Abstract

“Yacon” is a plant from Andean region (South America) whence it has spread to other countries. It produces roots with high content of fructooligosaccharides, inulin, some phenolic compounds among others substances. With sweet taste and low-energetic value, these roots are considered prebiotic food due to some medicinal properties. The encapsulation process via spray drying was used in this work from a pilot plant with aim to obtain a juice from this root (YJ). Solid whey (W) and maltodextrin (MD) was added in different ratios. Optimisation conditions were determined, and the best encapsulation process was YJ with MD:W ratio 80:20, which results are in agreement with those obtained by thermogravimetry/derivative thermogravimetry, differential scanning calorimetry and confirmed by field emission gun scanning electron microscopy. Thus, thermoanalytical techniques are important tools that can be used in quality control of industrial encapsulation process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Yacon (Smallanthus sonchifolius Poepp. & Endl.) is a native and perennial plant that belongs to the sunflower family (Compositae or Asteraceae). It is a crop native from Andean region in South America. Plants grow in altitude range 1000–3200 m mainly in Peru, Bolivia and Colombia whence it has spread to other countries around the world. The plant produces tuberous root weighing about 200–500 g with similar appearance to sweet potatoes; however, it does not containing starch. These roots have much sweeter taste and a crunchy pulp that is an abundant source of β-(2→1) fructooligosaccharides (FOS) and inulin. Beyond these compounds, the literature reports that yacon roots contain some quantity of antioxidants (phenolic compounds), some carbohydrates as fructose, glucose and sucrose, high water content and reduced energetic value [1–8].

In agreement with [9], yacon roots have a sweet taste due to their main soluble carbohydrate content (FOS and inulin) responsible by low-energetic value and so found with some medicinal attribute. In addition, phenolic compounds and other bioactive substances in yacon roots have been extensively described in literature which is responsible by many properties as antidiabetic, antioxidative, anti-inflammatory, anticancer and antimicrobial effects [2, 3, 8, 10].

Due to the relatively high amount of FOS and inulin in yacon roots and its prebiotic function, special attention has been given by the scientific community to these foods and substances [11–13].

The fructooligosaccharides (FOS) occur in many plants but in lower quantity than those in yacon roots [4]. The FOS are fructose oligosaccharides linked by β-(2→1) or β-(2→6) linkages and finished with a glucose molecule linked to fructose by an α-(1→2) bond [14, 15].

Inulin is a natural and non-digestible polysaccharide containing a mixture of oligomers with variable number of fructose units (degree of polymerisation 2–60 units) and with a terminal glucose molecule [6, 7].

In agreement with some authors, these substances (FOS and inulin) are responsible for some physiological benefits for consumers such as: reducing digestive problems, promoting the immune response, increasing the resistance to infection, reducing digestive allergies [3, 8, 11–13].

The drying process in industrial field is the procedure that involves removing liquid from solids by evaporation. This process has been used for various years to reduce transport weight and increase the storage life of numerous products.

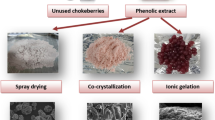

The encapsulation process via spray drying is a technique that combines several controlled unit operations as mixing, shearing, kneading, heating, cooling and forming of encapsulated material. The material is compressed to form a semisolid mass and forced to pass through a restricted opening at a predetermined rate. The temperature in the extruder can be as high as 200 °C, while the residence time is short (10 up to 60 s) [16].

The spray drying has been used in microencapsulation of bioactive compounds as prebiotics carbohydrates, micro-organisms probiotics [17]. The main advantages of this process are productivity, reduction time [18], continuous product, particle size control [19, 20] and low cost [21].

The aim of this investigation was to evaluate the optimisation of encapsulation process of yacon juice with solid maltodextrin (dextrose equiv., DE = 20) and whey in different proportions as well as operating conditions. The study was conducted with physico-chemical, thermoanalytical (TG/DTG, DSC), microscopic techniques (FEG-SEM) and measures of colour parameters.

Materials and methods

The yacon roots were obtained from CEASA-PR, Brazil, and from them was prepared the juice. The roots were maintained at 10 °C by 24 h up to juice production. Solid whey was obtained from Sooro Ltd., and solid maltodextrin (DE = 20; DE = the number of α-d-glucose unities coupled to polymer degree), from Corn Prod. Ltd.

After washing and peeling, the roots were milled and sieved with addition of 300 mg L−1 Na2S2O5 [22]. The juice obtained was freezed at −80 °C by 24 h, milled and centrifuged at room temperature. After repeated cycles, the total solid soluble from liquid fraction was analysed in refractometer up to obtain 18 °Bx. The higher solid content increases the viscosity and density and decreases the time of obtention of final product [20].

The whey and maltodextrin were dissolved in yacon juice, which was stirred by 5 min up to homogenisation. The yacon juice and proportions maltodextrin: whey were 60:40, 70:30 and 80:20 (w/w).

The encapsulation by spray-drying process was performed in agreement with literature [23], with modifications. The instrument (IWK Werke Karlsruhe Instr.—Germany, model LZT 2/10 C 280 A) was from a pilot plant in Federal University of Paraná—Brazil, with a dual-fluid nozzle spraying system. In agreement with the literature [24–26], the inlet and outlet air temperatures were 100 ± 2 and 40 ± 3 °C, respectively. The compressed air pressure to the spray flow was 1 kg cm−2 and feed flow rate of 10 mL min−1. After, the obtained product was stored in desiccator with anhydrous calcium chloride at room temperature.

The aim of the study was microencapsulation of Lactobacillus casei LC-01 in further work.

The physico-chemical analysis was performed in agreement with the literature [27] and AOAC methods [28], which protocols were: moisture (925.09), ash (923.03), proteins (920.87), lipid (968.20) and water activity (978.18). The hygroscopicity of yacon juice (YJ) encapsulated with different quantities of maltodextrin (MD) and whey (W) was determined according the method described by [27] with modifications: quantitatively, 1.0 g of encapsulated sample was stored in a container with sodium chloride saturated solution at 25 °C and with relative humidity 75 %. After 1 week, each sample was weighed and hygroscopicity expressed as g of adsorbed moisture per 100 g dry solid.

The thermogravimetric curves (TG) were obtained using the TGA-50 thermobalance (Shimadzu, Japan). The derivative thermogravimetric curves (DTG) were calculated with the software TA-60 WS. Samples were heated in alumina crucibles with heating from 30 to 600 °C, in an air flow of 100 mL min−1. The initial mass of the samples was about 9 mg. The heating rate was 10 °C min−1. The mass losses were calculated using the software TGA-50 and determining temperatures of the main stages [29–31]. The instrument was preliminarily calibrated with weight standard and with standard calcium oxalate monohydrate. The differential scanning calorimeter was used to obtain the DSC curves, and the instrument was a DSC model Q-200 (T.A. Instr. Ltd.). The curves were performed and recorded in the instrument software under an air flow of 50 mL min−1, heating rate of 10 °C min−1. The instrument was previously calibrated using indium 99.99 % purity, m.p. = 156.6 °C, ΔH = 28.56 J g−1 [29–31]. This technique was performed in two conditions. The first: each solid or semisolid substance (7.0 mg) was transferred to an open aluminium crucible, and each sample was heated from 30 to 250 °C, heating rate 10 °C min−1, dynamic atmosphere of air at 100 mL min−1. The second: upon each sample (mass around 2.0 mg), it was added 8.0 µL of distilled water in aluminium crucible with perforated lid, and each DSC curve was performed in cycles of cooling (+25 up to −50 °C) following by heating (−50 up to +250 °C). Before the analysis, the crucible and each substance were maintained for 60 min in order to equilibrate the moisture content.

The surface images of encapsulated material were obtained using a field emission gun scanning electron microscope (FEG-SEM) model MIRA 3, Tescan (Czech Rep). The parameters were: reading scale of 20 µm and 20 kV tension on field emission gun generated by a lamp with tungsten filament. The samples were pulverised over a carbon tape. As the starch is not conductive, it was necessary the metallisation with gold and palladium to promote the passage of electrons on the samples and then obtain the images through the software [29].

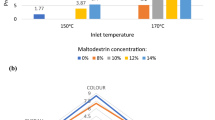

To determine the colour parameters of the encapsulated material, a MiniScan XE 45/0-L Plus (Hunter Inc., USA) reflectance spectrophotometer was used. It consists of three colour components: L*, brightness ranging from 0 (black) to 100 (white); a* ranging from positive (red) to negative (green) and b* which varies from positive (yellow) to negative (blue) [29, 32, 33]. The sample was placed on a Petri dish, and colour coordinate values were recorded.

Results and discussion

The physico-chemical analysis was determined the moisture, protein, lipids and ash content of yacon juice (c) and encapsulated yacon juice (d), (e) and (f), respectively.

All the obtained values are depicted in Table 1.

As it can be observed, different quantities of maltodextrin (MD) had significant influence (p < 0.05) upon the water adsorption values in encapsulated juice. The decrease in hygroscopicity occurs with increase in MD. The results are in agreement with literature which reports that higher MD concentrations led to powder with greater stability [20, 34].

TG/DTG curves, Fig. 1a, b, were performed with solid substances, except the yacon juice, Fig. 1c, that was concentrated up to liquid viscosity at 18 °Bx. The other substances were encapsulated via spray drying, Fig. 1d–f. All the calculated results can be observed in Table 2.

TG/DTG curves of samples: a solid whey, 9.07 mg; b solid maltodextrin, 9.31 mg; c semisolid yacon juice, 9.81 mg; d encapsulated yacon juice with whey and maltodextrin ratio 60:40, 9.61 mg; e encapsulated yacon juice with whey and maltodextrin ratio 70:30, 9.51 mg; f encapsulated yacon juice with whey and maltodextrin ratio 80:20, 9.24 mg

Solid whey (W) (Fig. 1a) shows mass loss in fourth main stage, being the first (2.57 %) due to dehydration process. The second is due to protein denaturation with decomposition that occurs simultaneously and followed by decomposition of the organic matter.

Maltodextrin (MD) (Fig. 1b) show mass loss in three steps, similarly to starches, from which this substance is obtained. The first stage of decomposition was attributed to dehydration process, followed by stability up to 189 °C. Once dehydrated occur the decomposition and oxidation of organic matter in two consecutive reactions.

The yacon juice (YJ), a viscous liquid, 18 °Bx, Fig. 1c, shows mass loss in three steps; the first was higher due to the water content (84.66 %—TG and 83.40 % physico-chemical analysis). The second and third mass losses of yacon juice are attributed to decomposition of FOS and inulin (the major components) of yacon. These results are in agreement with literature [12, 13] in which were found that FOS and/or inulin from chicoria exhibit the similar behaviour.

After encapsulated the yacon juice with maltodextrin and whey, the sample (d, MD:W ratio 60:40) shows mass loss in four stages. The samples (e, MD:W ratio 70:30) and (f, MD:W ratio 80:20) show mass loss in five steps. In all samples, the first mass loss is due to dehydration, and the others attributed to decomposition and oxidation of organic matter. In agreement with the increase in maltodextrin in samples (e) and (f), these substances showed five mass losses (according DTG peaks). The final stability of the treated yacon juice was directly proportional to increase in maltodextrin, which were displaced to higher temperatures.

Figure 2 shows the DSC curves from 30 to 250 °C. These curves were performed in agreement with the first conditions previously described and in order to monitor the TG/DTG curves.

The “onset”, “peak” and “conclusion” temperatures (T o, T p and T c) were determined as well as the enthalpy. The obtained results are shown in Table 3.

Solid whey (W) (Fig. 2a) shows a large endotherm up to 97 °C attributed to slow dehydration process and followed by protein denaturation that begins at 97 °C with T p = 145 °C. The endotherm peak at 195 °C was due to decomposition of organic matter.

The solid MD (Fig. 2b) show a main endotherm at 49 °C due the dehydration process followed by an second endotherm that occurs simultaneously with decomposition as described in TG/DTG results.

Yacon juice at 18 °Bx, (YJ), Fig. 2c, exhibits only the main endotherm peak at 72 °C that was due the dehydration process, in correspondence with TG/DTG and physico-chemical analysis.

The encapsulated yacon juice (YJ) with maltodextrin and whey (MD:W) in different ratios (60:40, 70:30 and 80:20, respectively), Fig. 2d–f, shown three main consecutive endotherm peaks in correspondence with the mass loss in TG/DTG curves.

Figure 3 shows all the DSC curves with cycles of cooling and heating of each sample.

As observed in Fig. 3, all the substances show in the first cycle (cooling) an exotherm phenomenom due to the crystallisation process. In Table 4 are collected all the obtained parameters, onset, peak and conclusion temperatures (T o, T p and T c) as well as the calculated enthalpy (ΔH).

When the substances reached −50 °C started the second cycle (heating) that was from this temperature up to +250 °C. The first endothermic peak was attributed to melting of water with each substance. Differences in Tp and ΔH values between fusion and crystallisation processes are attributed to dehydration that occurs in low temperatures, since the crucibles were covered with perforated lid.

As can be seen in Fig. 3, the first endothermic peak is due to melting of water with each substance and the second endotherm peaks observed in DSC curves is due to evaporation and decomposition process that occurs in consecutive and superposed stages, in correspondence with TG/DTG curves. These endothermic events were displaced to higher temperatures attributed to use of perforated lid and differences in thermal conductivity of the used crucibles. All the parameters of this first decomposition stage are shown in Table 4.

The field emission gun scanning electon microscopy (FEG-SEM) microimages of the substances after microencapsulated material with magnification of 750× are collected in Fig. 4. As it can be observed the encapsulation via spray drying of yacon juice YJ with maltodextrin and whey MD:W ratio 80:20, Fig. 4f, presents major homogeneity in encapsulation and particle size [10, 35].

Figure 4d, e showed wrinkled surface with high tendency to agglomeration due to high higroscopicity, which is undesirable. Similar results were obtained by other authors [10, 36, 37].

Table 5 shows the results of colour parameters from the encapsulated yacon juice with maltodextrin and whey. As observed, the values from (L*), lightness, increased when the (a*), redness to greenness, and (b*), yellowness to blueness, decreased [38–40].

These results are in correspondence with the efficiency of encapsulation process and tendency to yellow once the whey is a substance with this colour. In other work, the biotechnological application of cheese whey the author describes similar behaviour [41].

Conclusions

Thermal analysis techniques are important tools to assess and establish parameters with purpose of applications in encapsulation process via spray drying aiming industrial applications.

The best homogeneity process of encapsulated yacon juice was observed in the ratio MD:W 80:20 (f) which results are in agreement with stability observed by TG and DSC curves. The same homogeneity was observed with FEG-SEM microimages that show continuous particle size. The efficiency of encapsulation was observed also in the final colour of encapsulated material, as expected (f), which increase in L* value and lower tendency to yellow due to minor ratio of whey.

The thermal analysis techniques were important tools to choose the best concentration of encapsulation agent (whey and maltodextrin) and the range temperature. The TG/DTG and DSC techniques allowed to obtain values of degradation of main components of yacon juice (FOS and Inulin). This work was performed with the aim of encapsulation of probiotic micro-organism (Lactobacillus casei—LC 01; in future work) in yacon juice once that some substances degrade in relatively low temperature.

References

Lachman J, Fernández EC, Orsák M. Yacon [Smallanthus sonchifolia (Poepp. et Endl.) H. Robinson] chemical composition and use—a review. Plant Soil Environ. 2003;49:283–90.

Campos D, Betalleluz-Pallardel I, Chirinos R, Aguilar-Galvez A, Noratto G, Pedreschi R. Prebiotic effects of yacon (Smallanthus sonchifolia Poepp. et Endl.), a source of fructooligosaccharides and phenolic compounds with antioxidant activity. Food Chem. 2012;135:1592–9.

Delgado GTC, Tamashiro WMSC, Júnior MRM, Pastore GM. Yacon (Smallanthus sonchifolius): a functional food. Plant Food Hum Nutr. 2013;68:222–8.

Genta S, Cabrera W, Habib N, Pons J, Carillo IM, Grau A. Yacon syrup: beneficial effects on obesity and insulin resistance in humans. Clin Nutr. 2009;28:182–7.

Valentová K, Lebbeda A, Dolezalová I, Jirovski D, Simonovska B, Vovk I, Kosina P, Gasmanová N, Dziechciarková M, Ulrichová J. The biological and chemical variability of yacon. J Agric Food Chem. 2006;54:1347–52.

Reis FR, Lenzi MK, Masson ML. Effect of vacuum drying conditions on the quality of yacon (Smallanthus sonchifolius) slices: process optimization toward color quality. J Food Process Pres. 2012;36:67–73.

Pedreschi R, Campos D, Noratto G, Chirinos R, Cisneros-Zevallos L. Andean yacon root (Smallanthus sonchifolius Poepp. Endl) fructooligosaccharides as a potential novel source of prebiotics. J Agric Food Chem. 2003;51:5278–84.

Yan X, Suzuki M, Ohnishi-Kameyama M, Sada Y, Nakanishi T, Nagata T. Extraction and identification of antioxidants in the roots of yacon (Smallanthus sonchifolius). J Agric Food Chem. 1999;47:4711–3.

Cazetta ML, Martins PMM, Monti R, Contiero J. Yacon (Smallanthus sonchifolius) extract as a substrate to produce inulinase by Kluyveromyces marxianus var. bulgaricus. J Food Eng. 2005;66:301–5.

Lago CC, Bernstein A, Brandelli A, Norena CZ. Characterization of powered yacon (Smallanthus sonchifolius) juice and pulp. Food Bioproc Technol. 2012;5:2183–91.

Santana I, Cardoso MH. Yacon tuberous root (Smallanthus sonchifolius): cultivation potentialities, technological and nutritional aspects. Cienc Rural. 2008;38:898–905.

Leone RS, Colman TAD, Schnitzler E, Ellendersen LN, Massom ML. Evolved gas analysis (coupled TG–DSC–FTIR) applied in the study of fructooligosaccharides from chicory. J Microbiol Biotechnol Food Sci. 2014;4:10–2.

Leone RS, Colman TAD, Schnitzler E, Ellendersen LN, Massom ML. Evolved gas analysis (coupled TG–DSC–FTIR) applied to thermal behaviour od inulin. J Anal Appl Pyrol. 2014;108:323–6.

Fernández EC, Rajchl A, Lachman J, Cízková H, Kvasniczka F, Kotíková Z, Milella L, Voldrich M. Impact of yacon landraces cultivated in the Czech Republic and their ploidy on the short- and long-chain fructooligosaccharides content in tuberous roots. LWT Food Sci Technol. 2013;54:80–6.

Campbell JM, Bauer LL Jr, GC Fahey, Hogarth AJCL, Wolf BW, Hunter DE. Selected fructooligosaccharide (1-kestose, nystose, and 1F-β-fructofuranosylynstose) composition of foods and feeds. J Agric Food Chem. 1997;45:3076–82.

Hijo AACT, Costa JMG, Silva EK, Azevedo VM, Yoshida MI, Borges SV. Physical and thermal properties of oregano (Oregano vulgare L.) essential oil microparticles. J Food Proc Eng. 2015;38:1–10.

Krishnaiah D, Nithyanandam R, Sarbatly RA. Critical review on the spray drying of fruit extract: effect of additives on physicochemical properties. Crit Rev Food Sci. 2014;54:449–73.

Santivarangkna C, Kulozik U, Foerst P. Effect of carbohydrates on survival of Lactobacillus helveticus during vacuum drying. Lett Appl Microbiol. 2006;42:271–6.

Madene A, Jacquot M, Scher J, Desobry S. Flavour encapsulation and controlled release—a review. Int J Food Sci Technol. 2006;41:1–21.

Gharsallaoui A, Roudaut G, Chambin O, Voilley A, Saurel R. Applications of spray drying in Microencapsulation of food ingredients: an overview. Food Res Int. 2007;40:1107–21.

Desobry SA, Netto FM, Labuza TB. Comparison of spray drying, drum drying and freeze drying for (1–3, 1–4)-b-carotene encapsulation and preservation. J Food Sci. 1997;62:1158–62.

Maia GA, Monteiro JCS, Guimarães ACL. Estudo da estabilidade físico-química e química do suco de caju com alto teor de polpa. Cienc Technol Aliment. 2001;21:43–6.

Kingwatee N, Apichartsrangkoon A, Chaikham P, Worametrachanon S, Techarung J, Pankasemsuk T. Spray drying Lactobacillus casei 01 in lychee juice varied carrier materials. LWT Food Sci Technol. 2014;xxx:1–7.

Duongthingoc D, George P, Katopo L, Gorczyca E, Kasapis S. Effect of whey protein agglomeration on spray dried microcapsules containing Saccharomyces boulardii. Food Chem. 2013;141:1782–8.

Obón JM, Castellar MR, Alacid M, Fernández-López JA. Production of a red–purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. J Food Eng. 2009;90:471–9.

Rajam R, Anandharamakrishnan C. Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharide as wall material by spray drying. Food Sci Technol. 2015;60:773–80.

Tonon RV, Brabet C, Hubinger MD. Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. J Food Eng. 2008;88:411–8.

AOAC. Official methods of analysis, 14th edn. Washington, DC: Association of Official Analytical Chemists; 1990.

Hornung PS, Oliveira CS, Lazzarotto M, Lazzarotto SR, Schnitzler E. Investigation of the photo-oxidation of cassava starch granules—thermoanalytical, rheological and structural behaviour. J Therm Anal Calorim. 2016;123:2129–37.

Beninca C, Colman TAD, Lacerda LG, Carvalho Filho MAS, Bannach G, Schnitzler E. The thermal, rheological and structural behaviour of cassava starch granules modified with hydrochloric acid at different temperatures. Thermochim Acta. 2013;552:65–9.

Costa FJOG, Leivas CL, Waszczynskyj N, Godoi RCB, Helm CV, Colman TAD, Schnitzler E. Characterisation of native starches of seeds of Araucaria angustifolia from four germplasm collections. Thermochim Acta. 2013;565:172–7.

Colman TAD, Demiate IM, Schnitzler E. The effect of microwave radiation on some thermal, rheological and structural properties of cassava starch. J Therm Anal Calorim. 2014;115:2245–52.

Andrade MMP, Oliveira CS, Colman TAD, Costa FJOG, Schnitzler E. Effects of heat-moisture treatment on organic cassava starch. Thermal, rheological and structural study. J Therm Anal Calorim. 2014;115:2115–22.

Shahidi F, Han XQ. Encapsulation of food ingredients. Crit Rev Food Sci Nutr. 1993;33:501–47.

Wang W, Jiang Y, Zhou W. Characteristics of soy sauce powders spray-dried using dairy whey proteins and maltodextrins as drying aids. J Food Eng. 2013;119:724–30.

Rodriguez-Hernandez GR, Gonzalez-Garcia R, Grazales-Lagunes A, Ruiz-Cabrera MA, Abud-Archila M. Spray drying of cactus pear juice (Opuntia streptacantha):effect on the physicochemical properties of the powder and reconstituted product. Dry Technol. 2005;23:955–73.

Mishra P, Mishra S, Mahanta CL. Effect of maltodextrin concentration and inlet temperatureduring spray drying on physicochemical and antioxidantproperties of amla (Emblica officinalis) juice powder. Food Bioprod Process. 2014;92:252–8.

Caliskan G, Dirim SN. The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technol. 2016;287:308–14.

Ahmed M, Akter MS, Lee JC, Eun JB. Encapsulation by spray drying of bioactive components, physicochemical and morphological properties from purple sweet potato. LWT Food Sci Technol. 2010;43:1307–12.

Nadeem HS, Torun M, Ozdemir F. Spray drying of the mountain tea (Sideritis strica) water extract by using different hydrocolloid carriers. LWT Food Sci Technol. 2011;44:1626–35.

Siso MGI. The biotechnological utilization of cheese whey: a review. Bioresour Technol. 1996;57:1–11.

Acknowledgements

The authors gratefully acknowledge the financial resources provided by the Coordination of Research and Superior Education (CAPES), Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bisinella, R.Z.B., de Oliveira, C.S., Zappani, P.S.C. et al. Thermal analysis as screening technique to assess spray-drying process of encapsulated “yacon” juice. J Therm Anal Calorim 126, 1841–1849 (2016). https://doi.org/10.1007/s10973-016-5696-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5696-z