Abstract

The Kluyveromyces marxianus yeast has been arousing great interest as a biocatalyst for biorefineries due to its ability to assimilate different sugars, in addition to its rapid growth, thermotolerance, and GRAS status. In this research, different sources of nutrients, such as rice bran and extracts of malt, yeast, and peptone, were evaluated for the cultivation of K. marxianus ATCC 36,907 aiming at ethanol production in submerged fermentations conducted in a batch system. Mineral supplementation of the medium was also evaluated. The best results of process performance for production, yield, and productivity in ethanol were obtained in the medium supplemented with rice bran extract, calcium chloride, and ammonium sulfate (25.50 g/L; Y(P/S) 0.49 g/g; QP 2.13 g/Lh), and the medium supplemented only with yeast-malt extract peptone (YMP) (24.88 g/L; Y(P/S) 0.50 g/g; QP 2.06 g/Lh), after 12 h of cultivation. Supplementation of the medium with malt extract without adding mineral salts also contributed to similar values of production and yield in ethanol after 24 h of cultivation (25.59 g/L; Y(P/S) 0.50 g/g; QP 1.16 g/Lh−1). The results revealed no need for mineral supplementation of the media added with YMP or malt extract for ethanol production by the yeast. On the other hand, rice bran extract, mainly associated with calcium chloride and ammonium sulfate, represents an excellent and inexpensive source of nutrients for this yeast and has the potential to replace traditional commercial supplements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rice is the second most consumed cereal in the world. According to data released by OECD-FAO [1], the average world production of rice between 2017 and 2019 was 515 million tons. For this, 164.9 million hectares were cropped, with an average yield of 3.12 t/ha. Over the next 10 years, global rice production is expected to increase by 66.8 million tons, reaching approximately 582 million tons in 2029 [1].

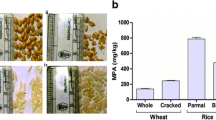

Rice bran consists primarily of the outer layers of brown rice that are removed during the milling process to produce polished rice. Rice bran is a source of nutrients such as vitamin A and B, tocopherols with vitamin E activity, 11–12% of protein, 12–15% of lipids, and 2,750 kcal/kg of metabolizable energy. It has been used as a source of low-cost nutrients in animal feed, mainly pigs and poultry [2, 3], as well as in the human diet [4].

Rice bran extract (RBE) proved to be an alternative supplement for the proliferation and the production of mammalian cells [5] and the cultivation of probiotic microorganisms [6] and bacterial cellulose synthesis by Acetobacter xylinum [7]. RBE was able to effectively replace yeast extract in ethanol fermentation by Saccharomyces cerevisiae, contributing to the sustainability of the ethanol industry by reducing costs for large-scale fermentation [8].

The potential of RBE as a culture medium supplement was also demonstrated in second-generation ethanol studies from cellulosic and hemicellulosic fractions. RBE was nutritionally as effective as corn steep during the simultaneous saccharification and fermentation (SSF) of rice straw with S. cerevisiae since it also increased the sugar concentration, thus improving the initial growth rate of the yeast and rapidly creating a stable SSF condition [9]. During the fermentation of sugarcane bagasse hemicellulosic hydrolysate, RBE was a promising alternative nitrogen source for yeast species such as Scheffersomyces shehatae, Spathaspora arborariae [10], and Scheffersomyces (Pichia) stipitis for ethanol production and Candida guilliermondii for xylitol production [11].

Kluyveromyces marxianus is a hemiascomycetous, homotallic yeast, widely known for its biotechnological potential due to traits such as thermotolerance, the fastest growth rate of any eukaryotic microbe, with a low doubling time of approximately 70 min [12]; wide intraspecific genetic diversity [13]; the capacity to assimilate a wide range of sugars such as sucrose, lactose, inulin, xylose, and xylose/glucose [14, 15]; and secretion of lytic enzymes, and the production of ethanol by fermentation from lactose [12, 16].

As a result of its long history of association with safe food and other products, it has achieved the status of GRAS (Generally Recognized As Safe) and QPS (qualified presumption of safety) in the USA and the European Union, which makes it a suitable yeast for the production of pharmaceutical and food-grade proteins [17].

Studies have shown that K. marxianus represents a novel candidate for second-generation ethanol production, mainly in SSF processes, due to its ability to grow and produce ethanol at temperatures above 40 °C [18, 19]. More recently, the genome sequencing of K. marxianus strains [20], in addition to transcriptomic analysis [20, 21] and evolutionary adaptation studies [22], have brought more profound knowledge about the potentialities of this non-conventional yeast, arousing interest in its use as a microbial cell factory for the production of substances of industrial interest. Considering that metabolomic data can more directly reflect the cellular metabolism than transcriptomic or proteomic data, a recent study has used untargeted metabolomic analysis to explore K. marxianus’s stress responses during high-temperature fermentation, thus providing rich information for further metabolic engineering towards improved stress tolerance and efficient bioethanol production [23]. To overcome the low ethanol tolerance in K. marxianus, a modified Monod model was designed, and it can contribute to the future application of this yeast in large-scale fermentations [24]. Moreover, advancements in synthetic biology, for example, the design of a set of promoters for controlling gene expression [25] as well as the CRISPR-Cas9 system (clustered regularly interspaced short palindromic repeats with Cas9)-mediated genome editing, will enable to develop an engineered yeast for the production of biochemicals and biopharmaceuticals having a myriad of industrial applications [26].

It is worth noting that malt extract (ME), yeast extract (YE), and peptone have been used to propagate yeasts and molds. Such materials are nutritionally rich supplements for the formulation of culture media, but they are relatively expensive. Malt extract contains a high concentration of carbohydrates, particularly maltose, and a complex mixture of peptides. Yeast extract provides carbonaceous compounds, sulfur, trace nutrients, and a complex mixture of peptides. Peptone provides nitrogenous and carbonaceous compounds, long-chain amino acids, and vitamins. However, there is no exact composition for these hydrolysates. The commercial products themselves do vary from one manufacturer to the other. Recently, the peptide content of a commercial YE was investigated by setting up a complete analytical workflow based on mass spectrometry (peptidomics), which allowed for the identification of around 4,600 different oligopeptides ranging from 6 to more than 30 amino acids in length [27].

Ammonium sulfate (AS) and di-ammonium phosphate (DAP) are mineral salts relevant to K. marxianus growth. AS and DAP act as supplementary nitrogen in protein anabolism and the gene expression of glycolytic and fermentative pathway components, favoring sugar conversion into ethanol by yeasts such as S. cerevisiae [28]. Calcium acts as a key cofactor in enzymatic reactions and a second messenger in several signal transduction pathways in eukaryotic cells [29].

Despite all the features mentioned above and the growing number of studies that promote K. marxianus as a promising industrial host for the biosynthesis of biofuels and other valuable chemicals, separately or in a biorefinery context, so far, there are no studies regarding the use of rice brain extract for second-generation ethanol production by K. marxianus. The few reports found in the literature reveal the use of rice bran solution (10% w/v) by K. marxianus to produce higher alcohols and acetate esters [30]. Thus, the present study proposed to evaluate the use of RBE as an economical and alternative nutrient source for the formulation of a medium to improve its fermentative performance.

2 Material and methods

2.1 Microorganism and inoculum cultivation

The experiments were conducted with the thermotolerant yeast Kluyveromyces marxianus ATCC 36,907, obtained from the Tropical Culture Collection (CCT) from the André Tosello Foundation. The culture was maintained in malt extract agar slants (30 g/L malt extract, 5.0 g/L mycological peptone, and 15 g/L agar), at 4 °C. The inoculum was grown in Erlenmeyer flasks of 250 mL, containing 100 mL of the YMP medium (10 g/L glucose, 3.0 g/L malt extract, 3.0 g/L yeast extract, and 5.0 g/L peptone). Cultivation was performed in a rotary incubator shaker (Marconi MA-420) at 200 rpm, temperature of 35 °C, for 16 h [31]. Then, the cells were centrifuged (Fanen 206 MP) at 2000 rpm for 20 min, washed with sterile distilled water, and after further centrifugation, resuspended in sterile distilled water to be used as inoculum at an initial cellular concentration of 1.0 g/L.

2.2 Rice bran extract (RBE) preparation and fermentation conditions

Rice bran was supplied by the food company Itasa Alimentos Ltda from Santa Tereza do Oeste, Paraná, Brazil. The concentrated water-soluble rice bran extract was prepared by mixing 200 g of rice bran with 1.0 L of 50 mmol/L sodium citrate buffer solution. The mixture was autoclaved at 110 °C (0.5 atm) for 15 min. Then, the solids were separated by centrifugation (Fanen 206 MP) at 2000 × g, 20 min, under sterile conditions, and the supernatant was stored at 4 °C before being used as a culture medium supplement.

To evaluate the effect of different nutrients on the metabolism of K. marxianus, the following media were prepared: non-supplemented medium (T1: 90 g/L glucose); medium supplemented with RBE (T2: 90 g/L glucose and 20 g/L RBE); medium supplemented with RBE plus mineral nutrients (T3: 90 g/L glucose, 20 g/L RBE, 0.1 g/L CaCl2 and 2.0 g/L (NH4)2SO4); medium supplemented with malt extract (T4: 90 g/L glucose and 3.0 g/L malt extract); medium supplemented with yeast extract (T5: 90 g/L glucose and 3.0 g/L yeast extract); medium supplemented with peptone (T6: 90 g/L glucose and 5.0 g/L peptone); and control-YMP medium (T7: 90 g/L glucose, 3.0 g/L malt extract, 3.0 g/L yeast extract, and 5.0 g/L peptone). All the media were prepared with 50 mmol/L sodium citrate buffer, pH 5.5, to avoid pH decrease due to the production of acetic acid by the yeast. The glucose concentration of 90 g/L was defined by Tavares et al. [32] as the optimal substrate concentration for K. marxianus ATCC 36,907.

The assays were performed in triplicate in Erlenmeyer flasks of 250 mL containing 100 mL of the culture media. The flasks were incubated in a rotary incubator shaker (Marconi MA-420) at 200 rpm, 40º C for 96 h [32]. Every 12 h, aliquots were taken to evaluate cell growth, glucose consumption, ethanol production, and by-products such as acetic acid and glycerol.

2.3 Analytic methods

The rice bran was characterized by determining moisture, crude protein, and lipid contents. Moisture was determined by weighing 5.0 g of rice bran (triplicate) with subsequent drying in an oven at 105 °C for 24 h. The samples were cooled in a desiccator for 30 min, re-weighed, and the moisture was determined by the difference of the weighing values recorded and expressed as a percentage [33].

Crude protein content was determined using the micro-Kjeldahl method (nitrogen-protein conversion factor of 6.25) and the lipids by the Soxhlet method [33].

Glucose, ethanol, acetic acid, and glycerol were measured by high-performance liquid chromatography (HPLC) on a Shimadzu LC-20A system equipped with a refractive index detector and column Phenomenex Rezex ROA-Organic Acid H + (8%) 150 × 7.8 mm, using H2SO4 0.005 mol/L as mobile phase, a flow rate 0.6 mL/min, 10 µL injection volume, and oven temperature of 65 °C [31]. The samples were filtered through polytetrafluoroethylene (PTFE) syringe filters (pore 0.45 μm, diameter 13 mm), and the mobile phase was vacuum filtered through hydrophilic polyvinylidene fluoride (PVDF) membrane (0.45 μm). The concentrations of the compounds were determined from curves obtained with high purity standards (98–99%).

The cellular concentration of the inoculum and during the fermentations were determined by spectrophotometry (Femto 700 Plus) by measuring the optical density (OD) at 600 nm and by converting values using a standard curve that correlated the OD600 nm values to the dry weight of cells grown in YMP medium (1 g cells/L 1:10 corresponded to OD600 nm 0.6).

2.4 Statistical analysis

Statistical analysis was performed using parametric analysis of variance tests (ANOVA) after checking the results’ normal distribution and the variance’s homoscedasticity. The Tukey post-test compared the groups, and the value set for statistical significance was p < 0.05.

3 Results and discussion

3.1 Chemical characterization of rice bran

The raw rice bran, as expected, presented a low moisture content (9.95%) and showed to be rich in minerals (9.87% mineral residue), lipids (17.24%), and crude protein (15.80%). These values corroborate those found by other authors concerning the moisture content (5.59–9.7%), lipids (13.43–20.79%), proteins (14–19.30%), and ashes (8.47–18%) [34, 35].

3.2 Effect of the nutritional conditions on glucose consumption, ethanol production, and cell growth

The profiles of glucose consumption, ethanol production, and cell growth observed in fermentations with the different nutritional media studied are shown in Figs. 1a, b, and c. Glucose (Fig. 1a) was fully consumed within 24 h in the treatment T3 (medium supplied with RBE and calcium chloride and ammonium sulfate), as well as in the treatment T7 (YMP medium). In treatments T2, T5, and T6, glucose was consumed within 36 h, whereas in treatment T4, this consumption was slower and remained around 10 g/L of residual glucose in the medium at the end of fermentation. As expected, in fermentations containing glucose (T1), the consumption was much slower, with a residual glucose content of 59.86 g/L after 96 h.

Glucose consumption, ethanol production and cell concentration during cultivation of K. marxianus ATCC 36,907 in the non-supplemented medium, T1 (♦); medium supplemented with RBE, T2 (■); medium supplemented with RBE, calcium chloride and ammonium sulfate, T3 (▲); medium supplemented with malt extract, T4 (x); medium supplemented with yeast extract, T5 (ӿ); medium supplemented with peptone, T6 (●); and control-YMP medium, T7 ( +)

Nitrogen is a necessary macroelement for synthesizing amino acids, the backbone of proteins, and therefore of enzymes vital for maintaining metabolism. Nitrogen availability also influences the kinetics of glucose assimilation due to the combined effect of different nitrogen and glucose concentrations on the expression of HXT transcripts in hexose uptake systems (HXT). The activity of hexose uptake systems has been considered an essential factor in limiting the activity of alcoholic fermentation in yeasts [36].

As illustrated in Fig. 1b, ethanol production occurred under all the cultivation conditions, being the maximum production (25.50 g/L) observed in the treatments T3 (glucose associated with RBE and minerals) and T7 (control-YMP medium: 24.88 g/L), both after 12 h. Similar ethanol production (25.59 g/L) was observed in the T2 treatment (medium based on glucose supplemented with RBE), however, in a longer fermentation time (24 h).

The medium containing only glucose (T1) presented the lowest ethanol production, on average 2.11 g/L. Likewise, lower ethanol concentrations were observed in the media based on glucose supplemented with malt extract (T4: 16.34 g/L), yeast extract (T5: 14.29 g/L), and peptone (T6: 16.51 g/L) compared to T3 and T7 fermentation conditions. These results indicate that RBE favors glucose consumption and ethanol production by K. marxianus ATCC 36,907, especially when supplemented with calcium chloride and ammonium sulfate, with results similar to those obtained in the YMP medium (T7).

In addition to the role of calcium as a cofactor in enzymatic reactions [29], mineral nutrients such as calcium have a protective effect at appropriate concentrations, contributing to the maintenance of the structural stability of the plasma membrane, acting in the maintenance of the permeability barrier in adverse conditions, as in the presence of ethanol [37]. Salts such as KCl/KOH are suggested to increase potassium uptake allowing an efficient proton efflux, increased membrane integrity, and strengthened membrane electrochemical potential. In K. marxianus Kmx24, supplementation of the culture medium with KCl/KOH (40/10 mM) resulted in more significant cell viability and greater tolerance to acetic acid, an inhibitor present in lignocellulosic biomass hydrolysates, with improved production of second-generation ethanol [38]. Ammonium sulfate, besides providing sulfur, is an inorganic nitrogen source easily assimilated by yeasts [39]. This nutrient is part of the structure of amino acids such as cysteine and methionine, essential for protein synthesis [40].

It is important to note that except in the T1 fermentation condition (Fig. 1b), ethanol concentration gradually decreased in the fermented media. It can be attributed to the consumption of ethanol as a carbon source by the yeast, presumably due to the depletion of glucose in the fermentation medium. Other authors, such as Tavares et al. [32], also reported ethanol consumption by this same K. marxianus strain during fermentation in semi-defined media. Similarly, Leonel et al. [41] verified the same phenomenon in fermentations with K. marxianus and C. guilliermondi FTI 20,037 grown in a medium based on apple pomace hemicellulosic hydrolysate after 72 h of fermentation. According to Mo et al. [22], two routes may exist for directly consuming ethanol in K. marxianus. One way is via cytoplasmic ADH6, which catalyzes ethanol to acetaldehyde, facilitated by NADP+. The other is mitochondrial ATF1, which promotes ethanol esterification with the aid of acetyl-CoA.

The effect of RBE as a nitrogen source was also evaluated with S. stipitis NRRL Y-7124 in sugarcane bagasse hemicellulosic hydrolysate. The medium supplemented with RBE plus ammonium sulfate and calcium chloride presented better results than the medium containing yeast extract and peptone, as well as the medium containing yeast extract, peptone, and malt extract, with maximum ethanol production of 8.6 g/L, 8.1 g/L, and 7.4 g/L, respectively [42].

Martiniano et al. [10] evaluated the potential of RBE for ethanol production by yeast strains isolated from Brazilian forests (Scheffersomyces shehatae CG8-8BY and Spathaspora arborariae UFMG-HM19.1A) and concluded that it is a promising nitrogen source to replace peptone and yeast extract. S. shehatae and S. arborariae, both in a fermentation medium consisting of sugarcane bagasse hemicellulosic hydrolysate supplemented with RBE, produced 17.0 g/L and 5.4 g/L of ethanol, respectively. In this context, when rice bran was evaluated as a cheap nutritional supplement for ethanol production by S. cerevisiae in fed-batch fermentation with simultaneous saccharification of rice straw, a high ethanol production (69.3 g/L) was found by Mochidzuki et al. [9].

Besides the carbon source, nitrogen is one of the essential nutrients for ethanol production, in addition to vitamins and trace elements necessary for yeast growth and metabolites production. Rice bran is rich in vitamins such as vitamin E, niacin, thiamin, and minerals such as calcium, phosphorus, potassium, and magnesium, among others [43], which may have contributed to better fermentation performance in fermentations containing RBE. As already mentioned, RBE, yeast and malt extracts, and peptone have a complex nutritional composition (yet chemically undefined) that varies according to the source and the manufacturing process. Identifying substances in complex media, especially the peptides diversity, is still a technically challenging step.

The growth profiles of K. marxianus ATCC 36,907 in the different media evaluated (T1 to T7) are shown in Fig. 1c. All treatments showed the same trend, with maximum growth observed between 12 and 24 h, coincident with the period of maximum ethanol production (Fig. 1b). A correlation between cell growth and ethanol production was already expected since ethanol is a primary metabolite.

Similar to that observed for glucose consumption and ethanol production, the highest cell concentration (9.11 g cell/L) was verified in the treatment T3 (supplemented with RBE, calcium chloride, and ammonium sulfate), followed by the treatment T7 (control-YMP medium, 7.05 g cell/L), and treatment T2 (supplemented with RBE, 7.03 g cell/L). On the other hand, a slight decrease in the growth of K. marxianus was observed between 48 and 72 h in the treatments T2, T4, and T7. Oda et al. [44] correlated the cell viability of K. marxianus with the amount of ethanol produced and found that cell viability decreased dramatically with ethanol accumulation in the medium.

The effect of RBE supplementation on yeast growth has been reported in several studies. S. shehatae CG8-8BY and S. arborariae UFMG-HM19 showed the highest cell growth (2.27 and 5.38 g/L, respectively, from the initial 0.5 g/L) when grown in sugarcane bagasse hemicellulosic hydrolysate supplemented with 20 g/L of RBE, 2.0 g/L of ammonia sulfate, and 0.1 g/L of calcium chloride [10]. In the same study, the authors reported that in a medium supplemented with 3.0 g/L of yeast extract, the growth of both yeasts was lower. In fermentations performed by Milessi et al. [42], the supplementation of sugarcane bagasse hydrolysate with 10% (v/v) of RBE, 0.1 g/L of calcium chloride, and 2.0 g/L of ammonium sulfate supported the growth of S. stipitis NRRL Y-7124 (12.8 g/L in 96 h from the initial 1.0 g/L). However, the highest cell concentration was obtained from the fermentation of the medium supplemented with yeast extract and/or peptone. Although microorganisms can assimilate different nitrogen sources, inorganic and organic, some may have preferences for one or the other, depending on their nutritional needs [45], which can vary between the species and strains [46]. For example, in fermentation using Lactobacillus plantarum, peptides with molecular weights in the range of 200–1,400 Da present in the oat extract and 100–700 Da in the malt extract were preferentially absorbed and utilized by the microorganism [47].

3.3 Effect of the nutritional conditions on by-products formation

The formation of by-products, such as acetic acid and glycerol, by K. marxianus in the different cultivation media was quantified and is depicted in Fig. 2a and b. The highest acetic acid production (9.54 g/L), which accounted for approximately 1/3 of ethanol production, occurred at 12 h in T3 treatment, coinciding with the highest cell growth and ethanol production rates. Similar performance was observed in the control treatment T7 (7.68 g/L), while in the other treatments, the maximum production occurred between 24 and 36 h, not undergoing subsequent variations.

Acetic acid and glycerol production during cultivation of K. marxianus ATCC 36,907 in the non-supplemented medium, T1 (♦); medium supplemented with RBE, T2 (■); medium supplemented with RBE, calcium chloride and ammonium sulfate, T3 (▲); medium supplemented with malt extract, T4 (x); medium supplemented with yeast extract, T5 (ӿ); medium supplemented with peptone, T6 (●); and control-YMP medium, T7 ( +)

The production of high levels of acetic acid is a common feature of K. marxianus species, occurring in the exponential growth phase [48]. This behavior has also been reported with the ATCC 36,907 strain, which produced 1.0–1.5 g/L of acetic acid when grown in a synthetic medium (90 g/L glucose) at 40 °C [32]; NBRC 1777 strain, with a maximum acetic acid concentration of 7.0 g/L when grown in YPD broth (500 g/L glucose continuously fed) under an anaerobic condition at 30 °C [49]; and IMB3 strain, with a maximum acetic acid concentration of 2.6 g/L in submerged fermentation with sugarcane bagasse 15% (w/v) at 45 °C [50].

A possible explanation for the high levels of acetic acid in K. marxianus is that the enzyme pyruvate decarboxylase has low activity. In contrast, acetaldehyde dehydrogenase and acetyl CoA synthetase have relatively high activity [51], which are enzymes involved in the production of acetate in situations of cytoplasmic redox imbalance since it is produced along with NADH and also when there is a need for cytoplasmic acetyl-CoA for biomass production [48].

Regarding glycerol production (Fig. 2b), the fermentations supplemented with RBE, T2, and T3, promoted the highest glycerol concentrations, 0.53 and 0.52 g/L at 12 h and 0.71 and 0.62 g/L at 96 h, respectively. Different from the observed for acetic acid, in some treatments, glycerol production did not coincide with the ethanol formation. Glycerol production was only observed after 36 h in the treatments T1 and T5 and after 48 h in T4.

Relatively higher concentrations of glycerol have been observed for K. marxianus. Camargo, Gomes, and Sene [31] verified the formation of up to 2.62 g/L of glycerol by this same strain, K. marxianus ATCC 36,907, in the SSF using sunflower bran, while Pessani et al. [52], using the IMB3 strain, observed glycerol concentrations of 2.4 and 3.2 g/L, with an increase in temperature from 37 to 45 °C, during the SSF of switchgrass.

As the acetic acid, glycerol is a by-product commonly formed by yeast species to maintain redox balance in response to stress conditions such as high temperature, presence of ethanol, and oxygen-limiting conditions [53]. In addition, its accumulation can occur in osmotic stress situations as an osmolyte, protecting cells against cell lysis [54].

3.4 Effect of the nutritional conditions on the fermentative parameters

The fermentative parameters maximum ethanol concentration, conversion factor of glucose to ethanol (YP/S, ethanol yield), conversion factor of glucose to cells (YX/S), volumetric ethanol productivity (QP), and volumetric cell productivity (QX) are shown in Table 1. The ethanol yield ranged from 0.28 to 0.50 g/g, and as expected, according to the ethanol production trend (Fig. 1b), the treatments T2 (medium supplemented with RBE), T3 (RBE plus mineral salts), and T7 (YMP medium) presented the highest values. There were no significant differences between them (p < 0.05), and these yields are very close to the theoretical yield (0.511 g/g) of ethanol from glucose. In these fermentation conditions, ethanol yield values (YP/S) of 0.50 g/g (T2, 24 h), 0.49 g/g (T3, 12 h), and 0.50 g/g (T7, 12 h) were found, respectively.

Similar to that observed with the ethanol yield, the highest ethanol volumetric productivity (QP) also occurred in the treatments T2 (1.16 g/L.h−1), T7 (2.06 g/L.h−1), and T3 (2.13 g/L.h−1). Treatment T3 showed a better result of volumetric productivity in ethanol in 12 h of cultivation, statistically differing (p < 0.05) from the other cultivation conditions. As expected, as it reflects the behavior of biomass production shown in Fig. 1c, the highest cell yield (YX/S) was observed in the treatment T3 (2.13 g/g at 12 h, p < 0.05), corresponding to a growth rate of 0.67 g/L.h−1. These values were followed by T7 (2.06 g/g) and T2 (1.16 g/g) at 12 h and 24 h of growth, respectively.

YMP medium at an initial glucose concentration of 90 g/L was also studied by Tavares et al. [32], which evaluated the effect of vacuum removal of ethanol on the fermentative performance of the same yeast strain in a bench bioreactor, using two 36 h sequential batches system. These authors reported lower values of yield and volumetric productivity in ethanol. Thus, our results indicate that RBE supplied the nutritional requirements of the strain ATCC 36,907, resulting in a better fermentative performance. The rice bran extract (RBE), mainly associated with calcium chloride and ammonium sulfate, is a viable and economical source of nutrients capable of favoring ethanol production by K. marxianus ATCC 36,907.

Table 2 presents an overview of the fermentative performance of several strains of K. marxianus cultivated in glucose media added with different nutritional supplements.

Table S1 (see Supplementary Table S1) shows the analysis of variance data (ANOVA) of the factors media and fermentation times, indicating that significant interaction occurred among the factors under evaluation (F = 6.187).

As can be seen from Table 3, T3 (RBE plus calcium chloride and ammonium sulfate) and T7 (YMP medium), which showed the highest ethanol productions (25.50 and 24.81 g/L, respectively) after 12 h of fermentation, did not differ from each other (p > 0.05), but differed among the other treatments (p < 0.05), except for T2, which showed the highest ethanol production, 25.59 g/L, after 24 h of fermentation.

The YMP broth has been long-established for the isolation and cultivation of yeasts and molds and presents in its composition carbon, nitrogen, vitamin B complex, nutrients, and other growth factors. Therefore, the use of RBE as a supplement, especially when in conjunction with calcium chloride and ammonium sulfate, as used in this study for the formulation of T3 medium, proved to be nutritionally equivalent and as efficient as YMP broth for ethanol production by K. marxianus ATCC 36,907.

Table S2 shows (see Supplementary Table S2) the ANOVA analysis of cell concentration considering the seven different treatments and the fermentation times since there was interaction among them (F = 4.17).

As shown in Table 4, the T3 treatment presented the highest cell concentration (9.11 g/L) at 12 h of fermentation, followed by treatments T2 and T7, which showed similar values without statistical difference (p < 0.05). The values of all treatments remained constant, with no significant statistical difference (p > 0.05) after 12 h of fermentation due to total sugar consumption in the first 36 h. This directly reflected in bioethanol production, with consequent reduction of productivity, as already observed.

4 Conclusions

By comparing water-soluble rice bran extract (RBE) with other nutrient sources for the cultivation of K. marxianus ATCC 36,907, it was demonstrated that RBE successfully supplied the nutritional requirements of this yeast, supporting growth, and ethanol production. When RBE was supplemented with calcium chloride and ammonium sulfate, the yeast showed the same fermentative performance as observed in the YMP medium. The medium based on RBE supplemented with minerals also favored the cell growth with maximum cell concentration and productivity at 12 h. Thus, RBE, mainly if supplemented with calcium chloride and ammonium sulfate, represents a suitable and low cost substitute for commercially available supplements for K. marxianus ATCC 36,907. Given the metabolic traits of K. marxianus and its ability to assimilate a variety of carbon sources, it would be worthwhile to evaluate RBE supplementation for this yeast in lignocellulosic hydrolysates, together with an economic analysis, aiming at large-scale, sustainable ethanol production.

Data availability

The datasets generated during the current study are available in the manuscript itself.

References

OECD/FAO (2020) OECD-FAO Agricultural Outlook 2020–2029. In: Table C.1 - World Cereal Proj. OECD-FAO Agric. Outlook 2020–2029. https://www.oecd-ilibrary.org/agriculture-and-food/oecd-fao-agricultural-outlook-2020-2029_1112c23b-en. Accessed 1 Apr 2022

Huang B, Huang C, Lyu Z et al (2018) Available energy and amino acid digestibility of defatted rice bran fed to growing pigs1. J Anim Sci 96:3138–3150. https://doi.org/10.1093/jas/sky191

Bodie AR, Micciche AC, Atungulu GG, et al (2019) Current trends of rice milling byproducts for agricultural applications and alternative food production systems. Front Sustain Food Syst 3:Article 47. https://doi.org/10.3389/fsufs.2019.00047

SpaggiariDall’Asta MC, Galaverna G, del Castillo Bilbao MD (2021) Rice bran by-product: from valorization strategies to nutritional perspectives. Foods 10:85. https://doi.org/10.3390/foods10010085

Moriyama S, Fukumoto K, Taniguchi M et al (2013) Rice bran extract (RBE) as supplement for cell culture. BMC Proc 7:P106. https://doi.org/10.1186/1753-6561-7-S6-P106

Seyoum Y, Humblot C, Baxter BA, et al (2022) Metabolomics of rice bran differentially impacted by fermentation with six probiotics demonstrates key nutrient changes for enhancing gut health. Front Nutr 8:Article 795334. https://doi.org/10.3389/fnut.2021.795334

Narh C, Frimpong C, Mensah A, Wei Q (2018) Rice bran, an alternative nitrogen source for Acetobacter xylinum bacterial cellulose synthesis. BioResources 13:4346–4363. https://doi.org/10.15376/biores.13.2.4346-4363

Moreira VR, Lebron YAR, Freire SJ et al (2019) Evaluation of rice bran as a supplement for production of bioethanol by Saccharomyces cerevisiae. Floresta e Ambient 26:e20180423. https://doi.org/10.1590/2179-8087.042318

Mochidzuki K, Kobayashi S, Wang H et al (2015) Effect of rice bran as a nitrogen and carbohydrate source on fed-batch simultaneous saccharification and fermentation for the production of bioethanol from rice straw. J Japan Inst Energy 94:151–158. https://doi.org/10.3775/jie.94.151

Martiniano SE, Philippini RR, Chandel AK et al (2014) Evaluation of rice bran extract as a nitrogen source for improved hemicellulosic ethanol production from sugarcane bagasse by new xylose-fermenting yeast strains isolated from Brazilian forests. Sugar Tech 16:1–8. https://doi.org/10.1007/s12355-013-0219-8

da Silva DDV, de Cândido EJ, de Arruda PV et al (2014) New cultive medium for bioconversion of C5 fraction from sugarcane bagasse using rice bran extract. Brazilian J Microbiol 45:1469–1475. https://doi.org/10.1590/S1517-83822014000400043

Lane MM, Burke N, Karreman R et al (2011) Physiological and metabolic diversity in the yeast Kluyveromyces marxianus. Antonie Van Leeuwenhoek 100:507–519. https://doi.org/10.1007/s10482-011-9606-x

Ortiz-Merino RA, Varela JA, Coughlan AY, et al (2018) Ploidy variation in Kluyveromyces marxianus separates dairy and non-dairy isolates. Front Genet 9:Article 94. https://doi.org/10.3389/fgene.2018.00094

Arora R, Behera S, Sharma NK, Kumar S (2019) Evaluating the pathway for co-fermentation of glucose and xylose for enhanced bioethanol production using flux balance analysis. Biotechnol Bioprocess Eng 24:924–933. https://doi.org/10.1007/s12257-019-0026-5

Dasgupta D, Ghosh D, Bandhu S, Adhikari DK (2017) Lignocellulosic sugar management for xylitol and ethanol fermentation with multiple cell recycling by Kluyveromyces marxianus IIPE453. Microbiol Res 200:64–72. https://doi.org/10.1016/j.micres.2017.04.002

Lane MM, Morrissey JP (2010) Kluyveromyces marxianus: a yeast emerging from its sister’s shadow. Fungal Biol Rev 24:17–26. https://doi.org/10.1016/j.fbr.2010.01.001

Tseng C-C, Lin Y-J, Liu W et al (2020) Metabolic engineering probiotic yeast produces 3S, 3′S-astaxanthin to inhibit B16F10 metastasis. Food Chem Toxicol 135:110993. https://doi.org/10.1016/j.fct.2019.110993

da Silva FL, de Oliveira CA, dos Santos DA et al (2018) Valorization of an agroextractive residue-Carnauba straw for the production of bioethanol by simultaneous saccharification and fermentation (SSF). Renew Energy 127:661–669. https://doi.org/10.1016/j.renene.2018.05.025

da Costa Correia JA, de Sousa SJ, Gonçalves LRB, Rocha MVP (2020) Different design configurations of simultaneous saccharification and fermentation to enhance ethanol production from cashew apple bagasse pretreated with alkaline hydrogen peroxide applying the biorefinery concept. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00796-w

Lertwattanasakul N, Kosaka T, Hosoyama A et al (2015) Genetic basis of the highly efficient yeast Kluyveromyces marxianus: complete genome sequence and transcriptome analyses. Biotechnol Biofuels 8:47. https://doi.org/10.1186/s13068-015-0227-x

Wang D, Wu D, Yang X, Hong J (2018) Transcriptomic analysis of thermotolerant yeast Kluyveromyces marxianus in multiple inhibitors tolerance. RSC Adv 8:14177–14192. https://doi.org/10.1039/C8RA00335A

Mo W, Wang M, Zhan R et al (2019) Kluyveromyces marxianus developing ethanol tolerance during adaptive evolution with significant improvements of multiple pathways. Biotechnol Biofuels 12:63. https://doi.org/10.1186/s13068-019-1393-z

Li P, Tan X, Fu X et al (2021) Metabolomic analysis reveals Kluyveromyces marxianus’s stress responses during high-temperature ethanol fermentation. Process Biochem 102:386–392. https://doi.org/10.1016/j.procbio.2021.01.024

Tinôco D, da Silveira WB (2021) Kinetic model of ethanol inhibition for Kluyveromyces marxianus CCT 7735 (UFV-3) based on the modified Monod model by Ghose & Tyagi. Biologia (Bratisl) 76:3511–3519. https://doi.org/10.1007/s11756-021-00876-w

Lang X, Besada-Lombana PB, Li M et al (2020) Developing a broad-range promoter set for metabolic engineering in the thermotolerant yeast Kluyveromyces marxianus. Metab Eng Commun 11:e00145. https://doi.org/10.1016/j.mec.2020.e00145

Leonel LV, Arruda PV, Chandel AK et al (2021) Kluyveromyces marxianus: a potential biocatalyst of renewable chemicals and lignocellulosic ethanol production. Crit Rev Biotechnol 41:1131–1152. https://doi.org/10.1080/07388551.2021.1917505

Proust L, Sourabié A, Pedersen M, et al (2019) Insights into the complexity of yeast extract peptides and their utilization by Streptococcus thermophilus. Front Microbiol 10:Article 906. https://doi.org/10.3389/fmicb.2019.00906

Almeida ELM, Moreira e Silva G, Vassalli IA et al (2020) Effects of nitrogen supplementation on Saccharomyces cerevisiae JP14 fermentation for mead production. Food Sci Technol 40:336–343. https://doi.org/10.1590/fst.11219

Busti S, Mapelli V, Tripodi F et al (2016) Respiratory metabolism and calorie restriction relieve persistent endoplasmic reticulum stress induced by calcium shortage in yeast. Sci Rep 6:27942. https://doi.org/10.1038/srep27942

Guneser O, Yuceer YK, Hosoglu MI et al (2022) Production of flavor compounds from rice bran by yeasts metabolisms of Kluyveromyces marxianus and Debaryomyces hansenii. Brazilian J Microbiol. https://doi.org/10.1007/s42770-022-00766-6

Camargo D, Gomes SD, Sene L (2014) Ethanol production from sunflower meal biomass by simultaneous saccharification and fermentation (SSF) with Kluyveromyces marxianus ATCC 36907. Bioprocess Biosyst Eng 37:2235–2242. https://doi.org/10.1007/s00449-014-1201-x

Tavares B, Felipe MGA, dos Santos JC et al (2019) An experimental and modeling approach for ethanol production by Kluyveromyces marxianus in stirred tank bioreactor using vacuum extraction as a strategy to overcome product inhibition. Renew Energy 131:261–267. https://doi.org/10.1016/j.renene.2018.07.030

AOAC International (2016) Official Methods of analysis, 20th ed. AOAC INTERNATIONAL, Rockville, MD

Huang SC, Shiau CY, Liu TE et al (2005) Effects of rice bran on sensory and physico-chemical properties of emulsified pork meatballs. Meat Sci 70:613–619. https://doi.org/10.1016/j.meatsci.2005.02.009

Ademola Za A, Ganiyat Ta O (2008) Comparative utilization of biodegraded rice husk in the diets of Clarias gariepinus. J Fish Aquat Sci 3:312–319. https://doi.org/10.3923/jfas.2008.312.319

Palma M, Madeira SC, Mendes-Ferreira A, Sá-Correia I (2012) Impact of assimilable nitrogen availability in glucose uptake kinetics in Saccharomyces cerevisiae during alcoholic fermentation. Microb Cell Fact 11:99. https://doi.org/10.1186/1475-2859-11-99

Ciesarová Z, Šmogrovičová D, Dömény Z (1996) Enhancement of yeast ethanol tolerance by calcium and magnesium. Folia Microbiol (Praha) 41:485–488. https://doi.org/10.1007/BF02814663

Castillo-Plata AK, Sigala JC, Lappe-Oliveras P, Le Borgne S (2021) KCl/KOH supplementation improves acetic acid tolerance and ethanol production in a thermotolerant strain of Kluyveromyces marxianus isolated from henequen (Agave fourcroydes). Rev Mex Ing Química 21:1–18. https://doi.org/10.24275/rmiq/Bio2567

Santos J, Sousa MJ, Leão C (2012) Ammonium is toxic for aging yeast cells, inducing death and shortening of the chronological lifespan. PLoS One 7:e37090. https://doi.org/10.1371/journal.pone.0037090

de Melo AT, Martho KF, Roberto TN et al (2019) The regulation of the sulfur amino acid biosynthetic pathway in Cryptococcus neoformans: the relationship of Cys3, Calcineurin, and Gpp2 phosphatases. Sci Rep 9:11923. https://doi.org/10.1038/s41598-019-48433-5

Leonel LV, Sene L, da Cunha MAA et al (2020) Valorization of apple pomace using bio-based technology for the production of xylitol and 2G ethanol. Bioprocess Biosyst Eng 43:2153–2163. https://doi.org/10.1007/s00449-020-02401-w

Milessi TSS, Antunes FAF, Chandel AK, Silva SS (2013) Rice bran extract: an inexpensive nitrogen source for the production of 2G ethanol from sugarcane bagasse hydrolysate. 3 Biotech 3:373–379. https://doi.org/10.1007/s13205-012-0098-9

Zarei I, Brown DG, Nealon NJ, Ryan EP (2017) Rice bran metabolome contains amino acids, vitamins & cofactors, and phytochemicals with medicinal and nutritional properties. Rice 10:24. https://doi.org/10.1186/s12284-017-0157-2

Oda Y, Nakamura K, Shinomiya N, Ohba K (2010) Ethanol fermentation of sugar beet thick juice diluted with crude cheese whey by the flex yeast Kluyveromyces marxianus KD-15. Biomass Bioenerg 34:1263–1266. https://doi.org/10.1016/j.biombioe.2010.03.014

Clarke KG (2013) Microbiology. In: Clarke KG (ed) Bioprocess Engineering. Elsevier, pp 7–24

Demiray E, Ertuğrul Karatay S, Dönmez G (2020) Efficient bioethanol production from pomegranate peels by newly isolated Kluyveromyces marxianus. Energy Sources Part A Recover Util Environ Eff 42:709–718. https://doi.org/10.1080/15567036.2019.1600621

Jiang Y, Shi Y, Li R et al (2021) The peptides in oat and malt extracts that are preferentially absorbed by Lactobacillus plantarum and stimulates its proliferation in milk. Int J Food Sci Technol 56:4690–4699. https://doi.org/10.1111/ijfs.15140

Pentjuss A, Stalidzans E, Liepins J et al (2017) Model-based biotechnological potential analysis of Kluyveromyces marxianus central metabolism. J Ind Microbiol Biotechnol 44:1177–1190. https://doi.org/10.1007/s10295-017-1946-8

Sakihama Y, Hidese R, Hasunuma T, Kondo A (2019) Increased flux in acetyl-CoA synthetic pathway and TCA cycle of Kluyveromyces marxianus under respiratory conditions. Sci Rep 9:5319. https://doi.org/10.1038/s41598-019-41863-1

Silva GM, Giordano RLC, Cruz AJG, Ramachandriya KD et al (2015) Ethanol production from sugarcane bagasse using SSF process and thermotolerant yeast. Trans ASABE 58:193–200. https://doi.org/10.13031/trans.58.11024

Van Urk H, Voll WSL, Scheffers WA, Van Dijken JP (1990) Transient-state analysis of metabolic fluxes in crabtree-positive and crabtree-negative yeasts. Appl Environ Microbiol 56:281–287. https://doi.org/10.1128/aem.56.1.281-287.1990

Pessani NK, Atiyeh HK, Wilkins MR et al (2011) Simultaneous saccharification and fermentation of Kanlow switchgrass by thermotolerant Kluyveromyces marxianus IMB3: The effect of enzyme loading, temperature and higher solid loadings. Bioresour Technol 102:10618–10624. https://doi.org/10.1016/j.biortech.2011.09.011

Fu X, Li P, Zhang L, Li S (2019) Understanding the stress responses of Kluyveromyces marxianus after an arrest during high-temperature ethanol fermentation based on integration of RNA-Seq and metabolite data. Appl Microbiol Biotechnol 103:2715–2729. https://doi.org/10.1007/s00253-019-09637-x

Saini P, Beniwal A, Malik RK, Vij S (2017) Comparative physiology of Kluyveromyces marxianus and Saccharomyces cerevisiae during batch cultivation on glucose as a sole carbon source. Indian J Dairy Sci 70:427–433

Rodrussamee N, Lertwattanasakul N, Hirata K et al (2011) Growth and ethanol fermentation ability on hexose and pentose sugars and glucose effect under various conditions in thermotolerant yeast Kluyveromyces marxianus. Appl Microbiol Biotechnol 90:1573–1586. https://doi.org/10.1007/s00253-011-3218-2

Madeira-Jr JV, Gombert AK (2018) Towards high-temperature fuel ethanol production using Kluyveromyces marxianus: on the search for plug-in strains for the Brazilian sugarcane-based biorefinery. Biomass Bioenerg 119:217–228. https://doi.org/10.1016/j.biombioe.2018.09.010

Costa DA, de Souza CJA, Costa PS et al (2014) Physiological characterization of thermotolerant yeast for cellulosic ethanol production. Appl Microbiol Biotechnol 98:3829–3840. https://doi.org/10.1007/s00253-014-5580-3

Arora R, Behera S, Sharma NK, Kumar S (2017) Augmentation of ethanol production through statistically designed growth and fermentation medium using novel thermotolerant yeast isolates. Renew Energy 109:406–421. https://doi.org/10.1016/j.renene.2017.03.059

Funding

The authors are grateful to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) for funding the scholarship of T.C. Pintro and L.V. Leonel (Financing Code 001).

Author information

Authors and Affiliations

Contributions

L. Sene and T.C. Pintro: experiment design; T.C. Pintro, L.V. Leonel, and S. Bender: investigation and laboratory analysis. T.C. Pintro: data analysis. L. Sene and T.C. Pintro: writing (original draft). L. Sene and M.A.A. Cunha: writing (review and editing).

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All the authors have read and understood the editorial policies for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sene, L., Pintro, T.C., Leonel, L.V. et al. Rice bran extract as an alternative nutritional supplement for Kluyveromyces marxianus. Biomass Conv. Bioref. 14, 11479–11489 (2024). https://doi.org/10.1007/s13399-022-03252-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03252-z