Abstract

Bacterial cellulose (BC) is a biopolymer with a wide range of potential applications starting from the food industry and biomedicine to electronics and cosmetics. Despite that, BC industrial production to date still is associated with certain difficulties. One of them is the high cost of growth media, which can reach up to 30% of production costs. To decrease production costs, use of industrial and agricultural by-products, including whey, as alternative growth media has been reported. Whey, as the main high-volume by-product of dairy industry, which is known for its low valorisation opportunities and negative environmental impact, can nevertheless be considered as an alternative growth medium for BC production. To date, several studies aimed at evaluating BC production on whey and lactose substrates have been reported, but they are still insufficient. Reviews of them showed that, in general, BC production on untreated whey- and lactose-containing media was lower than that on the standard medium. However, some wild and recombinant strains have been reported to produce BC on whey as good as the standard medium. Enzymatic and acidic pre-treatment of whey significantly enhanced BC yield. Changes in the microstructure of BC obtained from whey were also recognised, which should be considered regarding the impact on physical properties of the desired BC product. This mini-review indicates that currently whey can be recognised as quite a problematic alternative growth substrate for industrial BC production; however, further extensive studies may improve the prospects in both the search for a cheap alternative growth substrate for industrial BC production and valorisation of whey.

Key points

• Whey is a by-product in which valorisation is still challenging.

• Whey can be used for bacterial cellulose (BC) production.

• BC yield and properties vary upon cultivation conditions and producer strains.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biomaterials and biopolymers are gaining considerable importance as potential environmentally friendly materials that provide a wide range of applications in different fields (Yadav et al. 2015). Bacterial cellulose (BC)—an exopolysaccharide synthesised by certain strains of acetic acid bacteria (AAB) (Semjonovs et al. 2017)—is widely recognised as one of these materials. It is alleged that AAB form BC, possibly as a self-defence mechanism from the UV rays and to help bacteria float at air-liquid interface, in order to secure the required oxygen supply (Reiniati et al. 2017). BC can be obtained by way of static or agitated microbial fermentation (Azeredo et al. 2019). It is known that BC exhibits higher purity compared with plant cellulose which contains lignin, pectin, and hemicellulose, thus making it a more favourable cellulose source for varied use (Huang et al. 2014). Moreover, BC biotechnological production reduces the need to destroy forests for plant-origin cellulose production or overexploit an agricultural land for the same. BC is known for its properties that include high purity, flexibility, high water holding capacity, durability, high polymerisation degree, hydrophilicity, high crystallinity, mouldability into different shapes, and biomimetic 3D nano matrix—a network which resembles an extracellular matrix and high biocompatibility (Azeredo et al. 2019; Gorgieva and Trček 2019; Blanco Parte et al. 2020). Moreover, the fibrous structure of BC can serve as a matrix for composite materials, thus providing additional properties to the composite such as hydrophobicity, flexibility, increased mechanical strength, and antimicrobial, magnetic, and conducting properties, which are not present in pure BC itself (Ul-Islam et al. 2015).

Because of these properties, BC has a potential application in many fields and can be used to produce high-value eco-friendly products with the properties of outstanding existing products (Azeredo et al. 2019). In the food industry, BC can be used as an edible antimicrobial food coating increasing shelf life, as well as a healthy food supplement for patients with gastrointestinal disorders, obesity, cardiovascular diseases, and diabetes (Cho and Almeida 2017; Shi et al. 2014). BC food coatings make it possible to significantly decrease the use of preservatives and other chemical compounds in food (Rydz et al. 2018). Furthermore, it is widely known that high-fat diets can be harmful to human health, but low-fat products are recognised as less desirable due to inferior sensory properties. In turn, BC can be used as a potential fat replacer in food products such as cakes and ice cream by mimicking fat functionality and not providing any calories (Azeredo et al. 2019). Moreover, BC is a microbiota-friendly product which enhances the human immune system, reduces inflammation and cholesterol level (Holscher 2017), and is “generally recognised as safe” (GRAS status) (Shi et al. 2014). An example of BC application in food is nata de coco, which is traditionally obtained by fermentation of coconut milk with BC-forming AAB (Blanco Parte et al. 2020). BC can also be used in the production of composite packaging materials, instead of that mostly made from unbiodegradable petroleum-derived plastic, which is harmful to the environment and humans (Proshad et al. 2017). BC seems to be a promising alternative for the production of environment-friendly durable packaging materials and has the potential to replace plastics in the future. BC has a wide range of potential biomedical applications such as wound dressings, artificial skin and blood vessels, tissue engineering scaffolds, and coverings in nerve surgery and in prosthetics of fascia, bone, and cartilage (Wan et al. 2011; Picheth et al. 2017). It has been reported that in wound dressing, BC films attach to skin, thus providing the correct environment for skin regeneration (Gorgieva and Trček 2019). Antimicrobial agents can be added to these films in order to reduce the risk of infection (Rouabhia et al. 2014). BC can be merged with different types of drugs and provide matrix for controlled drug delivery and release (Pavaloiu et al. 2014; Ullah et al. 2016). Furthermore, different synthetic prostheses are often not biocompatible and may induce the rejection reaction by the host organism, whereas BC-based prosthesis is biocompatible and allows cell proliferation, blood vessel formation inside of BC prosthesis, because of the ability BC to resemble extracellular matrix (Ul-Islam et al. 2015). In electronics, different BC composites have the potential to be an environment-friendly material for flexible screen production (Ummartyotin et al. 2011), organic light-emitting diodes (Legnani et al. 2008), and humidity and gas sensors (Hu et al. 2011). Magnetically responsive flexible BC films with magnetite (Fe3O4) nanoparticles can be used in magnetic resonance imaging (Ul-Islam et al. 2015). In cosmetics, BC is reported to have already been used as a natural skin care facial mask and scrubs, mostly due to its ability to moisten skin and non-toxicity (Ullah et al. 2016). The use of BC immobilisation platforms for enzymatic reactions in chemical industry made it possible to improve the properties of industrial lipases compared with free lipases (Sheldon and van Pelt 2013). It was reported that BC-immobilised lipases show improved activity under both acidic and alkaline conditions, as well as higher activity at temperatures under 30 °C, making it possible to decrease energy demand in factories (Cai et al. 2018). Additionally, BC can be used in filtration membranes to provide a porous network for graphene oxide, showing good mechanical strength, water stability, and ion permeation, thus allowing it to be recognised as prospective for water purification (Fang et al. 2016).

Despite all the advantages of BC application, its industrial production is still problematic, which is impeding it from being successfully commercialised (da Gama and Dourado 2018). Several companies have tried to commercialise BC, but yet with quite limited success. In the 1990s, several Japanese companies and national institutions collaborated to produce BC. However, because of the lack of efficient fermentation systems, commercial production of BC was not achieved. Another example of a commercial-scale BC production attempt was made by two American joint companies—the Cetus Corporation and Weyerhaeuser Company. In addition, the Brazilian company BioFill Produtos Bioetecnológicos produced several biomedical products from BC. However, it was unsuccessful in large-scale commercialisation and is no longer active. There have only been several successful attempts at BC commercialisation. As previously mentioned, nata de coco is an example of BC application in food that has been active since 1954 and is characterised by high production volumes, but low profit margins. In the 1980s, Johnson & Johnson initiated an attempt to commercialise BC on a large scale. Research was conducted mostly in biomedical fields. Despite making several patents and BC products, the company did not reach commercial scale, probably due to high capital and production cost intensity. In 1996, Xylos Corporation acquired the rights to use these patents and in 2001–2003 commercialised several wound care products. In 2012, this business was bought by Lochmann and Rauscher which has continued producing BC product up to this day. In 2006, Polish scientists from the Lodz University of Technology published their results on BC application in the clinical treatment of different degree burns. After a while, the technology was bought by a Polish company BOWIL Biotech Ltd., which has started production of BC wound dressing materials and cosmetic products marketed under the trade name CELMAT® (da Gama and Dourado 2018).

Alternative substrates for industrial BC production

As previously stated, it is difficult to achieve BC commercialisation due to high production costs. One of the biggest problems is the high cost of standard BC growth medium, which can take up to 30% of the process’s production costs (Rivas et al. 2004). In order to decrease production costs, it is necessary to optimise the production process. One possible solution that should be considered is the use of alternative low-cost carbon sources (Semjonovs et al. 2017). Consequently, use of industrial by-products and agricultural wastes for BC production has been reported: crude glycerol remaining from biodiesel production, grape bagasse, molasses, corn steep liquor, rotten fruits, and milk whey (Table 1). However, several problems are connected to the use of alternative and less expensive carbon sources because they affect not only productivity, but also BC properties such as crystallinity, O2 and H2O transmission, and the degree of polymerisation. Moreover, growth media requirements and BC productivity broadly vary within AAB species and strains (Jozala et al. 2015; Salari et al. 2019).

Whey—a challenging dairy by-product

It is widely recognised that among agriculture and industry by-products, whey is problematic regarding its environmental impact, high volumes, and relatively little options of efficient valorisation. Milk production and processing have increased worldwide at a high rate of over 10% every 4 years. During processing of milk products, only 10–20% of milk volume is recovered as desired end product (cheese, casein, yoghurt, etc.), with 80–90% remaining as whey (Panghal et al. 2018). Annual whey production is about 180–190 × 106 tons (Baldasso et al. 2011). Most whey dry mass consists of 70% lactose with the presence of small amounts of glucose, galactose, lactulose, and arabinose. The well-known high biological value of milk whey is attributed to the content of proteins (mainly albumins and globulins), amino acids, vitamins (B6 and B12), lactic and citric acids, and minerals such as calcium, magnesium, phosphorous, as well as other minor biologically active compounds (Revin et al. 2018). Cheese whey is the most abundant and environment polluting waste generated by the dairy industry (Prazeres et al. 2012). As far as whey is concerned, the general problem is that only about 50% is processed with different technologies, while the rest is dumped as waste because of a lack of efficient further processing technologies. Due to its high organic load, disposal of whey industries has severe polluting effects on the environment, and on waters in particular (Panghal et al. 2018).

Considerable effort was made in the last few decades to find new whey valorisation techniques and decrease the polluting effects of whey (Koutinas et al. 2009). Whey is rich in sugars that makes it suitable for industrial production of different biotechnological products (Prazeres et al. 2012). There are several modern approaches to whey valorisation summarised in Fig. 1. Besides the applications mentioned in Fig. 1, a sustainable solution for whey valorisation can be provided by its bacterial conversion into a cheap fermentation medium for the production of varied biopolymers and other bioactive compounds (Zotta et al. 2020), including BC.

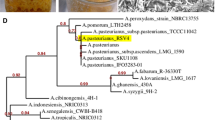

Whey as a substrate for BC synthesis

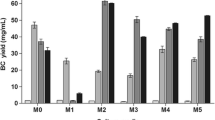

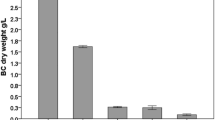

Only a few studies have aimed to evaluate whey as a substrate for BC production. In the study conducted in 2018 by Revin et al. (2018), Gluconobacter sucrofermentans B-11267 strain was used to evaluate whey as an alternative substrate for BC production. It was shown that on whey, BC production by this strain reached 5.45 g/L (dry weight), which is higher when compared with that obtained on the standard Hestrin-Schramm (HS) medium (2.14 g/L). The maximum rate of product formation occurred on the first day of the fermentation process. In that time, the amount of lactose decreased from 42.1 to 22.4 g/L indicating that this strain was able to use lactose as a C source. In this study, whey was shown to be a good alternative C source, mainly because of the strain’s ability to hydrolyse lactose. However, changes in BC micromorphology and crystallinity were observed after cultivation in whey compared with the standard HS medium. By using atomic force microscopy, it was determined that the widths of BC microfibrils were 60–90 nm and 100–180 nm for HS standard medium and for whey, respectively. In addition, as reported, changes in morphology resulted in changes in crystallinity. By using X-ray chromatography, it was shown that BC crystallinity index in whey was lower (50.2%) than that in HS (79.9%). However, it was shown that whey did not affect the chemical structure of BC (Revin et al. 2018). Obviously, alteration of BC growth medium by use of alternative C substrates, e.g. whey during the production process, can cause changes in BC microstructure, thus affecting the physical and mechanical properties (crystallinity index, polymerisation degree, molecular weight, water holding capacity, oxygen and water transmission rate) of the desired final product (Jozala et al. 2015; Gorgieva and Trček 2019). For example, using whey as an alternative media would decrease the crystallinity of BC from 80 to 50% (Revin et al. 2018) thus decreasing its mechanical strength and making it less suitable for application, e.g. as a durable bioplastic material.

In the study conducted in 2014 by Jozala et al. (2015) with the BC-producing Gluconacetobacter xylinus ATCC 53582 strain, milk whey was compared with standard HS medium, as well with media containing other alternative substrates such as rotten fruits, rotten fruits and whey mixtures in different ratios. Experiments showed that the use of whey medium resulted in lower BC yield (25 mg/mL) compared with standard HS medium (30.8 mg/mL) and rotten fruit medium, respectively (60.2 mg/mL). It was emphasised that G. xylinus ATCC 53582 preferably metabolises monosaccharides such as fructose and glucose. Furthermore, fruit-whey mixed media were evaluated differently in the study. It was shown that these mixtures are not more effective as a rotten fruit-only substrate, thus attributing a somewhat negative effect to whey on BC production in the presence of no-whey originated sugars. As previously stated, the main C source in whey is lactose which is a disaccharide and is not conducive to G. xylinus (Jozala et al. 2015) and other AAB.

Thus, it was reported that the use of whey- and lactose-containing media resulted in relatively low BC production. A study carried out by Tsouko et al. (2015) demonstrated that lactose was not efficiently metabolised by Komagataeibacter sucrofermentans DSM 15973. Bacteria were able to produce only 1.6 g/L of BC by growing on lactose, while it was able to produce 4.9 g/L by growing on sucrose (Tsouko et al. 2015). In another study, Acetobacter xylinum was able to produce 1.62 g/L BC by growing on lactose. To compare, this strain achieved its maximum BC production of 7.38 g/L on fructose (Embuscado et al. 1994).

Moreover, several other studies show that lactose does not support significant BC production. It has been shown that cheese whey permeate does not support a significant BC production by Acetobacter xylinum 10821 and Acetobacter xylinum 23700 (Thompson and Hamilton 2001). Another study showed low levels of BC production by Gluconacetobacter sacchari isolated from Kombucha tea on HS media modified by replacement of glucose with lactose (0.31 g/L) and cheese whey medium without any additional supplementations (0.08 g/L). BC production levels were lower compared with the standard HS media after 96 h of cultivation (2.7 g/L) (Carreira et al. 2011). Likewise, another study showed that Gluconacetobacter xylinus K3 showed BC yield on lactose (0.07 g/L) (Nguyen et al. 2008). Moreover, in another study, the final BC production of 0.09 g/L by G. xylinus ATCC 53524 grown on galactose (Mikkelsen et al. 2009) was reported. The minimal presence of BC in lactose- and whey-containing media was attributed to inoculum remnants or free glucose release upon lactose hydrolysis (Carreira et al. 2011). Low BC production on whey- or lactose-containing media can be caused by lack of lacZ gene responsible for β-galactosidase enzyme which ensures lactose hydrolysis to glucose and galactose monomers (Thompson and Hamilton 2001; Battad-Bernardo et al. 2004).

As a solution, construction of recombinant AAB strain capable of hydrolysing lactose and producing BC was proposed. A recombinant strain of Acetobacter xylinum was created by inserting lacZ gene, thus allowing the hydrolysis of lactose (Battad-Bernardo et al. 2004). The lacZ gene, which codes β-galactosidase, is one of the three enzymes responsible for the ability of Escherichia coli to metabolise lactose. The mini-Tn10:lacZ:kan gene was inserted into a wild-type strain of A. xylinus by mean of random transposon mutagenesis, thus creating lactose utilising and BC-producing strain ITz3. It was revealed that the lacZ gene was inserted into the chromosome of the bacteria. The strain maintained the stability of the inserted gene in the non-selective medium after more than 60 generations. The mutant strain was able to produce 1.82 g/L BC in whey-based substrate, which means a 28-fold increase of BC production compared with wild-type strain (Battad-Bernardo et al. 2004). Nevertheless, BC production still was not high enough to implement this strain in commercial BC production.

Another approach to facilitate BC production by AAB on whey lies in its hydrolytic pre-treatment. This can be achieved by two methods: enzymatic hydrolysis by adding β-galactosidase enzyme to the lactose-containing media or acidic hydrolysis, which can be achieved by adding acids instead of enzymes (Amaro et al. 2019). Pre-treatment was used in the study conducted by Salari et al. (2019). In this study, commercial β-galactosidase was used to hydrolyse whey in the culture media. The results showed that enzymatic pre-treatment improved BC production (3.55 g/L) by G. xylinus PTCC 1734 on enzymatically hydrolysed cheese whey, which according to the authors was higher than untreated whey and higher than the standard HS medium (3.2 g/L). However, despite its effectiveness, enzymatic pre-treatment significantly increases production costs (Amaro et al. 2019). Moreover, changes in BC microstructure compared with those of standard media were observed. BC produced on whey had a crystallinity index of 61.86% which is lower than the crystallinity index for BC on standard untreated HS media (79.07%) (Salari et al. 2019).

Discussion and conclusions

Since the process for BC commercial production should be simple and cost-effective, whey can be considered as a cheaper growth medium for BC production, in addition to reducing environmental pollution from dairy waste. However, at present, reported BC productivity on whey remains relatively low (not higher than 5.4 g/L) and BC production varies strongly within different strains. Thus, further extensive research aimed at evaluating BC-producing strains suitable for whey fermentation is required, including taking into account the physical properties of BC synthesised on whey. An important fact is, as reported, that the use of industrial and agricultural by-products as alternative growth media can lead to changes in produced BC microstructure and physical properties, which would significantly affect the physical and mechanical properties of desired BC products (Revin et al. 2018). For efficient BC production on whey, AAB strains with active lacZ genes enabling the hydrolysis of lactose should be applied (Battad-Bernardo et al. 2004) and/or hydrolytic pre-treatment should be performed. Despite the ability to hydrolyse lactose, AAB should usually use only glucose for further metabolism, leaving galactose unassimilated (Mikkelsen et al. 2009). The search for strains assimilating both glucose and galactose would have a significant impact on increased BC production. Another problem could be attributed not to lactose metabolism, but to weak hydrolysis of whey proteins. Relatively weak protease activity (Bossi et al. 2006) may not be enough to enable AAB to obtain all the required growth substances from whey, e.g. N, which restricts BC production. This question is still left mostly unstudied. Although whey can provide cheaper C source for BC synthesis than standard synthetic media, its use may result in the loss of some desired BC properties essential to the desired end product. To conclude, it is necessary to say that whey can currently be recognised as quite a problematic alternative growth substrate for industrial BC production. However, further studies may improve the prospects for both the search for a cheap alternative growth substrate for industrial BC production and valorisation of whey.

References

Amaro TMMM, Rosa D, Comi G, Iacumin L (2019) Prospects for the use of whey for polyhydroxyalkanoate (PHA) production. Front Microbiol 1. https://doi.org/10.3389/fmicb.2019.00992

Azeredo HMC, Barud H, Farinas CS, Vasconcellos VM, Claro AM (2019) Bacterial cellulose as a raw material for food and food packaging applications. Front Sustain Food Syst 3. https://doi.org/10.3389/fsufs.2019.00007

Bae S, Shoda M (2004) Bacterial cellulose production by fed-batch fermentation in molasses medium. Biotechnol Prog 20:1366–1371. https://doi.org/10.1021/bp0498490

Baldasso C, Barros TC, Tessaro IC (2011) Concentration and purification of whey proteins by ultrafiltration. Desalination 278:381–386. https://doi.org/10.1016/j.desal.2011.05.055

Battad-Bernardo E, McCrindle SL, Couperwhite I, Neilan BA (2004) Insertion of an E. coli lacZ gene in Acetobacter xylinus for the production of cellulose in whey. FEMS Microbiol Lett 231:253–260. https://doi.org/10.1016/S0378-1097(04)00007-2

Blanco Parte FG, Santoso SP, Chou CC, Verma V, Wang HT, Ismadji S, Cheng KC (2020) Current progress on the production, modification, and applications of bacterial cellulose. Crit Rev Biotechnol 40:1–18. https://doi.org/10.1080/07388551.2020.1713721

Bossi A, Bonizzato L, Zapparoli G (2006) Acidic extracellular proteases from microrganisms of fairly acidic niche. Protein Pept Lett 13:737–741. https://doi.org/10.2174/092986606777790647

Cai Q, Hu C, Yang N, Wang Q, Wang J, Pan H, Hu Y, Ruan C (2018) Enhanced activity and stability of industrial lipases immobilized onto spherelike bacterial cellulose. Int J Biol Macromol 109:1174–1181. https://doi.org/10.1016/j.ijbiomac.2017.11.100

Carreira P, Mendes JAS, Trovatti E, Serafim LS, Freire CSR, Silvestre AJD, Neto CP (2011) Utilization of residues from agro-forest industries in the production of high value bacterial cellulose. Bioresour Technol 102:7354–7360. https://doi.org/10.1016/j.biortech.2011.04.081

Cerrutti P, Roldán P, García RM, Galvagno MA, Vázquez A, Foresti ML (2016) Production of bacterial nanocellulose from wine industry residues: importance of fermentation time on pellicle characteristics. J Appl Polym Sci 133:1–9. https://doi.org/10.1002/app.43109

Chen L, Hong F, Yang X-x, Han S-f (2013) Biotransformation of wheat straw to bacterial cellulose and its mechanism. Bioresour Technol 135:464–468. https://doi.org/10.1016/j.biortech.2012.10.029

Cho S, Almeida N (2017) Diatery fiber and health. CRC Press, Boca Raton

da Gama FMP, Dourado F (2018) Bacterial nanocellulose: what future? BioImpacts 8:1–3. https://doi.org/10.15171/bi.2018.01

Embuscado ME, Marks JS, BeMiller JN (1994) Bacterial cellulose. I. Factors affecting the production of cellulose by Acetobacter xylinum. Top Catal 8:407–418. https://doi.org/10.1016/S0268-005X(09)80084-2

Fang Q, Zhou X, Deng W, Zheng Z, Liu Z (2016) Freestanding bacterial cellulose-graphene oxide composite membranes with high mechanical strength for selective ion permeation. Sci Rep 6:1–11. https://doi.org/10.1038/srep33185

Gorgieva S, Trček J (2019) Bacterial cellulose: production, modification and perspectives in biomedical applications. Nanomaterials 9:1–20. https://doi.org/10.3390/nano9101352

Holscher HD (2017) Dietary fiber and prebiotics and the gastrointestinal microbiota Hannah D. Holscher, PhD, RD Assistant Professor of Nutrition and Human Microbiome, Department of Food Science and Human Nutrition and Division of Nutritional Sciences, University of Ill. 1–23

Hu W, Chen S, Liu L, Ding B, Wang H (2011) Formaldehyde sensors based on nanofibrous polyethyleneimine/bacterial cellulose membranes coated quartz crystal microbalance. Sensors Actuators B Chem 157:554–559. https://doi.org/10.1016/j.snb.2011.05.021

Huang Y, Zhu C, Yang J, Nie Y, Chen C, Sun D (2014) Recent advances in bacterial cellulose. Cellulose 21:1–30. https://doi.org/10.1007/s10570-013-0088-z

Jahan F, Kumar V, Saxena RK (2018) Distillery effluent as a potential medium for bacterial cellulose production: a biopolymer of great commercial importance. Bioresour Technol 250:922–926. https://doi.org/10.1016/j.biortech.2017.09.094

Jozala AF, Pértile RAN, dos Santos CA, de Carvalho S-EV, Seckler MM, Gama FM, Pessoa A (2015) Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Appl Microbiol Biotechnol 99:1181–1190. https://doi.org/10.1007/s00253-014-6232-3

Koutinas AA, Papapostolou H, Dimitrellou D, Kopsahelis N, Katechaki E, Bekatorou A, Bosnea LA (2009) Whey valorisation: a complete and novel technology development for dairy industry starter culture production. Bioresour Technol 100:3734–3739. https://doi.org/10.1016/j.biortech.2009.01.058

Kurosumi A, Sasaki C, Yamashita Y, Nakamura Y (2009) Utilization of various fruit juices as carbon source for production of bacterial cellulose by Acetobacter xylinum NBRC 13693. Carbohydr Polym 76:333–335. https://doi.org/10.1016/j.carbpol.2008.11.009

Legnani C, Vilani C, Calil VL, Barud HS, Quirino WG, Achete CA, Ribeiro SJL, Cremona M (2008) Bacterial cellulose membrane as flexible substrate for organic light emitting devices. Thin Solid Films 517:1016–1020. https://doi.org/10.1016/j.tsf.2008.06.011

Mikkelsen D, Flanagan BM, Dykes GA, Gidley MJ (2009) Influence of different carbon sources on bacterial cellulose production by Gluconacetobacter xylinus strain ATCC 53524. J Appl Microbiol 107:576–583. https://doi.org/10.1111/j.1365-2672.2009.04226.x

Nguyen VT, Flanagan B, Gidley MJ, Dykes GA (2008) Characterization of cellulose production by a Gluconacetobacter xylinus strain from Kombucha. Curr Microbiol 57:449–453. https://doi.org/10.1007/s00284-008-9228-3

Panghal A, Patidar R, Jaglan S, Chhikara N, Khatkar SK, Gat Y, Sindhu N (2018) Whey valorization: current options and future scenario – a critical review. Nutr Food Sci 48:520–535. https://doi.org/10.1108/NFS-01-2018-0017

Pavaloiu RD, Stoica A, Stroescu M, Dobre T (2014) Controlled release of amoxicillin from bacterial cellulose membranes. Cent Eur J Chem 12:962–967. https://doi.org/10.2478/s11532-014-0541-3

Phong HX, Lin LT, Thanh NN, Long BHD, Dung NTP (2017) Investigating the conditions for nata-de-coco production by newly isolated Acetobacter sp. Americ J of Food Sci and Nutr 4:1–6

Picheth GF, Pirich CL, Sierakowski MR, Woehl MA, Sakakibara CN, de Souza CF, Martin AA, da Silva R, de Freitas RA (2017) Bacterial cellulose in biomedical applications: a review. Int J Biol Macromol 104:97–106. https://doi.org/10.1016/j.ijbiomac.2017.05.171

Prazeres AR, Carvalho F, Rivas J (2012) Cheese whey management: a review. J Environ Manag 110:48–68. https://doi.org/10.1016/j.jenvman.2012.05.018

Proshad R, Kormoker T, Islam MS, Haque MA, Rahman MM, Mithu MMR (2017) Toxic effects of plastic on human health and environment: a consequences of health risk assessment in Bangladesh. Int J Heal 6:1. https://doi.org/10.14419/ijh.v6i1.8655

Reiniati I, Hrymak AN, Margaritis A (2017) Recent developments in the production and applications of bacterial cellulose fibers and nanocrystals. Crit Rev Biotechnol 37:510–524. https://doi.org/10.1080/07388551.2016.1189871

Revin V, Liyaskina E, Nazarkina M, Bogatyreva A, Shchankin M (2018) Cost-effective production of bacterial cellulose using acidic food industry by-products. Braz J Microbiol 49:151–159. https://doi.org/10.1016/j.bjm.2017.12.012

Rivas B, Moldes AB, Domínguez JM, Parajó JC (2004) Development of culture media containing spent yeast cells of Debaryomyces hansenii and corn steep liquor for lactic acid production with Lactobacillus rhamnosus. Int J Food Microbiol 97:93–98. https://doi.org/10.1016/j.ijfoodmicro.2004.05.006

Rouabhia M, Asselin J, Tazi N, Messaddeq Y, Levinson D, Zhang Z (2014) Production of biocompatible and antimicrobial bacterial cellulose polymers functionalized by RGDC grafting groups and gentamicin. ACS Appl Mater Interfaces 6:1439–1446. https://doi.org/10.1021/am4027983

Rydz J, Musioł M, Zawidlak-w B, Sikorska W (2018) Present and of biodegradable polymers for food packaging applications. In: Grumezescu AM and Holban (ed) AM Biopolymers for food design. Academic Press, London, pp 431–467

Salari M, Sowti Khiabani M, Rezaei Mokarram R, Ghanbarzadeh B, Samadi Kafil H (2019) Preparation and characterization of cellulose nanocrystals from bacterial cellulose produced in sugar beet molasses and cheese whey media. Int J Biol Macromol 122:280–288. https://doi.org/10.1016/j.ijbiomac.2018.10.136

Semjonovs P, Ruklisha M, Paegle L, Saka M, Treimane R, Skute M, Rozenberga L, Vikele L, Sabovics M, Cleenwerck I (2017) Cellulose synthesis by Komagataeibacter rhaeticus strain P 1463 isolated from Kombucha. Appl Microbiol Biotechnol 101:1003–1012. https://doi.org/10.1007/s00253-016-7761-8

Sheldon RA, van Pelt S (2013) Enzyme immobilisation in biocatalysis: why, what and how. Chem Soc Rev 42:6223–6235. https://doi.org/10.1039/c3cs60075k

Shi Z, Zhang Y, Phillips GO, Yang G (2014) Utilization of bacterial cellulose in food. Food Hydrocoll 35:539–545. https://doi.org/10.1016/j.foodhyd.2013.07.012

Thompson DN, Hamilton MA (2001) Production of bacterial cellulose from alternate feedstocks. Appl Biochem Biotechnol Part A Enzym Eng Biotechnol 91–93:503–513. https://doi.org/10.1385/ABAB:91-93:1-9:503

Tsouko E, Kourmentza C, Ladakis D, Kopsahelis N, Mandala I, Papanikolaou S, Paloukis F, Alves V, Koutinas A (2015) Bacterial cellulose production from industrial waste and by-product streams. Int J Mol Sci 16:14832–14849. https://doi.org/10.3390/ijms160714832

Ul-Islam M, Khan S, Ullah MW, Park JK (2015) Bacterial cellulose composites: synthetic strategies and multiple applications in bio-medical and electro-conductive fields. Biotechnol J 10:1847–1861. https://doi.org/10.1002/biot.201500106

Ullah H, Santos HA, Khan T (2016) Applications of bacterial cellulose in food, cosmetics and drug delivery. Cellulose 23:2291–2314. https://doi.org/10.1007/s10570-016-0986-y

Ummartyotin S, Juntaro J, Sain M, Manuspiya H (2011) Si-O barrier technology for bacterial cellulose nanocomposite flexible displays. Carbohydr Polym 86:337–342. https://doi.org/10.1016/j.carbpol.2011.04.057

Vazquez A, Foresti ML, Cerrutti P, Galvagno M (2013) Bacterial cellulose from simple and low cost production media by Gluconacetobacter xylinus. J Polym Environ 21:545–554. https://doi.org/10.1007/s10924-012-0541-3

Wan Y, Gao C, Han M, Liang H, Ren K, Wang Y, Luo H (2011) Preparation and characterization of bacterial cellulose/heparin hybrid nanofiber for potential vascular tissue engineering scaffolds. Polym Adv Technol 22:2643–2648. https://doi.org/10.1002/pat.1692

Wu JM, Liu RH (2013) Cost-effective production of bacterial cellulose in static cultures using distillery wastewater. J Biosci Bioeng 115:284–290. https://doi.org/10.1016/j.jbiosc.2012.09.014

Yadav P, Yadav H, Shah VG, Shah G, Dhaka G (2015) Biomedical biopolymers, their origin and evolution in biomedical sciences: a systematic review. J Clin Diagnostic Res 9:21–25. https://doi.org/10.7860/JCDR/2015/13907.6565

Zhong C, Zhang GC, Liu M, Zheng XT, Han PP, Jia SR (2013) Metabolic flux analysis of Gluconacetobacter xylinus for bacterial cellulose production. Appl Microbiol Biotechnol 97:6189–6199. https://doi.org/10.1007/s00253-013-4908-8

Zotta T, Solieri L, Iacumin L, Picozzi C, Gullo M (2020) Valorization of cheese whey using microbial fermentations. Appl Microbiol Biotechnol 104:2749–2764. https://doi.org/10.1007/s00253-020-10408-2

Funding

This study was supported by the Ministry of Agriculture and Rural Support Service of the Republic of Latvia (grant number 19-00-A01612-000004). The funders had no role in study design, data collection and interpretation, or the decision to submit the work for publication.

Author information

Authors and Affiliations

Contributions

General writing of the manuscript, investigation, literature search and data analysis, editing: Sergejs Kolesovs. Conceptualisation, critical revision, and supervision: Pavels Semjonovs. All authors contributed to the study conception and design and read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that there are no competing interests.

Ethical approval

Not applicable, since the work does not involve any study with human participants or animals.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kolesovs, S., Semjonovs, P. Production of bacterial cellulose from whey—current state and prospects. Appl Microbiol Biotechnol 104, 7723–7730 (2020). https://doi.org/10.1007/s00253-020-10803-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-020-10803-9