Abstract

Higher moisture content and inefficient post-harvest handling result in huge losses and scanty availability of the fruits. Spray drying is one such technique to handle the problem of post-harvest losses as powder production not only cuts the storage and transportation cost but also provides higher shelf stability. This review provides a detailed description of the process of spray drying and the effect of each parameter on powder characteristics. It also summarizes that addition of different wall materials resulted in the production of high-quality fruit juice powders.There are two major approaches material based i.e., encapsulation and process-based which aim to improve the economic value of spray drying by controlling the problems of stickiness, hygroscopicity, and thermal degradation of heat-sensitive compounds. Stickiness is majorly due to the low glass transition temperature of fruit juices (sugars and acids) which is elevated with the addition of encapsulating agents. Control over operational parameters is essential to deliver fruit powders within acceptable quantity and quality, both in terms of organoleptic and nutritional parameters. Various studies revealed that encapsulation act as protective shield for bioactive and probiotics retention. Maltodextrin (Dextrose equivalence 10–20) is reported as the most efficient drying aid. Prebiotics like nutriose and skimmed milk powder can also be used as drying aids. Most suitable conditions for spray drying of fruit juices like pomegranate, ber, and jamun are 25% maltodextrin at 124 °C, 8–10% maltodextrin at 160–190 °C, and 10% maltodextrin at 185 °C, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With a surplus production of 99.07 million tonnes (MT) in the year 2019–20, India is the second-largest fruits basket in the world right after China [1]. Despite tremendous production, millions of fresh and processed fruits and vegetables are imported into India. From the year 2004–05 to 2019–20 production of fruits alone in India has increased from 50.86MT to 99.06MT [1, 2]. Andhra Pradesh (18.2%), U.P. (10.9%), and Maharashtra (10.1%) are three major contributing states to the annual fruit production for the year 2018–19 [1]. Major commodity to the world fruit production are banana & plantain (18%) contribute highest, followed by watermelon (11%), apple (10%), orange (9%), grapes (9%) and other fruits (43%) [3]. Major fruits in the Indian fruit production are banana (930.8MT), orange (8.7MT), grapes (2.9MT), and apple (2.3MT) [4]. A minimum intake of 400 g of fruits and vegetables/person/day is recommended by WHO and FAO [5]. As per the world production availability should be 390 g/person/day. However, world and Indian consumption of fruits and vegetables is just 66% (267 g/person/day) and almost half (207.9 g/day/person) of the dietary recommendation respectively [2, 5].

Post-harvest losses are one of the main reasons for the import as well as reduced per capita availability of fruits in our country. The high moisture content of fruits needs to be reduced for increasing the income and economy of fruit growers. Enzymatic reactions and microbial proliferation elevate post-harvest losses during improper storage and processing. Due to improper storage and processing, various enzymatic reactions and microbial proliferation results in spoilage and hence elevated post-harvest loses. Fruits are an abundant source of multiple functional compounds which are beneficial to human health [6]. To avail these functional compounds throughout the year and manage post-harvestlosses, the processing is done to develop products like juices, jams, squash, marmalades, fruit powders, and health products. Out of all the products fruitjuice powders are the one in which water activity of these fruits is reduced to shelf-stable levels with minimum degradation of the functional compounds [6].

Fruit juice powders are mainly prepared by carrying out dehydration through different methods such as spray drying, drum drying, tray drying, foam mat drying, and freeze-drying. Poor rehydration capacity, powder stickiness, degradation of heat-sensitive compounds i.e., vitamins, pigments, proteins, etc., and loss of original color are the major defects in fruit juice powders obtained through tray/drum drying. High capital and running cost despite excellent product quality limits the application of freeze-drying and foam mat drying in the production of fruit juice powder [7]. Spray drying is one of the most commonly practiced techniques for the production of fruit juice powders at the commercial level [6] owing to its ability to produce high-quality powders with economic feasibility. This review aims to provide background about the concept of spray drying and its associated aspects. The review will initially provide a detailed description of the spray drying process and encapsulation. Further, highlights some major technical issues with spray drying along with methods to eliminate their influences. Insights about how encapsulation can overcome one of the major challenges of spray drying and effect of important technical parameters on powder properties. Lastly, covers an overview of the current work in the field of spray drying of fruits juices.

Spray drying

Spray drying of fruit juices is a well-established technique.It results in the production of powders which are cutting storage and transportation cost based on their microbiologically and chemically stable nature [8]. This technique is economically viable for commercial production as general problems of stickiness and hygroscopicity are well managed duringthe production of fruit juice powders. It produces particles that are homogenous in terms of particle size [8] along with intact organoleptic and nutritional properties, especially heat-sensitive compounds.

It is a unit operation involving the application of hot gas currents which can be air or an inert gas like nitrogen to an atomized liquid feed for the production of powders, granules, or agglomerates. For controlling the drop size of the initial liquid feed which can be a suspension, solution, or emulsion either an atomizer or spray nozzle is used. When these sprayed or atomized droplets come in contact with hot drying gas (heating medium) moisture evaporation takes place. These hot gas currents can be in counter-current, co-current, or mix flow concerning atomizer [9,10,11] (Fig. 1).

There are mainly five-unit operations performed during spray drying.

Feed preparation

Preparation of feed involves pre-concentration which ought to reduce the moisture content of the feed and carrier agent addition which controls stickiness. This considerably reduces the energy requirements during spray drying and makes the drying operation cost-effective [12]. Feed Concentration increases solid content and reduced liquid content. Ona large scale, spray dryer feed is normally concentrated up to 50–60%. However, to avoid clogging by viscous feed in a small-scale spray dryer feed is furthermore diluted before drying [12, 14]. To control the final product yield and losses of physical attributes due to stickiness, some carrier agents such as hydrolyzed starch (maltodextrin, cyclodextrin), milk proteins (whey protein isolate, sodium caseinate), gum arabic, and plant proteins (soy protein) are added into the liquid feed prior spray drying [12].

Atomization

Atomization is a regulatory step for the further drying process wherein prepared liquid feed on passage through a nozzle is transformed into spray/ mist of tiny droplets [14,15,16]. The purpose of this step is to increase the effective drying surface between the feed and drying medium (air) for efficient heat and mass transfer [17]. Application of centrifugal forces or pressure inside the nozzle produces homogeneous tiny droplets. Spraying increases the surface area of the feed which exponentially increases with subsequent drying [14, 15]. Viscosity, characteristics of feed, desired properties, and particle size of the final product are the factors based on which nozzles (pneumatic nozzle, pressure nozzle, sonic nozzle, hydraulic nozzle, ultrasonic nozzle, etc.) are selected [14,15,16,17].

Hot air droplet contact

The drying medium which can be a filtered atmospheric gas, nitrogen, or other inert gases (depending on the sensitivity of feed to oxygen) is preheated to a predefined temperature (based on the nature of the liquid feed) using a heating element located just before the chamber for drying. This preheated drying medium comes in contact with feed just after atomization in the drying chamber and commences the process of drying [9, 14,15,16,17]. During these few seconds of contact, the thermal energy of the drying medium is taken up by the feed leaving behind a cool air after evaporation and exchange of energy which carries the dried particles through the spray dryer[9, 14,15,16]. Depending upon the direction of the drying medium and atomized feed there can be three types of hot air droplet contact modes namely counter-current type, co-current type, and mix flow type. In counter-current type feed is atomized in the direction opposite to the flow of the drying medium. Immediate exposure to high temperature makes it a less preferred model for thermo-sensitive feed; however, it is more economic (less energy consumption). Feed is atomized in the direction same as the drying medium in the co-current type. This limits the thermal degradation of feed as it encounters moderate temperatures. Mixed flow type is a combination of both co-current and counter-current types of drying models [9, 14,15,16].

Droplet moisture evaporation

The temperature difference and partial vapor pressure developed after the hot air &droplet contact initiates heat and mass (water) transfer resulting inthe drying of atomized feed droplets. Heat travels from the drying medium to feed droplets by convection. Mass transfer occurs due to evaporation (vapor pressure difference) of water from feed to drying medium. During evaporation, heat is converted to latent heat. The relative velocity of the drying medium and feed droplets and diameter of droplets are the factors on which the rate of heat transfer is dependent [9, 14,15,16]. Moisture evaporation takes place in the following steps: (i) Heat transfer from the drying medium elevates the temperature of the feed droplet. This transfer of heat causes droplets to gradually reduce in size (increasing the surface area) due to the evaporation of moisture from the surface of droplets. (ii) Droplet temperature reaches a constant value. Thereafter the evaporation occurs at a constant temperature and vapor pressure i.e., the rate of water diffusion from the surface and core of the droplet reaches equilibrium. (iii) Finally, the moisture content of droplets reaches a critical value and then begins the falling rate period of drying where the rate of drying falls gradually. Drying/moisture evaporation is discontinuous until the temperature of the feed particles rises to the temperature of the air in the drying chamber [9, 10, 14,15,16].

Separation of dried particles from the humid air

To avoid loss of dried particles in the atmosphere a cyclone separator is placed outside the dryer system for separation. Dense particles settle in the bottom of the drying chamber while the fine particles along with humid air enter the cyclone separator. Fine particles separate from the humid air inside the cyclone separator by moving out of separate outlets. Other than cyclone separators spray dryers are also provided with filters also known as baghouses and chemical scrubbers. The former is used to separate fine powders and the latter is used to remove volatile pollutants such as flavorings, etc. [9, 11] (Table 1).

Encapsulation

Encapsulation is a technique of entrapping or packaging small particles (active compounds or core material) of one or more (gaseous/ liquid/solid) material within a continuous, protective and stable system which is also referred to as carrier encapsulant, shell, and wall or coating material. It results inthe production of capsules of varying sizes (micrometer to millimeter) having two structural elements core material and wall material [54,55,56].

It is carried out to avoid the contact of active compounds with light, moisture, oxygen, and heat [57] and undesirable interactions between food and active compound [58]. It slows down/prevents the degradation of active compounds during processing, storage, and prior to delivery to the site of action [58]. It helps to control the release of active compounds [59] which ensures that optimum concentration is uniformly dispersed at the site of action [54]. It aids in increasing the bioavailability of certain food ingredients such as bioactive compounds inside the human gastrointestinal tract [54]. It ensures that encapsulated ingredients are easily handled without any contaminants [54, 59] and damage its technological functions [59] (Fig. 2).

Wall materials

Wall/shell material also commonly referred to as encapsulation matrix, agent or carrier is a film-forming material that encloses the core material. This coating material can be natural or synthetic polymer. Properties of an ideal carrier agent are that it should be food-grade material and inert to the encapsulated substance during processing or prolonged storage [57, 61]. It should be flexible, tasteless, and non-hygroscopic in nature [61]. Capable of forming and stabilizing colloidal dispersion/ emulsion with the active substance it is encapsulating and ensuresthe release of active compound at the targeted site under specific conditions [57, 61]. It should be soluble in solvents such as water, alcohol, etc., and capable of ensuring protection against environmental factors such as light, heat, moisture, etc. [57]. Natural polymers for encapsulation belong majorly to carbohydrates, gums, lipids, and proteins. Carbohydrates- Maltodextrins, corn sugar solids, modified starch, cyclodextrins, modified cyclodextrins, sucrose, chitosan, cellulose[57], nutriose, fructooligosaccharides, etc. Gums- Seaweed extracts (Alginates, agar, carrageenan), exudates gums (gum acacia, gum karaya, gum tragacanth), etc. [57]. Lipids- Wax (paraffin wax, bee wax), acetoglycerides, lecithin, liposomes, etc. [57]. Proteins- Gelatin, gluten, caseins, albumins [57], whey protein isolate, soy protein isolate, skim milk powder, etc. Most commonly used wall materials for spray drying of fruit juice at the commercial level are maltodextrin, starches, and gums.

Controlled release of the core material

Controlled release is a method to ensure the delivery of one or more active ingredients at a desirable site at a particular time and specific rate [66]. This method ensures that during the period of cooking/processing the desirable ingredient’s losses are reduced or avoided, reactive components are well separated from each other, and desirable ingredients are released for a prolonged duration at controlled rates [67]. Diffusion of the volatile compounds through the matrix, type and geometry of the compounds, transfer of the compound from the matrix to the processing environment, and degradation/dissolution of the coating material are some of the factors affecting rate release [66].

Mechanisms of control release

Diffusion, biodegradation, dissolution, swelling, and fracture are five different mechanisms for the controlled release in encapsulation.

Diffusion

Diffusion is a random movement of molecules driven bya concentration gradient. Diffusion of compounds from microcapsules is governed by volatile substances vapor pressure on the matrix wall, solubility, and permeability with the matrix [68, 69]. The principal steps for the flow of core ingredient from the wall/matrix system of the microcapsule via diffusion are dissolution of the core ingredient at the higher concentration side of the wall material matrix, diffusion from the matrix based on concentration gradient between matrix environment and environment outside the matrix and finally evaporation of this diffused core ingredient from the surface of matrix [68, 70, 71]. Diffusion can take place via two different mechanisms molecular or static and eddy or convective. In the case of static diffusion, molecules show random movement within a stagnant fluid whereas in the eddy mechanism these solutes are carried along with the fluid after dissolution. The rate of diffusion is much faster and independent of the solute nature in the latter mechanism than in the former [72].

Biodegradation

It involves the controlled release of the core material through the degradation of the wall material which can be both homogeneous and heterogeneous. Homogeneously, degradation is occurring uniform throughout the wall matrix whereas heterogeneous degradation is only confined to a portion of the wall matrix [66]. For example- The degradation of lipid-based coating using lipase to release the active compound at the targeted site [57].

Dissolution/melting

The core material is released out of the capsule after dissolution or melting of the wall material by desirable solvents or temperature conditions [57]. It involves attacking the integrity of the coating material based on its nature.For wall material of water-soluble and insoluble type melting is achieved by increasing the moisture content and addition of appropriate solvent or thermal release in the system, respectively [57]. For example- fat capsules will be melted by application of heat to release the active ingredients.

Swelling

It involves placing the capsule in a thermodynamically compatible medium for the polymer of the wall material to absorb the fluid and swell. Upon swelling, the walls become more easily diffusible for the core ingredient [71]. Solvents such as glycerin, propylene glycerol, etc. are used to keep a control on the degree of swelling of the wall material [73].

Fracturation

It involves the formation of wall material of capsules using water-soluble and hardened substances like fats or waxes etc. Then these wall materials are fractured or broken through the application of various external (pressure, shear, increasing temperature to melt fat or waxes, extra sonics, etc.) and internal forces (vapor pressure of core material, etc.) [57].

Major issues in spray drying of fruits

Powder stickiness due to the presence of natural low molecular weight sugars and organic acids is one of the most prominent issues during fruit juice powder production [74]. Natural sugars are highly hygroscopic and thermoplastic in nature. These sugars and organic acids, due to their low molecular weight have a glass transition temperature (Tg) much lower than the normal drying temperatures. Figures 3a and b depict the glass transition temperature of sugars and organic acids commonly present in fruit juices. Hence, they tend to soften during drying leading to powder stickiness. Powder stickiness involves cohesion (stickiness between the particles) and adhesion (stickiness between the particles and dryer surface) resulting in lump formation and poor product yield. Ultimately, a product with inferior quality and increased cost of production is obtained.

The efficiency of the spray drying process is expressed in terms of product recovery. In the case of materials with lower Tg, product yield is decreased significantly due to adhesion/deposition of the particles on the walls of the dryer chamber [75]. Low yield also indicates that the produced powder would be sticky or unable to exhibit free-flowcharacteristics. Generally, a product yield above 50% is expected (sugar-rich products) from a laboratory scale spray dryer [74].

Two groups of methods i.e., material-based and process-based can be applied to overcome the problem of stickiness with fruit juice powders.

Material based method

Generally, the Tg of sugars and acids which are the main constituents of fruit juices is low. Temperatures during spray drying are usually higher than the Tg of the sugars and acids. Such high temperatures result in the formation of a viscoelastic rubbery mass of sugars and acids which adhere to the wall of the drying chamber [81].To increase the overall glass transition temperature, the feed solution is supplemented with high molecular weight drying aids (Fig. 3c) prior to atomization [35, 56, 82]. These high molecular weight drying aids not only limit the prominent issue of stickiness but also minimize hygroscopicity and protect heat-sensitive compounds of fruit juices [33, 83].

Figure 4 depicts the study of Yousef et al. [47] and Shrestha et al. [82] on spray drying of pomegranate juice and orange juice using different wall materials. Major constitutes contributing to low Tg of orange juice are fructose, glucose, and citric acid [82]. Similarly, fructose, glucose, citric acid, and malic acid are major constituents of pomegranate juice [84]. Low Tg of orange and pomegranate juice owing to the above constituents was increased significantly after the addition of certain wall material as depicted in Fig. 3. In Fig. 4a Tg of orange juice increased gradually with increasing concentration of maltodextrin (DE 6) and reached a maximum of 97.3 °C when a ratio of 25:75 of orange juice: maltodextrin was used. Similarly, Tg of pomegranate juice was increased to 52.83 °C and 39.96 °C after the addition of gum arabic and maltodextrin (DE 20) respectively (Fig. 3c).

Process-based method

Dehumidified air, scrapped surfaced drying chamber, and cooling of the wall of the drying chamber are the few process-based methods that can prevent sticking of fruit juices to the drying chamber wall as well as lumping [75]. Modifying the drying chamber in a spray dryer to have scrappers to scrap off the adhering fruit juice powder will enhance the product yield with a compromise in the reconstitution properties. As abrasion due to scrapping will cause the textural damage which will ultimately result in poor reconstitutions [75]. Even after the addition of scrappers in the design, fruits juices need carrier agents in large volumes for spray drying. The addition of scrappers will not only increase the capital cost but also make the dryer design more complex [75].

Another modification is the replacement of a regular drying chamber with a double-wall chamber. This replacement lowers the temperature of the drying chamber wall below the Tgof the fruit juice which lowers the sticking of the particles to the dryer wall [75]. Chegini et al. [85] in their study utilized a double-wall chamber semi-industrial spray dryer. An evaluation of the dryer during his study indicated that in all his trials, the chambers wall temperature was 44 °C which is much lower than the Tg of the powder. They also observed that a double wall chamber reduces wall deposition by 15% along with a dryer yield in the range of 65–90% [85].

Goula and Adamopoulos [86] in their study reduced powder loss as the air temperature was lowered and the drying rate was increased by application of dehumidified air for spray-drying concentrated orange juice. Theyconcluded that dehumidified air resulted in the production of products with lower hygroscopicity, moisture content, and degree of cakingwhile higher rehydration ability and density. Jedlińska et al. [87] also performed spray drying of honeydew honey at low temperature (inlet/outlet: 75/50 °C) with the application of dehumidified air. They reported that dehumidified air reduced the concentration of carrier agent in feedby 20% and enhanced the powder recovery by 90% or above [87]. Utilizing dehumidified air as a drying medium resolves the problems of adhesions of the fruit juice powder to the drying chamber wall and reduces the quantity of carrier agent in the fruit feed solution [75].

Spray drying and encapsulation of various fruits

Samborska et al. [88] spray dried apple concentrate using four different carrier agents [maltodextrin DE 10, nutriose, kleptose, and skimmed milk powder (SMP)]. SMP came out to be the most appropriate carrier agent. Based on the characteristics of the apple concentrate skimmed milk powder (Table 2), SMP could be a beneficial substitute for traditional wall material. At a lower concentration in the feed solution, SMP supports higher recovery of powder having morphological characteristics of the non-sticky powder. SMP wasobserved to have a protective effect on antioxidant compounds in apple concentrate and contribute toa new antioxidant generation. The addition of SMP adds-on lower Tg lactose to the mixture was the only drawback reported by Samborska et al. [88]. These trials demonstrated that dehumidified air can reduce the concentration of wall material in the feed solution.

Pandey et al. [89] run 13 trials to optimize the spray drying conditions of ber powder. These runs were carried out at varying inlet air temperatures (153.79 to 196.21 °C) and maltodextrin (MD) concentrations (4.17 to 9.83%). Pandey et al. [89] observed that moisture content of spray-dried powder decreased with increasing inlet air temperature and MD concentration which could be due to increased rate of heat transfer and total solid content (bounds more water) respectively. A similareffect of the two parameters was observed on bulk density. Higher temperature and increasing MD concentration decrease moisture content which increases the solubility (> 90%) of powder. Protein content, total sugar, reducing sugar, and total soluble solids increased significantly due to the concentration effect after spray drying. Vitamin A and C content of ber juice decreased significantly after spray drying due to degradation and oxidation at high temperatures. Pandey et al. [89] concluded that 166.64 °C inlet air temperature and 9.26% MD are optimum for ber juice spray drying.

Singh et al. [90] performed spray drying of ber at different values of parameters such as carrier agent concentration (maltodextrin) (4, 6, 8, 10, and 12%), feed pump capacity (9, 12, 15, 18 and 21%), inlet air temperature (170, 180, 190, 200, 210 °C) and aspirator blower capacity (40, 50, 60, 70 and 80%). It was observed that biochemical properties such as moisture content, acidity, and ascorbic acid content of the spray-dried powder decreased with increasing inlet temperature (170 to 210 °C) and encapsulating agent concentration (4 to 12%). Similarly, Singh et al., [90] reported that values of moisture content, acidity, and ascorbic acid content increased with increasing values of aspirator blower capacity (40 to 80%) and feed pump capacity (9 to 21%). Singh et al. [90] concluded that inlet temperature of 190 °C at 60% aspirator blower capacity and 15% feed pump capacity along with 8% carrier agent concentration yield ber powder with the best qualities (3.9% moisture content, 38.4 mg/100 g ascorbic acid content and 0.55% acidity).

Zhang et al. [91] spray-dried cranberries using four different wall materials, then also studied their effect on phenolic content after drying and during storage at three temperatures (4, 25, and 45 °C) for 12 weeks. GAM1 and GA particles had better spray drying performance than M1 and M3 particles which is faster evaporation and early crust formation. GA particles were observed to have the highest moisture content and lower water activity which could be due to the higher water-binding ability of GA polymer (protein and a high number of hydrophilic groups). GA and GAM1 particles have higher retention of phenolic content after spray drying because of higher and early film formation (GA > 2% protein). M1 and M2 particles had higher retention of phenolic content during storage due to the protective effect of a less wrinkled and smooth surface after spray drying (reduces surface area). Zhang et al. [91] reported that out of the three storage temperatures 25 °C was most appropriate for the storage of cranberry powder.

Moghbeli et al. [92] spray-dried dates by combining WPC, pectin, and surfactant. The optimum powder was obtained using 10–14% WPC, 5% pectin, and 1% surfactant at 5 pH and 170 °C inlet temperature. Highest and lowest powder yield were 67% (1% surfactant, 5% pectin, 14% WPC at pH 5 and temperature 170 °C) and 29% (2% surfactant, 4% pectin, 12% WPC at pH 5 and temperature 190 °C) respectively. It was observed that pectin and WPC had a major effect on drying yield as their combination increases the Tg which thereby prevents sticking of particles to the dryer wall and improves production efficiency. Proteins of WPC create a thermal film around the particles which raise the Tg. Also, the strong and weak electrostatic bonding of pectin and WPC raises the Tg. Surfactant forms a film around the particles which reduces the surface tension and prevent stickiness among the particles and with a dryer wall. The increasing temperature was observed to increase stickiness which reduced production efficiency. Moghbeli et al. [92] stated that pectin and WPC contribute to the brightness of the powder (powders with higher pectin and WPC were whiter). Moghbeli et al. [92] stated that WPC concentration has a crucial impact on the thermal and structural properties of date powder.

Dev et al. [93] spray dried dates using two materials (maltodextrin [MD] and gum arabic [GA]) at different temperatures (150, 170 °C) and feed flow rates (25, 40 mL/min). GA particles were morphologically opposite in characteristics to MD particles. Lower temperature and lower feed flow rate contribute to better rheological properties (higher density and porosity). Dev et al. [93] concluded that temperature and feed flow rate are inversely proportional to the rheological characteristics of spray-dried powders. Temperature and flow rate together alter the exposure time of the particles to high temperature during spray drying which positively affect the product quality by either increasing particle density or higher porosity. Higher density and porosity particles contributed to better wettability and solubility which gives better rheological properties. Industrially viable spray-dried date powder can be obtained involving MD at a lower temperature (150 °C) with a slower flow rate (2.5 mL/min). Dev et al. [93] stated that using MD raises both dietary calorific value and glycemic index of the date powder while GA improves the colon health as colon bacteria ferment these non-digestible polymers.

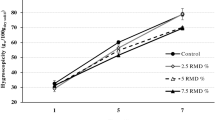

Yusof et al. [94] carried out the study for optimization of white dragon fruit spray drying. For optimization resistant maltodextrin (RMD) was mixed in the feed solution at three different concentrations (20%, 25%, and 30%) and then spray dried at three different inlets (140 °C, 150 °C, and 160 °C) and outlet (75 °C, 80 °C, and 85 °C) temperatures. Yusof et al. [94] observed that powder yield decreases with increased RMD concentration, increases with increased outlet temperature, and decreased inlet temperature. Moisture content and aw increase with increasing RMD concentration up to 25% as concentration beyond these decreases both parameters. Solubility of spray-dried powder increases while hygroscopicity decreases with increased RMD concentration. Bulk density is inversely proportional to the outlet temperature. Yusof et al. [94] concluded that industrial spray drying of white dragon fruit can be carried out at153°C inlet temperature, 82 °C outlet temperature, and 20% RMD concentration.

Moser et al. [95] spray-dried grapes using protein/maltodextrin blend at different carrier agent concentration (CAC) and protein/carrier concentration ratio (R%) as a drying agent. Higher CAC was observed to increase powder recovery and produce particles with higher sphericity irrespective of the protein type (whey protein concentrate/soy protein isolate). Both protein/maltodextrin blends depicted higher solubility powders (WM- 92 to 97% and SM- 87 to 95%). Moser et al. [93] reported that anthocyanin retention and encapsulation efficiency (EE) increased with increasing CAC of WM blend and SM blend respectively. SM blend particles were more spherical and less agglomerated than WM blend particles. Brighter powders were obtained at higher CAC and R%. The color of the reconstituted juice was the same as fresh grape juice; however better reconstitution was observed in SM blend powder. Moser et al., [95] concluded that protein/maltodextrin blends result in superior anthocyanin reconstitution and encapsulation efficiency.

Singh et al. [96] optimized spray drying parameters for jamun pulp. For optimization, trials were carried out at different inlet temperatures (175–185 °C) and maltodextrin (MD) concentrations (5–10%). The moisture of the powder decreased with increasing inlet temperature and MD concentration. Singhet al., [96] reported that solubility (> 80%) of the jamun pulp powder increased with increasing concentration of carrier agent (MD). Increasing concentration of MD had a protective effect on the total phenolic and anthocyanin content of the jamun powder unlike increasing inlet air temperature which is reported to have a negative impact. Singh et al. [96] concluded that inlet temperatures of 185 °C and 10% MD are optimum for the production of jamun pulp powder with lower moisture content (< 3%), maximum solubility (> 90%), maximum dispersibility (> 90%) and better retention of total phenolic and anthocyanin content.

Sathyashree et al. [97] spray dried sweet orange juice to understand the influence of different inlet temperatures (130, 140, and 150 °C) and maltodextrin concentration (6, 9, and 12%) on the rehydration properties of sweet orange powder. Sathyashree et al. [97] observed that dispersibility increases with increasing inlet temperature and decreasing MD concentration. Sathyashree et al. [97] deduced that wettability increases and solubility decrease with increasing inlet temperature and MD concentration.

Santos Monteiro et al. [98] experimented to prepare probiotic passion fruit drink, further microencapsulated the optimally fermented passion fruit pulp using spray drying. Santos Monteiro et al. [98] stated that higher atomization flow rate results in smaller droplet size which has a less protective effect of temperature on probiotic cells. The inclusion of gelatin had a negative impact on powder yield as gelatin results in larger droplets (smaller surface area and slow evaporation) which tend to stick to the drying chamber wall. Hence, it was concluded that a higher atomization flow rate (smaller droplet size) without gelatin inclusion results in higher powder recovery. It was observed that a lower inlet temperature (112 °C) was inefficient to reduce the moisture content of final powders. Santos Monteiro et al., [98] also revealed that maltodextrin alone had a less protective effect on phenolic content, but the inclusion of gelatin had a positive effect on phenolic content retention as well as lowering the moisture content of the powder.

Miravet et al. [52] spray dried concentrated pomegranate juice (CPJ) using different drying aids maltodextrin (MD) (DE 19 & 6), fructooligosaccharides (FOS), and resistant dextrin (nutriose). For spray drying different CPJ concentrations (0.02, 0.04, and 0.1 g CPJ/g solution) were prepared using different spray drying aid concentrations (0.5 and 1.5 g drying aid/g CPJ) at different inlet air temperatures (120, 160, and 200 °C) and feed flow rate (0.72–1.08 L/h). Drying yield was highest using resistant dextrin followed by FOS, MD DE19, and MD DE6 at the same wall material concentration. Both resistant dextrin and MD DE6 depicted higher bioactive compound retention after spray drying but retention of bioactive compounds decreased with increasing inlet temperature. It was reported that bulk density increased and dissolution time decreased with increasing concentration of both (resistant dextrin and MD DE6) drying aid. Miravet et al. [52] concluded that resistant dextrin is the best drying-aid with also exhibits excellent prebiotic properties.

Jafari et al. [99] spray dried pomegranate juice at different inlet temperature (124 and 143 °C) and maltodextrin (MD) concentration (25, 35 & 45%). Spray-dried powder yield increased (17–25%) at higher temperatures and MD concentrations. However, the yield was lower than the acceptable levels. The density of the spray-dried powder decreased at higher MD concentrations and temperatures. Jafariet al. [99] observed that both inlet temperature and MD concentration have a negative impact on the anthocyanin content of the spray-dried powder. After scanned electron microscopy (SEM) analysis revealed that smaller and smoother particles were obtained at higher air inlet temperatures and lower MD concentrations. Jafariet al. [99] concluded that spray drying at 25% MD concentration and 124 °C inlet temperature yields powder with a higher solubility index, anthocyanin content, and higher density.

Araujo et al. [100] studied the influence of different wall materials/drying aids [maltodextrin (MD), gum arabic (GA), and maltodextrin gum arabic mixture (MG)] on the antioxidant activity and physicochemical compounds in the sapota juice powder. All the wall materials were added at 30% concentration in the feed solution. After spray drying these powders were rehydrated for comparative evaluation with fresh sapota juice. Antioxidant activity comparable to the fresh juice was retained in the gum arabic sapota powder (SG). The only quantifiable organic acid in the sapota juice and reconstituted juice was fumaric acid. Fumaric acid was highest in the SG, even higher than the fresh juice. Glucose and fructose were the only sugar identified in spray-dried samples. The highest concentration of both sugars was reported in the SG sample. Most of the phenols and flavonoids were degraded in the sapota juice after spray drying. Araujo et al. [100] observed that spray drying significantly alters the bioactive profile of sapota juice as many compounds are degraded during the process. On comparing all the results Araujo et al. [100] concluded that gum arabic is the most appropriate encapsulating agent for efficient protection of bioactive compounds in sapota juice in comparison to all other encapsulating agentscited in the work.

Li et al. [101] carried out experiment to compare the effect of microencapsulation (Maltodextrin DE15 (MD): Beta-cyclodextrin (C): Gum arabic (GA) = 7: 2: 1) on plum phenolic extract. It was reported that the addition of a coating agent to the feed prior to spray drying improved the physicochemical properties such as moisture content and water activity while at the same time decreasing the phenolic content of the spray-dried plum powder. After storability studies, it was observed that microencapsulation has a positive impact on phenolic content retention. For the first 40 days (25 °C) there was no effect on the phenolic content and phenolic content was above 85% after 60 days (25 °C). It was concluded that to achieve microencapsulation efficiency of 87.7% plum extract must be spray-dried at 143 °C with the core material content of 23.7% and feed solids content of 11.7% [101].

Watermelon juice spray drying feasibility was evaluated by Minh et al. [102]. During spray drying effect of different conditions such as carrier agent concentration (2:8, 4:6, 6:4, 8:2% w/v), (2:8, 4:6, 6:4, 8:2% w/v), speed flow rate (6, 12, 18, 24 ml/ min), air inlet and air outlet temperature (140 °C: 75 °C, 150 °C: 80 °C, 160 °C: 85 °C, 170 °C: 90 °C) on spray drying was evaluated. In this study, it was concluded that gum arabic: maltodextrin at a concentration of 4:6% w/v, 160 °C inlet temperature, 85 °C outlet temperatures and feed flow rate 18 ml/min are optimum for spray drying of watermelon juice [102].

Maltodextrin (MD) especially with a dextrose equivalence of 10 to 20 came out to be the most acceptable carrier agent for encapsulation based on the yield and physical properties of powders. The protective effect of MD on nutritional retention is limited. A higher concentration of MD is not suitable for daily consumption due to its higher glycemic index. MD concentration could be reduced at higher inlet air temperatures which negativelyaffectsthe nutritional profile. Limitations of MD could be supplemented by combining it with other wall materials.In some of the studies amalgamation of maltodextrin with drying aids such as gum arabic (GA), whey protein concentrate (WPC), soy protein isolates (SPI), and cyclodextrin in different concentrations was evaluated. These drying aids improved the performance of maltodextrin as a carrier agent in spray drying operations. Trials of Zhang et al. [91] and Minh et al. [102] demonstrated that the addition of gum arabic with maltodextrin at the ratio of 1:1 and 2:3 respectively manifolds the retention of various bioactive compounds and their activities post spray drying.GA and MD together promote faster evaporation and early crust formation that results in higher nutritional retention. However, bioactive retention during storage is better in maltodextrin-based powder due to a smoother surface (less wrinkled) [88]. Supplementation of MD with proteinous carrier agents such as WPC and SPI support the higher recovery of powder having better morphology, nutritional profile, and rehydration properties. Li et al. [101] observed that a combination of MD, cyclodextrin, and GA can also facilitate higher microencapsulation efficiency (> 85%) of shelf-stable powder. This combination also ensures bioactive retention during spray drying and storage. One of the studies demonstrated that maltodextrin along with gelatin (1–2%) can preserve the probiotic cells and phenolic content of probiotic passion fruit powder [98].

Many of the studies covered in this review demonstrate the application of innovative wall materials such as skimmed milk powder (SMP), WPC, SPI, resistant maltodextrin (RMD), kleptose, fructooligosaccharides, and resistant dextrin (RD) in fruit juice spray drying. Most of these innovative wall materials have enhanced the physicochemical properties of powder thanmaltodextrin-based. In the study of Samborska et al. [88], SMP proves to be top-quality wall material for apple concentrate in terms of powder recovery, water activity, lower stickiness, total phenolic content, and antioxidant activity retention. However, other wall materials such as nutriose and kleptose were also better than maltodextrin for their higher Tg, powder recovery,and nutritional retention.A combination of WPC (< 15%) and pectin (5%) evaluated by Moghbeli et al. [92] in date fruit spray drying produced whiter powder with better morphological properties. Yusof et al. [94] produced shelf stable dragon fruit powder (moisture content < 2.5% and aw < 0.2) with higher solubility (> 95%) by availing 20% RMD. Miravet et al. [52] compared the performance of resistant dextrin and fructo-oligosaccharides with maltodextrin (DE 19&6) on pomegranate concentrate spray drying. Fructo-oligosaccharide as a carrier agent failed to yield any powder. Resistant dextrinsupported higher powder yield with better nutritional storage stability, lower dissolution time, and higher bioactivity at the same concentration as maltodextrin samples [50].For fruits like pomegranate, ber, jamun, cranberries, sapota and dates 25% maltodextrin at 124 °C, 8–10% maltodextrin at 160–190 °C, 10% maltodextrin at 185 °C, 15% gum arabic-maltodextrin blend at 185 °C, 30% gum arabic at 140 °C, and 10–14% whey protein concentrate at 170 °C, respectively are most suitable conditions for spray drying.

Conclusion and future perspectives

Spray drying is an economical and feasible technique to handle the major problem of post-harvest losses of fresh produce. Stickiness is the major problem which can be handled by two approaches process and material based techniques. Encapsulation using drying aids which comes under material-based approach is a reliable tool to overcome the problems of stickiness, hygroscopicity, and thermal degradation of heat-sensitive compounds. Encapsulation has a positive impact on the retention and storage stability of various bioactive compounds (pigments, phenols, ascorbic acid, antioxidants, etc.). Therefore, it can be stated that drying aids act as a protective shield for various sensitive and essential bioactives. Maltodextrin is one of the most commonly used wall materials due to its higher powder recovery (> 85%). MD can be replaced with various innovative wall materials which are healthier and produce physico-chemically superior powders. Wall materials such as Resistant maltodextrin (soluble dietary fiber) and Resistant Dextrin (insoluble dietary fiber) are pre-biotic and known to improve gut health, lower serum lipid content, and have other functional attributes. Innovative wall materials are added at a lower concentration and yield good quality powder at a lower temperature. Innovative and non-conventional wall material have a huge scope to be explored by the industries which will increase the profits and health of the consumers. However, the application of innovative material needs more detailed understanding of the fruit juice characteristics. Generally, the powder recovery with innovative wall material is in the range of 65–90%. Dehumidification of air prior to spray drying is a promising solution to reduce wall material concentration and spray drying temperature. Lower values of feed flow rate have a positive influence on all physico-chemical characteristics of the spray-dried powders. Higher inlet air temperature, atomization and carrier concentration positively affect the moisture content, solubility, particle size, glass transition temperature with increased powder recovery. Hence, it is essential to have a detailed understanding to control these parameters to obtain powders within acceptable quantity as well as quality both in terms of organoleptically and nutritional parameters. These fruit juice powders have numerous benefits over their liquid counterpart as they are having an extended shelf life, instant nature, reduced weight, and volume. In view of the above benefits fruit juice powders are a more convenient and readily available source of various bioactive compounds to the consumers with better shelf life and storability. This review will provide a detailed understanding to industries about the overall process of spray drying. It will provide insight to start-ups about sections that still need improvement in the sector of fruit powders production. It will also provide a brief discussion about innovative wall materials and their effect on the powder properties. Industries will get a clear vision of how to enhance the nutritional profile of fruit juice powders without compromising on the economic aspects like product yield and quality. It will also generate consumers awareness regarding the current scenario of fruit powders production.

References

National Horticulture Board, Area Production Statistics, (Department of Agriculture, Cooperation & Farmers’ Welfare, Horticulture Statistics Division, Ministry of Agriculture & Farmers’ Welfare (GOI), (2019–2020), http://nhb.gov.in/StatisticsViewer.aspx?enc=MWoUJibk35dW2g36TUJWAoZqESmAYFi7h2irlsmjlINTcFl1rG/kLbq8ZQbWUvuM Accessed 21–03–2022

Horticulture Statistics, Area Production Statistics, (Department of Agriculture, Cooperation & Farmers’ Welfare, Horticulture Statistics Division, Ministry of Agriculture & Farmers’ Welfare (GOI), (2018), http://nhb.gov.in/Statistics.aspx?enc=WkegdyuHokljEtehnJoq0KWLU79sOQCy+W4MfOk01GFOWQSEvtp9tNHHoiv3p49g. Accessed on 20–11- 2020.

FAOSTAT, Statistical Yearbook 2021 https://doi.org/10.4060/cb4477en-figB1 Accessed on 12–04–2022.

Our world in data 2020 https://ourworldindata.org/agricultural#fruits-and-vegetables Accessed on 12–04–2022.

European Parliament, At a Glance, International Year of Fruits and Vegetables (2021)https://www.europarl.europa.eu/RegData/etudes/ATAG/2021/689367/EPRS_ATA(2021)689367_EN.pdfAccessed on 21–03–2022

N. Phisut, Spray drying technique of fruit juice powder: some factors influencing the properties of product. Int. Food Res. J. 19(4), 1297 (2012)

A. Sangamithra, S. Venkatachalam, S.G. John, K. Kuppuswamy, Foam mat drying of food materials: A review. J. Food Process. Preserv. 39(6), 3165–3174 (2015)

J.M. Obón, M.R. Castellar, M. Alacid, J.A. FernándezLópez, Production of a red-purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. J. Food Eng. 90, 471–479 (2009)

A. Gharsallaoui, G. Roudaut, O. Chambin, A. Voilley, R. Saurel, Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 40(9), 1107–1121 (2007)

I Filkova, AS Mujumdar in Industrial spray drying systems, ed. By A. S. Mujumdar Handbook of industrial drying, (CRC/Taylor & Francis: Boca Raton 2007)

A.M. Goula, K.G. Adamopoulos, Spray drying of tomato pulp in dehumidified air: II. The effect on powder properties. J. Food Eng. 66, 35–42 (2005)

I. Tontul, A. Topuz, Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. Technol. 63, 91–102 (2017)

G. Chegini, B. Ghobadian, Spray dryer parameters for fruit juice drying. World J. Agricult. Sci. 3, 230–236 (2007)

R. Murugesan, V. Orsat, Spray drying for the production of nutraceutical ingredients—a review. Food Bioprocess Technol. 5(1), 3–14 (2012)

K. Masters, Spray drying: The unit operation today. Indian J. Sci. Technol. 60, 53–63 (1986)

R.P. Patel, P.M. Patel, M.A. Suthar, Spray drying technology: an overview. Indian J. Sci. Technol. 10, 44–47 (2009)

K. Cal, K. Sollohub, Spray drying technique. I: Hardware and process parameters. J. Pharmaceut. Sci. 99(2), 575–586 (2010)

J. Du, Z.-Z. Ge, Z. Xu, B. Zou, Y. Zhang, C.-M. Li, Comparison of the efficiency of five different drying carriers on the spray drying of persimmon pulp powders. Drying Technol. 32(10), 1157–1166 (2014)

I. Tontul, A. Topuz, C. Ozkan, M. Karacan, Effect of vegetable proteins on physical characteristics of spray-dried tomato powders. Food Sci. Technol. Int. 22(6), 516–524 (2016)

B. Adhikari, T. Howes, B.J. Wood, B.R. Bhandari, The effect of low molecular weight surfactants and proteins on surface stickiness of sucrose during powder formation through spray drying. J. Food Eng. 94(2), 135–143 (2009)

K. Muzaffar, P. Kumar, Effect of soya protein isolate as a complementary drying aid of maltodextrin on spray drying of tamarind pulp. Drying Technol. 34(1), 142–148 (2015)

A. Can Karaca, O. Guzel, M.M. Ak, Effects of processing conditions and formulation on spray drying of sour cherry juice concentrate. J. Sci. Food Agricult. 96(2), 449–455 (2016)

E.L. Avila, M.C. Rodríguez, H.J.C. Velásquez, Influence of maltodextrin and spray drying process conditions on sugarcane juice powder quality. RevistaFacultad Nacional de AgronomíaMedellíng 68(1), 7509–7520 (2015)

S.E. Papadakis, C. Gardeli, C. Tzia, Spray drying of raisin juice concentrate. Drying Technol. 24(2), 173–180 (2006)

H. Vardin, M. Yasar, Optimisation of pomegranate (Punica Granatum L.) juice spray-drying as affected by temperature and maltodextrin content. Int J Food Sci Technol 47(1), 167–176 (2012)

S.Y. Chong, C.W. Wong, Production of Spray-Dried Sapodilla (Manilkara zapota) Powder from Enzyme-Aided Liquefied Puree. J. Food Process. Preserv. 39(6), 2604–2611 (2015)

Z. Fang, B. Bhandari, Comparing the efficiency of protein and maltodextrin on spray drying of bayberry juice. Food Res. Int. 48(2), 478–483 (2012)

S. Bhusari, K. Muzaffar, P. Kumar, Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 266, 354–364 (2014)

B. Adhikari, T. Howes, B.R. Bhandari, T.A.G. Langrish, Effect of addition of proteins on the production of amorphous sucrose powder through spray drying. J. Food Eng. 94(2), 144–153 (2009)

M. Fazaeli, Z. Emam-Djomeh, A. Kalbasi-Ashtari, M. Omid, Effect of process conditions and carrier concentration for improving drying yield and other quality attributes of spray dried black mulberry (Morus nigra) juice. Int. J. Food Eng. 8, 1–20 (2012)

P. Chen, L. Zhang, New evidences of glass transitions and microstructures of soy protein plasticized with glycerol. Macromol. Biosci. 5(3), 237–245 (2005)

M.O.P. Bicudo, A.D. Oliveira, F.P. Chaimsohn, M.R. Sierakowski, R. A. d Freitas, Microencapsulation of juçara (Euterpe edulis M) pulp by spray drying using different carriers and drying temperatures. Drying Technol. 33, 153–161 (2015)

C.C. Ferrari, S.P.M. Germer, I.D. Alvim, F.Z. Vissotto, J.M. de Aguirre, Influence of carrier agents on the physicochemical properties of blackberry powder produced by spray drying. Int. J. Food Sci. Technol. 47, 1237–1245 (2012)

M.A. Watson, J.M. Lea, K.L. Bett-Garber, Spray drying of pomegranate juice using maltodextrin/cyclodextrin blends as the wall material. Food Sci. Nutr. 5(3), 820–826 (2017)

S. Santhalakshmy, S.J.D. Bosco, S. Francis, M. Sabeena, Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol. 274, 37–43 (2015)

M. KhalilianMovahhed, M. Mohebbi, Spray drying and process optimization of carrot-celery juice. J Food Process Preservat 40, 212–225 (2016)

P. Mishra, S. Mishra, C.L. Mahanta, Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 92(3), 252–258 (2014)

A.M. Goula, K.G. Adamopoulos, Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Drying Technology 26, 726–737 (2008)

Q. Bi, J. Chen, Q., Y. Zhou, X. Liu, X. Wu, R. Chen, Multi-objective optimization of spray drying of jujube (Zizyphus jujuba Miller) powder using response surface methodology. Food Bioproc Technol 7, 1807–1818 (2014)

J. Bakar, S.C. Ee, K. Muhammad, D.M. Hashim, N. Adzahan, Spray-drying optimization for red pitaya peels (Hylocereus polyrhizus). Food Bioprocess Technol. 6, 1332–1342 (2013)

A.D. Moghaddam, M. Pero, G.R. Askari, Optimizing spray drying conditions of sour cherry juice based on physicochemical properties, using response surface methodology (RSM). J. Food Sci. Technol. 54, 174–184 (2017)

K. Muzaffar, B.V. Dinkarrao, P. Kumar, Optimization of spray drying conditions for production of quality pomegranate juice powder. Cogent Food & Agriculture 2, 1127583 (2016)

A. Manickavasagan, K. Thangavel, S. Dev, D. AniesraniDelfiya, E. Nambi, V. Orsat, Physicochemical characteristics of date powder produced in a pilot scale spray dryer. Drying Technol. 33(9), 1114–1123 (2015)

E. Horuz, A. Altan, M. Maskan, Spray drying and process optimization of unclarified pomegranate (Punica granatum) juice. Drying Technol. 30, 787–798 (2012)

T.C. Kha, M.H. Nguyen, P.D. Roach, Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 98, 385–392 (2010)

M. Ahmed, M.S. Akter, J.C. Lee, J.B. Eun, Encapsulation by spray drying of bioactive components, physicochemical and morphological properties from purple sweet potato. LWT-Food Sci. Technol. 43, 1307–1312 (2010)

S. Yousefi, Z. Emam-Djomeh, S.M. Mousavi, Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica Granatum L.). J. Sci. Technol. 48(6), 677–684 (2011)

C.C. Ferrari, S.P. Marconi Germer, I.D. Alvim, J.M. de Aguirre, Storage stability of spray-dried blackberry powder produced with maltodextrin or gum arabic. Drying Technol. 31, 470–478 (2013)

T. Moreno, E. de Paz, I. Navarro, S. Rodríguez-Rojo, A. Matías, C. Duarte, Spray drying formulation of polyphenols-rich grape marc extract: Evaluation of operating conditions and different natural carriers. Food and Bioprocess Technol. 9, 1–13 (2016)

G. Chegini, B. Ghobadian, Effect of spray-drying conditions on physical properties of orange juice powder. Drying Technol. 23(3), 657–668 (2005)

S.P. Tan, C.K. Tuyen, S.E. Parks, C. E., Stathopoulos, P. D. Roach, Effects of the spray-drying temperatures on the physiochemical properties of an encapsulated bitter melon aqueous extract powder. Powder Technol 281, 65–75 (2015)

G. Miravet, M. Alacid, J.M. Obon, J.A. Fernandez-Lopez, Spray-drying of pomegranate juice with prebiotic dietary fibre. Int. J. Food Sci. Technol. 51(3), 633–640 (2016)

W. Wang, Y. Jiang, W. Zhou, Characteristics of soy sauce powders spray dried using dairy whey proteins and maltodextrins as drying aids. J. Food Eng. 119, 724–730 (2013)

K.G.H. Desai, H. Jin Park, Recent developments in microencapsulation of food ingredients. Drying Technol 23(7), 1361–1394 (2005)

C. Anandharamakrishnan, S. Padma Ishwarya, Spray drying techniques for food ingredient encapsulation, (John Wiley & Sons, Ltd, U.S.A., 2015)

Y. Srivastava, A.D. Semwal, G.K. Sharma, Application of various chemical and mechanical microencapsulation techniques in food sector-A review. Int. J. Food Fermentation Technol. 3(1), 1–8 (2013)

F. Shahidi, X.Q. Han, Encapsulation of food ingredients. Crit. Rev. Food Sci. Nutr. 33, 501–547 (1993)

U. Lesmes, D.J. McClements, Structure–function relationships to guide rational design and fabrication of particulate food delivery systems. Trends Food Sci. Technol. 20(10), 448–457 (2009)

J. Uhlemann, B. Schleifenbaum, H.J. Bertram, Flavor encapsulation technologies: an overview including recent developments. Perfumer and Flavorist. 27, 52–61 (2002)

B.V.N. Nagavarma, H.K. Yadav, A.V.L.S. Ayaz, L.S. Vasudha, H.G. Shivakumar, Different techniques for preparation of polymeric nanoparticles-a review. Asian J. Pharm. Clin. Res 5(3), 16–23 (2012)

V. Suganya, V. Anuradha, Microencapsulation and nanoencapsulation: a review. Int. J. Pharmaceut. Clin. Res. 9(3), 233–239 (2017)

Y.N. Konan, R. Gurny, E. Allémann, Preparation and characterization of sterile and freeze-dried sub-200 nm nanoparticles. Int. J. Pharm. 233(1–2), 239–252 (2002)

P.B. Salunkhe, P.S. Shembekar, A review on effect of phase change material encapsulation on the thermal performance of a system. Renewable and Sustainable Energy Rev 16(8), 5603–5616 (2012)

T.E. Alam, J.S. Dhau, D.Y. Goswami, E. Stefanakos, Macroencapsulation and characterization of phase change materials for latent heat thermal energy storage systems. Appl. Energy 154, 92–101 (2015)

H. Umer, H. Nigam, A.M. Tambol, M.S.M. Nainar, Microencapsulation: Process, techniques and applications. Int. J. Res. Pharmaceut. Biomed. Sci. 2(2), 474–481 (2011)

U.R. Pothakamury, G.V. Barbosa-Canovas, Fundamental aspects of controlled release in foods. Trends Food Sci. Technol. 6, 397–406 (1995)

L. Brannon-Peppas, in Controlled Release in the Food and Cosmetics Industries, ed. By M. A.El-Nokaly, D. M. Piatt, B. A. Charpentier, Properties and applications: Polymeric Delivery Systems (ACS Symposium Series 520, American Chemical Society: Washington, D.C., 1993) pp. 52.

C. Mannheim, N. Passy, in Choice of packages for foods with specific considerations of water activity, ed. ByD. Simatos, J. L. MultonProperties of Water in Foods, (MartinusNijhoff Publishers: Dordrecht, Netherlands, 1985) pp. 375–391.

B.F. Gibbs, S. Kermasha, I. Alli, C.N. Mulligan, Pressure-and heat-induced gelation of mixed beta-lactoglobulin/polysaccharide solutions: scanning electron microscopy of gels. Food Hydrocolloids 13, 339–351 (1999)

B. Pascat, in Study of some factors affecting permeability, eds. ByM. Mathlouthi, Food Packaging and Preservation: Theory and Practice (Elsevier Applied Science Publishers: London, 1986) pp. 7.

L.T. Fan, S.K. Singh, Controlled Release: A Quantitative Treatment (Springer-Verlag, Berlin Heidelberg, 1989)

K.B. Roos, Effect of texture and microstructure on flavour retention and release. Int. Dairy J. 13, 593–605 (2003)

B.F. Gibbs, S. Kermasha, I. Alli, C.N. Mulligan, Encapsulation in the food industry. Int. J. Food Sci. Nutrition 50, 213–224 (1999)

B.R. Bhandari, N. Datta, T. Howes, Problems associated with spray drying of sugar-rich foods. Drying Technol. 15(2), 671–684 (1997)

M. Sobulska, I. Zbicinski, Advances in spray drying of sugar-rich products. Drying Technology, 1–26 (2020)

Y. H. Roos, S. Drusch, in Food components and polymers, Phase transitions in foods,(Academic Press. Waltham, US, 2015) pp. 117)

Y. Ismail, L.J. Mauer, Phase transitions of ascorbic acid and sodium ascorbate in a polymer matrix and effects on vitamin degradation. J. Food Process Eng 43(5), e13073 (2020)

A. Kumar, A. De, S. Mozumdar, Synthesis of acrylate guar-gum for delivery of bio-active molecules. Bull. Mater. Sci. 38(4), 1025–1032 (2015)

D.A. Pai, V.R. Vangala, J.W. Ng, W.K. Ng, R.B. Tan, Resistant maltodextrin as a shell material for encapsulation of naringin: Production and physicochemical characterization. J. Food Eng. 161, 68–74 (2015)

F. Avaltroni, P.E. Bouquerand, V. Normand, Maltodextrin molecular weight distribution influence on the glass transition temperature and viscosity in aqueous solutions. Carbohyd. Polym. 58(3), 323–334 (2004)

The effect of drying agents on powder properties, K. Samborska, P. Gajek, A. Kami_nska-Dw_orznicka, Spray drying of honey. Polish J. Food Nutrit. Sci. 65, 109–118 (2015)

A.K. Shrestha, T. Ua-Arak, B.P. Adhikari, T. Howes, B.R. Bhandari, Glass transition behavior of spray dried orange juice powder measured by differential scanning calorimetry (DSC) and thermal mechanical compression test (TMCT). Int. J. Food Prop. 10(3), 661–673 (2007)

G. Caliskan, S.N. Dirim, The effects of the different drying conditions and the amounts of maltodextrin addition during spray drying of sumac extract. Food Bioprod. Process. 91(4), 539–548 (2013)

M.A. Magerramov, A.I. Abdulagatov, N.D. Azizov, I.M. Abdulagatov, Effect of temperature, concentration, and pressure on the viscosity of pomegranate and pear juice concentrates. J. Food Eng. 80(2), 476–489 (2007)

G.R. Chegini, J. Khazaei, B. Ghobadian, A.M. Goudarzi, Prediction of process and product parameters in an orange juice spray dryer using artificial neural networks. J. Food Eng. 84(4), 534–543 (2008)

A.M. Goula, K.G. Adamopoulos, A new technique for spry drying orange juice concentrate. Innov. Food Sci. Emerg. Technol. 11(2), 342–351 (2010)

A. Jedlińska, K. Samborska, A. Wieczorek, A. Wiktor, E. Ostrowska-Ligęza, W. Jamróz, D. Witrowa-Rajchert, The application of dehumidified air in rapeseed and honeydew honey spray drying-Process performance and powders properties considerations. J. Food Eng. 245, 80–87 (2019)

K. Samborska, A. Barańska, K. Szulc, E. Jankowska, M. ruszkowska, E. strowska-Ligęza, A. Jedlińska, Reformulation of spray-dried apple concentrate and honey for the enhancement of drying process performance and the physicochemical properties of powders. J. Sci. Food Agricult. 100(5), 2224–2235 (2020)

S. Pandey, A. Poonia, S. Rai, Optimization of spray drying conditions for the production of quality ber (ZizyphusmauritianaLamk.) fruit powder. Nutrition & Food Science 49, 1088–1098 (2019)

V.K. Singh, B.L. Mandhyan, P. Sheela, R.B. Singh, Process development for spray drying of Ber (Ziziphus jujube L.) juice. Am. J. Food Technol. 8(3), 183–191 (2013)

J. Zhang, C. Zhang, X. Chen, S.Y. Quek, Effect of spray drying on phenolic compounds of cranberry juice and their stability during storage. J. Food Eng. 269, 109744 (2020)

S. Moghbeli, S.M. Jafari, Y. Maghsoudlou, D. Dehnad, Influence of pectin-whey protein complexes and surfactant on the yield and microstructural properties of date powder produced by spray drying. J. Food Eng. 242, 124–132 (2019)

S.R. Dev, M. Annamalai, V. Orsat, V.G. Raghavan, M. Ngadi, Nanostructural characterization and sorption isotherm analysis of spray-dried date powder. Drying Technol. 36(13), 1531–1541 (2018)

N. Yusof, N.M. Adzahan, K. Muhammad, Optimization of Spray Drying parameters for white dragon fruit (Hylocereus undatus) juice powder using response surface methodology (RSM). Malaysian J. Applied Sci. 5(2), 45–56 (2020)

P. Moser, R.T.D. Souza, V.R. Nicoletti Telis, Spray drying of grape juice from hybrid cv. BRS Violeta: microencapsulation of anthocyanins using protein/maltodextrin blends as drying aids. J. Food Proc. Preservation 41(1), 12852 (2017)

C.S. Singh, V.K. Paswan, D.C. Rai, Process optimization of spray dried Jamun (Syzygiumcumini L.) pulp powder. LWT 109, 1–6 (2019)

H.S. Sathyashree, C.T. Ramachandra, P.F. UdaykumarNidoni, N. Naik, Rehydration properties of spray dried sweet orange juice. J. Pharmacognosy Phytochemistry 7(3), 120–124 (2018)

S. Santos Monteiro, Y. Albertina Silva Beserra, H. Miguel Lisboa Oliveira, M. A. D. B. Pasquali, Production of probiotic passion fruit (Passiflora edulis Sims f Flavicarpa Deg) drink using Lactobacillus reuteri and microencapsulation via spray drying. Foods 9(3), 335 (2020)

S.M. Jafari, M.G. Ghalenoei, D. Dehnad, Influence of spray drying on water solubility index, apparent density, and anthocyanin content of pomegranate juice powder. Powder Technol. 311, 59–65 (2017)

H. C. S. Araujo, M. S. Jesus, M. T. S. Leite Neta, N. C. Gualberto, C. M. S. Matos, M. Rajan,... &N. Narain,Effect of maltodextrin and gum arabic on antioxidant activity and phytochemical profiles of spray-dried powders of sapota (Manilkara zapota) fruit juice. Drying Technology 1–13 (2020).

Y. Li, B. Tang, J. Chen, P. Lai, Microencapsulation of plum (Prunus salicinaLindl.) phenolics by spray drying technology and storage stability. Food Sci. Technol. 38(3), 530–536 (2018)

N.P. Minh, T.T.Y. Nhi, T.N. Nguyen, S.N. Bich, D.T.T. Truc, Some factors influencing the properties of dried watermelon powder during spray drying. J. Pharm. Sci. Res. 11(4), 1416–1421 (2019)

Acknowledgements

The authors wish to thank the Ministry of Food Processing Industries, New Delhi for fellowship and financial support.

Funding

This work was supported by the Ministry of Food Processing Industries, India, under grant number F.No. Q-11/4/2020-R&D (1/69368/2020) Dated-13.05.2020.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Srivastava, S., Bansal, M., Jain, D. et al. Encapsulation for efficient spray drying of fruit juices with bioactive retention. Food Measure 16, 3792–3814 (2022). https://doi.org/10.1007/s11694-022-01481-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01481-4