Abstract

γ-Aminobutyric acid (GABA) is a non-protein amino acid with a variety of physiological functions. Recently, yeast Kluyveromyces marxianus strains involved in the catabolism and anabolism of GABA can be used as a microbial platform for GABA production. Okara, rich in nutrients, can be used as a low-cost fermentation substrate for the production of functional materials. This study first proved the advantages of the okara medium to produce GABA by K. marxianus C21 when l-glutamate (l-Glu) or monosodium glutamate (MSG) is the substrate. The highest production of GABA was obtained with 4.31 g/L at optimization condition of culture temperature 35 °C, fermentation time 60 h, and initial pH 4.0. Furthermore, adding peptone significantly increased the GABA production while glucose and vitamin B6 had no positive impact on GABA production. This research provided a powerful new strategy of GABA production by K. marxianus C21 fermentation and is expected to be widely utilized in the functional foods industry to increase GABA content for consumers as a daily supplement as suggested.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

γ-Aminobutyric acid (GABA) is a four-carbon non-protein amino acid, as an important inhibitory neurotransmitter, showing a variety of physiological activities [1], including anti-hypertensive [2], anti-insomnia, and anti-oxidant [3], anti-obesity [4] and immunity enhancement [5]. It is considered to be a functional ingredient in food [6] and pharmaceutical industries, so the application of GABA in various industries has led to a demand for efficient production.

GABA synthesis is the irreversible enzymatic decarboxylation of glutamate catalyzed by the glutamate decarboxylase (GAD), using 5'-pyridoxal phosphate (PLP) as a cofactor [7]. Although GABA was found in a variety of plants and animals, a larger number of microorganisms contribute to an important source of GABA. Many varieties of microorganisms were already found in fermented foods and beverages [8, 9] such as cheese [10], yogurt-sake [9], and fermented soybeans [11]. At present, lactic acid bacteria (LAB) [12], molds and yeasts are the most common strains as GABA producers [13], for example, Lactobacillus brevis RK03 [14], L. brevis TISTR 860 [15], Streptococcus thermophilus Hp [9], L. plantarum Taj-Apis362 [16], L. paracasei [17], Aspergillus oryzae [18], Pichia silvicola UL6-1 [19], etc. As a functional food additive, GABA should meet very strict safety requirements, it has recently been reported that GABA can be produced by yeast Kluyveromyces marxianus [20], which is characterized by fast growth, thermotolerance, broad substrate spectrum [21]. So the K. marxianus is generally regarded as a safe food or pharmaceutical processing material [22], what’s more it has been awarded QPS (Qualified Presumption of Safety) and GRAS status from the European Food Safety Authority (EFSA). The study [20] reported that 50 strains of K. marxianus isolated from different dairy products released a low amount of GABA, and the production only ranged from 2.54 to 7.33 μg/mL. Therefore, increasing the production of extracellular GABA remains to be explored. In addition, using low-cost substrates to obtain GABA to reduce production costs is a possible prospective strategy and okara (soybean residue) can be a good candidate substrate [23].

Okara, is a by-product, mainly from the production of tofu, soymilk and other soybean products, containing approximately 40–60% carbohydrates and 20–30% protein [24] with rich l-glutamate [25], providing necessary nutrients for the growth of specific microorganisms [26]. China is a major producer and largest consumer of soybeans, producing approximately 2.8 million tons of okara every year [24], and recycling a large amount of okara is an extremely important approach in soybean industries. Our previous studies showed that K. marxianus C21, which was isolated from Kefir grain, not only grew well in the okara matrix but also improved the function and physicochemical properties of okara [25, 27].

To further extend the quality of okara, in this study, we explored the ability of GABA production from okara by K. marxianus C21 fermentation, then optimized the fermentation process conditions for GABA production through single-factor experiments and response surface methodology (RSM) to increase GABA production in okara. This study will provide strong evidence for the add-value utilization of large-scale production from agricultural residues, such as okara.

Materials and methods

Materials and strain

Soybeans (HeiHe 43, Heilongjiang, China) were purchased from Shandong Shengfeng Seeds Co., Ltd. (Jining, Shandong, China). YPD, PDA culture medium, and peptone were purchased from AoBoXing Biotechnology (Beijing, China). Glucose and vitamin B6 were purchased from Beijing Chemical Works (Beijing, China). l-Glutamate (l-Glu) was purchased from Shanghai Chemical Industry Park (Shanghai, China). Monosodium glutamate (MSG) was purchased from China Huishi biochemical reagent Co., Ltd (Shanghai, China). Commercial LAB starter including S. thermophilus, L. bulgaricus, Bifidobacterium infantis, B. lactis, B. longum, B. breve, and B. bifidum was purchased from Qingdao Kemason Food Technology Co., Ltd. Yeast of K. marxianus C21 isolated from Kefir grain [28] was preserved by the Chinese Microbe Preservation Management Committee (CGMCC, No. 13907, Beijing, China).

Preparation of okara

According to the method described by our previous study [25]. raw soybeans were soaked in tap water at a ratio of 1:5 (w/v) for 8–12 h and then ground with water (80 °C) at a low speed for 3 min using a soymilk machine (JYL-Y20, Joyang Co., Ltd., Shandong, China) at a ratio of 1:9 (w/v). The slurry was filtered through a 60-mesh sieve to obtain the fresh okara. The fresh okara was then sterilized at 121 °C for 20 min in a vertical pressure steam sterilization pot (YXQ-S-50A, Shanghai Boxun Enterprise Co., Ltd., Shanghai, China).

Culture of K. marxianus C21

For seed cultures, strain K. marxianus C21 was grown in YPD medium and was incubated at 30 °C in an incubator shaker (ZHWY-1120, Shanghai Zhicheng analytical instrument Co., Ltd, Shanghai, China) at 120 rpm for 12 h. After incubation, the suspension was centrifuged at 5500 rpm and 4 °C for 5 min (3k15, Sigma, Berlin, Germany). The centrifuged yeast was washed with sterile water three times, resuspended [25] and adjusted to 107 cfu/mL as a fermentation starter.

GABA production in okara

Okara soaked in distilled water at a ratio of 1:5 (w/v) with 34 mM l-Glu or MSG was placed in a 250-mL Erlenmeyer flask, sterilized at 121 °C for 20 min and cooled to room temperature. 10% (v/v) K. marxianus C21 and 0.1% (w/v) commercial LAB starter were added separately or 5% (v/v) K. marxianus C21 and 0.05% LAB (w/v) were mixed to the okara, and they were fermented for 60 h under aerobic conditions. The GABA content in the supernatant was measured after centrifugation at 12,000 rpm for 10 min.

Optimization of fermentation conditions of GABA production by K. marxianus C21 in okara medium

Single-factor experiments

Kluyveromyces marxianus C21 was the fermentation strain; single-factor experiment was performed to study the influence of the following six factors: initial pH, culture temperature, fermentation time, inoculum level, rotation speed, and l-Glu amount, on the production of GABA. The optimization conditions of the single factor experiment included initial pH (3.0, 3.5, 4.0, 4.5 and 5.0), culture temperature (20, 25, 30, 35 and 40 °C), fermentation time (24, 48, 60, 72 and 96 h), inoculum level (8, 9, 10, 11 and 12%), rotation speed (60, 90, 120, 150 and 180 rpm) and l-Glu amount (7, 20, 34, 48 and 61 mM). Then, the production of GABA was analyzed. Each experiment was repeated in triplicate.

Response surface methodology (RSM)

By analyzing and processing the results of the single-factor experiment, the temperature, initial pH, and fermentation time were selected for RSM experiment based on a Box–Behnken center combination design (DTD) [29], and the production of GABA as the response values. The factors and levels of the research design are shown in Table 1.

Qualitative and quantitive of GABA

TLC analysis

Thin-layer chromatography with a silica gel plate (10 × 10 cm) (Qingdao, China) was used for the qualitative analysis of GABA. The method was described by Cho et al. [30] with slight modifications. An aliquot (4 μL) of the fermentation supernatant was loaded onto a silica gel plate. Using a mixture of n-butanol: acetic acid: distilled water (3:1:2, v/v/v) as the developing solvents. The plate was used 2 g/L ninhydrin solution as a colorant and then the color was developed in the oven at 100 °C.

Colorimetric method

GABA content was determined according to the method of Chi et al. [31] with minor modifications. The suspension was centrifuged at 12,000 rpm for 10 min. 200 μL of the supernatant was reacted with 400 μL borate buffer (pH 9), 200 μL phenol (6%, w/v) and 1 mL sodium hypochlorite (10%, v/v) and allowd tostand for about 3 min and then for 10 min in hot water (98 °C) and immediately put into an ice bath for 10 min. Finally, 4 mL alcohol (60%, v/v) was added to each sample, and absorbance was measured at 645 nm. The standard curve of GABA was drawn in the same way as above described. The absorbance of the sample to be measured was substituted into the standard curve to convert the GABA production.

Cell biomass

The effects of different culture media on the growth of cells were determined by the plate enumeration method on YPD agar. The method was described by Marino et al. [32] with slight modifications. The fermentation microbial suspension was serially diluted with 0.85% (w/v) saline; 100 μL of microorganism suspensions were plated on YPD agar at 37 °C for 48 h to count the yeast colony.

Statistical analysis

Microsoft Excel 2010 software was used to draw the standard curve of the test data. GraphPad Prism 7 software was used to draw the test curve, and SPSS 20 software (SPSS Inc., Chicago, IL, USA) was used to analyze the significant differences. The difference was considered to be significant when p < 0.05 using Duncan's multiple range test. Design expert 8.0.6 software (STAT-EASE Inc., MN, USA) was used to design, optimize, and analyze the response surface.

Results and discussion

Yeast K. marxianus C21 effectively produced GABA during okara fermentation

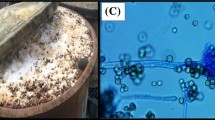

First, the feasibility of GABA production by K. marxianus C21 in okara was particularly analyzed. l-Glu or MSG was used as substrates separately to compare the converting ability of GABA by K. marxianus C21 in okara fermentation as well as LAB. Surprising results were that K. marxianus C21 effectively converted GABA from both of l-Glu or MSG while LAB has almost no GABA production in the okara matrix. And when K. marxianus C21 ferments with LAB, no significant difference in GABA production was observed compared with only K. marxianus C21 fermentation, which shows that the dominance of K. marxianus C21 in okara environment to produce GABA (Fig. 1a and b).We have observed that the LAB we used did not have a conversion effect in okara, but many studies reported that the LAB isolated from other environments was GABA-producer, such as Linares et al. reported the use of S. thermophilus APC151 strain, isolated from the digestive tract of fish, for production of GABA [33], Gangaraju et al. confirmed the highest production of GABA (37 mM) in TYG medium by L. bulgaricus CFR 2028 [34], and Yunes et al. confirmed the most efficient GABA-producers were Bifidobacterium strains (up to 6 g/L) [35], which may be due to the different metabolic abilities of the same LAB species isolated from different environments in different media. However, whether the LAB we used has the ability of GABA production in other media or other LABs have the ability to produce GABA in okara, was not mentioned in this paper and remains to be verified. Considering the specific substrate, the production of l-Glu was higher than that of MSG, indicating that l-Glu was more appropriate for K. marxianus C21 to produce GABA in the okara matrix (Fig. 1a and b). Furthermore, the ability of K. marxianus C21 to produce GABA was measured under different kinds of media and the results showed that K. marxianus C21 in the medium of okara, YPD and PDA effectively produced GABA (Fig. 1c and d). Compared with okara, more free amino acids were detected in YPD and PDA medium. This will inevitably lead to the difficulty and recovery of GABA in the future. The strain of K. marxianus C21 used in this study was not only a high β-glucosidase-producing yeast [28] but also confirmed a great secretion of β-glucosidase in okara fermentation. An interesting study showed that date residue treated with carbohydrate-degrading enzymes was greatly increased GABA production by L. brevis JCM 1059T fermentation, but the reason also remains unknown [36]. It is speculated that the K. marxianus C21 has a high GABA production capacity, which may also be related to the expression ability of β-glucosidase or the degradation products of β-glucosidase, and further research is needed. Overall, K. marxianus C21 isolated from Kefir grain in dairy products showed a wide range of ability to produce extracellular GABA without restriction by culture medium, regardless of Glu or MSG as substrate and the mechanism remains to be explored.

Establishment a quantitative method for GABA in okara

There are many quantitative methods for GABA, such as radioreceptor (RRA) [37], high-performance liquid chromatography (HPLC) [38], and colorimetry [31, 39]. The detection of GABA by using HPLC can be relatively accurate and usually used in many GABA studies, but it requires sample derivatization and does not meet for a large number of GABA detection [38]. Colorimetric determination of GABA is based on Berthelot reaction using phenol and sodium hypochlorite to react with ω-amino acids to generate colored substances to determine trace amounts of ammonia and its salts in different systems, with extremely high sensitivity [39]. It is suitable for the detection of GABA in fermentation broth matrices because it is fast, valuable, and cost-effective, and there was no significant difference between the Berthelot colorimetric and the HPLC [40]. To determine the influence of the composition in the determination of GABA in K. marxianus C21 fermented okara solution, the standard curves of GABA in water and okara were established, respectively (Fig. 2). The results showed that the l-Glu did not interfere with the determination of GABA either in water nor okara solution. The R2 in water was 0.9997 (Fig. 2a) while 0.9950 in okara fermentation broth (Fig. 2b) indicating that the colorimetric method can be used for precise quantification of GABA in the okara fermentation broth.

Effect of different culture media on cell biomass and GABA production by K. marxianus C21

To further determine the advantages of okara medium in producing GABA, PDA and YPD medium were used to compare the biomass and GABA production by K. marxianus C21 (Fig. 3). The results showed that GABA production reached the highest point when the fermentation time was 60 h in media. At this time 2.14 g/L of GABA in okara (Fig. 3a), 2.54 g/L in YPD (Fig. 3b), and 1.28 g/L in PDA (Fig. 3c) were obtained, respectively. The amount of GABA produced by K. marxianus C21 in YPD was much higher than that reported by Perpetuini et al. [20]. This may be due to differences in strains, culture temperature, and substrates. In this study, l-Glu was used as a substrate for optimization experiments. Perpetuini et al. [20] used MSG as a substrate, and the amounts of the two substrates were different. The interesting thing is that the biomass in the PDA medium is higher (8.17 log cfu/mL) than that of okara (8.05 log cfu/mL) and YPD (8.02 log cfu/mL). These data indicated that there was no direct relationship between biomass and GABA production similar to observation reported by LAB fermentation [41]. To be sure, although the production of GABA in okara was slightly lower than that in YPD medium, okara is undoubtedly a feasible substrate for the production of GABA in terms of economic costs.

Effect of fermentation conditions for the production of GABA by K. marxianus C21 in okara medium

Continuously, the effect of fermentation conditions for GABA production in okara medium was carried out and the results are shown in Fig. 4. Compared with the different ranges of initial pH (3–5) in okara, the highest GABA was observed at pH 4 and the production was 3.94 g/L (Fig. 4a). A study has shown that the optimal conditions of fermenting microorganisms vary according to the different properties of GADs, with optimal pH ranging from pH 3.5–5.0 [12]. The highest GABA production was observed at 35 °C than other temperatures (20, 25, 30, and 40 °C), reaching values of 3.23 g/L (Fig. 4b). This may be related to the specific high-temperature resistance of K. marxianus C21 [42]. The initial pH and culture temperature were key factors for GABA production by strains because it not only influences the growth of microorganisms but also affects the GAD activity [43, 44].

The control of fermentation time also plays an important role in the production of GABA. The highest GABA production was detected at a fermentation time of 60 h at 30 °C and pH 5, after which the production was significantly reduced to only 63% of the highest production at 96 h (Fig. 4c). On the one hand, it may be due to the decreased metabolic capacity of microorganisms and GAD activity in the later fermentation period so that nutrients cannot continue to provide the growth of microorganism cells. On the other hand, it may be that the accumulated GABA was converted firstly to succinic semialdehyde (SSA) by GABA transaminase (GABA-T) and then to succinate (Suc) by succinic semialdehyde dehydrogenase (SSADH) [16].

The inoculum level is another important factor that directly affects the initial viable amounts of microorganisms in the fermentation broth, and the amounts of microorganisms in the fermentation broth directly affect the growth and metabolism of microorganisms [42], so it was necessary to investigate the inoculum level. It showed the enhancement of GABA concentration with increasing inoculum level from 8 to 11% (v/v), where the highest GABA (2.73 g/L) was obtained (Fig. 4d).

Rotation speed determines the oxygen flow of the medium, and yeast was aerobic microorganisms [42], so it was necessary to investigate the rotation speed. Figure 4e shows the enhancement of GABA concentration with increasing rotation speed from 60 to 120 rpm, where the highest GABA was obtained. This may be due to the increase in rotation speed that slowed down the aggregation of the yeast and increased the mass transfer rate of oxygen [45]. However, with the increase of rotating speed to 180 rpm, the production of GABA slowly decreased. It was supposed that the high rotational speed might have formed a certain shear force, which would cause certain damage to the cells, and the normal physiological metabolism could not be maintained. l-Glu was aimed to stimulate the production of GABA by GAD via the GABA shunt way. Increased concentration of GABA 3.84 g/L was obtained by K. marxianus C21 in okara supplemented with 20 mM of l-Glu (Fig. 4f). A further increase in l-Glu amount to 61 mM inhibited GABA production that high concentrations of l-Glu may inhibit the ability of yeast to produce GABA [16]. The conversion rate reached to 128%, which is due to the endogenous l-Glu from okara [41] and the generation of l-Glu from protease enzymatic okara in the yeast fermentation process [46] participated in the GABA conversion.

Optimization of fermentation conditions for the production of GABA by K. marxianus C21 in okara medium

RSM results

To model the fermentation process based on single variable optimization, the initial pH of 4, culture temperature of 35 °C, and fermentation time of 60 h were chosen as effective variable and the central point for response surface analysis as shown in Table 2. Quadratic multiple regression fitting was carried with the results of the Box–Behnken experimental design and a multiple quadratic response surface regression model was established. The obtained quadratic regression Eq. (1) was as follows:

where Y represents the GABA production, A represents the initial pH, B represents the culture temperature, C represents the fermentation time.

The results of ANOVA are shown in Table 3. The F test of the regression model presented high significance (p < 0.01), the R-squared was 96.52%, indicating that the fitting degree of this model was good, and only 3.48% of the variation could not be explained. The lack of fit was 0.2308 more than 0.05, which was non-significant. The Adeq Precision of this design was 15.846. It shows that the model can be used to predict the production of GABA.

RSM analysis of the best process parameters

The analysis charts were drawn using the linear regression equation fitted by the RSM, and the shape of the fitted response surface was examined to determine the optimal value of each factor. The RSM analysis diagrams are shown in Fig. 5. It could be seen from the 3D response surface diagrams that there was a good interaction between the culture temperature, initial pH, and fermentation time, and the effects of these three factors were all significant. By analyzing the obtained linear regression equation, it was found that there was a stable point, which was also the maximum point in this experiment. In the linear regression equation of the three significant impact factors for partial derivatives, respectively, the final results encompassed culture temperature 35 °C, initial pH 4.0, fermentation time 60 h. Under these optimized conditions, the GABA production reached a maximum of 4.50 g/L. To verify the reliability of the regression equation, under the optimized conditions, the production of GABA was 4.31 g/L, reaching 95.6% of the predicted value, and the phase pair error was only 4.4%, indicating that the established equation model had high accuracy. It is very noteworthy that the conversion of GABA under this condition is as high as 140%, which showed the strong potential of K. marxianus C21 to produce GABA in the okara medium.

The ability of GABA production varies with the strain and the substrate. A few studies showed that many yeasts produce limited amounts of GABA, such as P. silvicola UL6-1 showed a maximum GABA production of 136.5 μg/mL when it was cultured for 30 h at 30 °C in yeast extract-peptone-glucose medium [19]. The amount of GABA produced by P. guilliermondii 89-J-1 was 98.2 μg/mL. From the results of this study, K. marxianus C21 as a strain for producing GABA seems to be very suitable. A large number of studies showed that LAB was effective producers of GABA but the composition of the medium was not economical and practical compared with the okara medium. For example, Lactobacillus brevis BJ-20 [47] produced only 0.08 g/L of GABA during the fermentation of sea tangle extract and Lactobacillus plantarum Taj-Apis362 [16] produced 0.74 g/L of GABA in YPD medium. In contrast, high production of GABA of 44.47 mM (4.53 g/L) was reported in YPD medium with 10% red kidney beans by Lactobacillus brevis TISTR 860 [15] but it took a long time of 12 days. In general, the yeast of K. marxianus C21 produced above 4 g/L of GABA in okara medium (okara and l-Glu), a cost-effective substrate, just through 60 h of fermentation time. Convincing results have been obtained, that is the physicochemical and functional properties of K. marxianus C21 fermented okara have been significantly improved [47, 48]. Coupled with the high content of GABA, it can be fully believed that the okara-related products fermented by K. marxianus C21 can be better applied in the development of functional foods.

Effect of glucose, peptone, and vitamin B6 on GABA production at the optimal conditions

Many studies confirmed that the carbon source and nitrogen source in the medium have a significant impact on GABA production [47, 48] as well as a coenzyme of glutamate decarboxylase such as vitamin B6 [49]. Therefore, after optimization, 1% (w/v) glucose, 1% (w/v) peptone, and vitamin B6 were added to the okara medium to preliminary explore the effect on GABA production. It was found that both glucose and vitamin B6 could not further promote GABA production, but reduced GABA production. The good thing was peptone highly promoted the production of GABA by 18.6% than control (Fig. 6) indicating that the medium with sufficient nitrogen source had the greatest impact on the production of GABA. The similar phenomenon was reported by other researches [15, 50], such as during the fermentation of red kidney bean and barley grain by Lactobacillus brevis TISTR 860; there were no statistical differences in the maximal GABA production among the tested concentrations of glucose, while GABA production increased significantly according to the concentration of peptone [15]. Park et al. reported that the production of GABA using Lactobacillus plantarum with simple medium, when glucose was increased, was inhibited. Conversely, GABA production increased as the amount of yeast extract increased [50]. This provides a good direction for us to further efficiently produce GABA on the basis of a single-okara medium.

Conclusions

This study attempted to use K.marxianus C21 fermented okara to produce GABA which provides a prerequisite for the production of a novel GABA-enriched products. It was found that K. marxianus C21 could convert l-Glu or MSG to GABA in okara fermentation. The highest production (4.31 g/L) of GABA was displayed under optimized fermentation conditions by K. marxianus C21. Adding peptone had a significant positive impact on GABA production. How to utilize and regulate the nitrogen source and other inducers in the okara medium to further adjust the amount of GABA products added economically and effectively was worth exploring and developing.

References

Kostowski W, Hamon M (1999) Anti-anxiety activity—involvement of serotonergic and GABA-ergic activity. Eur Neuropsychopharmacol. https://doi.org/10.1016/S0924-977X(99)90095-0

Suwanmanon K, Hsieh P-C (2014) Effect of γ-aminobutyric acid and nattokinase-enriched fermented beans on the blood pressure of spontaneously hypertensive and normotensive Wistar–Kyoto rats. J Food Drug Anal 22:485–491. https://doi.org/10.1016/j.jfda.2014.03.005

Ren T, Zheng P, Zhang K, Liao J, Xiong F, Shen Q, Ma Y, Fang W, Zhu X (2021) Effects of GABA on the polyphenol accumulation and antioxidant activities in tea plants (Camellia sinensis L.) under heat-stress conditions. Plant Physiol Biochem 159:363–371. https://doi.org/10.1016/j.plaphy.2021.01.003

Ikegami R, Shimizu I, Sato T, Yoshida Y, Hayashi Y, Suda M, Katsuumi G, Li J, Wakasugi T, Minokoshi Y, Okamoto S, Hinoi E, Nielsen S, Jespersen NZ, Scheele C, Soga T, Minamino T (2018) Gamma-aminobutyric acid signaling in brown adipose tissue promotes systemic metabolic derangement in obesity. Cell Rep 24:2827-2837.e2825. https://doi.org/10.1016/j.celrep.2018.08.024

Nájera-Martínez M, López-Tapia BP, Aguilera-Alvarado GP, Madera-Sandoval RL, Sánchez-Nieto S, Giron-Pérez MI, Vega-López A (2020) Sub-basal increases of GABA enhance the synthesis of TNF-α, TGF-β, and IL-1β in the immune system organs of the Nile tilapia. J Neuroimmunol 348:577382. https://doi.org/10.1016/j.jneuroim.2020.577382

Diana M, Quílez J, Rafecas M (2014) Gamma-aminobutyric acid as a bioactive compound in foods: a review. J Funct Foods 10:407–420. https://doi.org/10.1016/j.jff.2014.07.004

Small PLC, Waterman SR (1998) Acid stress, anaerobiosis and gadCB: lessons from Lactococcus lactis and Escherichia coli. Trends Microbiol 6:214–216. https://doi.org/10.1016/S0966-842X(98)01285-2

Sahab NRM, Subroto E, Balia RL, Utama GL (2020) Gamma-Aminobutyric acid found in fermented foods and beverages: current trends. Heliyon 6:e05526. https://doi.org/10.1016/j.heliyon.2020.e05526

Ohmori T, Tahara M, Ohshima T (2018) Mechanism of gamma-aminobutyric acid (GABA) production by a lactic acid bacterium in yogurt-sake. Process Biochem 74:21–27. https://doi.org/10.1016/j.procbio.2018.08.030

Redruello B, Szwengiel A, Ladero V, del Rio B, Alvarez MA (2020) Identification of technological/metabolic/environmental profiles of cheeses with high GABA contents. LWT-Food Sci Technol 130:109603. https://doi.org/10.1016/j.lwt.2020.109603

Hwang CE, Kim SC, Kim DH, Lee HY, Suh HK, Cho KM, Lee JH (2021) Enhancement of isoflavone aglycone, amino acid, and CLA contents in fermented soybean yogurts using different strains: screening of antioxidant and digestive enzyme inhibition properties. Food Chem 340:128199

Cui Y, Miao K, Niyaphorn S, Qu X (2020) Production of gamma-aminobutyric acid from lactic acid bacteria: a systematic review. Int J Mol Sci. https://doi.org/10.3390/ijms21030995

Radhika Dhakal VKB, Baek K-H (2012) Production of GABA (γ-aminobutyric acid) by microorganisms: a review. Braz J Microbiol. https://doi.org/10.1590/s1517-83822012000400001

Hsueh YH, Liaw WC, Kuo JM, Deng CS, Wu CH (2017) Hydrogel film-immobilized Lactobacillus brevis RK03 for gamma-aminobutyric acid production. Int J Mol Sci. https://doi.org/10.3390/ijms18112324

Saraphanchotiwitthaya A, Sripalakit P (2018) Production of γ-aminobutyric acid from red kidney bean and barley grain fermentation by Lactobacillus brevis TISTR 860. Biocatal Agric Biotechnol 16:49–53. https://doi.org/10.1016/j.bcab.2018.07.016

Tajabadi N, Ebrahimpour A, Baradaran A, Rahim RA, Mahyudin NA, Manap MY, Bakar FA, Saari N (2015) Optimization of gamma-aminobutyric acid production by Lactobacillus plantarum Taj-Apis362 from honeybees. Molecules 20:6654–6669. https://doi.org/10.3390/molecules20046654

Komatsuzaki N, Shima J, Kawamoto S, Momose H, Kimura T (2005) Production of γ-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. Food Microbiol 22:497–504. https://doi.org/10.1016/j.fm.2005.01.002

Ando A, Nakamura T (2016) Prevention of GABA reduction during dough fermentation using a Baker’s yeast dal81 mutant. J Biosci Bioeng 122:441–445. https://doi.org/10.1016/j.jbiosc.2016.03.006

Han SM, Lee JS (2017) Production and its anti-hyperglycemic effects of gamma-aminobutyric acid from the wild yeast strain Pichia silvicola UL6-1 and Sporobolomyces carnicolor 402-JB-1. Mycobiology 45:199–203. https://doi.org/10.5941/MYCO.2017.45.3.199

Perpetuini G, Tittarelli F, Battistelli N, Suzzi G, Tofalo R (2020) Gamma-aminobutyric acid production by Kluyveromyces marxianus strains. J Appl Microbiol 129:1609–1619. https://doi.org/10.1111/jam.14736

Pentjuss A, Stalidzans E, Liepins J, Kokina A, Martynova J, Zikmanis P, Mozga I, Scherbaka R, Hartman H, Poolman MG, Fell DA, Vigants A (2017) Model-based biotechnological potential analysis of Kluyveromyces marxianus central metabolism. J Ind Microbiol Biotechnol 44:1177–1190. https://doi.org/10.1007/s10295-017-1946-8

Guneser O, Karagul-Yuceer Y, Wilkowska A, Kregiel D (2016) Volatile metabolites produced from agro-industrial wastes by Na-alginate entrapped Kluyveromyces marxianus Braz. J Microbiol 47(965):972. https://doi.org/10.1016/j.bjm.2016.07.018

Swallah MS, Fan H, Wang S, Yu H, Piao C (2021) Prebiotic impacts of soybean residue (okara) on Eubiosis/Dysbiosis condition of the gut and the possible effects on liver and kidney functions. Molecules. https://doi.org/10.3390/molecules26020326

Li B, Lu F, Nan H, Liu Y (2012) Isolation and structural characterisation of okara polysaccharides. Molecules 17:753–761. https://doi.org/10.3390/molecules17010753

Hu Y, Piao C, Chen Y, Zhou Y, Wang D, Yu H, Xu B (2019) Soybean residue (okara) fermentation with the yeast Kluyveromyces marxianus. Food Biosci 31:100439. https://doi.org/10.1016/j.fbio.2019.100439

Queiroz Santos VA, Nascimento CG, Schmidt CAP, Mantovani D, Dekker RFH, da Cunha MAA (2018) Solid-state fermentation of soybean okara: isoflavones biotransformation, antioxidant activity and enhancement of nutritional quality. LWT-Food Sci Technol 92:509–515. https://doi.org/10.1016/j.lwt.2018.02.067

Wang X, Zhang Y, Li Y, Yu H, Wang Y, Piao C (2020) Insoluble dietary fibre from okara (soybean residue) modified by yeast Kluyveromyces marxianus. LWT-Food Sci Technol 134:110252. https://doi.org/10.1016/j.lwt.2020.110252

Su Min PC, Yang Deok Chun, Qi Chu, Yuhua Wang, Shang Wang, Chen Yue HU, Yang Huo Yue (2018) Screening and identification of β-glucosidase-producing yeast and its application in the bioconversion of ginsenoside Rg3. Food Sci 39:172–178. https://doi.org/10.7506/spkx1002-6630-201814026

Wenyan Ma JZ, Shu L, Tan X, An Ya, Yang X, Wang D, Gao Q (2020) Optimization of spray drying conditions for the green manufacture of γ-aminobutyric acid-rich powder from Lactobacillus brevis fermentation broth. Biochem Eng J. https://doi.org/10.1016/j.bej.2020.107499

Cho YR, Chang JY, Chang HC (2007) Production of γ-aminobutyric acid (GABA) by Lactobacillus buchneri isolated from Kimchi and its neuroprotective effect on neuronal cells. J Microbiol Biotechnol 17:104–109. https://doi.org/10.1016/j.mimet.2006.07.012

Chi Z, Dai Y, Cao S, Wei Y, Shao X, Huang X, Xu F, Wang H (2021) Exogenous calcium chloride (CaCl2) promotes γ-aminobutyric acid (GABA) accumulation in fresh-cut pears. Postharvest Biol Technol 174:111446. https://doi.org/10.1016/j.postharvbio.2020.111446

Marino A, Bellinghieri V, Nostro A, Miceli N, Taviano MF, Guvenc A, Bisignano G (2010) In vitro effect of branch extracts of Juniperus species from Turkey on Staphylococcus aureus biofilm. FEMS Immunol Med Microbiol 59:470–476. https://doi.org/10.1111/j.1574-695X.2010.00705

Linares DM, O’Callaghan TF, O’Connor PM, Ross RP, Stanton C (2016) Streptococcus thermophilus APC151 strain is suitable for the manufacture of naturally GABA-enriched bioactive yogurt. Front Microbiol 7:1876. https://doi.org/10.3389/fmicb.2016.01876

Gangaraju D, Murty VR, Prapulla SG (2013) Probiotic-mediated biotransformation of monosodium glutamate to γ-aminobutyric acid: differential production in complex and minimal media and kinetic modelling. Ann Microbiol 64:229–237. https://doi.org/10.1007/s13213-013-0655-4

Yunes RA, Poluektova EU, Dyachkova MS, Klimina KM, Kovtun AS, Averina OV, Orlova VS, Danilenko VN (2016) GABA production and structure of gadB/gadC genes in Lactobacillus and Bifidobacterium strains from human microbiota. Anaerobe 42:197–204. https://doi.org/10.1016/j.anaerobe.2016.10.011

Hasegawa M, Yamane D, Funato K, Yoshida A, Sambongi Y (2018) Gamma-aminobutyric acid fermentation with date residue by a lactic acid bacterium, Lactobacillus brevis. J Biosci Bioeng 125:316–319. https://doi.org/10.1016/j.jbiosc.2017.10.003

Hamoudi Mousah PJaML (1987) The quantification of gamma-aminobutyric acid in the cerebrospinal fluid by a radioreceptorassay. Clin Chim Acta 170:151–160. https://doi.org/10.1016/0009-8981(87)90123-9

Kamisaki Y, Itoh T (1990) Determination of y-aminobutyric acid in human cerebrospinal fluid by isocratic high-performance liquid chromatography. J Chromatogr 529:417–423. https://doi.org/10.1016/S0378-4347(00)83848-7

Rayavarapu B, Tallapragada P, Usha MS (2019) Statistical optimization of γ-aminobutyric acid production by response surface methodology and artificial neural network models using Lactobacillus fermentum isolated from palm wine. Biocatal Agric Biotechnol 22:101362. https://doi.org/10.1016/j.bcab.2019.101362

Chaoyang Y, Xu L, Yuke M, Kaixuan J, Yuanxiu W (2020) Optimization of berthelot colorimetric method for determination of γ-aminobutyric acid. J Univ Jinan 34:306–312. https://doi.org/10.13349/j.cnki.jdxbn.2020.03.016. (In Chinese)

Le Hong P, Parmentier N, Le Trung T, Raes K (2021) Evaluation of using a combination of enzymatic hydrolysis and lactic acid fermentation for γ-aminobutyric acid production from soymilk. LWT-Food Sci Technol 142:111044. https://doi.org/10.1016/j.lwt.2021.111044

Karim A, Gerliani N, Aider M (2020) Kluyveromyces marxianus: an emerging yeast cell factory for applications in food and biotechnology. Int J Food Microbiol 333:108818. https://doi.org/10.1016/j.ijfoodmicro.2020.108818

Li H, Qiu T, Huang G, Cao Y (2010) Production of gamma-aminobutyric acid by Lactobacillus brevis NCL912 using fed-batch fermentation. Microb Cell Fact 9:85. https://doi.org/10.1186/1475-2859-9-85

Kim JY, Lee MY, Ji GE, Lee YS, Hwang KT (2009) Production of gamma-aminobutyric acid in black raspberry juice during fermentation by Lactobacillus brevis GABA100. Int J Food Microbiol 130:12–16. https://doi.org/10.1016/j.ijfoodmicro.2008.12.028

Long R, Yang W, Huang G (2020) Optimization of fermentation conditions for the production of epothilone B. Chem Biol Drug Des 96:768–772. https://doi.org/10.1111/cbdd.13682

Foukis A, Stergiou PY, Theodorou LG, Papagianni M, Papamichael EM (2012) Purification, kinetic characterization and properties of a novel thermo-tolerant extracellular protease from Kluyveromyces marxianus IFO 0288 with potential biotechnological interest. Bioresour Technol 123:214–220. https://doi.org/10.1016/j.biortech.2012.06.090

Kim D-H, Dasagrandhi C, Park S-K, Eom S-H, Huh M-K, Mok J-S, Kim Y-M (2018) Optimization of gamma-aminobutyric acid production using sea tangle extract by lactic acid bacterial fermentation. LWT-Food Sci Technol 90:636–642. https://doi.org/10.1016/j.lwt.2018.01.011

Li H, Qiu T, Gao D, Cao Y (2010) Medium optimization for production of gamma-aminobutyric acid by Lactobacillus brevis NCL912. Amino Acids 38:1439–1445. https://doi.org/10.1007/s00726-009-0355-3

Chen L, Alcazar J, Yang T, Lu Z, Lu Y (2018) Optimized cultural conditions of functional yogurt for gamma-aminobutyric acid augmentation using response surface methodology. J Dairy Sci 101:10685–10693. https://doi.org/10.3168/jds.2018-15391

Park SJ, Kim DH, Kang HJ, Shin M, Yang S-Y, Yang J, Jung YH (2021) Enhanced production of γ-aminobutyric acid (GABA) using Lactobacillus plantarum EJ2014 with simple medium composition. LWT-Food Sci Technol 137:110443. https://doi.org/10.1016/j.lwt.2020.110443

Acknowledgements

The authors are grateful to Jilin Province Innovation Center for Biological Food and Manufacturing Technology of China for their excellent technical assistance. Financial support was provided China Agriculture Research System of MOF and MARA (CARS-04) and Jilin Provincial Science and Technology Department (20170312022ZX).

Funding

China Agriculture Research System of MOF and MARAJilin Provincial Science and Technology Department 20170312022ZX.

Author information

Authors and Affiliations

Contributions

CP and HY designed the study; LZ, YY and WD acquired and analyzed the data; LZ, CP and XW drafted the manuscript; all authors critically revised the manuscript and approved the final version of the manuscript to be submitted.

Corresponding authors

Ethics declarations

Conflict of interest

We believe that this manuscript is appropriate for publication on bioprocess and biosystem engineering, because our research is aimed to investigate. On behalf of, and having obtained permission from all the authors, we declare that: (a) the material has not been published in whole or in part elsewhere, (b) the paper is not currently being considered for publication elsewhere, (c) all authors have been personally and actively involved in substantive work leading to the report, and will hold themselves jointly and individually responsible for its content, (d) all relevant ethical safeguards have been met in relation to subject protection, (e) all authors declare no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, L., Yue, Y., Wang, X. et al. Optimization of fermentation for γ-aminobutyric acid (GABA) production by yeast Kluyveromyces marxianus C21 in okara (soybean residue). Bioprocess Biosyst Eng 45, 1111–1123 (2022). https://doi.org/10.1007/s00449-022-02702-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-022-02702-2