Abstract

Itacolumite is a particular type of sandstone constituted of quartz grains, with an interlocked microstructure and large intergranular decohesions. This article is devoted to the study of the thermo-elastic behaviour of this material during thermal cycles between 20 and 800 °C. This was made by using an ultrasonic pulse-echo measurement technique of Young’s modulus E, coupled to thermal expansion experimentation and to acoustic emission. An unusual evolution of elastic properties versus temperature is found, with strong irreversible effects around the temperature of the α–β transition of quartz. A damage parameter, representing the fractional number of cracks, is calculated with a Kachanov type formulation, by using the experimental data for itacolumite and the values of E, obtained from literature for an hypothetic ideal quartz polycrystal. The evolution of this parameter versus temperature is explained by internal stresses that are developed by both thermal and elastic effects in quartz grains.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Classically, crystallised silicate compounds—natural rocks or ceramics—exhibit a linear elastic mechanical behaviour at temperatures inferior to the brittle—ductile transition domain. Consequently, these materials do not admit large strains before rupture when they are subjected to thermal or/and mechanical solicitations. Solutions for decreasing brittleness of inorganic material are to be researched in mechanisms increasing fracture energy (or toughness): for example plasticity (case of metals), dispersion of particles or fibres in the matrix (concept of composites), generation of a crack array in the material or design of particular microstructure shapes. These two last cases are perfectly illustrated by itacolumite which is frequently called “flexible sandstone” [1]. Sandstone is a generic name of rocks constituted of sand grains (mainly quartz) embedded into a natural cement. Itacolumite is a particular case where quartz grains are angular and characterised by intergranular spaces arranged as an interlocked structure like a jigsaw puzzle. The cohesion of this material is not achieved by an intergranular mineral cement (only a few secondary phases are present) but by the morphology of the fabric which allows some free motion from grain to grain into the void spaces, as illustrated in Fig. 1 which schematically represents a cross section subjected to flexion.

Stress–strain flexion curves of such materials show two regimes: at first a large possibility of deformations of the side in tension; then followed by stiffening when most of grains are locked, before rupture [2]. Therefore, itacolumite can be used as a model for designing new refractory materials with large decohesions between constituents, which are expected to exhibit an improved thermal shock resistance. Though the effect of decohesions due to thermal expansion mismatches has been studied in many industrial refractories [3], no similar study exists for itacolumite.

This article deals with the evolutions of elastic behaviour and thermal expansion of itacolumite during thermal cycles between room temperature and 800 °C. Young’s modulus and thermal expansion have been measured by using a high-temperature pulse-echo ultrasonic technique and by dilatometry, respectively. In order to correlate the observed evolutions to the effects of temperature on intergranular decohesions, results of acoustic emission during thermal cycles, performed in the same conditions, are used. The interpretation is rather complex because of large non-linear thermo-elastic effects which occur in quartz at the α–β transition (573 °C). Nevertheless, the variation versus temperature of a Kachanov damage parameter, representing the evolution of cracks and intergranular decohesions, is calculated. It is obtained by comparing the theoretical variations versus temperature of thermo-elastic properties of an ideal quartz polycrystal, derived from literature data in single crystals, and the experimental results. Finally, this result is used to suggest an interpretation of the particular behaviour of itacolumite versus temperature.

Experimental

Material

Itacolumite slabs of 1–2 cm in thickness and around 10 cm in width and length have been extracted from Minas Gerais in Brazil. They are flexible and stratified plates which present some difficulties to be cut and polished, because of weak bonds among hard quartz grains. An anisotropic texture being expected, samples have been machined according to three main axes as referred in Fig. 2.

SEM pictures of polished surfaces are presented in Fig. 3 for two sections corresponding to a x–y plane (a) and to a y–z plane (b). They show that the microstructure has the same morphology in both sections with interlocked quartz grains of some 100 μm in size. The average width of the intergranular voids seems to be slightly larger in the cross section than along the length of the plate.

The XRD analysis mainly revealed, as expected, that the material is constituted of quartz, with a few amount of alumino-silicate inclusions (kaolinite, mica, muscovite) which were identified by EDS. Figure 4 shows a typical muscovite platelet inclusion inter-grown with quartz.

Measurement techniques at high temperature

Ultrasonic pulse-echo measurement of Young’s modulus

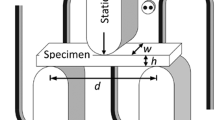

The measurement of Young’s modulus variations during thermal cycles was performed with an ultrasonic pulse-echo device, working in the conditions of long bar propagation mode, which was described elsewhere [4]. The principle is schematically presented in Fig. 5.

Ultrasonic compressional waves are generated by a magnetostrictive transducer. For itacolumite, a low working frequency was chosen, 40 kHz, because of the high attenuation due to intergranular decohesions. The ultrasonic pulse is sent into a parallelepipedic sample through a refractory alumina waveguide. An electronic equipment (a digital oscilloscope and a specific software package) automatically measures and records the time delay τ corresponding to one round-trip of the waves through the sample [4]. Then, the Young’s modulus E of the material is given by the following equation:

where L and ρ are sample length and density, respectively.

If phenomena involving significant dimensional changes occur during measurements versus temperature, the value of E should be corrected as follows:

where the suffix 0 is related to the values measured at room temperature and \(\frac{\Updelta{L}}{{L}_{\rm 0}}\) is obtained from thermal expansion measurements in the same conditions as ultrasonic ones. Though in the case of itacolumite, the α–β quartz transition involves thermal expansion effects, they remain inferior to 2% as it will be seen after. Therefore, this correction was considered to be negligible compared to the amplitude of the variations of Young’s modulus.

For itacolumite, the dimensions of samples were 7 × 7 × 100 mm3, machined along the x direction.

Acoustic emission

Acoustic emission (AE) is a useful technique to detect damage evolutions in materials. It consists in recording and analysing transient elastic waves (hits), generated by the rapid release of energy from localised sources within a material. In particular, crack formation and propagation are important sources of AE hits. These hits are received by a piezoelectric transducer (AE sensor) and are transformed into electric signals (bursts) which are amplified, then are sent to an acquisition card linked to a computer and finally are treated by a specific software package. Usually, the frequency domain of the used sensors is between 100 kHz and 1 MHz. Each electric burst represents a hit, which consists of counts. A hit is recorded only if the amplitude of counts reaches a tension threshold. The tension threshold is chosen by the user in order to filter undesirable noises. The parameters of interest, which can be obtained from a typical AE hit, are defined in Fig. 6.

In order to follow the AE activity associated to the evolution of the microstructure of itacolumite during thermal cycles, a specific equipment has been used, using an alumina waveguide between the AE sensor and the sample placed in a furnace (Fig. 7). Samples were parallelepipeds of 23 × 6.6 × 6.1 mm3 cut along the x direction.

Thermal expansion measurements

Measurements were performed by using a TMA SETSYS dilatometer with parallelepipedic samples. For itacolumite, their length was about 10 mm and they were cut along the x or y axis plates in order to detect an eventual textural effect.

Results

Thermal expansion

The thermal expansion (TE) along the plate length (x axis) during a thermal cycle, at a rate of 5 °C/min, was measured between 20 and 1,200 °C. There is quite no expansion between 800 and 1,200 °C. In this temperature range, the material is stabilised with the β quartz structure which has a very low (slightly negative) TE [5, 6] and no noticeable sintering effect exists. Consequently, the results are only plotted between 20 and 800 °C in Fig. 8, and subsequent dilatometric, ultrasonic and AE measurements will be only performed in this temperature range.

During the temperature increase, the aspect of the curve is quite similar to the quartz one, with a marked effect at the so-called α–β transition \((T_{\alpha{-}\beta}=573\,^{\circ}\hbox{C}).\) At this point, TE reaches up to 1.6% for itacolumite, which could be compared with the TE value, 1.7%, of a quartz crystal along a-axis [6]. This could suggest the existence of a preferential orientation of grains along the plate axis. When cooling, a reverse contraction is observed at the quartz transition, but for itacolumite, TE is not reversible and a permanent expansion of about 0.85% remains at room temperature.

This behaviour is also observed in a sample cut along the y axis (Fig. 9). In that case, the TE at the quartz point is lower (1.2%) than along the x axis. This behaviour could be due to a different average orientation of quartz grains in this direction and/or to the effect of intergranular voids, which seem to be wider than along the x axis (Fig. 3). A second thermal cycle performed on the same sample, shows a quite good reversibility between heating and cooling stages.

Young’s modulus variations

Measurements versus temperature have been performed in samples cut along the x axis. The characteristics of the cycles were: heating and cooling rates of 5 °C/min, with a short dwell (6 min) at 800 °C.

The E value measured at room temperature, as reported in Fig. 10, is very low (7 GPa) when compared to the dense silica polymorphs ones (between 70 and 110 GPa depending on the crystalline structure). This is due to intergranular decohesions, which have the same effect on elastic properties than a crack array in a dense elastic material. Moreover, the important scattering of results found in different samples (between 6 and 10 GPa), suggests that the itacolumite plates are not homogeneous.

Figure 10 shows the result of two successive thermal cycles. The first cycle exhibits important irreversible effects:

-

During the first temperature rise, the trend is an increase of E up to 530 °C, followed by a transient small drop around Tα–β;

-

Above Tα–β, E remains approximately constant;

-

When cooling, a deep drop of E (−50%) is observed around Tα–β;

-

Below Tα–β, E regularly increases as in a stable material;

-

The final value at room temperature is lower (5 GPa) than before the thermal cycle.

The second thermal cycle is quasi reversible with a regular variation of E versus temperature and with a modulus shift of about 1 GPa at Tα–β, between the α and β quartz phases.

Acoustic emission

The cumulative number of hits of AE has been recorded in samples cut along the x axis during two successive thermal cycles realised in the same conditions than the ultrasonic measurements. For both thermal cycles, the curves of cumulated hits versus temperature exhibit similar aspects. Nevertheless, the values obtained during the second cycle are an order of magnitude lower than the ones of the first cycle (Fig. 11)

For the first heating, no significant AE is observed up to 350 °C. Then, AE activity progressively increases, to reach a maximum around Tα–β and progressively decreases above 650 °C. When cooling, there is no AE down to Tα–β. Around this temperature a jump is observed but it is less important than during heating. Below 500 °C there is a very low level of AE.

The acoustic activity recorded during the second thermal cycle is globally 10 times lower than during the first one. The number of hits is quite similar between heating (45% of hits) and cooling (55% of hits) with symmetrical AE effects around Tα–β.

Discussion

Itacolumite is constituted of more than 90% of interlocked quartz grains with intergranular voids (Figs. 1, 3). Due to the thermal expansion of quartz grains, the volume density of opened voids depend on temperature. Therefore, at a given temperature T, the material can be modelled as an isotropic elastic solid (corresponding to a perfect quartz polycrystal) with an array of opened cracks (mainly corresponding to intergranular voids). Using a Kachanov type formulation [7], the Young’s modulus E(T) of this damaged material at a given temperature T can be expressed by the following equation:

where EQ(T) is the Young’s modulus of an ideal uncracked quartz polycrystal and D(T) is a damage parameter, which, in the case of itacolumite, is an indicator of the density of opened cracks (intergranular and eventually intragranular).

Then, the evolution of D(T) versus temperature can be obtained from the measured value, E(T) and from the theoretical value EQ(T) by:

Theoretical evaluation of EQ(T)

The Young’s modulus of an hypothetic ideal quartz polycrystal, EQ(T), has been evaluated from literature data on elastic constants Cij. Results of measurements in quartz single crystals [8, 9] and results of theoretical calculations using molecular dynamics approaches [10] in both α and β states, show that silica polymorphs—cristobalite and quartz—exhibit an unusual elastic behaviour near Tα–β, in particular with a negative Poisson’s ratio (auxetic behaviour). Table 1 summarises results given in literature for elastic constants of quartz at different temperatures. It can be seen that, around Tα–β, C12 and C13 undergo large variations with negative values and that, logically, C14 = 0 for the β hexagonal symmetry.

Therefore, Young’s modulus of a polycrystalline quartz is expected to present some abnormal evolutions versus temperature at the α–β transition.

The bulk modulus, B, and the shear modulus, G, for an isotropic aggregate of α-quartz, can be calculated from the Cij values by means of a Voigt–Reuss–Hill average for the trigonal symmetry [11].

The Voigt bulk modulus, BV and the shear modulus, GV, are determined by Eqs. 5 and 6:

where M and C66 are given by:

The Reuss bulk modulus, BR, and the shear modulus, GR, are determined by Eqs. 9 and 10.

where c 2 is given by:

Then, the Hill bulk modulus, BH, and the shear modulus, GH, are given by Eqs. 12 and 13.

Finally, EQ(T) can be derived from the bulk and shear moduli by:

For the hexagonal β quartz, the formalism is the same with the condition: C14 = 0.

Therefore the theoretical variation of EQ in the 20–800 °C temperature range can be calculated. This evolution is plotted in Fig. 12

.

At room temperature, EQ0 is about 100 GPa, which is much higher than the measured value of Young’s modulus of itacolumite. Then, EQ slowly decreases when temperature increases, as it is usual in most stable crystallised ceramics, up to approximately 400 °C. Above this temperature, the Young’s modulus of polycrystalline α quartz strongly decreases down to 60 GPa at Tα–β. As soon as the α–β transformation occurs, EQ quickly increases up to 100 GPa at 600 °C and then, seems to remain approximately constant up to 800 °C.

Evaluation of D(T)

With the reasonable assumption that no phase transformation, susceptible to induce noticeable Young’s modulus variation, occurs in this temperature range, the measured value of E is the result of damage, i.e. of the opened cracks array. Therefore, the evolution of D(T) can be calculated with Eq. 4, where the values of E(T) and EQ(T) are given by Figs. 10 and 12, respectively. The variation of Young’s modulus of polycrystalline quartz was supposed to be reversible versus temperature. Figure 13 shows the result of this calculation. The following remarks are to be pointed out:

-

The damage, mainly corresponding to opened intergranular voids in the natural itacolumite, as evaluated by ultrasonic measurements, is very high (∼92%), in agreement with SEM observations (Fig. 3);

-

When heating, this ratio decreases, with a drop down to 85% at Tα–β;

-

Between Tα–β and 600 °C, D(T) increases up to about 90% and then remains approximately constant up to 800 °C;

-

When cooling, the ratio increases of about 4% between 600 and 500 °C (around the quartz transformation point);

-

The value of D(T) after the first cycle is 3% higher than in the natural state;

-

During the second cycle, there is no significant variation of D(T), except a small reversible effect at Tα–β, which suggests that a steady state of intergranular decohesion is achieved after the first heat treatment.

Interpretation

From these experimental results, an attempt can be made to interpret the main effects characterizing the behaviour of itacolumite in the 20–800 °C range.

1. First heating from 20 to 530 °C: The anisotropic thermal expansion of individual quartz grains first decreases the intergranular voids ratio (cf. Fig. 13) and induces acoustic emission (cf. Fig. 11), which could be provoked by grain-to-grain friction at contact points.

2. First heating from 530 °C to Tα–β: The thermal expansion mismatch between grains in contact becomes very important at the vicinity of the transformation quartz point, involving an important intergranular voids closure (cf. the drop of D(T) in Fig. 13), but also internal stresses when grains become in contact. Theses stresses are rather low because of the low elastic modulus of quartz grains at Tα–β (cf. Fig. 11).

3. First heating from Tα–β to 600 °C: The sudden augmentation of stiffness of quartz grains (Fig. 12) strongly increases the internal stress field which becomes sufficient to induce irreversible cracking between and into grains in contact. This phenomenon is consistent with the high level of acoustic emission in this temperature range (cf. Fig. 11). Though the thermal expansion of quartz grains becomes negligible in the β state, this new damage involves an increase of D(T) (cf. Fig. 13). This is illustrated on the SEM picture of Fig. 14: compared to the picture of Fig. 4, quartz grains are obviously highly damaged after heating at 800 °C.

4. Cooling after the first heating: Small increases around Tα–β of AE activity (cf. Fig. 11) and of damage (cf. Fig. 13) are the only noticeable observed effects. They can be attributed to the changes of TE and of elasticity at the quartz point, which can induce grain sliding and some additional damage due to internal stresses.

5. At room temperature after the first cycle: Itacolumite exhibits a permanent expansion (cf. Figs. 8, 9) and a permanent increase of D(T) because of the irreversible damage created in step 3.

6. During a second temperature cycle: TE expansion curves (cf. Fig. 9) and D(T) curves (cf. Fig. 13) are almost reversible. Only a few AE activity and a small transient variation of D(T) are observed around Tα-β which are probably related to the high and anisotropic thermal expansion of quartz grains. The microstructure of itacolumite has been stabilised by heat treatment. Unfortunately, it has been observed that the “flexibility” coming from the interlocked structure is partially destroyed.

Conclusion

Complementary techniques, such as high-temperature ultrasonic evaluation of Young’s modulus, thermal expansion measurements and high temperature acoustic emission, are useful tools to investigate the evolution of damage with temperature in ceramic materials with intergranular cracks. In the case of natural itacolumite, they have been used to show that a first thermal cycle up to 800 °C induces an irreversible increase of the damage parameter, which has been explained by the particular thermo-elastic behaviour of quartz in the vicinity of the α–β transition. In order to open future prospects for designing microstructures of refractories with improved thermal shock resistance, itacolumite can be used as a model material to process synthetic flexible ceramics by mixing phases with large differences of thermal expansion properties [12]. Further work is now undertaken to investigate the thermomechanical properties of such materials, by using the experimental methods described in this article.

References

Devries RC, Jugle DB (1968) J Am Ceram Soc 51:387

Dusseault MB (1980) Q J Eng Geol London 13:119

Huger M, Tessier-Doyen N, Chotard T, Gault C (2007) Ceram Forum Int 84:E93

Huger M, Fargeot D, Gault C (2002) High Temp High Press 34:193

Smirnov MB (1999) Phys Rev B 59:4036

Raz U, Girsperger S, Thompson AB (2007). https://doi.org/www.e-collection.ethbib.ethz.ch, as on 5 july 2007

Kachanov LM (1959) J Appl Math Mech l23:880

Ono I (1995) J Phys Earth 43:157

Zubov VG, Firsova MM (1962) Sov Phys Crystallogr 7:374

Kimizuka H, Kaburaki H (2005) Phys Stat Sol 242:607

Peselnick L, Meister R (1965) J Appl Phys 36:2879

Sato I, Ichikawa Y, Sakanoue J, Mizutani M, Adachi N, Ota T (2008) J Am Ceram Soc 91:607

Acknowledgement

The authors are grateful to the Federation for International Refractories Research and Education (FIRE) for its financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Doncieux, A., Stagnol, D., Huger, M. et al. Thermo-elastic behaviour of a natural quartzite: itacolumite. J Mater Sci 43, 4167–4174 (2008). https://doi.org/10.1007/s10853-007-2414-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2414-z