Abstract

The effects of microbial polysaccharides xanthan and curdlan on the pasting, viscoelastic properties and retrogradation of rice starch were studied. The additions of xanthan and curdlan increased the peak viscosities and decreased the final viscosities. The breakdown viscosities were increased by the curdlan addition, but were decreased by the xanthan addition. The dynamic viscoelastic results showed that the addition of xanthan in rice starch significantly increased storage modulus and loss modulus. The rice starch gel with xanthan addition exhibited higher resistances to the stress and produced a stronger microstructure network. The creep recovery data were well fitted by a 4-element Burger’s model. Differential scanning calorimetry showed that the addition of curdlan and xanthan decreased the melting enthalpy values and retarded the retrogradation of the rice starch gel during storage at 4 °C for 12 days. The pasting and thermal results demonstrated that the addition of xanthan could significantly inhibited the retrogradation of rice starch. It was concluded that the addition of curdlan and xanthan modified the rheology of rice starch gel in different ways and interacted under different models based on their molecular structures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rice is one of the major cereal crops consumed in China and other Asian countries (Techawipharat et al. 2008). There are many rice products on the market, such as puffed grain, noodles, rice cakes, baby foods and snack foods. Recent publications (Banchathanakij and Suphantharika 2009; Lee and Yoo 2014; Singh et al. 2016) have shown that rice flour or starch can be used as a good alternative to make gluten-free products, due to its good flavor, high nutrient levels and hypoallergenicity of its proteins. However, the use of rice flour or starch as a wheat substitute exhibits some drawbacks, such as the weak ability to form viscoelastic dough (Witczak et al. 2016). Additionally, during storage of rice starch-based foods, the retrogradation of starch leads to an increase of hardness and roughness in texture, and undesirable gels especially after freezing and thawing (Banchathanakij and Suphantharika 2009; Witczak et al. 2016).

The addition of various polysaccharide hydrocolloids (gums) to starch-based foods offers a good way to overcome these shortcomings, and guarantee constant product quality (Correa et al. 2013; Itthivadhanapong et al. 2016; Kaur et al. 2015). A few studies indicated that the addition of hydrocolloids such as xanthan (Heyman et al. 2014; Kaur et al. 2015) and guar gums (Ptaszek and Ptaszek 2011; Von Borries-Medrano et al. 2016) to raw starch gave synergistic effects and significantly improved the quality of products during processing and storage. It is hypothesized that the synergistic effects on starch-hydrocolloids combination may due to many models, such as phase separation, granule gelatinization and starch-gum intermolecular associations (Appelqvist and Debet 1997; Shi and BeMiller 2002). The understanding of pasting and rheological properties on starch-hydrocolloids combinations, and possible interactions between them are important to develop new products and improve the textural quality of rice starch-based products (Witczak et al. 2016). Samutsri and Suphantharika (2012) systematically studied the effects of guar gum and xanthan with salts on the pasting and rheological properties of rice starch. The effects of locust bean gum on five varieties of rice starch with different amylose contents focusing on the rheological properties have also been investigated (Correa et al. 2013). In recent studies, Chen et al. (2014, 2015) systematically investigated the effects of pullulan as a neutral polysaccharide on the chemical and physical properties of rice flour and its possible interaction models. However, when compared to other starch, there are still less efforts that devote to study the influence of various hydrocolloids on rice starch or flour (Appelqvist and Debet 1997; Banchathanakij and Suphantharika 2009; Yoo et al. 2005).

Xanthan gum with excellent emulsifying, thickening and stabilizing capacity is widely used microbial anionic polysaccharide in the food industry (Kaur et al. 2015; Lo et al. 2009). Because of its high molecular weight with abundant intermolecular associations, xanthan gum can improve the rheological and textural properties of starch such as shear-thinning and ability to form weak-gel network (Kim and Yoo 2006; Viturawong et al. 2008). On the other hand, curdlan gum is also a microbial polysaccharide but with different molecular structure as homopolymer of glucose with β-1,3-glucosidic linkage (Lo et al. 2009). Curdlan gel is stable against freezing and thawing which is different from gels made from other gelling agents, such as carrageenan and konjac gums (Hahm and Kuei 2015; Zhang and Edgar 2014). Many studies have applied xanthan and curdlan alone or in combination to improve rheological, textural properties and retard retrogradation in various starch (Banchathanakij and Suphantharika 2009; Shiroodi et al. 2015). Previous studies showed that a hydrogel complex formed by xanthan and curdlan gums significantly reduced water loss (syneresis) over repeated freeze–thaw cycles and retained rheological properties (Williams et al. 2009, 2011). Recently, the xanthan-curdlan hydrogel complex were found to have positive affects on the freeze–thaw stability and rheological properties of whey protein isolate gel (Shiroodi and Lo 2015) and cooked rice (Hahm and Kuei 2015). However, despite excellent properties given by xanthan and curdlan in combination or alone, there are no studies to compare the influence of two microbial polysaccharides on the pasting and rheological behavior of rice starch and possible interactions between them.

Accordingly, the present study was carried out to examine the influence of curdlan and xanthan on the pasting, viscoelastic and thermal properties of rice starch. The possible interactions between rice starch and curdlan or xanthan were explored based on these physicochemical characterizations. A better understanding of effects and interactions of these microbial polysaccharides on rice starch will be beneficial for the utilization of them to improve textural quality and storage stability of rice starch-based foods.

Materials and methods

Materials

Rice starch was obtained from Jinnong Corporation (Jiangxi, China). White powder curdlan was provided by Zhongke Biological Technology Corporation (Shandong, China). Xanthan gum was provided by Aladdin reagent company (Shanghai, China). Ultrapure water (18.2 MΩ-cm resistivity) was used throughout the work to prepare the suspension samples.

The composition of rice starch was determined by using the method of standard (Meng et al. 2014). It contains approximately 90.5 ± 1.4% total starch, 24.7 ± 0.3% of amylose, 0.90 ± 0.06% protein and 7.70 ± 0.03% moisture. The size distribution of rice starch is determined by a dynamic light scattering (DLS) instrument (Mastersizer 2000, Malvern Instruments Ltd., Worcestershire, UK). The DLS results show that the starch particles from rice starch used in this study have volume-based mean diameter D[4,3] of 5.73 ± 0.01 μm.

Pasting properties

The pasting characteristic of rice starch (RS), rice starch with curdlan (RS/curdlan) and rice starch with xanthan (RS/xanthan) mixtures were determined by a rapid visco analyzer (model RVA-4, Newport Scientific Pty. Ltd, Warriewood, Australia) with the method described previously (Meng et al. 2014). Dispersions of curdlan and xanthan in ultrapure water (0.1% in mass fraction) were prepared respectively and stirred at 80 °C for 1 h. RS/curdlan and RS/xanthan suspensions were prepared by adding 3 g rice starch to 25 g curdlan and xanthan dispersions in an aluminum RVA canister, respectively. In RVA measurement, the suspensions were first equilibrated at 50 °C for 1 min, then increased to 95 °C within 225 s and kept at 90 °C for 180 s. The measured sample was decreased to 50 °C at a constant rate, and maintained at 50 °C for 90 s. The rotation speed of the plastic paddle was kept at a constant value of 160 rpm during measurement. Parameters including peak viscosity (PV), trough viscosity (TV), final viscosity (TV), setback viscosity (SV), breakdown viscosity (SV) and pasting temperature (PT) were obtained from the RVA curves. All the pasting parameters are presented as mean ± standard deviation of triplicate determinations.

Viscoelastic properties

Starch paste was prepared following the same method as described above by the RVA instrument. Samples were cooled to the room temperature and quickly transferred to the rheometer plate. A controlled-stress rheometer (model AR-G2, TA Instruments, New Castle, USA) with a 40-mm parallel plate was used for the rheological measurements. Air bubbles trapped in the paste were removed by centrifugation. Samples were placed on the rheometer plate and excess paste is removed carefully. Silicon oil was used to prevent the evaporation of sample moisture during measurements.

Dynamic viscoelastic measurements

Frequency sweep tests were carried out over the range of 0.1–10 Hz at a constant 1% strain (within the linear viscoelastic region) at 25 °C with a 40 mm parallel plate. The gap was set at 1 mm. The dynamic rheological parameters, storage modulus (G′), loss modulus (G″) and loss tangent (tanδ) as a function of angular frequency were obtained from TA rheometer Data Analysis software (version 5.7.1). The data were presented as mean ± standard deviation of three experimental results.

Creep-recovery measurements

In creep-recovery tests, the fresh prepared gel was placed on the rheometer plate, and equilibrated for 5 min to allow residual stress to relax and make temperature constant at 25 °C. The creep-recovery test program was carried out by applying a constant stress (30 Pa) on the sample for 120 s and recovering the strain for 180 s after the stress removed. The sample’s deformation or strain was recorded as a function of time. Each test was performed in triplicate.

The data from creep tests are modeled to a 4-element Burgers model with a mechanical analog composed of springs and dashpots (Ronda et al. 2014). This model is given by equation as:

where J c(t) is the creep compliance (strain of gels divided by the stress), t is the time (s) after loading, J 0c is the instantaneous compliance, J 1c is the viscoelastic compliance or retarded elastic compliances, λ 1c is the retardation time in the Kelvin body and μ 0 represents the coefficient of viscosity associated with viscosity flow.

Thermal properties

Gelatinization temperatures and enthalpy values of rice starch in the absence or presence of curdlan and xanthan were measured by using a differential scanning calorimeter (Tian-Calvet Setaram C80, Setaram, France). For the preparation of samples, 5 g rice starch and 15 g aqueous solution of curdlan or xanthan gums (0.15% in mass) were mixed and stirred for 2 h. About 4 g of above well-stirred suspensions were exactly weighed into an aluminum crucible and immediately hermetically sealed to prevent moisture loss. The sealed samples were equilibrated for 24 h at room temperature. Scans were performed from 30 to 100 °C at a controlled constant rate of 0.5 °C/min. The instrument was calibrated by using an indium and an empty pan was used as reference. Parameters including the onset temperature (T o), peak temperature (T p), conclusion temperature (T c), and gelatinization enthalpy (∆H) were obtained based on the DSC heating curves in the first-run. The ∆H expressed in terms of J/g of dry starch was evaluated based on the area of the main endothermic peak.

After the first-run heating, the gelatinized samples were cooled down and kept at 4 °C for 12 days. The stored gels were determined by differential scanning calorimeter (DSC) again to study the retrogradation of rice starch. The retrogradation ratio was obtained by dividing the retrogradation enthalpy in the second-run test by the gelatinization enthalpy in the first-run heating (Banchathanakij and Suphantharika 2009).

Statistical analysis

Experimental data were subjected to an analysis of variance for a completely random design using SPSS package (16.0, SPSS Inc., USA) for windows program. Duncan’s multiple range tests were applied to determine the difference among means at a statistical significance P < 0.05.

Results and discussion

Pasting properties

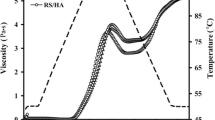

The pasting curves of RS, RS/curdlan and RS/xanthan are shown in Fig. 1. Compared with RS alone, the addition of xanthan and curdlan increased the peak viscosities, whereas decreased the final viscosities. On the other hand, the breakdown viscosities were increased by the curdlan addition, but were decreased by the xanthan addition. The peak times (time to reach the peak viscosity) were almost unaffected by addition of curdlan, but increased by the addition of xanthan gum.

The parameters from rapid visco analyzer (RVA) curves with statistical analyses are shown in Table 1. It is pointed out that the rice starch paste can be seen as a biphasic system comprised with a continuous phase that were mostly leached amylose and low molecular weight amylopectin in aqueous solution, and a dispersed phase of swollen amylopection granules. The RVA properties of starch paste were mostly affected by the dispersed hydrocolloids in the continuous phase (Heyman et al. 2014). During the pasting process, the swelled starch granules made the volume of the continuous phase that reduced accessibility to hydrocolloids reduced, which resulted in increase of viscosity of the phase (Samutsri and Suphantharika 2012; Yoo et al. 2005).

Compared with RS/curdlan, the RS/xanthan paste gave higher PV. It was most likely that when the viscosity of continuous phase increased by these polysaccharides additions, the shear forces acting on the swollen granules become larger than those in water system only (Lee and Yoo 2014). This resulted in an increase of the disintegration of swollen starch granules and consequently released more starch, primarily amylose during continuous shearing. It was known that the more disintegration of starch granules generally resulted in lower trough viscosities and higher breakdown viscosities (Appelqvist and Debet 1997), as can be found in the RS/curdlan mixtures. But, a decrease of breakdown viscosity was found in the RS/xanthan paste which was caused by the dramatic increase of TV viscosity. We suppose that the great release of solubilized starch and high levels of granules swelling, that due to the cohesive gel network and interactions between swollen amylopectin granules and anionic xanthan molecules, led to an increase in TV viscosity of the RS/xanthan paste.

The additions of curdlan and xanthan both decreased the final and setback viscosity compared to the RS sample alone. In the cooling process, amylose began retrogradation with the decreasing temperature and the hydrogen bonds between the chains of the molecules formed again, which resulted in a significant increase in the viscosity. It was pointed out that the amylose content, rapidly aggregation and formation of amylose junction zones of solubilized starch molecules were responsible for the final and setback viscosity during the cooling of starch paste (Chen et al. 2014; Witczak et al. 2016). A lower setback viscosity always means a higher resistance to retrogradation. Similar findings were previously reported that hydrocolloids addition could retard the retrogradation of amylose (Chen et al. 2015). However, the results showed that a sharp lowering of the setback viscosity of rice starch in the presence of xanthan. This effect again contributed to not only the cohesive gel network which prevented the moisture migration, but also the intermolecular associations between xanthan and solubilized starches. Shi and BeMiller (2002) studied the pasting curves of many starches in dilute hydrocolloid solutions and concluded that xanthan interacted with all starches examined and with probably intermolecular interactions.

Although both xanthan and curdlan are derived from bacteria, these polysaccharides have quite different molecular sizes, side chain structures and net charges. The backbone of xanthan consists of two repeating (1 → 4)-β-d-glucose units, while curdlan consists repeating (1 → 3)-β-glucose units (Lo et al. 2009; Zhang and Edgar 2014). The leached starches mainly amylose in the continuous phase are biopolymers consisting of (1 → 4)-α-d-glucose units. It is assumed that, although little differences in glucose conformation, the same 1 → 4 linkage of glucose subunits between xanthan and amylose may increase their structure accommodation or compatibility. On the other hand, the hydrophilic α-d-mannose, β-d-glucuronic acid, and β-d-mannose trisaccharide side branches on C3 of every other glucose subunits in the xanthan gum molecules give more molecular interaction sites (Lo et al. 2009). So, a more cohesive gel network can be formed in the RS/xanthan paste through the hydrogen bonds network, electrophoretic interactions and three-dimensional structure linkages (Witczak et al. 2016).

Viscoelastic properties

Dynamic viscoelastic properties

Small deformation oscillatory measurements were applied to characterize the dynamic rheology and elucidate structural insights of these viscoelastic materials. The storage modulus (G′) and loss modulus (G″) parameters which represent the elastic properties of energy storage and the viscous properties of energy dissipation respectively, can be obtained. The frequency sweep oscillatory curves of RS, RS/curdlan and RS/xanthan gels are shown in Fig. 2. It can be seen that the G′ and G″ over the whole frequency range are increased by the increase in angular frequency. Both the additions of hydrocolloids increase the values of G′ and G″ as compared to the RS sample. These results indicate that rice starch with and without xanthan and curdlan can be classified rheologically as a typical weak gel (Singh et al. 2007).

The values of G′, G″ and dynamic mechanical loss tangent (tanδ) at an oscillatory frequency of 10 Hz for each rice starch gel are also shown in Table 1. As can be seen from the figure and table, the addition of xanthan significantly increases the values of G′ and G″, and decreases the tanδ as compared to the RS sample. It indicates that the RS/xanthan gel has a much stronger gel network structure than RS and rice RS/curdlan gels. This is consistent with that concluded from the pasting results discussed above.

Samutsri and Suphantharika (2012) compared the effluence of guar and xanthan gums on the properties of rice starch, and also found the addition of xanthan gum gave the highest G′ and the lowest tanδ values. This may again be attributed to the synergistic effects between ionic xanthan gum and rice starch molecules in the construction of crosslinked hydrogel network (Samutsri and Suphantharika 2012). It is known that starch gels are defined as composites consisting of swollen granules filling interpenetrating polymer networks, and the major network polymer is amylose (Appelqvist and Debet 1997; Singh et al. 2008). Furthermore, a strong interaction between the amylose matrix and other components is required to obtain gels with higher strength (Singh et al. 2008). It is reasonable that more hydrophilic and ionic side branches in the xanthan molecule result in a stiffer, more elastic network, which consequently leading to a stronger network structure of the RS/xanthan gel. On the other hand, both amylose and amylopectin play important roles in the formation of starch gels and affect the dynamic viscoelastic properties of starch gels (Singh et al. 2008). Also, many studies have revealed that xanthan could exhibit significantly effects on physical properties of waxy starches, such as waxy corn starch (Achayuthakan et al. 2006; Lim et al. 2002) and waxy potato starch (Heyman et al. 2014), in which there was no leached amylose in the continuous phase. Heyman et al. (2014) proposed that xanthan addition could affect the physical properties of waxy starch either by restricting the swelling or by stabilizing the amylopectin granules. Taking into account the pasting results discussed above, we therefor expected that xanthan gum interact with not only with amylose matrix to form strong gel network but also with restricted the swelling of amylopectin granules, and made them more rigidity against disintegration. These interactions consequently made the RS/xanthan gel behaved more solid-like as observed. Similar results were found for other starch with ionic carbohydrates such as CMC gum (Appelqvist and Debet 1997).

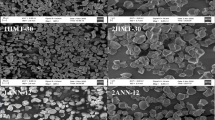

Creep recovery properties

Figure 3 exhibits the creep recovery curves of RS, RS/curdlan and RS/xanthan samples. It can be seen that the creep recovery patterns are consistent with the normal behaviors of viscoelastic materials that combine both elastic and viscous components. Results show that the deformations of gels follow the order: RS > RS/curdlan > RS/xanthan. The values of creep compliance J(t) range from 0.0001 to 0.003 Pa−1 which are closed to values reported for rice flour based gluten free formulations (Mancebo et al. 2015). It is known that the creep and recovery behaviors of a viscoelastic material are linked to the reorientation of bonds and alignment of microstructures (Samutsri and Suphantharika 2012). Figure 3 shows that the strains subjected to a constant stress of RS decrease slightly by the addition of curdlan, but significantly decrease with the xanthan addition in the creeping stage. It suggests that the RS gel with xanthan addition exhibits higher resistances to the stress and produces a stronger microstructure network. The results are in good agreement with the above RVA and viscoelastic tests.

The parameters of Burger’s model, Eq. (1), obtained by fitting the experimental data are summarized in Table 2. The RS sample presents the highest value of instantaneous compliance. Also, the smallest value of the zero-shear stress viscosity μ 0 is obtained for RS sample. Results show that the addition of curdlan and xanthan decreases the values of J 1c which means an improvement in the elasticity of samples. This effect is related to the ability of hydrocolloids to form interconnected networks with starch molecules, which in turn promote water retention of the gels (Appelqvist and Debet 1997; Hahm and Kuei 2015). On the other hand, The RS/xanthan gel gives much lower J 0c values, while RS/curdlan sample shows only slight variations. It is known that the smaller J 0c value reflects greater hardness. The greater rigidity of the gel for RS/xanthan can again attribute to the higher three-dimensional structure and stronger intermolecular interactions (Samutsri and Suphantharika 2012).

Thermal properties

The thermal properties of the RS, RS/curdlan and RS/xanthan and their corresponding retrograded gels under 4 °C for 12 days, determined by DSC are listed in Table 3. For the first run (0 days), the onset gelatinization temperatures (T o) and the gelatinization enthalpies (ΔH) of RS are slightly increased by addition of hydrocolloids at the concentration tested. On the other hand, the gelatinization temperatures in the second run (12 days) shifted to a lower temperature at around 50 °C. It suggests that the process of gelatinization involving loss of helical conformation and destruction of starch crystallite may affected by the addition of hydrocolloids. In general, the addition of hydrocolloids may reduce the available water or delay the water diffusion process during starch granules gelatinization. Other hydrocolloids have also been reported to elevate starch gelatinization parameters, such as acacia gum, k-carrageenan (Kim and Wang 1999) and guar gum (Tester and Sommerville 2003).

The reheating DSC data of the RS, RS/curdlan and RS/xanthan retrograded gels stored at 4 °C for 12 days are also listed in Table 3. It is known that the retrogradation of amylopectin is a reversible process below 100 °C, and the retrogradation of amylose needs more energy to revert the crystal formation (Tian et al. 2009). Within temperature range used in this study (30–100 °C), only amylopectin retrogradation was quantified by the DSC results. Results showed that the endothermic transition temperatures (T o, T p and T c) of retrogradation were lower than the gelatinization temperatures. The values of ΔH of retrograded gels were smaller than the gelatinization enthalpies, especially for gels with hydrocolloids addition. In the absence of curdlan and xanthan gels, the amylopectin retrogradation ratio of gelatinized rice starch significantly increased to about 86% after 12 days. The effect of curdlan and xanthan on preventing the amylopectin retrogradation of rice starch could be clearly seen when it was added to rice starch. The rate-limiting step in starch retrogradation process under 4 °C is nucleation, which requires mobility of the polymer chains in the amylopectin molecules. Therefore, the addition of these microbial polysaccharides xanthan and curdlan decreased the mobility of the starch chains and in turn retarded the retrogradation of the rice starch gel during storage. On the other hand, the addition of xanthan exhibited a slightly larger effect on the retardation of amylopectin retrogradation than curdlan at the same concentration tested. In RVA analysis, the addition of xanthan significantly decreased the setback value of rice starch, which was related to the retrogradation tendency of amylose. These results suggest that the addition of xanthan can significantly inhibit the retrogradation of amylose and amylopectin of rice starch.

Conclusion

The presence of curdlan and xanthan strongly affected the pasting, viscoelastic and thermal properties of rice starch. RVA results showed that the addition of xanthan and curdlan increased the peak viscosities, while decreased the final and setback viscosities of rice starch. Compared with rice starch alone, the addition of xanthan significantly decreased the breakdown viscosities. The rice starch/xanthan gel with larger storage modulus (G′) and loss modulus (G″) values has a stronger gel network structure than rice starch and rice starch/curdlan gels. The creep recovery patterns are consistent with behaviors of viscoelastic materials. The rice starch gel with xanthan addition exhibited higher resistances to the stress. The experimental creep data were well fitted by a 4-element Burger’s model. Thermal results showed that the additions of curdlan and xanthan retarded the retrogradation of the rice starch gel during storage. The pasting and thermal results suggest that the addition of xanthan can significantly retarded the retrogradation of amylose and amylopectin of rice starch. These results have important implications for using these microbial polysaccharides in the formulation of the rice starch-based products with improved rheological properties and storage stability.

References

Achayuthakan P, Suphantharika M, Rao MA (2006) Yield stress components of waxy corn starch–xanthan mixtures: effect of xanthan concentration and different starches. Carbohydr Polym 65:469–478. doi:10.1016/j.carbpol.2006.02.007

Appelqvist IAM, Debet MRM (1997) Starch-biopolymer interactions—a review. Food Rev Int 13:163–224. doi:10.1080/87559129709541105

Banchathanakij R, Suphantharika M (2009) Effect of different β-glucans on the gelatinisation and retrogradation of rice starch. Food Chem 114:5–14. doi:10.1016/j.foodchem.2008.09.016

Chen L, Tong Q, Ren F, Zhu G (2014) Pasting and rheological properties of rice starch as affected by pullulan. Int J Biol Macromol 66:325–331. doi:10.1016/j.ijbiomac.2014.02.052

Chen L, Ren F, Zhang Z, Tong Q, Rashed MMA (2015) Effect of pullulan on the short-term and long-term retrogradation of rice starch. Carbohydr Polym 115:415–421. doi:10.1016/j.carbpol.2014.09.006

Correa MJ, Ferrero C, Puppo C, Brites C (2013) Rheological properties of rice-locust bean gum gels from different rice varieties. Food Hydrocoll 31:383–391. doi:10.1016/j.foodhyd.2012.11.022

Hahm TS, Kuei CY (2015) Effect of curdlan and xanthan on the texture and moisture retention of cooked rice. J Food Process Preserv 39:3198–3206. doi:10.1111/jfpp.12386

Heyman B, De Vos WH, Depypere F, Van der Meeren P, Dewettinck K (2014) Guar and xanthan gum differentially affect shear induced breakdown of native waxy maize starch. Food Hydrocoll 35:546–556. doi:10.1016/j.foodhyd.2013.07.011

Itthivadhanapong P, Jantathai S, Schleining G (2016) Improvement of physical properties of gluten-free steamed cake based on black waxy rice flour using different hydrocolloids. J Food Sci Technol 53:2733–2741. doi:10.1007/s13197-016-2245-5

Kaur A, Shevkani K, Singh N, Sharma P, Kaur S (2015) Effect of guar gum and xanthan gum on pasting and noodle-making properties of potato, corn and mung bean starches. J Food Sci Technol 52:8113–8121. doi:10.1007/s13197-015-1954-5

Kim Y, Wang SS (1999) Starch cooking with limited water as affected by zein and guar gum. J Food Sci 64:133–135. doi:10.1111/j.1365-2621.1999.tb09876.x

Kim C, Yoo B (2006) Rheological properties of rice starch–xanthan gum mixtures. J Food Eng 75:120–128. doi:10.1016/j.jfoodeng.2005.04.002

Lee S, Yoo B (2014) Effect of sucrose addition on rheological and thermal properties of rice starch–gum mixtures. Int J Food Eng 10:849–856. doi:10.1515/ijfe-2014-0072

Lim ST, Han JA, Lim HS, Bemiller JN (2002) Modification of starch by dry heating with ionic gums. Cereal Chem 79:601–606. doi:10.1094/CCHEM.2002.79.5.601

Lo YM, Ziegler RC, Agrin-Soysal S, Hsu CH, Wagner NJ (2009) Effects of intermolecular interactions and molecular orientation on the flux behavior of xanthan gum solution during ultrafiltration. J Food Process Eng 32:623–644. doi:10.1111/j.1745-4530.2007.00235.x

Mancebo CM, Miguel MAS, Martínez MM, Gomez M (2015) Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J Cereal Sci 61:8–15. doi:10.1016/j.jcs.2014.10.005

Meng YC, Sun MH, Fang S, Chen J, Li YH (2014) Effect of sucrose fatty acid esters on pasting, rheological properties and freeze–thaw stability of rice flour. Food Hydrocoll 40:64–70. doi:10.1016/j.foodhyd.2014.02.004

Ptaszek P, Ptaszek A (2011) The time evolution of the viscoelastic retardation in starch pastes with guar gum. J Food Eng 104:14–22. doi:10.1016/j.jfoodeng.2010.11.020

Ronda F, Villanueva M, Collar C (2014) Influence of acidification on dough viscoelasticity of gluten-free rice starch-based dough matrices enriched with exogenous protein. LWT Food Sci Technol 59:12–20. doi:10.1016/j.lwt.2014.05.052

Samutsri W, Suphantharika M (2012) Effect of salts on pasting, thermal, and rheological properties of rice starch in the presence of non-ionic and ionic hydrocolloids. Carbohydr Polym 87:1559–1568. doi:10.1016/j.carbpol.2011.09.055

Shi X, BeMiller JN (2002) Effects of food gums on viscosities of starch suspensions during pasting. Carbohydr Polym 50:7–18. doi:10.1016/S0144-8617(01)00369-1

Shiroodi SG, Lo YM (2015) The effect of pH on the rheology of mixed gels containing whey protein isolate and xanthan–curdlan hydrogel. J Dairy Res 82:506–512. doi:10.1017/S0022029915000370

Shiroodi SG, Rasco BA, Lo YM (2015) Influence of xanthan–curdlan hydrogel complex on freeze–thaw stability and rheological properties of whey protein isolate gel over multiple freeze–thaw cycle. J Food Sci 80:1498–1505. doi:10.1111/1750-3841.12915

Singh N, Nakaura Y, Inouchi N, Nishinari K (2007) Fine structure, thermal and viscoelastic properties of starches separated from indica rice cultivars. Starch Starke 59:10–20. doi:10.1002/star.200600527

Singh N, Nakaura Y, Inouchi N, Nishinari K (2008) Structure and viscoelastic properties of starches separated from different legumes. Starch Starke 60:349–357. doi:10.1002/star.200800689

Singh JP, Kaur A, Singh N (2016) Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol 53:1269–1278. doi:10.1007/s13197-015-2103-x

Techawipharat J, Suphantharika M, BeMiller JN (2008) Effects of cellulose derivatives and carrageenans on the pasting, paste, and gel properties of rice starches. Carbohydr Polym 73:417–426. doi:10.1016/j.carbpol.2007.12.019

Tester RF, Sommerville MD (2003) The effects of non-starch polysaccharides on the extent of gelatinization, swelling and a-amylase hydrolysis of maize and wheat starches. Food Hydrocoll 17:41–54. doi:10.1016/S0268-005X(02)00032-2

Tian Y, Yin L, Manthey FA et al (2009) Influence of β-cyclodextrin on the short-term retrogradation of rice starch. Food Chem 116:54–58. doi:10.1016/j.foodchem.2009.02.003

Viturawong Y, Achayuthakan P, Suphantharika M (2008) Gelatinization and rheological properties of rice starch/xanthan mixtures: effects of molecular weight of xanthan and different salts. Food Chem 111:106–114. doi:10.1016/j.foodchem.2008.03.041

Von Borries-Medrano E, Jaime-Fonseca MR, Aguilar-Méndez MA (2016) Starch-guar gum extrudates: microstructure, physicochemical properties and in vitro digestion. Food Chem 194:891–899. doi:10.1016/j.foodchem.2015.08.085

Williams PD, Sadar LN, Lo YM (2009) Texture stability of hydrogel complex containing curdlan gum over multiple freeze–thaw cycles. J Food Process Pres 33:126–139. doi:10.1111/j.1745-4549.2009.00364.x

Williams PD, Oztop MH, McCarthy MJ, McCarthy KL, Lo YM (2011) Characterization of water distribution in xanthan–curdlan hydrogel complex using magnetic resonance imaging, nuclear magnetic resonance relaxometry, rheology, and scanning electron microscopy. J Food Sci 76:472–478. doi:10.1111/j.1750-3841.2011.02227.x

Witczak M, Ziobro R, Juszczak L, Korus J (2016) Starch and starch derivatives in gluten-free systems—a review. J Cereal Sci 67:46–57. doi:10.1016/j.jcs.2015.07.007

Yoo D, Kim C, Yoo B (2005) Steady and dynamic shear rheology of rice starch–galactomannan mixtures. Starch Starke 57:310–318. doi:10.1002/star.200400390

Zhang R, Edgar KJ (2014) Properties, chemistry, and applications of the bioactive polysaccharide curdlan. Biomacromolecules 15:1079–1096. doi:10.1021/bm500038g

Acknowledgements

This research is supported by the Food Science and Engineering-the most important discipline of Zhejiang province (JYTSP20141092).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, T., Fang, S., Zuo, X. et al. Effect of curdlan and xanthan polysaccharides on the pasting, rheological and thermal properties of rice starch. J Food Sci Technol 53, 4076–4083 (2016). https://doi.org/10.1007/s13197-016-2414-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2414-6