Abstract

The present study explored the applicability of tamarind gum in making gluten-free rice bread. Hydration properties of gums and pasting properties of rice flour with the gums were analyzed with Rapid ViscoAnalyzer. Batter properties and bread quality characteristics of rice bread containing gums were analyzed. Except for guar and xanthan gum, the final viscosity after hydration of other gums and the pasting properties of rice flour with the gums were similar. The batter properties and the quality of rice bread containing tamarind gum were equivalent or superior to those containing other gums. Cross-sections of rice bread showed that addition of tamarind gum and pectin resulted in a fine appearance, but pectin may not be preferred due to its lower pH causing unpleasant sour taste and smell of the rice bread containing the gum. Therefore, tamarind gum can be a useful gum for applying to make gluten-free rice bread.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recently, the demand for gluten-free foods has been increasing not only by people with a gluten allergy, but also due to the influence of the media that healthy people can lose weight, reduce susceptibility to infections and depression, and improve their health by reducing gluten consumption. The global gluten-free food market amassed $3.284 billion in 2015, and the average annual growth rate of gluten-free foods from 2014 to 2019 is expected to be 6.2% (Euromonitor International, 2016).

Gluten-free foods must contain less than 20 ppm of gluten (US Food and Drug Administration, 2013). Celiac disease, an allergy to gluten protein, is an autoimmune disease caused by ingesting gluten as a component of wheat, and its main symptoms include chronic diarrhea, vomiting, and abdominal distension in young infants (Green and Jabri, 2003). Patients with celiac disease should absolutely intake gluten-free foods to avoid the pain caused by this allergy.

Rice is a staple food for Koreans. Since the self-sufficiency rate of rice was 100% in the early 1980s, consumption has been steadily decreasing. Consequently, the annual consumption of rice in 2016 (61.9 kg/person) decreased by almost half compared to that in 1986 (127.7 kg/person) (Statistic Korea, 2016). As a strategy for revitalizing the rice processing industry, many attempts have been made to produce commercial rice flour and promote its application in baking (Choi et al., 2015; Kim, 2016; Lee and Lee, 2006; Song and Shin, 2007).

Numerous studies have been performed to develop bread using rice flour (Choi et al., 2015; Han et al., 2012; Kang et al., 2013; Kang et al., 2014; Lee and Lee, 2006; Mancebo et al., 2015; Mohammadi et al., 2014; Nishita et al., 1976; Song and Shin, 2007) and gums have been used extensively as gluten substitutes in rice bread to provide the viscoelastic properties of gluten protein in wheat flour. The impact of different gums on dough characteristics and bread quality is known to be highly dependent on raw materials used and the nature and quantity of the gum (Mir et al., 2016). Until now, gums like carrageenan, xanthan gum, guar gum, pectin, hydroxypropyl methylcellulose (HPMC), and methyl cellulose (MC) have been commonly used in gluten-free bread baking (Anton and Artified, 2008; Hager and Arendt, 2013; Hwang et al., 2017; Joung et al., 2017; Lazaridou et al., 2007; Mir et al., 2016; Mohammadi et al., 2014; Nishita et al., 1976; Sabanis and Tzia, 2010; Sciarini et al., 2010), but tamarind gum, which was recently approved as generally recognized as safe (GRAS), has not been used much yet (Angalet and Kweon, 2017a; 2017b).

Tamarind gum is a xyloglucan present in the seed of black Tamarindus indica, and has a β-(1,4) linked D-glucan backbone that is partially substituted at the O-6 position of its glucopyranosyl residues with α-D-xylopyranose. Tamarind seed xyloglucan (TSX) is used as a food additive for a thickener, stabilizer, gelling agent, ice crystal stabilizer, and starch improving agent in Japan (Nishinari et al., 2009). Maeda et al. (2007) reported that bread dough containing xyloglucan treated with cellulase exhibited improved stability by strengthening the gluten film, compared with the xyloglucan without cellulase treatment, and improved the bread volume, appearance, pore size, and texture. Angalet and Kweon (2017a; 2017b) and Angalet et al. (2017) showed that tamarind gum could be successfully applied for making gluten-free pan bread, steam bread baked in an electrical resistance oven (ERO) for producing bread crumbs through uniform heating of dough, cakes, and pancakes made of wheat starch, compared with xanthan gum application. No study has yet reported the application of tamarind gum to manufacture of rice bread. Therefore, it is worthwhile to evaluate the suitability of tamarind gum for making gluten-free rice bread.

In order to explore the applicability of tamarind gum in rice bread, five gums (HPMC, pectin, guar, tamarind, and xanthan) were selected, and their hydration curve and viscosity as well as pasting properties of rice flour containing gums were analyzed using a Rapid ViscoAnalyzer (RVA). The baking performance of rice bread formulated with the gums was also evaluated.

Materials and methods

Materials

Commercial wet milled rice flour (Nongshim, Asan, Korea) was purchased from a local market and had moisture and ash contents of 12.2, and 0.27%, respectively. Hydroxypropyl methylcellulose (Methocel F4M, Dow Chemical Co., USA), guar gum (MSC, Gyeongnam, Korea), pectin (GENU pectin type 105, Namyoung, Seoul, Korea), xanthan gum (CJ CheilJedang Corp., Seoul, Korea), tamarind gum (Glyloid 3S, Socius Ingredients LLC, Evanston, IL, USA) were supplied by the respective manufacturers. Based on manufacturer’s data, Methocel F4M has a specified viscosity range of 3800–4800 mPa s at 2% solution at 20 °C, and its average degree of polymerization and number average molecular weight (Mn) are 460 and 86,000, respectively. Soymilk powder (non-defatted) (Benesoy, Rock City, IL, USA), salt (Haepyo, Seoul, Korea), and dry yeast (Lesaffre, Marcqen-Baroeul, France) were purchased from a local market.

Measurement of gum hydration properties

Hydration curve and viscosity of gums were measured using a RVA (RVA 4, Newport Scientific, Warriewood, Australia). Each gum sample (0.5 g) was added to a 25-mL water to make 2% gum solution and mixed with a RVA plastic paddle to obtain a good suspension. The RVA of the gum solution was run at 160 rpm for 30 min at 25 °C and calculated a final viscosity with a RVA software program (Thermocline for Windows, ver.2.5, Newport Scientific, Warriewood, Australia).

Measurement of pasting properties of rice flour containing various gums

The pasting properties of the rice flour were measured using the RVA (RVA 4, Newport Scientific, Warriewood, Australia) with minor modifications to the methods of Song and Shin (2007) and Hwang et al. (2017). Rice flour (3.5 g) mixed with 0.14 g gum to make 4% gum based on flour weight was added to 25 mL of water in a RVA canister and mixed well with a RVA plastic paddle. RVA was run with the Standard 1 method. Pasting temperature and viscosity were calculated by the software program (Thermocline for Windows, ver. 205, Newport Scientific, Warriewood, Australia).

Preparation of rice bread

The ingredients used and the formulation for the rice bread were slightly modified from the method of Hera et al. (2013): 100 g of rice flour, 5 g of soybean oil, 7 g of sugar, 3 g of soy milk powder, 2 g of salt, 3 g of yeast, 100 g of water, and 4 g of gum. Table 1 shows the bread-making process.

The dried ingredients, including rice flour, were weighed and placed in a transparent jar with a lid, and the mixture was shaken 30 times. The homogenously mixed mixture was placed in a 100 g pin mixer bowl (National Mfg. Co., Lincoln, NE, USA), and soybean oil and water were added. After mixing for five minutes, 210 g of batter was placed in a baking pan (Non-stick mini loaf pan, 14.6 cm × 8.3 cm × 5.7 cm, Chicago Metallic, Lake Zurich, IL, USA) and the photo of each batter formulated with each gum was taken with a digital camera (Canon, Tokyo, Japan). The batter contained in the baking pan was placed in a fermentation cabinet (Phantom M301 Combi, Samjung, Gyeonggi, Korea) at 30 °C and 85% RH for 40 min. After fermentation, it was baked for 20 min in an oven (Phantom M301 Combi, Samjung, Gyeonggi, Korea) at 215°C and cooled for 20 min at room temperature. Then, the bread was taken out of the baking pan and cooled for 30 min to analyze bread volume, color, and texture. The bread baking for each gum was repeated in triplicate.

Before and after fermentation, 5 g of batter was mixed well with 50 mL of distilled water and its pH value was measured before and after fermentation using a pH meter (SevenEasy pH meter S20, Mettler Toledo, Columbus, OH, USA). Batter height was also measured by inserting metal bars in the center of the baking pan. The specific gravity of the batter was measured by adding 5 g of batter to 30 mL of distilled water in a 50-mL graduate cylinder. Each measurement was performed in duplicate.

Evaluation of rice bread quality

Bread height and volume were measured by the method of Jung et al. (2016). For a seed replacement method for bread volume, millet seeds were used. A 1.5-L plastic container was filled with millet to determine the density (mL/g) of millet used for converting a weight into a volume. After a loaf of bread was placed in a container full of millet, the weight of the millet pushed out of the container was measured, and the volume (mL) of the bread was calculated based on the calculated density. Each measurement was performed in duplicate.

The color of the crumb of bread was measured as L* (lightness), a* (redness), b* (yellowness) values using a colorimeter (CR-20, Minolta, Co., Tokyo, Japan). Measurements were performed in five replicates.

The bread firmness was measured using a Texture Analyzer (Brookfield CT3, Middleboro, MA, USA) according to the AACC Approved Method 74-09.01 (2010). The measurement conditions were set as follows: Mode: Measure force in compression, Pretest speed: 2.0 mm/s, Test speed: 2.0 mm/s, Posttest speed: 5.0 mm/s, Probe: 1.27 cm ball, Penetration distance: 15 mm. One loaf of bread was cut from the center into 3 pieces with 2 cm thickness. One piece was used for a fresh sample (0 day), the remaining 2 pieces were sealed in an aluminum foil package capable of avoiding moisture loss during storage, and placed in a refrigerator. Measurement of firmness during storage was performed on days 1 and 4 of storage after baking. Three loaves were used for the firmness measurement.

The moisture content of the bread samples was measured using the AACC Approved Method 44-15.02 (2010). About 2 g of pre-weighed bread crumb in a weighing container was placed in a hot-air drying oven (FO 600-M, Jeio Tech, Daejeon, Korea) at 130 °C for exactly 1 h, and cooled at room temperature for 30 min. The moisture content of the bread was calculated from the reduction in weight during drying.

Statistical analysis

All results were evaluated by two or more repeated experiments. The SPSS statistical program (ver. 22.0, IBM Corp., Armonk, NY, USA) was used for the analysis of variance and the Tukey–Kramer’s test at a significance threshold of P < 0.05.

Results and discussion

Comparison of gum hydration properties

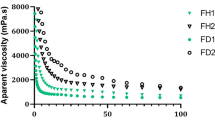

The hydration curves of various gums measured by RVA are shown in Fig. 1. When each gum was hydrated at 2% in water at 25 °C for 30 min, guar gum showed the fastest increase in viscosity, and its final viscosity was 2481 cP, a much larger value than those of the other gums. Guar gum has good solubility in cold water owing to its high degree of branching that could contribute to high viscosity solutions at low concentrations (Wüstenberg, 2015). The final viscosity of xanthan gum was 1117.5 cP, which was lower than that of guar gum but higher than those of HPMC, pectin, and tamarind gum. The final viscosities of tamarind gum and HPMC were 679.5 and 754 cP, respectively, and their hydration curves were similar. Pectin showed the lowest final viscosity (93 cP) among all samples, and no significant change was observed in viscosity during 30 min of hydration. Thickening effect of pectin is usually low and occurs only after gelation. Pectin used in the study was high methyl ester pectin that could only gel in the presence of sugars or other co-solutes (Endreß et al., 2009; Wüstenberg, 2015). Viscosity of tamarind gum in aqueous solution could be expected by its behavior as flexible random coil polymers as well as its strong tendency of self-aggregation (Nishinari et al., 2009). It is anticipated that the different hydration properties of the various gums could affect the physical properties of the rice bread batter formulated with these gums. Therefore, it is predicted that the batter of rice bread containing guar gum would be the most viscous and that containing pectin would be the least viscous.

Sabanis and Tzia (2010) reported that various gums, such as HPMC, xanthan, kappa-carrageenan, and guar gum had different effects on the rheology of gluten-free bread made from corn starch and rice flour. However, the amount of the gums used, the amount of added water, and the sources of the gums in their study were different from those used in our experiment, making it difficult to compare their results with ours. In addition, the ratio of the amount of added gum to the amount of added water in the above study was not constant and resulted in an inconsistent pattern in the viscosity change by increasing the amount of added gum.

Pasting characteristics of rice flour containing gums

The RVA results of the pasting characteristics of rice flour containing 4% of each gum that was the same concentration used in bread baking are shown in Fig. 1. The initial pasting temperature of all samples was 66.4–69.9 °C. Among the samples, the rice flour containing guar, xanthan and tamarind gum showed relatively lower pasting temperatures than that containing HPMC and pectin. The initial pasting temperatures of the rice flour containing HPMC and pectin were similar to that not containing gum. The peak viscosity of the rice flour containing guar gum was significantly higher than those of the rice flour containing other gums, and a noticeably different pasting pattern was observed. Shi and BeMiller (2002) suggested interactions between specific gums and specific molecules leached from granules that are responsible for early stage viscosity increases of starches cooked in gum solutions by mainly amylose-gum interactions. Xanthan and guar gum increased greatly pasting viscosity of rice starch that indicated interactions. Rosell et al. (2011) also reported interactions of three different gums with rice starch that guar and xanthan gum gave much greater effects on the pasting properties than HPMC. Our result showed a good agreement with the above finding. It is expected that such a high pasting viscosity of the rice flour containing guar gum might increase the viscosity of rice bread batter during the baking process and suppress bread volume expansion. A study of rice bread formulated with HPMC and different amounts of water by Nishita et al. (1976) showed that an insufficient amount of water made the dough too thick to expand during fermentation and resulted in bread with a much smaller volume.

In contrast, the final viscosity of pasting of rice flour containing HPMC was relatively high, which could lead to a relatively large bread volume by avoiding the collapse of bread by gravity during cooling. Rice flour samples containing tamarind gum and pectin showed similar pasting patterns, which could be a potential link to similar bread baking qualities.

Characteristics of batter of rice bread

The batter appearances are shown in Fig. 2, and the specific gravities of rice bread batter formulated with the various gums are shown in Table 1. From the appearance of mixed batter, the batter became thinner in the following order: guar gum > xanthan gum > HPMC > tamarind gum > pectin > no gum addition. Gum addition made the batter thicker, and the batter of rice bread devoid of any gum looked very thin and watery compared to the appearance of batters containing gum. The result confirmed the major function of the gums tested in the study as a thickening agent.

The appearance of batter was similar to the ranking of the final viscosity of hydrated gums and might be linked to bread volume. Sciarini et al. (2010) reported the effect of hydrocolloids on gluten-free batter properties and bread quality and showed increased batter consistencies upon adding hydrocolloids, and a positive correlation between bread specific volume and batter consistency. For gluten-free bread added gums, the viscoelastic properties of the rice flour-gum mixtures assessed often to determine their network stability although some studies did show little or no relationship of the dynamic rheological parameters of dough with the functionality during processing and end-use performance (Lazaridou et al., 2007). Yoshimura et al. (1999) and Tempsiripong et al. (2005) reported the increased storage and loss Young’s moduli for mixed gels of corn and tapioca starch, respectively, with increasing xyloglucan (tamarind gum) concentration. For confirming the viscoelastic property of tamarind gum in rice bread batter, it will be worth to measure the dynamic rheological parameters in a future study.

The specific gravity of rice bread batter containing gums was 0.9–1.1 g/mL, and that without gum addition was 1.3 g/mL, indicating that specific gravity of the batter significantly decreased upon gum addition (P < 0.05). The specific gravity of rice bread batter containing HPMC (0.9 g/mL) was significantly lower (P < 0.05) indicating a much lighter and airier batter compared with those containing other gums (1.1 g/mL for the four other gums), which would affect the batter and bread volume. In particular, HPMC might act as a very high, excellent foam generator by reduction of surface tension (Wüstenberg, 2015) that would link to such lower specific gravity of the batter containing HPMC. In a study performed by Turabi et al. (2008), cake batter containing gums and emulsifiers exhibited lower specific gravity than the control batter without gums, resulting in a much larger cake volume.

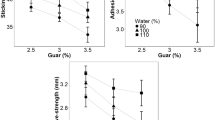

The batter pH and height before and after fermentation are shown in Fig. 3. Except for the batter containing pectin, the pH of the batters was between 6.0 and 6.2. Regardless of gum addition, a decrease in pH of rice bread batter was observed after fermentation. The pH change in all batters upon fermentation was about 0.2–0.4, indicating no significant difference in acid formation by yeast during fermentation. The observed decrease in pH by fermentation was similar to that reported by Blanco et al. (2011) who showed a pH change from 5.8 to 5.6 in rice bread containing HPMC after 50 min of fermentation. Only the pH of the rice bread batter containing pectin was relatively low (pH 5.1) because the pH of the pectin itself (pH 3.2) was much lower than that of other gums (pH 6.0–7.0). Therefore, a future study should elucidate how this difference in pH affects the bread baking performance.

Change in batter height and pH of gluten-free rice breads formulated with various gums at 4% by fermentation (BF–before fermentation; AF–after fermentation): NG, no gum addition; H, HPMC; G, guar gum: P, pectin; X, xanthan gum; T, tamarind gum. Bars with different letters are significantly different (P < 0.05) as determined by Tukey–Kramer’s test

The height of rice bread batter containing HMPC before fermentation (2.5 cm) was significantly higher (P < 0.05) because of its relatively airy, fluffy, and light batter caused by its lower specific gravity. Except for the batter containing HPMC, the height of rice bread batter was not significantly different with and without gum addition (1.9–2.0 cm) (P < 0.05), although the specific gravity of the batter without gum addition was a slightly high. After fermentation, the batter height for all samples increased almost 1.75–2.10 times compared to levels before fermentation. The batter without gum addition increased the smallest amount and that containing guar gum increased the most. The final height of batter after fermentation was increased in the following order: no gum addition < pectin ≈ xanthan gum ≈ tamarind gum < guar gum < HPMC.

Quality characteristics of rice bread

The quality characteristics of rice bread formulated with various gums are shown in Table 1. The side views and cross sections of the bread samples are shown in Fig. 4. The bread loaves weighed 173–182 g, and those containing HPMC and devoid of gum were little lighter. This difference could be caused by the differences in batter weight before baking.

The height of the rice bread samples to which gums had not been added and those with guar gum were almost similar, and they were relatively lower than those containing other gums. The height of rice bread containing HPMC was twice as high as those containing pectin, xanthan, and tamarind gum. There were no significant differences in the height of the bread samples containing pectin, xanthan gum, and tamarind gum. The height of the bread samples decreased in the following order: HPMC > pectin ≈ xanthan gum > tamarind > guar gum ≈ no gum addition. Although the height of bread containing guar gum was similar to that without gum, the shapes of breads were different; the former had a dome shape but the latter had a collapsed center (Fig. 4). In this study, there was no link bread height with batter height because the height of batter containing guar gum was similar to those containing other gums, but the resulting bread height was much lower.

The data of the volume of rice bread in Table 1 show that adding HPMC resulted in significantly larger bread, whereas addition of guar gum resulted in significantly smaller bread, compared to the volume obtained on the addition of other gums (P < 0.05). Even the volume of the bread without gum was larger than that of the bread containing guar gum. As explained previously, two bread samples showed similar bread height (measured center height), but the bread, to which gum was not added, showed higher edge height, compared to bread containing guar gum. This result could be because the thin batter without gum addition may expand easily during baking, but the baked bread may collapse by gravity after removing out of oven due to no firm network formation. The ability of HPMC to improve bread volume explained by the fact that its hydrated chains release the water molecules at high temperature and allow stronger interaction among HPMC chains. Consequently created a temporal network gives strength to the gas cells of the dough, which expand during baking and reduce the gas losses (Bárcenas and Rosell, 2005).

As shown the bread crumb color in Table 1, the bread containing HPMC had a significantly higher L * value than the other breads because of the presence of more air cells. In contrast, the bread devoid of gum showed a significantly lower L * value, indicating the existence of fewer air cells and greater density, compared bread containing gum.

As shown in Fig. 4, among the bread samples, the bread containing HPMC was remarkably large and asymmetrical, and that lacking gum addition was not dome-shaped. The cross-section of the rice bread containing HPMC was shrunken and irregularly shaped because the bread expanded too much, resulting in an airy and weak crumb cell structure, weak crust walls, and difficulty in obtaining a clean cut after cooling. This relatively large volume of rice bread containing HPMC compared to that in breads containing other gums was similar to the results of a study by Nishita et al. (1976). Authors of this study baked rice breads with several gums (HPMC, CMC, xanthan gum, carrageenan, locust gum, and guar gum) at levels to give the same consistency and found that except for HPMC, none of the breads was able to retain gases during fermentation, resulted in a very low bread volume. In addition, the specific volume of the bread loaf containing HPMC in the study was about 5.0 mL/g and those containing other gums were 1.2–1.4 mL/g. Our baking results also showed a similar trend in specific volume: about 4.3 mL/g was observed for the loaf containing HPMC and about 1.5–2.1 mL/g for those containing other gums. The side view and cross-section of the bread containing xanthan gum showed a rough crust and relatively large air cells in the bread crumb. Overall, rice breads containing pectin and tamarind gum were superior in appearance to those containing HPMC, guar gum, and xanthan gum, but bread containing pectin has too strong of a sour taste that could be a deterring factor for consumers. The results demonstrated tamarind gum as a useful gum enable to apply for producing gluten-free rice bread. For a successful application of tamarind gum commercially, a future study needs for optimizing formula of rice bread with respect to gum concentration, water addition, mixing time and fermentation.

Changes in moisture content and firmness of rice bread during storage

The changes in moisture content and firmness of rice bread containing gums during storage at a refrigerator are shown in Fig. 5. The moisture content of all bread samples was around 50% (51–49%) and kept well during storage. The firmness analysis of bread samples showed that the bread without gum was the softest, whereas that with guar gum was the firmest. The firmness of the bread samples was increased in the following order: no gum addition < pectin < xanthan gum ≈ tamarind gum < HPMC < guar gum. Changes in the firmness during storage showed the highest slope for the bread containing guar gum and showed the most rapid increase in firmness, and the breads containing tamarind gum and HPMC showed relatively low firmness compared to those containing guar gum. However, on the fourth day of storage, the bread samples containing tamarind gum, HPMC, and guar gum were too hard to measure the firmness using a texture analyzer with a 4.5 kg load cell capacity. The bread samples containing pectin and xanthan gum showed a relatively slow change in firmness and the bread without gum showed a mild slope in the change of firmness during storage. Although firming rate of rice bread during storage depends on types of added gums, fast retrogradation of rice bread is anticipated because the higher amount of starch contained in rice flour than in wheat flour and the moisture content of rice bread is the most favorable condition for starch retrogradation (Zeleznak and Hoseney, 1986). Therefore, it is necessary to carry out an antistaling experiment of rice bread containing tamarind gum in a future study. Nishita et al. (1976) showed that bread containing HPMC was satisfactory when fresh, but became stale fairly quickly. Sciarini et al. (2012) also reported the increased enthalpy of gluten free bread formulated with rice flour and cassava starch containing gums measured by DSC, indicating increased amylopectin recrystallization during storage. However, they showed reduced initial crumb firmness and firming rate upon gum incorporation due to the higher water content of bread samples containing gums, which differed from results of the present study.

References

AACC. Approved Methods of Analysis, 11th Ed. Method 44-15.02, Method 74-09.01. American Association of Cereal Chemists, St. Paul, MN, USA (2010)

AACC. Approved Methods of Analysis, 11th Ed. Method 74-09.01. American Association of Cereal Chemists, St. Paul, MN, USA (2010)

Angalet S, Kweon M. Applicability of tamarind gum for gluten-free pan bread using a simple starch bread formula (abstract no. P-094). In: Abstracts: IFT Annual Meeting & Food Expo. July 25–28, Las Vegas, NV, USA. Institute of Food Technology, Chicago, IL, USA (2017a)

Angalet S, Kweon M. Tamarind gum applications in baking for superior quality gluten-free bread baked in ERO oven (abstract no. P-503). In: Abstracts: AACC International Annual Meeting 2017. October 8-11, San Diego, CA, USA. American Association of Cereal Chemists, St. Paul, MN, USA (2017b)

Angalet S, Kweon M, Hunt L. Applicability of tamarind gum for gluten-free yellow cake and pancake (abstract no. P-502). In: Abstracts: AACC International Annual Meeting 2017. October 8-11, San Diego, CA, USA. American Association of Cereal Chemists, St. Paul, MN, USA (2017)

Anton AA, Artifield SD. Hydrocolloids in gluten-free breads: A review. Int. J. Food Sci. Nutr. 59: 11–23 (2008)

Bárcenas ME, Rosell CM. Effect of HPMC addition on the microstructure, quality and aging of wheat bread. Food Hydrocoll. 19: 1037–1043 (2005)

Blanco CA, Ronda F, Pérez B, Pando V. Improving gluten-free bread quality by enrichment with acidic food additives. Food Chem. 127: 1204–1209 (2011)

Choi OJ, Jung HN, Shin SH, Kim YD, Shim JH, Shim KH. Quality characteristics of guten-free rice bread formulated with soft-type rice flour mixed with black-rice flour. Korean J. Community Living Sci. 26: 447–456 (2015)

Endreß H-U, Christensen SH. Pectins. pp. 274–297. In: Handbook of hydrocolloids. Philips GO and Williams PA (eds). Woodhead Publishing Ltd. and CRC Press LLC, Cambridge, UK and Boca Raton, FL, USA (2009)

Euromonitor International. (2016). Gluten-free fast becoming new industry standard in baked goods, with high fibre one to watch. Available from: https://blog.euromonitor.com. Accessed March 05, 2018.

Green PHR, Jabri B. Coeliac disease. Lancet 362: 383–391 (2003)

Hager AS, Arendt EK. Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and the combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocoll. 32: 195–203 (2013)

Han HM, Cho JH, Kang HW, Koh BK. Rice varieties in relation to rice bread quality. J. Sci. Food Agric. 92: 1462–1467 (2012)

Hera E, Martinez M, Gomez M. Influence of flour particle size on quality of gluten-free rice bread. LWT–Food Sci. Technol. 54: 199–206 (2013)

Hwang SO, Kim JM, Shin M. Effects of hydrocolloids on the quality of protein and transglutaminase added gluten-free rice bread. Korean J. Food Cook Sci. 33: 198–208 (2017)

Joung KY, Song KY, O H, Shin SY, Kim YS. Effects of xanthan gum and guar gum on the quality characteristics of gluten-free bread using teff (Eragrostis tef) flour. Culinary Sci. Hospitality Res. 23: 147–157 (2017)

Jung SH. Quality of cookie and bread formulated with Jeju magma seawater. Master thesis, Pusan National University, Busan, Korea (2016)

Kang TY, Choi E, Jo HY, Yoon MR, Lee JS, Ko S. Effects of Japonica rice cultivar on quality of gluten-free rice bread. Food Eng. Prog. 17: 305–310 (2013)

Kang TY, Choi E, Jo HY, Yoon MR, Lee JS, Ko S. Effects of rice flour particle of gluten-free rice bread. Food Eng. Prog. 18: 319–324 (2014)

Kim JM. Characteristics of rice flours prepared from different rice varieties and development of gluten-free bakery products using them. PhD thesis, Chonnam National University, Gwangju, Korea (2016)

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 79: 1033–1047 (2007)

Lee MH, Lee YT. Properties of gluten-free breads using different rice flours prepared by dry, wet and semi-wet milling. Food Eng. Prog. 10:180–185 (2006)

Maeda T, Yamashita H, Morita N. Application of xyloglucan to improve the gluten membrane on breadmaking. Carbohydr. Polym. 68: 658–664 (2007)

Mancebo CM, Miguel MAS, Martinez MM, Gomez M. Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J. Cereal Sci. 61: 8–15 (2015)

Martinez MM, Gomez M. Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J. Food Eng. 197: 78–86 (2017)

Mir SA, Shah MA, Naik HR, Zargar IA. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 51: 49–57 (2016)

Mohammadi M, Sadeghnia N, Azizi MH, Neyestani TR, Mortazavian AM. Development of guten-free flat bread using hydrocolloids: Xanthan and CMC. J. Ind. Eng. Chem. 20: 1812–1818 (2014)

Nishinari K, Takemasa M, Yamamota K, Shirakawa M. Xyloglucan. pp. 535–566. In: Handbook of hydrocolloids. Philips GO and Williams PA (eds). Woodhead Publishing Ltd. and CRC Press LLC, Cambridge, UK and Boca Raton, FL, USA (2009)

Nishita KD, Roberts RL, Bean MM. Development of a yeast-leavened rice-bread formula. Cereal Chem. 53: 626–635 (1976)

Rosell CM, Yokoyama W, Shoemaker C. Rheology of different hydrocolloids-rice starch blends. Effect of successive heating-cooling cycles. Carbohydr. Polym. 84: 373–382 (2011)

Sabanis D, Tzia C. Effect of hydrocolloids on selected properties of gluten-free dough and bread. Food Sci. Technol. Int. 17(4): 279–291 (2010)

Sciarini LS, Ribotta PD, León AE, Pérez GT. Effect of hydrocolloids on gluten-free batter properties and bread quality. Int. J. Food Sci. Technol. 45: 2306–2312 (2010)

Sciarini LS, Ribotta PD, León AE, Pérez GT. Incorporation of several additives into gluten free breads: Effect on dough properties and bread quality. J. Food Eng. 111: 590–597 (2012)

Shi X, BeMiller JN. Effects of food gums on viscosities of starch suspensions during pasting. Carbohydr. Polym. 50: 7–18 (2002)

Song JY, Shin M. Effects of soaking and particle sizes on the properties of rice flour and gluten-free rice bread. Food Sci. Biotechnol. 16: 759–764 (2007)

Statistic Korea. Food grain consumption survey report: 14–15 (2016)

Temsiripong T, Pongsawatmanit R. Ikeda S, Nishinari K. Influence of xyloglucan on gelatinization and retrogradation of tapioca starch. Food Hydrocoll. 19: 1054–1063 (2005)

Turabi E, Sumnu G, Sahin S. Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocoll. 22: 305–312 (2008)

US Food and Drug Administration. Food labeling; Gluten-free labeling of foods. Federal Register 78: 47154–47179 (2013)

Wüstenberg T. General overview of food hydrocolloids. pp. 1–68. In Cellulose and cellulose derivatives in the food industry. Wüstenberg T (ed). Wiley-VCH, Weinheim, Germany (2015)

Yoshimura M, Takaya T, Nishinari K. Effects of xyloglucan on the gelatinization and retrogradation of corn starch as studied by rheology and differential scanning calorimetry. Food Hydrocoll. 13: 101–111 (1999)

Zeleznak KJ, Hoseney RC. The role of water in the retrogradation of wheat starch gels and bread crumb. Cereal Chem. 63: 407–411 (1986)

Acknowledgements

We thank Mr. Jin Hong Kim at MS Bio Co., Ltd. for his kind support in supplying the pectin and guar gum samples for the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Jang, Kj., Hong, Y.E., Moon, Y. et al. Exploring the applicability of tamarind gum for making gluten-free rice bread. Food Sci Biotechnol 27, 1639–1648 (2018). https://doi.org/10.1007/s10068-018-0416-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-018-0416-z