Abstract

Optimum technology of spray-dried jujube powder was studied using a Box-Benhnken design. Effects of weight ratio of maltodextrin and the dry matter weight of jujube pulp (WR, 3–5), inlet air temperature (T, 140–160 °C), and shift of feed flow rate (FFR, 3–5) on the quality attributes (moisture content, lightness, the total color difference, vitamin C (VC) content and hygroscopicity) of jujube powder were systematically studied by response surface methodology and perturbation plot. Analysis of variance showed that a second-order polynomial equation could predict the experimental data well (R 2 > 0.92). Moisture content and the total color difference (∆E) were significantly affected by WR, T, and FFR. The higher WR and lower FFR resulted in a decrease in moisture content and ∆E. WR and FFR had extremely significant effects on VC content and hygroscopicity (P < 0.01); with lower WR and FFR, higher values of VC content and hygroscopicity would be received. The effect of WR was the most significant variable among others. The optimum conditions that maximizing VC content and minimizing contents of moisture, ∆E, and hygroscopicity of jujube powder were found as WR of 3, inlet air temperature of 140 °C, and FFR of 3 ( i.e., 11 ml/min). Under these conditions, the response values were moisture content of 3.36 %, lightness of 83.32, ∆E of 9.92, VC content of 205.10 mg/100 g, and hygroscopicity of 18.59 %, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Jujube (Zizyphus jujuba Miller) is the fruit of the genus Ziziphus, which is widely consumed in more than 30 countries around the world (Fang et al. 2011). Jujube is indigenous in China with more than 4,000 years of history (Fang et al. 2009a), and it is famous for its high nutritional value. Meanwhile, it has been used as traditional medicine treatment such as analeptic, palliative, and antibechic in China (Li et al. 2007). In recent years, other functional activities of jujube have also been extensively studied, including the functions of liver protection (Wang et al. 2012; Guil-Guerrero et al. 2004 ), antioxidant (Wang et al. 2012; Gao et al. 2011; Li et al. 2005 ), and antitumor (Fatemeh et al. 2008). However, fresh jujube fruit was perishable and 20–30 % of fresh jujube was decayed every year. Moreover, it can only be kept for a few days after harvest because of its high moisture (75 ~ 80 %). Hence, it is crucial to do in-depth study on jujube processing and preservation.

Drying is a common method to preserve the jujube. The drying methods for jujube include traditional drying and artificial drying. Traditional drying methods like sun and air drying have many disadvantages, resulting in lower economic efficiency (Fang et al. 2009b). However, artificial drying methods such as spray drying and microwave drying can greatly improve the quality of dried products (Fang et al. 2010). In a previous study, hot air drying, microwave drying, and hot air combined with microwave drying for the whole jujube had been reported (Fang et al. 2009a; Fang et al. 2009b; Fang et al. 2010; Fang et al. 2011). The jujube powder is one of the most popular forms for jujube industry application; however, it has not been systematically investigated. Only Kim et al. (2012) analyzed the physical and chemical properties of jujube powder made by air, vacuum, and freeze drying.

Spray drying is a extensively used industrial technology in a large scale for drying materials from liquid into powders, which not only can extend the shelf-life, but reduce volume to a convenient handing level as well (Sagar and Suresh Kumar 2010; Tze et al. 2012). This technique offers the advantages of low water activity, relatively low temperatures and short particle residence time (Kha et al. 2010; León-Martínez et al. 2010). Hence, certain properties of materials, such as nutrients, color and flavor, are maintained in high percentages (Rodríguez-Hérnandez et al. 2005). Now, spray drying has been successfully applied to produce dried fruits and vegetable powders from concentrated bayberry juice (Gong et al. 2008), blackberry pulp (Ferrari et al. 2012), Gac fruit aril juice (Kha et al. 2010), nopal mucilage extracts (León-Martínez et al. 2010), cantaloupe juice (Solval et al. 2012), and fermented mixed juice of carrot and watermelon (Mestry et al. 2011). However, there is no research on the preparation of jujube powder by spray drying.

The purpose of this study was to obtain the optimal processing conditions of jujube pulp powder by spray drying using response surface methodology. The independent variables were inlet air temperature (T), weight ratio of maltodextrin and the dry matter weight of jujube pulp (WR), and shift of feed flow rate (FFR); moisture content, color, VC content, and hygroscopicity, which were very important parameters of jujube powder and significantly affected by independent variables, were chosen as responses.

Materials and Methods

Materials and Reagents

Fresh Chinese jujube (Z. jujuba Miller) samples were harvested in October 2012 from Zhanhua, Shangdong Province, China. Samples were stored at 4 °C in a refrigerator until use. Citric acid and oxalic acid were of analytical grade and purchased from Beijing Beihua Fine Chemicals Company (Beijing, China); pectinase was supplied by Novozymes Company (Beijing, China). 2, 6-Dichloroindophenol sodium salt hydrate (purity ≥ 95 %) was obtained from Sigma-Aldrich Company (St. Louis, MO, USA). Maltodextrin (LuZhou Bio-Chem Technology Co., Ltd., Shandong, China) with 10–15 dextrose equivalents (DE) was used in the experiments.

Sample Preparation

Fresh jujube samples were washed, pitted, sliced into eight parts, and weighed (100 g). Then, 500 ml water was added, and the mixture was heated with boiling water for 3 min until jujube was softened. pH value of the mixture was adjusted to 4.0 by citric acid, and 0.1 % pectinase was further added. The temperature and time of pectinase enzymolysis were 50 °C and 50 min, respectively. After that, the mixture was placed in 90 °C water bath and held for 1 min for enzyme deactivation. Maltodextrin was then added into the pulp, and the mixture was homogenized for 5 min in a JMS 50 colloid mill (Langfang TongYi machinery Co., Ltd., Hebei, China) before spray drying.

Spray Drying Process

A laboratory-scale spray dryer (SD-Basic, Labplant UK Ltd., North Yorkshire, UK) was used in the process, which was mainly supplied with control panel, electric resistance heater, peristaltic pump, two fluid nozzle, drying chamber, and cyclone. Ambient air was heated by an electric resistance heater and the heated air was blown in co-current of the sprayed liquid through the drying chamber. The inlet air temperature was measured and the mixture was fed through a self-priming peristaltic pump to the two fluid nozzles where it was atomized and sprayed into the drying chamber. Thus, the jujube powder and dust were separated in the cyclone separator. All the spray-dried jujube powders were collected, weighed, sealed in a bottle, and stored at 4 °C.

Experimental Design

Weight ratio of maltodextrin and the dry matter weight of jujube pulp (WR, X 1), inlet air temperature (T, X 2), and FFR (X 3) were selected as the independent variables based on the preliminary study results. Response surface methodology (RSM) was used for modeling and analyzing of the optimization process. The experimental design employed in the experiment was a Box–Benhnken design which consisted of 17 runs and five replicates of the central point for the estimation of pure error. The response variables (Y n ) were moisture content (Y 1), lightness value (L, Y 2), the total color difference (∆E, Y 3), VC content (Y 4), and hygroscopicity (Y 5).

Each independent factor was varied over three levels: the high level (+1), the low level (−1), and the center points (coded level 0). The relations between the coded and original values can be obtained using the following equation:

where X 1, X 2, and X 3 were the coded values of weight ratio of maltodextrin and the dry matter weight of jujube pulp, inlet air temperature, and shift of feed flow rate. WR, T, and FFR were the corresponding original values. WRc, T c, and FFRc were the original values in the center of the domain: WRc = 3, T c = 150 °C, FFRc = 4 (equivalently 11 ml/min). ∆WR, ∆T, and ∆FFR were the increments of WR, T, and FFR corresponding to one unit of X 1, X 2, and X 3, respectively: ∆WR = 1, ∆T = 10 °C, ∆FFR = 1. Coded and original levels for independent variables are shown in Table 1. All the experiments were carried out in a random order to minimize the effect of unexpected variability due to extraneous factors.

Statistical Analysis

As for optimization of spray-drying process, the responses were analyzed using Design Expert software (Version 8.0.6, Stat-Ease Inc., MN, USA). A second-order polynomial regression model was assumed for predicting all Y responses (Y 1 − Y 5) which could be expressed by the following equation:

where A 0 was a constant; A 1, A 2, and A 3 were linear coefficients; A 12, A 13, and A 23 were cross-product coefficients; and A 11, A 22, and A 33 were quadratic coefficients. The fitness of the model was evaluated by the coefficient of determination R 2 and the analysis of variance (ANOVA, F-test). The effects of the independent variables were displayed in response surfaces and perturbation plots. All samples were treated and analyzed in triplicate. A value of p < 0.05 was considered as statistically significant.

Physicochemical Properties of the Jujube Powder

Moisture Content

The moisture content of jujube powder was determined by drying in an oven at 105 °C until a constant weight was obtained (AOAC 1984). Moisture loss was expressed in terms of percent wet basis (wb).

Color

The color of jujube powder was measured in terms of the CIE L *, a *, and b * values using a colorimeter (DL-25, Hunterlab, America). L * represents the lightness (L * = 0 for black and L * = 100 for white), a * indicates red (+) to green (−) axis, and b * illustrates yellow (+) to blue (−) axis (Duangmal et al. 2008). The total changes in color could be expressed by ∆E which showed the difference between the measured object and the standard whiteboard. It could be calculated as formula (5):

where L, a, and b represent the values of powder sample. L *, a *, and b* represent the values of standard whiteboard which were calculated as 91.44, −0.95, and 0.69, respectively (Cui et al. 2003).

VC Content

Vitamin C content was determined by the 2,6-dichloroindophenol titrimetric method (AOAC 1995). Ten grams of jujube powder was dispersed in 10 ml 2 % oxalic acid solution and pounded to homogenate. Then, the mixture was transferred into a 100-ml volumetric flask, diluted with 2 % oxalic acid solution to constant volume, mixed, and filtered. Accurately10 ml of filtrate was titrated with 2,6-dichloroindophenol sodium salt hydrate solution until the solution turned pink and then kept for at least 15 s. The result was expressed as milligrams of vitamin C per 100 g of jujube powder.

Hygroscopicity

Hygroscopicity (HG, %) is the ability of a substance to attract and hold water molecules from the surrounding environment. HG of jujube powder was determined according to the previous study with some modifications (Cai and Croke 2000; Caparino et al. 2012; Ferrari et al. 2012). Briefly, one gram of jujube powder was placed in a dry aluminum specimen box which had constant weight. The aluminum specimen box was put in a glass desiccator containing saturated NaCl solution (75.5 % humidity) and stored for 7 days. Three parallel tests had been done. HG (%) represented the grams of absorbed moisture per 100 g dry solids and was calculated by Eq. (6) (Caparino et al. 2012):

where M was the initial weight of jujube powder, ∆m (g) was the change in weight of jujube powder, and M i was the free water content of the jujube powder before exposing to 75.5 % humidity environment.

Results and Discussion

In the present study, effects of independent factors (WR, T, and FFR) on the responses in spray drying process were analyzed by RSM and perturbation plot. The design layout and responses for each experiment are shown in Table 1.

Influence of Variables on the Moisture Content of Jujube Powder

Moisture content is one of the major factors that affect powder stability. As a plasticizer, only a small amount of water will increase the food matrix mobility and cause stickiness and agglomeration during powder product storage (Moreira et al. 2009). As shown in Table 1, the moisture content of jujube powder varied from 1.97 to 6.65 % wb. To examine the conditions that affected the moisture content of jujube powder, its regression model could be predicted by Eq. (7) as follows:

where X 1, X 2, and X 3 were coded levels of WR, T, and FFR, respectively. From Table 2, results of ANOVA showed that experimental data were well represented by the obtained second-degree polynomial equation (R 2 = 0.9718, Adj. R 2 = 0.9356). According to the model, linear term of WR (X 1) and FFR(X 3) and quadratic terms of WR (X 1 2) reached an extremely significant level (P < 0.01), and the effect of inlet air temperature (X 2) on the moisture content of jujube powder was also significant (P < 0.05).

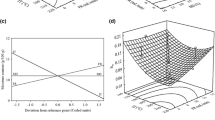

The best way of visually expressing the effect of variables on the responses within the experimental space under investigation was to generate response surface plots of the model (Özkal et al. 2005). Response surfaces for the effects of variables on the moisture content of jujube powder were shown in Fig. 1a–c. The region of low moisture content which could be easily identified from the three-dimensional plot was around WR = 4, T = 160 °C, and FFR = 3. The trend of moisture content changes as one factor moved from the design range with the other factor held constant at the reference value was shown by the perturbation plot (Fig. 1d). In the present study, the reference point was set at the middle of the design space (WRc = 3, T c = 150 °C, FFRc = 4). Results showed that WR and T had negative effects on the moisture content of jujube powder (curves A and B), while FFR had a positive effect on moisture content (curve C). A higher WR led to the reduction of moisture content because the addition of maltodextrin to the feed solution increased the total solid content and reduced the total amount of water available for evaporation (Ferrari et al. 2012). Increasing inlet air temperature (T) resulted in greater loss of water due to the higher rate of heat transfer into the particles, providing higher driving force for water removal. Consequently, jujube powder had lower moisture content. The larger the FFR value was, the higher moisture content would be obtained. Higher FFR reduced the residence time between droplets and drying air, leading to less efficient heat transfer. This resulted in higher moisture content of jujube powder (Kurozawa et al. 2009). Additionally, these results were consistent with those reported by Ferrari et al. (2012), Moreira et al. (2009), and Kha et al. (2010).

Influence of Variables on the Color of Jujube Powder

The color of powder is one of the most obvious attributes of jujube powder. The regression models obtained for L and ∆E are given by Eqs. (8) and (9) as follows:

As shown in Table 2, the correlation coefficients were relatively high for two models: R 2 = 0.9833, Adj. R 2 = 0.9617 for the L value of jujube powder; R 2 = 0.9740, Adj. R 2 = 0.9406 for ∆E of jujube powder. ANOVA results showed that both lightness and ∆E were significantly impacted by WR and T (P < 0.05). For ∆E, it was also significantly affected by FFR and quadratic terms of WR. However, the interactions between variables had no significant effect on L and ∆E.

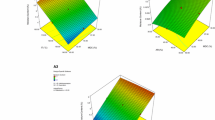

Response surfaces for effects of variables on the L value are shown in Fig. 2a–c. As shown in Fig. 2a–c, the optimum conditions for the maximum value of L were around WR = 4, FFR = 3, and T = 145–150 °C. The higher L value of jujube powder was progressively obtained by increasing WR from 2 to 4 (curve A in Fig. 2d). Similar results have also been observed in blackberry (Ferrari et al. 2012), Pitaya fruit (Tze et al. 2012), and gac fruit aril (Kha et al. 2010) produced by spray drying. L value was lower at a higher inlet air temperature (curve B in Fig. 2d); this phenomenon was mainly because of the high sugar content in jujube, which contributed to browning of the powder. However, FFR had no significant (P >0.05) effect on the L value of jujube powder.

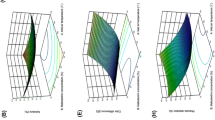

The ∆E in the samples was found to vary between 8.53 and 11.92. Response surface for the effects of variables on the ∆E of jujube powder was shown in Fig. 3a–c. It was shown that the highest level of ∆E were found at WR = 2, T = 160 °C, and FFR = 5, and the lowest values of ∆E were found at WR = 4, T = 140 °C, and FFR = 3. Results of perturbation plot (Fig. 3d) showed that WR had a negative effect on ∆E of jujube powder (curve A), and FFR and T had positive effects on ∆E value (curves B and C). ∆E value decreased with the increasing maltodextrin concentration. Rodríguez-Hérnandez et al. (2005) also found that maltodextrin concentration had a significant influence on ∆E of cactus pear juice, but there were positive relationships between them. Their differences may be due to the different color characteristics of their raw materials. Increasing inlet air temperature significantly resulted in an increase in ∆E. Similar results were also found by Kha et al. (2010). The higher the FFR, the larger ∆E will be. According to Figs. 1d and 3d, with increasing FFR (line C), higher moisture content and ∆E values could be gained. The same results could be obtained by comparing with experiments (5) and (16) and (13) and (17) (Table 1). In this study, when the moisture content of jujube powder was high, the color of the powder was darker. Hence, the relatively high moisture content under high FFR conditions may result in an increase of ∆E.

Influence of Variables on the VC Content of Jujube Powder

VC is widely presented in jujube which has many functional activities. It is critical to detect the change of VC content before and after spray drying. The quadratic model for VC content of jujube powder was represented by Eq. (10):

ANOVA results presented in Table 2 showed that both R 2 and adjusted R 2 for the model were greater than 0.98, indicating well fitting of the second-order equations. VC content of jujube powder was significantly affected by WR, FFR, and quadratic terms of WR. However, T had no significant effect on VC content in this study.

As shown in Fig. 4a–c, the highest VC content was obtained when WR = 2, T = 150 °C, and FFR = 3, while when under the condition of WR = 4, T = 160 °C, and FFR = 5, VC content was the lowest. From the perturbation plot analysis (Fig. 4d), the curve shape of WR (A line) was steeper than those of T and FFR (B and C lines). It indicated that VC content was more sensitive to WR than others, i.e., effect of WR on VC content was the most significant variable among others. Increasing WR resulted in a decrease in VC content. The higher value of WR means less content of jujube, so VC content was correspondingly decreased. However, inlet air temperature did not show a significant effect on VC content. This result was different with others. Nizori et al. (2012) reported that the inlet air temperature showed a significant effect on the retention of VC; increasing inlet air temperature led to increasing of VC retention, whereas Selvamuthukumaran and Khanum (2013) indicated that the inlet air temperature had maximum influence on VC content. The loss of VC was due to use of high temperature during processing (148–191 °C). Goula and Adamopoulos (2005) showed that lycopene loss increased with increase in inlet air temperature during spray drying (110–140 °C). Ferrari et al. (2012) also found that anthocyanin retention was lower when increasing the inlet air temperature (140–180 °C). Their differences may be due to the raw materials and operation conditions.

Influence of Variables on the Hygroscopicity of Jujube Powder

Hygroscopicity could be defined as a measurement of the ability of the food to contain occluded moisture which also was an important property to be considered during the storage of jujube powder (Rodríguez-Hérnandez et al. 2005). The second-order equation obtained for hygroscopicity of jujube powder was given as follows:

Results of ANOVA presented in Table 2 showed that there were highly statistically significant multiple regression relationships (P < 0.01) between WR, FFR, and the hygroscopicity of jujube powder. T did not show a significant effect on the hygroscopicity. Results also showed that the experimental data was well expressed by the obtained equation (R 2 = 0.9264, Adj. R 2 = 0.8317).

A demarcation for hygroscopicity of jujube powder ranged from 16.27 to 20.65 % in this study. From the response surfaces for hygroscopicity of jujube powder (Fig. 5a–c), it was obvious that the lowest value of hygroscopicity was at WR = 4, T = 140 °C, and FFR = 5. The opposite effect, i.e., the most hygroscopic jujube powder, was obtained at WR = 2, T = 150 °C, and FFR = 3. The least hygroscopicity values were obtained when the highest maltodextrin concentrations were used. This is due to the low hygroscopicity of maltodextrin, confirming its efficiency as a carrier agent during spray drying process (Ferrari et al. 2012; Caparino, et al. 2012). The lower hygroscopicity values were obtained with decreasing T and increasing FFR (Fig. 5d), which affected the moisture content of jujube powder in an opposite way. That indicated that the lower the moisture content, the greater is their ability to absorb water, i.e., higher hygroscopicity would be obtained. Goula et al. (2004) confirmed that hygroscopicity increased inversely with moisture content in the study of spray-dried tomato powder. Tonon et al. (2008) also found that the low-moisture spray-dried açai had the greater capacity to absorb moisture from the surrounding air and was more hygroscopic, but Ahmed et al. (2010) reported that the hygroscopicity of spray-dried sweet potato had no direct relationship with different moisture contents, but it was correlated with the carrier agent. By this token, the moisture–hygroscopicity relationship cannot be generalized for all commodities, but it was suitable for the situation in the present study.

Optimization and Verification

WR, T, and FFR were optimized simultaneously through a desirability function which would satisfy all the responses with requirements to obtain optimum spray drying conditions. The ultimate aim was to obtain the lowest moisture content, ∆E, and hygroscopicity of jujube powder while maintaining the highest VC content. So, the optimization processes for the variables were investigated in the present study.

The numerical optimization for the optimum conditions during spray drying is shown in Table 3. Through comprehensive optimization, the predicted optimum conditions were obtained at WR = 3, T = 143 °C, and FFR = 3. Verification experiment was carried out to confirm the adequacy of the models at WR = 3, T = 140 °C, and FFR = 3, and results showed that the experimental values were in perfect agreement to the predicted values with less than 5 % error (Table 4). Hence, the optimum conditions for preparation of jujube powder by spray drying were as follows: weight ratio of maltodextrin and the dry matter weight of jujube pulp was 3, inlet air temperature was 140 °C, and shift of feed flow rate was 3. Under these conditions, the response values were moisture content of 3.36 %, L value of 83.32, ∆E of 9.92, VC content of 205.10 mg/100 g, and hygroscopicity of 18.59 %, respectively.

Conclusions

RSM and perturbation plot were successfully applied for estimating the effect of WR, T, and FFR on the quality attributes (moisture content, color, VC content, and hygroscopicity) of jujube powder. Results showed that WR had an extremely significant effect on all the responses (P < 0.01), and the effect of WR was the most significant among the variables. The optimum conditions maximizing VC content and minimizing moisture content, ∆E, and hygroscopicity of jujube powder were found as WR of 3, inlet air temperature of 140 °C, and FFR of 3 (i.e., 11 ml/min). Under these conditions, the response values were moisture content of 3.36 %, L value of 83.32, ∆E of 9.92, VC content of 205.10 mg/100 g, and hygroscopicity of 18.59 %, respectively.

References

Ahmed, M., Akter, M. S., & Eun, J. B. (2010). Impact of alpha-amylase and maltodextrin on physicochemical, functional and antioxidant capacity of spray-dried purple sweet potato flour. Journal of the Science of Food and Agriculture, 90, 494–502.

AOAC (1984). Official methods of analysis of the association of official analytical chemist (14th ed.). Washington, DC.

AOAC (1995). Ascorbic acid in vitamin preparations and juices. In: Official methods of analysis (16th ed.). Arlington, VA.

Cai, Y. Z., & Croke, H. (2000). Production and propertied of spray-dried Amaranthus betacyanin pigments. Journal of Food Science, 65(6), 1248–1252.

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘carabao’ var.) powder. Journal of Food Engineering, 11, 135–148.

Cui, Z. W., Xu, S. Y., & Sun, D. W. (2003). Dehydration of garlic slices by combined microwave–vacuum and air drying. Drying Technology, 21(7), 1173–1184.

Duangmal, K., Saicheua, B., & Sueeprasan, S. (2008). Colour evaluation of freeze-dried roselle extract as a natural food colorant in a model system of a drink. LWT--Food Science and Technology, 41(8), 1437–1445.

Fang, S. Z., Wang, Z. F., & Hu, X. S. (2009a). Hot-air drying of whole fruit Chinese jujube (Zizyphus jujuba Miller): thin-layer mathematical modeling. International Journal of Food Science and Technology, 44, 1818–1824.

Fang, S. Z., Wang, Z. F., Hu, X. S., & Datta, A. K. (2009b). Hot-air drying of whole fruit Chinese jujube (Zizyphus jujuba Miller): physicochemical properties of dried products. International Journal of Food Science and Technology, 44, 1415–1421.

Fang, S. Z., Wang, Z. F., Hu, X. S., Li, H., Long, W. R., & Wang, R. (2010). Shrinkage and quality characteristics of whole fruit of Chinese jujube (Zizyphus jujuba Miller) in microwave drying. International Journal of Food Science and Technology, 45, 2463–2469.

Fang, S. Z., Wang, Z. F., Hu, X. S., Chen, F., Zhao, G. H., Liao, X. J., et al. (2011). Energy requirement and quality aspects of Chinese jujube (Zizyphus jujuba Miller) in hot air drying followed by microwave drying. Journal of Food Process Engineering, 34, 491–510.

Fatemeh, V., Mohsen, F. N., & Kazem, B. (2008). Evaluation of inhibitory effect and apoptosis induction of Zizyphus jujuba on tumor cell lines, an in vitro preliminary study. Cytotechnology, 56, 105–111.

Ferrari, C. C., Germer, S. P. M., & De Aguirre, J. M. (2012). Effects of spray-drying conditions on the physicochemical properties of blackberry powder. Drying Technology, 30, 154–163.

Gao, Q., Wu, P., Liu, J., Wu, C., Parry, J., & Wang, M. (2011). Physico-chemical properties and antioxidant capacity of different jujube (Ziziphus jujuba Mill.) cultivars grown in loess plateau of China. Scientia Horticulturae, 130(1), 67–72.

Gong, Z., Zhang, M., Mujumdar, A. S., & Sun, J. (2008). Spray drying and agglomeration of instant bayberry powder. Drying Technology, 26, 116–121.

Goula, A. M., & Adamopoulos, K. G. (2005). Stability of lycopene during spray drying of tomato pulp. LWT--Food Science and Technology, 38(5), 479–487.

Goula, A. M., Adamopoulos, K. G., & Kazakis, N. A. (2004). Influence of spray drying conditions on tomato powder properties. Drying Technology, 22(5), 1129–1151.

Guil-Guerrero, J. L., Delgado, A. D., González, M. C. M., & Isasa, M. E. T. (2004). Fatty acids and carotenes in some ber (Ziziphus jujuba Mill) varieties. Plant Foods for Human Nutrition, 59(1), 23–27.

Kha, T. C., Nguyen, M. H., & Roach, P. D. (2010). Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. Journal of Food Engineering, 98, 385–392.

Kim, S. H., Choi, Y. J., Lee, H., Lee, S. H., Ahn, J., Noh, B., et al. (2012). Physicochemical properties of jujube powder from air, vacuum, and freeze drying and their correlations. Journal of the Korean Society for Applied Biological Chemistry, 55, 271–279.

Kurozawa, L., Morassi, A., Park, K., & Hubinger, M. (2009). Spray drying of protein hydrolysate of chicken breast meat (pp. 251–256). Montréal, Canada: 4th inter-American drying conference.

León-Martínez, F. M., Méndez-Lagunas, L. L., & Rodríguez-Ramírez, J. (2010). Spray drying of nopal mucilage (Opuntia ficus-indica): effects on powder properties and characterization. Carbohydrate Polymers, 81, 864–870.

Li, J. W., Ding, S. D., & Ding, X. L. (2005). Comparison of antioxidant capacities of extracts from five cultivars of Chinese jujube. Process Biochemistry, 40(11), 3607–3613.

Li, J. W., Fan, L. P., & Ding, S. D. (2007). Nutritional composition of five cultivars of Chinese jujube. Food Chemistry, 103, 454–460.

Mestry, A. P., Mujumdar, A. S., & Thorat, B. N. (2011). Optimization of spray drying of an innovative functional food: fermented mixed juice of carrot and watermelon. Drying Technology, 29(10), 1121–1131.

Moreira, G. E. G., Costa, M. G. M., De Souza, A. C. R., De Brito, E. S., De Meeiros, M. F. D., & De Azeredo, H. M. C. (2009). Physical properties of spray dried acerola pomace extract as affected by temperature and drying acids. LWT- Food Science and Technology, 42(2), 641–645.

Nizori, A., Bui, L. T. T., & Small, D. M. (2012). Microencapsulation of ascorbic acid by spray drying: influence of process conditions. World Academy of Science, Engineering and Technology, 72, 453–457.

Özkal, S. G., Yener, M. E., & Bayindirli, L. (2005). Response surfaces of apricot kernel oil yield in supercritical carbon dioxide. LWT- Food Science and Technology, 38, 611–616.

Rodríguez-Hérnandez, G. R., González-García, R., Grajales-Lagunes, A., Ruizcabrera, M. A., & Abud-Archila, M. (2005). Spray-drying of cactus pear juice (Opuntia streptacantha): effect on the physicochemical properties of powder and reconstituted product. Drying Technology, 23(4), 955–973.

Sagar, V. R., & Suresh Kumar, P. (2010). Recent advances in drying and dehydration of fruits and vegetables: a review. Journal of Food Science and Technology, 47(1), 15–26.

Selvamuthukumaran, M., & Khanum, F. (2013). Optimization of spray drying process for developing seabuckthorn fruit juice powder using response surface methodology. Journal of Food Science and Technology. doi:10.1007/s13197-012-0901-y.

Solval, K. M., Sundararajan, S., Alfaro, L., & Sathivel, S. (2012). Development of cantaloupe (Cucumis melo) juice powders using spray drying technology. LWT--Food Science and Technology, 46, 287–293.

Tonon, V. R., Brabet, C., & Hubinger, M. D. (2008). Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. Journal of Food Engineering, 88, 411–418.

Tze, N. L., Han, C. P., Yusof, U. A., Ling, C. N., Talib, R. A., Taip, F. S., et al. (2012). Physicochemical and nutritional properties of spray-dried Pitaya fruit powder as natural colorant. Food Science and Biotechnology, 21(3), 675–682.

Wang, D., Zhao, Y., Jiao, Y., Yu, L., Yang, S., & Yang, X. (2012). Antioxidative and hepatoprotective effects of the polysaccharides from Zizyphus jujube cv. Shaanbeitanzao. Carbohydrate Polymers, 88(4), 1453–1459.

Acknowledgments

This work was supported by the National Science & Technology Pillar Program during the 12th Five-Year Plan Period (No. 2012BAD31B06) and Special Fund for Agro-scientific Research in the Public Interest (No. 201303073) and the Fundamental Research Funds for Incremental Project Budget of Chinese Academy of Agricultural Sciences (No. 2013ZL014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Q., Bi, J., Zhou, Y. et al. Multi-objective Optimization of Spray Drying of Jujube (Zizyphus jujuba Miller) Powder Using Response Surface Methodology . Food Bioprocess Technol 7, 1807–1818 (2014). https://doi.org/10.1007/s11947-013-1171-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-013-1171-z