Abstract

The pyruvate dehydrogenase complex was deleted to increase precursor availability in Corynebacterium glutamicum strains overproducing l-valine. The resulting auxotrophy is treated by adding acetate in addition glucose for growth, resulting in the puzzling fact of gluconeogenic growth with strongly reduced glucose uptake in the presence of acetate in the medium. This result was proven by intracellular metabolite analysis and labelling experiments. To increase productivity, the SugR protein involved in negative regulation of the phosphotransferase system, was inactivated, resulting in enhanced consumption of glucose. However, the surplus in substrate uptake was not converted to l-valine; instead, the formation of up to 289 μM xylulose was observed for the first time in C. glutamicum. As an alternative to the genetic engineering solution, a straightforward process engineering approach is proposed. Acetate limitation resulted in a more efficient use of acetate as cosubstrate, shown by an increased biomass yield Y X/Ac and improved l-valine formation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

l-Valine is an essential amino acid mainly used for pharmaceutical purposes. It is found in infusion solutions and is a component of antiviral drugs such as Valacyclovir and Lopinavir. Although fermentative production by randomly mutated strains has been the subject of research since the 1950s [1], l-valine is mainly produced by the hydrolysis of natural proteins derived from animals (e.g., chicken feathers) [2] or from the enzymatic conversion of d,l-acyl-valine [3]. Today, l-valine production by fermentation is preferred thus avoiding the use of animal sources. Hence, several approaches are undertaken in order to optimise the fermentative production.

For several decades, Corynebacterium glutamicum has been the workhorse of amino acid fermentation and this organism is also used for l-valine production [4]. The starting point for fermentation development was an increase in precursor availability (i.e., pyruvate), which can be achieved by pantothenate limitation [5, 6] or by the deletion of the aceE gene encoding the E1p subunit of the pyruvate dehydrogenase complex (PDHC) [7]. Both attempts resulted in an increase of intracellular pyruvate, whereby aceE deletion led to the successful accumulation of pyruvate and decoupled growth and production phase. The auxotrophy for acetyl-CoA resulting from the deletion of the aceE gene encoding the E1 subunit of PDHC was overcome by supplementation with acetate.

For l-valine biosynthesis, two molecules of pyruvate are condensed to acetolactate, which is further metabolised to l-valine. The accumulated pyruvate is channelled towards l-valine, achieved by overexpressing the respective l-valine biosynthetic genes [6, 8]. A further increase in l-valine yield is achieved by enhanced availability of the cofactor NADPH [9, 10].

However, C. glutamicum ∆aceE did not take up glucose in the presence of acetate and no l-valine was formed [7]. This observation in PDHC-deficient strains contracts the results for the wild type C. glutamicum ATCC 13032 obtained by Wendisch et al. [11], who describe the parallel uptake of glucose and acetate. Compared to the consumption rates of glucose or acetate alone, the uptake rates in the presence of both substrates were reduced to about 50% for each substrate. Hence, glucose uptake may be the starting point for further optimisation of l-valine formation.

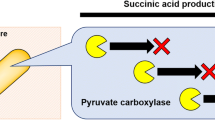

Glucose is mainly taken up in C. glutamicum by the phosphotransferase system (PTS). The genes for the glucose-specific uptake system (PTSGlc), fructose-specific uptake system (PTSFru) and sucrose-specific uptake system (PTSSuc) are constitutively expressed [12, 13]. Recently, the regulation of the different PTSs in C. glutamicum has been described by several authors [14–16]. In the presence of gluconeogenic substrates such as acetate, the regulator protein SugR binds at the DNA upstream of the ptsG gene and inhibits its expression. When glucose is present in the medium and taken up by the cell, the intracellular concentration of fructose-6-phosphate (F6P) is elevated. F6P binds to SugR and induces a change in conformation, which releases SugR from the DNA [14]. Hence, the genes encoding the PTS are transcribed. Apart from F6P, fructose-1-phosphate (F1P) is also discussed as an effector of SugR [15].

The basis for further optimisation of l-valine production should be the analysis and optimisation of glucose uptake in the presence of acetate. We used metabolomics for the determination of metabolites in the presence and absence of acetate to understand the behaviour of the cell [17]. The use of LC–MS/MS for quantitative target analysis led to the quantification of known metabolites of the central metabolic pathways at nanomolar intracellular concentrations [18]. The application of GC–TOF–MS for metabolic profiling allowed the unbiased analysis of a broad range of metabolic compounds [19] in order to unravel the byproduct spectra concerning most likely known, but unexpected compounds.

In the present study, we used metabolome analysis in the presence and absence of acetate in order to understand l-valine formation before and after depletion of acetate. The insights gained into the intracellular metabolism were the basis for further research. The downregulation of glucose consumption can be accompanied by further genetic modifications of the production strain or by procedural attempts within process control. Process control should create environmental conditions for the production cell, allowing the formation of l-valine in parallel to growth in order to increase the productivity. In this study, the PTS was deregulated by deletion of the sugR gene and the resulting strains were characterised by fermentation, GC–TOF and LC–MS/MS analysis. In a further attempt to increase l-valine formation, we optimised the fermentation regime by changing the acetate feed.

Materials and methods

Organisms and cultivation

For the present study the wild type C. glutamicum ATCC 13032 and several genetically modified l-valine producers were used. Pantothenate synthesis has been inactivated in the strain C. glutamicum ΔilvA ΔpanB pJC4ilvBNCD [6] to enhance pyruvate availability.

Increased intracellular pyruvate concentrations were also achieved by inactivation of the PDHC in the strains C. glutamicum ΔaceE [20], C. glutamicum ΔaceE pJC4ilvBNCE [7], and C. glutamicum ΔaceE Δpqo Δpgi pJC4ilvBNCE [10]. Additionally, the gene encoding the PTS regulator SugR was deleted in the strains C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE and C. glutamicum ΔaceE Δpqo ΔsugR pJC4ilvBNCE [21].

Deletion of the sugR gene in the strain C. glutamicum ΔaceE pJC4ilvBNCE was performed as described for the strain C. glutamicum ΔaceE Δpqo pJC4ilvBNCE [21]. The successful deletion of sugR was proven by PCR using the primers sugRfow (5-GTTCGTCGCGGCAATGATTGACG-3) and sugRrev (5-CTCACCACATCCACAAACCACGC-3).

The cells were cultivated in a 3.6 l bioreactor (Infors) in CGXII minimal medium containing 225 mM (40 g/l) glucose and 100 mM (6 g/L) acetate as described [9]. After the initial 100 mM acetate was depleted, acetate was fed to promote cell growth in acetyl-CoA deficient strains in order to achieve sufficient cell density for metabolome analysis. 9.8 mmol/l h glacial acetic acid was supplemented as acetate source. Acetate feed rates using glacial acetic acid between 76.3 and 10 mmol/l h (4.5 and 0.29 g/l h) were analysed as part of process development.

Determination of biomass, product and by-product formation

The biomass concentration was analysed as described previously by measuring optical density (OD) at λ = 546 nm [5]. Cell dry mass was calculated from the OD using the experimentally determined factor of 0.33. Glucose was measured using the AccuChek sensor or the Ebio compact system (Eppendorf) as described previously [22, 23]. Organic acids and amino acids were determined by HPLC measurements as described [22, 24].

Determination of intracellular metabolite concentrations

Intracellular metabolite concentrations were determined as described [5]. The metabolic quenching method according to de Koning and van Dam [25] was used to stop metabolic activities. Samples were measured by LC-MS/MS using the method of Luo et al. [18] for intermediates of the central metabolism or the method of Stein [26] for the analysis of intracellular amino acid concentrations.

The specific cell volume varies according to growth phase and osmolality [27]. For the calculation of intracellular metabolite concentrations, a factor of 1.4 ml/g cell dry weight (CDW) was used for samples taken during the growth phase and a factor of 1.0 ml/g CDW for samples taken during the transition or stationary phase.

Analysis of substrate uptake by labelling experiments

Shake flask experiments with 13C-labelled substrates were performed to analyse whether glucose, acetate, or both substrates were used for growth. After preculture in LB medium [28], shake flasks with CGXII medium containing 100 mM (6 g/l) acetate and 55 mM (10 g/l) glucose were inoculated to obtain an OD of 0.1. Before inoculation, the cells were washed with 0.9% sodium chloride to avoid effects by the preculture medium. The medium contained either U–13C glucose and unlabelled acetate or U–13C acetate and unlabelled glucose.

The cells were harvested when an OD between one and two was reached. 5 ml of biomass suspension was hydrolysed in 6 M hydrochloric acid solution to analyse the labelling pattern of proteinogenic amino acids [29]. The labelling pattern of cytoplasmic intermediates was analysed by quenching the cells with methanol. The fraction of different isotopomers was determined by LC–MS/MS measurements.

GC–TOF measurements for the analysis of the fermentation medium

Samples of the fermentation supernatant from the end of the cultivations were analysed by GC–TOF (chromatography: Agilent 6890N, Agilent; mass spectrometry: GCT Premier, Waters) to look for yet unknown by-products. The samples were treated as described by Strelkov et al. [30] and derivatised with methoxyamine·HCl and N-methyl-N-trimethylsilyl trifluoroacetamide. The resulting chromatograms were analysed comparing the mass spectra and the retention indices using the public database from MPI Golm [31], the NIST database (version 2005) and our in-house spectral database covering commonly observed compounds (JuPOD, unpublished).

LC–MS/MS measurements for the analysis of extracellular saccharides

Samples of the supernatant from the end of the cultivations were also measured by LC–MS/MS (Agilent 1100 system and QTrap4000 Applied Biosystems) to confirm the findings of GC–TOF analysis and to quantify the saccharides. The method of Rogatsky et al. [32] was used with fructose, galactose, lactose, maltose, mannose, sucrose, trehalose, xylose and xylulose as standards.

Results

Analysis of cytoplasmic intermediates in PDHC-deficient l-valine production strains

The product yield in l-valine fermentations with C. glutamicum is based on precursor availability [7]. The accumulation of the precursor pyruvate was achieved by deletion of the aceE gene, resulting in acetyl-CoA deficiency. This can be overcome by supplementation with acetate. However, in the presence of acetate, almost no glucose is taken up and no l-valine is formed. This phenomenon in PDHC-deficient strains is not observed in the wild type C. glutamicum ATCC 13032, which consumes both substrates in parallel [11].

For further analysis, the metabolome of the l-valine production strain C. glutamicum ΔaceE pCJ4ilvBNCE was analysed during the growth, early and late production phase (Table 1). Reduced concentrations of most glycolytic and pentose phosphate pathway (PPP) intermediates were found during the growth phase when compared to the production phase. Within the production phase, a further increase in metabolite concentrations was detected. Especially cytoplasmic pyruvate increased during production from 1.0 to 17.8 mM. A remarkable enhancement was also observed for α-ketoglutarate (from 146 to 2864 μM) and other tricarboxylic acid cycle (TCA cycle) intermediates, whereas no uniform trend was observed for TCA metabolites in general.

The absence of pyruvate in the presence of acetate during the growth phase was further analysed by comparing the situation in different l-valine producers (Table 2). In the wild type C. glutamicum ATCC 13032, cytoplasmic pyruvate concentration was not influenced by the presence of acetate, showing concentrations of 0.51–0.55 mM. The pantothenate auxotrophic strain C. glutamicum ΔpanB ΔilvA pJC4ilvBNCD even showed a roughly 50% decrease in pyruvate concentration in the presence of acetate. As expected, neither PDHC-deficient strain was able to grow without acetate supplementation. An intracellular pyruvate concentration below the detection limit of 0.024 mM in the presence of acetate was also found for the second PDHC-deficient strain C. glutamicum ΔaceE Δpqo Δpgi pJC4ilvBNCE.

Within the growth phase, no pyruvate was detected in PDHC-deficient strains, which may explain the absence of l-valine formation. l-valine overproduction is impossible without the crucial precursor pyruvate. However, a small flux via pyruvate towards the branched-chain amino acids is obviously present, since cell growth is observed (μ = 0.33 1/h) although no branched chain amino acids were added to the medium. The increased uptake of glucose in the presence of acetate is required to enable l-valine formation in parallel to growth.

Fermentative characterisation of PDHC- and SugR-deficient l-valine producers

The results described above indicate that in PDHC-deficient strains l-valine formation during growth is restricted by an insufficient supply of pyruvate, probably due to a reduced uptake of glucose. Hence, the gene encoding the PTS repressor SugR was deleted to deregulate glucose uptake. This deletion should result in higher glucose uptake and l-valine formation during growth in the presence of acetate. The strains C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE and C. glutamicum ΔaceE Δpqo ΔsugR pJC4ilvBNCE were newly constructed.

As shown in Table 3, glucose uptake was successfully increased from 1.04 mmol/h g CDW by 78% to 1.86 mmol/g h CDW by deleting the sugR gene in the strain C. glutamicum ΔaceE pJC4ilvBNCE (Table 3). A difference of as much as 55% with respect to glucose uptake was observed for the strains C. glutamicum ΔaceE Δpqo pJC4ilvBNCE and C. glutamicum ΔaceE Δpqo ΔsugR pJC4ilvBNCE. In both ΔsugR strains, glucose was already consumed in the presence of acetate (Fig. 1b). However, the glucose uptake rate was still significantly below 3.73 mmol/g h CDW, as detected for the wild type without acetate (Table 3).

In parallel, more biomass was formed and the supplemented acetate was used more efficiently. The biomass yield on acetate increased from Y X/Ac = 0.89 g CDW/g acetate (C. glutamicum ΔaceE Δpqo pJC4ilvBNCE) to Y X/Ac = 2.08 g CDW/g acetate after introducing the deletion of sugR. The strain C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE consumed 110 mM acetate for 15 h, whereas it only took 8 h for the original strain C. glutamicum ΔaceE pJC4ilvBNCE to consume a comparable amount of acetate (Fig. 1a).

Growth stopped between 4 and 6 h after the depletion of acetate (Fig. 1). The continued growth without acetate may be explained by its intracellular accumulation or accumulation of other metabolites due to the fast uptake of acetate. Presumably, growth is no longer possible after the depletion of these metabolites. However, metabolome analysis showed slightly increased pools for citrate and glyoxylate (Table 1). Neither the intracellular concentration of acetate or nor that of acetate-phosphate were not analysed [33].

The main objective of the deregulation of glucose uptake was early l-valine formation. Though slight formation was observed in both ΔsugR-strains during the production phase, product formation over the whole process decreased dramatically by around 50%. The l-valine yield of the strain C. glutamicum ΔaceE pJC4ilvBNCE decreased from 0.50 mol Val/mol Glc to 0.23 mol Val/mol Glc by the strain C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE. The same negative effect was observed for l-valine formation with C. glutamicum ∆aceE ∆pqo ∆sugR pJC4ilvBNCE.

The low formation of l-valine after deregulation of glucose uptake led to the assumption that new by-products may be formed. Although glucose consumption was increased as intended by deletion of the sugR genes, a negative result was obtained for l-valine formation.

Metabolome analysis of ΔsugR strains

Intracellular metabolite concentrations of the l-valine production strains were analysed by LC–MS/MS during the late production phase without acetate present in the medium to identify the cause of decreased l-valine formation. The wild type and the strain C. glutamicum ΔsugR were analysed during the growth phase. A significant difference between the strains analysed (C. glutamicum ATCC 13032, C. glutamicum ΔsugR, C. glutamicum ΔaceE pJC4ilvBNCE and C. glutamicum ΔsugR ΔaceE pJC4ilvBNCE) was found for pyruvate. Based on one fermentation and four analytical replicates, a pyruvate concentration of 1.8 ± 0.5 mM was found in the wild type. The cytoplasmic pyruvate availability increased after inactivation of PDHC to 20.5 ± 2.3 mM in C. glutamicum ΔaceE pJC4ilvBNCE. A further accumulation of pyruvate was found after deletion of both genes, aceE and sugR, up to 164.9 ± 2.9 mM (C. glutamicum ΔsugR ΔaceE pJC4ilvBNCE). However, deletion of the sugR gene in the wild type showed no difference concerning pyruvate compared to the wild type (1.9 ± 0.3 mM). Hence, it can be concluded that excessive accumulation of pyruvate might not be beneficial for l-valine formation.

Analysis of by-product formation of C. glutamicum ΔaceE ΔsugR strains by GC–TOF measurements

Less l-valine was formed after deletion of the gene encoding SugR (Fig. 1a, b). However, the cytoplasmic pyruvate concentration was about 165 mM and the carbon balance of different ΔsugR-strains could not be closed. In some cases, only 60% of the initial carbon was found at the end of the experiment. Therefore, the fermentation supernatant at the end of the cultivation was analysed by GC–TOF to identify the unknown by-products. Two samples taken at the end of the cultivation of four different strains were analysed.

Compared to the chromatograms of the original strain, the chromatograms of the ΔsugR-strains showed additional peaks at retention times of 9.98, 15.59 and 16.23 min, which were not found in the supernatant of the strains with the sugR gene. They were identified by database analysis as xylulose and trehalose. The identification of both saccharides was verified by analysing standards of xylulose and trehalose by GC–TOF, showing the same retention indices and fragmentation pattern.

The extracellular formation of xylulose has not yet been described for C. glutamicum. The formation was quantified for C. glutamicum ΔaceE Δpqo ΔsugR pJC4ilvBNCE by LC-MS/MS analysis, revealing the formation of at least 543 μM trehalose and 249 μM xylulose (Table 4).

The formation of both saccharides was also analysed for the strains C. glutamicum ΔsugR (100 μM trehalose, 72 μM xylulose), C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE (1670 μM trehalose, 171 μM xylulose), for the wild type C. glutamicum ATCC 13032 (160 μM trehalose) and for C. glutamicum ΔaceE Δpqo pJC4ilvBNCE (215 μM trehalose). Both saccharides were formed during the growth phase. Xylulose was formed only after deletion of the sugR gene and not in the wild type. Trehalose was consumed during the stationary phase by the strains still containing the sugR gene, whereas the concentration of the strains with deregulated PTS showed a constant concentration or a slow increase.

13C labelling experiments for analysis of substrate uptake

The absence of glucose uptake in the presence of acetate in the strain C. glutamicum ΔaceE pJC4ilvBNCE during the growth phase contradicts the results of Wendisch et al. [34]. These authors showed slower, but still significant glucose uptake in the presence of acetate in the wild type of C. glutamicum. We performed experiments using the strains C. glutamicum ATCC 13032, C. glutamicum ΔaceE pJC4ilvBNCE and C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE in the presence of both substrates for a deeper understanding of carbon utilisation in the modified strains. Either U13C labelled glucose and unlabelled acetate or unlabelled glucose and U13C labelled acetate were employed to determine which substrate is preferably used during the growth phase by different strains.

One metabolite derived from glycolysis and one from anaplerosis was chosen for the analysis of the labelling pattern. The samples of the amino acids l-serine (glycolysis) and aspartate (anaplerosis/TCA cycle) were obtained from biomass hydrolysis. Two experimental replicates and two analytical replicates were performed for each strain and each combination of substrates.

Analysing the isotopomer distribution of the wild type in the presence of labelled glucose and unlabelled acetate (Table 5a), it can be concluded that in the wild type l-serine was partly formed from glucose and partly from acetate, if both substrates were present. 31.3% of l-serine was uniformly labelled in the presence of labelled glucose. In the presence of labelled acetate and unlabelled glucose, 49.0% of l-serine was completely labelled, indicating that the carbon skeleton of l-serine was derived to a larger extent from acetate than from glucose. A further shift towards acetate as the source of l-serine was observed in the l-valine producer C. glutamicum ΔaceE pJC4ilvBNCE. 60.1% of l-serine was totally labelled in the strain C. glutamicum ΔaceE pJC4ilvBNCE in the case of labelled acetate.

l-Serine was formed almost exclusively from glucose after the additional deletion of the sugR gene. This can be seen from the 69% labelled l-serine in the presence of labelled glucose and the reverse relation with labelled acetate (82.1% of l-serine completely unlabelled).

l-Aspartate is formed by the transamination of oxaloacetate, which can be formed from malate within the TCA cycle or by anaplerotic reactions from phosphoenolpyruvate (PEP) or pyruvate (Fig. 2). The labelling pattern of aspartate after biomass hydrolysis of the wild type C. glutamicum ATCC 13032 indicated that this amino acid was mainly formed from acetate. In the presence of labelled glucose, 70.3% of l-aspartate was not labelled and in the presence of labelled acetate, the same amount of l-aspartate was completely labelled.

Glycolysis and entry into the citric acid cycle in Corynebacterium glutamicum. Relevant enzymes are given in grey ellipses; the regulator of PTS, SugR, is shown in a black ellipse. Metabolites with analysed labelling patterns are highlighted in grey, and as the desired product l-valine is marked by a box. PTS phosphotransferase system, PQO pyruvate-quinone oxidoreductase, PDHC pyruvate dehydrogenase complex, CS citrate synthase, KGDHC α-ketoglutarate dehydrogenase complex

The labelling pattern found for the modified strain C. glutamicum ΔaceE pJC4ilvBNCE agreed with the results from the wild type. l-Aspartate was again predominantly formed from acetate. After deregulation of glucose uptake, carbon atoms derived from glucose were incorporated to a large extent. In the presence of labelled glucose, only 39.0% of the l-aspartate was unlabelled and several isotopomers were found.

Minimising acetate feed rate for early l-valine formation

The desired effect of l-valine formation in the presence of acetate was not achieved by the deregulation of glucose uptake, thus an alternative may be found in optimising the production process. In a first approach to facilitate l-valine formation and growth in parallel, different acetate feed rates were analysed. Acetate feed was started after 100 mM of initial acetate was depleted. No notable changes of the total biomass concentration were observed with decreasing feed rates (around 25 g/l) when analysing the strain C. glutamicum ΔaceE pJC4ilvBNCE (Table 6a). However, the biomass yield on acetate Y X/Ac increased from 0.51 g CDW/g acetate (feed rate of 4.50 g/l h) to 0.82 g CDW/g acetate (0.58 g/l h feed rate). In parallel, the final l-valine concentration increased from 163.8 to 324 mM with decreasing acetate feed, also resulting in an increased l-valine yield on glucose Y Val/Glc.

The same experiment was performed using the strain C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE with even lower acetate feed rates (Table 6b). Decreasing the feed rate from 0.87 to 0.29 g/l h resulted in decreased biomass formation (24.5 and 14.3 g/l, respectively). However, the biomass yield on acetate Y X/Ac was increased at reduced feed rates. No trend was observed concerning l-valine formation and l-valine yield on glucose Y Val/Glc. The strain C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE showed an l-valine yield on glucose of Y Val/Glc of 0.15 mM/mM with the analysed feed rates, which was again below the values obtained with the strain C. glutamicum ΔaceE pJC4ilvBNCE (0.35 and 0.56 mM/mM with the same feed rates).

Discussion

The efficient production of l-valine depends on the successful enhancement of precursor availability, which can be achieved, for example, by the inactivation of the PDHC [7]. PDHC inactivation results in reduced glucose uptake and reduced cytoplasmatic concentrations of glycolytic and PPP metabolites in the presence of acetate. Although the conclusion from fluxes to metabolite pools is not valid, increased metabolite pools during the production phase as observed may be explained by the increased glucose uptake during the production phase. Some pools of glycolytic and PPP intermediates increased during the production phase, especially pyruvate accumulated from 1.0 mM 25 h after inoculation to 17.8 h within 8 h. The first concentration is in good agreement with 2.3 mM pyruvate determined in earlier measurements [7]. However, the difference to the second measurement point indicates that intracellular pool sizes change over time and that the exact description of cultivation conditions should be taken into account.

PDHC inactivation results in auxotrophy for acetyl-CoA, which is treated by acetate supplementation. However, no glucose is consumed and therefore no product is formed in the presence of acetate by the strain C. glutamicum ΔaceE pJC4ilvBNCE. In contrast, the wild type C. glutamicum ATCC 13032 is capable of consuming glucose and acetate in parallel [34]. These results obtained by Wendisch et al. are in good agreement with our findings concerning the wild type and the l-valine producer C. glutamicum ΔilvA ΔpanB pJC4ilvBNCD. However, no intracellular pyruvate was found for the strain C. glutamicum ΔaceE pJC4ilvBNCE in the presence of acetate and the cytoplasmic concentrations of glycolytic and PPP intermediates are strongly reduced. The labelling pattern of this strain in the presence of labelled acetate revealed labelled l-serine and labelled P5P, indicating gluconeogenic growth to a significant extent.

These findings contrast with those found for the wild type and may be ascribed to the inactivation of the PDHC. In l-valine producers based on the deletion of pantothenate biosynthesis, intracellular pyruvate is detected even in the presence of acetate. In parallel to the PDHC-deficient l-valine producer, the formation of l-lysine, l-valine and pyruvate in the PDHC-deficient l-lysine producer C. glutamicum DM1729-BB1 also begins after depletion of acetate [35].

The combination of the intracellular metabolite concentration of these strains with the labelling pattern of several metabolites in the presence of labelled glucose or labelled acetate revealed a coherent picture of the behaviour of PDHC-deficient strains in the presence of both substrates. The observed growth of this strain and the formation of l-valine in the presence of acetate by the strain C. glutamicum ΔilvA ΔpanB pJC4ilvBNCD indicate that neither the l-valine pathway nor the l-valine exporter is explicitly affected by the presence of acetate. However, there is still no explanation for this phenomenon and the cellular regulation enabling sufficient l-valine formation for growth without product formation in PDHC-deficient strains will be the subject of further research.

The target of the early start of product formation was followed by the deletion of sugR in the PDHC-deficient l-valine producers. The protein SugR has been shown to deregulate the PTS [14]. The deletion resulted in the desired enhancement of glucose uptake and l-valine formation in the presence of acetate. Glucose uptake was dramatically enhanced between 55 and 78% and the strains involved showed a reduced utilisation of acetate for the formation of PPP or glycolysis intermediates if both substrates are present. We determined a specific glucose uptake rate of 3.73 mmol/g h for the wild type C. glutamicum ATCC 13032, which is slightly less than the 4.8 mmol/g h determined for the wild type C. glutamicum ATCC 17965 [36]. The specific glucose uptake rate of 1.8 mmol/g h observed for the strain C. glutamicum ΔaceE ΔsugR pJC4ilvBNCE is below this value. However, 1.8 mmol/g h was still sufficient for enhanced l-valine formation as the main carbon sink since growth is not possible without acetate.

The enhanced glucose uptake in the SugR-deficient strain resulted in the intracellular accumulation of 165 mM pyruvate and reduced product formation. The decrease in l-valine formation may be explained by the inhibitory effects of pyruvate. Most likely, the accumulation of 165 mM pyruvate has regulatory and osmotically effects, since the formation of trehalose and xylulose is observed in SugR-deficient strains. The extracellular formation of xylulose has not been observed in C. glutamicum yet, hence, its function is not yet known. Xylulose-5-phosphate is known as an intermediate of the PPP and 1-deoxy-d-xylulose-5-phosphate as an intermediate of the cell wall biosynthesis of prokaryotes [37]. Trehalose acts as an osmoregulator and is formed as result of hyperosmotic conditions [38]. It is likely that the extracellular formation of trehalose is a reaction to the accumulation of pyruvate.

The detection of xylulose and trehalose is not sufficient to close the carbon balance of the PDHC and SugR deficient strain. The secretion of pyruvate would be expected in the presence of 165 mM cytoplasmic pyruvate. However, it is assumed that pyruvate cannot pass the cell membrane by diffusion and an active export system has not been identified so far [39]. Therefore, it may be possible that the high pyruvate concentration accumulate without export into the medium. The formation of xylulose and trehalose indicated that the effects from the obtained genetic modifications are not tolerable for the cellular metabolism. At least, this deletion is unfavourable for l-valine production.

Since the molecular genetic approach was not successful in achieving early l-valine formation, process development was now undertaken to optimise the product formation. In the first experiments, different acetate feed rates were analysed. Acetate feed is necessary to achieve high cell densities due to the inhibitory effects of high acetate concentrations [33]. An optimisation of biomass yield on acetate was successfully achieved using different linear feed rates. Using increased feed rates resulted in enhanced carbon dioxide formation, but showed no positive effect on biomass formation. A similar effect was observed to provide acetate concentrations between 20 and 200 mM for the batch phase of the fermentation; the same biomass yield was achieved from different batch concentrations (not shown). Thus, minimisation of the acetate feed in order to increase the biomass yield on acetate Y X/Ac is an important tool in the development of an efficient l-valine production process. The optimisation of the fermentation regime showed to be an appropriate alternative if genetic modifications are not successful.

No acetate was detected during the acetate feed; it was immediately consumed by the cells. It can be assumed that the observed absence of glucose uptake in the presence of acetate in PDHC-deficient strains is influenced by the concentration of acetate or the amount of acetate consumed. Taking this assumption into account, reduced acetate concentrations or reduced feed rates will allow an increased glucose uptake, what is followed by increased l-valine formation. The benefit of low acetate feed rates in order to establish an efficient process was also shown by the enhanced l-valine formation under these conditions. For the production phase, a yield of Y Val/Glc = 0.56 mol/mol was achieved by applying an acetate feed rate of 0.58 g/l h. This yield is close to the theoretically possible yield of Y Val/Glc = 0.86 mol/mol [9], but further optimisation is still necessary. This may be achieved by optimising NADPH supply, which was shown to be beneficial.

Further changes in the fermentation regime may be of benefit for optimised production. The use of an exponential feed strategy employing a minimised acetate feed rate could result in an increase of total productivity due to faster cell growth in parallel to product formation. For the future, the analysis of alternative carbon sources such as ethanol may also be an option for overcoming the negative aspects of acetate supplementation [21].

Conclusion

Different methods were used within the present study to analyse the effect of the inactivation of the PDHC and of the PTS-regulating protein SugR. The analysis of the labelling pattern of amino acids in different strains showed a coherent view of the substrate uptake of PDHC-deficient strains. Furthermore, the combination of advanced analytical methods such as GC–TOF and LC-MS/MS analysis allowed the identification of the xylulose metabolite, which is as yet unknown in C. glutamicum. In view of an assumed extended application of these analytical techniques, a better understanding of the used biological systems and thus a selective construction of production strains can be expected for the future. However, the deletion of the sugR gene resulted in a decline in l-valine yield, whereas modifications of the fermentation regime achieved an l-valine yield of 0.56 mol l-valine per mol glucose suggesting a promising approach for process optimisation.

References

Sugisaki Z (1959) Studies on l-valine fermentation. Part 1- Production of l-valine by Aerobacter Bacteria. J Gen Appl Microbiol 5:138–149

Eggeling L, Pfefferle W, Sahm H (2001) Amino acids. In: Colin R, Bjoern K (eds) Basic biotechnology. Cambridge University Press, Cambridge, New York, pp 281–303

Leuchtenberger W, Huthmacher K, Drauz K (2005) Biotechnological production of amino acids and derivatives: current status and prospects. Appl Microbiol Biotechnol 69:1–8

Demain AL, Adrio JL (2008) Contributions of microorganisms to industrial biology. Mol Biotechnol 38:41–55

Bartek T, Makus P, Klein B, Lang S, Oldiges M (2008) Influence of l-isoleucine and pantothenate auxotrophy for l-valine formation in Corynebacterium glutamicum revisited by metabolome analyses. Bioprocess Biosyst Eng 31:217–225

Radmacher E, Vaitsikova A, Burger U, Krumbach K, Sahm H, Eggeling L (2002) Linking central metabolism with increased pathway flux: l-valine accumulation by Corynebacterium glutamicum. Appl Environ Microbiol 68:2246–2250

Blombach B, Schreiner ME, Holatko J, Bartek T, Oldiges M, Eikmanns BJ (2007) l-valine production with pyruvate dehydrogenase complex-deficient Corynebacterium glutamicum. Appl Environ Microbiol 73:2079–2084

Leyval D, Uy D, Delaunay S, Goergen JL, Engasser JM (2003) Characterisation of the enzyme activities involved in the valine biosynthetic pathway in a valine-producing strain of Corynebacterium glutamicum. J Biotechnol 104:241–252

Bartek T, Blombach B, Zönnchen E, Makus P, Lang S, Eikmanns BJ, Oldiges M. Importance of NADPH supply for improved l-valine formation in Corynebacterium glutamicum. Biotechnol Prog. doi:10.1002/btpr.345

Blombach B, Schreiner ME, Bartek T, Oldiges M, Eikmanns BJ (2008) Corynebacterium glutamicum tailored for high-yield l-valine production. Appl Microbiol Biotechnol 79:471–479

Wendisch VF, Bott M, Kalinowski J, Oldiges M, Wiechert W (2006) Emerging Corynebacterium glutamicum systems biology. J Biotechnol 124:74–92

Mori M, Shiio I (1987) Phosphoenolypyruvate—sugar phosphotransferase systems and sugar metabolism in Brevibacterium flavum. Agric Biol Chem 51:2671–2678

Yokota A, Lindley ND (2005) Central metabolism: sugar uptake and conversion. In: Bott M, Eggeling L (eds) Handbook of Corynebacterium glutamicum. Taylor and Francis, Boca Raton, pp 215–240

Engels V, Wendisch VF (2007) The DeoR-type regulator SugR represses expression of ptsG in Corynebacterium glutamicum. J Bacteriol 189:2955–2966

Gaigalat L, Schlüter J-P, Hartmann M, Mormann S, Tauch A, Pühler A, Kalinowski J (2007) The DeoR-type transcriptional regulator SugR acts as a repressor for genes encoding the phosphoenolpyruvate:sugar phosphotransferase system (PTS) in Corynebacterium glutamicum. BMC Mol Biol 8:104

Tanaka Y, Teramoto H, Inui M, Yukawa H (2008) Regulation of expression of general components of the phosphoenolpyruvate: carbohydrate phosphotransferase system (PTS) by the global regulator SugR in Corynebacterium glutamicum. Appl Microbiol Biotechnol 78:309–318

Oldiges M, Lütz S, Pflug S, Schroer K, Stein N, Wiendahl C (2007) Metabolomics: current state and evolving methodologies and tools. Appl Microbiol Biotechnol 76:495–511

Luo B, Groenke K, Takors R, Wandrey C, Oldiges M (2007) Simultaneous determination of multiple intracellular metabolites in glycolysis, pentose phosphate pathway and tricarboxylic acid cycle by liquid chromatography-mass spectrometry. J Chromatogr A 1147:153–164

Villas-Boas SG, Mas S, Akesson M, Smedsgaard J, Nielsen J (2005) Mass spectrometry in metabolome analysis. Mass Spectrom Rev 24:613–646

Schreiner ME, Eikmanns BJ (2005) Pyruvate : quinone oxidoreductase from Corynebacterium glutamicum: purification and biochemical characterization. J Bacteriol 187:862–871

Blombach B, Arndt A, Auchter M, Eikmanns BJ (2009) l-Valine production during growth of pyruvate dehydrogenase complex-deficient Corynebacterium glutamicum in the presence of ethanol or by inactivation of the transcriptional regulator SugR. Appl Environ Microbiol 75:1197–1200

Brik-Ternbach M, Bollman C, Wandrey C, Takors R (2005) Application of model discriminating experimental design for modeling and development of a fermentative fed-batch l-valine production process. Biotechnol Bioeng 91:356–368

Link T, Backstrom M, Graham R, Essers R, Zorner K, Gatgens J, Burchell J, Taylor-Papadimitriou J, Hansson GC, Noll T (2004) Bioprocess development for the production of a recombinant MUC1 fusion protein expressed by CHO-K1 cells in protein-free medium. J Biotechnol 110:51–62

Zelic B, Gostovic S, Vuorilehto K, Vasic-Racki B, Takors R (2004) Process strategies to enhance pyruvate production with recombinant Escherichia coli: from repetitive fed-batch to in situ product recovery with fully integrated electrodialysis. Biotechnol Bioeng 85:638–646

de Koning W, van Dam K (1992) A method for the determination of changes of glycolytic metabolites in yeast on a subsecond time scale using extraction at neutral pH. Anal Biochem 204:118–123

Thiele B, Füllner K, Stein N, Oldiges M, Kuhn AJ, Hofmann D (2008) Analysis of amino acids without derivatization in barley extracts by LC–MS–MS. Anal Bioanal Chem. doi:10.1007/s00216-008-2167-9

Rönsch H, Krämer R, Morbach S (2003) Impact of osmotic stress on volume regulation, cytoplasmic solute composition and lysine production in Corynebacterium glutamicum MH20–22B. J Biotechnol 104:87–97

Sambrook J, Russel DW (2001) Molecular cloning. Cold Spring Harbor Laboratory Press, Cold Spring Harbor

Shimizu K (2004) Metabolic flux analysis based on C-13-labeling experiments and integration of the information with gene and protein expression patterns. In: Recent Progress of biochemical and biomedical engineering in Japan Ii. Springer, Berlin, pp 1–49

Strelkov S, von Elstermann M, Schomburg D (2004) Comprehensive analysis of metabolites in Corynebacterium glutamicum by gas chromatography/mass spectrometry. Biol Chem 385:853–861

Wagner C, Sefkow M, Kopka J (2003) Construction and application of a mass spectral and retention time index database generated from plant GC/EI–TOF–MS metabolite profiles. Phytochemistry 62:887–900

Rogatsky E, Jayatillake H, Goswami G, Tomuta V, Stein D (2005) Sensitive LC MS quantitative analysis of carbohydrates by Cs+ attachment. J Am Soc Mass Spectrom 16:1805–1811

Gerstmeir R, Wendisch VF, Schnicke S, Ruan H, Farwick M, Reinscheid D, Eikmanns BJ (2003) Acetate metabolism and its regulation in Corynebacterium glutamicum. J Biotechnol 104:99–122

Wendisch VF, De Graaf AA, Sahm H, Eikmanns BJ (2000) Quantitative determination of metabolic fluxes during coutilization of two carbon sources: comparative analyses with Corynebacterium glutamicum during growth on acetate and/or glucose. J Bacteriol 182:3088–3096

Blombach B, Schreiner ME, Moch M, Oldiges M, Eikmanns BJ (2007) Effect of pyruvate dehydrogenase complex deficiency on L-lysine production with Corynebacterium glutamicum. Appl Microbiol Biotechnol 76:615–623

Gourdon P, Raherimandimby M, Dominguez H, Cocaign-Bousquet M, Lindley ND (2003) Osmotic stress, glucose transport capacity and consequences for glutamate overproduction in Corynebacterium glutamicum. J Biotechnol 104:77–85

Dover LG, Cerdeno-Tarraga AM, Pallen MJ, Parkhill J, Besra GS (2004) Comparative cell wall core biosynthesis in the mycolated pathogens, Mycobacterium tuberculosis and Corynebacterium diphtheriae. FEMS Microbiol Rev 28:225–250

Wolf A, Krämer R, Morbach S (2003) Three pathways for trehalose metabolism in Corynebacterium glutamicum ATCC13032 and their significance in response to osmotic stress. Mol Microbiol 49:1119–1134

Jolkver E, Emer D, Ballan S, Krämer R, Eikmanns BJ, Marin K (2009) Identification and characterization of a bacterial transport system for the uptake of pyruvate, propionate, and acetate in Corynebacterium glutamicum. J Bacteriol 191:940–948

Acknowledgments

This work was financially supported by the Fachagentur Nachwachsende Rohstoffe of the BMVEL—Federal Ministry of Food, Agriculture and Consumer Protection—(grant 04NR003/22000304) and by Evonik Degussa GmbH. The authors wish to thank Verena Engels from IBT 1 of Forschungszentrum Jülich GmbH as well as Robert Gerstmeir and Andreas Karau from Evonik Degussa GmbH for fruitful cooperation and the valuable discussion of results, and Pia Makus for her assistance in performing the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bartek, T., Rudolf, C., Kerßen, U. et al. Studies on substrate utilisation in l-valine-producing Corynebacterium glutamicum strains deficient in pyruvate dehydrogenase complex. Bioprocess Biosyst Eng 33, 873–883 (2010). https://doi.org/10.1007/s00449-010-0410-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-010-0410-1