Abstract

The main objective of this study was to optimize the baking conditions of bread in a halogen lamp–microwave combination oven. Independent variables were the baking time (4, 4.5, 5, 5.5, and 6 min), the power of the microwaves (20, 30, 40, 50, and 60%), and the power of the upper and lower halogen lamps (40, 50, 60, 70, and 80%). The quality parameters measured were the weight loss, the color, the specific volume, the porosity, and the texture profile of the breads. For the optimization, the response surface methodology was used. Baking time, upper halogen lamp power, and microwave power were found to be significant in affecting most of the quality parameters. On the other hand, the lower halogen lamp power was found to be an insignificant factor. The optimum baking conditions in the halogen lamp–microwave combination oven were determined as 5 min of baking time at 70% upper halogen lamp power, 50% lower halogen lamp power, and 20% microwave power. Breads baked at the optimum condition had comparable quality with conventionally baked ones. When the halogen lamp–microwave combination oven was used, the conventional baking time of breads was reduced by 60%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One of the stablest foods consumed by humanity is “bread”. Traditionally bread is based on flour derived from the cereal wheat [1]. There are three steps involved in the production of bread: dough formation, fermentation, and baking. The baking process is usually performed by conventional heating, during which heat is transferred by convection from the heating media and by radiation from the oven walls to the product surface followed by conduction to the center. There are also other baking systems, like microwave baking or halogen lamp baking.

Microwave baking has the potential for reducing the baking time and energy. In microwave baking there is internal heat generation and therefore the heating rate is very rapid. Microwave energy is distributed throughout the dough piece, and the oven is at ambient temperature. Consequently, the surface temperature of the dough is not high enough to promote browning and crust formation [2]. Microwave baking also has other disadvantages, like unacceptable texture [3], high moisture loss [4], and rapid staling [5]. Various research have been conducted in order to improve the quality of breads baked in microwave ovens. The effects of different formulations on the quality of microwave-baked breads were studied and it was found that breads formulated with lower gluten flour had higher quality [6]. The effects of susceptor, coating, and conventional browning applications on color and crust formation during microwave baking were investigated by Sahin et al. [7]. According to their research, susceptors and conventional browning were found to be successful in obtaining sufficient color and crispness at the bottom surface, but coating was found to be not effective, so microwave baking was not advisable. A response surface methodology (RSM) study, which combines conventional browning and microwave baking, was performed by Willyard [2] and it was found that 4.5 min of conventional browning at 232 °C followed by 50 s of microwave baking produced the best result.

Halogen lamp heating provides near-IR radiation. Its region in the electromagnetic spectrum is near that of visible light with low penetration depth. Therefore, the radiation is focused at the surface, which can provide the required surface temperature for the browning reactions to occur [4]. Halogen lamp baking was not recommended for bread baking because of the formation of a very thick crust [4]. High weight loss, low specific volume, and firm texture were also reported as disadvantages of halogen lamp baking.

A halogen lamp–microwave combination oven combines the time-saving advantages of a microwave oven with the browning advantages of halogen lamp heating. Studies on halogen lamp–microwave combination baking are limited in the literature. Halogen lamp–microwave combination oven baking has recently been used in bread baking and it has reduced the conventional baking time of breads by about 75% [4]. Enzymes were found to be effective in reducing the firmness of breads baked in a halogen lamp–microwave combination oven [8].

In this study, in order to optimize the processing conditions in a halogen lamp–microwave combination oven, RSM was used. RSM is more efficient than traditional methods because it provides the minimum time and cost required to determine the optimum product [9]. RSM was also used by other researchers in baking studies [2, 10, 11,12]. The processing conditions in the halogen lamp–microwave combination oven have not been optimized yet. Therefore, the main objective of the study was to optimize the baking conditions in the halogen lamp–microwave combination oven so that the quality of breads in this oven would be comparable with that of breads baked in a conventional oven.

Materials and methods

Preparation of dough

The bread flour, which contains 32% wet gluten, 13.1% moisture, and 0.55% ash, was supplied by Ankara Un (Turkey). The composition of the dough on a flour basis was 100% flour, 8% sugar, 6% milk powder, 2% salt, 3% yeast, 8% margarine, and 55% water.

Dough was prepared by using a straight dough method. First, all the dry ingredients were mixed for 1 min by a mixer (Kitchen Aid, 5K45SS, USA) and then yeast dissolved in 30 °C water and margarine, which was melted, was added. All the ingredients were mixed again for 2.5 min using the same mixer and during mixing water was added to the mixture. After mixing, the dough was fermented in an incubator (Nüve EN 400, Turkey) at 30 °C with 85% relative humidity. The total fermentation time was 105 min. After the first 70 min, the dough was punched to remove the carbon dioxide and was again placed into the incubator. A second punch took place after 35 min. Then, the dough was divided into 50-g pieces and shaped. The shaped samples were again placed into the incubator for 20 min in order to maintain the proofing step, which is defined as the last fermentation. Then, the samples were ready for baking.

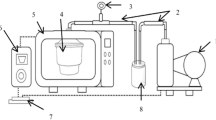

Microwave–halogen lamp combination oven baking

A halogen lamp–microwave oven (Advantium oven, General Electric Company, Louisville, KY, USA) is the combination of microwave heating and halogen lamp heating. There are two halogen lamps at the top of the oven and one halogen lamp at the bottom of the turntable. The turntable maintains uniform cooking conditions for the food sample. Preliminary experiments showed that breads baked in a combination oven lost a significant amount of moisture. Therefore, two beakers, which contained 400 ml water, were placed at the corners of the oven to provide the required humidity during baking. The power of the combination oven when microwaves were being produced was calculated as 706 W by the IMPI 2L test [13]. One bread was baked at a time.

Conventional baking

For the conventional baking, breads having the same formulation were baked in a commercial electrical oven (Arçelik ARMF 4 Plus, Turkey). The dough samples were baked at 200 °C for 13 min, which was determined as the optimum baking condition in a previous study [4]. The oven was preheated at 200 °C for 2 min before the baking process. Four breads were baked at a time. These breads were used as controls.

Experimental design

RSM was used to relate baking responses to baking conditions. RSM is a statistical technique that uses quantitative data to determine and simultaneously solve multivariate equations, which specify the optimum product for a specified set of factors through mathematical models. These models consider interactions among the test factors and can be used to determine how the product changes with changes in the factor levels [9]. In this study, a central composite design was used. There were four independent variables, which were baking time (X1; 4, 4.5, 5, 5.5, and 6 min), the power of the upper halogen lamps (X2; 40, 50, 60, 70, and 80%), the power of the lower halogen lamp (X3; 40, 50, 60, 70, and 80%), and the power of the microwaves (X4; 20, 30, 40, 50, and 60%). For convenience, the actual values were converted to coded values. The experimental design is shown in Table 1 by both uncoded and coded values.

Bread analysis

The weight loss of the breads was calculated by measuring the weight of the bread samples before and after the baking process. The weight after the baking process was subtracted from the initial dough weight and the result was divided by the initial value. The weight loss was expressed as a percentage.

The crust color of the samples were measured using a Minolta color reader (CR-10, Japan) and expressed as Hunter L*, a*, b* color values. Three sets of data were taken from each sample and the total color change (ΔE) was calculated from Eq. (1):

Dough was selected as the reference point and its L*, a*, and b* values was represented as L0, a0, and b0. The specific volumes of the breads were determined by the rape seed displacement method [14]. The firmness, chewiness, and springiness values of the breads were measured using a texture analyzer (TAPlus, Lloyd Instruments, UK). Bread samples were compressed for 25% at a speed of 55 mm/min. A load of 50 N was used and the samples were prepared according to the method of the American Association of Cereal Chemists [14].

Porosity was measured by using the method of Zanoni et al. [15]. Porosity can be defined as the ratio of the volume of the pores to the total volume of the product:

where Vt is the total volume of the sample and Vnp is the volume of the nonporous material in the sample.

An apparatus having a constant base area was designed, which allowed pores to be removed from the bread samples, to measure porosity. The samples were put inside this apparatus and a constant force was applied for 1 min. Since the base area was constant, the porosity can be defined as

where H0 is the initial height of the sample (millimeters) and Hf is the final height of the sample (millimeters) after compression.

Statistical analysis

Multiple regression analysis was performed to fit second-order models or third-order models to dependent variables, by using Minitab release 13.1 software. The models were used to plot contour surfaces and to determine the optimum baking conditions. In order to find the optimum baking conditions, Matlab version 6.5 software was used. The program was written to find the optimum point by considering a maximum specific volume, a minimum firmness and weight loss, and a constraint of the ΔE value. The constraint was obtained by using quality values of conventionally baked breads. Analysis of variance was performed in order to determine the significant differences between the independent variables (p≤0.05). If significant differences were observed, variable means were compared by Duncan’s multiple range test.

Results and discussion

In this study, second-order polynomial models were fitted for independent variables of Y (weight loss, ΔE value, specific volume, firmness):

In this equation, the X i are the independent variables (baking time, power of upper halogen lamps, power of lower halogen lamp, power of the microwave) and the b i are the model constants.

The regression equations and coefficients were determined from multiple regression analysis of the experimental data. The model equations and the regression coefficients are given in Table 2. The regression coefficients (r2), which show the measure of fitting the data, were very high, especially for weight loss and color.

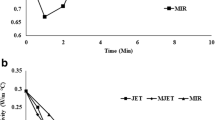

Baking time, the power of the upper halogen lamp, and the power of the microwaves were found to be the most significant variables (p=0.000 for all three) in affecting the weight loss of breads. As the baking time and the power of the microwaves increased, the weight loss increased (Fig. 1). As the microwave power increased, the interior pressure increased, which increased the liquid flow through the food boundary [16]. As the upper halogen lamp power increased, the heat radiated to the bread increased, so more energy penetrated and higher weight loss was observed (Fig. 2). When the microwave power and the upper halogen lamp power were compared, the microwave power was found to be more effective in resulting in weight loss (Fig. 3). This situation was also observed by other researchers [4]. The lower halogen lamp power did not have a significant effect on the weight loss of the breads (Table 2).

The increase in the upper halogen lamp power and the baking time increased the ΔE value significantly, which is an index of color change (Fig. 4). The color change of the breads was also reported to be affected by halogen lamp power and baking time by other researchers [4]. The increase in time at higher upper halogen lamp powers was found to be insignificant for the color change of the breads. This was also supported by Duncan’s multiple comparison test, which showed that there was no significant difference between the coded values of 0, 1, and 2 of time. The ΔE values for the conventionally baked breads were about 35.7. The color of the breads that were baked at higher halogen lamp powers had similar ΔE values compared with the color of breads baked in a conventional oven. This result could be explained by the higher oven temperature during resulting from high halogen lamp powers, which allowed the Maillard browning reactions to occur. The power of the lower halogen lamp was not found to be effective in changing the color of the breads (p=0.202) (Table 2). The increase in the microwave power did not affect the color change for short baking times (Fig. 5). However, when the baking time was long, the increase in the microwave power increased the color change. This might be explained by drying of the product.

Time, the power of upper halogen lamps, and the power of the microwaves were found to be significant factors affecting the specific volume of the breads (Table 2). As the baking time and the microwave power increased, the specific volume increased (Fig. 6). The specific volume was influenced more by an increase in the microwave power compared to time. The increase in specific volume when the microwave power was increased was also reported by other researchers [4]. When the upper halogen lamp power was increased, the specific volume of the breads decreased (Fig. 7). This may be due to the sudden crust formation, which prevents the transfer of heat to the inner parts, necessary for the formation of the starch–gluten matrix. This matrix provides optimum dough development and gas retention, which results in a higher specific volume [4].

The increase in the microwave power and the baking time increased the firmness of the breads (Fig. 8). The firmness value for the conventionally baked breads was found to be 0.71 N. At shorter baking times and lower microwave power combinations, firmness values similar to those of conventionally baked breads were observed. For shorter values of time and lower microwave powers, the effect of the microwave power was insignificant but as the microwave power increased, its significance also increased (Fig. 8). The increase in the firmness of the breads with respect to time may be explained by the increase in weight loss during the baking process. For constant baking time and power of the lower halogen lamp, the optimum firmness value was observed at lower microwave and upper halogen lamp powers (Fig. 9).

The porosity, springiness, and chewiness data of the breads were also modeled. For chewiness, a second-order model was fitted and a high coefficient of determination was observed (r2=0.837) (Table 2). For porosity and springiness, third-order models were developed (r2=0.751 and r2=0.880, respectively) since the data did not fit a second-order model. Some of the terms were missing in the model equations of the porosity and springiness, since the Minitab program removed these terms as they were highly correlated with other X variables.

In order to find the optimum point a Matlab program was written by considering the minimum firmness and weight loss, the maximum specific volume, and a constraint of color. The constraint was determined by using the ΔE value of the conventionally baked breads, which was 35.9. The optimum point found by the program was 0.1574 for X1, 1.0888 for X2, −1.3177 for X3, and −2.0000 for X4. These values were rounded and the corresponding uncoded values were calculated as 5 min of baking at 70% upper halogen lamp power, 50% lower halogen lamp power, and 20% microwave power. The responses calculated from the model equations by using the optimum point are given in Table 3. In order to make a comparison, the responses measured for the conventionally baked breads are also given in Table 3.

As can seen from Table 3, breads baked in the halogen lamp–microwave combination oven were comparable in quality in terms of textural characteristic, specific volume, porosity, and color with conventionally baked ones. The firmness and chewiness values of these breads were found to be slightly higher than those of the conventionally baked ones. This may be due to the higher moisture loss in the combination oven. In this study, lower and acceptable firmness and weight loss values were obtained in the halogen lamp–microwave combination oven compared with the study performed by Keskin et al. [4] since water was also used in the oven during baking to provide humidity. In the halogen lamp–microwave combination oven, it was possible to achieve a ΔE value of the crust that was very close to that obtained with a conventional oven.

Conclusions

RSM was successfully applied to optimize the quality of breads baked in a halogen lamp–microwave combination oven. As the baking time, the upper halogen lamp power, and the microwave power increased, the weight loss of the breads increased. The upper halogen lamp power and time were found to be significant in affecting the color change. The lack of browning in microwave baking was eliminated by using the halogen lamp–microwave combination oven. When time and the microwave power increased, a higher specific volume was observed. However, the increase in the upper halogen lamp power resulted in a decrease in the specific volume of the breads. Baking time and microwave power were found to be the most significant factors in increasing the firmness. The power of the lower halogen lamp did not affect any of the quality parameters significantly. Breads baked in the halogen lamp–microwave combination oven had quality comparable to conventionally baked breads and the baking time was significantly reduced. Therefore, the halogen lamp–microwave combination oven can be recommended for baking bread.

References

Cauvain SP, Young LS (1999) Technology of breadmaking. Aspen, Maryland

Willyard MR (1998) Cereal Foods World 43:131–138

Ovadia DZ, Walker CE (1996) Proceedings of the 31st microwave power symposium. International Microwave Power Institute, Manassas, pp 89–92

Keskin SO, Sumnu G, Sahin S (2004) Food Res Int 37 (in press). DOI10.1016/j.foodres.2003.10.001

Seyhun N, Sumnu G, Sahin S (2003) Nahrung 47:248–251

Ozmutlu O, Sumnu G, Sahin S (2001) Eur Food Res Technol 213:38–42. DOI10.1007/s002170100325

Sahin S, Sumnu G, Zincirkiran D (2002) J Microwave Power Electromagn Energy 37:223–236

Keskin SO, Sumnu G, Sahin S (2004) Nahrung 48:156–160

Giovanni M (1983) Food Technol 37:41–83

Sumnu G, Ndife MK, Bayindirli L (2000) Eur Food Res Technol 211:169–174. DOI10.1007/s002170050018

Lahtinen S, Levola M, Jouppila K, Salovaara H (1998) Cereal Chem 75:547–550

Collar C, Andreu P, Martinez JC, Armero E (1999) Food Hydrocolloids 13:467–475

Buffler C (1993) Microwave cooking and processing: engineering fundamentals for the food scientist. Avi, New York

American Association of Cereal Chemists (1988) Approved methods of the AACC, method 74–09. American Association of Cereal Chemists, St Paul, MN

Zanoni B, Peri C, Gianotti R (1995) J Food Eng 26:497–510

Datta AK (1990) Chem Eng Prog 86:47–53

Acknowledgement

General Electric Company is greatly acknowledged for the donation of the halogen lamp–microwave combination oven (Advantium oven).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demirekler, P., Sumnu, G. & Sahin, S. Optimization of bread baking in a halogen lamp–microwave combination oven by response surface methodology. Eur Food Res Technol 219, 341–347 (2004). https://doi.org/10.1007/s00217-004-0969-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-0969-3