Abstract

In this study, the effects of different gums on dielectric properties of doughs and breads baked in infrared-microwave combination oven were investigated. In addition, the quality parameters of breads formulated with different gums baked in infrared-microwave combination oven were determined. The gums used were xanthan, guar, xanthan-guar blend and κ-carrageenan. The gums were added to the formulation at 0.5% concentration. The dielectric properties and quality parameters of breads baked in infrared-microwave combination oven were found to be dependent on gum type. κ-carrageenan resulted in undesirable final bread quality, while xanthan-guar blend addition improved bread quality (high specific volume and porosity, low hardness values). The dielectric properties of bread samples formulated with κ-carrageenan were found to be the highest among the other gum types.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The dielectric properties of food materials are finding increasing interest as microwave processing and new combination processing technologies are adapted to be used in food industry. The interaction of microwave energy with a material is highly dependent on the dielectric properties of that material. The dielectric properties describe a material's ability to absorb, transmit and reflect electromagnetic energy [1]. Knowledge of the dielectric properties of food materials is not only important to understand the heating patterns during microwave and microwave-assisted (i.e. infrared-microwave combination heating) heating of foods, but it also plays a critical role in developing product, process and equipment with consistent and predictable properties [2]. Dielectric properties are dielectric constant and dielectric loss factor, which are dependent on composition of a substance (moisture, oil, salt content, etc.), temperature and frequency [3].

The near infrared-microwave combination heating is a new method for baking industry. It combines the colour and crust formation advantages of near infrared heating with the time saving advantage of microwave heating [4]. Infrared-microwave combination heating has been recently used for baking of breads [4, 5] and cakes [6]. Crumb firmness and weight loss of breads baked in infrared-microwave combination oven were found to be higher as compared to that of conventionally baked ones [4] and therefore, it was aimed to prevent this problem by modifying the bread formulation with the addition of different gums.

Gums are widely used in baked goods to enhance dough handling properties, to increase overall quality of the fresh products and to extend shelf-life of stored goods. There are studies in literature about the effects of different hydrocolloids on quality of conventionally baked breads [7–9]. Rosell et al. [7] investigated the effects of different hydrocolloids (sodium alginate, κ-carrageenan, xanthan gum and HPMC) on the final quality of breads and found that the hydrocolloids increased the specific volume, with the exception of alginate, as well as both moisture retention and water activity. The effect of hydrocolloids (sodium alginate, κ-carrageenan, xanthan gum and HPMC) on fresh bread quality and bread staling were studied by Guarda et al. [8] and it was found that bread quality was improved with the usage of these hydrocolloids. In addition, all hydrocolloids were able to reduce the loss of moisture content during bread storage. Ribotta et al. [9] investigated the effects of hydrocolloids (low molecular weight sodium alginate, carob gum, guar gum, xanthan gum, high metoxyl pectin and carrageenan isoforms) on bread quality and found that the addition of hydrocolloids affected bread quality in different ways. The effects of gums (xanthan and guar) at different concentrations on fresh and frozen microwave-reheated breads were studied by Mandala [10]. It was found that both hydrocolloid type and concentration influenced the final quality of the fresh bread samples to a different extent.

For microwaveable food formulations, it is important to have information on the water binding capacity of the gums and viscosity of the solution to have an idea about the dielectric properties and microwave heatability of these formulations. Gums have ability to bind high amount of free water in the system. Therefore, depending on the moisture bound to the gums, which can change polarization, interaction of food with microwaves is expected to change in the presence of gums [1].

In literature, the studies about dielectric properties of gums are limited. Predictive models were determined by expressing both the dielectric constant and loss factor of gums in powdered form as a function of moisture, temperature and stoichiometric charge of the molecule [11]. There is no study in literature about the effects of different gums on dielectric properties of bread dough and bread. Moreover, quality parameters of breads formulated with different gums baked in infrared-microwave combination oven have not been studied yet.

The objective of this study was to investigate the effects of different gums on dielectric properties of doughs and breads baked in infrared-microwave combination oven. In addition, the quality parameters (moisture content, specific volume, hardness, porosity) of breads formulated with different gums and baked in infrared-microwave combination oven were also compared.

Materials and methods

Dough preparation

Bread flour containing 30% wet gluten, 13.5% moisture and 0.54% ash was used in the study. The dough was prepared according to the hamburger bread formulation, which was 100% flour, 8% sugar, 6% milk powder, 2% salt, 3% yeast, 8% margarine, 55% water on flour weight basis. The gums used were guar gum (Guar Gum Powder HV-101 FCC, AEP Colloids Inc., NY, USA), xanthan gum (XAN-80 NF FCC, AEP Colloids Inc., NY, USA), κ-carrageenan (Calcium Carrageenan, AEP Colloids Inc., NY, USA) and xanthan-guar blend. The gums were added to the dough formulation at 0.5% concentration. The gums, xanthan and guar gums were mixed at equal concentrations to obtain the blend. As a control, no gum was added to the formulation. Dough was prepared by using straight dough method [12]. First of all, the dry ingredients were mixed. Yeast was dissolved in water at 30 °C. Margarine was melted and added to the dry ingredients in liquid phase together with dissolved yeast. All the ingredients were mixed by a mixer (Kitchen Aid, 5K45SS, USA) for 3 min. After complete mixing of the dough, it was placed into the incubator at 30 °C for fermentation. The total duration of the fermentation was 105 min. After the first 70 min, the dough was taken out of the incubator, punched and placed into the incubator again. A second punch took place after 35 min. After fermentation, the dough was divided into 50 g pieces. Each piece was shaped and placed into the incubator for the last time for 20 min under the same incubation conditions.

Infrared-microwave combination baking

Infrared-microwave baking was performed in combination oven (Advantium ovenTM, General Electric Company, Louisville, KY, USA). The power of microwave oven has been determined as 706 W by using IMPI 2-l test [13]. There was a rotary table in the oven to improve heating uniformity of samples. Halogen lamps at the top and bottom were operated at the same power during halogen lamp baking. Four breads were baked at 70% halogen lamp power and 20% microwave power for 8 min. Preliminary experiments showed that breads baked in combination oven lost a significant amount of moisture [4], therefore, two beakers, each containing 400 ml water, were placed at the back corners of the oven to provide humidity during baking [5].

Analysis of dough and bread

Temperature measurement

Fiber optic temperature probes were placed at the center of the dough and temperature was measured using a FISO real-time measurement system (FISO Technologies, Inc., Quebec, Canada).

Specific bulk volume and porosity

Bread specific bulk volume (V b) was determined by the rapeseed displacement method [14]. Specific solid volume (V s) of the same bread was also determined by rapeseed method after compacting the bread to exclude all the pores. Then, total porosity was calculated from the following equation;

Hardness

The hardness of bread samples was measured with Texture Analyser (TA Plus, Lloyd Instruments, UK) equipped with a 50 N load cell. Breads were compressed for 25% at a speed of 55 mm/min. Bread samples were prepared according to the method of AACC [14]. A cylindrical probe with a diameter of 10 mm was used. The texture analysis of bread samples were performed after 1 h cooling at 25 °C.

Moisture content

Moisture content of bread samples was determined by drying the samples in an oven at 105 °C until constant weight was obtained.

Dielectric properties

The open-ended coaxial probe method was used to measure dielectric properties of dough and bread samples. The dielectric measurement system includes HP85070 open-ended coaxial high temperature probe (Agilent Technologies Inc., Palo Alto, CA, USA) and a S-parameter network analyser (Agilent 8722ES, Agilent Technologies, Inc., Palo Alto, CA, USA). The system was calibrated by measurements on air, short and distilled water. Measurements were made at 2450 MHz.

Dielectric properties of dough and bread samples were measured at 23 °C. Doughs were prepared without yeast addition and fermentation. Dielectric properties of dough were measured immediately after the dough was prepared. When breads were considered, they were taken out of the oven, covered with stretch film and kept in a plastic bag until measurement. Breads were sliced in the radial direction to have a thickness of 20 mm by using a razor blade for measuring dielectric properties of crumb. Probe was contacted to the cut bread surface at the central region.

Water binding capacity

The water binding capacities of gums were measured using the method of Medcalf and Gilles [15]. Two and a half g of the mixture of dry ingredients of dough was mixed with 37.5 ml deionised water in a tarred 50 ml centrifuge tube. The tube was then capped and agitated using an environmental incubator shaker for 1 h. It was then centrifuged for 10 min at 2200×g. The water was decanted and the tube tipped up and allowed to drain for 10 min. The tube was then weighed and the amount of water held by the sample determined by subtracting the initial weight of the sample from the weight of ‘treated’ sample. The water binding capacity was calculated from the following equation:

Statistical analysis

Analyses of variance (ANOVA) was performed to determine whether there is significant difference between different gum types (p≤0.05). Variable means were compared by Tukey Single Range test by using Minitab, statistics programme (Minitab 14).

Results and discussion

In the first part of the study, the effects of different gums (xanthan, guar, xanthan-guar blend and κ-carrageenan) on quality parameters (moisture content, specific volume, hardness, porosity) of breads baked in infrared-microwave combination oven were investigated.

The effects of different hydrocolloids on specific volume of the breads baked in infrared-microwave combination oven can be seen in Fig. 1. Although, the specific volume of breads formulated with xanthan or guar gums were not significantly different from the control breads, breads formulated with xanthan-guar blend showed a significant increase in specific volume of bread samples. This may be explained by the synergistic effects of xanthan and guar gums. Breads formulated with κ-carrageenan had the lowest specific volume (Fig. 1). There are some studies in literature showing that κ-carrageenan addition to the formulation resulted in an increase of specific volume [7, 8]. On the other hand, Ribotta et al. [9] showed that κ-carrageenan did not improve the specific volume of breads. The difference in the results of different studies may be due to quality of wheat flour, the amount of water used in the bread recipe and differences in nature, origin, particle size and dosages of hydrocolloids. κ-carrageenan is a natural hydrocolloid isolated from red seaweeds, showing different properties depending upon its specie source and extraction procedure followed by the suppliers.

The hardness of the breads formulated with xanthan, guar and κ-carrageenan gums were found to be not different from that of control breads (Fig. 2). Similar results were obtained for κ-carrageenan gum in a study by Guarda et al. [8], which showed that κ-carrageenan did not produce any effect on hardness of breads. On the other hand, xanthan-guar blend addition to the formulation resulted in a significant decrease in hardness value of breads. Textural attributes could be correlated to structural characteristics of the crumb (specific volume and porosity), indicating their mutual dependence [16]. Since the specific volume and porosity of breads formulated with xanthan-guar blend were the highest (Figs. 1 and 3), their hardness values were found to be the lowest (Fig. 2). The addition of xanthan to the formulation did not reduce bread hardness at the studied concentration (Fig. 2). Softer products may be obtained at lower concentration. Xanthan can thicken the crumb air cell walls [7] and its high concentration can enhance this phenomenon leading to a more compact structure. Similar results were obtained in literature for conventionally baked breads [8, 9].

As expected from specific volume results, the porosity of breads formulated with xanthan-guar blend was the highest (Fig. 3). κ-carrageenan containing breads had lowest porosity values, since specific volume of these breads were the lowest according to Fig. 1. The decrease in porosity value of conventionally baked breads formulated with xanthan or guar gums alone as compared to control breads, was also observed in other studies [10, 16].

In the second part of the study, the effects of different gums on dielectric properties (dielectric constant, dielectric loss factor) of doughs and breads baked in infrared-microwave combination oven were investigated.

When dielectric properties of doughs were considered, dielectric constant of dough formulated with xanthan-guar gum blend was found to be lower than control dough (Fig. 4a). However, the magnitude of this change may not be of practical importance. Dielectric properties of xanthan-guar blend is not the average of that of xanthan and guar gum when used alone. This can be explained by the synergistic effects of gums. There was no significant difference between xanthan and xanthan-guar blend containing dough in affecting dielectric constant. The significantly low dielectric constant of doughs formulated with xanthan-guar blend might be due to their higher water binding capacities (Table 1). Since gums have the ability to bind high amount of free water in the system, and dielectric properties depend on free moisture content, interaction of bread with microwaves is expected to change in the presence of gums.

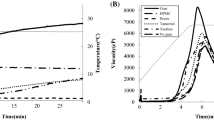

When dielectric loss factors of dough were taken into account, dielectric loss factor of doughs formulated with κ-carrageenan was found to be the highest (Fig. 4b). This result may be due to the ionic nature of gum κ-carrageenan, which increases the dielectric loss factor due to the effect of the ionic property in increasing the free charge density in the system [1]. The loss factor affects the microwave heatability of a food product. Since the loss factor of κ-carrageenan containing dough is significantly higher; the temperature increase of this dough is significantly higher than that of the other dough at the initial stages of heating which can be seen in Fig. 5.

When dielectric properties of breads were taken into account, both dielectric constant and loss factor of breads formulated with κ-carrageenan was found to be the highest (Fig. 6a and b). This result may be due to the ionic nature of gum κ-carrageenan. Temperature profiles of samples support the results of dielectric properties also (Fig. 5). The high dielectric loss factor may increase the heating rate resulting in slightly higher temperatures. Moisture content of the breads containing different gums was not significantly different from control breads (Table 2). Gums are added at low concentrations to the formulation. Therefore, the overall increase in dough water absorption due to the addition of a gum is small. Thus, dielectric properties of these gums except carrageenan were not significantly different.

a The effects of different gums on dielectric constant of breads baked in infrared-microwave combination oven (* Bars with different letters (a, b, c, d) are significantly different p≤0.05); b The effects of different gums on loss factor of breads baked in infrared-microwave combination oven (* Bars with different letters (a, b, c, d) are significantly different p≤0.05)

The high dielectric properties of carrageenan containing bread may also be related to its low porosity. The increase in dielectric properties with bulk density is well known in the literature [3, 17]. Additionally, since dielectric properties of dough formulated with κ-carrageenan were found to be higher, it was not surprising to obtain breads, formulated with κ-carrageenan, with high dielectric properties.

The dielectric properties of breads were lower than those of doughs which may be explained by the low moisture content and high porosity of breads. It is known that high moisture content [18–21] and low porosity [3, 17] causes high dielectric properties.

Conclusion

Specific volume, hardness, porosity and dielectric properties of breads baked in infrared-microwave combination oven were found to be dependent on gum type. The addition of xanthan-guar gum blend to the formulation resulted in an increase in specific volume and porosity and a decrease in hardness of breads. Xanthan-guar blend can be recommended to be used in bread formulations for baking in infrared-microwave combination oven. When xanthan-guar gum blend was added to the formulation, the dielectric constant and dielectric loss factor of dough decreased as compared to control dough. Dielectric properties of the bread samples formulated with κ-carrageenan were found to be higher than that of control breads and breads formulated with other gums. This high dielectric loss factor of κ-carrageenan containing dough may increase the initial heating rate significantly resulting in higher temperatures at the initial stages of baking. Dielectric constant and loss factor data will be helpful for modeling of microwave and infrared-microwave combination baking of foods and for developing new microwaveable products.

References

Ryynänen S (1995) J Food Eng 26:409–429

Datta AK, Sumnu G, Raghavan GSV (2005) Dielectric properties of foods. In: Rao MA, Rizvi SSH, Datta AK (eds) Engineering properties of foods, 3rd edn. CRC Press, New York, pp 501–565

Calay RK, Newborough M, Probert D, Calay PS (1995) Int J Food Sci Technol 29:699–713

Keskin SO, Sumnu G, Sahin S (2004) Food Res Int 37:489–495

Demirekler P, Sumnu G, Sahin S (2004) Eur Food Res Technol 219:341–347

Sevimli KM, Sumnu G, Sahin S (2005) Eur Food Res Technol 221(1–2):61–68

Rosell CM, Rojas JA, Benedito de Barber C (2001) Food Hydrocolloids 15:75–81

Guarda A, Roll CM, Benedito C, Galotto MJ (2004) Food Hydrocolloids 18:241–247

Ribotta PD, Ausar SF, Beltramo DM, Leon AE (2005) Food Hydrocolloids 19:93–99

Mandala IG (2005) J Food Eng 66:291–300

Prakash A, Nelson SO, Mangino ME, Hansen PMT (1992) Food Hydrocolloids 6:315–322

Cauvain SP, Young LS (1999) Technology of bread baking. Aspen, MD, pp 22–24

Buffler C (1993) Microwave cooking and processing. In: Engineering fundamentals for the food scientist. Avi Book, New York, pp 6–7, 150–151

AACC (2004) Approved methods of the AACC. Methods 10-05, 74-09. American Association of Cereal Chemists, St. Paul, MN

Medcalf DG, Gilles KA (1965) Cereal Chem 42:558–567

Mandala IG, Sotirakoglou K (2005) Food Hydrocolloids 19:709–719

Nelson S (1983) Trans ASAE 26:1823–1825, 1829

Bengtsson NE, Risman PO (1971) J Microwave Power 6:107–123

Roebuck BD, Goldblith SA, Westphal WB (1972) J Food Sci 73:199–204

Nelson SO (1978) J Microwave Power 13:213–218

Ndife M, Sumnu G, Bayındırlı L (1998) Food Res Int 31:43–52

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keskin, S.O., Sumnu, G. & Sahin, S. A study on the effects of different gums on dielectric properties and quality of breads baked in infrared-microwave combination oven. Eur Food Res Technol 224, 329–334 (2007). https://doi.org/10.1007/s00217-006-0334-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-006-0334-9