Abstract

The evolution of permeability in coal seams plays an important role in the exploitation of coalbed methane, and the Klinkenberg effect is an important factor affecting the permeability. In most studies, the Klinkenberg coefficient is considered a constant although it is closely related to the cleat width which changes dynamically due to the competing processes of change in effective stress and adsorption induced deformation. In this work, based on the double strain spring model and the effective stress principle, a new stress–strain relationship is proposed for cleat space. In addition, the influence of the adsorption induced swelling effect on coal deformation is considered. By considering both stress-induced strain and adsorption-induced strain, the cleat width model and Klinkenberg coefficient model are established. Finally, we develop an improved permeability model with variable cleat width and Klinkenberg coefficient based on cubic law. This improved permeability model is compared with experimental data and several classical models under conditions of constant effective stress and constant confining stress. Furthermore, the relationship between Klinkenberg coefficient and pore pressure under different conditions is analyzed. Our results indicate that the improved apparent permeability model matches the experimental data well and has a wider range of applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal is often considered as a dual porosity medium containing cleats and pores (Wang et al. 2012; Liu et al. 2011; Wang et al. 2015). Coalbed methane (CBM) exists in cleats and pores in the form of free or dissolved state, and is adsorbed in the organic matter in coal (Cui et al. 2009). In the process of coal mining, CBM has long been considered as a disaster material causing gas outbursts, gas blasting, etc. (Sobczyk 2014; Kim et al. 2014). However, with the development of mining technology and the improvement of environmental protection, coalbed methane, as a clean gas, is being actively exploited by countries around the world (Ji et al. 2015). Many challenges exist for CBM development, and one of the major difficulties is the low permeability and poor connectivity of coal seams. In order to improve the recovery of CBM and reduce the dependence on conventional energy, it is more and more important to study the permeability of coal seam during production.

The main migration channels of gas in coal seams are cleats and pores, which are different from conventional reservoirs. Coal deformation is affected by the combination of mechanical and chemical effects (Wang et al. 2018b; Cao et al. 2016). For deformation caused by mechanical loading, Biot (1941) proposed that pore pressure could not completely offset the influence of confining stress, and developed the effective stress principle by introducing Biot coefficient. For deformation caused by adsorption, Langmuir (1918) proposed an isotherm equation to describe the adsorbed gas content as a function of pressure and this equation was later extended to link the effect of adsorption on swelling for coal and shale. Importantly, these two processes compete with each other in controlling the net deformation and permeability. During CBM production as the pore pressure in the coal decreases, on one hand, the effective stress increases and the pore volume is compressed, and as a result the permeability decreases. On the other hand, the gas desorption from the matrix to the cleat causes the coal matrix to shrink and thus widens the cleat, which increases the permeability of the system. The net permeability of coal depends on the competitive action of these two processes. However, a large number of experimental studies have shown that the influence of adsorption strain is overestimated when calculating permeability in coal seam (Connell et al. 2010; Liu and Rutqvist 2009). Therefore, the influence factor f is introduced to evaluate the contribution of adsorption to deformation, and the value of f is 0–1(Zhou et al. 2016; Guo et al. 2014). In addition, when the pore pressure is low, the gas migration in the coal seam is not completely the same (Anez et al. 2014; Ashrafi Moghadam and Chalaturnyk 2014; Li et al. 2018; Cui et al. 2018; Si et al. 2018; Wang et al. 2019; He et al. 2017). When the average free path of gas molecules is the same order of magnitude as the cleat width, the molecular velocity at the pore wall is not zero, causing the permeability measured in the laboratory greater than the absolute permeability of coal sample, this phenomenon is called the Klinkenberg effect (Klinkenberg 1941). In order to better understand the flow state of gas in cleats, Knudsen (1909) proposed the Knudsen number to determine the flow regime, which was defined as the average free path of molecules divided by the pore size. When 0.001 < Kn < 0.1, the flow in the cleat is completely in the state of slip flow (Anez et al. 2014). In this paper, the effects of effective stress, adsorption induced swelling, and Klinkenberg effect on permeability are studied.

In order to study the evolution of permeability in coal seams, a large number of permeability models have been proposed in the literature. Seidle and Huitt (1995) put forward a model to explain the relationship between permeability and effective stress, ignoring the elastic property of coal. Palmer and Mansoori (1998) developed a model describing permeability changes caused by adsorption strain. Shi and Durucan (2004) proposed a permeability model based on the uniaxial strain condition, which can match most experimental data. Based on the different stiffness of cleats and matrix, Wang et al. (2012) established a permeability model by assuming that the system is transformed from globally unconstrained to locally constrained. Liu et al. (2009) proposed a dual-strain spring model, suggesting that different Hooke’s law should be applied to calculate the deformation of coal seams when the fracture and matrix are subjected to effective stress. Liu and Rutqvist (2009) then considered the influence of adsorption strain on the basis of the dual-strain spring model, and considered that there was an internal interaction between matrix and fracture. Chen et al. (2012) considered that part of the adsorption strain had an effect on cleat width, and introduced the concept of sensitivity of adsorption strain to cleat width to describe the effect of adsorption strain on permeability.

Due to the influences of effective stress and adsorbed strain, the cleat width is constantly changing, which causes the Klinkenberg effect to change as well. The Klinkenberg coefficient, an important parameter controlling the Klinkenberg effect, is closely related to the cleat width and can be calculated from the image of the reciprocal of apparent permeability and mean pore pressure (Harpalani and Chen 1997). When considering the Klinkenberg effect, only a few studies have taken the variation of cleat width into account. Wang et al. (2014) only considered the effect of adsorption-induced strain when the variable Klinkenberg coefficient model was established. Zhou et al. (2016) developed a cleat width model based on effective stress principle,.However, his model lacked further validation.

The effects of variable Klinkenberg effect and variable cleat width on permeability are studied in this paper. Based on previous works, this paper argues that different Hooke’s law should be applied to cleat space when they are subjected to same effective stress, and that the cleat width is affected by both matrix deformation and fracture deformation under the action of effective stress. On this basis, the adsorption and its induced swelling effect is considered. Different from the previous permeability models, we believe that the adsorption and swelling only partially affects the coal deformation. Therefore, the sensitivity of expansion and deformation on cleat width is introduced to describe this change. In addition, the Klinkenberg effect cannot be ignored because the pore pressure used in the laboratory and the actual pore pressure in the field are often low. Considering the fact that the Klinkenberg coefficient varies with different gas migration, an improved Klinkenberg coefficient model is established. Then an improved apparent permeability model is derived based on the cubic law and its fidelity is subsequently verified under the conditions of constant effective stress and constant confining stress.

2 Development of Fracture Aperture Model Under the Influence of Effective Stress and Gas Adsorption

2.1 Evaluation of Effective Stress Effect

Coal can be considered as a dual porosity medium containing micropores, mesopores and macropores. Gas is stored in and flows through such pore systems. Due to the unique deformation characteristics of the cleat, its width in the coal seam is easily changed, which has a significant impact on the flow behavior and permeability in the coal. Compared with the fracture system, the permeability of coal matrix can be as much as 8 orders of magnitude smaller than that of the fracture system (Wang et al. 2018a; Liu and Rutqvist 2009). Therefore, the permeability of coal matrix is sometimes neglected in numerical models. Liu et al. (2009) argued that different Hooke’s law should be applied to rock regions with significant differences in stress–strain behavior. We expanded the concept by dividing cleat space into “hard” and “soft” parts, these two parts follow different Hooke’s law when subject to the same stress. This theory is similar to previous works (Chen et al. 2012; Berryman 2006; Wang et al. 2018c).

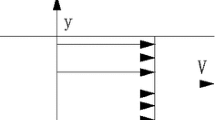

Natural strain (volume change divided by rock volume under current stress state) is used to represent “soft” part deformation, and engineering strain (volume change divided by rock volume under stress-free state) is used to represent “hard” part deformation, as shown in Fig. 1. These two parts follow different Hooke’s law. We assume that the cleats are embedded into the rock sample to undergo the effect of effective stress σeff. For the “hard” part, Hooke’s law can be expressed as

where Kf,e is the “hard” part modulus of cleat space, εc,e is the engineering strain for the cleat width, which can be defined as

where be is the stressed cleat width for the “hard” part, and b0,e is the unstressed cleat width for the “hard” part. This is done by applying a boundary condition: be = b0,e when σeff = 0. By simplifying and integrating Eqs. (1) and (2), we obtain

For the “soft” part, Hooke’s law can be expressed as

where Kf,n is the “soft” part modulus of cleat space, εc,n is the natural strain for the cleat width, which can be defined as

where bn is the stressed cleat width for the “soft” part. This is done by applying a boundary condition: bn = b0,n when σeff = 0. By simplifying and integrating Eqs. (4) and (5), we obtain

where b0,n is the unstressed cleat width for the “soft” part. The deformation of cleat width in non-absorbent media are composed of two components: “hard” part and “soft” part, the volumetrically averaged cleat width (b) is given by

Through the above analysis, it can be obtained that the cleat width beff under effective stress σeff is

Combining Eqs. (3), (6) and (8), the influence of “hard” part and “soft” part on cleat width under the action of effective stress can be obtained as

Since the modulus of “hard” part Kf,e is much larger than the modulus of “soft” part Kf,n and the “soft” part deformation is much larger than the “hard” part deformation under high effective stress, 1 − σeff/Kf,e ≈ 1 is obtained. The above equation can be simplified to:

where Cf = 1/Kf,n is defined as the cleat compressibility in coal.

2.2 Evaluation of Strain Effect Induced by Adsorption

The transport of gas in coal seams is obviously different from that of other rocks, because during the transport, there are processes of gas adsorption or desorption and coal seam expansion or shrinkage. The shrinkage and swelling of coal matrix may increase or decrease the width of cleats, which will affect the porosity and permeability of fractures in the reservoir. A large number of studies have shown that there is a close relationship between coal volume expansion and gas adsorption capacity (Wang et al. 2011, 2018a; Li and Feng 2015). The relationship between them can be expressed by the Langmuir type equation

where εms represents the strain caused by adsorption on the matrix block, εL represents the maximum strain caused by adsorption, PL represents the Langmuir pressure, and specifically represents the pore pressure when the measured strain equals 0.5εms, P represents the pore pressure, and P0 represents the initial pore pressure. The width change of matrix block Δas can be written as

where a0 is the initial width of the matrix block.

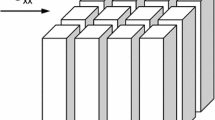

Under the condition of constant volume, the expansion and contraction of matrix are directly regulated by the decrease and increase of cleat width. In the literature, it is usually assumed that the swelling strain is completely regulated by the change cleat width (Wang et al. 2012; Karacan 2007). However, this assumption has been considered to overestimate the impact of swelling strain. Therefore, a factor f was introduced to estimate the contribution of adsorption-induced strain to cleat width, as shown in Fig. 2. The matrix width is considered to be unit 1, so the contact part is equivalent to f, and the value ranges from 0 to 1. Therefore, the variation of cleat width caused by the adsorption strain of matrix block can be expressed as

By using the cubic model, combining Eqs. (11), (12) and (13), and Eq. (13) can then be rewritten as

defining the evolution of cleat width as a function of sorption contributing factor, initial cleat width, initial porosity, the material coefficients of the Langmuir strain and pressure, and the change in gas pressure. This is the component response required to determine the influence of shrinkage deformations on permeability evolution during CBM production.

2.3 Development of Cleat Width Model

As shown above, we have derived the variation of cleat width under effective stress and sorption-induced strain respectively. However, as we know, in the process of CBM exploitation, due to gas migration and pore pressure changes, the strain caused by desorption and effective stress will affect the change of cleat width simultaneously. Combining Eqs. (10) and (14), the cleat width under the effects of effective stress and desorption can be expressed as

Based on the double-strain spring model, the “hard” part deforms less under the action of stress, then b0,e≪ b0, and b0,e ≈ 0, therefore Eq. (15) can be simplified as

where we define Sf = f/ϕ0 to describe the sensitivity of sorption induced strain to the cleat width. Under the same boundary conditions, the larger the Sf, the greater contribution of sorption-induced strain to the cleat width. In other words, the change of cleat width is more sensitive to sorption induced strain when the contributing factor is large. In the following, we will consider Sf as a variable and adjust it to match the experimental data.

3 Improved Variable Klinkenberg Coefficient and Apparent Permeability Model

3.1 Improved Variable Klinkenberg Coefficient Model

In the previous section, we obtained the cleat width model closely related to the Klinkenberg coefficient. However, the flow in the cleat is not necessarily Darcy flow. When gas flows in the coal seam, the gas molecules collide with each other. The velocity of the gas molecules near the fracture wall is not zero, causing the apparent permeability greater than the absolute permeability. Klinkenberg proposed an equation to describe the linear relationship between apparent permeability and absolute permeability as

where kab is the absolute permeability of coal, kap is the actual measured apparent permeability, and B is the Klinkenberg coefficient, which can be obtained from the following equation

where c is a constant of 0.9, μ is the dynamic viscosity of gas, ω is the throat width, R and T are gas constant and absolute temperature, respectively. M is molecular weight. The Klinkenberg coefficient B is usually obtained by the linear relationship between the apparent permeability Kap measured in the laboratory and the reciprocal of the average pore pressure P. However, when permeability is measured by sorptive gas, the Klinkenberg coefficient cannot be obtained directly by this method, because the slippage effect and the swelling/shrinkage caused by adsorption/desorption affect the value of B. Therefore, we should first separate the slippage effect and adsorption effect with inert gas (Wang et al. 2015), and then use it to get the Klinkenberg coefficient of adsorptive gas CH4 from

where b is the cleat width; μ is the dynamic viscosity of gas; M is the gas molar mass; B is the gas Klinkenberg coefficient. The subscripts na and CH4 represent non-adsorbed gas and methane, respectively.

When the non-adsorbent gas passes through the coal seam, its cleat width is only affected by the effective stress. While when CH4 passes through the coal seam, the cleat width is affected by both the effective stress and the strain caused by adsorption. Based on Eq. (16), the cleat width for non-adsorbent gas and CH4 can be written as

By substituting Eqs. (20) and (21) into Eq. (19), we can obtain a new Klinkenberg coefficient model under the coupled effects of adsorption and effective stress as

3.2 Improved of Apparent Permeability Model

According to the cubic law, the ratio of the absolute permeability under stress to the initial absolute permeability is

Therefore, the absolute permeability evolution can be rewritten as

kab,P and kab,i are absolute permeability at P MPa and i MPa, respectively. bP and bi are cleat width at P MPa and i MPa, respectively. σeff,P and σeff,i are effective stresses at P MPa and i MPa, respectively. Equation (22) and (24) are then substituted into Eq. (17) to obtain the ratio of apparent permeability models at P MPa and i MPa.

This allows the apparent permeability to be evaluated as a function of stress, coal properties, depletion, and Klinkenberg effect.

4 Application and Evaluation of the Model

4.1 Evaluation of the Model Under the Condition of Constant Effective Stress

Fracture compressibility can be calculated from Cf = 1/Kf,n = α/ϕKbulk. Using parameters listed in Table 1, we obtain Cf = 0.0328 MPa−1, The parameter Sf was determined by fitting the model to the permeability data using a least-squares analysis. Through matching the experiment data, The parameter Sf is equal to 23.The improved apparent permeability model was then used to verify the coal seam of Sun Juan Basin, and the experimental data were derived from the literature (Harpalani and Chen 1997). During the experiment, the effective stress was maintained at 5.4 MPa, and the experimental temperature was maintained at 44 °C. When the stress reached stability, the pore pressure decreased from 6.2 MPa to 0.62 MPa. σ0 and P0 are assumed to be zero. Parameters are substituted into Eq. (25) and compared with experimental data, as shown in Fig. 3.

Our model divided cleat space into “hard” and “soft” parts, these two parts follow different Hooke’s law when subject to the same stress, and takes only part of adsorption induced strain having an impact on the cleat width, while considering variable Klinkenberg effect simultaneously. The model shows a good match with the experiment data and the Pearson correlation coefficient value reached 0.973. When not considering slippage effect (B = 0), the model becomes Eq. (24), and the results show that the Klinkenberg effect has a significant impact on permeability.

4.2 Evaluation of the Model Under the Condition of Constant Confining Stress

When considering the Klinkenberg effect on permeability, Klinkenberg coefficient B is a key parameter. Sampath and Keighin (1982) provided the method to calculate the Klinkenberg coefficient when the confining stress was constant, and the pore pressure of the three groups selected by them was all less than 0.24 MPa. According to Eqs. (18) and (19), when pore pressure is low, Klinkenberg effect is more profound (Anez et al. 2014; Guo et al. 2014). Therefore, when calculating the Klinkenberg coefficient, we selected the data from Robertson and Christiansen (2005) with low pore pressure from 0.8 MPa to 5.6 MPa when confining stress was constant at 6.895 MPa (1000 psi). The Klinkenberg coefficient BN2 of N2 we calculated is 0.66. When calculating the Klinkenberg coefficient, Harpalani and Chen (1997) ignored the influence of cleat width change and assumed that the cleat width in coal when helium flows is equal to that when methane flows (bHe = bCH4). However, cleat width is variable due to the influence of gas type and stress effect. In our improved permeability model, the effects of adsorption and effective stress are both taken into account. In addition, we believe that the adsorption and swelling only partially affects the coal deformation. Then the Klinkenberg coefficient of CH4 can be obtained according to the Eq. (22).

In this section, the data of Anderson 01 coal sample in Robertson and Christiansen (Robertson and Christiansen 2005) were used for verification. During the test, the confining stress remained constant at 6.895 MPa (1000 psi), and the pore pressure changed from 0.8 MPa to 5.6 MPa. Methane data were selected for the comparison. In addition, because Biot coefficient α was not measured, and the sorption contributing factor f cannot be directly measured neither, hence in the process of model validation, we took the fracture compressibility Cf and the sensitivity factor Sf as variables. The sensitivity factor Sf and fracture compressibility factor Cf were calculated as 7.33 and 0.065 MPa−1 by matching the curve, respectively. In the process of verification, relevant parameters of S-D model, C-B model and P-M model are directly obtained from Guo et al. (2014). The model comparison results are shown in Fig. 4.

Comparing the model without slippage effect (Eq. (24)) with the new model developed in this work, it can be seen that the influence of Klinkenberg effect on permeability is significant and cannot be ignored. Since S-D model, C-B model, and P-M model all consider the influence of total swelling strain on permeability, it is observed from the trend in Fig. 4 that these models can overestimate permeability in the whole process. In addition, since these models are based on the assumption of uniaxial strain and the experimental data were measured under constant confining stress, these models cannot match the experimental data well. According to the new model developed in this study, it could be inferred that only part of the adsorption strain has an effect on coal permeability, and the Klinkenberg coefficient changes with different gas migration, so the model results match well with the experimental data.

4.3 Evaluation of Variable Klinkenberg Coefficient Under Different Conditions

According to Eq. (22), the Klinkenberg coefficient is related to effective stress and adsorption, which is similar to the improved apparent permeability model. In this following, the variable Klinkenberg coefficient will be analyzed under the condition of constant effective stress and constant confining stress. We assume both σ0 and P0 are 0. The relationship between the Klinkenberg coefficient and pore pressure is shown in Fig. 5 and 6.

Constant effective stress: The effective stress is 5.4 MPa, σc − P = 5.4 MPa. The sensitivity factor Sf of adsorption induced strain to cleat width is 23. The fracture compressibility Cf is 0.0328 MPa−1. The relationship between the Klinkenberg coefficient and pore pressure is shown in Fig. 5.

Constant confining stress: The confining stress is 6.89 MPa, σc = 6.89 MPa. The sensitivity factor Sf of adsorption induced strain to cleat width is 7.33. The fracture compressibility Cf is 0.065 MPa−1. The relationship between the Klinkenberg coefficient and pore pressure is shown in Fig. 6.

As shown in Fig. 5, the Klinkenberg coefficient increases with the increase of pore pressure. This is because with the increase of pore pressure, the gas moves from the fracture to the matrix, and the adsorbed gas expands the matrix, narrowing the cleat width, so the Klinkenberg coefficient increases. When the confining stress is constant, the increasing trend of Klinkenberg coefficient gradually slows down, as shown in Fig. 6. This is because the effect of adsorption induced swelling on cleat width begins to dominate. With the continuous increase of pore pressure, the effect of effective stress on cleat width will gradually dominate, so the Klinkenberg coefficient will increase more and more slowly.

5 Conclusions

In this work, the effects of cleat space deformation on cleat width under the variable Klinkenberg effect and effective stress during gas migration in coal are analyzed. Based on the assumption that only part of the adsorption induced strain has an impact on deformation, an improved apparent permeability model is established. The model is verified under two conditions: constant effective stress and constant confining stress. The following conclusions can be drawn from this study.

- (1)

Based on the double-strain spring model, the influence of “hard” and “soft” parts deformation on cleat width under effective stress is considered, and it is considered that only partial adsorption strain affects coal deformation, then the cleat width model is established.

- (2)

On the basis of the cleat width model, the variable Klinkenberg effect of different gas migration is considered, and the variable Klinkenberg coefficient model is established. When the effective stress is constant, the Klinkenberg coefficient increases with the increase of pore pressure. When the confining stress is constant, the increase of Klinkenberg coefficient gradually slows down with the increase of pore pressure.

- (3)

The improved apparent permeability model was verified under the condition of constant effective stress, which matches the experimental data well. Under the condition of constant confining stress, the improved model was compared with several commonly used models, and the results showed that the improved model was capable of matching the laboratory data with constant confining stress, while the other models could not well match the laboratory data well. Therefore, our newly developed model could be applicable to wider applications.

Abbreviations

- σ eff :

-

Effective stress (MPa)

- σ c :

-

Confining stress (MPa)

- K f,e :

-

“Hard” part modulus of cleat space (MPa)

- K f,n :

-

“Soft” part modulus of cleat space (MPa)

- K bulk :

-

Bulk modulus of coal (MPa)

- ε c,e :

-

Engineering strain for the cleat width

- ε c,n :

-

Natural strain for the cleat width

- ε ms :

-

Matrix block strain caused by adsorption

- ε L :

-

Langmuir strain or maximum adsorption strain

- b e :

-

Stressed cleat width for the “hard” part

- b 0,e :

-

Unstressed cleat width for the “hard” part

- b n :

-

Stressed cleat width for the “soft” part

- b 0,n :

-

Unstressed cleat width for the “soft” part

- b eff :

-

Influence of “hard” and “soft” parts on cleat width under the action of effective stress

- b ms :

-

Cleat deformation caused by the adsorption strain of matrix block

- b 0 :

-

Initial averaged cleat width

- a 0 :

-

Initial width of the matrix block

- Δas :

-

Width change of matrix block

- k ab :

-

Absolute permeability of coal (mD)

- k ap :

-

Apparent permeability of coal (mD)

- B :

-

Klinkenberg coefficient

- C f :

-

Cleat compressibility (MPa−1)

- f :

-

Contribution of adsorption to matrix deformation

- S f :

-

Sensitivity of sorption induced strain to the cleat width

- ϕ 0 :

-

Fracture porosity of the coal sample

- P:

-

Pore pressure (MPa)

- P L :

-

Langmuir pressure (MPa)

- μ :

-

Dynamic viscosity of gas (cp)

- ω :

-

Throat width or cleat width

- M:

-

Molecular weight (g/mol)

- α :

-

Biot coefficient

- 0:

-

Initial state

- CH4 :

-

Methane

- na:

-

No-adsorption gas

References

Anez L, Calas-Etienne S, Primera J, Woignier T (2014) Gas and liquid permeability in nano composites gels: comparison of Knudsen and Klinkenberg correction factors. Micropor Mesopor Mat 200:79–85. https://doi.org/10.1016/j.micromeso.2014.07.049

Ashrafi Moghadam A, Chalaturnyk R (2014) Expansion of the Klinkenberg’s slippage equation to low permeability porous media. Int J Coal Geol 123:2–9. https://doi.org/10.1016/j.coal.2013.10.008

Berryman JG (2006) Estimates and rigorous bounds on pore-fluid enhanced shear modulus in poroelastic media with hard and soft anisotropy. Int J Damage Mech 15(2):133–167

Biot MA (1941) General theory of three-dimensional consolidation. J Appl Phys 12:155–164

Cao P, Liu J, Leong Y-K (2016) General gas permeability model for porous media: bridging the gaps between conventional and unconventional natural gas reservoirs. Energ Fuel 30(7):5492–5505. https://doi.org/10.1021/acs.energyfuels.6b00683

Chen Z, Liu J, Pan Z, Connell LD, Elsworth D (2012) Influence of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: model development and analysis. Int J Greenhouse Gas Control 8:101–110

Connell LD, Lu M, Pan Z (2010) An analytical coal permeability model for tri-axial strain and stress conditions. Int J Coal Geol 84(2):103–114. https://doi.org/10.1016/j.coal.2010.08.011

Cui X, Bustin AMM, Bustin RM (2009) Measurements of gas permeability and diffusivity of tight reservoir rocks: different approaches and their applications. Geofluids 9(3):208–223. https://doi.org/10.1111/j.1468-8123.2009.00244.x

Cui G, Liu J, Wei M, Feng X, Elsworth D (2018) Evolution of permeability during the process of shale gas extraction. J Nat Gas Sci Eng 49:94–109. https://doi.org/10.1016/j.jngse.2017.10.018

Guo P, Cheng Y, Jin K, Li W, Tu Q, Liu H (2014) Impact of effective stress and matrix deformation on the coal fracture permeability. Transp Porous Media 103(1):99–115

Harpalani S, Chen G (1997) Influence of gas production induced volumetric strain on permeability of coal. Geotech Geol Eng 15(4):303–325

He Y, Cheng J, Dou X, Wang X (2017) Research on shale gas transportation and apparent permeability in nanopores. J Nat Gas Sci Eng 38:450–457. https://doi.org/10.1016/j.jngse.2016.12.032

Ji H, Li Z, Yang Y, Hu S, Peng Y (2015) Effects of organic micromolecules in coal on its pore structure and gas diffusion characteristics. Transp Porous Med 107(2):419–433. https://doi.org/10.1007/s11242-014-0446-9

Karacan CÖ (2007) Swelling-induced volumetric strains internal to a stressed coal associated with CO2 sorption. Int J Coal Geol 72(3–4):209–220. https://doi.org/10.1016/j.coal.2007.01.003

Kim WK, Mogi T, Dobashi R (2014) Effect of propagation behaviour of expanding spherical flames on the blast wave generated during unconfined gas explosions. Fuel 128:396–403. https://doi.org/10.1016/j.fuel.2014.02.062

Klinkenberg LJ (1941) The permeability of porous media to liquids and gases. Paper Presented at Drilling andProduction Practice American Petroleum Institute

Knudsen M (1909) DieGesetze derMolekularströmung und der inneren Reibungsströmung derGase durch Röhren. Ann Phys Berl 333(1):75–130

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica, and platinum. J Am Chem Soc 40:1361–1403. https://doi.org/10.1021/ja02242a004

Li CJ, Feng JL (2015) Adsorption-induced permeability change of porous material: a micromechanical model and its applications. Arch Appl Mech 86(3):465–481. https://doi.org/10.1007/s00419-015-1041-4

Li J, Chen Z, Wu K, Li R, Xu J, Liu Q, Qu S, Li X (2018) Effect of water saturation on gas slippage in tight rocks. Fuel 225:519–532. https://doi.org/10.1016/j.fuel.2018.03.186

Liu H-H, Rutqvist J (2009) A new coal-permeability model: internal swelling stress and fracture-matrix interaction. Transp Porous Med 82(1):157–171. https://doi.org/10.1007/s11242-009-9442-x

Liu H-H, Rutqvist J, Berryman JG (2009) On the relationship between stress and elastic strain for porous and fractured rock. Int J Rock Mech Min 46(2):289–296. https://doi.org/10.1016/j.ijrmms.2008.04.005

Liu J, Chen Z, Elsworth D, Qu H, Chen D (2011) Interactions of multiple processes during CBM extraction: a critical review. Int J Coal Geol 87(3–4):175–189. https://doi.org/10.1016/j.coal.2011.06.004

Liu S, Harpalani S, Pillalamarry M (2012) Laboratory measurement and modeling of coal permeability with continued methane production: part 2-Modeling results. Fuel 94(1):117–124. https://doi.org/10.1016/j.fuel.2011.10.053

Mitra A, Harpalani S, Liu S (2012) Laboratory measurement and modeling of coal permeability with continued methane production: part 1-Laboratory results. Fuel 94(1):110–116. https://doi.org/10.1016/j.fuel.2011.10.052

Palmer I, Mansoori J (1998) How permeability depends on stress and pore pressure in coalbeds: a new model. SPE 1(6):539–544. https://doi.org/10.2118/52607-pa

Robertson EP, Christiansen RL (2005) Modeling permeability in coal using sorption-induced strain data. In: Idaho National Laboratory (INL)

Sampath K, Keighin CM (1982) Factors affecting gas slippage in tight sandstones of cretaceous age in the Uinta basin. JPT 34:2715–2720

Seidle J, Huitt LG (1995) Experimental measurement of coal matrix shrinkage due to gas desorption and implications for cleat permeability increases. Paper SPE 30010 presented at the international meeting on petroleum engineering, Beijing, pp 14–17. https://doi.org/10.2118/24361-ms

Shi JQ, Durucan S (2004) Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp Porous Med 56(1):1–16

Si L, Li Z, Yang Y (2018) Influence of the pore geometry structure on the evolution of gas permeability. Transp Porous Med 123(2):321–339. https://doi.org/10.1007/s11242-018-1044-z

Sobczyk J (2014) A comparison of the influence of adsorbed gases on gas stresses leading to coal and gas outburst. Fuel 115:288–294. https://doi.org/10.1016/j.fuel.2013.07.016

Wang S, Elsworth D, Liu J (2011) Permeability evolution in fractured coal: the roles of fracture geometry and water-content. Int J Coal Geol 87(1):13–25. https://doi.org/10.1016/j.coal.2011.04.009

Wang S, Elsworth D, Liu J (2012) A mechanistic model for permeability evolution in fractured sorbing media. J Geophys Res-Sol Ea. https://doi.org/10.1029/2011jb008855

Wang G, Ren T, Wang K, Zhou A (2014) Improved apparent permeability models of gas flow in coal with Klinkenberg effect. Fuel 128:53–61. https://doi.org/10.1016/j.fuel.2014.02.066

Wang Y, Liu S, Elsworth D (2015) Laboratory investigations of gas flow behaviors in tight anthracite and evaluation of different pulse-decay methods on permeability estimation. Int J Coal Geol 149:118–128. https://doi.org/10.1016/j.coal.2015.07.009

Wang G, Wang K, Jiang Y, Wang S (2018a) Reservoir permeability evolution during the process of CO2-enhanced coalbed methane recovery. Energies 11(11):2996. https://doi.org/10.3390/en11112996

Wang G, Wang K, Wang S, Elsworth D, Jiang Y (2018b) An improved permeability evolution model and its application in fractured sorbing media. J Nat Gas Sci Eng 56:222–232. https://doi.org/10.1016/j.jngse.2018.05.038

Wang J, Hu B, Liu H, Han Y, Liu J (2018c) Effects of ‘soft-hard’compaction and multiscale flow on the shale gas production from a multistage hydraulic fractured horizontal well. J Petrol Sci Eng 170:873–887

Wang F, Jiao L, Lian P, Zeng J (2019) Apparent gas permeability, intrinsic permeability and liquid permeability of fractal porous media: carbonate rock study with experiments and mathematical modelling. J Petrol Sci Eng 173:1304–1315. https://doi.org/10.1016/j.petrol.2018.10.095

Zhou Y, Li Z, Yang Y, Zhang L, Si L, Kong B, Li J (2016) Evolution of coal permeability with cleat deformation and variable Klinkenberg effect. Transp Porous Media 115(1):153–167. https://doi.org/10.1007/s11242-016-0759-y

Acknowledgements

This study was supported by the “Project funded by China Postdoctoral Science Foundation”(No. 2019M662402).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, G., Xiao, Z., Yu, J. et al. An Improved Coal Permeability Model with Variable Cleat Width and Klinkenberg Coefficient. Geotech Geol Eng 38, 3041–3051 (2020). https://doi.org/10.1007/s10706-020-01205-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01205-9