Abstract

Heparin and chondroitin sulfate are used as anti-thrombic and anti-osteoarthritis drugs, respectively, but their pharmacological actions depend on their structural characteristics such as their sulfation grade and their molecular weight. In the last years, new fermentation-based biotechnological approaches have tried to obtain heparin and chondroitin sulfate starting from the heparosan and chondroitin-like capsular polysaccharides produced by Escherichia coli K5 and K4. The study of the microbial capsular polysaccharide molecular weight is critical to obtain nature-like or structural tailor cut glycosaminoglycan homologues. However, so far, it has been scarcely investigated. In this paper, for the first time, a new protocol was set up to determine the molecular weights of the capsular polysaccharides of three wild-type and three engineered E. coli K5 and K4 strains. The protocol includes a small-scale downstream train to purify the intact polysaccharides, directly from the fermentation broth supernatants, by using ultrafiltration membranes and anion exchange chromatography, and it couples size exclusion chromatography analyses with triple detector array. In the purification high recovery (> 85.0%) and the removal of the main contaminant, the lipopolysaccharide, were obtained. The averaged molecular weights of the wild-type capsular polysaccharides ranged from 51.3 to 90.9 kDa, while the engineered strains produced polysaccharides with higher molecular weights, ranging from 68.4 to 130.6 kDa, but with similar polydispersity values between 1.1 and 1.5.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Heparin and chondroitin sulfate

Heparin (HP) and chondroitin sulfate (CS) are negatively charged and highly sulfated glycosaminoglycans (GAGs) that are found in animal cartilages, tissues, or organs. Heparin is primarily made of a trisulfated disaccharide repeating unit chain of [4)-2-O-sulfo-α-L-IdoA-(1 → 4)-6-O-sulfo-N-sulfo-α-d-GlcNAc-(1→]n (IdoA = iduronic acid, GlcNAc = N-acetyl-glucosamine), together with less sulfated and variably sulfated domains, having an average molecular weight ranging (Mw) from 12.0 to 15.0 kDa (Linhardt 2003; Onishi et al. 2016). CS, instead, is made by [4)-β-d-GlcA-(1 → 3)-β-d-GalNAc-(1→]n disaccharide repeating units (GlcA = glucuronic acid, GalNAc = N-acetyl-galactosamine) that in nature could be mono- or di-sulfated, with molecular weight values ranging from 14.0 to 70.0 kDa, according to the animal origin of the tissues or the age of the animals (Restaino et al. 2013a; Restaino et al. 2017a; Collin et al. 2017). HP and CS have different pharmacological properties. HP is used as an anticoagulant drug; it is mainly sold as fractionated chains (3–8 kDa) obtained by enzymatic or chemical hydrolysis of the heparin extracted and purified from porcine and bovine intestine or lung, for a total market of 100 metric tons per year (Linhardt 2003; Bashkar et al. 2012; Onishi et al. 2016). CS is used, orally administered, as active principle of anti-arthritis and anti-osteoarthritis drugs, as well as dietary supplements (Restaino et al. 2013a, 2017a). CS is produced by extraction and purification from shark fins, bovine, chicken trachea, or pig muzzles, and it counts a global market, as raw material, of around 600 metric tons (Restaino et al. 2013a). HP and CS manufacturing processes have to handle many safety, ecological, and economic issues like the difficulty to recover the animal sources, the complex, not environment-friendly purification procedures, based on the use of large volumes of organic solvents, and the risk of uncontrolled contaminations or intentional adulterations. Furthermore, recent, new, more strict legislation constraints have prohibited in some countries the use of any animal derived molecules for pharmaceutical applications (Guerrini et al. 2008; Pomin et al. 2012; Restaino et al. 2017a).

Biotechnological production from microbial capsular polysaccharides

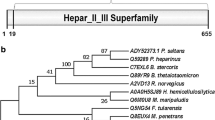

To overcome all these issues, in the last years, new alternative, biotechnological approaches have been studied to produce HP and CS natural like homologues starting from Escherichia coli capsular polysaccharides (CPS) whose structures resemble the two glycosaminoglycan ones. Both strains E. coli O10:K5:H4 (E. coli K5) and E. coli O6:K5:H1 (E. coli Nissle 1917) produce non-sulfated heparosan-like CPSs (K5 CPS) made of [→4)-β-d-GlcpA-(1 → 4)-α-d-GlcpNAc-(1→]n disaccharides (Vann et al. 1981; Grozdanov et al. 2004) (Fig. 1a). The second strain is considered non-pathogenic and probiotic, lacking defined virulence factors, showing only a semirough lipopolysaccharide (LPS) and expressing fitness factors such as microcins and adhesins that allow its colonization in the human gut (Grozdanov et al. 2004). Escherichia coli O5:K4:H4 (E. coli K4) produces a non-sulfated capsular polysaccharide whose backbone is similar to chondroitin (K4 CPS), made of [→4)-β-d-GlcpA-(1 → 3)-β-d-GalpNAc-(1→]n, with an extra fructose monosaccharide bound to the glucuronic acid residue (Rodriguez et al. 1998) (Fig. 1a). However, a defructosylated form can also be produced during the bacterial growth (D-K4 CPS). E. coli K5 and E. coli K4, but not E. coli Nissle 1917, have been widely employed to produce HP and CS through two similar biotechnological approaches that coupled high cell density fermentation strategies (Cimini et al. 2010a; Wang et al. 2010; Restaino et al. 2011; Liu et al. 2012; Restaino et al. 2013b) with innovative downstream protocols (Schiraldi et al. 2011; Bashkar et al. 2012; Schiraldi et al. 2012), followed by enzymatic or chemical sulfation reactions (Bedini et al. 2011; Bashkar et al. 2012; Restaino et al. 2013c). Moreover, especially in the case of E. coli K4, different engineering strategies and numerous molecular biology tools were employed to obtain new over-producing strains (Cimini et al. 2010b; Zanfardino et al. 2010; Zhang et al. 2012; Cimini et al. 2013; Cimini et al. 2014; Cimini et al. 2018). EcK4r3, for example, that over-expresses the transcriptional activator RfaH showed a 3.8-fold improvement of CPS titer compared to the wild-type strain in DO-stat fed-batch experiments (Cimini et al. 2013). RfaH was demonstrated to guarantee read through transcription of region 2 and 3 genes and also to regulate expression of other virulence factors (Stevens et al. 1997). In fact, mutations of rfaH in E. coli K5 strongly reduced the expression of kfi and kps genes, thus abolishing capsule expression (Stevens et al. 1994; Stevens et al. 1994). On the other hand, the introduction of additional rfaH copies in E. coli K5 and in E. coli Nissle 1917, as CPS boosting strategy, has not been investigated so far. Since the capsular polysaccharides are produced during the bacterial growth under precise conditions, and then released in the culture medium in the stationary phase, the biotechnological process design has included, so far, investigations on both new fermentation and engineering strategies to increase the CPS production, as well as studies on downstream processes that could allow the removal of the main contaminant, the lipopolysaccharide endotoxin, that is simultaneously produced and released in the medium (Schiraldi et al. 2011; Bashkar et al. 2012).

Purification and characterization of biotechnological heparin and chondroitin sulfate

To initially purify the K5 CPS from E. coli K5 fermentation broth supernatants, diverse downstream protocols were exploited that included ethanol precipitations coupled with 1 M sodium hydroxide bleaching procedures, or 30% hydrogen peroxide treatments with dialyses or with weak anion exchange chromatography purification (Ly et al. 2011; Higashi et al. 2011). The obtained crude material was then photochemically depolymerized down to 8.0–9.0 kDa, a molecular size useful for the following enzymatic sulfation that was performed by using recombinant mammalian C5-epimerase, 2,3,6-O-sulfotransferases, and N-deacylase/N-sulfotransferase (Bashkar et al. 2012). A K4 CPS with a 90% purity grade was obtained from the fermentation of E. coli K4 followed by two ultrafiltration and diafiltration steps on different cut-offs (100 and 30 kDa), alternated with a mild acid hydrolysis that caused the defructosylation of the K4 CPS and the cleavage of the lipophilic portion of the LPS at the same time (Schiraldi et al. 2011). The purification grade and the Mw (45.0 kDa) obtained for the K4 CPS after this downstream protocol were suitable for the following chemical sulfation reaction that drove to a nature-like, biotechnological CS (Bedini et al. 2011). Although all these protocols allowed to prepare K5 and K4 CPS crude materials of the size and purification grade suitable for the manufacturing of the biotechnological HP and CS homologues, they might have also selected the molecular size or degraded the initial intact capsular polysaccharide chains. The exact molecular weight of the K5 and K4 CPS has been only scarcely investigated so far. Precisely determining it could provide new insights on the microbial biosynthetic machinery and drive to exploit new potential applications of the biotechnologically produced heparosan and chondroitin. So far, the molecular weight of the intact heparosan from E. coli Nissle 1917 has been determined only by PAGE gel electrophoresis (Hickey et al. 2013), while no one has reported the Mw of the intact K4 CPS from E. coli K4. The intact K5 CPS from E. coli K5 has been investigated more, but different averaged molecular weights were found according to the diverse purification protocols or analytical methods used. The Mw resulted between 21.0 and 24.1 kDa by isocratic PAGE gel analyses or between 51.5 and 57.5 kDa by gradient PAGE gel analyses (Ly et al. 2011), while values between 1.5 and 16.0 kDa or between 29.0 and 77.8 kDa were obtained by gel permeation chromatography with UV or refractive index detection, respectively (Manzoni et al. 1996; Higashi et al. 2011). Furthermore, so far, no data have been reported in literature on the Mw of K5 or K4 CPSs from engineered E. coli strains. The only exception is the determination of the capsular polysaccharide Mw of a waaR deletion mutant of E. coli K5 that resulted lower than the wild-type value (Huang et al. 2016). In order to precisely determine the molecular weights and the polydispersity values of the intact K5 and K4 capsular polysaccharides, in this paper, a new protocol was set up to purify the latter directly from the fermentation broth supernatants, by coupling membrane-based ultrafiltration steps and weak anion exchange chromatography. The purified products were successively analyzed by high-performance capillary electrophoresis (HPCE) and size exclusion chromatography with triple detection array (SEC-TDA) (Fig. 1b). The Mw values of the intact K5 and K4 capsular polysaccharides from both E. coli K5 and E. coli Nissle 1917 and from E. coli K4 wild-type strains were determined. This strategy was also used to establish whether the overexpression of rfaH in all the afore mentioned wild-type strains had also affected the molecular weight distribution of the produced capsular polysaccharides.

Materials and methods

Materials and strains

The growth medium components, the salts used in the fermentation experiments, in the purification process and in the analytical procedures, as well as the glycosaminoglycan standards, were supplied by Sigma-Aldrich (St. Louis, USA), except for the yeast extract that was furnished by OXOID (United Kingdom). E. coli O10:K5:H4 (ATCC 23506) was purchased by the American Type Culture Collection (Virginia, USA); E. coli O5:K4:H4 (U1-41,11307) was purchased from the Culture Collection of the University of Göteborg (Sweden), while E. coli O6:K5:H1 (E. coli Nissle 1917) was kindly provided by Ardeypharm GmbH, Herdecke (Germany). The expression cassette containing the rfaH gene under the control of the pgapA promoter (Cimini et al. 2013) was cloned in the XL vector (Invitrogen, Carlsbad, CA) and electroporated in E. coli O10:K5:H4 and E. coli Nissle 1917 resulting in strains EcK5r1 and EcNr1 respectively. Wild-type electrocompetent cells were prepared according to the instrument’s instructions, and electroporation was conducted on a Bio-Rad Gene Pulser (2 mm cuvettes, 2.5 kV, 200 Ω, 25 μF). After, electroporation engineered cells were selected on LB plates supplemented with 50 μgmL-1 kanamycin. Genomic and plasmid DNA were isolated by using Qiagen DNeasy kit, Qiagen miniprep kit (Qiagen, Valencia, CA), respectively, according to the manufacturer’s instructions. The construction of the EcK4r3 strain, instead, was previously reported (Cimini et al. 2013). All the strains were stored in 20% (v/v) glycerol stock solutions at − 80 °C. A growth medium containing glucose (10.0–20.0 g L−1), yeast extract (2.0–4.0 g L−1), and 2.0 g L−1 KH2PO4 ; 9.7 g L−1 K2HPO4; 0.5 g L−1 Na3C6H5O7; 1.0 g L−1 (NH4)2SO4; 0.1 g L−1 MgCl2 was used for both shake flask and fermentation experiments.

Shake flask and fermentation experiments

For shake flask growths, single colonies, obtained from freshly streaked glycerol stabs, were used to inoculate pre-cultures that were incubated o/n at 37 °C in shaking conditions. Shake flask experiments were conducted in triplicate in 1-L baffled flasks containing 200 mL of medium, in order to keep a 1 to 5 medium/air volume ratio, for 24 h at 37 °C and 200 rpm in a rotary shaker incubator (model Minitron, Infors, Botthingen, Switzerland). Fermentation experiments were performed in a 2.5- L in situ sterilisable Biostat CT plus fermenter (Braun Biotech International, Sartorius Group, Germany). The pO2 electrode calibration was performed using a pure oxygen flow for the 100% value. A 16-h old pre-culture was used as starter to inoculate the bioreactor (10% v/v). Batch experiments were conducted for 20 h, at least in duplicates, at 37 °C, at a constant pH of 7.5 maintained by addition of 30% (v/v) NH4OH or 30% (v/v) H2SO4, and at 30% of air saturation. Pulse additions of kanamycin were performed throughout the experiments to keep a high selection pressure and reduce plasmid loss. Time course samples for the determination of the bacterial growth and the capsular polysaccharide production were withdrawn during the course of both shake flask and fermentation experiments: the biomass formation was monitored by measuring the optical density (OD) of the culture at 600 nm (Spectrophotometer DU800, Beckman Coulter, USA), while the polysaccharide production was established by HPCE. The capsular polysaccharide yield on substrate (YCPS/x) and the capsular polysaccharide yield on biomass (YCPS/OD) were calculated by dividing the CPS concentration obtained by HPCE analyses, in terms of milligrams per liter, by the grams per liter of consumed glucose or by the maximum OD value (ODmax) reached during the growth. The μmax value was calculated as the maximum specific growth rate per hour. Plasmid maintenance was evaluated at the end of each growth experiment. In particular, cultures were serially diluted with physiological solution and plated on LB and on LB supplemented with 50 μg/mL -1 of kanamycin, simultaneously. Plasmid maintenance was calculated as the percentage ratio of colony-forming units (cfu) obtained on LB with antibiotic supplementation and the units obtained on antibiotic-free LB.

Ultrafiltration purification

The fermentation broths of the batch experiments of both wild-type and engineered strains were collected at 20 h, and the cells were separated by centrifugation at 5500×g for 30 min (Avanti J-20XP, Beckman Coulter, USA). The supernatants were treated with protease from Aspergillus oryzae (Sigma-Aldrich, St. Louis, USA), as previously reported (Schiraldi et al. 2011; Schiraldi et al. 2012) and then purified from residual proteins and salts by ultrafiltration on 5.0 kDa cut-off membranes (0.1 m2 of total filtering area, Sartorius Group, Germany) by using an automatic tangential flow filtration system (Uniflux 10, UNICORN, GE Healthcare, USA) connected to a software to control, to handle, and to monitor the process parameters (Schiraldi et al. 2011; Schiraldi et al. 2012). After filtering 90% of the samples, a continuous diafiltration procedure was performed by adding about 3 volumes of milliQ water to the retentate (in relation to the concentrated volume) and by concentrating the samples from 8 to 10 times. During the filtration processes, the trans-membrane pressure (TMP) was calculated according to the following formula: TMP = [(inlet pressure + retentate pressure)/2], considering a permeate pressure of zero. Fluxes (LMH, L/m2·h) were calculated as volumes of permeate in a period of time (L/h) divided by the membrane surface area. Samples of the retentate and permeate were collected during the purification processes to be analyzed by HPCE in order to determine the CPS concentrations and the process recovery. Most of the CPSs (> 85.0%) were retained by the membranes and collected in the retentate samples as determined by HPCE analyses.

Anion exchange chromatography

The capsular polysaccharides of both wild-type and engineered strains contained in the concentrated retentate samples were purified by weak anion exchange chromatography on small diethylamine (DEAE) resin devices (Vivapure D maxi H, Sartorius Group, Germany), by loading 1.0 ml of CPS concentrated solutions containing between 12.0 and 16.0 mg of polysaccharides, and by eluting in gradient conditions with 4 volumes of diverse NaCl solutions in the range from 0.05 to 1.00 M, containing 0.02 M of CH3COONa and all buffered at pH 4.0, by centrifuging at 615×g and at 4 °C, for 5 min (Avanti J-20XP, Beckman Coulter, USA). Three different elution profiles, with diverse gradient steps, were investigated in order to maximize the CPS recovery, after an initial resin washing step (1.00 M NaCl plus 0.02 M of CH3COONa at pH 4.0) and a conditioning one (0.05 M NaCl plus 0.02 M of CH3COONa at pH 4.0): profile A [0.10 M NaCl, 0.25 M NaCl, 0.35 M NaCl, 0.60 M NaCl, 1.00 M NaCl, all plus 0.02 M of CH3COONa and all buffered at pH 4.0]; profile B [0.10 M NaCl, 0.25 M NaCl, 0.30 M NaCl, 0.35 M NaCl, 0.40 M NaCl, 1.00 M NaCl, all plus 0.02 M of CH3COONa and all buffered at pH 4.0]; and profile C [0.10 M NaCl, 0.25 M NaCl, 0.30 M NaCl, 0.32 M NaCl, 0.35 M NaCl, 0.40 M NaCl, 0.60 M NaCl, 1.00 M NaCl, all plus 0.02 M of CH3COONa and all buffered at pH 4.0]. Every fraction was precipitated with 4 volumes of cold ethanol at 4 °C, for 18 h, centrifuged at 3100×g and at 4 °C, for 20 min (Avanti J-20XP, Beckman Coulter, USA) and dissolved in 1 mL of milliQ water to be then analyzed by HPCE and SEC-TDA.

High-performance capillary electrophoresis analyses

The concentrations of CPSs (K5, K4, D-K4), as well as that of the lipopolysaccharide contaminants present in the broth samples of wild-type and engineered strains or obtained from the different purification steps, were analyzed by HPCE by using a P/ACE MDQ instrument (Beckman Coulter, USA) according to previously described methods (Restaino et al. 2009, Restaino et al. 2017b).

Molecular weight analyses by SEC-TDA

Molecular weight analyses of the concentrated ultrafiltered samples or of the purified K5 and K4 capsular polysaccharide fractions, obtained from the anion exchange chromatography, were performed by a high-performance size exclusion chromatographic system (Viscotek , Malvern, Italy), equipped with a triple detector array module including a refractive index detector (RI), a four-bridge viscosimeter (VIS), and a laser detector (LS) made of a right-angle light scattering (RALS) detector and a low-angle light scattering (LALS) one, as previously reported (Restaino et al. 2017a). Two gel-permeation columns (TSK-GEL GMPWXL, 7.8 × 30.0 cm, Tosoh Bioscience, Italy), equipped with a guard column, were set in series to perform the analyses. The OmniSEC software program was used for the acquisition and analysis of the data. Elution was performed in isocratic conditions with 0.1 M NaNO3 at pH 7.0, at a flow rate of 0.6 mL min−1, at 40 °C in 50 min runs, after injection of 0.1 mL of the sample. The calibration of the instrument was performed by using a polyethylene oxide (PEO) standard (22 kDa PolyCAL, Viscotek, Malvern, Italy). All the different samples of K5, K4 and D-K4 CPSs in a concentration range between 0.4 and 2.5 g L−1 were analyzed in duplicate. Specific evaluation of the CPSs average molecular weight (Mw), of the polidispersity index (Mw/Mn), and of the intrinsic viscosity (IV) of the every single eluted fractions from the anion exchange chromatography was determined by all the detector signals applying the equations reported by the manufacturer (data from Viscotek) and on the basis of the CPS dn∙dc−1 values. The dn∙dc−1 values of the K5, K4 and D-K4 CPSs were calculated according to the following formula suggested by the manufacturer (data from Viscotek) [dn∙dc−1 = ((Area RI/g mL−1)/(kRI∙injection volume))∙refractive index of the solvent] (where the injection volume was 0.1 mL; the refractive index of the solvent was 1.33; the constant kRI was 2.0293∙107)], after injecting in duplicate solutions of the purified CPSs in a concentration range from 0.4 to 2.5 g L−1 and by plotting these concentrations versus the obtained peak areas of the RI signal. The calculated dn∙dc−1 values of the microbial CPSs were then compared with the ones of the animal sourced HP, CS, and HA standards reported in literature (data from Viscotek).

Results

Shake flask and fermentation experiments

E. coli Nissle 1917 and E. coli K5 strains transformed with XL- pgapArfaH vector were grown in shake flasks to identify the best CPS over-producers compared to each respective wild -type. Quite similar results were obtained among the different clones screened for each transformation, results are indicated in Table 1. Both recombinant strains demonstrated an increase of polysaccharide production after 24 h of growth compared to the wild -types. However, a major effect was observed in EcK5r1 that showed a 3-fold higher final CPS titer and an almost 4-fold higher yield on substrate (YK5CPS/x) compared to E. coli K5. This result was also accompanied by a 20% lower growth rate. In controlled batch experiments on lab scale (2.5 L), both recombinant strains demonstrated an almost 30% higher yield on biomass (YK5CPS/OD) compared to the wild -type and a high maintenance of the expression vector until the end of the experiment (Table 1). The final concentration of K5 CPS produced by EcK5r1 and EcNr1 increased by 30.0% and 50.0%, respectively, demonstrated the efficacy of the engineering strategy. Batch experiments were also performed on the E. coli K4 and EcK4r3 strains; growth and K4 CPS production resulted similar to the previously reported data (Cimini et al. 2010a; Cimini et al. 2013).

Ultrafiltration and anion exchange chromatography purification

Ultrafiltration processes were set up to recover the CPSs from the broth supernatants of batch experiments after centrifugation and protease treatment. In all cases, a single step on 5.0 kDa cut-off membranes was performed; all the processes resulted similar in terms of permeate flux decrease that was around 20.0 ± 5.0%, from 7.2 ± 0.5 to 5.5 ± 0.7 LMH. The trans-membrane pressure increased from 0.45 ± 0.05 to 0.90 ± 0.05 bar (Fig. S1). The CPSs were collected in the 5.0 kDa retentate with a recovery higher than 85.0%. The concentrated CPS samples obtained by ultrafiltration were then further purified by anion exchange chromatography using small column devices. By using only one step of elution, with 1.0 M NaCl plus 0.02 M of CH3COONa, similarly to a previously reported protocol (Ly et al. 2011), we did not obtain the separation of CPSs from the lipopolysaccharides (Data not shown). In order to optimize the CPS recovery, three different elution profiles of 5, 6, or 8 different steps (profile A, B, and C, respectively, described above) were investigated after two initial steps for the washing and conditioning of the resin (Fig. 2a, b). By eluting with a 6 step gradient (profile B), the maximum recovery of CPS was obtained (> 92.0%); lower or higher number of steps reduced the recovery values (about 67.0% and 50.0%, respectively) (Fig. 2a, b). The recovery values of the CPSs obtained by applying the profile B after an eventual second and third purification step resulted similar, around 81.0–86.0%. HPCE analyses demonstrated that all the six CPSs were completely eluted in a range from 0.25 to 0.40 M NaCl plus 0.02 M of CH3COONa; no CPSs were found at fractions eluted with lower or higher NaCl molarity.

High-performance capillary electrophoresis and molecular weight analyses

After the ultrafiltration purification step, the concentrated CPS samples of all the six strains showed a residual LPS contamination in SEC-TDA analyses (Fig. 3a, b). This contamination was lower in the case of the probiotic strains, E. coli Nissle 1917 and EcNr1, around 0.04 in terms LPS/CPS concentration ratios and higher in the case of E. coli K5 and K4 wild-type and engineered strains ranging from 2.44 to 10.2 in terms of LPS/CPS concentration ratios, as determined by HPCE analyses (Figs. 4a, b, 5a, b, and 6a, b. Note: in the case of E. coli Nissle 1917 and EcNr1 HPCE analyses, the LPS contamination was not visible in the concentration range used for the K5 CPS quantification; thus, it is not visible in the shown electropherograms. LPS quantification was performed by injecting 25 times more concentrated solutions; electropherograms not shown). The purification process by anion exchange chromatography allowed to obtain purified fractions with only one (E. coli Nissle 1917 and EcNr1), two (E. coli K5 and K4), or three steps of purifications (EcK5r1, EcK4r3) (Figs. 3c, d, 4a, b, 5a, b, and 6a, b). Purified K5, K4, and D-K4 materials were used to determine the dn∙dc−1 values of these polysaccharides by SEC-TDA analyses; these values were compared to the ones of the HP, CS, and HA standards (0.130, 0.146, and 0.155, respectively) as reported in literature (data from Viscotek). The dn∙dc−1 value of the K5 CPS resulted to be 0.129, thus similar to the one reported for HP, while the dn∙dc−1 of D-K4 CPS (0.155) was identical to the HA one. This data is consistent considering that the two polysaccharides have similar not-sulfated disaccharide units that differ only for an epimer ([4)-β-d-GlcA-(1 → 3)-β-d-GalNAc-(1→]n for D-K4 CPS and [4)-β-d-GlcA-(1 → 3)-β-d-GlcNAc-(1→]n for ΗΑ]. The K4 CPS dn∙dc−1 value was between the one obtained for HA and CS (0.152). Thanks to these new determined dn∙dc−1 values, the Mw, Mw/Mn, and the IV of the purified CPS fractions were determined by SEC-TDA analyses (Figs. 4c, d, 5c, d, and 6c, d; Table 2). The K5 CPSs from E. coli K5 and E. coli Nissle 1917 showed diverse Mw values of 51.3 ± 3.5 and 90.9 ± 4.8 kDa, respectively (Table 2). The K5 CPS from E. coli K5 showed a wider range of molecular weight species, from 45.4 to 62.13 kDa, compared to E. coli Nissle 1917 K5 CPS, whose fractions had a Mw difference of only 5.0 kDa and higher polydispersity that was 1.5 versus 1.2 (Table 2). This difference was also visible in the anion exchange elution profiles or in the broader peak shapes in HPCE analyses (Figs. 4a, c and 5a, c). The anion exchange chromatography separated the K4 and D-K4 CPSs that showed Mw values of 70.0 ± 1.9 kDa and 76.9 ± 2.0 kDa, respectively, and similar polydispersity (Fig. 6a, c; Table 2). The engineering strategy was able to increase not only the concentrations but also the length of the capsular polysaccharide chains produced by EcK5r1, EcNr1, and EcK4r3. The elution profiles of the CPSs polysaccharides produced by the engineered strains, as a matter of fact, showed fractions with higher molecular weight species compared to the wild-type ones (Figs. 4b, d, 5b, d, and 6b, d). The Mw values of the K5 CPSs produced by EcK5r1 and EcNr1 were 33.3% and 43.6% higher than the wild-type Mw values, ranging from 68.4 ± 2.5 to 130.6 ± 4.5 kDa, respectively. The K4 and D-K4 polysaccharides from EcK4r3 showed weighed averaged Mw values of 85.4 ± 1.2 kDa and 95.9 ± 1.8 kDa, thus 22.0% higher than the wild -type ones. Although the Mw values had increased, similar polydispersity values were noted (Table 2). The intrinsic viscosity values of all the six strains were also reported in Table 2.

SEC-TDA analyses of the intact K5 and K4 capsular polysaccharides in the ultrafiltered samples (a, b) and after anion-exchange purification (c, d). [In the chromatograms, the refractive index (red line), the right and low angle laser scattering (green and black line) and the viscometer (blue line) profiles are overlaid]

HPCE chromatograms of K5 CPS from E. coli K5 and EcK5r1 in the ultrafiltered samples (black lines) and after purification by anion exchange chromatography (blue lines) (a, b). Percentages of K5 CPS in the different fractions of the anion exchange chromatography (diamonds) and the corresponding molecular weights (bars) (c, d)

HPCE chromatograms of K5 CPS from E. coli Nissle 1917 and EcNr1 in the ultrafiltered samples (black lines) and after purification by anion exchange chromatography (blue lines) (a, b). Percentages of K5 CPS in the different fractions of the anion exchange chromatography (diamonds) and the corresponding molecular weights (bars) (c, d)

HPCE chromatograms of K4 CPS from E. coli K4 and EcK4r3 in the ultrafiltered samples (black lines) and after purification by anion exchange chromatography (blue and pink lines) (a, b). Percentages of K4 CPS in the different fractions of the anion exchange chromatography (diamonds) and the corresponding molecular weights (bars) (c, d)

Discussion

Molecular weight evaluation of biotechnological heparin and chondroitin sulfate

Wild-type and engineered over-producing E. coli K5 and E. coli K4 strains have been used so far as microbial cell factories for the biotechnological production of heparin and chondroitin sulfate (Cimini et al. 2010a; Wang et al. 2010; Restaino et al. 2011; Bashkar et al. 2012; Liu et al. 2012; Restaino et al. 2013b). In order to be considered similar to the animal homologues, the biotechnologically produced HP and CS should have the same structural characteristics in terms of sulfation grade and molecular weight. So far, acid hydrolysis or photochemical depolymerization and chemical or enzymatic sulfation reactions have been successfully employed to turn the microbial capsular polysaccharides into nature-like molecules (Bedini et al. 2011; Higashi et al. 2011; Schiraldi et al. 2011; Bashkar et al. 2012). Although so many valuable results have been reached, a lack still exists on the determination of the exact molecular weights of the intact bacterial capsular polysaccharide chains. In previous papers, the K5 CPS Mw of the wild-type E. coli K5 strain resulted to have different values according to the diverse analytical methods and the purification procedures employed. By using isocratic or gradient PAGE gel electrophoresis analyses, the Mw resulted to be in the range from 21.0 to 24.1 kDa and from 51.5 to 57.5 kDa, respectively (Ly et al. 2011). Values between 1.5 and 77.8 kDa were obtained by gel permeation chromatography with UV or refractive index detection (Manzoni et al. 1996; Higashi et al. 2011). Instead, the Mw of the K5 CPS from E. coli Nissle 1917 resulted to be 75.4 kDa as determined by PAGE gel electrophoresis (Hickey et al. 2013). The K4 CPS Mw values from both the wild-type and the engineered E. coli K4 strains, instead, have never been reported so far. The precise determination of the molecular weights of the K5 and K4 CPSs could also be useful to prepare structural tailor-cut molecules of the non-sulfated microbial heparosan and chondroitin chains that could have new potential applications in the biomedical field. As a matter of fact, heparosan chains in a range from 20.0 to 99.0 kDa have been recently tested as polymeric conjugating vehicles for delivering injectable therapeutics such as the granulocyte-colony stimulating factor to treat neutropenia or to coat liposomes used for the encapsulation of chemotherapic agents (Jing et al. 2017; Lane et al. 2017). On the other hand, the microbial chondroitin of 35.0 kDa has already demonstrated to exert higher anti-inflammatory actions than the animal chondroitin sulfate on human chondrocytes in in vitro cultures (Stellavato et al. 2016) and has also shown protective properties against amyloid and AGE-induced toxicity (Iannuzzi et al. 2019).

Molecular weight differences of K5 and K4 CPSs from wild-type and engineered Escherichia coli strains

For all these reasons in this paper, we have proposed a new protocol to precisely determine the molecular weights of the capsular polysaccharides of three wild-type and three engineered E. coli K5 and K4 strains by coupling ultrafiltration and anion exchange chromatography purification steps with analyses by size exclusion chromatography with triple detector array. In the CPS purification process, the removal of the lipopolysaccharide contaminants from the fermentation broth supernatant is critical, but, so far, no one has reported a specific investigation on the removal of the LPS from the K5 CPS broth supernatants. The removal of the endotoxins from the K4 CPS broth supernatant, instead, was performed by using an acid hydrolytic step to break the LPS structure, but this treatment also caused the defructosylation and the Mw reduction of the K4 CPS chain (Schiraldi et al. 2011; Schiraldi et al. 2012). All the purification procedures employed so far could also damage or reduce the capsular polysaccharide chains; thus, new downstream purification protocols are needed to remove the endotoxins without breaking or degrading the capsular chains. Moreover, up to date analytical tools are also been necessary to characterize in depth the capsular polysaccharide molecular weight and polydispersity. These analytical methods would be more precise than the ones used before (e.g., PAGE gel electrophoresis analyses and gel permeation chromatography) and might be able to discriminate small variations between the molecular weight values of the capsular polysaccharides produced by wild-type strains compared to the engineered ones. In this research, the 5.0 kDa membrane ultrafiltration step, used in the new designed downstream protocol, allowed a high recovery of the CPSs, by concentrating the supernatant samples. The following anion exchange chromatographic step assured an adequate removal of the endotoxins to precisely analyze the samples, and guaranteed a capsular polysaccharide purification fold up to 10, with very high recovery. The analyses of the intact chains by SEC-TDA were able to precisely determine a Mw variation of the CPS produced by the wild-type strains and to distinguish differences of the CPS Mw produced by the engineered strains, as never reported before. The K5 CPS Mw values seemed to change according to the bacterial strain, as well as the LPS production: chains of about 51.0 kDa or of about 91.0 kDa could be potentially produced for different applications by alternatively growing E. coli K5 or E. coli Nissle 1917. However, in the perspective of a biomedical application, the K5 CPS from E. coli Nissle 1917 could certainly be preferred, as it could be purified more easily from the LPS contaminant. The K4 CPS Mw was determined for the first time; the coupled purification protocol and analytical procedure also allowed to precisely distinguish the Mw of its defructosylated form. The purification of K5, K4, and D-K4 CPS material allowed also, as never reported before, to determine their dn∙dc−1 values, useful for SEC-TDA analyses, and to compare them with the dn∙dc−1 values of the animal sourced glycosaminoglycans, like HP, HA, and CS, already known in literature. The newly engineered K5 producer strains, over-expressing the positive regulator RfaH, both demonstrated a higher production of CPS in shake flask experiments, as previously observed for E. coli K4 (Cimini et al. 2013). Improved results were also confirmed in small-scale batch fermentation experiments where more similar performances were obtained by the two strains. EcNr1 demonstrated a slightly higher CPS titer compared to EcK5r1 probably due to a higher loss of the recombinant plasmid from the latter. Interestingly, Mw analyses demonstrated, for the first time, that this approach also influenced the CPS chain length thereby increasing the Mw from about 10.0 to 43.0%. By employing different strains, and by coupling engineering strategies and fermentation approaches, a panel of different heparosan and chondroitin molecular weight chains could be potentially obtained. Furthermore, these microbial chains are ready to be used, having the right length for diverse potential applications, without necessity of any modifications. In fact to obtain animal-like heparin and chondroitin sulfate, the heparosan and chondroitin-like microbial CPSs have to be wisely hydrolyzed. But, for other applications, it would not be necessary to cut or modify the microbial chains. For example, the capsules produced by the wild-type and engineered E. coli Nissle 1917 strains could be directly employed as polymeric conjugating vehicles without any structural modification. On the other hand, the anion exchange chromatography purification method could be employed also to select fractions of K5 and K4 CPSs of the appropriate size for different uses. In conclusion, this paper has reported for the first time a new protocol that includes an efficient downstream approach that allows purification directly from the fermentation broth supernatants, of the intact K5 and K4 CPSs produced by both wild-type and engineered E. coli strains. This could take place even in the presence of a 10-fold higher LPS contamination. By using a precise instrumental technique such as the SEC-TDA, the determination of the polysaccharide chain Mw values was obtained, thus opening the way to a deep characterization of the microbial glycosaminoglycan-like CPSs in the perspective of different pharmaceutical and biomedical applications.

References

Bashkar U, Sterner E, Hickey AM, Onishi A, Zhang F, Dordick JS, Linhardt RJ (2012) Engineering of routes to heparin and related polysaccharides. Appl Microbiol Biotechnol 93:1–16. https://doi.org/10.1007/s00253-011-3641-4

Bedini E, De Castro C, De Rosa M, Di Nola A, Iadonisi A, Restaino OF, Schiraldi C, Parrilli M (2011) A microbial-chemical strategy to produce chondroitin sulfate A,C. Angew Chem Int Ed Eng 50(27):6160-6-63. https://doi.org/10.1002/anie.201101142

Cimini D, Restaino OF, Catapano A, De Rosa M, Schiraldi C (2010a) Production of capsular polysaccharide from Escherichia coli K4 for biotechnological applications. Appl Microbiol Biotechnol 85(6):1779–1787. https://doi.org/10.1007/s00253-009-2261-8

Cimini D, De Rosa M, Viggiani A, Restaino OF, Carlino E, Schiraldi C (2010b) Improved fructosylated chondroitin production by kfoC overexpression in E. coli K4. Aust J Biotechnol 150:324–331. https://doi.org/10.1016/j.jbiotec.2010.09.954

Cimini D, De Rosa M, Carlino E, Ruggiero A, Schiraldi C (2013) Homologous overexpression of rfaH in E. coli K4 improves the production of chondroitin-like capsular polysaccharide. Microb Cell Factories 12:46

Cimini D, Fantaccione S, Volpe F, De Rosa M, Restaino OF, Aquino G, Schiraldi C (2014) IS2-mediated overexpression of kfoC in E. coli K4 increases chondroitin-like capsular polysaccharide production. Appl Microbiol Biotechnol 98(9):3955-3964. https://doi.org/10.1186/1475-2859-12-46

Cimini D, Russo R, D'Ambrosio S, Dello Iacono I, Rega C, Carlino E, Argenzio O, Russo L, D'Abrosca B, Chambery A, Schiraldi C (2018) Physiological characterization and quantitative proteomic analyses of metabolically engineered E. coli K4 strains with improved pathways for capsular polysaccharide biosynthesis. Biotechnol Bioeng 115(7):1801–1814. https://doi.org/10.1002/bit.26597

Collin EC, Carroll O, Kilcoyne M, Peroglio M, See E, Hendig D, Alin M, Grad S, Pandit A (2017) Ageing affects chondroitin sulfates and their synthetic enzymes in the invertebral disc. Signal Transduct Target Ther 2:17049. https://doi.org/10.1038/sigtrans.2017.49

Grozdanov L, Raasch C, Schulze J, Sonnenborn U, Gottschalk G, Hacker J, Dobrindt U (2004) Analysis of the genome structure of the nonpathogenic probiotic Escherichia coli strain Nissle 1917. J Bacteriol 186:5432-5441. https://doi.org/10.1128/JB.186.16.5432-5441.2004

Guerrini M, Beccati D, Shriver Z, Naggi A, Viswanathan K, Bisio A, Capila I, Lansing JC, Guglieri S, Fraser B, Al-Hakim A, Gunay NS, Zhang Z, Robinson L, Buhse LF, Nasr M, Woodcock J, Langer R, Venkataraman G, Linhardt RJ, Casu B, Torri G, Sasisekharan R (2008) Oversulfated chondroitin sulfate is a contaminant in heparin associated with adverse clinical events. Nat Biotechnol 26(6):669–675. https://doi.org/10.1038/nbt1407

Huang H, Liu X, Lv S, Zhong W, Zhang F, Linhardt RJ (2016) Recombinant Escherichia coli K5 strain with the deletion of waaR gene decreases the molecolar weight of the heparosan capsular polysaccharide. Appl Microbiol Biotechnol 100:7877-7885. https://doi.org/10.1007/s00253-016-7511-y

Hickey AM, Bhaskar U, Linhardt RJ, Dordick JS (2013) Effect of eliminase gene (elmA) deletion on heparosan production and shedding in Escherichia coli K5. J Biotechnol 165(3–4):175–177. https://doi.org/10.1016/j.jbiotec.2013.03.018

Higashi K, Ly M, Wang Z, Masuko S, Bhaskar U, Sterner E, Zhang F, Toida T, Dordick JS, Linhardt RJ (2011) Controlled photochemical depolymerization of K5 heparosan, a bioengineered heparin precursor. Carbohydr Polym 86:1365–1370. https://doi.org/10.1016/j.carbpol.2011.06.042

Iannuzzi C, Borriello M, D'Agostino A, Cimini D, Schiraldi C, Sirangelo I (2019) Protective effect of extractive and biotechnological chondroitin in insulin amyloid and advanced glycation end product-induced toxicity. J Cell Physiol 234(4):3814–3828. https://doi.org/10.1002/jcp.27153

Jing W, Roberts JW, Green DE, Almond A, DeAngelis PL (2017) Synthesis an characterization of heparosan granulocytes colony stimulating factor conjugates: a natural sugar-based drug delivery system to treat neutropenia. Glycobiology 27(11):1052–1061. https://doi.org/10.1093/glycob/cwx072

Lane RS, Haller FM, Chavaroche AAE, Almond A, DeAngelis P (2017) Heparosan-coated liposomes for drug delivery. Glycobiology 27(11):1062–1074. https://doi.org/10.1093/glycob/cwx070

Linhardt RJ (2003) Heparin: structure and activity. J Med Chem 46:2551–2564. https://doi.org/10.1021/jm030176m

Liu Y, Liu L, Chen J, Li J, Du G, Chen J (2012) Effects of carbon sources and feeding strategies on heparosan production by Escherichia coli K5. Bioprocess Biosyst Eng 35(7):1209-1218. https://doi.org/10.1007/s00449-012-0708-2

Ly M, Wang Z, Laremore TN, Zhang F, Zhong W, Pu D, Zagorevski DV, Dordick JS, Linhardt RJ (2011) Analysis of E. coli K5 capsular polysaccharide heparosan. Anal Bioanal Chem 399:737-745. https://doi.org/10.1007/s00216-010-3679-7

Manzoni M, Bergomi S, Cavazzoni V (1996) Production of K5 polysaccharides of different molecular weight by Escherichia coli. J Bioact Compat Polym 11:310–311

Onishi A, St Angel K, Dordick JS, Linhardt RJ (2016) Heparin and anticoagulation. Front Biosci Landmark 21:1372–1392. https://doi.org/10.2741/4462

Pomin VH, Piquet AA, Pereira MS, Mourão PA (2012) Residual keratan sulfate in chondroitin sulfate formulations for oral administration. Carbohydr Polym 90:839–846. https://doi.org/10.1016/j.carbpol.2012.06.009

Restaino OF, Cimini D, De Rosa M, De Castro C, Parrilli M, Schiraldi C (2009) High-performance CE of Escherichia coli K4 surface polysaccharides. Electrophoresis 30(22):3877–3883. https://doi.org/10.1002/elps.200900279

Restaino OF, Cimini D, De Rosa M, Catapano A, De Rosa M, Schiraldi C (2011) High cell density cultivation of Escherichia coli K4 in a microfiltration bioreactor: a step towards improvement of chondroitin precursor production. Microb Cell Factories 10:10. https://doi.org/10.1186/1475-2859-10-10

Restaino OF, De Rosa M, Cimini D, Schiraldi C (2013a) Manufacturing chondroitin sulfate: from animal source extraction to biotechnological production in: Pomin VH chondroitin sulfate: structure, uses and health implications. Nova Science Publishers, New York, pp 41–56

Restaino OF, di Lauro I, Cimini D, Carlino E, De Rosa M, Schiraldi C (2013b) Monosaccharide precursors for boosting chondroitin-like capsular polysaccharide production. Appl Microbiol Biotechnol 97(4):1699–1709. https://doi.org/10.1007/s00253-012-4343-2

Restaino OF, Bhaskar U, Paul P, Li L, De Rosa M, Dordick JS, Linhardt RJ (2013c) High cell density of a recombinant E. coli strain expressing a key enzyme in bioengineered heparin production. Appl Microbiol Biotechnol 97(9):3893-3900. https://doi.org/10.1007/s00253-012-4682-z

Restaino OF, Finamore R, Diana P, Marseglia M, Vitiello M, Casillo A, Bedini E, Parrilli M, Corsaro MM, Trifuoggi M, De Rosa M, Schiraldi C (2017a) A multi-analytical approach to better assess the keratan sulfate contamination in animal origin chondroitin sulfate. Anal Chim Acta 958:59–70. https://doi.org/10.1016/j.aca.2016.12.005

Restaino OF, di Lauro I, Di Nuzzo R, De Rosa M, Schiraldi C (2017b) New insight into chondroitin and heparosan-like capsular polysaccharide synthesis by profiling of the nucleotide sugar precursors. Biosci Rep 20:37(1). https://doi.org/10.1042/BSR20160548

Rodriguez M-L, Jann B, Jann K (1998) Structure and serological characteristics of the capsular K4 antigen of Escherichia coli O5:K4:H4, a fructose-containing polysaccharide with chondroitin backbone. Eur J Biochem 177:117–124

Schiraldi C, Carcarino IL, Alfano A, Restaino OF, Panariello A, De Rosa M (2011) Purification of chondroitin precursor from Escherichia coli K4 fermentation broth using membrane processing. Biotechnol J 6(4):410–419. https://doi.org/10.1002/biot.201000266

Schiraldi C, Alfano A, Cimini D, De Rosa M, Panariello A, Restaino, OF, De Rosa M (2012) Application of a 22-L scale membrane bioreactor and cross-flow ultrafiltration to obtain purified chondroitin. Biotechnol Prog 28(4):1012–1018. https://doi.org/10.1002/btpr.1566

Stellavato A, Tirino V, de Novellis F, Della Vecchia A, Cinquegrani F, De Rosa M, Papaccio G, Schiraldi C (2016) Biotechnological chondroitin a novel glycosamminoglycan with remarkable biological function on human primary chondrocytes. J Cell Biochem 117(9):2158–2169. https://doi.org/10.1002/jcb.25556

Stevens MP, Hänfling P, Jann B, Jann K, Roberts IS (1994) Regulation of Escherichia coli K5 capsular polysaccharide expression: evidence for involvement of RfaH in the expression of group II capsules. FEMS Microbiol Lett 124(1):93–98

Stevens MP, Clarke BR, Roberts IS (1997) Regulation of the Escherichia coli K5 capsule gene cluster by transcription antitermination. Mol Microbiol 24(5):1001–1012

Vann WF, Schmidt MA, Jann B, Jann K (1981) The structure of the capsular (K5 antigen) of urinary infective Escherichia coli O10:K5:H4. A polymer similar to desulpho-heparin. Eur J Biochem 116:359–364

Viscotek, information available from http://www.viscotek.com

Wang Z, Ly M, Zhang F, Zhong W, Suen A, Hickey AM, Dordick JS, Linhardt RJ (2010) E. coli K5 fermentation and preparation of heparosan, a bioengineered heparin precursor. Biotechnol Bioeng 107(6):964–973. https://doi.org/10.1002/bit.22898

Zanfardino A, Restaino OF, Notomista E, Cimini D, Schiraldi C, De Rosa M, De Felice M, Varcamonti M (2010) Isolation of an Escherichia coli K4 kfoC mutant over-producing capsular chondroitin. Microb Cell Factories 9:34. https://doi.org/10.1186/1475-2859-9-34

Zhang C, Liu L, Teng L, Chen J, Liu J, Du G, Chen J (2012) Metabolic engineering of Escherichia coli BL21 for biosynthesis of heparosan, a bioengineered heparin precursor. Metab Eng 14(5):521–527. https://doi.org/10.1016/j.ymben.2012.06.005

Funding

This work was supported by “Programma VALERE” of the University of Campania “Luigi Vanvitelli” with a grant for RTD-A researchers to Dr. Odile Francesca Restaino.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 66 kb)

Rights and permissions

About this article

Cite this article

Restaino, O.F., D’ambrosio, S., Cassese, E. et al. Molecular weight determination of heparosan- and chondroitin-like capsular polysaccharides: figuring out differences between wild -type and engineered Escherichia coli strains. Appl Microbiol Biotechnol 103, 6771–6782 (2019). https://doi.org/10.1007/s00253-019-09969-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-019-09969-8