Abstract

Ultrasonic and response surface methodology were used to extract phenolic compounds from date pits and optimize extraction parameters including ultrasonic time, solid to liquid ratio and ethanol concentration. A mathematical model of the three parameters for a high extraction yield was established. The results showed that all the extraction parameters and the interaction between solid to liquid ratio and ethanol concentration significantly affected the extraction yield. The optimized extraction parameters were ultrasonic time of 42 min, solid to liquid ratio of 1:46 g/mL, and ethanol concentration of 60%, under which the extraction yield was 8.26%. In vitro antioxidant activity and components of the phenolic compounds was investigated by the antioxidant tests and HPLC, respectively. The antioxidant assays of DPPH and ABTS free radicals, reducing power and total antioxidant capacity suggested that the phenolic compounds from date pits had a high antioxidant activity, and the HPLC analyses revealed that the extracts were mainly composed of seven phenolics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Date palm (Phoenix dactylifera L.) is an important crop in the world’s arid and semi-arid regions [1]. Date fruits are rich in carbohydrates, dietary fiber, minerals, fatty acids, vitamins, amino acids and protein, which provides potential health benefits for the human body [2,3,4]. Date pits are 10–15% of date fruit weight. They are the by-products of date fruit processing and have not been fully utilized [5,6,7]. Date pits have recently been studied as potential sources for edible oil, dietary fiber, animal feed, poultry feed, coffee drink alternative, water filter medium, antimicrobial agent, and compost preparation because they are rich in nutrients [8]. Recently, recovery of bioactive substances from the food processing by-products is of great interest [9,10,11]. Date pits are rich in phenolic compounds, so they are the ideal raw materials for exploiting as a new phenolic resource. However, based on our knowledge, few reports are available on ultrasonic-assisted extraction, antioxidant activity and component identification of the phenolic compounds from date pits. Therefore, it is important to recover the phenolic compounds from date pits to develop high value-added products for the food and pharmaceutical industries.

Free radical-mediated reactions play an important role in aging, cancer, allergies, viral infections, inflammation, coronary heart disease and Alzheimer’s disease [12, 13]. Natural antioxidants have recently received great attention because of the support of the human body’s antioxidant defense system and the consideration of the side effects of synthetic antioxidants [14]. Phenolic compounds from natural sources are the important antioxidants for scavenging the free radicals and reducing the risks of some human diseases. Natural phenolic compounds are generally from fruits and vegetables. Extraction is the crucial stage of separating and recovering phenolic compounds from natural materials. Ultrasonic-assisted extraction (UAE) is an efficient and fast extraction technology. It has strong cavitation effect and mechanical function, and is increasing used to extract bioactive substances [15, 16]. Response surface methodology (RSM) is an experimental statistical technology for optimizing extraction parameters and investigating parameters’ interactions [17, 18]. UAE and RSM are increasingly combined to extract bioactive substances from various natural resources because of their advantages [19,20,21,22].

In this work, date pits were used as the raw materials to extract the phenolic compounds from the pits by UAE and RSM. The extraction variables, like ultrasonic time, solid to liquid ratio, and ethanol concentration, were investigated and optimized for the highest extraction yield. DPPH free radicals, ABTS free radicals, reducing power (RP), and total antioxidant capacity (TAOC) tests were used to investigate in vitro antioxidant capacity of the extracts. HPLC was also performed to analyze the components of the extracts.

Materials and methods

Materials and chemicals

Date pits were procured from the farmer. Coumaric acid, Folin–Ciocalteu phenol reagent, chlorogenic acid, sodium carbonate, DPPH, caffeic acid, ammonium molybdate, trichloroacetic acid, ferric chloride, protocatechuic acid, potassium ferricyanide, gallic acid, potassium persulfate, ABTS, vitamin C, and ferulic acid were procured from Shanghai Aladdin Reagent Co. Ltd.

Optimization design

Based on the Box–Behnken (BBD) design principle and the single-factor tests, ultrasonic time (A), solid to liquid ratio (B), and ethanol concentration (C) as the independent variables for the extraction yield (Y) were optimized by RSM using a quadratic polynomial model. The selected levels of three variables and the test results were presented in Table 1.

Extraction of phenolic compounds and determination of phenolic yield

Dry date pits (the shells were removed) were powdered by a pulverizer (XS-10B, Longxin, China) and passed through an 80-mesh sieve to obtain the pit powders. For each extraction experiment, the powders (0.10 g) and ethanol solution were mixed in a 10-mL sealed glass bottle and the bottle was placed in an ultrasonic generator (500 W, 53 kHz, SK8200H, Kedao, China) to extract phenolic compounds. After a period of extraction, the bottle was centrifuged for 10 min at 10,000 rpm, and total phenolic content in the supernatant was determined by Folin–Ciocalteu method [20]. The phenolic weight was calculated from the standard curve of gallic acid. The extraction yield of phenolic compounds was calculated as follows:

Antioxidant activity tests

The DPPH radical scavenging activity and RP were estimated as described by Liu [23]. The ABTS radical scavenging activity and TAOC were measured as reported Ye [24] and Raza [25], respectively. Vitamin C was the positive control.

HPLC analyses

An HPLC (1200 series, Agilent) with an Eclipse XDB-C18 column (5 mm, 250 mm × 4.6 mm, Agilent) and a UV detector (G1314B, Agilent) was performed for the component analyses. The mobile phase consisted of 100% methanol and 0.1% H3PO4 with a ratio of 5 to 5. The column temperature, injection volume, detection wavelength and flow rate were 25 °C, 20 μL, 280 nm and 0.5 mL/min, respectively. The phenolic compounds were identified based on the standards for the comparison of retention times. The content of components in the extracts is achieved according to the standard curve.

Statistical analyses

All data were measured three times. Design Expert software was used to analyze the tests and build the extraction model. Statistical significance was defined at p < 0.05.

Results and discussion

Single-factor test analyses

Effect of ultrasonic time

The relationship between extraction yield and ultrasonic time (Fig. 1a) showed that the extraction yield increased first with increasing ultrasonic time, and then decreased, and peaked at 40 min. This was related to the functional characteristics of ultrasonic. Ultrasonic possessed the cavitation, mechanical agitation and thermal effects [23, 26] and improved the transport and release of the phenolic compounds from the extracted materials, causing an increasing extraction yield; but long ultrasonic time also caused the decomposition and subsequent decrease of the extracts [27, 28]. Therefore, the ultrasonic time of 40 min was suitable.

Effect of solid to liquid ratio

The relationship between extraction yield and solid to liquid ratio (Fig. 1b) displayed that the extraction yield increased first and then reduced as solid to liquid ratio increased, and achieved a maximum yield at 1:50 g/mL. This was ascribed to the ultrasonic energy distribution and the mass transfer principle. Increasing solid to liquid ratio improved the mass concentration difference of the phenolic compounds and consequently increased the mass transport driving force in the extraction solution [29, 30], which was convenient to extract the phenolic compounds; at the same time, high solid to liquid ratio also reduced the ultrasonic energy density per unit volume of the extraction solution [31], which was not conducive to extract the phenolic compounds. Therefore, the solid to liquid ratio of 1:50 g/mL was suitable.

Effect of ethanol concentration

The relationship between extraction yield and ethanol concentration (Fig. 1c) exhibited that the extraction yield increased and peaked at 60% with ethanol concentration increasing, and then decreased. This was responsible for the polarity of the extraction solution and phenolic compounds. The polarity of water was higher than that of ethanol, and consequently different concentrations of ethanol aqueous solution had different polarities [32]. The polarity of 60% ethanol solution was like that of the phenolic compounds from date pits, resulting in the maximum yield. Therefore, the ethanol concentration of 60% was suitable.

Optimization of extraction parameters

Model fitting and statistical analyses

Multiple regression statistics were analyzed by Design-Expert software according to the data (Table 1). The mathematical model for extraction yield (Y, %) was achieved by the quadratic polynomial regression equation of ultrasonic time (A, min), solid to liquid ratio (B, g/mL), and ethanol concentration (C, %). The model in terms of coded variables was as follows:

Analysis of variance (ANOVA) is a statistical analysis method to evaluate the significance of the experimental data and to analyze the adequacy of the fitting model [33]. The statistical results (Table 2) showed that the determination coefficient (R 2) of the model was 0.9897 and the adjusted determination coefficient (R2 adj) was 0.9713, which demonstrated that the fitting model was reasonable for the test results [34] and the test results were highly consistent with the predicted values [35]. The fitting model for the extraction yield was highly significant because of the p value was 0.0002. The lack of fit (p value = 0.0810) was not significant, exhibiting the fitting model was good for interpreting the test data. Simultaneously, the coefficient of variation (C.V. = 0.89%) was very low, showing the better reliability of the experimental data.

The significance of linear, quadratic term, and interaction term coefficients was generally assessed by the p value. Table 2 showed that the linear coefficients (A, B and C) and the quadratic term coefficients (A 2, B 2 and C 2) were significant effect on the extraction yield (Y) for the p value < 0.05, and the effect was non-linear. The interaction term coefficients (AB and AC) didn’t significantly affect the extraction yield (Y) for the p value > 0.05, while that of BC was significant for the p value < 0.05. These statistical results showed that the effect of the three variables (A, B and C) on the extraction yield (Y) was significant and the same as the interaction between B and C, but that of the interaction between A and B, as well as A and C was not significant. Depending on the p values, the three variables that significantly affected the extraction yield (Y) was in the order of ultrasonic time (A), solid to liquid ratio (B), and ethanol concentration (C).

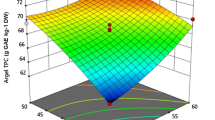

Response surface analyses

3D response surfaces are a graphical interpretation for the relationship of independent and dependent variables [36, 37]. The 3D response surfaces and 2D contours were plotted in Fig. 2. The extraction yield (Y) increased with increasing ultrasonic time (A), solid to liquid ratio (B), and ethanol concentration (C), respectively, and reached a maximum extraction yield (Y) at 42.18 min, 1:46.12 g/mL and 59.76%, respectively. Additionally, all three response surfaces were convex, meaning the selected parameter levels according to the single-factor test were reasonable. By observing the contour plots in Fig. 2, the interaction between B and C significantly affected the extraction yield (Y), while the two interactions (AB and AC) were not significant.

Predictive model verification

The optimum parameters for the phenolic compounds extraction obtained by Design-Expert software were as follows: 42.18 min ultrasonic time, 1:46.12 g/mL solid to liquid ratio, and 59.76% ethanol concentration. Following consideration of the practical operation convenience, the optimum extraction parameters were adjusted as follows: 42 min ultrasonic time, 1:46 g/mL solid to liquid ratio, and 60% ethanol concentration. Under the adjusted conditions, the extraction yield was 8.26% (n = 3) and was close to the predicted value (8.31%), which indicated that the model for extracting the phenolic compounds from date pits was reliable and effective.

Antioxidant activity analyses

DPPH and ABTS radical scavenging activity

DPPH radicals were generally used to measure the antioxidant capacity of various samples because of their good stability and short reaction time [38]. The DPPH radical scavenging effect of the phenolic compounds and vitamin C was illustrated in Fig. 3a. The scavenging effect of the two samples increased linearly with increasing the sample concentration. The scavenging effect of the phenolic compounds was 85.91% as the sample concentration was at 0.06 mg/mL and that of vitamin C was 93.02%. For the phenolic compounds and vitamin C, the IC50 calculated from the linear regression equation was 0.035 and 0.030 mg/mL, respectively, which illustrated that the antioxidant ability of the phenolic compounds from date pits had 85.71% that of vitamin C. ABTS assay was an extensively method to assess the lipophilic and hydrophilic samples’ antioxidant activity [25]. The ABTS radical scavenging effect of the phenolic compounds and vitamin C was displayed in Fig. 3b. As the sample concentration increased, the scavenging effect of the phenolic compounds and vitamin C increased linearly, and reached 74.52 and 91.36% at 0.09 mg/mL, respectively, and their IC50 was 0.062 and 0.047 mg/mL, respectively, which revealed that the antioxidant ability of the phenolic compounds from date pits possessed 75.81% that of vitamin C. The results indicated the extracts from date pits had a high capacity to scavenge DPPH and ABTS free radicals.

Reducing power (RP) and total antioxidant capacity (TAOC)

RP was an important index for evaluating antioxidant capacity of various samples [39]. Figure 4a showed that the RP of the phenolic compounds and vitamin C increased as a function of sample concentration and the RP of the phenolic compounds was lower than that of vitamin C in the experimental range. For the phenolic compounds and vitamin C, the slope obtained from the linear regression equation was 6.05 and 7.02 respectively, which meant that the RP of the phenolic compounds was equivalent to 86.18% that of vitamin C. TAOC assay was widely accepted method for determining various samples’ antioxidant activity. The TAOC of the phenolic compounds and vitamin C was presented in Fig. 4b. The TAOC of vitamin C was higher than that of the phenolic compounds and the two samples were a linear increase. The slope of the phenolic compounds and vitamin C was 4.09 and 4.55 respectively, which revealed that the TAOC of the phenolic compounds was equivalent to 89.89% that of vitamin C. Therefore, the phenolic compounds from date pits exhibited a significant TAOC. Therefore, the extracts from date pits exhibited a significantly RP and TAOC.

HPLC analyses

The HPLC chromatograms of the samples in Fig. 5 showed that, in addition to two unknown components, the phenolic compounds were mainly composed of gallic acid, protocatechuic acid, chlorogenic acid, caffeic acid, coumaric acid and ferulic acid and their contents calculated from the respective standard calibration curve were 46.53, 8.12, 21.16, 10.68, 5.71 and 4.85%, respectively. The results showed that gallic acid was the highest component (46.53%) in the extracts. These were the cause of the high antioxidant activity of the extracts.

Conclusions

This work was to provide a way to exploit a new phenolic resource from the date pit by-product. The ultrasonic was used to assist in extracting the phenolic compounds from the date pits, and the extraction parameters were optimized by RSM for the highest extraction yield. Ultrasonic time, solid to liquid ratio, and ethanol concentration were all significant effect on the yield. The optimized conditions were 42 min ultrasonic time, 1:46 g/mL solid to liquid ratio, and 60% ethanol concentration, under which the yield was 8.26%. The phenolic compounds from the date pits had a significant antioxidant ability and were mainly composed of seven phenolics.

References

A.M.M. Basuny, M.A. Al-Marzooq, Food Nutr. Sci. 2, 938–943 (2011)

R.D. Cagno, P. Filannino, I. Cavoski, A. Lanera, B.M. Mamdouh, M. Gobbetti, J. Funct. Foods 31, 9 (2017)

F.A. Lattieff, J. Clean. Prod. 139, 1191 (2016)

S. Khalid, N. Khalid, R.S. Khan, H. Ahmed, A. Ahmad, Trends Food Sci. Technol. 63, 60 (2017)

A. Sami, G. Suliman, A. Abudabos, M. Abdelrahman, Pak. J. Agric. Sci. 53, 713 (2016)

W. Herchi, H. Kallel, S. Boukhchina, Food Sci. Technol. 34, 464 (2014)

S. Sirisena, K. Ng, S. Ajlouni, Compr. Rev. Food Sci. Food Saf. 14, 813 (2015)

M.Z. Hossain, M.I. Waly, V. Singh, V. Sequeira, M.S. Rahman, Pol. J. Food Nutr. Sci. 64, 215 (2014)

R. Castro-Muñoz, J. Yáñez-Fernández, V. Fíla, Food Chem. 213, 753 (2016)

E. Roselló-Soto, C.M. Galanakis, M. Brnčić, V. Orlien, F.J. Trujillo, R. Mawson, K. Knoerzer, B.K. Tiwari, F.J. Barba, Trends Food Sci. Technol. 42, 134 (2015)

M.A. Nunes, F.B. Pimentel, A.S.G. Costa, R.C. Alves, M.B.P.P. Oliveira, Innov. Food Sci. Emerg. Technol. 35, 139 (2016)

S.Y. Lin, C.C. Wang, Y.L. Lu, W.C. Wu, W.C. Hou, Food Chem. Toxicol. 46, 2485 (2008)

T.C. Ngo, D.Q. Dao, N.M. Thong, P.C. Nam, RSC Adv. 6, 30824 (2016)

M.S. Ozer, C. Sarikurkcu, B. Tepe, RSC Adv. 6, 64986 (2016)

T. Ma, X. Sun, C. Tian, J. Luo, C. Zheng, J. Zhan, Int. J. Biol. Macromol. 88, 162 (2016)

G. Yu, S.J. Zhang, M.C. Fan, Y.N. Sun, X.L. Hu, W.X. Li, J. Food Meas. Charact. (2017). https://doi.org/10.1007/s11694-017-9556-8

B. He, L.L. Zhang, X.Y. Yue, J. Liang, J. Jiang, X.L. Gao, P.X. Yue, Food Chem. 204, 70 (2016)

A.D. Assefa, R.K. Saini, Y.S. Keum, J. Food Meas. Charact. 11, 364 (2017)

Y. Liu, S. Wei, M. Liao, Ind. Crop. Prod. 49, 837 (2013)

G. Sharmila, V.S. Nikitha, S. Ilaiyarasi, K. Dhivya, V. Rajasekar, N.M. Kumar, K. Muthukumaran, C. Muthukumaran, Ind. Crop. Prod. 84, 13 (2016)

F. Al-Juhaimi, O.Q. Adiamo, K. Ghafoor, E.E. Babiker, CyTA-J. Food 14, 369 (2016)

F. Chemat, N. Rombaut, A.G. Sicaire, A. Meullemiestre, A.S. Fabiano-Tixier, M. Abert-Vian, Ultrason. Sonochem. 34, 540 (2017)

Y. Liu, H. Zhang, S. Wei, RSC Adv. 5, 46598 (2015)

Z. Ye, W. Wang, Q. Yuan, H. Ye, Y. Sun, H. Zhang, X. Zeng, Carbohydr. Polym. 147, 354 (2016)

A. Raza, F. Li, X. Xu, J. Tang, Int. J. Biol. Macromol. 94, 335 (2017)

A. Tomšik, B. Pavlić, J. Vladić, M. Ramić, J. Brindza, S. Vidović, Ultrason. Sonochem. 29, 502 (2016)

H.I. Odabas, I. Koca, Ind. Crop. Prod. 91, 114 (2016)

C. Carrera, A. Ruiz-Rodríguez, M. Palma, C.G. Barroso, Anal. Chim. Acta 732, 100 (2012)

S. Şahin, R. Şamlı, Ultrason. Sonochem. 20, 595 (2013)

K.N. Prasad, K.W. Kong, R.N. Ramanan, A. Azlan, A. Ismail, Sep. Sci. Technol. 47, 2417 (2012)

Y. Xu, F. Cai, Z. Yu, L. Zhang, X. Li, Y. Yang, G. Liu, Food Chem. 194, 650 (2016)

G. Spigno, D.M.D. Faveri, J. Food Eng. 93, 210 (2009)

E.A. Diler, R. Ipek, Mater. Sci. Eng. A 548, 43 (2012)

J. Deng, Q. Liu, C. Zhang, W. Cao, D. Fan, H. Yang, Molecules 21, 1 (2016)

F. Yan, K. Fan, J. He, M. Gao, J. Food Qual. 38, 377 (2016)

J.H. Xie, C.J. Dong, S.P. Nie, F. Li, Z.J. Wang, M.Y. Shen, M.Y. Xie, Food Chem. 186, 97 (2015)

L. Guo, J. Guo, W. Zhua, X. Jiang, Food Bioprod. Process. 100, 303 (2016)

Ì Gülçin, İ.G. Şat, Ş. Beydemir, M. Elmastaş, Ö.İ. Küfrevioǧlu, Food Chem. 87, 393 (2004)

Y. Zheng, Y. Li, W.D. Wang, Carbohydr. Polym. 111, 315 (2014)

Acknowledgements

This work is financially supported by Science and Technology Project of Zhaoqing City (No. 2014F012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Wei, S., Wu, M. et al. Phenolic compounds from date pits: ultrasonic-assisted extraction, antioxidant activity and component identification. Food Measure 12, 967–973 (2018). https://doi.org/10.1007/s11694-017-9711-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9711-2