CA-treated fresh-cut sweet potatoes also exhibited lower malondialdehyde content (0.58 µmol g−1) and lipoxygenase activity (3.19 U g−1), while showing higher activities of antioxidant enzymes such as catalase and ascorbate peroxidase, and enhanced free radical scavenging capacity, indicating that CA treatment helps mitigate cutting-induced oxidative stress. In conclusion, our findings highlight the significant potential of CA treatment in preserving the storage quality of fresh-cut sweet potatoes and provide new insights into its regulatory mechanisms.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sweet potato (Ipomoea batatas (L.) Lam) is recognized as one of the most crucial and versatile, yet underutilized, staple crops globally. It is extensively cultivated in tropical and subtropical regions across Asia, Africa, and Latin America [1]. In 2021, China alone produced 47 million tons of sweet potatoes, representing 53% of global production [2]. Beyond their caloric content, sweet potatoes are rich in protein, minerals, and bioactive compounds, such as phenolic compounds, carotenoids, polysaccharides, and phytosterols, which confer substantial health benefits [3]. Fresh-cut sweet potatoes are increasingly popular among consumers and food service establishments due to their convenience, high edible rate, and significant retention of nutritional value, marking a new market trend [4]. Studies have shown that fresh-cut processing can enhance the synthesis and accumulation of phenolic compounds in agricultural products, boosting their antioxidant capacity [5]. However, the mechanical stress from cutting accelerates surface browning, dehydration, texture changes (e.g., softening or hardening), and internal tissue degradation in sweet potato slices, potentially deterring consumer purchases [6].

Enzymatic browning is a critical factor limiting the edibility and commercial value of fresh-cut sweet potatoes [7]. Two primary perspectives exist regarding enzymatic browning. The predominant view is that mechanical cutting exposes internal plant tissues to oxygen, which activates the synergistic action of polyphenol oxidase (PPO) and peroxidase (POD) on endogenous phenolic compounds, leading to enzymatic oxidation [8,9,10]. Alternatively, some studies suggest that reactive oxygen species (ROS) play a significant role in browning. Under stress, ROS can accumulate excessively, causing oxidative damage to cell membranes and accelerating the browning reaction [11]. Wang et al. [12] found that tissue cell integrity and lipid peroxidation levels might explain browning differences among potato cultivars, as increased enzyme activity, soluble quinone, and malondialdehyde (MDA) content were linked to higher browning sensitivity. Enhanced antioxidant enzyme activity also improves free radical scavenging efficiency, thus increasing anti-browning capacity.

Citric acid (CA), a naturally occurring organic acid in fruits, is generally recognized as safe (GRAS) and has broad-spectrum antibacterial activity against foodborne pathogens such as Escherichia coli, Salmonella, and Staphylococcus aureus [13]. CA treatment can also inhibit enzymatic browning in various fresh-cut agricultural products, including water chestnuts [14], apples [15], persimmons [16], and melons [13]. CA is reported to be one of the most commercially viable anti-browning agents [15], maintaining the pH of fresh-cut products at levels unsuitable for PPO activity. Specifically, soaking fresh-cut sweet potatoes in a 2% sodium metabisulfite solution adjusted to pH 2.91 with CA significantly preserved their sensory attributes and extended shelf life [17]. Interestingly, Tsouvaltzis and Brecht found that while adjusting pH with sulfuric acid or sodium hydroxide reduced browning in fresh-cut potatoes, it did not replicate CA's anti-browning effect [18], indicating that CA's efficacy involves more than just acidification.We hypothesize that CA treatment delays browning in fresh-cut products not only by inhibiting enzymatic browning but also by regulating antioxidant capacity and lipid peroxidation. Additionally, the effectiveness of CA treatment is closely related to its concentration and the type of product. Chen et al. [19] found that 0.5% CA treatment promoted browning in fresh-cut apples. Ansorena et al. [20] reported that the CA concentration significantly affected browning in broccoli, with browning decreasing up to a critical CA concentration, beyond which it worsened. Similar findings were observed in fresh-cut potatoes [21], where high CA concentrations affected color quality during storage. Thus, optimizing CA treatment strategies for different fresh-cut products is necessary.

Currently, limited research exists on the regulation of storage quality of fresh-cut sweet potatoes by CA treatment, particularly regarding the combined analysis of lipid metabolism, antioxidant metabolism, and oxidative browning. This study aims to determine the optimal CA concentration as an anti-browning agent for fresh-cut sweet potatoes and measure physiological parameters related to lipid and antioxidant metabolism during storage to explore potential physiological mechanisms of browning delay. Additionally, microbial growth and physiological indicators were analyzed to evaluate the safety and product quality effects of CA treatment. This study aims to provide technical insights into extending the shelf life of fresh-cut sweet potatoes and underscore CA's reliability and potential value in the food processing industry.

Materials and methods

Plant materials

Sweet potatoes (Ipomoea batatas (L.) Lam cv Liankaoshu No.1) were sourced from the Dalian Special Crops Research Institute in Pulandian District, Dalian City. Upon acquisition, the sweet potatoes were promptly transported to the laboratory and stored in a constant temperature chamber maintained at 15 °C to facilitate subsequent experiments. Selection criteria for the sweet potato storage roots designated for fresh-cut processing included uniform size (250–300 g), freedom from disease, and absence of physical damage.

CA treatment

In the preliminary experiments, CA concentrations of 0.05, 0.1, and 0.2% (w/v) were selected for investigation. Based on the experimental findings (Fig. 1), the optimal concentration was determined to be 0.1%. Throughout the experiment, stringent sanitation practices were followed, including disinfecting the peeler, slicer, and cutting board with 75% (v/v) alcohol before use. The selected sweet potato storage roots underwent a sequential treatment process: initial rinsing with tap water for 2 min, followed by immersion in a 0.2% (v/v) sodium hypochlorite solution for 5 min, subsequent peeling, and slicing into 5 mm thick sections. The slices were then soaked in deionized water for 5 min to remove excess starch, after which they were randomly allocated into two groups: one group was immersed in deionized water (Control group, CK), while the other group was soaked in a 0.1% CA solution for 10 min. Post-treatment, the slices were air-dried at room temperature (25 °C), placed into nylon (PA) + polyethylene (PE) vacuum bags (each containing 3 slices), and vacuum-sealed (vacuum time: 30 s; sealing time: 2 s; cooling time: 3 s). The packaged slices were then stored at 4 ± 0.5 °C with 80–85% relative humidity (RH) for a duration of 8 d, during which sensory quality evaluations and assessments of quality parameters were conducted every other day. Simultaneously, equivalent quantities of samples were promptly frozen in liquid nitrogen, ground into powder using a grinder (M20, IKA, Germany), and stored at − 80 °C for subsequent experimental analyses. All measurements were performed with three biological replicates to ensure statistical robustness.

Appearance and color evaluation

At each specified sampling interval, visual observations of the sweet potato slices were recorded through photography. Subsequently, a colorimeter (CR-400, Japan) was used to measure the L* (lightness), a* (red-green), and b* (yellow-blue) values of the freshly cut sweet potatoes. Three predetermined points on the surface of each slice were selected for measurement, with nine measurements taken for each sample. The browning index (BI) and whiteness index (WI) were calculated according to the method described by Jiang et al. [22], using the following formulas:

Total bacterial counts

The determination of the total viable count was performed following a modified method by Wang et al. [10]. First, 25 g of sweet potato samples were picked up with sterile tweezers, weighed, and placed into a sterile homogenization bag. Then, 225 mL of sterile water was added to the bag. The mixture was homogenized using a homogenizer (SCIENTZ-09, China). After homogenization, 15–20 mL of plate count agar was added to each petri dish. Before the agar solidified, the sample was poured onto the agar surface and thoroughly mixed. Once the agar had solidified, the petri dishes were inverted and incubated at 36 °C for 48 h. Subsequently, 2–3 appropriate dilution gradients were selected for calculation. The results were expressed as log CFU g−1.

Starch and soluble sugar content

The starch and soluble sugars content were assessed following the methodology outlined by Sun et al. [23] with minor adaptations. Briefly, 2 g of frozen powder were homogenized with 6 mL of 80% (v/v) ethanol and incubated at 80 °C in a water bath for 30 min. After cooling, the mixture underwent centrifugation, and the supernatant was collected. This procedure was repeated twice. Subsequently, the supernatant was treated with boiling water for 2 h, and after cooling, the volume was adjusted to 50 mL with distilled water. The quantification of soluble sugar content was conducted using the anthrone method, and absorbance was measured at 630 nm with a UV–Visible spectrophotometer (UV-2600, Shimadzu, Japan).

The resultant precipitate was dispersed in 3 mL of distilled water and incubated in a boiling water bath for 15 min. Subsequently, 2 mL of 9.2 mol L−1 cold perchloric acid was meticulously added and mixed, followed by the addition of 3 mL of distilled water prior to centrifugation. The resulting supernatant was collected and then diluted to 50 mL with distilled water. The determination of starch content was carried out using the 3,5-dinitrosalicylic acid method, and absorbance was measured at 540 nm using a glucose-based standard curve.

MDA content and lipoxygenase (LOX) activity

To determine MDA content, we adopted the improved method outlined by Xu et al. [24]. A total of 1 g of sample powder was combined with 5 mL of 100 g L−1 trichloroacetic acid solution. Following grinding into a slurry, the mixture was centrifuged at 4 °C and 10,000 × g for 20 min. Subsequently, 2 mL of the supernatant was mixed with 2 mL of 0.67% (w/v) thiobarbituric acid and incubated in a boiling water bath for 20 min. After cooling, the mixture was centrifuged again. The absorbance values of the resulting supernatant at wavelengths of 450 nm, 532 nm, and 600 nm were measured, and the data were expressed as μmol g−1 fresh weight.

LOX activity was determined according to the protocol described by Zhou et al. [25]. Initially, 1 g of frozen powder was homogenized in 5 mL of 0.1 mol L−1 phosphate-buffered saline (PBS, pH 6.8) containing 1% (v/v) Triton X-100 and 4% (w/v) polyvinylpyrrolidone (PVPP). The resultant supernatant obtained after centrifugation was collected. Subsequently, 100 μL of linoleic acid solution (comprising 0.25% (v/v) Tween-20 and 0.5% (v/v) NaOH) was added to 2.7 mL of 0.1 mol L−1 PBS, followed by incubation at 30 °C for 10 min. Thereafter, 0.2 mL of the supernatant was introduced to the mixture. The reaction mixture without enzyme extract was used as a control. The absorbance of the samples was measured at 234 nm. One unit of LOX enzyme activity (U g−1) was defined as an absorbance change of 1 per minute.

Lignin, total phenol, and soluble quinone content

To determine the lignin content, we adapted the method proposed by Xie et al. [26] with minor modifications. Initially, 1 g of sweet potato tissue powder was homogenized in 5 mL of pre-cooled 95% (v/v) ethanol, followed by centrifugation at 4 °C and 14,000 × g for 10 min. The resultant precipitate was subjected to three washes with 95% (v/v) cold ethanol and ethanol-hexane and subsequently air-dried for 24 h. The dried precipitate was then incubated with 1 mL of bromoacetic acid-acetic acid solution (25%, v/v) at 70 °C for 30 min. Sequential addition of 1 mL of 2 mol L−1 NaOH solution, 2 mL of acetic acid, and 0.1 mL of 7.5 mol L−1 hydroxylamine hydrochloride followed. After centrifugation, 0.5 mL of the supernatant was withdrawn and diluted to 5 mL. The lignin content was expressed as the change in absorbance at 280 nm per gram of sample.

The determination of total phenols and soluble quinone content was carried out following the method described by Wang et al. [12], with slight adjustments. Initially, 1 g of frozen powder was homogenized in 5 mL of 70% (v/v) methanol, followed by extraction at 55 °C for 1 h in an 80 W ultrasonic bath. Subsequent centrifugation was performed at 8000 × g for 15 min. For the total phenols assay, 0.5 mL of crude extract was combined with 2.5 mL of Folin-Ciocalteu reagent and 7.5% (w/v) Na2CO3. Following incubation in darkness at room temperature for 2 h, the absorbance of the reaction mixture was measured at 760 nm, and the total phenol content was determined using a gallic acid standard curve, expressed as mg 100 g−1 fresh weight.

For the determination of soluble quinone content, 1 g of sample powder was homogenized in 5 mL of methanol, followed by centrifugation at 10,000 × g for 20 min at 4 °C. The absorbance of the supernatant at 437 nm was recorded. The result was expressed as OD437 nm per gram of fresh weight.

Phenylalanine deaminase (PAL), PPO, and POD activity

To quantify PAL activity, we followed the protocol outlined by Pan et al. [27]. Initially, 1 g of sweet potato tissue was homogenized in 5 mL of 1 mol L−1 borate buffer (pH 8.8) supplemented with 40 g L−1 PVPP, 2 mmol L−1 ethylenediaminetetraacetic acid (EDTA), and 5 mmol L−1 β-mercaptoethanol. Following centrifugation at 4 °C, the supernatant was collected as the crude enzyme extract. Subsequently, 0.5 mL of the enzyme solution was mixed with 3 mL of borate buffer and 0.5 mL of 20 mmol L−1 phenylalanine solution and incubated at 37 °C for 1 h. The change in absorbance at 290 nm was determined. One unit of PAL activity (U g−1) was defined as an increase in absorbance of 1 per hour.

The determination of PPO activity followed the methodology described by Zhou et al. [28]. Initially, 1 g of frozen sweet potato powder was homogenized in 100 mL of acetate-sodium acetate buffer (pH 6.4) containing 1 mmol L−1 polyethylene glycol 6000, 4% (w/v) PVPP, and 1% (v/v) Triton X-100. Following centrifugation at 4 °C for 20 min, the supernatant was collected. The reaction system consisted of 0.6 mL of 50 mmol L−1 catechol, 2.4 mL of 50 mmol L−1 sodium acetate buffer, and 100 μL of supernatant. The change in absorbance at 420 nm was measured. One PPO activity unit (U g−1) was defined as an increase in absorbance of 1 per minute.

POD activity was assessed using the guaiacol method [29]. The reaction mixture comprised 0.1 mL of enzyme extract, 1 mL of PBS (0.1 mol L−1, pH 7.8), 0.9 mL of 0.2% (v/v) guaiacol, and 1 mL of 0.3% (v/v) H2O2. An increase in absorbance of the reaction system of 1 per minute at 470 nm was defined as 1 unit of POD activity (U g−1).

Catalase (CAT), ascorbate peroxidase (APX), and superoxide dismutase (SOD) activity

In accordance with the improved method devised by Gu et al. [30], we conducted assessments of CAT, APX, and SOD activities. Initially, frozen sweet potato powder was homogenized in 5 mL of PBS (0.1 mol L−1, pH 7.8) supplemented with 0.5% (w/v) PVPP and subjected to centrifugation at 4 °C for 20 min at 10,000 × g. The resulting supernatant was utilized for CAT activity analysis. For APX, 1 g of frozen sweet potato powder was extracted with 5 mL of potassium phosphate buffer (50 mmol L−1, pH 7.5) containing 0.1 mmol L−1 EDTA, 1 mmol L−1 ascorbic acid (AsA), and 2% (w/v) PVPP. Meanwhile, in the SOD assay, sweet potato samples (1 g) were extracted with 5 mL of 0.1 mol L−1 PBS (pH 7.8) containing 5 mmol L−1 DTT and 5% (w/v) PVPP. The resulting mixture underwent centrifugation at 4 °C for 20 min at 10,000 × g, and the crude extracts were utilized for APX and SOD activity analysis.

The CAT reaction compound consisted of 0.1 mL supernatant, 0.9 mL 0.3% (v/v) H2O2, and 2 mL of 0.1 mol L−1 PBS (pH 7.8). The APX reaction mixture consisted of 0.1 mL of enzyme extract, 0.3 mL of 2 mmol L−1 H2O2, and 2.6 mL of 50 mmol L−1 PBS (pH 7.5, containing 0.1 mmol L−1 EDTA and 0.5 mmol L−1 AsA). Activity units for CAT and APX were defined as a decrease of 1 in absorbance change per minute at 240 nm and 290 nm, respectively.

For SOD activity determination, 0.1 mL of supernatant was added to a mixture of 2.9 mL of 50 mmol L−1 PBS (pH 7) containing 13 mmol L−1 L-cysteine, 0.75 mmol L−1 nitroblue tetrazolium (NBT), 1 μmol L−1 EDTA-Na2, and 1 μmol L−1 riboflavin. SOD activity was assessed by measuring the absorbance of the reaction mixture at 560 nm. One unit of SOD activity (U g−1) was defined as the amount of enzyme necessary to inhibit 50% of the photochemical reduction of NBT per minute.

DPPH and ABTS radical scavenging capacity

The free radical scavenging capacity of the sweet potato samples was assessed using a modified method reported by Hua et al. [31]. First, 1 g of powdered sample was placed in a centrifuge tube containing 5 mL of ethanol solution. The mixture was then centrifuged at 10,000 × g for 20 min at 4 °C. The resulting supernatant was collected for subsequent experiments.

For the DPPH radical scavenging activity assay, the supernatant was combined with DPPH in a 1:1 ratio, vigorously shaken for 30 s, and then incubated at 20 °C for 30 min. Subsequently, the absorbance was measured at 517 nm.

For the ABTS radical scavenging activity assay, 20 μL of the supernatant was mixed with 80 μL of working solution. The resultant mixture was shaken for 15 s and then incubated at 20 °C for 6 min. The absorbance was measured at 734 nm. Results for both DPPH and ABTS were expressed as percentage inhibition.

Statistical analysis

Statistical analysis was performed using SPSS 24.0 software (SPSS Inc.). All experiments were conducted in triplicate. Data are presented as the mean ± standard error of three replicates. An independent sample T-test was conducted to compare the data between the CK and CA groups at the same storage time. Asterisks (*) denote significant differences (P < 0.05).

Results

Effects of CA treatment on appearance, L* value, a* value, BI and WI

Visual appearance constitutes one of the pivotal sensory attributes influencing the acceptability of fresh-cut sweet potatoes. Figure 1 delineates the comprehensive impact of various concentrations of CA treatment on the visual appearance of sweet potato slices stored at 4 °C for 8 d. By the 4th day of storage, a notable increase in browning incidence was observed in the CK samples, whereas sweet potato samples treated with 0.5% CA exhibited slight browning. Notably, both 0.1% and 0.2% CA treatment groups effectively delayed the escalation in browning incidence of sweet potato slices over the storage period. Consequently, the 0.1% concentration was identified as the most suitable for subsequent experiments.

To further quantitatively assess the disparities in appearance quality between CA and CK groups, Fig. 2 elucidates the color attributes (L* value, a* value, BI, and WI) of sweet potato slices. As depicted in Fig. 2a, on the second day of storage, the L* value of the CK group commenced a rapid decline, while the CA group's L* value consistently remained higher throughout the storage period. Following 8 d of storage, the reduction in L* value in the CK group was 2.36 times greater than that in the CA group.

In contrast to the alterations in L* value, the a* value exhibited a continual decrease with prolonged storage time (Fig. 2b). Relative to the CK group, the CA group manifested a slower rate of increase in a* value, with the CK group's a* value being 40.36% lower than that of the CA group after 8 d of storage.

BI indicates the degree of browning, with higher BI values representing more severe browning in sweet potato slices. Throughout the storage period, the overall BI of both groups exhibited a relatively steady upward trend (Fig. 2c). Notably, the BI of fresh-cut sweet potatoes treated with CA increased at a slower rate, becoming significantly lower than that of the CK group starting from the 6th day of storage (P < 0.05). By the end of the storage period, the BI of the CA group and the CK group increased by 5.5% and 15.2%, respectively, compared to their initial values.

Throughout the storage period, the WI of sweet potato slices in the CA group displayed a fluctuating trend, whereas the WI of the CK group showed an initial increase within the first 6 d, peaking at 66.32, followed by a rapid decline (Fig. 2d). This decline can be attributed to the accelerated browning observed in the CK samples during the later stages of storage. Ultimately, at the conclusion of the storage period, the WI of CK slices was significantly lower compared to that of the CA group (P < 0.05).

Effects of CA treatment on the total bacterial counts

During the storage period of sweet potatoes, there was a notable escalation in the total bacterial counts, as depicted in Fig. 3. Nevertheless, the application of CA exhibited a mitigating effect on this increase, as the total bacterial count of the CK group samples was markedly higher than that of the CA group starting from the 4th day of storage (P < 0.05). By the end of the storage period, the total bacterial counts of the CK group and the CA group were observed to be 3.35 times and 2.58 times, respectively, compared to their initial values.

Effects of CA treatment on starch and soluble sugar content

As illustrated in Fig. 4a, both the CK and CA groups exhibited a declining trend in starch content; however, fresh-cut sweet potatoes treated with CA maintained a higher starch content by the conclusion of the experiment.

Furthermore, the overall level of soluble sugars displayed an increasing trend, as depicted in Fig. 4b. Starting from the 6th day of storage, the soluble sugar content in the CK group exhibited a notable surge, significantly surpassing that of the CA group (P < 0.05). By the end of the storage period, the soluble sugar content in the CK group was observed to be 1.84 times that of the CA group.

Effects of CA treatment on MDA content and LOX acticity

The MDA content of the samples exhibited a notable surge followed by a decline during storage, reaching its peak on the second day of storage (Fig. 5a). Notably, apart from the 6th day, the MDA levels in the CA group were consistently higher than those in the CK group (P < 0.05).

As depicted in Fig. 5b, over the 8 d storage period, LOX activity displayed an ascending trend across all groups. Significant disparities between the CK group and the CA group were evident from the 4th day onwards (P < 0.05). By the end of storage, the LOX activity in the CA group and the CK group had escalated by 156.92% and 110.11%, respectively, relative to their initial values.

Effects of CA treatment on lignin, total phenol and soluble quinone content

Throughout the entire storage period, both the CK and CA groups exhibited an increasing trend in lignin content, with the CK group displaying higher levels except on the 4th day (Fig. 6a). By the end of refrigeration, the lignin content in samples treated with 0.1% CA amounted to only 70.23% of that in the CK group, indicating the efficacy of CA treatment in delaying the lignification of sweet potato slices.

The total phenolic content of fresh-cut sweet potatoes demonstrated a fluctuating pattern during refrigeration. Specifically, the total phenolic content in the CK group exhibited an initial increase followed by a decline, while that in the CA group initially increased, followed by a decrease before stabilizing (Fig. 6b). With the exception of the 4th day of storage, the total phenolic content in CK samples significantly exceeded that in CA sweet potato slices (P < 0.05). By the end of storage, the total phenolic content in the CK group surpassed that in the CA group by 0.80 mg 100 g−1.

Additionally, as illustrated in Fig. 6c, soluble quinone levels showcased initial fluctuations followed by a steady rise during storage. Starting from the 6th day, the soluble quinone content in the CK group significantly outstripped that in the CA group (P < 0.05). Ultimately, at the conclusion of refrigeration, the soluble quinone content in the CK group was 1.34 times higher than that in the CA group.

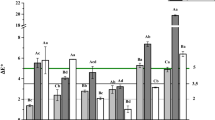

Effects of CA treatment on PAL, PPO and POD activity

Throughout storage, both the CK and CA samples demonstrated elevated PAL activity (Fig. 7a). After 8 d of refrigeration, PAL activity in both the CK and CA groups escalated by 7.52 and 5.28 times, respectively, relative to the initial levels.

Regarding changes in PPO activity (Fig. 7b), notable increases were discernible in the CK group from day 4 onwards, while the CA group exhibited a fluctuating pattern. By the conclusion of refrigeration, the PPO activity in sweet potato slices treated with CA amounted to only 5.83% of that in the CK group.

In the assessment of POD activity, a similar trend to PPO was evident during the 8 d storage period (Fig. 7c). The POD activity of both groups steadily rose during the initial 6 d, followed by a pronounced surge in the CK group towards the end, reaching 1.68 times that of the CA samples.

Effects of CA treatment on CAT, APX and SOD activity

CAT activity in all sample groups exhibited a single peak on the second day of storage, with the CA group maintaining higher activity except on the 4th day (Fig. 8a). By the conclusion of refrigeration, CAT activity in the CK and CA groups increased by 17.96% and 37.86%, respectively, relative to the initial values.

CA treatment notably elicited the activity of APX in fresh-cut sweet potatoes (Fig. 8b). Specifically, the APX activity in the CK group displayed a notable downward trend, while CA samples showcased an initial surge in the first 6 d of storage, reaching a peak of 1.40 U g−1, followed by a rapid decline, concluding the storage period 24.74% higher than the CK group.

Throughout storage, the SOD activity in sweet potato slices of each group exhibited some fluctuations, depicting an overall pattern of oscillation with an initial increase, a decrease, and then a subsequent rise again (Fig. 8c). It is noteworthy that the CA group delayed the descent in SOD activity peak compared to the CK group. On the 8th day of storage, no significant difference in SOD activity was observed between the CK and CA groups (P > 0.05).

Effects of CA treatment on DPPH and ABTS

In this study, except for the eighth day in the CA group, the DPPH levels showed a trend of initially increasing and then decreasing during the storage period, reaching peaks on the second and fourth days, respectively (Fig. 9a). Specifically, the peak in the CA group was 19.2%, which was 34% higher than that in the CK group.

In the detection of ABTS, both groups followed a similar trajectory of change (Fig. 9b). They increased during the initial storage period and then decreased after reaching the peak. Conversely, CA treatment effectively delayed the appearance of its peak and maintained a higher scavenging ability during the late storage period.

Correlation analysis

In this experiment, the Pearson coefficient was employed to assess the correlation among various parameters. As depicted in Fig. 10, the BI of both sets of fresh-cut sweet potatoes exhibited significant positive correlations with soluble quinone content, LOX, PAL, and POD activities (P < 0.05), alongside significant negative correlations with starch content (P < 0.05). Notably, the total colony count exhibited a significant positive correlation with LOX activity (P < 0.05), suggesting that the augmentation in membrane peroxidation degree serves as a pivotal factor fostering microbial proliferation. Furthermore, CAT displayed positive correlations with APX, DPPH, and ABTS in the CK group, while exhibiting a negative correlation with SOD activity. In contrast, in the CA group, there was a positive correlation between CAT activity and all four parameters.

Discussion

CA, recognized as a safe organic acid, is widely used in the food industry as a food additive and anti-browning agent for fresh-cut fruits and vegetables [32]. Previous studies have highlighted CA's effectiveness in inhibiting microbial growth, reducing postharvest respiration rates, and mitigating browning and related diseases in horticultural crops postharvest [33]. Mechanical damage to fresh-cut agricultural products triggers various physiological changes, such as moisture loss, accelerated browning, increased membrane peroxidation, and disrupted ROS metabolism, all contributing to deteriorated appearance quality and reduced storage life. However, our study reveals that treating fresh-cut sweet potatoes with 0.1% CA for 10 min can mitigate these negative effects. CA treatment slows the increase in total colony count, reduces lignin accumulation, and inhibits starch degradation, thereby preserving better edible quality. Furthermore, CA treatment effectively suppresses browning incidence, lowers MDA content, and diminishes LOX activity. Additionally, compared to water immersion, CA treatment induces alterations in the antioxidant system, thereby extending the storage life of sweet potato slices. These findings underscore the potential of CA as a valuable tool in maintaining the quality and extending the shelf life of fresh-cut sweet potatoes.

Surface color, total colony count, starch, and lignin content are crucial quality parameters influencing the consumer acceptance of fresh-cut sweet potatoes. Minor changes in surface color during storage can be attributed to the accumulation of certain plant chemicals like phenolics and carotenoids. However, excessive discoloration typically indicates oxidative deterioration, negatively impacting product quality and market acceptability [34]. The L* value serves as a primary indicator of surface browning in stored sweet potatoes, with its decrease correlating with an increase in BI, often involving cell rupture due to cutting [27]. Mechanical stress induces cell deformation, leading to plant cell wall extension and eventual rupture [35]. Additionally, decreased antibacterial activity in fresh-cut products increases susceptibility to pathogen invasion [36].

This study reveals that CA significantly delays oxidative browning of sweet potato slices during storage, exhibiting noticeable differences in brightness from the second day compared to the CK group. This effect may be attributed to the chelating and colloidal properties of CA [37], consistent with findings in other fresh-cut produce such as mangoes [38] and papayas [39]. Interestingly, CA treatment impedes the increasing trend of total colony count post-cutting, similar to observations in studies on peaches, where a 10 g L−1 CA treatment inhibited postharvest decay, thereby extending shelf life [40]. Starch is the main source of carbohydrates in sweet potato slices and responds to environmental signals, such as storage temperature, to interconvert starch and sugar during the storage period, regulating their accumulation levels [25]. CA immersion significantly retards starch degradation and the accumulation of soluble sugars in sweet potato slices while inhibiting lignification by maintaining lower lignin content. Previous research has suggested that high starch levels may enhance stress tolerance and antioxidant capacity in hardy kiwifruit [41], a concept potentially applicable to fresh-cut sweet potatoes based on our experimental results. These findings underscore the efficacy of CA treatment in preserving quality and extending the shelf life of fresh-cut sweet potatoes.

Phenolic substrates, browning-related enzymes, and oxygen are recognized as essential components for enzymatic browning to occur. Key enzymes involved in this process include PAL, PPO, and POD, which catalyze the conversion of phenylalanine into phenolic compounds and their subsequent oxidation to form soluble quinones [12]. Our study found a positive correlation between BI and the activity of the oxidative enzyme system, as well as soluble quinone content, supporting the role of these enzymes in the oxidative browning reaction and the beneficial effect of CA treatment in slowing down this process. It's noteworthy that POD can serve both as an excess ROS scavenger and as a catalyst for enzymatic browning [36]. Although there was no significant difference in POD activity between the two groups in the initial 6 d, the sharp increase in POD activity in the CK group towards the end of storage exacerbated browning. This suggests that in fresh-cut sweet potatoes, POD may primarily drive the oxidative browning reaction, with a minor contribution from the antioxidant enzyme system [1].

Phenolic compounds not only contribute to browning but also enhance plant antioxidant capacity by slowing down chain oxidation reactions and inhibiting lipid peroxidation [34, 42]. Our study observed a trend of initial decrease followed by an increase in total phenolic content. The initial decrease may be attributed to their continuous consumption as substrates, while the subsequent increase could result from stimulated phenolic compound synthesis due to elevated PAL activity, aimed at tissue repair [43]. Interestingly, in the CK group, total phenolic content positively correlated with soluble quinones, PAL, PPO, and POD activity, while in the CA group, it showed negative correlations. This suggests that CA modulated the physiological metabolism of fresh-cut sweet potatoes, primarily by regulating substrate concentration to slow down the browning process.

Under normal conditions, agricultural products maintain a delicate balance between the removal and production of ROS [44]. However, mechanical damage incurred during fresh-cut processing disrupts cell membrane integrity, a key factor in the occurrence of browning. This damage triggers an abnormal increase in ROS levels, leading to membrane lipid peroxidation. This peroxidation, in turn, allows browning-related enzymes to come into contact with phenolic compounds, exacerbating the browning process [45]. The chain reactions of membrane lipid peroxidation are initiated by ROS or lipid-oxidizing enzymes like LOX, which catalyze the oxidation of polyunsaturated fatty acids [1].

Hydrogen peroxide and superoxide anion (O2−.), as primary forms of ROS, can regulate various physiological metabolic processes at low concentrations [24] but can cause lipid peroxidation at excessive levels [46]. MDA, the main product of membrane lipid peroxidation, is a commonly used indicator to assess the degree of membrane damage [47]. Studies have linked high LOX activity, associated with ROS, to browning in longan fruit peel [48]. In our study, while we didn't measure the content of ROS-related substances, we observed that CA treatment significantly inhibited MDA levels and LOX activity in sweet potatoes. This suggests that CA treatment may help preserve cell membrane function, alleviate oxidative damage caused by injury stress, and ultimately maintain the physiological quality of sweet potato slices. These findings are consistent with research by Bata Gouda et al. [37], which demonstrated that CA composite coatings inhibited MDA accumulation and limited oxidative stress in fresh-cut lotus root slices.

Organisms possess enzymatic antioxidant defense systems that function to maintain cellular homeostasis and eliminate excess ROS, thereby mitigating the negative effects of oxidative stress [49]. SOD, POD, CAT, and APX are key antioxidant enzymes in this defense system. SOD acts as the first line of defense, converting O2−. into H2O2, which is further detoxified to water by the coordinated action of POD, CAT, and APX [50]. Previous studies have demonstrated that CA can enhance the activity of SOD, POD, and CAT, effectively clearing the accumulation of ROS in pear fruits [51]. Our experimental findings support this, as CA treatment significantly induced the activity of CAT and APX in fresh-cut sweet potatoes. Additionally, in the CK group, the activities of CAT and APX were positively correlated with the scavenging ability of DPPH and ABTS radicals. In the CA group, CAT was positively correlated with DPPH and ABTS radicals, while APX showed a significant positive correlation with ABTS radical scavenging ability. This indicates a close relationship between antioxidant enzyme activity and the presence of free radical scavengers.

It is noteworthy that high levels of antioxidant activity and their synergistic effects have been reported to delay lipid peroxidation and aging processes in some horticultural crops [52]. This aligns with the findings of Xu et al. [53], who observed that 1-Methylcyclopropylene promotes antioxidant metabolism in kiwifruit, inhibiting membrane oxidation damage and fruit softening. Considering that CA, as a component of the tricarboxylic acid cycle, is continuously consumed during storage, exogenous CA may inhibit oxidative stress in fresh-cut agricultural products through continuous ATP signal transduction [40]. Based on these results, we can infer that the maintenance of storage quality of fresh-cut sweet potatoes by CA treatment may be attributed to the increased activity of antioxidant enzymes, thereby enhancing their antioxidant capacity.

Conclusions

In this study, 1% (w/v) CA soaking treatment effectively delayed the browning process of fresh-cut sweet potatoes by reducing oxidative stress and lipid peroxidation under injury stress, thus maintaining their visual appeal. Specifically, these beneficial effects are likely attributed to the induction of antioxidant enzyme activities and free radical scavenging capacity, as well as the reduction of browning-related enzyme activities and substrate levels. Moreover, CA treatment also reduced microbial growth, lignification, and starch degradation, thereby preserving the commercial value of the fresh-cut sweet potatoes. In summary, these findings highlight the potential of CA treatment in maintaining the storage quality of fresh-cut sweet potatoes, particularly in delaying enzymatic browning. Future research should further explore the molecular regulatory mechanisms of CA treatment on fresh-cut sweet potatoes and optimize treatment methods in combination with other preservation techniques to achieve better application effects. Additionally, the application of CA treatment should be expanded to the preservation of other fresh-cut products.

Data availability

The data that has been used is confdential.

References

Y. Li, L. Zhang, L. Zhang, G. Nawaz, C.X. Zhao, J. Zhang, Q.H. Cao, T.T. Dong, T. Xu, Exogenous melatonin alleviates browning of fresh-cut sweetpotato by enhancing anti-oxidative process. Sci. Hortic. 297, 110937 (2022). https://doi.org/10.1016/j.scienta.2022.110937

FAOSTAT. Statistics division of food and agriculture organization of the United Nations. (2022). http://www.fao.org/faostat/en/#data

T.M.R. de Albuquerque, K.B. Sampaio, E.L. de Souza, Sweet potato roots: unrevealing an old food as a source of health promoting bioactive compounds—a review. Trends. Food Sci. Tech. 85, 277–286 (2019). https://doi.org/10.1016/j.tifs.2018.11.006

X.J. Li, Y.Q. Jiang, Y. Liu, L. Li, F.H. Liang, X.D. Wang, D.D. Li, N. Pan, X.H. Li, X.Z. Yang, T. Yao, Effects of short-term high oxygen pre-stimulation on browning resistance and low-temperature tolerance of fresh-cut potatoes in supercooled storage. Food Bioprocess Technol. 17(3), 709–721 (2024). https://doi.org/10.1007/s11947-023-03157-3

W.Z. Hu, Y.G. Guan, Y.R. Ji, X.Z. Yang, Effect of cutting styles on quality, antioxidant activity, membrane lipid peroxidation, and browning in fresh-cut potatoes. Food Biosci. 44, 101435 (2021). https://doi.org/10.1016/j.fbio.2021.101435

B. Wen, D. Li, D. Tang, Z. Huang, P. Kedbanglai, Z.B. Ge, X.F. Du, S. Supapvanich, Effects of simultaneous ultrasonic and cysteine treatment on antibrowning and physicochemical quality of fresh-cut lotus roots during cold storage. Postharvest Biol. Tec. 168, 111294 (2020). https://doi.org/10.1016/j.postharvbio.2020.111294

N. Fukuoka, M. Miyata, T. Hamada, E. Takeshita, Histochemical observations and gene expression changes related to internal browning in tuberous roots of sweet potato (Ipomea batatas). Plant Sci. 274, 476–484 (2018). https://doi.org/10.1016/j.plantsci.2018.07.004

R.F. Dibanda, E.P. Akdowa, Q.M. Tongwa, Effect of microwave blanching on antioxidant activity, phenolic compounds and browning behaviour of some fruit peelings. Food Chem. 302, 125308 (2020). https://doi.org/10.1016/j.foodchem.2019.125308

X.Y. Ru, N. Tao, Y.Y. Feng, Q.Q. Li, Q.G. Wang, A novel anti-browning agent 3-mercapto-2-butanol for inhibition of fresh-cut potato browning. Postharvest Biol. Tec. 170, 111324 (2020). https://doi.org/10.1016/j.postharvbio.2020.111324

D. Wang, L.K. Chen, Y. Ma, M. Zhang, Y.W. Zhao, X.Y. Zhao, Effect of UV-C treatment on the quality of fresh-cut lotus (Nelumbo nucifera Gaertn.) root. Food Chem. 278, 659–664 (2019). https://doi.org/10.1016/j.foodchem.2018.11.102

T.T. Bai, J.X. Li, A. Murtaza, A. Iqbal, L.J. Zhu, J. Zhang, B. Zhang, X.Y. Xu, S.Y. Pan, W.F. Hu, Scavenging of ROS after eugenol treatment as mechanism of slowing down membrane lipid metabolism to maintain the surface color of fresh-cut yam. Food Bioprocess Tech. 15(8), 1821–1835 (2022). https://doi.org/10.1007/s11947-022-02833-0

T.T. Wang, T. Yan, J.K. Shi, Y.M. Sun, Q.G. Wang, Q.Q. Li, The stability of cell structure and antioxidant enzymes are essential for fresh-cut potato browning. Food Res. Int. 164, 112449 (2023). https://doi.org/10.1016/j.foodres.2022.112449

H. Song, A.R. Jang, S. Lee, S.Y. Lee, Application of sodium alginate-based edible coating with citric acid to improve the safety and quality of fresh-cut melon (Cucumis melo L.) during cold storage. Food Sci. Biotechnol. 33, 1741–1750 (2024). https://doi.org/10.1007/s10068-023-01475-y

Y.M. Jiang, L.T. Pen, J.R. Li, Use of citric acid for shelf life and quality maintenance of fresh-cut Chinese water chestnut. J. Food Eng. 63(3), 325–328 (2004). https://doi.org/10.1016/j.jfoodeng.2003.08.004

S.N. Marghmaleki, S.M.H. Mortazavi, H. Saei, A. Mostaan, The effect of alginate-based edible coating enriched with citric acid and ascorbic acid on texture, appearance and eating quality of apple fresh-cut. Int. J. Fruit Sci. 1(21), 40–51 (2020). https://doi.org/10.1080/15538362.2020.1856018

G. Sortino, A. Allegra, A. Gallotta, F. Saletta, R. Passafume, R. Gaglio, P. Inglese, V. Farina, Efects of combinational use of controlled atmosphere, cold storage and edible coating applications on shelf life and quality attributes of fresh-cut persimmon fruit. Chem. Biol. Technol. Ag. 9, 60 (2022). https://doi.org/10.1186/s40538-022-00324-0

S.C. Sgroppo, L.E. Vergara, M.D. Tenev, Effects of sodium metabisulphite and citric acid on the shelf life of fresh cut sweet potatoes. Span. J. Agric. Res. 8(3), 686–693 (2010). https://doi.org/10.5424/sjar/2010083-1266

P. Tsouvaltzis, J.K. Brecht, Inhibition of enzymatic browning of fresh-cut potato by immersion in citric acid is not solely due to pH peduction of the solution. J. Food Process. Pres. 41(2), e12829 (2017). https://doi.org/10.1111/jfpp.12829

C. Chen, W.Z. Hu, Y.B. He, A.L. Jiang, R.D. Zhang, Effect of citric acid combined with UV-C on the quality of fresh-cut apples. Postharvest Biol. Tec. 111, 126–131 (2016). https://doi.org/10.1016/j.postharvbio.2015.08.005

M.R. Ansorena, M.R. Moreira, S.I. Roura, Combined effect of ultrasound, mild heat shock and citric acid to retain greenness, nutritional and microbiological quality of minimally processed broccoli (Brassica oleracea L.): an optimization study. Postharvest Biol. Tec. 94, 1–13 (2014). https://doi.org/10.1016/j.postharvbio.2014.02.017

P. Rocculi, F.G. Galindo, F. Mendoza, L. Wadsö, S. Romani, M.D. Rosa, I. Sjöholm, Effects of the application of anti-browning substances on the metabolic activity and sugar composition of fresh-cut potatoes. Postharvest Biol. Tec. 43(1), 151–157 (2007). https://doi.org/10.1016/j.postharvbio.2006.08.002

T.J. Jiang, Effect of alginate coating on physicochemical and sensory qualities of button mushrooms (Agaricus bisporus) under a high oxygen modified atmosphere. Postharvest Biol. Technol. 76, 91–97 (2013). https://doi.org/10.1016/j.postharvbio.2012.09.005

Y.J. Sun, Z.D. Shi, Y.P. Jiang, X.H. Zhang, X.A. Li, F.G. Li, Effects of preharvest regulation of ethylene on carbohydrate metabolism of apple (Malus domestica Borkh cv. Starkrimson) fruit at harvest and during storage. Sci. Hortic. 276, 109748 (2021). https://doi.org/10.1016/j.scienta.2020.109748

D.Y. Xu, C. Chen, F.H. Zhou, C.H. Liu, M.X. Tian, X.J. Zeng, A.L. Jiang, Vacuum packaging and ascorbic acid synergistically maintain the quality and flavor of fresh-cut potatoes. LWT-Food Sci. Technol. 162, 113356 (2022). https://doi.org/10.1016/j.lwt.2022.113356

F.H. Zhou, D.Y. Xu, S.G. Xiong, C. Chen, C.H. Liu, A.L. Jiang, Transcriptomic and metabolomic profiling reveal the mechanism underlying the inhibition of wound healing by ascorbic acid in fresh-cut potato. Food Chem. 410, 135444 (2023). https://doi.org/10.1016/j.foodchem.2023.135444

P.D. Xie, Y.Y. Yang, W. Oyom, T.T. Su, Y.B. Tang, Y. Wang, Y.C. Li, D. Prushy, B. Yang, Chitooligosaccharide accelerated wound healing in potato tubers by promoting the deposition of suberin polyphenols and lignin at wounds. Plant Physiol. Bioch. 199, 107714 (2023). https://doi.org/10.1016/j.plaphy.2023.107714

Y.F. Pan, L. Chen, L.L. Pang, X.T. Chen, X.Y. Jia, X.G. Li, Ultrasound treatment inhibits browning and improves antioxidant capacity of fresh-cut sweet potato during cold storage. Rsc Adv. 10(16), 9193–9202 (2020). https://doi.org/10.1039/C9RA06418D

F.H. Zhou, A.L. Jiang, K. Feng, S.T. Gu, D.Y. Xu, W.H. Hu, Effect of methyl jasmonate on wound healing and resistance in fresh-cut potato cubes. Postharvest Biol. Tec. 157, 110958 (2019). https://doi.org/10.1016/j.postharvbio.2019.110958

Y.X. Wang, F.H. Zhou, J.H. Zuo, Q.L. Zheng, L.P. Gao, Q. Wang, A.L. Jiang, (2018) Pre-storage treatment of mechanically-injured green pepper (Capsicum annuum L.) fruit with putrescine reduces adverse physiological responses. Postharvest Biol. Technol. 145, 239–246 (2018). https://doi.org/10.1016/j.postharvbio.2018.08.002

S.T. Gu, D.Y. Xu, F.H. Zhou, K. Feng, C. Chen, A.L. Jiang, Repairing ability and mechanism of methyl jasmonate and salicylic acid on mechanically damaged sweet cherries. Sci. Hortic. 292, 110567 (2022). https://doi.org/10.1016/j.scienta.2021.110567

X.W. Hua, T.T. Li, C. Wu, D.D. Zhou, G.J. Fan, X.J. Li, K.P. Cong, Z.C. Yan, Z.H. Wu, Novel physical treatments (pulsed light and cold plasma) improve the quality of postharvest apricots after long-distance simulated transportation. Postharvest Biol. Tec. 194, 112098 (2022). https://doi.org/10.1016/j.postharvbio.2022.112098

C.H. Sommers, X.T. Fan, A.P. Handel, K. Baxendale Sokorai, Effect of citric acid on the radiation resistance of Listeria monocytogenes and frankfurter quality factors. Meat Sci. 63(3), 407–415 (2003). https://doi.org/10.1016/S0309-1740(02)00100-6

V. Pilizota, G.M. Sapers, Novel browning inhibitor formulation for fresh-cut apples. J. Food Sci. 69(4), 140–143 (2004). https://doi.org/10.1111/j.1365-2621.2004.tb06354.x

A.K. Dovene, L. Wang, S.U. Bokhary, M.P. Madebo, Y.H. Zheng, P. Jin, Effect of cutting styles on quality and antioxidant activity of stored fresh-cut sweet potato (Ipomoea batatas L.) cultivars. Foods 8(12), 674 (2019). https://doi.org/10.3390/foods8120674

M.D. Ferreira, S.A. Sargent, J.K. Brecht, C.K. Chandler, Strawberry fruit resistance to simulated handling. Sci. Agr. 65, 490–495 (2008). https://doi.org/10.1590/S0103-90162008000500007

S.G. Xiong, F.H. Zhou, A.L. Jiang, L. Yang, W.Z. Hu, Ethanol vapor ameliorates chilling injury and maintains postharvest quality by increasing antioxidant capacity of hardy kiwifruit (Actinidia arguta). Sci. Hortic. 327, 112796 (2024). https://doi.org/10.1016/j.scienta.2023.112796

M.H. Bata Gouda, C.J. Zhang, S.J. Peng, X.X. Kong, Y.R. Chen, H. Li, X.R. Li, H.B. Luo, L.J. Yu, Combination of sodium alginate-based coating with L-cysteine and citric acid extends the shelf-life of fresh-cut lotus root slices by inhibiting browning and microbial growth. Postharvest Biol. Tec. 175, 111502 (2021). https://doi.org/10.1016/j.postharvbio.2021.111502

M. Chiumarelli, C.C. Ferrari, C.I.G.L. Sarantópoulos, M.D. Hubinger, Fresh cut “Tommy Atkins” mango pre-treated with citric acid and coated with cassava (Manihot esculenta Crantz) starch or sodium alginate. Innov. Food Sci. Emerg. 12(3), 381–387 (2011). https://doi.org/10.1016/j.ifset.2011.02.006

R.B. Waghmare, U.S. Annapure, Combined effect of chemical treatment and/or modified atmosphere packaging (MAP) on quality of fresh-cut papaya. Postharvest Biol. Tec. 85, 147–153 (2013). https://doi.org/10.1016/j.postharvbio.2013.05.010

C. Yang, T. Chen, B.R. Shen, S.X. Sun, H.Y. Song, D. Chen, W.P. Xi, Citric acid treatment reduces decay and maintains the postharvest quality of peach (Prunus persica L.) fruit. Food Sci. Nutr. 7(11), 3635–3643 (2019). https://doi.org/10.1002/fsn3.1219

S.G. Xiong, X.S. Sun, M.X. Tian, D.Y. Xu, A.L. Jiang, 1-Methylcyclopropene treatment delays the softening of Actinidia arguta fruit by reducing cell wall degradation and modulating carbohydrate metabolism. Food Chem. 411, 135485 (2023). https://doi.org/10.1016/j.foodchem.2023.135485

S.S. Nassarawa, Z.S. Luo, Effect of light irradiation on sugar, phenolics, and GABA metabolism on postharvest grape (Vitis vinifera L.) during storage. Food Bioprocess Technol. 15(12), 2789–2802 (2022). https://doi.org/10.1007/s11947-022-02919-9

J.H. Chen, Y.H. Xu, Y. Yi, W.F. Hou, L.M. Wang, Y.W. Ai, H.X. Wang, T. Min, Regulations and mechanisms of 1-methylcyclopropene treatment on browning and quality of fresh-cut lotus (Nelumbo nucifera Gaertn.) root slices. Postharvest Biol. Tec. 185, 111782 (2022). https://doi.org/10.1016/j.postharvbio.2021.111782

Y. Chen, Y.J. Zhang, G. Nawaz, C.X. Zhao, Y.X. Li, T.T. Dong, M.K. Zhu, X.M. Du, L. Zhang, Z.Y. Li, T. Xu, Exogenous melatonin attenuates post-harvest decay by increasing antioxidant activity in wax apple (Syzygium samarangense). Front. Plant Sci. 11, 569779 (2020). https://doi.org/10.3389/fpls.2020.569779

P.T. Chen, J.X. Li, Q.Q. Luo, J.K. Zong, J.L. Gao, R.H. Qin, H.R. Ran, T.F. Zhao, Y.F. Fu, Transcriptome and physiological analysis revealed the difference of resistance to fresh-cut browning among sweetpotato genotypes. Postharvest Biol. Tecnnol. 205, 112504 (2023). https://doi.org/10.1016/j.postharvbio.2023.112504

L. Wang, H. Zhang, P. Jin, X.F. Guo, Y. Li, C. Fan, J. Wang, Y.H. Zheng, Enhancement of storage quality and antioxidant capacity of harvested sweet cherry fruit by immersion with β-aminobutyric acid. Postharvest Biol. Technol. 118, 71–78 (2016). https://doi.org/10.1016/j.postharvbio.2016.03.023

S.S. Nassarawa, T. Belwal, M. Javed, Z.S. Luo, Influence of the red LEDs light irradiation on the quality and chemical attributes of postharvest table grape (Vitis vinifera L.) during storage. Food Bioprocess Technol. 15(6), 1436–1447 (2022). https://doi.org/10.1007/s11947-022-02824-1

Y.F. Lin, M.Y. Chen, H.T. Lin, M.S. Lin, Y.C. Hung, Y.X. Lin, Y.H. Chen, H.W.M.A. Ritenour, Phomopsis longanae-induced pericarp browning and disease development of longan fruit can be alleviated or aggravated by regulation of ATP-mediated membrane lipid metabolism. Food Chem. 269, 644–651 (2018). https://doi.org/10.1016/j.foodchem.2018.07.060

J. Xie, Z.Y. Qin, J.L. Pan, J. Li, X. Li, H.E. Khoo, X.H. Dong, Melatonin treatment improves postharvest quality and regulates reactive oxygen species metabolism in “Feizixiao” litchi based on principal component analysis. Front. Plant Sci. 13, 965345 (2022). https://doi.org/10.3389/fpls.2022.965345

R. Mittler, Oxidative stress, antioxidants and stress tolerance. Trends Plant Sci. 7(9), 405–410 (2002). https://doi.org/10.1016/S1360-1385(02)02312-9

K. Robards, P.D. Prenzler, G. Tucker, P. Swatsitang, W. Glover, Phenolic compounds and their role in oxidative processes in fruits. Food Chem. 66(4), 401–436 (1999). https://doi.org/10.1016/S0308-8146(99)00093-X

Y.Y. Sun, H.J. Sun, M.L. Luo, X. Zhou, Q. Zhou, B.D. Wei, S.C. Cheng, S.J. Ji, Membrane lipid metabolism in relation to core browning during ambient storage of “Nanguo” pears. Postharvest Biol. Technol. 169, 111288 (2020). https://doi.org/10.1016/j.postharvbio.2020.111288

D.Y. Xu, F.H. Zhou, S.T. Gu, K. Feng, W.Z. Hu, J. Zhang, X.S. Sun, X.W. Liang, A.L. Jiang, 1-Methylcyclopropene maintains the postharvest quality of hardy kiwifruit (Actinidia aruguta). J. Food Meas. Charact. 15(4), 3036–3044 (2021). https://doi.org/10.1016/j.foodchem.2022.132190

Acknowledgements

This work was supported by the Science and Technology Major Project of Gansu Province (21ZD4NA016-02), and the Fundamental Research Funds for the Central Universities (0919-140005).

Author information

Authors and Affiliations

Contributions

Wen Li: conceptualization, data curation, formal analysis, investigation, methodology, visualization, writing-original draft, writing-review & editing. Si-Guo Xiong: data curation, formal analysis, supervision, writing-review & editing. Cheng-Hui Liu: supervision, methodology & writing-review. Ai-Li Jiang: supervision, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no confict of interests regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Xiong, SG., Liu, CH. et al. Citric acid treatment maintains fresh-cut sweet potatoes storage quality by reducing browning levels and increasing antioxidant capacity. Food Measure 18, 7480–7494 (2024). https://doi.org/10.1007/s11694-024-02742-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02742-0