Abstract

Even if up to date, betulonic acid (BA) was not investigated for biological activities as much as other triterpenic derivatives like betulinic acid, and there are several papers describing the synthesis, isolation and investigations—both instrumental and biological—of this compound. In this paper, the kinetic behavior associated with thermal decomposition of BA in oxidative conditions is presented. The kinetic study was realized on the main decomposition process which occurs in the 200–300 °C temperature range, according to the ICTAC 2000 protocol, namely employing three isoconversional methods, one differential (Friedman) and two integral (Kissinger–Akahira–Sunose and Flynn–Wall–Ozawa). In order to separate the multistep contributions to the degradation process of BA, the NPK method was employed. This method suggested that the degradation occurs by two parallel processes, with different energetic contributions, with a mean value of 162.1 ± 5.5 kJ mol−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is well known that plants are a good source of numerous bioactive molecules, which can be separated, purified, functionalized or included in supramolecular structures [1] in order to modify their biodisponibility. The main advantages of naturally occurring compounds consist in their complex structures which are difficult to be obtained by a total chemical synthesis, starting from simple reagents. Betulin and its derivatives were greatly investigated in the last 10 years, with more than 1500 indexations on Web of Knowledge up to date [2].

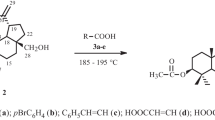

Betulonic acid (BA) [3-oxolup-20(29)-en-28-oic acid] (Fig. 1) is a pentacyclic triterpene derivative belonging to the lupane family, which is currently studied for several biological and pharmacological activities. Even if up to date, BA and derivatives were not investigated as much as other compounds from the triterpenoid class (betulin and betulinic acid), and around 150 scientific articles published data regarding antiviral [3], antimalarial [4], antibacterial [5, 6], anti-inflammatory, genotoxic and mutagenic properties [7] and, in particular, antitumor and antineoplastic properties [8–10].

Literature describes the isolation of BA from several trees and plants [11–14], but as well by several functionalization procedures of other triterpenic derivatives, like betulin or betulinic acid [15–17].

The literature data regarding the solid-state characterization by physicochemical instrumental techniques and kinetic evaluation of betulin-type derivatives is relatively poor. Anghel et al. [18] reported in 2013 the thermal stability and degradation kinetics for betulin and betulinic acid. In this case, NPK method was able to separate the degradation process in two elementary steps, and each contribution was discussed.

Since no reference data were found, according to our knowledge, regarding the thermal decomposition of BA, in this paper we present the results obtained by our group of study in the solid-state evaluation of this compound. The kinetic study was realized according to the ICTAC 2000 protocol on the main decomposition process which occur in the 200–300 °C temperature range, namely employing three isoconversional methods, one differential (Friedman) and two integral (Kissinger–Akahira–Sunose and Flynn–Wall–Ozawa). In order to evaluate whether the solid-state degradation occur in single-process degradation or follows parallel reactions with different energetic contributions, the NPK method was employed.

Materials and methods

Starting material betulin was previously obtained in our laboratory, by Soxhlet extraction from the white outer birch bark (Betula pendula), and the functionalization method for obtaining BA was previously described by our group [16]: Betulin was oxidized with freshly prepared Jones’ reagent (consisting in dissolved CrO3 in a mixture of concentrated H2SO4 and water) in acetone. After purification procedure, BA with purity >96 % was obtained. TG/DTG/HF measurements were performed on a PerkinElmer DIAMOND TG/DTA instrument. The experiments were carried out using about 3–4 mg of sample which was weighted into an open aluminum crucible. The temperature was programmed to increase under non-isothermal conditions from 35 °C up to 550 °C, linearly at heating rates β = 5, 7, 10, 12 and 15 °C min−1. The experiments were completed in oxidative conditions (synthetic air atmosphere) at a flow rate of 100 mL min−1. All the measurements were carried out in triplicate, and the results were comparable.

Results and discussion

Thermal analysis

The thermoanalytical curves of BA obtained during heating at β = 5 °C min−1 in air atmosphere exhibit a multistage decomposition route (Fig. 2). For BA, a good thermal stability was noticed, and the first mass loss begins at a significant high temperature, namely 222 °C with a DTGmax = 273 °C (Δm = 12 %), followed by another process which begins at 286.7 °C and DTGmax at 307.6 °C (Δm = 41 %). The two mass loss steps occurring in the range 200–400 °C are accompanied by a strong exothermic effect, probably associated with intense thermo-oxidations of the triterpenic moiety. The heating of BA at 525 °C determines a total mass loss of 100 %, so no final decomposition product remained for analysis.

On the heat flow curve, the effects are not well separated, although the steps are well separated on DTG curve.

Kinetic study

Pharmaceutical technology deals with numerous physical parameters that are modified during formulation steps, and these parameters can influence the stability of the active pharmaceutical ingredient (API), which is known to be the “key compound” in this field. Before analyzing the stability of final formulation, it is important to evaluate the thermal stability of the API. In previous published papers, the role of thermal analysis and kinetic studies in the class of pharmaceuticals and other potential bioactive compounds was presented [19–26]. Following Arrhenius-type dependencies for reaction rate, the stability and decomposition mechanism can be obtained by the analysis of activation energy (E a), reaction order (n) and pre-exponential factor (A). Up to date, according to International Confederation for Thermal Analysis and Calorimetry (ICTAC), the superiority of model-free kinetic methods versus model-fitting models was proven, so in this study we employed the Friedman’s differential method (FR) along with two integral ones: Flynn–Wall–Ozawa (FWO) and Kissinger–Akahira–Sunose (KAS), respectively. Since a considerable variation of activation energy (E a) versus conversion degree (α) was obtained after applying isoconversional methods, it was assumed that the degradation follows parallel reactions, and NPK method was employed in order to separate each contribution. This method suggested that the degradation occur by two parallel processes, with different energetic contributions. It is to be mentioned that the mean values of activation energies obtained for each isoconversional method are presented solely for comparative analysis with the ones obtained by the employing of the NPK method.

The nonparametric kinetics method (NPK) was firstly proposed and elaborated by Serra et al. [27, 28] and then modified by Vlase et al. [29]. Isoconversional methods present the advantages that it is not necessary to know the explicit equation of the conversion function, and, by the analysis of E a versus conversion degree (α) variation, can suggest whether the mechanism of thermal decomposition is dependent/independent with the modification of temperature. However, the main disadvantage is that a concrete separation for contribution of each step cannot be achieved by the use of these methods.

The mathematical models that describe the selected isoconversional methods of Friedman (FR) [30], Kissinger–Akahira–Sunose (KAS) [31, 32] and Flynn–Wall–Ozawa (FWO) [33, 34] are discussed in numerous papers. We present solely the linearized forms, in Table 1.

For BA, the kinetic analysis was carried out using the DTG experimental data recorded at five heating rates which are presented in Fig. 3. The analyzed process was the solid-state degradation that took place in 200–300 °C temperature range.

The graphical representation of the transformation rate versus temperature for BA corresponding to the five heating rates under non-isothermal conditions is presented in Fig. 4.

Data plotting is presented in Fig. 5. All the linear correlations by using isoconversional methods and the estimation of E a values were realized from the slopes of those lines, for 0.05 ≤ α ≤ 0.95, with a α variation step of 0.05. The obtained results are presented in Table 2, and for each case determination coefficients were higher than 0.969, indicating good linear correlations.

In order to evaluate the nature of the decomposition process(es) and to be able to separate the steps of chemical versus physical transformation, we employed the NPK method.

The nonparametric kinetics (NPK) was developed as an alternative method for processing the thermoanalytical data in order to evaluate the kinetic parameters described by Arrhenius equation. The superiority of the method mainly consists in the fact that no approximation is used, like in the case of isoconversional methods, while it only needs to consider that the reaction rate can be considered as a product of two independent functions, f(α)—a function of the degree of conversion, and k(T)—a temperature dependence. The data processing consists in obtaining a matrix which is decomposed using the singular value decomposition algorithm was elsewhere reported [20, 29, 35].

The nature of physical/chemical contributions to the degradation processes is presented in Table 3, where n and m are reaction orders suggested by the kinetic model of Šesták and Berggren [36]:

The explained variance λ represents the contribution of each process to the mean value of activation energy, so in a case with two parallel processes of degradation \( \bar{E} = \lambda_{1} E_{1} + \lambda_{2} E_{2} \).

The 3D reaction surface obtained by the NPK method is presented in Fig. 6.

According to the NPK method, BA is degraded by two processes. The main degradative process has an explained variance λ = 78.4 % consisting in both chemical transformation (reaction order n = 1) and physical process (m = 1). The second process has a considerable greater value for activation energy, but its contribution to the mean value is smaller (48.0 kJ mol−1), with λ = 20.2 %).

Conclusions

The results obtained by using the kinetic models describing the solid-state degradation of BA are in good agreement. Only the NPK method provided information regarding the decomposition mechanism of BA. The increased thermal stability, which was confirmed by both thermal analysis and kinetic study, can be explained not only by the high stability of the triterpenic moiety, but as well by the presence of the grafted functional groups, like carboxyl and oxo. Due to their presence, the solid-state stability of betulonic acid is increased by intermolecular hydrogen-bonding, which create a superior stability comparative to molecules where these types of interaction are impossible to be formed.

Abbreviations

- α :

-

Conversion degree

- T :

-

Temperature

- f(α):

-

Differential conversion function

- g(α):

-

Integral conversion function

- R :

-

Universal gas constant

- β :

-

Heating rate and β = dT/dt (where t—time)

- k(T):

-

Temperature dependence

- A :

-

Pre-exponential factor

- E a :

-

Activation energy given by the Arrhenius equation

References

Soica C, Danciu C, Savoiu-Balint G, Borcan F, Ambrus R, Zupko I, Bojin F, Coricovac D, Ciurlea S, Avram S, Dehelean CA, Olariu T, Matusz P. Betulinic acid in complex with a gamma-cyclodextrin derivative decreases proliferation and in vivo tumor development of non-metastatic and metastatic B164A5 cells. Int J Mol Sci. 2014;15(5):8235–55.

Boryczka S, Jastrzebska M, Bebenek E, Kusz J, Zubko M, Kadela M, Michalik E. X-ray diffraction and infrared spectroscopy of N, N-dimethylformamide and dimethyl sulfoxide solvatomorphs of betulonic acid. J Pharm Sci. 2012;101(12):4458–71.

Tolstikov GA, Flekhter OB, Shultz EE, Baltina LA, Tolstikov AG. Betulin and its derivatives. Chemistry and biological activity. Chem Sustain Dev. 2005;13:1–29.

Tolstikova TG, Sorokina IV, Tolstikov GA, Tolstikov AG, Flekhter OB. Biological activity and pharmacological prospects of lupane terpenoids: II. Semisynthetic lupane derivatives. Russ J Bioorg Chem. 2006;32:291–307.

Alakurtti S, Makela T, Koskimies S, Yli-Kauhaluoma J. Pharmacological properties of the ubiquitous natural product betulin. Eur J Pharm Sci. 2006;29:1–13.

Frolova TS, Kukina TP, Sinitsyna OI. Genotoxic and mutagenic properties of synthetic betulinic acid and betulonic acid. Russ J Bioorg Chem. 2015;41(4):409–13.

Yang SJ, Liu MC, Zhao Q, Hu DY, Xue W, Yang S. Synthesis and biological evaluation of betulonic acid derivatives as antitumor agents. Eur J Med Chem. 2015;96:58–65.

Kazakovaa OB, Medvedeva NI, Lopatina TV, Apryshko GN, Pugacheva RB, Yavorskaya NP, Golubeva IS, Tolstikov GA. Synthesis and the antineoplastic activity of imidazolides of betulonic acid. Russ J Bioorg Chem. 2015;41(3):305–14.

Saxena BB, Zhu L, Hao MR, Kisilis E, Katdare M, Oktem O, Bomshteyn A, Rathnam P. Boc-lysinated-betulonic acid: a potent, anti-prostate cancer agent. Bioorgan Med Chem. 2006;14(18):6349–58.

Chen BN, Yang GE, Li JK, Du HJ, Li QS, Zhang ZM. Cytotoxic constituents from Viscum coloratum. Chem Nat Compd. 2009;45(4):547–9.

Choi SZ, Yang MC, Choi SU, Lee KR. Cytotoxic terpenes and lignans from the roots of Ainsliaea acerifolia. Arch Pharm Res. 2006;29(3):203–8.

Abyshev AZ, Agaev EM, Guseinov AB. Studies of the chemical composition of birch bark extracts (Cortex betula) from the Betulaceae family. Pharm Chem J. 2007;41:419–23.

Yang GE, Chen B, Zhang Z, Gong J, Bai H, Li J, Wang Y, Li B. Cytotoxic activities of extracts and compounds from Viscum coloratum and its transformation products by Rhodobacter sphaeroides. Appl Biochem Biotechnol. 2009;152:353–65.

Goswami A, Guo Z, Tully TP, Rinaldi FA, Huang XS, Swidorski JJ, Regueiro-Ren A. Microbial transformations of betulinic and betulonic acid. J Mol Catal B Enzym. 2015;117:45–53.

Ledeti I, Bosca CS, Cosma C, Badea V, Todea A, Bercean VN. Study on obtaining 3-oxolup-20(29)-en-28-oic acid (betulonic acid) from (3β)-lup-20(29)-en-3,28-diol (betulin). Rev Chim Buchar. 2014;65(11):1289–93.

Melnikova N, Burlova I, Kiseleva T, Klabukova I, Gulenova M, Kislitsin A, Vasin V, Tanaseichuk B. A practical synthesis of betulonic acid using selective oxidation of betulin on aluminium solid support. Molecules. 2012;17(10):11849–63.

Anghel M, Vlase G, Bilanin M, Vlase T, Albu P, Fulias A, Tolan I, Doca N. Comparative study on the thermal behavior of two similar triterpenes from birch. J Therm Anal Calorim. 2013;113(3):1379–85.

Fulias A, Popoiu C, Vlase G, Vlase T, Onetiu D, Săvoiu G, Simu G, Pătruţescu C, Ilia G, Ledeti I. Thermoanalytical and spectroscopic study on methotrexate—active substance and tablet. Dig J Nanomater Bios. 2014;9(1):93–8.

Ledeti I, Fulias A, Vlase G, Vlase T, Bercean V, Doca N. Thermal behaviour and kinetic study of some triazoles as potential anti-inflammatory agents. J Therm Anal Calorim. 2013;114:1295–305.

Fulias A, Vlase G, Grigorie C, Ledeti I, Albu P, Bilanin M, Vlase T. Thermal behaviour studies of procaine and benzocaine. J Therm Anal Calorim. 2013;113(1):265–71.

Ledeti I, Vlase G, Vlase T, Fulias A. Kinetic analysis of solid-state degradation of pure pravastatin versus pharmaceutical formulation. J Therm Anal Calorim. 2015. doi:10.1007/s10973-015-4842-3.

Karolewicz B, Gajda M, Pluta J, Górniak A. The effect of Pluronic F127 on the physicochemical properties and dissolution profile of lovastatin solid dispersions. J Therm Anal Calorim. 2015. doi:10.1007/s10973-015-4935-z.

Ledeti I, Vlase G, Vlase T, Suta LM, Todea A, Fulias A. Selection of solid-state excipients for simvastatin dosage forms through thermal and nonthermal techniques. J Therm Anal Calorim. 2015. doi:10.1007/s10973-015-4832-5.

Górniak A, Karolewicz B, Żurawska-Płaksej E, Pluta J. Thermal, spectroscopic, and dissolution studies of the simvastatin–acetylsalicylic acid mixtures. J Therm Anal Calorim. 2013;111:2125–32.

Sovizi MR, Hosseini SG. Studies on the thermal behavior and decomposition kinetic of drugs cetirizine and simvastatin. J Therm Anal Calorim. 2013;111:2143–8.

Serra R, Nomen R, Sempere J. The non-parametric kinetics. A new method for the kinetic study of thermoanalytical data. J Therm Anal Calorim. 1998;52:933–43.

Serra R, Sempere J, Nomen R. A new method for the kinetic study of thermoanalytical data: the non-parametric kinetics method. Thermochim Acta. 1998;316:37–45.

Vlase T, Vlase G, Birta N, Doca N. Comparative results of kinetic data obtained with different methods for complex decomposition steps. J Therm Anal Calorim. 2007;88:631–5.

Friedman HL. New methods for evaluating kinetic parameters from thermal analysis data. J Polym Sci. 1965;6C:183–7.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Akahira T, Sunose T. Joint convention of four electrical institutes. Research Report Chiba Institute of Technology. Sci Technol. 1971;16:22–31.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Flynn JH, Wall LA. A quick direct method for determination of activation energy from thermogravimetric data. J Polym Sci B. 1966;4:323–8.

Wall ME. Singular value decomposition and principal component analysis. In: Berrar DP, Dubitzky W, Granzow M, editors. A practical approach to microarray data analysis. Norwel: Kluwer; 2003. p. 91–109.

Šesták J, Berggren G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperatures. Thermochim Acta. 1971;3:1–12.

Acknowledgements

This work was supported by a grant from the University of Medicine and Pharmacy “Victor Babeş” Timişoara (Grant PIII-C1-CFI-2014/2015-03 to I.L., A.L. and L.-M.S).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ledeţi, I., Bercean, V., Vlase, G. et al. Betulonic acid. J Therm Anal Calorim 125, 785–791 (2016). https://doi.org/10.1007/s10973-016-5299-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5299-8