Abstract

Growing demands on thermal barrier coatings (TBCs) for gas turbines regarding their temperature and cyclic capabilities, corrosion resistance, and erosion performance have instigated the development of new materials and coating systems. Different pyrochlores, perovskites, doped yttria-stabilized zirconia, and hexaaluminates have been identified as promising candidates. However, processing these novel TBC materials by plasma spraying is often challenging. During the deposition process, stoichiometric changes, formation of undesired secondary phases or non-optimum amorphous contents, as well as detrimental microstructural effects can occur in particular. This article describes these difficulties and the development of process-related solutions by employing diagnostic tools.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In modern gas turbines, plasma-sprayed thermal barrier coating (TBC) systems have been applied for several decades to improve performance (Ref 1-3). The thermally insulating layer can reduce the temperature of the metallic substrate resulting in improved component durability. Furthermore, an increase in efficiency can be achieved by permitting an increase of the turbine inlet temperatures. Thus, TBCs offer great benefits for the operation of aircraft gas turbine engines, shipboard gas turbine engines, and land-based industrial gas turbine engines.

Presently, research on TBCs is facing new demands. Coatings are needed for resisting degradation induced by environmental air-borne deposits ingested into the engine especially in the case of aircraft gas turbine engines where in-take air filtration is not possible. The so-called CMAS (which stands for calcium-magnesium-aluminum-silicate) attack is caused by the deposition of glass-forming constituents and infiltration above the melting temperature of the glass phases (Ref 4). At solidification, large parts of the TBC spall off because of the considerable loss of strain tolerance of the glass phases. Presently, anti-CMAS approaches under investigation aim to induce early crystallization to stop infiltration by dopants, such as dissolved Al, Ti, or Gd (Ref 5, 6).

Another demand of future TBCs is to provide fuel flexibility. New problems limiting component life occur because of higher temperatures and new combustion gases (syngas, hydrogen, or natural gas contaminants (Ref 7)) causing overheating and hot corrosion (Ref 8). Currently, research activities are undertaken to understand dominant damage mechanisms and to identify cost-effective alternatives for materials and coating technologies.

TBC systems are complex, multilayered, and multimaterial systems with many variants related to composition, processing, and microstructure. They consist of at least two layers: a bondcoat layer, and an insulating ceramic topcoat. The bondcoat is often a metal and has two major functions: it improves bonding between the substrate and the topcoat, and it protects the substrate from corrosion and oxidation. The ceramic topcoat provides heat insulation by its low thermal conductivity resulting from bulk material characteristics as well as from microstructural features such as pores and voids.

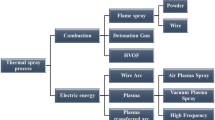

In terms of deposition techniques, two methods have become well established. One is electron beam-physical vapor deposition (EB-PVD), and the other is atmospheric plasma spraying (APS). Coatings deposited by EB-PVD have specifically columnar microstructures (Ref 9) and are mainly used for highly thermomechanically loaded blades of aircraft gas turbine engines. The APS process (Ref 10, 11) meanwhile displays often operational robustness comparable to EB-PVD and improved economic viability; hence, more TBCs are now being developed based on this process. Typically, static components, such as combustor cans and vane platforms, are coated by APS. In stationary gas turbines, blades are also frequently coated by thermal-spray processes (Ref 12).

In thermally sprayed coatings, splats are separated by interlamellar pores resulting from rapid solidification, very fine voids formed by incomplete intersplat contact or around nonmolten particles, and cracks due to thermal stresses, and tensile quenching stress (Ref 13). Such porosity is a key characteristic of modern thermally sprayed ceramic TBCs. In particular, the heat flux transfer to the metallic bondcoat and component is reduced by evenly spaced porosity (Ref 14). Moreover, the more porous the coating microstructure is the more scattering centers are introduced into it. In this way, the radiative heat load deposited onto the gas turbine components is also reduced (Ref 15). To achieve specific porosities, the melting status of the powder particles plays a key role which can be controlled on the basis of in-flight particle temperature measurements (Ref 16). Typical porosities for TBC topcoats are 15% by volume and higher. Moreover, segmentation cracks can increase the strain tolerance of TBCs resulting in a reasonable thermal shock resistivity (Ref 17).

Partially yttria-stabilized zirconia (YSZ) with yttria contents ranging from 6 to 8 wt.% is frequently used as TBC material because of its high thermal expansion coefficient (TEC) and its relatively good fracture toughness. YSZ as formed by the APS or EB-PVD process consists of the metastable t′-phase. On prolonged exposure at elevated temperatures, it decomposes into high-yttria and low-yttria phases. The latter transforms on cooling into the monoclinic phase with an associated large volume increase, which may result in the catastrophic failure of the TBC (Ref 18). The accepted upper limit for long-term use is 1200 °C. In addition to the limited phase stability, sintering coarsens the pores and reduces the high-temperature capability as it leads to an increase of thermal conductivity and a loss of strain tolerance of the coatings and hence early failure (Ref 19).

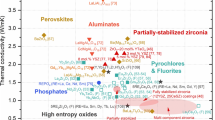

To overcome these shortcomings of YSZ-based TBCs, alternative materials with higher-temperature capabilities are under investigation (Ref 12). Interesting candidates are those materials with pyrochlore (e.g., La2Zr2O7, Gd2Zr2O7), spinel (MgAl2O4), perovskite (e.g., SrZrO3), or magnetoplumbite (e.g., LaLiAl11O19) structures with high melting points (Ref 20, 21). In particular, more complex perovskite forms such as Ba(Mg1/3Ta2/3)O3 and La(Al1/4Mg1/2T1/4)O3 have promising bulk properties for TBC applications. However, the TECs of these new materials are still lower than those of substrates and bondcoats, leading to thermal stresses in the TBC system. Moreover, relatively low toughness values are observed. As a result, the thermal cycling properties are poorer than those of YSZ coatings. One way for the remediation of this shortcoming is to use layered topcoats. Failure of TBC systems often occurs in the TBC close to the bondcoat/topcoat interface. At this location, YSZ is used as a TBC material with a relatively high TEC and high toughness (Ref 22, 23).

In this study, recent research activities on the responses of new TBC materials to the complex demands of modern gas turbine applications are reviewed. Figure 1 visualizes that material design is a coordinated result from materials science on the one hand, and processing development on the other hand. Thus, successful solutions require competences in both these fields as well as knowledge on the application-specific issues. This context is the basis for the research study on TBCs in the Institute of Energy and Climate Research (IEK-1) at Forschungszentrum Jülich, Germany. Also new thermal-spray processes are developed here, namely, the suspension plasma spraying (SPS) and plasma spraying-physical vapor deposition (PS-PVD). However, this article is confined to ceramic TBC coating systems manufactured by APS with particular emphasis on process-related solutions by employing diagnostic tools. New processing methods as well as bondcoat developments are part of other publications (Ref 24-26).

Pyrochlores

Lanthanum Zirconate

Several zirconate pyrochlores show low thermal conductivities as well as high thermal stabilities. Among them, lanthanum zirconate La2Zr2O7 (LZ) is phase stable to its melting point as it can largely tolerate vacancies at the La3+, Zr4+, and O2− sites. At the same time, it displays a lower thermal conductivity (1.56 Wm−1 K−1, bulk material) and a lower sintering tendency when compared with YSZ. As mentioned before, pyrochlores are applied in combination with YSZ in double-layer TBC systems.

The La2O3·ZrO2 phase diagram shows a stable pyrochlore region up to the melting temperature of 2295 ± 10 °C and the stability region ranges from approximately 33 to 35 mol.% La2O3 at 1500 °C (Ref 27). Below the melting temperature, no fluorite phase occurs since solidification starts directly in the form of pyrochlore. However, considerable amounts of metastable fluorite phase are formed in the case of rapid solidification, which is typical of plasma-spray conditions. Such fluorite phase is transformed to pyrochlore at temperatures above 1000 °C (Ref 28, 29). This is not critical as such transformation is not associated with significant volume change.

The processing of LZ by atmospheric plasma spraying is challenging because La2O3 is prone to evaporate in the plasma plume resulting in non-stoichiometric coatings (Ref 27). This might be detrimental for TBC performance as thermophysical properties are affected (Ref 30, 31). Similar problems are known to emanate from EB-PVD LZ coatings (Ref 32). La2O3 shows considerably higher vapor pressure when compared with ZrO2 (Ref 33). Although reference data from the literature are not in good agreement, it is evident that the vapor pressure of lanthania is at least one magnitude higher than that of zirconia.

In a recent study (Ref 34), atmospheric plasma spray (APS) experiments were performed with a TriplexPro™-200 plasma torch (Sulzer Metco, Wohlen, Switzerland) at different power levels between 15 and 51 kW to adjust different degrees of evaporation and thus stoichiometry. For this, the current was varied between 200 and 525 A while the plasma gas flow was 46 slpm Ar + 4 slpm He and the spray distance was 90 mm. Figure 2 shows the lanthania contents determined by chemical analysis versus torch input power between 15 and 51 kW. The feedstock powder showed an almost stoichiometric composition. The lanthania content in the sprayed LZ coatings already exhibits a small initial drop at low torch input power down to 32.9 mol.% (La/Zr atomic ratio of 0.99) and if the power is raised, then it continues to decrease to 27.0 mol.% at 51 kW corresponding to a La/Zr atomic ratio of 0.75. Here, up to 24.8% of the lanthanum content in the powder feedstock was lost.

Lanthania contents determined by chemical analysis vs. torch input power between 15 and 51 kW (Ref 34)

X-ray diffraction (XRD) analyses of the LZ coatings revealed that the content of the defective fluorite phase grows as the torch input power is raised. Furthermore, with increasing torch input power, the XRD peaks shift to larger 2θ values indicating the increasing non-stoichiometry. The lattice parameters were found to be directly correlated to the stoichiometry (Ref 34). At 30 kW and above, the fluorite phase content is 90 wt.% or more. In each case, the balance is pyrochlore phase. Obviously, the formation of the defective fluorite phase, which is less ordered than the pyrochlore phase, is an effect of the rapid cooling upon impingement on the substrate of such material fractions which are still molten at that time. In contrast, the material fractions which have already solidified during flight may be deposited as pyrochlore.

Quantitative energy dispersive spectroscopy (EDS) point analyses of the coatings sprayed at the highest torch power of 51 kW confirmed the existence of areas with considerable lanthanum depletion resulting in large amounts of zirconia along with the lanthanum zirconate. Very low La/Zr atomic ratios down to 0.28 were found corresponding to zirconia contents of up to 82 mol.% with only 18 mol.% lanthanum zirconate. Consequently, significant amounts of metastable cubic zirconia can develop. This was confirmed by phase analysis of annealed coatings sprayed at low and high torch powers. During annealing for 4 h at 1400 °C, the fluorite transformed to pyrochlore phase and, in particular, the sample sprayed at high torch power developed monoclinic and metastable zirconia phases which transform and undergo specific volume changes during thermal cycling leading to early failure.

In-flight particle characteristics were measured by the DPV-2000 (TECNAR, St-Bruno, QC, Canada) diagnostic system (Ref 35). The particle temperature distributions for the lower range of torch input power show multimodal shapes, as shown in Fig. 3. Hence, the distributions were fitted with Gaussian functions to identify different particle fractions. The first two peaks at constant and almost constant temperature, respectively, are assumed to be associated with solidification (or the powder melting temperature) and release of fusion enthalpy. Details can be found elsewhere (Ref 34). Hence, particle diagnostics proved to be an effective tool to determine the melting degree. Based on such an analysis, spray parameters can be identified ensuring minimal lanthania evaporation, and at the same time, suitable microstructures and deposition efficiencies.

LZ particle temperature distributions as estimated using two-color pyrometry for the lower range of torch input power between 15.0 and 21.9 kW (Ref 34)

Gadolinium Zirconate

Currently, one of the most promising resistant materials against high-temperature corrosion of CMAS is gadolinium zirconate, Gd2Zr2O7. This material has been found to play an important role in damage mitigation of TBCs in aircraft engines (Ref 5). CMAS glass penetrating the conventional YSZ-TBC forms a stiff glaze on cooling, which results in the reduction of strain tolerance of the coatings during thermal cycles (Ref 5, 36). However, in the case of gadolinium zirconate, upon infiltration of CMAS melt, an impervious reaction zone composed of complex anorthite, appatite, and calcium zirconate phases is formed in the region where CMAS infiltration stops (Ref 37, 38).

Since, gadolinium zirconate is very costly, a composite coating with YSZ can have additional benefits of durability and affordability (Ref 39). To deposit coatings by APS, such a powder mixture is, however, challenged by the different melting characteristics of the particles. With TriplexPro™ (Sulzer Metco, Wohlen, Switzerland) and Ar/He plasma gas flow of 46/4 slpm, an electric arc current of 500 A is typically required to deposit YSZ, while a maximum of only 350 A is needed for gadolinium zirconate to achieve minimalistic decomposition of Gd2O3 during spraying. As shown in Fig. 4, although the difference in their melting temperature is quite small, gadolinium zirconate has a large number of particles with very high temperatures as compared with YSZ. This could be attributed to the higher heat capacity of YSZ as compared with most pyrochlores (Ref 20). Spray parameters for the TriplexPro™ torch were carefully optimized to achieve a compatible set of parameters for the composite mixture. The 350 A current was adopted with 50/4 slpm Ar/He plasma gas flow. The resulting as-sprayed coating for 1:1 YSZ-GZO is shown in Fig. 5(a). About 16% porosity was detected by mercury intrusion. Corrosion resistance test was conducted isothermally in an oven at 1400 °C for 5 h using a CMAS corrosion agent with additional high Fe-composition. The reaction products and microstructure were evaluated using XRD and scanning electron microscope (SEM). Figure 5(b) shows that only up to 30% of the total coating thickness is infiltrated with CMAS after 2 h and a reaction zone has been formed. Iron-rich phases crystallize on the surface of the coating. Therefore, the presented method of producing GZO-YSZ composite coatings could certainly work regardless of whether non-stoichiometric gadolinium zirconate phases are deposited together with YSZ.

Perovskites

The perovskites with structural formula ABO 3 are characterized by high melting points, low thermal conductivities, and high TECs. Additionally, they offer the possibility of extensive substitution of ions at the A or/and B site, which enables the properties of the materials to be selectively influenced (Ref 40).

Complex Perovskites Ba(Mg1/3Ta2/3)O3 and La(Al1/4Mg1/2T1/4)O3

The most promising candidates for advanced TBC materials development are those with high melting temperatures in addition to phase stability and low thermal conductivity in general. Among these materials, complex perovskite with Ba(Mg1/3Ta2/3)O3 (BMT) composition has melting temperature of ~3000 °C and is considered among the most refractory oxides ever known to science (Ref 41, 42). Another material candidate from this system is La(Al1/4Mg1/2T1/4)O3 (LAMT). It can accommodate three cations in the B-site and has lower thermal conductivity than BMT. The bulk properties include low values of thermal conductivity (~2 Wm−1 K−1) and high coefficient of thermal expansion (~11 × 10−6 K−1) similar to YSZ making it very promising for TBC applications (Ref 43, 44).

APS of these perovskite materials is often challenged by the formation of secondary phases which are deficient in Mg (indicated by white arrows in Fig. 6). These phases are more pronounced after annealing at 1200 °C (Ref 45-47). Their presence caused an integral effect on the low thermal cycling lifetime of the coatings because of the differences in their thermal properties. To avoid deposition of inhomogeneous coatings, in-flight particle diagnostics during APS were focused on preventing the formation of secondary phases during plasma spraying (Ref 48).

SEM micrographs of plasma-sprayed (a) BMT and (b) LAMT coatings after annealing at 1200 °C for 3 h (Ref 48)

Different process maps were generated to investigate the influence of plasma parameters to the deposited phases. A process map for LAMT obtained by spraying with the Triplex II gun (Sulzer Metco, Wohlen, Switzerland) suggests that at 40/4 slpm Ar/He gas flow rate, 550 A of gun current and increasing spray distance until an optimum value of 200 mm, the particle temperature increases as the particle decelerates in the plasma plume (Ref 48).

The residence time of the particles in the plasma plume was also found to strongly influence the decomposition of the component phases (Ref 48). This was proven by investigating the composition of the particles during flight by spraying into water. This technique was adopted to capture the component phases during particle flight. A composition with excess Mg was used as powder feedstock. Spherical particles collected from spraying into water using the parameter set mentioned above show that some dark spots which are Mg rich are found on the surface of the particles. Among the oxide components of BMT and LAMT, MgO has the highest vapor pressure and is therefore more prone to decompose (Ref 49). As the particles are heated up during spraying, Mg diffuses to the surface prior to vaporization. Owing to rapid cooling upon spraying into water, some of the Mg atoms from incompletely molten large particles are not able to volatilize and re-solidify with other phases on the surface of the particles. Increasing decomposition of Mg was also reported with increasing amount of electric arc current (Ref 44, 48, 50).

Apart from particle diagnostics, analyses of single splats were also conducted for the complex perovskites. With higher torch power, the splats are more fingered as shown in Fig. 7 indicating that the particles have very low viscosity upon landing. At lower power, the BMT splat is more cracked, while the LAMT is more of a pancake which is characteristic for solidified amorphous phases (Ref 48).

The lifetime of the coatings were found to improve significantly with the application of reduced power of either Triplex II or TriplexPro torch as shown in Fig. 8 (Ref 51). The complex perovskite coatings had minimal secondary phases present and were tested in double-layer systems with YSZ as sub-layer.

Strontium Zirconate and the Gd- and Yb-Doped Systems

Strontium zirconate SrZrO3 is another promising perovskite material for TBC application due to its high melting point (2610 °C) and high TEC (~11 × 10−6 K−1) (Ref 20, 43). During plasma spraying, SrO having a higher intrinsic vapor pressure was found to volatilize faster than ZrO2 resulting to the deviation of stoichiometric composition in the deposited coating (Ref 52). The existence of excess ZrO2 in the plasma-sprayed SrZrO3 coating might also influence the coating properties. Quantitative investigation of the partial evaporation of SrZrO3 by spraying powders into water was therefore conducted (Ref 53). Some new needle-like structures were collected from the water container and they contain only Sr (Fig. 9). These are probably condensates of Sr during plasma spraying.

Once the initial composition of the powders was fixed, the final Sr/Zr ratio of the sprayed coating was determined by the spraying current, distance and particle size of the starting powders. Particle diagnostics using Accuraspray-g3 (TECNAR, St-Bruno, QC, Canada) revealed that increasing spray current lead to higher particle temperature and higher evaporation of Sr (Ref 53). Similar behavior was also observed when the spray distance was increased. This evaporation can also be effectively reduced by effectively increasing the particle size of the starting feedstock (Ref 44, 50, 53). When traces of SrCO3 and metastable tetragonal ZrO2 can be detected in the as-sprayed coating, during sintering, SrCO3 reacts with part of ZrO2 to form SrZrO3 again and the remaining metastable tetragonal ZrO2 transformed into monoclinic ZrO2 (m). After sintering, pure SrZrO3 coating can be produced only when the Sr/Zr ratio of the coating is a little larger than unity.

An attempt to improve the thermophysical properties of SrZrO3 by doping with Gd and Yb, was also conducted (Ref 43).The results of specific heat capacity and thermal conductivity measurements reveal that doping Yb2O3 is more effective in reducing the specific heat capacity and thermal conductivity of SrZrO3 than doping with Gd2O3. The Young’s moduli of the modified SrZrO3 were found to be lower than that of YSZ, which might yield higher strain tolerance for coatings. Furthermore, comparing the thermal cycling lifetime of the single-layer and the double-layer systems, the latter have much longer thermal cycling lifetimes at a surface temperature of 1250 °C, which are comparable to that of the YSZ coating at similar surface temperature. In particular, a major advantage for Sr(Zr0.9Yb0.1)O2.95/YSZ double-layer system is that its thermal cycling lifetime is better compared to that of the optimized single-layer YSZ topcoat at a surface temperature of 1350 °C. This could be a good alternative for single-layer YSZ coating at higher temperature applications (Ref 43).

Aluminates

Materials from some aluminate systems as yttrium aluminium garnet (YAG) or rare earth (RE) hexaaluminates are promising TBC candidates for use at surface temperatures exceeding 1300 °C due to their high melting point, high thermal expansion, low thermal conductivity, excellent longtime sintering resistance, and structural stability (Ref 54). As mentioned above, increased resistance against glassy deposits can also be expected because of the inherent Al content of those materials (Ref 5). Previous results not reported here indicate the validity of this expectation.

From the practical point of view of plasma-spray processing, a special feature of those materials is their tendency to be deposited in partly amorphous state during thermal-spray processing. Upon subsequent annealing, e.g., during operation, rapid recrystallization occurs which is coupled with reduction of bulk volume (Ref 54, 55). This causes a microstructure with cracks on the meso-scale which offers potentially advantageous thermal shock properties (Ref 56). Depending on the deposition parameters and subsequent heat treatment, a network of segmentation cracks is formed. The microstructure is similar to that found in flexible sandstone (Ref 57) and can be assumed to support improved strain tolerance.

An example of the influence of processing parameters is given here on the hexaaluminate type of LaLiAl11O18.5 with magnetoplumbite structure which shows extraordinary pronounced shrinkage and segmentation crack formation. Figure 10 shows micrographs from two free standing coatings in the as-sprayed condition which have been manufactured from the same feedstock with a Sulzer Triplex II gun by distinctly different thermal spray parameters. Parameters and some properties are summarized in Table 1. The first coating, having an initial porosity of 14% (named “porous”), has been sprayed with relatively lower power and shorter distance to the target compared with the second one, having an initial porosity of 8% (named “dense”).

Optical micrographs of LaLiAl11O18.5 hexaaluminate coatings manufactured with parameters as summarized in Table 1

Achieving lower porosities by means of increasing the gun power is not unusual in plasma spraying because of the typically associated higher degree of melting and the higher particle velocity. Nevertheless, in the given example a more thorough analysis of the spraying process by means of DPV 2000 reveals that relative values of the average particle temperature and velocity are reversely proportional to the trend expected from porosity results. As can be seen from the upper part of Fig. 11, for an arc current of 450 A, the spread and the average of particle temperatures is decreasing with increasing distance. This indicates that melting of the particles presumably occurs already at low distances within the plasma plume and particles are allowed to cool down and slow down before impact. The temperature distribution of particles sprayed with the “dense” parameter set of the given example is shown in the lower part of Fig. 11 thereby clarifying that the influence of the increased distance overbalances the increased gun power regarding temperatures and velocities.

Considering the material feature of amorphous quenching and the apparent downward shift of temperature for the “solidifying particle” fraction with distance from Fig. 11, the deposition behavior of the hexaaluminate can be rather interpreted by assuming solidification and crystallization of potentially undercooled melts as it has been similarly discussed for YAG (Ref 55). The larger heat carried with the particles on impact for conditions “porous” might allow for a larger degree of re-crystallization compared with potentially undercooled particles of condition “dense”. The local volume shrinkage accompanied with splat-wise re-crystallization can be correlated with the increased porosity as found. This interpretation is also supported by observations of higher crystallinity in the XRD characterization and lower residual shrinkage on macroscopic crystallization treatment in the case of the “porous” coating. Further important parameters influencing the controlled crystalline deposition for these kinds of materials are specially substrate temperature and particle size, both influencing the degree of melting and the kinetics of re-solidification.

Doped YSZ

YSZ Doped by TiO2

A recent study has found that substitution of up to ~15 mol.% TiO2 for ZrO2 into the single-phase tetragonal (t′) 7-8 wt.% YSZ increases toughness and diminishes the transformation phenomenon even up to 1600 °C (Ref 58). This offers a unique opportunity to enhance the performance of the standard YSZ-based TBCs. To develop an improved YSZ-TBC system based on the addition of titania, a better understanding of the process parameters is necessary. Other than particle diagnostics using two-color pyrometry, the surface roughness of the plasma-sprayed single splats have also been reported to provide information on the status of molten and solidifying particles as they are deposited to form into splats (Ref 59). Figure 12 shows the morphology of a partly molten splat and its corresponding three-dimensional surface profile with exaggerated height obtained by a white light profilometer (LT-9000 confocal laser microscope, Keyence, Neu-Isenburg, Germany). Surface roughness was determined using the international measurement standard ISO 4287. The R z values were determined from the differences of the height and depth of the splat topography to a median height. The values were then averaged for every material composition for the overall surface roughness of the deposited single splats. The thickness or roughness of the formed splat suggests the degree of particle melting. Rougher splats are formed from solidified particles which are probably slightly molten upon impact while thin splats are formed from flattening of majorly molten particles as they impact the substrate. Table 2 shows a summary of the average roughness of YSZ splats with varying amount of titania. The values obtained suggest that there is no direct relationship between TiO2-doping and the overall surface roughness of the deposited single splats. Therefore, doping with up to 15 mol.% of titania does not significantly alter the melting characteristics and coating microstructure of pure YSZ.

The lamellae formed from the flattening of plasma-sprayed feedstock have a heterogeneous microstructure composed of randomly distributed pores, micro-cracks and unmolten particles (Ref 59). The mercury porosity measurement conducted on the coatings reveal that at gun current of 500 A (TriplexPro™), plasma gas flow of 46/4 slpm Ar/He, the total average porosities of the coatings are nearly the same as shown in Fig. 13. The increased addition of titania has no direct influence on the porosity of the coating with varying gun current supply. However, as the applied gun current increases, the porosity of the coatings decreases. This is consistent with the observations in the particle temperature distribution reported in Ref 48 where increasing gun current results in increasing amount of molten particles that lead to the deposition of coatings with decreased porosity. The coating lamellae are formed from increasing amount of molten particles of low viscosity with increasing gun current. The influence therefore is not chemical but rather process controlled. In this case, it would be erroneous to assume that since higher Ti induces melting, then denser coatings should be produced. As revealed in the surface roughness and porosity measurements, titania doping does not have a significant influence on the coating microstructure. Also, on plasma spraying, particles may fragment as they exit the plasma injector causing the smaller-sized particles to flow along the plasma fringes and not into the main spray stream. These particles are deposited into the coatings as unmolten particles that may significantly contribute to the increased amount of micropores which are also included during porosity measurements. As the results suggest, the addition of titania does not significantly influence such a process phenomenon.

Up to now, the phase diagrams of the ternary ZrO2-TiO2-YO1.5 systems above 1300 °C are still unknown. Derivations from correlated experimental and mathematical investigations reveal that on increasing the temperature from 1300 to 1600 °C, the stability region of the pyrochlore phase widens as more Ti is accommodated (Ref 60). The maximum solubility of yttria and titania into the tetragonal zirconia at 1300 °C was also reported to be limited to approximately 6 and 12 mol.%, respectively. Mathematical calculations on experimental data and phase analyses derived from slow heating and cooling experiments, predicted considerably varying phase boundaries at higher temperature values for the ternary systems. The composition therefore with 15.2 mol.% TiO2 is vulnerable to the formation of brittle Ti-rich pyrochlore phases during spraying where plasma temperature reaches extremely high values. This phenomenon is clearly manifested in the microstructure profile of the thermally cycled samples at 1400 °C (Ref 61). Although the as-sprayed coatings have slightly increased in tetragonality with increasing amount of titania, the lifetime of the coatings is not influenced by the doping of titania at the investigated composition range. The tips of the cracks of the cycled samples are rich in Ti and this is more pronounced for samples with higher amount of Ti-dopant as shown in Fig. 14. This would imply that coating embrittlement is induced by the formation of pyrochlore phases. It is therefore recommended to dope yttrium-stabilized zirconia with lower percentages of TiO2 than the investigated compositions of 7.5-15 mol.%.

YSZ Doped by Yb2O3

Ytterbium cation (Yb3+) doped into the YSZ structure in similar manner as doping with Ti, was found to improve the thermomechanical properties and particularly lower the thermal conductivity of the state-of-the-art TBC (Ref 62). Ytterbium cation has smaller ionic radius compared with Ti4+. Characteristics of YSZ powder compositions doped with Yb and Ti were compared during plasma spraying. Feedstock powders were sprayed with TriplexPro™ plasma torch with current of 500 A and Ar/He gas flow of 50/4 slpm and spray distance of 200 mm. The particle temperature profiles and corresponding ionic radii of dopant cation are plotted in Fig. 15 (Ref 63). Results show that the Yb-doped YSZ has the lowest melting temperature (as indicated by the temperature at the first maxima which is assumed to be the powder melting temperature) compared with the undoped and Ti-doped YSZ. This implies that Yb cation dopant, with larger ionic radius has the higher tendency to decrease the melting temperature of YSZ ceramics during plasma spraying. With the same spray parameters, the porosity of the Yb-YSZ coating is about 15% which is also much lower than that of the Ti- and undoped YSZ coatings with porosity values above 20%. When the thermal cycling lifetime was obtained at 1400 °C surface temperature in a gradient burner rig test, the Yb-doped YSZ with the lowest porosity has the lowest lifetime compared with the other compositions. However, the performance of the Yb-doped coating can be improved by adjusting spray parameters like decreasing the plasma power to obtain higher coating porosity, thus obtain lower heat conduction through the coating during thermal cycles.

Conclusion and Outlook

In this study, recent research activities on responses of new TBC materials to the complex demands of modern gas turbine applications are reviewed. Such alternative materials with higher-temperature capabilities are those with pyrochlore, perovskite, or magnetoplumbite structures. However, their processing by thermal spraying often turns out to be challenging. The more complex the composition is, the more different is the stability and volatility of the constituents. Thus, stoichiometry of the deposited coatings can change and undesired secondary phases may be formed. Furthermore, the coating microstructure is affected if the melting behavior and thermal properties of the constituents differ. In addition, combining proper optimization of spray process parameters and selection of promising dopant cations, the existing superior properties of the zirconia-based TBCs can be well improved. Table 3 shows a summary of strengths and limitations of the reviewed new TBC materials reported in this manuscript.

The examples discussed in the present article reveal that material design needs coordinated efforts on materials science on the one hand and processing development on the other hand. In this context, process diagnostics were found to be valuable tools.

References

R.A. Miller, Current Status of Thermal Barrier Coatings—An Overview, Surf. Coat. Technol., 1987, 30, p 1-11

R. Vaßen, H. Kaßner, A. Stuke, F. Hauler, D. Hathiramani, and D. Stöver, Advanced Thermal Spray Technologies for Applications in Energy Systems, Surf. Coat. Technol., 2008, 202, p 4432-4437

G. Mauer and R. Vaßen, Technology Vision: Current Developments and Challenges in Thermal Barrier Coatings, Surf. Eng., 2011, 27(7), p 477-479

D.J. de Wet, R. Taylor, and F.H. Stott, Corrosion Mechanisms of ZrO2-Y2O3 Thermal Barrier Coatings in the Presence of Molten Middle-East Sand, J. Phys. IV France, 1993, 3, p C9-655-C9-663

A. Aygun, A.L. Vasilev, N.P. Padture, and X. Ma, Novel Thermal Barrier Coatings that are Resistant to High-Temperature Attack by Glassy Deposits, Acta Mater., 2007, 55(20), p 6734-6745

S. Krämer, J. Yang, and C.G. Levi, Infiltration-Inhibiting Reaction of Gadolinium Zirconate Thermal Barrier Coatings with CMAS Melts, J. Am. Ceram. Soc., 2008, 91(2), p 576-583

R. Wenglarz and J. Oakey, Gas Turbine Issues in Advanced Gasification Systems, Materials for Advanced Power Engineering 2006: Proceedings of the 8th Liège Conference, J. Lecomte-Beckers, M. Carton, F. Schubert, and P.J. Ennis, Ed., Forschungszentrum Jülich, Jülich, 2006

P. Mohan, B. Yuan, T. Patterson, V.H. Desai, and Y.H. Sohn, Degradation of Yttria-Stabilized Zirconia Thermal Barrier Coatings by Vanadium Pentoxide, Phosphorous Pentoxide, and Sodium Sulfate, J. Am. Ceram. Soc., 2007, 90(11), p 3601-3607

U. Schulz, B. Saruhan, K. Fritscher, and C. Leyens, Review on Advanced EB-PVD Ceramic Topcoats for TBC Applications, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 302-315

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed., John Wiley & Sons, Chichester, 2008

R.B. Heimann, Plasma Spray Coating, 2nd ed., Wiley-VCH, Weinheim, 2008

R. Vaßen, M.O. Jarligo, T. Steinke, D.E. Mack, and D. Stöver, Overview on Advanced Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 205, p 938-942

A. Kulkarni, A. Vaidya, A. Goland, S. Sampath, and H. Herman, Processing Effects on Porosity-Property Correlations in Plasma Sprayed Yttria-Stabilized Zirconia Coatings, Mater. Sci. Eng. A, 2003, 359, p 100-111

A. Feuerstein, J. Knapp, T. Taylor, A. Ashary, A. Bolcavage, and N. Hitchmann, Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review, J. Therm. Spray Technol., 2008, 17, p 199-213

R. Vaßen, A. Stuke, and D. Stöver, Recent Developments in the Field of Thermal Barrier Coatings, J. Therm. Spray Technol., 2009, 18, p 181-186

G. Mauer, R. Vaßen, and D. Stöver, Atmospheric Plasma Spraying of Yttria-Stabilized Zirconia Coatings with Specific Porosity, Surf. Coat. Technol., 2009, 204, p 172-179

M. Karger, R. Vaßen, and D. Stöver, Atmospheric Plasma Sprayed Thermal Barrier Coatings with High Segmentation Crack Densities: Spraying Process, Microstructure and Thermal Cycling Behavior, Surf. Coat. Technol., 2011, 206, p 16-23

U. Schulz, Phase Transformation in EB-PVD Yttria Partially Stabilized Zirconia Thermal Barrier Coatings During Annealing, J. Am. Ceram. Soc., 2000, 83(4), p 904-910

A. Cipitria, I.O. Golosnoy, and T.W. Clyne, A Sintering Model for Plasma-Sprayed Zirconia TBCs. Part I: Free-Standing Coatings, Acta Mater., 2009, 57(4), p 980-992

R. Vassen, X. Cao, F. Tietz, D. Basu, and D. Stöver, Zirconates as New Materials for Thermal Barrier Coatings, J. Am. Ceram. Soc., 2000, 83(8), p 2023-2028

H. Lehmann, D. Pitzer, G. Pracht, R. Vaßen, and D. Stöver, Thermal Conductivity and Thermal Expansion Coefficients of the Lanthanum Rare-Earth-Element Zirconate System, J. Am. Ceram. Soc., 2004, 86(8), p 1338-1344

R. Vaßen, F. Traeger, and D. Stöver, New Thermal Barrier Coatings Based on Pyrochlore/YSZ Double-Layer Systems, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 351-361

X.Q. Cao, R. Vaßen, F. Tietz, and D. Stöver, New Double-Ceramic-Layer Thermal Barrier Coatings Based on Zirconia-Rare Earth Composite Oxides, J. Eur. Ceram. Soc., 2006, 26, p 247-251

R. Vaßen, H. Kaßner, G. Mauer, and D. Stöver, Suspension Plasma Spraying: Process Characterization and Applications, J. Therm. Spray Technol., 2010, 19(1-2), p 219-225

A. Hospach, G. Mauer, R. Vaßen, and D. Stöver, Columnar Structured Thermal Barrier Coatings (TBCs) by Thin Film Low Pressure Plasma Spraying (LPPS-TF), J. Therm. Spray Technol., 2011, 20(1-2), p 116-120

B. Rajasekaran, G. Mauer, and R. Vaßen, Enhanced Characteristics of HVOF Sprayed MCrAlY Bond Coats for TBC Applications, J. Therm. Spray Technol., 2012, 20(6), p 1209-1216

A.V. Radha, S.V. Ushakov, and A. Navrotsky, Thermochemistry of Lanthanum Zirconate Pyrochlore, J. Mater. Res., 2009, 24(11), p 3350-3357

R. Vaßen, Entwicklung neuer oxidischer Wärmedämmschichten für Anwendungen in stationären und Flug-Gasturbinen, Schriften des Forschungszentrums Jülich, Energy Technology, vol 33, Forschungszentrum Jülich, Jülich, 2004 (in German)

H. Chen, Y. Gaoa, Y. Liua, and H. Luo, Coprecipitation Synthesis and Thermal Conductivity of La2Zr2O7, J. Alloy. Compd., 2009, 480, p 843-848

X.Q. Cao, R. Vaßen, W. Jungen, S. Schwartz, F. Tietz, and D. Stöver, Thermal Stability of Lanthanum Zirconate Plasma-Sprayed Coating, J. Am. Ceram. Soc., 2001, 84(9), p 2086-2090

H. Chen, Y. Gao, S. Tao, Y. Liu, and H. Luo, Thermophysical Properties of Lanthanum Zirconate Coating Prepared by Plasma Spraying and the Influence of Post Annealing, J. Alloy. Compd., 2009, 486, p 391-399

Z. Xu, L. He, R. Mu, S. He, and X. Cao, Preparation and Characterization of La2Zr2O7 Coating with the Addition of Y2O3 by EB-PVD, J. Alloy. Compd., 2010, 492, p 701-705

J.L. Margrave, Ed., The Characterization of High Temperature Vapors, Wiley, New York, 1967

G. Mauer, D. Sebold, R. Vaßen, and D. Stöver, Improving Atmospheric Plasma Spraying of Zirconate Thermal Barrier Coatings Based on Particle Diagnostics, J. Therm. Spray Technol., 2012, 21(3-4), p 363-371

G. Mauer, R. Vaßen, and D. Stöver, Comparison and Applications of DPV-2000 and Accuraspray-g3 Diagnostic Systems, J. Therm. Spray Technol., 2007, 16(3), p 414-424

W. Braue and P. Mechnich, Recession of an EB-PVD YSZ Coated Turbine Blade by CaSO4 and Fe, Ti-Rich CMAS-Type Deposits, J. Am. Ceram. Soc., 2011, 94(12), p 4483-4489

J.M. Drexler, A.D. Gledhill, K. Shinoda, A.L. Vasiliev, K.M. Reddy, S. Sampath, and N.P. Padture, Jet Engine Coatings for Resisting Volcanic Ash Damage, Adv. Mater., 2011, 23, p 2419-2424

A.D. Gledhill, K.M. Reddy, J.M. Drexler, K. Shinoda, S. Sampath, and N.P. Padture, Mitigation of Damage from Molten Fly Ash to Air-Plasma-Sprayed Thermal Barrier Coatings, Mater. Sci. Eng. A, 2011, 528, p 7214-7221

M.O. Jarligo, D.E. Mack, and R. Vaßen, Gd2Zr2O7-YSZ Composites for High Temperature Corrosion Resistant Thermal Barrier Coatings, Abstracts from the 36th International Conference and Exposition on Advanced Ceramics and Composites, January 22-27, 2012 (Daytona Beach, FL, USA), 2012

B. Heimberg, W. Beele, K. Kempter, U. Bast, T. Haubold, M. Hoffmann, A. Endriss, P. Greil, C. Hong, F. Alding, and H. Seifert, “Process for Producing a Ceramic Thermal Barrier Layer for Gas Turbine Engine Component,” U.S. Patent 06602553 B2, 2003

A.S. Bhalla, R. Guo, and R. Roy, The Perovskite Structure—A Review of Its Role in Ceramic Science and Technology, Mater. Res. Innov., 2000, 4, p 3-26

R. Guo, A.S. Bhalla, and L.E. Cross, Ba(Mg1/3Ta2/3)O3 Single Crystal Fiber Grown by the Laser Heated Pedestal Growth Technique, J. Appl. Phys., 1994, 75, p 4704-4708

W. Ma, M.O. Jarligo, D.E. Mack, D. Pitzer, J. Malzbender, R. Vaßen, and D. Stöver, New Generation Perovskite Thermal Barrier Coating Materials, J. Therm. Spray Technol., 2008, 17(5-6), p 831-837

M.O. Jarligo, D.E. Mack, R. Vaßen, and D. Stöver, Application of Plasma Sprayed Complex Perovskites as Thermal Barrier Coatings, J. Therm. Spray Technol., 2009, 18, p 187-193

A. Ansar, G. Schiller, O. Patz, J.B. Gregoire, and Z. Ilhan, Plasma Sprayed Oxygen Electrode for Solid Oxide Fuel Cells and High Temperature Electrolyzers, Thermal Spray 2008: Crossing Borders, on CD-ROM, E. Lugscheider, Ed., June 2-4, 2008 (Maastricht, The Netherlands), DVS Media, Düsseldorf, Germany, 2008

G. Schiller, M. Müller, and F. Gitzhofer, Preparation of Perovskite Powders and Coatings by Radio Frequency Suspension Plasma Spraying, J. Therm. Spray Technol., 1999, 8, p 389-392

C. Zhang, W.-Y. Li, H. Liao, C.-J. Li, C.-X. Li, and C. Coddet, Microstructure and Electrical Conductivity of Atmospheric Plasma-Sprayed LSM/YSZ Composite Cathode Materials, J. Therm. Spray Technol., 2007, 16, p 1005-1010

M.O. Jarligo, D.E. Mack, G. Mauer, R. Vaßen, and D. Stöver, Atmospheric Plasma Spraying of High Melting Temperature Complex Perovskites for TBC Application, J. Therm. Spray Technol., 2010, 19(1-2), p 303-310

G.V. Samsonov, Ed., The Oxide Handbook, 2nd ed., IFI/Plenum, New York, 1986

M.O. Jarligo, G. Mauer, D. Sebold, D.E. Mack, R. Vaßen, and D. Stöver, Decomposition of Ba(Mg1/3Ta2/3)O3 Perovskite During Atmospheric Plasma Spraying, Surf. Coat. Technol., 2012, 206(8-9), p 2515-2520

G. Mauer, M.O. Jarligo, D.E. Mack, R. Vaßen, and D. Stöver, Development of Plasma Spray Parameters for Ceramic Coatings in Gas Turbines, Proceedings of the 24th International Conference on Surface Modification Technologies (SMT 24), T.S. Sudarshan, E. Beyer, and L.M. Berger, Ed., September 7-9, 2010 (Dresden), Valardocs, Chennai, India, 2011, p 35-46

W. Ma, D.E. Mack, R. Vaßen, and D. Stöver, Perovskite-Type Strontium Zirconate as a New Material for Thermal Barrier Coatings, J. Am. Ceram. Soc., 2008, 91(8), p 2630-2635

Y. Zhang, D.E. Mack, M.O. Jarligo, X. Cao, R. Vaßen, and D. Stöver, Partial Evaporation of Strontium Zirconate During Atmospheric Plasma Spraying, J. Therm. Spray Technol., 2009, 18(4), p 694-701

C. Friedrich, R. Gadow, and T. Schirmer, Lanthanum Hexaaluminate—A New Material for Atmospheric Plasma Spraying of Advanced Thermal Barrier Coatings, J. Therm. Spray Technol., 2001, 10(4), p 592-598

C.M. Weyant and K.T. Faber, Processing-Microstructure Relationships for Plasma-Sprayed Yttrium Aluminum Garnet, Surf. Coat. Technol., 2008, 202(24), p 6081-6089

G. Pracht, R. Vaßen, and D. Stöver, Lanthanum-Lithium Hexaaluminate—A New Material for Thermal Barrier Coatings in Magnetoplumbite Structure—Material and Process Development, Ceram. Eng. Sci. Proc., 2008, 27(3), p 87-99

A. Doncieux, D. Stagnol, M. Huger, T. Chotard, C. Gault, T. Ota, and S. Hashimoto, Thermo-Elastic Behaviour of a Natural Quartzite: Itacolumite, J. Mater. Sci., 2008, 43(12), p 4167-4174

T.A. Schaedler, R.M. Leckie, S. Krämer, A.G. Evans, and C.G. Levi, Toughening of Non-transformable t′-YSZ by Addition of Titania, J. Am. Ceram. Soc., 2007, 90, p 3896-3901

M.O. Jarligo, G. Mauer, D.E. Mack, R. Vaßen, and D. Stöver, The Influence of Titania Doping on Plasma-Sprayed YSZ Thermal Barrier Coatings Proceedings of the 25th International Conference on Surface Modification Technologies (SMT 25), T.S. Sudarshan and P. Nylén, Ed., June 20-22, 2011 (Trollhättan, Sweden), Valardocs, 2012, p 165-173

T.A. Schaedler, O. Fabrichnaya, and C.G. Levi, Phase Equilibria in the TiO2-YO1.5-ZrO2 System, J. Eur. Ceram. Soc., 2008, 28, p 2509-2520

M.O. Jarligo, G. Mauer, D.E. Mack, R. Vaßen, and D. Stöver, Advanced Thermal Barrier Coatings from Ti-Doped YSZ Systems, International Thermal Spray Conference 2011, Sep 27-29, 2011 (Hamburg, Germany), DVS-Berichte 276, DVS Media, Düsseldorf, Germany, 2011

D. Zhu and R.A. Miller, Development of Advanced Low Conductivity Thermal Barrier Coatings, Int. J. Appl. Ceram. Technol., 2004, 1(1), p 86-94

M.O. Jarligo, D.E. Mack, and R. Vaßen, Ti,Yb-Doped YSZ Systems for Advanced Thermal Barrier Coating Applications, 10th CMCEE—International Symposium on Ceramic Materials and Components for Energy and Environmental Applications, May 20-23, 2012 (Dresden, Germany), 2012

Acknowledgments

The authors are grateful to Dr. Jürgen Malzbender (IEK-2), Mr. Mirko Ziegner (IEK-2), Mrs. Hannelore Lippert (ZCH), and the colleagues of IEK-1 in Forschungszentrum Jülich GmbH for their help in carrying out the experiments which results are reported in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mauer, G., Jarligo, M.O., Mack, D.E. et al. Plasma-Sprayed Thermal Barrier Coatings: New Materials, Processing Issues, and Solutions. J Therm Spray Tech 22, 646–658 (2013). https://doi.org/10.1007/s11666-013-9889-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9889-8