Abstract

The pasting, viscoelastic, morphological and retrogradation properties of rice starch as affected by low acyl (LA) and high acyl (HA) gellan gums were studied. The additions of both LA and HA gums increased the peak and trough viscosities, while decreased the final and setback viscosities of rice starch paste. The starch-HA mixed pastes exhibited superior viscoelastic properties to the starch-LA pastes as evidenced by their higher storage modulus and lower loss tangent values. The starch-HA system exhibited higher resistance to the stress and more pronounced recovery rate in in-shear structural recovery test. The creep recovery data were well fitted by a 4-element Burger’s model. The shrinkage measurements showed that the addition of both hydrocolloids, especially the HA gellan gum retarded the retrogradation of rice starch gel during cold storage. It was concluded that the addition of LA and HA gellan gums modified the rheology and textural properties of rice starch gel in different ways and interacted under different mechanisms based on their molecular structures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There are many rice starch-based foods on the market, such as rice noodles, infant rice flour, steamed rice bread and sponge rice cake. Recently, rice flour was used as an ideal wheat substitute in many gluten-free food products due to its good flavor and hypoallergenicity of its proteins [1, 2]. However, during storage of products made from rice starch or flour, the retrogradation of starch leads to an increase of roughness and hardness in texture. Additionally, in common with other cereal flours, it also has negative aspects like producing weak-bodied, rubbery pastes, and tendency to syneresis after cold storage [3, 4].

It has been shown that the addition of polysaccharide hydrocolloids to starch-based foods offers a good way to overcome these shortcomings and so guarantee constant food quality [3, 5]. The characterization of rheological and textural properties on starch-hydrocolloids combinations, and exploring the possible interactions are critical to improve overall food qualities and develop better products based on rice starch [5, 6]. Over the last decades, hydrocolloids such as xanthan [7, 8], hydroxypropyl methylcellulose [9, 10], pullulan [11], locust bean gum [12], beta-glucan [13], and konjac glucomannan [14] have been demonstrated to efficiently modify the rheological properties and alleviate the retrogradation rate of native starch. The differences in molecular characteristics such as molecular weight, intrinsic viscosity, macromolecular derivatives and substituents were hypothesized to be responsible for the different synergistic effects of starch and hydrocolloids [15, 16]. Several mechanisms such as phase separation owing to thermodynamic incompatibility, immobilization of water molecules by hydrocolloid molecules, and starch-gum intermolecular associations [5, 6, 17] have been proposed to explain the observed effects. Very recently, Luo et al. [18] investigated the influence of different pectin structures on the pasting properties of rice starch. However, there are still fewer efforts that devote to investigate the effects and mechanisms of various hydrocolloids on rice starch compared to other starches [13]. It appears to be general agreement that interaction between starch and hydrocolloids, which may have either positive or negative effects, depends on the specific hydrocolloid and the specific starch used [5].

Gellan gum as a natural anionic heteropolysaccharide is widely used and known for its capability of forming gel at very low concentration compared to other polysaccharides [19]. This property may make it an ideal candidate to improve moisture retention and viscoelasticity of rice starch products while maintain good food qualities [20]. On the other hand, gellan gum has a tetrasaccharide repeat unit composed of (1–3)-β-d-glucose, (1–4)-β-d-glucuronic acid, (1–4)-β-d-glucose, and (1–4)-α-l-rhamnose as the backbone. According to the degree of acetylation at C-2 and C-6 positions of the (1–3)-β-d-glucose section, the gellan gum can be divided into high acyl (HA) gellan gum and low acyl (LA) gellan gum. The presence of the acyl substituents is critical for gelation, rheological properties and physical appearance of the gels [21]. Sherafati et al. [22] studied the effects of low and high acyl gellan gums on the stabilities and sensory characteristics of carrot juice. To the best of our knowledge, the effect and comparison of different gellan gums on the pasting, rheological and textural behavior of rice starch have not yet been performed.

Accordingly, this study was carried out to investigate the influence of LA and HA gellan gums on the pasting, rheological, morphological and retrogradation properties of rice starch gel. Rheological properties including the steady shear parameters, the viscoelastic characteristics and the creep recovery response were measured. The possible interactions between rice starch and gellan gums were explored based on these physicochemical measurements. A better understanding of the effects and possible interactions of gellan gums on rice starch is beneficial for their utilization to improve the stability and overall textural properties of rice starch-based foods.

Materials and Methods

Materials

Rice starch was purchased from Jinnong Company (Jiangxi, China). The composition of rice flour was analyzed by standard procedures [23]. Results show that it contains approximately 90.5 ± 1.4% total starch, 24.7 ± 0.3% of amylose, 7.70 ± 0.03% moisture, and 0.90 ± 0.06% protein. The size distribution of rice starch determined by a dynamic light scattering (DLS) instrument (Mastersizer 2000, Malvern Instruments Ltd., Worcestershire, UK) and have volume-based mean diameter D[4,3] of 5.73 ± 0.01 μm. Low acyl gellan gum (Gelrite) and high acyl gellan gum (LT100-P) used in this study were kindly supplied by CP Kelco company (Shanghai, China). Samples were prepared using ultra-pure water with a resistivity of 18.2 MΩ·cm.

Pasting Properties

Rapid viscosity analysis of rice starch (RS) and RS-HA or RS-LA mixtures were with a RVA (Model RVA-4, Newport Scientific, Warriewood, Australia). The LA (0.1 wt.%) and HA (0.1 wt.%) gellan gums were independently dispersed in pure water and stirred for one hour at 80 °C. The RS-gum mixtures were prepared by adding 3 g rice starch to 25 g LA or HA solutions in the aluminum RVA canisters. Then the slurries were subjected to the following time–temperature profile: equilibration for 60 s at 50 °C, ramp to 95 °C in 225 s, holding at 90 °C for 180 s, cooling down to 50 °C at a constant rate, and holding at 50 °C for 90 s. The speed of the plastic paddle was kept at a constant value of 160 rpm during the test. Parameters (peak viscosity, trough viscosity, final viscosity, setback viscosity, and breakdown viscosity) can be obtained on RVA curves. All the pasting parameters were presented as the mean ± standard deviation of triplicate determinations.

Dynamic Oscillatory Measurements

The rheological properties of RS/LA and RS/HA pastes were obtained by using a controlled stress rheometer (AR-G2, TA Instruments, New Castle, USA) equipped with a geometry (40 mm of diameter and 1 mm gap). Samples were equilibrated at least for 5 min before the rheological test and were coated around their periphery with light silicone oil to diminish the loss of water.

The oscillatory tests were carried out at a constant strain 1% over a frequency range of 0.1–10 Hz (0.628–62.8 rad/s), which was in the linear viscoelastic region for all test samples. The storage modulus (G’), loss modulus (G”), and loss tangent (tanδ) as a function of angular frequency (ω) were obtained by using TA rheometer Data Analysis software (version 5.7.1). All measurements were performed at least in triplicate and reproducible results were achieved.

Creep-Recovery Measurements

In the creep-recovery measurements, the fresh prepared gel by RVA was placed on the rheometer plate as above, and equilibrated for 3 min to allow residual stress to relax and the gap was set at 3 mm. Samples were coated around their periphery with light silicone oil to minimize the water loss. During the test, a constant stress (30 Pa) was firstly applied on the gel for 120 s. In the recovery phase, the stress was removed and the sample was allowed for 180 s to recover the elastic (instantaneous and retarded) part of the deformation. The strain values were collected as a function of time. All measurements were performed in triplicate at 25 °C.

The data from creep measurements are correlated by the 4-element Burgers model. The model with a mechanical analog composed of springs and dashpots [10, 24] is given by equation as shown below:

where Jc(t) is the creep compliance (strain of gels divided by the stress), J0c is the instantaneous compliance, J1c is the retarded elastic compliances, λ1c is the retardation time in the Kelvin body, μ0 is the coefficient of viscosity associated with viscosity flow, and t represents the time (s) after loading.

In-Shear Recovery Measurements

In-shear structural recovery of the paste samples was determined according to the method of Achayuthakan & Suphantharika [16] with some modifications. The freshly prepared RS or RS-gum mixed paste was load onto the rheometer at 25 °C as described earlier. A three-stepped shear flow test was carried out as follows: (1) a constant shear rate at 1 s−1 for 2 min and immediately followed by (2) a constant shear rate at 300 s−1 for 1 min and then (3) a constant shear rate at 1 s−1 for 3 min. The value of in-shear recovery for the gel sample was obtained as the ratio of apparent viscosity of the third step to the average value of apparent viscosity determined in the first step.

Scanning Electron Microscope

The changes on micromorphology of RS gel with the addition of LA and HA gellan gums was investigated by scanning electron microscope (SEM). The RS, RS-LA, and RS-HA paste obtained by the RVA instrument as described above were subjected to freeze quickly and lyophilized. The freeze-drying gel samples were stuck on a specimen holder and then coated with gold palladium by a sputter coater. The microstructure was observed with using a Phenom Pro scanning electron microscope (Phenom, Netherlands) which operating at an accelerating voltage of 5 kV. The results at 500× and 3000× resolution were collected and analysed.

Results and Discussion

Pasting Properties

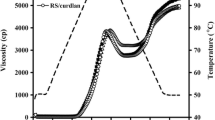

The typical pasting profiles of rice starch determined by RVA analysis in the presence or absence of LA and HA are shown in Fig. 1. Statistical analyses of all pasting parameters are also obtained and listed in Table 1.

As can be seen in figure and table, the values of peak and trough viscosity are around 3600 and 2800 mPa·s respectively, which is clearly in accordance with those previously reported for rice starch with an amylose content of about 23.3% by Chen et al. [7]. Compared with rice starch alone, both the additions of HA or LA increased the peak viscosity (PV) and trough viscosity (TV) of rice starch. The increase of peak and trough viscosities of were found in rice starch paste with the addition of many hydrocolloids [25, 26], such as guar and xanthan [27], carboxymethyl cellulose [10], and pectin [18]. The value of PV often correlates with the quality of final food products, since the swollen and collapsed granules relate to the texture and flavor of cooked starchy foods [28, 29]. On the other hand, it can be found that the final and setback viscosities were decreased with the addition of both gellan gums. These phenomena were also found by Leite, Nicoleti, Penna, & Franco [30] who studied the effects of the xanthan gum, sodium carboxymethyl cellulose, and carrageenan on the properties of cassava starch.

As discussed above, the increase in PV of rice starch paste in the presence of gellan gum agrees with the overall pasting behavior observed in the RS-hydrocolloids mixtures [25, 26]. It is well known that the pasting property of starch is primarily related to the swelling and rupture of starch granules [31]. During the RVA measurements, the viscosity increases with continuous heating until the rate of granule swelling equals the rate of granule collapse. PV shows the maximum swelling of the starch granule prior to disintegration and also is described as the equilibrium point between swelling and disintegration of the starch granule. It is supposed that both the gellan gum additions increase the PV values may own to its high thickening capability [32]. By the thickening effects of hydrocolloids additions, the shear forces acting on the swollen granules become larger than those in pure water system only [33]. It consequently resulted in an increase of swollen or disintegration of starch granules and released more starch molecules primarily amylose. It was pointed that the more disintegration of starch granules would result in a lower trough viscosity and a higher breakdown viscosity [5]. However, a lower value of breakdown viscosity was found in both the studied paste than rice starch sample which was caused by the increase of TV viscosity. It is supposed that the great release of solubilized starch, high levels of granules swelling and interactions between dissolved starch and gellan gum molecules, led to an overall increase of the TV viscosity. These interactions may include the water competition and steric hindrance between the rice starch and gellan gums. On the other hand, HA gellan gums in the continuous phase may create more junction zones on amylose or dissolved amylopectin via changes of conformational adjustment and intermolecular association by its acetyl and glyceroyl groups. As a result, the RS-HA paste exhibited a higher viscosity effects than the RS-LA.

The setback viscosity (SV) is defined as the difference between final viscosity and trough viscosity and its magnitude is considered to reflect the retrogradation tendency of amylose in a starch paste. Typically, starch presenting higher SV values has a greater tendency for retrogradation [4]. During the cooling process of RAV measurements, the rapid aggregation and the formation of junction zones of amylose by hydrogen bonds between the chains of the molecules are responsible for the retrogradation [28, 33]. It is shown that both additions of gellan gums decrease the final and SV compared to the rice starch sample. Many works also reported similar findings that the hydrocolloids additions could delay the retrogradation of amylose [3]. This effect again contributes to not only the cohesive gel network by hydrocolloids which delays the moisture migration, but also the intramolecular associations between hydrocolloids and solubilized starch molecules by structural winding or inclusion, hydrogen bonding and electrostatic interactions. Shi & Bemiller [17] studied the pasting properties of many starches in dilute solutions of hydrocolloids and found that ionic hydrocolloids such as xanthan and CMC can interact with starch molecules significantly by intramolecular associations. For both gellan gums, the carboxyl groups on glucuronic acid residues may induce the electrostatic interaction [21, 34] between gellan gum chains and with starch molecules, which shows the typical characteristics of ionic hydrocolloids. On the other hand, since HA gellan gum has more acetyl and glyceroyl groups, less linear structure and bigger steric hindrance [34], a more robust gel network can be formed which may further delay the retrogradation of amylose in the paste.

Dynamic Viscoelastic Properties

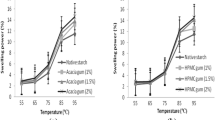

Small deformation oscillatory tests are always employed to elucidate structural insight of viscoelastic materials. It is known that the storage modulus (G’) and loss modulus (G”) represent the elastic property of energy storage and the viscous property of energy dissipation, respectively [29]. The dynamic mechanical spectra of the RS-LA and RS-HA mixed pastes are shown in Fig. 2. The results clearly suggest that G′ is much higher than G″ throughout the measured frequency range and increase with the increase of angular frequency. These results indicate that the rice starch gel without and with gellan gums can be treated rheologically as a normal weak gel structure [35]. It can also be seen that the addition of gellan gums increase the value of G’ and G” as compared to the rice starch sample.

The values of G’, G”, and dynamic mechanical loss tangent (tanδ = G”/G’) for each rice starch gels at an oscillatory frequency of 1 Hz are listed in Table 2. It is shown that the values of tanδ for all studied gels are much smaller than 1 which indicates their predominantly elastic behaviour. The addition of gellan gums leads to an increase of the storage modulus (G’) and the loss modulus (G”) for RS pastes, which can be interpreted that the presence of gellan gums appears to increase the association of gelatinized starch granules and contributed to the enhancement of G’ values in the mixed pastes. This result is consistent with other previous findings [17, 36, 37]. It is known that due to the absence of a binding agent in rice starch (such as gluten), there was less ability to form a definable structure and there were repulsive forces existing between the starch granules [9]. So the increase of moduli values can be attributed to the difference between the interaction of rice starch–gellan gums in mixed paste and the interaction in pure rice starch paste. On the other hand, in rice starch-gellan gum mixtures, gellan networks are formed around the swollen starch granules and systems with different degrees of elasticity are obtained depending on the extent of granules disruption, which in turn influence the segregation of gellan [38]. The rice starch granules in the paste act as filler that reinforces the gellan gum gel structure and also produce strong bonds to given higher modulus. So, both the swollen particles and gellan compact networks contribute to the elastic character of the mixtures enhancing the storage modulus. This effect will be beneficial for the rice starch to use as an alternative to make gluten-free breads [2].

It can be further found that the values of G’ and G” are largely increased by the addition of HA compared with the LA. Conversely, the HA additions reduce the value of tanδ as shown in Table 2. The value of tanδ is a dimensionless parameter that gives a direct measure of whether the material behaves as solid-like or liquid-like [23]. So the rice starch pastes with high-acyl gellan gum displayed higher elasticity than the pastes with low-acyl gellan gum. The result is consistent with that concluded from the paste observations. The overall dynamic viscoelastic properties of starch pastes would be determined not only by the density of cross-links in the continuous phase but also by the rigidity, entanglements between the amylose and amylopectin, and effective contacts between the dispersed phase [39]. It is suggested that the junction zones of starch gel can be strengthened by the interaction of HA gum in the continuous phase to form a stronger cross-linking network more effectively than LA. It was pointed out that acyl groups in gellan gum molecules lower the charge density of the molecular bundles, which would promote associations with other components or the stabilization of their double helix structures especially via glycerate groups [40]. So, the existence of acyl branched chain seems to strengthen the intermolecular association between soluble amylose and low molecular weight amylopectin, contributing to the elastic properties of RS paste synergistically.

In-Shear Structural Recovery

The in-shear structural recovery test is always employed to elucidate the capability of the mixed pastes to recover their original structure under low-shear conditions after decomposition under high-shear conditions. For the purpose of elucidation, the viscosity profiles versus time during the three-step function tests of the RS-LA, RS-HA mixed pastes and the RS alone are shown in Fig. 3. The recovery rate of each paste is also determined and shown in Table 2. The recovery of the all paste (heated in a RVA in this study) is less than 1, indicating the initial structure of the rice starch paste is damaged during the high-shear condition at the high shear rate stage, and the new structure formed is less resistant to the shear field. It is known that the in-shear structural recovery profiles for starch pastes are quite different when different pasting conditions were applied. Similar recovery values are reported for the starch pastes heated with similar program in a RVA [41] or a rheometer [16].

It can be seen that the addition of HA gellan gum could obviously affect the in-shear structural recovery of the rice starch paste, while LA gellan gum seems exhibit no or adverse effects on the recoveries with the concentration used. It means that the addition of HA gellan gum makes the paste more easily recover to its original structure than the LA gellan gum. It is pointed out that the starch pastes obtained by a rheometer was not very sufficient, and still contain many starch granule ghosts and fragments which determined their in-shear structural recovery properties, just like the one heated in the RVA in this study [41]. When under the high-rate shear conditions, the swollen gelatinized granules in the paste might be sheared into smaller fragments, thus the resistance to shear decreased as observed after the high-shear step. It is supposed that the addition of HA gellan gum could reduce the breakage of starch ghosts under high-shear conditions; furthermore, the rigid double helix structures of HA gellan gum molecule via glycerate groups could promote association of the gelatinized rice starch granules efficiently [42]. So under such conditions, the HA gellan gum stabilized the structures of the mixed pastes and consequently increased the in-shear structural recoveries. In contrast, LA gellan gum with fewer side chains and more linear structures may only interact with leached amylose and form a less strength gel network, which exhibited no or less effect on the recovery of paste.

Creep-Recovery

The creep-recovery curves of the RS pastes with different types of gellan gums are shown in Fig. 4. The results showed that all creep recovery curves of starch samples exhibited viscoelastic behaviour with both viscous fluid and elastic components. The variation in rice starch compliances in creep and creep-recovery tests described here is similar to that reported for rice flour based gluten-free formulations [9, 43]. The creep and recovery properties of a viscoelastic system are linked to the reorientation of bonds and alignment of microstructures [37]. It can be found that the strains subjected to a constant stress of rice starch significantly decrease with the HA gellan gum addition, but decrease slightly by the addition of LA gellan gum in the creeping stage. It means that the RS gel with HA gellan gum addition exhibits higher resistance to the stress and produces a stronger microstructure network.

The parameters of Burger’s model obtained by fitting the experimental data to the Eq. (1) are listed in Table 3. The results show that the model can fit the creep phase data well (R2 > 0.99). The RS sample presents the highest value of instantaneous compliance. Also, the smallest value of the zero shear stress viscosity μ0 is obtained for RS sample. It means that both of the additions give an improvement in the elasticity of the starch samples. The effect is connected with the capability of hydrocolloids additions to form gel networks with starch molecules, which can promote water retention of the gels [5, 8]. By comparing with the control sample, the RS-LA gellan gum gel gives lower J0c and J1c values, while RS-HA samples show small variations. On the other hand, the creep and recovery properties of a solid-like viscoelastic material are associated with the reorientation of bonds in the system [44]. The results show that with the HA gellan gums addition the RS gel can deform to a certain extent with the shortest time λ1c. It is suggested that more internal flexibility of LA gellan gum molecules and weaker interactions with starch make the gel more susceptible to stress and slower to recover. Again, the HA gellan gum molecules with a higher three-dimensional structure and more hydrogen-bond acceptors, lead to a higher molecular order in form and stronger intermolecular hydrogen bonds with both amylose and amylopectin, and consequently result in greater rigidity of gel.

Morphological Characteristics

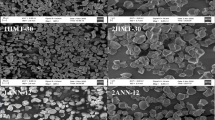

The surface morphology of rich starch gel without or with gellan gums after lyophilization observed by SEM are shown in Fig. 5. The results show that the structure of lyophilized rice starch gel is porosity like xerogels [45]. It can be seen that the addition of gellan gums changed the microstructures of starch gels. In the RS-LA mixed paste, more cracks were observed at the surface. It seems that the RS-LA gel forms a more sheet-like structure while the RS-HA gel gives a more three-dimensional structure. It is known that the gel which is formed by low acyl gellan gum is generally hard and fragile, while that by the high acyl gellan gum is soft and elastic, and has a good adhesive ability. The RS-HA mixed paste with fewer cracks may be caused by its soft and elastic properties and water binding capacity, preventing water from evaporating during lyophilization. It is again supposed that the addition of HA prevented the rearrangement and aggregation of solubilized amylose molecules and interact or entangle with the starch granules.

Surface morphology of rich starch gel with or without gellan gums: (A1) rice starch, 200×; (A2) rice starch, 3000×; (B1) rice starch with low acyl gellan gum, 200×; (B2) rice starch with low acyl gellan gum, 3000×; (C1) rice starch with high acyl gellan gum, 200×; (C2) rice starch with high acyl gellan gum, 3000 ×

Water Releasing Properties

The gel shrinkage and the release of water after 5 days’ cold storage are shown in Fig. 6. It can be seen that the rice starch gel give the most fragile structure and shrinkage after cold storage in a period. As shown in the figure, the gel without hydrocolloids addition was partially broken. The addition of HA dramatically reduces the gel shrinkage and releasing of water, and consequently results in an increase in gel strength and retard of the retrogradation of starch with storage time. The addition of hydrocolloids in the reduction of retrogradation may due to many synergistic mechanisms such as hydrophilic effect to fix the water molecules, interactions between gums and starch, and steric effect imposed on the bulky hydrophilic groups which prevent alignment of starch chains [46]. However, there are still many contradictory aspects in the synergistic effects between starch and gums. Shi and BeMiller [17] suggested that the synergistic effect was due to interactions between certain leached molecules, primarily amyloses and partially amylopectin with certain gums. In contrast, it was also assumed that it was likely to be due to the different polymers phase separation, rather than due to intermolecular associations [47]. In this study, it is possible that the retarding of hydrocolloids-starch gel retrogradation might have occurred by different polymers phase separation in-system and also the interaction between hydrocolloids and amylose molecules. Overall, these results suggest that the addition of HA gellan gum can inhibit the retrogradation of amylose and amylopectin of rice starch.

Conclusions

The additions of both gellan gums increase the peak and trough viscosities, while decrease the final and setback viscosities of rice starch paste. The addition of high acyl gellan gum significantly increased the values of storage modulus (G’) and decreased the tanδ value as compared to the low acyl gellan gum sample. The in-shear structural recovery test showed that the addition of HA gellan gum could obviously affect the in-shear structural recovery of the rice starch paste, while LA gellan gum seems had no or adverse effects. The creep recovery patterns indicated that the rice starch gel with HA gellan gum exhibited higher resistance to the stress and produce a stronger network. The experimental creep phase data are well fitted by a 4-element Burger’s model. The gel shrinkage results show that the additions of gellan gums especially the HA sample retard the retrogradation of the rice starch gel during cold storage. Overall, these results suggest that HA shows a greater impact on pasting, rheological properties and retrogradation of rice starch comparing with LA. The HA gellan gum with a higher steric hindrance structure and more hydrogen-bond acceptors, which lead to a higher molecular order in form and stronger intermolecular hydrogen bonds with both amylose and amylopectin, and consequently result in a greater rigidity and more stable gel structure.

References

S.A. Mir, M.A. Shah, H.R. Naik, I.A. Zargar, Trends Food Sci. Technol. 51, 49 (2016)

S. Heo, S.M. Lee, J.H. Shim, S.H. Yoo, S. Lee, J. Food Eng. 116, 213 (2013)

W. Katekhong, S. Charoenrein, Carbohydr. Polym. 89, 777 (2012)

S. Wang, C. Li, L. Copeland, Q. Niu, S. Wang, Compr. Rev. Food Sci. F. 14, 568 (2015)

I.A.M. Appelqvist, M.R.M. Debet, Food Rev. Intl. 13, 163 (1997)

Z. Fu, J.N. Bemiller, Food Hydrocoll. 69, 36 (2017)

T. Chen, S. Fang, X. Zuo, Y. Liu, J. Food Sci. Technol. 53, 1 (2016)

T.S. Hahm, C.Y. Kuei, J. Food Process. Preserv. 39, 3198 (2014)

H.P. Sivaramakrishnan, B. Senge, P.K. Chattopadhyay, J. Food Eng. 62, 37 (2004)

J. Sun, X.B. Zuo, S. Fang, H.N. Xu, J. Chen, Y.C. Meng, T. Chen, J. Texture Stud. 48, 241 (2017)

L. Chen, Q. Tong, F. Ren, G. Zhu, Int. J. Biol. Macromol. 66, 325 (2014)

M.J. Correa, C. Ferrero, C. Puppo, C. Brites, Food Hydrocoll. 31, 383 (2013)

R. Banchathanakij, M. Suphantharika, Food Chem. 114, 5 (2009)

T. Sasaki, K. Kohyama, Food Chem. 127, 541 (2011)

S. Qiu, M.P. Yadav, Y. Liu, H. Chen, E. Tatsumi, L. Yin, Food Hydrocoll. 53, 180 (2016)

P. Achayuthakan, M. Suphantharika, Carbohydr. Polym. 71, 9 (2008)

X. Shi, J.N. Bemiller, Carbohydr. Polym. 50, 7 (2002)

S.J. Luo, R.Y. Chen, L. Huang, R.H. Liang, C.M. Liu, J. Chen, Food Hydrocoll. 63, 580 (2017)

E.R. Morris, K. Nishinari, M. Rinaudo, Food Hydrocoll. 28, 373 (2012)

I. Giavasis, L.M. Harvey, B. Mcneil, Crit. Rev. Biotechnol. 20, 177 (2000)

E. Floreshuicochea, A.I. Rodríguezhernández, T. Espinosasolares, A. Tecante, Food Hydrocoll. 31, 299 (2013)

M. Sherafati, A. Kalbasi-Ashtari, S.M.A. Mousavi, J. Food Process Eng. 36, 418 (2013)

Y.C. Meng, M.H. Sun, S. Fang, J. Chen, Y.H. Li, Food Hydrocoll. 40, 64 (2014)

F. Ronda, M. Villanueva, C. Collar, LWT Food Sci. Technol. 59, 12 (2014)

D. Chandanasree, K. Gul, C.S. Riar, Food Hydrocoll. 52, 175 (2016)

M. Huang, J.F. Kennedy, B. Li, X. Xu, B.J. Xie, Carbohydr. Polym. 69, 411 (2007)

C.M. Rosell, W. Yokoyama, C. Shoemaker, Carbohydr. Polym. 84, 373 (2011)

J.N. Bemiller, Carbohydr. Polym. 86, 386 (2011)

A.A. Wani, P. Singh, M.A. Shah, U. Schweiggert-Weisz, K. Gul, I.A. Wani, Compr. Rev. Food Sci. F. 11, 417 (2012)

T.D. Leite, J.F. Nicoleti, A.L.B. Penna, C.M.L. Franco, Cienc. Tecnol. Aliment. 32, 579 (2012)

A. Gunaratne, S. Ranaweera, H. Corke, Carbohydr. Polym. 70, 112 (2007)

M.D. Torres, A. Raymundo, I. Sousa, Carbohydr. Polym. 98, 249 (2013)

S. Lee, B. Yoo, Int. J. Food Eng. 10, 205 (2014)

Y. Yuguchi, H. Urakawa, K. Kajiwara, Macromol. Symp. 120, 77 (1997)

A.H. Clark, Structural and mechanical properties of biopolymer gels (Springer, Berlin/Heidelberg, 1987), pp. 322–338

C. Kim, B. Yoo, J. Food Eng. 75, 120 (2006)

W. Samutsri, M. Suphantharika, Carbohydr. Polym. 87, 1559 (2012)

V.M. Oliveira Cardoso, F.C.B. Stringhetti, R.C. Evangelista, M.P. Daflon Gremião, J. Mech. Behav. Biomed. 65, 317 (2016)

C.G. Biliaderis, J.R. Tonogai, J. Agric. Food Chem. 39, 833 (1991)

S. Noda, T. Funami, M. Nakauma, I. Asai, R. Takahashi, S. Al-Assaf, S. Ikeda, K. Nishinari, G.O. Phillips, Food Hydrocoll. 22, 1148 (2008)

Y. Wang, L.J. Wang, D. Li, N. Özkan, X.D. Chen, Z.H. Mao, J. Food Eng. 89, 87 (2008)

N.A. Abdulmola, H. Mwn, R.K. Richardson, E.R. Morris, Carbohydr. Polym. 31, 65 (1996)

C.M. Mancebo, M.Á.S. Miguel, M.M. Martínez, M. Gómez, J. Cereal Sci. 61, 8 (2015)

L. Juszczak, T. Witczak, R. Ziobro, J. Korus, E. Cieślik, M. Witczak, Carbohydr. Polym. 90, 353 (2012)

L. Bao, X. Zhu, H. Dai, Y. Tao, X. Zhou, W. Liu, Y. Kong, Int. J. Biol. Macromol. 89, 389 (2016)

M. Janya, C. Sanguansri, Food Hydrocoll. 22, 1268 (2008)

M. Alloncle, J. Lefebvre, G. Llamas, J.L. Doublier, Cereal Chem. 66, 90 (1989)

Acknowledgments

The authors acknowledge supports from the National Natural Science Foundation of the People’s Republic of China (project-no: 31401570) and the Zhejiang Provincial Collaborative Innovation Center of Food Safety and Nutrition (project-no: 2017SICR116).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, S., Wang, J., Xu, X. et al. Influence of Low Acyl and High Acyl Gellan Gums on Pasting and Rheological Properties of Rice Starch Gel. Food Biophysics 13, 116–123 (2018). https://doi.org/10.1007/s11483-018-9517-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-018-9517-8