Abstract

This study focuses on developing a micromechanical model of poroelasticity with adsorption-induced permeability change occurred in porous material. The underlying pore pressure was represented by means of virial expansion to evaluate such adsorption-induced permeability change, in which the solid–gas interactions or the effects of interactions between molecules were involved. The relation between surface strain and volumetric strain under infinitesimal deformation conditions was presented to gain an explicit formulation of pore surface area with respect to volumetric strain and porosity. After the formulation of surface stress modified by Langmuir isothermal adsorption was derived, the differential micromechanical constitutive model of porous material was obtained. By providing that the ratio of current permeability to initial one was equal to the cubic ratio of current porosity to initial porosity, the differential equations for permeability change was consequently obtained. The present simulations showed that the predictions from the model are in good agreement with the experimental results of permeability change of coal induced by adsorption of CO\(_2\) and CH\(_4\) under confined pressure conditions in the literature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The knowledge how the deformed solid matrix affects the permeability of porous material is crucially concerned to many applications such as coal bed methane (CBM) recovery and carbon dioxide sequestration in coal reservoirs. It was indeed shown in terms of both theoretical analysis and experimental test that the gas molecules adsorbed in porous materials can induce the deformation of the solid matrix [1]. In situ adsorption-induced coal swelling has also been identified [19, 28, 38], which is regarded as the major factor that leads to a rapid decrease in CO\(_2\) injectivity during enhanced coal bed methane production by CO\(_2\) injection. As a typical porous material, coal is composed both macropores (like fracture porosity) and micropores (primary porosity), among which such macropores are also referred to as face and butt cleats [42]. Generally, the macropores in coal are referred to as pathways to enable gases such as CO\(_2\) and CH\(_4\) to pass, where there is little possible adsorption phenomenon observed, whereas the micropores are contributed to the most sites of surface area where there could be a large body of adsorbed gases under some geologic and thermal conditions. As adsorbate, CO\(_2\) or CH\(_4\) adsorbed on the coal surface enables to induce the swelling of coal matrix due to fluid–solid interactions and in turn decrease the fracture porosity under confined pressure conditions. However, as the bulk pressure is progressively increased, coal is eventually compressed, which leads to the enhancement of fracture porosity. In other words, the fracture porosity is significantly associated with the interaction between coal matrix and adsorbate, which implies that the permeability is also dependent of both micropore and macropores.

By the quantitative X-ray CT imaging technique, it was found that the different coal structures have the distinctive adsorption capacity and even behave with a different adsorption-induced swelling [16, 17]. Dunning [9] found that the properties of the molecules adsorbed at the surface were rather distinct from those at bulk state, and even the presence of adsorption could alter both the energy of special sites and the solid surface structure. However, it has not been completely understood how the presence of adsorbate influences the deformation mechanism and permeability of porous material at several scale levels. Consequently, it is necessary to develop appropriate models, not only to explain quantitatively the phenomenon of swelling or shrinking, but also to describe accurately the permeability change. The macroscopic constitutive models for porous materials under isothermal conditions can be derived by means of mechanics of porous media, provided that a representative volume element (RVE) whose typical size should certainly be much greater than that of heterogeneity, but much smaller than that of macrostructure [2, 7]. Considering the precipitation or dissolution of solid matrix, it was identified that there are some arguments of relevant macroscopic states from the finer scale in which physical chemistry meets mechanics in an RVE [37]. In the traditional mechanics of porous media, however, adsorption is not considered, which implies that all of the gas molecules are assumed to be in their bulk states, which arises from neglecting of surface energy or surface stress in the model of porous material.

Indeed, surface energy definitely plays a significant role in adsorption-induced swelling or desorption-induced shrinkage of porous materials. To consider such surface energy induced by adsorption, the corresponding constitutive model was proposed by Coussy [8] and Vandamme et al. [39], respectively. Recently, from the free energy balance of the open system composed of the solid skeleton and the interstitial fluid, this model was further extended to a general form, which is valid not only to characterize the adsorption effect of microporous material, but also to describe the adsorption response of macroporous material [3, 4]. Although the model is derived from very perspectives, it requires the help of molecular simulations for the theory to be applicable. The adsorption stress, which is defined as the derivative from the adsorbate grand thermodynamic potential with respect to the pore volume at fixed adsorbate chemical potential and isotherm conditions, was employed by Neimark and his co-workers to account for both capillary and disjoining pressure effects in a non-trivial fashion [11, 25] (Yang et al. 2011). Vermorel and Pijaudier-Cabot [40] presented a formulation of the swelling volumetric deformation increment as a function of the increment of bulk pressure and depending on a confinement coefficient which is referred to as the interstitial fluid high density compared with the bulk fluid. Vermorel and Pijaudier-Cabot [40] also showed that the effective pore pressure and the swelling strains may be deduced from adsorption measurements. Even though in the Gibbs adsorption framework the theoretical predictions by such model are in good agreement with several sets of experimental data in the literature, surface stress that is significant under considering adsorption in the microporous materials is indeed not dealt with in their model at all.

On the permeability issue, several permeability models for coal have been proposed by Palmer and Mansoori, Shi and Durucan [27, 35], and Gu and Chalaturnyk [12] to characterize the evolution of coal permeability. By assuming that the coal matrix blocks connected by coal matrix bridges and considering the couple interaction between them, a new permeability model for coal was recently developed by Liu et al. [21]. However, one of the disadvantages for most of the developed permeability models is that they cannot be used to satisfactorily explain the permeability experimental data of coal samples [32]. Bearing such surface stress and gas–solid interactions in mind, an analogous approach of virial expansion in thermodynamics is employed in the present work to represent a general formulation of pore pressure, which is appropriate to use in the development of a micromechanical model with adsorption effect. One of the advantages of the present model is that it can be used to not only deal the deformation of porous materials with several scales ranging from microscopic to macroscopic, but also well explain the experimental data of permeability change induced by adsorption.

The goal of the present study is to develop a micromechanical elastic constitutive model, which describes the swelling of connected porous material induced by gas adsorption, coupled with the permeability change. A general form of pore pressure is in detail derived from the principles of thermodynamics in Sect. 2.1, which can be used to describe the behavior of pressure imposed in the porous materials and is significant benefit to investigate the coupling mechanism between physical adsorption and deformation of porous material. In Sect. 2.2, emphasis is laid on the derivation of constitutive equations of porous material with adsorption effect by micromechanics, in which the surface stress of porous material is modified by combining with Langmuir isothermal adsorption. By assuming that the ratio of current permeability to initial one is equal to the cube of ratio of current porosity to initial porosity, the differential equations for permeability change is consequently obtained in Sect. 3. Numerical simulations under confined pressure conditions by the proposed model are presented in Sect. 4. The conclusion is finally given in Sect. 5.

2 Micromechanics with adsorption effect

In the viewpoint of thermodynamics, if the pores of porous material are referred to as macropores, it will be reasonable to treat the pore pressure of fluid imposed on the matrix surface as the bulk pressure. However, the pore pressure in the mesopores and micropores is much different from the fluid bulk pressure. For example, the Monte Carlo simulation indicated that the pore pressure in the micropores of coal is much larger than the bulk pressure and eventually can reach to 200 MPa [44]. One possible reason for this is the presence of the so-called disjoining pressure in slit-like micropores, but to directly measure it by experiment is almost impossible. Even though in the mesopores, the pressure imposed on the solid matrix is also apparently different from the bulk pressure due to the adsorption effect. In the present study, the virial expansion in thermodynamics is employed to represent a general form of pore pressure, which is able to not only describe the solvation pressure in micropores, but also evaluate the bulk pressure in the confined fluid at macroscale level. Such general pore pressure further included in the micromechanical model can be used to explain and predict for the swelling and permeability change of coal by adsorption effects.

2.1 A general form of pore pressure

Many experimental studies have demonstrated that the thickness of adsorbed phase is generally not null [1]. When adsorption occurs, the bulk gas interacted with the solid surface transforms into adsorbed gas. If the bulk and adsorbed gas and solid matrix are all together referred to as a thermodynamic system, there should be an external force field that should be applied on it due to adsorption effects [33]. We refer to this external force as adsorption force. If the system with no adsorption force field is in equilibrium, the chemical potential, the pressure, and the temperature of different phases must be coincided, respectively. Once an adsorption force field applies on the system, both the chemical potential and the temperature are still equal, respectively, but the pressure changes along the direction of the original force field [20]. Like the variation of atmospheric pressure in the gravity field, we assume that the pressure in adsorption field changes along the normal direction of the solid surface (as shown in Fig. 1).

Analogous to the virial expansion for some physical quantities in thermodynamics, we assume that the pore pressure imposed on the solid surface is a function of bulk pressure for a porous material under isothermal conditions, and we further assume that to such form of pore pressure p, n-order derivative with respect to the bulk pressure \(p_b\) exists. By applying the Taylor’s theorem at \(p=0\), the pore pressure is then expanded as

where \(c_0=p(p_b)\vert _{p_b=0} \), \(c_1=\frac{\mathrm {d}p}{\mathrm {d}p_b}\vert _{p_b=0}\), \(c_2=\frac{1}{2!}\frac{\mathrm {d}^2p}{\mathrm {d}p_b^2}\vert _{p_b=0} \), \(\ldots \), \(c_n=\frac{1}{n!}\frac{\mathrm {d}^np}{\mathrm {d}p_b^n}\vert _{p_b=0} \) are the coefficients, and \(r_n(p_b) \) the truncation error. It is emphasized that the dimension of \(c_0 \) is same as that of pressure, \(c_1 \) the dimensionless quantity, \(c_2 \) the reciprocal of pressure dimension, \(c_3 \) the reciprocal of square pressure dimension, \(\ldots \), and \(c_n \) the reciprocal of power (\(n-1\)) pressure dimension. In Eq. (1), let bulk pressure \(p_b \) be zero, and thus, the first coefficient \(c_0 \) can be determined, \(c_0=0 \). If all the pores of porous material are of macroscopic scale, the corresponding specific micropore surface is insignificant. In this case, the pore pressure is approximately evaluated by the formulation of bulk pressure, and the adsorption effect could not be considered for the time being. However, for most porous materials such as coal, its micropores are of dominant in the total pores [29], where its specific pore surface area is usually very large and even reaches to 425 m\(^2\)/g for coals [22]. As a result, in this case, Eq. (1) should be employed to evaluate the pore pressure. In order conveniently to compare the pore pressure and the bulk pressure, it is reasonably to decompose Eq. (1) into the following expression

where \(p_a=(c_1-1)p_b+c_2p_b^2+\cdots +c_np_b^n+r_n \) could be referred to as the adsorption pressure or excess pore pressure similar to the Gibbsian excess adsorption. In order to determine the coefficients of Eqs. (1) and (2), the data of the state equation of gas observed by the conventional experimental manner should be used, which are discussed in Sect. 4.

It is noted that in Eq. (1) or (2), if only taking linear term, we could obtain a form of pore pressure like the law of ideal gas. Further, if only dealing with quadratic approximation, obviously we could gain a form of pore pressure similar to the van der Waals equation of state. Since it is expected that the present expression of pore pressure is appropriately used to describe both the pore pressure in adsorbed gas and the bulk pressure in confined fluid under some isothermal conditions, the higher than 3-order terms in Eq. (1) or (2) are all omitted in the following development. The adsorption pressure or excess pore pressure is consequently rewritten as follows

On the other hand, the importance of these coefficients like virial coefficient lies in the fact that they are related directly to the interactions between fluid and solid molecules. The second virial coefficient indicates the departure from ideality due to interactions between pairs of molecules, the third virial coefficient represents the effects of interactions of molecular triplets, and so on. The physical meanings and their mathematical derivations of virial coefficients have been in detail treated in statistical physics and statistical mechanics, e.g., referred to [30]. It is emphasized that indeed the formulation mentioned above includes the interface effects of porous materials, i.e., the effects of interactions between solid matrix and gas molecule when being used to describe the adsorption effect. In the following development of micromechanical constitutive model with surface effect, the adsorption pressure or excess pore pressure will be employed to describe the gas adsorption-induced permeability change.

2.2 Constitutive model of microporous material with surface effect

Let the porosity of porous material in the reference configuration and the current configuration be \(\phi _0\) and \(\phi \), respectively. It is assumed that the macroscopic stress of the porous material, \(\sigma _{ij}\), can be additively decomposed into volumetric stress \(\sigma \) and deviatoric stress \(s_{ij}\). In the thermodynamic system with solid matrix and solid–gas interface, its Helmholtz free energy can be additively decomposed as

where \(F_s \) and U are the solid Helmholtz free energy and the interface free energy per unit volume of porous material, respectively. It is noted that the dimension of interface free energy per unit volume, J/m\(^{3}\), is different from that of surface free energy, J/m\(^{2}\). Under conditions of the isotropic infinitesimal deformation, the solid Helmholtz free energy per unit volume \(F_s \) is [8]

where K is the bulk modulus, b the Biot coefficient, N the Biot modulus, \(\epsilon \) the volumetric strain of porous material, \(\varphi \) the Lagrangian porosity, G the shear modulus, and \(e_{ij}\) the deviatoric strain.

The interface free energy per unit volume, U, reads

where A is the actual area of the pore walls per unit volume of the porous material in the current configuration and \(\gamma _{sf} \) denotes the surface free energy of the solid–gas interface in the current configuration. As did by Vandamme et al. [39], it is assumed that the specific area is a function of both the volumetric strain of the porous material (\(\epsilon \)) and the change of the Lagrangian porosity (\(\varphi =\phi -\phi _0 \)). Therefore, the differential form of A gives

By substituting Eqs. (5) and (6) combined with Eq. (7) into Eq. (4), and applying the energy balance law at equilibrium, the constitutive equations of microporous elasticity are written as [39]

where the stress \(\widehat{\sigma }_s \) and the pressure \(\widehat{p}_s \) that rise from the surface energy as a result of gas–solid interaction are given by

where \(\sigma _s \) is the surface stress expressed as

Eqs. (8), (9), and (10) are the basic constitutive equations of microporous elasticity with surface effect, which can also be treated as follows [45]

where \(\epsilon ^s \) is the volumetric strain of solid matrix induced by adsorption effect. The relation between \(\epsilon ^s \), \(\widehat{\sigma }_s \), and \(\widehat{p}_s \) is

In order to obtain the explicit expressions of Eqs. (11) and (12), the derivatives of specific surface area with respect to volumetric strain and porosity, respectively, are needed to be provided, and the surface stress induced by adsorption is also needed to know how to be evaluated. Particularly, the former can be completely determined for an ideal microstructure with monosized spherical pores, and the latter can be modified by some kinds of isothermal adsorption such as Langmuir isothermal adsorption, which result in the determination of both Eqs. (11) and (12). However, in most cases, the functional form of the specific surface area is rather ambiguous due to the complicated micro- and macrostructure of porous material. In the following, a general formulation between surface strain and volumetric strain is firstly derived under infinitesimal deformation conditions, and then, the explicit expressions for the derivative of A with respect to volumetric strain and porosity can be obtained.

By defining the surface strain \(\varepsilon _s=\ln ({A}/{A_0}) \) (\(A_0\) is the initial specific pore surface area), Eq. (13) can be rewritten as [36]

After introducing the Gibbs mathematical dividing surface [10], it is assumed that the thickness of solid surface is a constant during the deformation process. Therefore, the surface strain keeps constant across the surface. A further assumption is that the surface deformation is homogeneous when the bulk matrix is subjected to a deformation \(\bigtriangleup L \). Thus, the residual surface strain induced by the surface effect is defined by

where \(L_0 \) and L are the square of length in the free body and in the free surface, respectively. After deformation, the volumetric strain and the surface strain of solid matrix can be, respectively, expressed as follows

By using Taylor expansion and after some simple calculations, the surface strain is rewritten as

It should be noted that the quadratic and higher-order terms of volumetric strain can be ignored under infinitesimal deformation conditions. The relation between the volumetric strain of solid matrix and the volumetric dilation reads [8]

Again recalling the formulation of surface strain \(\varepsilon _s=\ln ({A}/{A_0}) \), combining Eqs. (20) and (21), the specific surface area that is a function of volumetric strain and porosity can be read as

Consequently, the first-order and second-order derivatives of specific surface area A with respect to volumetric strain \(\epsilon \) and porosity change \(\varphi \) are denoted by

To gain the solution of the differential governing equations (Eqs. 8, 9), there could be three kinds of boundary conditions imposed on them.

(1) The first one is that the porous material is placed in a container filled with gas at bulk pressure, which results in the corresponding volumetric stress \(\sigma =-p_b \). The differential forms of Eqs. (8) and (9) is thus given by

where \(B_{11}=\sigma _s\frac{\partial ^2A}{\partial \epsilon ^2}+M\left( \frac{\partial A}{\partial \epsilon }\right) ^2 \), \(B_{12}=B_{21}=\sigma _s\frac{\partial ^2A}{\partial \epsilon \partial \varphi }+M\frac{\partial A}{\partial \epsilon }\frac{\partial A}{\partial \varphi } \) and \(B_{22}=\sigma _s\frac{\partial ^2A}{\partial \varphi ^2}+M\left( \frac{\partial A}{\partial \varphi }\right) ^2 \), in which \(M=\frac{1}{A}\big (\frac{{\mathrm {d}}\gamma _{sf}}{{\mathrm {d}}\varepsilon _s}+\frac{{\mathrm {d}}^2\gamma _{sf}}{{\mathrm {d}}\varepsilon _s^2}\big ) \), is an intermediate variable similar to specific surface energy. Solving Eqs. (27) and (28) gives,

(2) The second one is that the confined pressure keeps constant during the deformation process so that the volumetric stress of porous material is given by \(\sigma =-p_c={\mathrm {constant}} \), which leads to the corresponding differential form as follows

It is readily derived from Eqs. (31) and (32) as follows

(3) The last one is that the displacement of porous material is confined so that the volumetric strain is constantly maintained, in which the differential forms are as follows

It should be emphasized that Eqs. (29), (30), (33), (34), (35), and (36) are the general formulations of the differential forms of microporous elasticity under three different boundary conditions, in which both the surface stress induced by adsorption is taken into account and the general pore pressure in Eq. (1) is employed. In general, Eqs. (29) and (30) can be used to predict the adsorption-induced swelling behavior of porous material along with the increasing bulk pressure, whereas Eqs. (33) and (34) can be to properly characterize the evolution of porosity of porous material induced by adsorption under confined pressure conditions. The latter could be better used to derive the change of adsorption-induced permeability which is only assumed to be a function of porosity change. In the following, the surface stress will be detailed via the Langmuir isothermal adsorption.

2.3 Surface stress associated with gas adsorption

As common thread with [43], the Gurtin–Murdoch theory is applied to spherical particles so as to obtain the free energy of the isotropic solid particles [13, 14]

where \(\gamma _s^0 \) is the free energy of interface for a stress-free solid matrix and \(\mu _s \) and \(\lambda _s \) are the elastic constants of solid surface. The surface free energy of the gas–solid interface can be understood by splitting it into two parts. First of all, unit areas of solid and gas are created and the corresponding surface free energies of solid and gas are denoted by \(\gamma _s \) and \(\gamma _f \), respectively. Then, the solid and gas are brought into contact, and the work of adhesion interacted solid–gas is expressed as \(-W_{sf} \). As a result, the surface free energy of the gas–solid interface is as follows [15]

To simplify the calculation for the swelling of porous material induced by adsorption, it is assumed here that \(\gamma _s \) and \(W_{sf} \) are independent of the surface strain \(\varepsilon _s \). Again recalling the above-mentioned definition of \(M=\frac{1}{A}\big (\frac{{\mathrm {d}}\gamma _{sf}}{{\mathrm {d}}\varepsilon _s}+\frac{{\mathrm {d}}^2\gamma _{sf}}{{\mathrm {d}}\varepsilon _s^2}\big ) \), the corresponding explicit expression can thus be denoted by

By substituting Eqs. (37) and (38) into Eq. (16), the surface stress can be expressed as

where \(\sigma _{s0}=\gamma _s+{{\mathrm {d}}\gamma _s}/{{\mathrm {d}}\varepsilon _s} \) is the solid surface stress when the solid contacts with vacuum. If there is no any gas adsorbed on the solid–gas interface, the term \(\gamma _f-W_{sf} \) should be a constant. However, once the gas adsorption occurs, the interface free energy between solid and gas should be modified by the adsorbed gas (adsorbate), which concentrates at the solid surface. The corresponding governing equations are given by the Gibbs’ isothermal adsorption formulae

where \(N_s \) is the number of moles of the surface gas excess, \(\mu \) the molar chemical potential of the gas, \(A_t \) the total pore surface area. Similarly, if it is assumed that the free energy of solid surface \(\gamma _s \) does not depend upon the molar chemical potential of the gas \(\mu \), Eq. (41) is rearranged as

By substituting Eq. (42) in Eq. (40), the solid surface stress is represented by

Considered the thermodynamic system with the adsorption force field, the chemical potentials of bulk and adsorbed gas are identified, and the Gibbs–Duhem relations for the bulk adsorbed gas are \({\hbox {d}}\mu =\overline{V}_b{\hbox {d}}p_b \) and \({\hbox {d}}\mu =\overline{V}_a{\hbox {d}}p_a \), respectively, under isothermal conditions. Thus, Eq. (43) can be rewritten as

where \(\overline{V}_b \) and \(\overline{V}_a \) are the molar volume of bulk gas and adsorbed gas, respectively. It should be noted here that Eq. (44a) is often used for the following calculation instead of Eq. (44b) due to the fact that the molar volume of adsorbed gas is difficultly determined. As it is one of the simplest models used to characterize for the monolayer gas adsorption in porous media, the Langmuir isothermal adsorption equation herein is employed to rewrite Eq. (44), which leads to the corresponding governing equation as follows

where B(T) is the Langmuir constant under isothermal conditions. The actual number of gas molecules per unit area adsorbed at the pore surface \(\Gamma \) is expressed as

where \(\Gamma ^m \) is the maximum number of gas molecules per unit area under isothermal conditions. By substituting Eq. (46) in Eq. (44), the surface stress is finally presented by

Without losing generality, the molar volume of the bulk gas governed by the state equation is a function of bulk gas pressure under isothermal conditions. If the gas is ideal, Eq. (47) can be integrated by

3 Permeability change of coal induced by adsorption swelling

The transport capacity of gases or fluid within the connected pores of porous material is permeability, whose driving force is either a concentration gradient or a pressure gradient [42]. The determination of permeability requires for the knowledge of the pore-size distribution in the porous material, the mechanical properties of solid matrix, and the physicochemical properties of gas. In this study, as did by [31], it is assumed that the ratio of the current permeability to the initial one is equal to the cubic ratio of the current porosity to the initial porosity

where \(k_0 \) is the initial permeability.

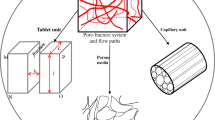

Let coal be a dual porosity structure as shown in Fig. 2a. If it is assumed that the porous structure is only composed by micropores and solid matrix (identical circular in 2D), the matrix permeability under confined pressure conditions is independent of the swelling, which indicates that the permeability keeps a constant in this case. This point could be proved in the following manner. As indicated in Fig. 2b, if the confined pressure \(p_c\) imposed on the porous material is prescribed in the 2D space, then the deformation of solid matrix is only induced by adsorption. The porosity in the reference configuration is read as

In the current configuration, the porosity is

By substituting Eqs. (50) and (51) in Eq. (49), it is readily concluded that \(k/k_0=1 \) is generally corresponding to a free expansion system, which is what we expect. Definitely, this point is also suitable in 3D space, but only after providing that the solid matrix is identical sphere. If other geometries are considered, strong nonlinear effects have to be taken into account. This point is readily identified from Eq. (49), even though it has been simplified considerably. To general geometries of pores, it should be noted that the adsorption-induced swelling of coal matrix generally has a significant effect on the permeability change of coal under confined pressure conditions due to its dual porosity. The adsorption mainly occurring in micropores induces the macroporosity change, which in turn results in the permeability change of the coal. Moreover, the increase in confined pressure also decreases the macroporosity of coal. Substituting Eq. (34) in the differential form of Eq. (49) and recalling that the porosity in the current configuration is defined as \(\phi =\varphi +\phi _0 \), we finally obtain the general differential form of permeability change under confined pressure conditions

It is apparently observed from Eq. (52) that the relation between porosity and bulk pressure is of strong nonlinearity, which is usually solved in terms of numerical methods rather than analytical forms. In the following numerical example, the surface stress is associated with the van der Waals equation of state at per mole of gas, which reads

where a and \(b_v\) are constants closely associated with the properties of gas. Eq. (53) can be transformed into Eq. (54), which is solved by the Cardanos method [5]

where \(A=\Big (\big (\frac{b_vp_b+RT}{3p_b}\big )^3-\frac{a(b_vp_b+RT)}{6p_b^2}+\frac{ab_v}{2p_b}+\sqrt{Q}\Big )^\frac{1}{3} \), \(B=\Big (\big (\frac{b_vp_b+RT}{3p_b}\big )^3-\frac{a(b_vp_b+RT)}{6p_b^2}+\frac{ab_v}{2p_b}-\sqrt{Q}\Big )^\frac{1}{3} \), and \(Q=\Big (-\frac{(b_vp_b+RT)^2}{9p_b^2}+\frac{a}{3p_b}\Big )^3+\Big (-\big (\frac{b_vp_b+RT}{3p_b}\big )^3+\frac{a(b_vp_b+RT)}{6p_b^2}-\frac{ab_v}{2p_b}\Big )^2 \).

Combined with van der Waals equation of state, the scheme of numerical algorithms for the model is implemented by the Runge–Kutta method in Sect. 4. The simulations by the model are presented and analyzed as well as compared with the experimental data of coal permeability change in the literature.

4 Numerical examples

4.1 Parameters

In the present study, the specific pore surface area of Anderson 01 is assumed to be measured by mercury porosimetry and the corresponding value is set to \(47.6\times 10^6\) m\(^{-1}\). The initial porosity of Anderson 01 \(\phi _0=1.31\) % is directly measured from experimental tests [32]. As a typical porous material, the bulk modulus of coal is generally about 1–3 GPa [41]. The bulk modulus and the Biot coefficient of Anderson 01 in the computation are \(K=2.0\) GPa and \(b=0.73\), respectively. The Biot modulus \(N=10.33\) GPa is obtained in terms of \(N=K/[(1-b)(b-\phi _0)] \). As examined the residual surface stress and strain of aluminum using Moire method by Wolfer [43], it is estimated that the residual surface stress and residual surface strain of coal matrix are 5.7 N/m and \(-\)0.067, respectively. It is noted that the negative residual surface strain as calculated previously indeed means that the coal surface tends to shrink in order to decrease the surface area and reduce the surface free energy. Additionally, the surface stretch modulus is assumed to be 68 N/m. The properties of Gilson 02 can be obtained like that of Anderson 01. These properties of the two samples are summarized in Table 1.

The constants are given by \(a=0.364\) m\(^6 \, \)Pa/mol\(^2\) and \(b_v=0.043\times 10^{-3}\) m\(^3\)/mol for CO\(_2\). The maximum number of adsorbed CO\(_2\) per unit area is \(2.76\times 10^{-5}\) mol/m\(^2\) and that of adsorbed CH\(_4\) per unit area \(1.39 \times 10^{-5}\) mol/m\(^2\) [39]. The Langmuir constants B for CO\(_2\) and CH\(_4\) are 0.26 and 0.16 MPa\(^{-1}\), respectively [32]. The saturation pressure of CO\(_2\) applied on the pore surface at 298 K is estimated to be \(p_0=16.5\times 10^6\) Pa and the gas constant is \(R=8.314\) J mol\(^{-1}\,\) K\(^{-1}\). The properties of CO\(_2\) and CH\(_4\) are summarized in Table 2.

To readily understand the implementation of the governing equations, Eqs. (33) and (34) (the second class of boundary conditions) can be rewritten as,

where \(\left\{ \begin{array}{l} f(p_b,\epsilon ,\varphi )=\frac{B_{12}-bN}{(B_{12}-bN)^2-(N+B_{22})(K+b^2N+B_{11})}\Big (1+\frac{{\mathrm {d}}p_a}{{\mathrm {d}}p_b}\Big )\\ g(p_b,\epsilon ,\varphi )=\frac{K+b^2N+B_{11}}{(N+B_{22})(K+b^2N+B_{11})-(B_{12}-bN)^2}\Big (1+\frac{{\mathrm {d}}p_a}{{\mathrm {d}}p_b}\Big ) \end{array} \right. \), \(p_{b0}\le p_b\le p_{bm} \). The differential equations (55) were calculated by the Runge–Kutta method [6], as shown in Box 1, in which the temperature of adsorption isotherm was fixed at 298 K with the initial bulk pressure 1\(\times \)10\(^5\) Pa.

4.2 Results and discussion

As indicated in Fig. 3, if the pore bulk pressure is relatively low (approximately lower than 3.5 MPa), it implies that the amount of adsorption-induced swelling of coal matrix is larger than that of pore bulk pressure-induced compression. The difference of such two deformations leads to the preference closure of fracture under constant confined pressure, which in turn accommodates to the decrease in permeability. However, the pore bulk pressure-induced compression is predominant along with the increasing pressure from 3.5 MPa, which finally enhances the permeability (Fig. 3a–c). It is very well known that the volumetric strain of coal matrix induced by CO\(_2\)-adsorption is larger than that induced by CH\(_4\)-adsorption due to the preferential adsorption properties of CO\(_2\) [39, 42]. This point is also supported by predicting the present model because, in Fig. 3a, b, the permeability change induced by CO\(_2\)-adsorption is more significant than that induced by CH\(_4\)-adsorption for the same coal sample. Moreover, it has been demonstrated in the literature that coal rank has a significant effect on permeability and porosity [42]. For example, since the coal ranks of Anderson and Gilson are sub-bituminous and high volatile, respectively [32], thus the permeability change induced by CO\(_2\) adsorption is more significant for low-rank coals (Fig. 3a, c). Particularly, the CH\(_4\) adsorption-induced permeability ratio is essential for high-rank coals (Fig. 3d). Comparing the predictions of the permeability ratio against the bulk pressure for the coal samples of Anderson 01 and Gilson 02 by Palmer and Mansoori, Shi and Durucan [27], and [35], simulations by the present model for adsorption-induced permeability change are in good agreement with the experimental data under a constant confined pressure of 1000 psi (6.897 MPa) by Robertson [32] and are much better than that predicted by the former two models. It should be re-emphasized that Shi–Durucan model and Palmer–Mansoori model are all phenomenal ones, whereas our model is supported by statistical physics so that the latter could be more reasonably used to explain the experimental results than the former.

Modeling of adsorption-induced permeability change under a constant confined pressure of 1000 psi (6.897 MPa) for a CO\(_2\) adsorption-induced permeability change of Anderson 01 coal, b CH\(_4\) adsorption-induced permeability change of Anderson 01 coal, c CO\(_2\) adsorption-induced permeability change of Gilson 02 coal, and d CH\(_4\) adsorption-induced permeability change of Gilson 02 coal (the predictions of permeability ratio in terms of Shi–Durucan model and Palmer–Mansoori model and the experimental data of permeability after [32])

In order to investigate the parameters listed in Tables 1 and 2 how to affect the deformation of porous material, we take only one parameter as a variable while the others are fixed. In Fig. 4, it is readily found that the bulk modulus K and Biot coefficient b play a key role in the characterization of permeability of the coals under coupled actions. Generally, Biot modulus N and van der Waals constants a and \(b_v\) have also significant effects on the simulations. As shown in Fig. 5, if the initial specific surface areas are less than approximately \(4.76\times 10^5\) m\(^{-1}\) (corresponding natural logarithm, 13.07) for Anderson 01 coal and \(9.5\times 10^4\) m\(^{-1}\) (corresponding natural logarithm, 11.46) for Gilson 02 coal, the numerical results for CH\(_4\) adsorption remain unchanging when the bulk pressure is fixed at 6.5 MPa. The reason for this is probably that macropores are in dominant in such two cases, and there is little adsorption occurring for them. When the initial specific surface areas are within the range of \(4.76\times 10^5\) m\(^{-1}\) to \(5.6\times 10^8\) m\(^{-1}\) (corresponding natural logarithm, 20.14) for Anderson 01 coal and of \(9.5\times 10^4\) m\(^{-1}\) to \(7.4\times 10^8\) m\(^{-1}\) (corresponding natural logarithm, 20.42) for Gilson 02 coal, the permeability ratio decreases with the increase in initial specific surface area, which implies that the adsorption-induced swelling is enhanced gradually. However, the influence of initial specific surface area on the permeability ratio is not obvious in these cases. The reasonable explain for these cases is that, compared with bulk modulus and Biot coefficient, the initial specific surface area does rarely influence the permeabilities. Once the initial specific surface area are larger than \(5.6\times 10^8\) m\(^{-1}\) for Anderson 01 coal and \(7.4\times 10^8\) m\(^{-1}\) for Gilson 02 coal, the permeabilities are also unchanging, which indicate that the gas adsorption is in saturated state when the bulk pressure is about 6.5 MPa. However, to the best of our knowledge, the assessment of the surface area and pore-size distribution of porous materials, particularly in micropores and mesopores, remains unsolved completely. For example, it was experimentally shown that the pore surface areas for different coals are of mostly rather different, and eventually, different test methods applied to the same coal also almost may provide the considerably different results of pore surface areas [23, 34]. Myers [24] and [28] believed that the surface area of micropores are ambiguous and undefined; thus, in their models, the surface area is bypassed to calculate the swelling ratio. But we believe that surface area is required from the viewpoint of surface energy of porous material, at least in our model (see Eq. 22), the initial specific surface area is still required. In addition, the Langmuir constant has less effect on the permeabilities. However, the numerical results of adsorption-induced permeability are strongly sensitive to the coefficients of pore pressure which are closely associated with the interactions between adsorbed gas and solid matrix. The best fits for the formulation of the adsorption or excess pore pressure (Eq. 3) are given in Table 3. It should be noted that if the physical parameters of coal and gas such as listed in Tables 1 and 2 are given in the present model, we could obtain the formulation of the adsorption or excess pore pressure, which can be further used to evaluate the permeability change induced by gas adsorption.

In Fig. 6, we present the relationship between pore pressure and bulk pressure by virtue of Eq. (2) to Anderson 01 and Gilson 02 coals under adsorption conditions. In these cases, except for Gilson 02 coal under CH\(_4\) adsorption conditions, all the pore pressures are negative when the bulk pressure is below 6 MPa, which arise from the swelling of solid matrix and the decrease in porosity that simultaneously induce the decrease in permeability. To Anderson 01 coal, the pore pressure approaches to maximum value, \(-\)11.6 MPa, when the bulk pressure of CO\(_2\) is about 3.4 MPa. From Fig. 6, it is readily found that because the relatively strong adsorption induced by CO\(_2\) and CH\(_4\) is prevailed in the two coals, the pore pressures are all larger or much larger than the corresponding bulk pressures. In fact, the pore pressure does not only influence the permeability, but also couples with the surface stress due to the gas–solid interactions.

5 Conclusions

We have proposed a theoretical micromechanical model of poroelasticity by virtue of statistical thermodynamics to evaluate the porosity change induced by gas (CO\(_2\) and CH\(_4\)) adsorption under confined pressure conditions. A general formulation of pore pressure that can be used to describe both the pore pressure in micropores and the bulk pressure on macropores was detailed from virial expansion in statistical physics. Computational model of permeability change induced by adsorption was correspondingly presented.

The differential micromechanical model of poroelasticity is based on the knowledge of micromechanics and statistical thermodynamics. When the relation between surface strain and volumetric strain of solid matrix was given under infinitesimal deformations conditions, the specific pore surface area with respect to volumetric strain and porosity was correspondingly obtained. By assuming that the ratio of current permeability to initial one was equal to the cube of ratio of current porosity to initial porosity, the differential equations for permeability change was also obtained.

The best fittings of the three coefficients of pore pressure for CO\(_2\) and CH\(_4\) adsorption-induced permeability change were obtained to Anderson 01 coal and Gilson 02 coal, respectively. The predictions of permeability change by the present model are in good agreement with the experimental data of the two coals and are much better than that of the other two models in the literature. The numerical results demonstrated that pore pressure plays a key role in the prediction of permeability change. The present model is a general form that can be applied to investigate any relevant permeability change where adsorption-induced deformation of solid matrix is significant.

Abbreviations

- \(\sigma \) :

-

Volumetric stress (Pa)

- \(\epsilon \) :

-

Volumetric strain of porous media (\(-\))

- \(s_{ij}\) :

-

Deviatoric stress tensor (Pa)

- \(e_{ij}\) :

-

Deviatoric strain tensor (\(-\))

- p :

-

Pore pressure (Pa)

- \(p_b\) :

-

Bulk pressure (Pa)

- \(p_a\) :

-

Adsorption pressure, \(p_a=p-p_b\) (Pa)

- \(\varphi \) :

-

Change of Lagrangian porosity (\(-\))

- \(\phi \) :

-

Porosity in the current configuration (\(-\))

- \(\phi _0\) :

-

Porosity in the reference configuration (\(-\))

- \(\sigma _s\) :

-

Surface stress (N/m)

- \(\sigma _{s0}\) :

-

Initial surface stress (N/m)

- \(\varepsilon _s \) :

-

Surface strain (\(-\))

- \(\varepsilon _0 \) :

-

Residual surface strain (\(-\))

- \(\epsilon ^s \) :

-

Volumetric strain of the solid matrix (\(-\))

- \(\overline{V}_b \) :

-

Molar volume of the bulk gas (m\(^3\)/mol)

- \(F_s \) :

-

Solid Helmholtz free energy per unit volume (J/m\(^3\))

- U :

-

Interface free energy per unit volume (J/m\(^3\))

- \(\gamma _{sf} \) :

-

Surface free energy of the solid–gas (J/m\(^2\))

- \(\gamma _s \) :

-

Surface free energy of solid (J/m\(^2\))

- \(\gamma _s^0 \) :

-

Initial surface free energy of solid (J/m\(^2\))

- \(\gamma _f \) :

-

Surface free energy of gas (J/m\(^2\))

- \(W_{sf} \) :

-

Work of adhesion interacted solid–gas (J/m\(^2\))

- \(\mu \) :

-

Molar chemical potential (J/mol)

- \(N_s \) :

-

Number of moles of surface amount excess

- A :

-

Actual pore area per unit volume (m\(^{-1}\))

- \(A_0 \) :

-

Initial pore area per unit volume (m\(^{-1}\))

- K :

-

Bulk modulus (Pa)

- b :

-

Biot coefficient (\(-\))

- N :

-

Biot modulus (Pa)

- G :

-

Shear modulus (Pa)

- \(\Gamma \) :

-

Amount of adsorption (mol/m\(^2\))

- \(\Gamma ^m \) :

-

Maximum amount of adsorption (mol/m\(^2\))

- B :

-

Langmuir constant (Pa\(^{1}\))

- \(\theta \) :

-

Fraction of surface covered (\(-\))

- \(\mu _s+\lambda _s \) :

-

Elastic constants of solid surface (N/m)

- R :

-

Gas constant (J mol\(^{-1}\,\) K\(^{-1}\))

- T :

-

Temperature (K)

- a :

-

Van der Waals constant (m\(^6 \,\)Pa/mol\(^2\))

- \(b_v \) :

-

Van der Waals constant (m\(^3\)/mol)

- \(c_1,c_2,\dots ,c_n \) :

-

Coefficients of pore pressure equation

References

Adamson, A.W., Gast, A.P.: Physical Chemistry of Surfaces. Wiley, Hoboken (1997)

Bear, J., Cheng, A.H.-D.: Modeling Groundwater Flow and Contaminant Transport. Springer, New York (2010)

Brochard, L., Vandamme, M., Pellenq, R.J.M.: Poromechanics of microporous material. J. Mech. Phys. Solids 60(4), 606–622 (2012a)

Brochard, L., Vandamme, M., Pellenq, R.J.M., Fen-Chong, T.: Adsorption-induced deformation of microporous materials: coal swelling induced by CO2-CH4 competitive adsorption. Langmuir 28(4), 2659–2670 (2012b)

Bronshtein, I.N., Semendyayev, K.A., Musiol, G., Muehlig, H.: Handbook of Mathematics, 5th edn. Springer, Berlin (2007)

Burden, R.L., Faires, J.D.: Numerical Analysis, 7th edn, pp. 315–316. Thomson Learning, London (2001)

Coussy, O.: Mechanics of Porous Continua. Wiley, Hoboken (1995)

Coussy, O.: Mechanics and Physics of Porous Solids. Wiley, Hoboken (2010)

Dunning, W.J.: Adsorption thermodynamics and the structure of crystal surfaces. J. Phys. Chem. 67(10), 2023–2029 (1963)

Gibbs, J.W.: The Collected Work of J. Willard Gibbs. Longmans, Green and Co., New York (1928)

Gor, G.Y., Neimark, A.V.: Adsorption-induced deformation of mesoporous solids. Langmuir 26(16), 13021–13027 (2010)

Gu, F., Chalaturnyk, J. J.: Analysis of coalbed methane production by reservoir and geomechanical coupling simulation. J. Canad. Petrol. Technol. 44(10), 33–42 (2005)

Gurtin, M.E., Murdoch, A.I.: A continuum theory of elastic material surfaces. Arch. Ration. Mech. Anal. 57(4), 291–323 (1975)

Gurtin, M.E., Murdoch, A.I.: Surface stress in solids. Int. J. Solids Struct. 14(6), 431–440 (1978)

Israelachvili, J.N.: Intermolecular and Surface Forces. Elsevier, Oxford (2011)

Karacan, C.O.: Swelling-induced volumetric strains internal to a stressed coal associated with CO\(_2\) sorption. Int. J. Coal Geol. 72(3–4), 209–220 (2007)

Karacan, C.O., Okandan, E.: Adsorption and gas transport in coal microstructure: investigation and evaluation by quantitative X-ray CT imaging. Fuel 80(4), 509–520 (2001)

Kowalczyk, P., Ciach, A., Neimark, A.V.: Adsorption-induced deformation of microporous carbons: pore size distribution effect. Langmuir 24(13), 6603–6608 (2008)

Larsen, J.W.: The effects of dissolved CO\(_2\) on coal structure and properties. Int. J. Coal Geol. 57(1), 63–70 (2004)

Landau, L.D., Lifshitz, E.M.: Statistical Physics. Pergamon, Oxford (1980)

Liu, J.S., Chen, Z.W., Elsworth, D., Miao, X.X., Mao, X.B.: Evaluation of stress-controlled coal swelling processes. Int. J. Coal Geol. 83(4), 446–455 (2010)

Mahajan, O.P.: CO2 surface area of coals: the 25-year paradox. Carbon 29(6), 735–742 (1991)

Meyers, R.A.: Coal Structure. Academic Press, New York (1982)

Myers, A.L.: Thermodynamics of adsorption in porous materials. AIChE J. 48(1), 145–160 (2002)

Neimark, A.V., Coudert, F.-X.: Stress-based model for the breathing of metal-organic frameworks. J. Phys. Chem. Lett. 1(1), 445–449 (2010)

Pijaudier-Cabot, G., Vermorel, R., Miqueu, C., Mendiboure, B.: Revisiting poromechanics in the context of microporous materials. C.R. Mech. 339(12), 770–778 (2011)

Palmer, I., Mansoori, J.: How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reserv Evalu Eng 1(6), 539–544 (1998)

Pan, Z.J., Connell, L.D.: A theoretical model for gas adsorption-induced coal swelling. Int. J. Coal Geol. 69(4), 243–252 (2007)

Parkash, S., Chakrabartty, S.K.: Microporosity in Alberta plains coals. Int. J. Coal Geol. 6(1), 55–70 (1986)

Pathria, R.K., Beale, P.D.: Statistical Mechanics, 3rd edn. Elsevier, Burlinton (2011)

Reiss, L.H.: The Reservoir Engineering Aspects of Fractured Formations. Gulf Publishing Company, Houston (1980)

Robertson, E.P.: Measurement and Modeling of Sorption-Induced Strain and Permeability Changes in Coal. Idaho National Laboratory, INL/EXT-06-11832 (2005)

Roque-Malherbe, R.M.A.: Adsorption and Diffusion in Nanoporous Materials. CRC PRESS, Boca Raton (2007)

Rouquerol, F., Rouquerol, J., Sing, K.S.W., Llewellyn, P., Maurin, G.: Adsorption by Powders and Porous Solids Principles, Methodology and Applications, 2nd edn. Elsevier, Oxford (2014)

Shi, J.Q., Durucan, S.: Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp. Porous Media 56(1), 1–16 (2004)

Shuttleworth, R.: The surface tension of solids. Proc. Phys. Soc. Sect. A 63, 444–457 (1950)

Ulm, F.-J.: Chemomechanics of concrete at finer scales. Mater. Struct. 36(7), 426–438 (2003)

van Bergen, F., Pagier, H., Krzystolik, P.: Field experiment of enhanced coalbed methane-CO\(_2\) in the upper Silesian basin of Poland. Environ. Geosci. 13(3), 201–224 (2006)

Vandamme, M., Brochard, L., Lecampion, B., Coussy, O.: Adsorption and strain: the CO2-induced swelling of coal. J. Mech. Phys. Solids 58(10), 1489–1505 (2010)

Vermorel, R., Pijaudier-Cabot, G.: Enhanced continuum poromechanics to account for adsorption induced swelling of saturated isotropic microporous materials. Eur. J. Mech. A/Solids 44, 148–156 (2014)

Wang, G.X., Massarotto, P., Rudolph, V.: An improved permeability model of coal for coal bed methane recovery and CO\(_2\) geosequestration. Int. J. Coal Geol. 77(1–2), 127–136 (2009)

White, C.M., Smith, D.H., Jones, K.L., Goodman, A.L., Jikich, S.A., LaCount, R.B., DuBose, S.B., Ozdemir, E., Morai, B.I., Schroeder, K.T.: Sequestration of carbon dioxide in coal with enhanced coalbed methane recovery-a review. Energy Fuels 19(3), 659–724 (2005)

Wolfer, W.G.: Elastic properties of surfaces on nanoparticles. Acta Mater. 59(20), 7736–7743 (2011)

Yang, K., Lu, X., Lin, Y., Neimark, A.V.: Deformation of coal induced by methane adsorption at geological conditions. Energy Fuels 24(11), 5964–5995 (2010)

Zhang, H., Liu, J., Elsworth, D.: How sorption-induced matrix deformation affects gas flow in coal seams: a new FE model. Int. J. Rock Mech. Mining Sci. 45(8), 1226–1236 (2008)

Acknowledgments

The financial supports from the National Science Foundation of China (Nos. 41172116, U1261212, and 51134005) are all gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C.J., Feng, J.L. Adsorption-induced permeability change of porous material: a micromechanical model and its applications. Arch Appl Mech 86, 465–481 (2016). https://doi.org/10.1007/s00419-015-1041-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-015-1041-4