Abstract

The present study analyses the moisture performance of nine wood species and wood-based materials determined in various laboratory and field trials to identify the method with the highest predictive power and determine the correlation between respective measurements. The moisture performance of wood and wood-based products has been recognised (besides inherent wood resistance) as the second most important parameter contributing to wood service life in above ground applications. Therefore, it is of great commercial importance to understand this phenomenon. In-service moisture monitoring trials can be unacceptably long, but on the other hand, they provide more realistic test conditions than laboratory tests. However, experiments in laboratory conditions enable a high level of reproducibility and are much faster than in-service tests. In order to assess the correlation between various tests, Pearson product moment correlation coefficients were calculated to determine the level of the strength of the linear relationship between the in-service and laboratory trials. Within this paper, it was attempted to identify laboratory methods suitable for quantification of moisture content during outdoor exposure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Information on the service life of the wood is essential, required by engineers, architects and end-users, as it is crucial for investment calculations, assessment of maintenance costs and life cycle analysis. Besides several indirect factors, such as design details, local climate or coating, the service life of wooden components exposed outdoors is a factor of the woods’ inherent durability (durability against fungal and bacterial decay), temperature and moisture content (MC) (Brischke et al. 2006). Water plays a central role since it affects all of the properties of the wood relevant to its performance. It is a well-known fact that wood is a hygroscopic material, which means that it absorbs and exchanges water molecules with its surroundings. Moisture influences the service life of wood and wood-based products, predominately because wood with a moisture content above a certain threshold is susceptible to fungal degradation (Time 1998; Rémond et al. 2007). The risk of decay increases when the wood MC is above 25%, which more or less matches the fibre saturation (FS) of wood (Rapp et al. 2000; Van Den Bulcke et al. 2009). Reducing the MC of wood is, therefore, a vital issue in the field of modern wood protection (Brischke et al. 2006; Meyer and Brischke 2015; Thybring et al. 2018a). In the past, wood protection was based on the impregnation of wood with toxic ingredients; nowadays more emphasis is put on non-biocidal modes of action, such as water exclusion efficacy (Winandy and Morrell 2017; Thybring et al. 2018b).

To characterise the wood-water relations of different wood-based materials, different field and laboratory trials were designed to test the interactions with liquid, liquid–vapour mixture or vapour water, namely various submersion, floating, water uptake, contact angle and vapour-uptake methods (Engelund et al. 2013; Meyer et al. 2016; Thybring et al. 2018a). While laboratory tests allow clearly defined conditions and a high level of reproducibility, it is usually impossible to fully mimic real-life conditions. In contrast, it is generally accepted that field tests provide more realistic test conditions but often suffer from unacceptably long test durations. Moisture content measurements could, therefore, serve as a cross-linking element between test methods, test sites, and other boundary conditions for comparative studies (Brischke et al. 2013). On the other hand, moisture performance is an essential criterion for assessment of the new wood-based materials, like modified wood (Thybring et al. 2018b). In such a test, the performance of the tested material should be compared to reference material, such as Norway spruce wood (Meyer-Veltrup et al. 2017).

Brischke et al. (2013) have found that for less severe exposure situations, moisture performance-based measures have the potential to serve as reliable indicators for timber durability. For screening purposes, even moisture uptake tests conducted in the laboratory, which are easy to perform and save time, can indicate the real outdoor performance. On the other hand, the 1-year results from field-test studies with façade and decking elements and segmented samples showed that one needs to consider more than a single year of exposure for both service life estimates and durability classification (Brischke et al. 2013). Tests should run for at least 3 years to avoid ignoring the effect of weathering on moisture performance, for example, through leaching of extractives and cracking of timber, as well as differences in the climate between years. Furthermore, another well-known fact is that impregnating timber with water repellents as well as modifying the wood cell walls aims at reduced water uptakes and minimising checking and splitting of impregnated wood in-service (Rowell and Banks 1985; Feist 1990; Esteves and Pereira 2009; Humar et al. 2017).

The prime objective of this paper was to compare the moisture performance of wood, thermally modified wood and wax-treated wood in the laboratory and outdoor conditions. The general idea of the manuscript is to identify the most appropriate methods for assessment of wood moisture performance in different outdoor, above ground applications, for example, use class 3 (CEN 2013a). These data are of vital importance for the assessment of the overall performance of wood and wood-based materials.

2 Materials and methods

2.1 Test samples and treatments

This study investigated the moisture performance of 22 different wood species and wood-based products used in a cladding application. Of these, nine materials (listed in Table 1) were chosen to illustrate the results of this study; six untreated wood species and three materials that were treated in different ways. For this study, materials that are frequently used in Europe in façade and decking applications were selected, namely materials based on Norway spruce (untreated, modified, wax-treated, Cu- treated), European larch and European oak. As reference species, European beech and Scots pine sapwood and heartwood were included as well. Besides, these materials are exposed to all cardinal locations on the model house, which enables easier comparison.

Thermal modification (TM) was performed according to the industrial process Silvapro® (Silvaprodukt, Slovenia) with an initial vacuum in the first step of treatment (Rep and Pohleven 2001; Rep et al. 2004). Modification of Norway spruce was performed for 3 h at 230 °C with the average mass loss of 7% due to the thermal modification. Impregnation of wood with 5% commercially available natural wax dispersion (Humar et al. 2017) was performed in a laboratory vacuum-pressure chamber according to the full-cell process [30 min vacuum (80 kPa), 180 min pressure (1 MPa), 20 min vacuum (80 kPa), respectively]. Solution uptake for untreated Norway spruce samples (PA-NW) was 620 kg/m3, and 570 kg/m3 for thermally modified Norway spruce (PA-TM-NW). Impregnated samples were conditioned in room conditions for 2 weeks prior to drying in a laboratory oven at 140 °C for 4 h to ensure sufficient melting of the wax.

2.2 Field trial

Field trials were based on two nearby locations; at the model house and on a test stand at the Department of Wood Science and Technology in Ljubljana, Slovenia (46° 02′ 55.7″ N 14° 28′ 47.3″ E, elevation above sea level 293 m) (Fig. 1). On the wooden model house, monitoring of the façade and the decking has taken place since October 2013. The materials listed in Table 1 were mounted on the façade [use class 3.1; EN 335 (CEN 2013a)] and decking applications (use class 3.2; EN 335). In addition, another exposure on the test stand (Fig. 2) started in December 2015, whereby samples were mounted horizontally and vertically facing north (Fig. 2). Samples were mounted at least 80 cm from the ground. The idea of this exposure was to compare horizontal and vertical exposure conditions. Although it was tried to make exposure conditions as uniform as possible, it should be considered that the upper samples were more exposed to the rain on mild rain events. The lower samples were more exposed to the rain as wind-driven rain accumulated on the top specimens was running to the samples exposed at the bottom.

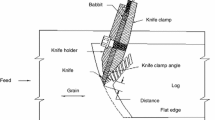

On both exposure locations, similar samples were exposed. Cross-section of the elements was 25 × 50 mm2, as prescribed by the EN 252 standard (CEN 2015a), but the length of the samples varied between 0.5 m (façade and test stand) and 1.0 m (decking) to fit on the load-bearing construction. The exposed samples were monitored by a variety of continuous and non-continuous measurement techniques. For moisture measurements, resistance sensors (Fig. 1) were applied to 150 positions and linked to a signal amplifier (Gigamodule, Scanntronik, Germany) that enables wood MC measurements between 6 and 60%. Stainless-steel screws with a diameter of 3.9 mm and length of 25 mm served as resistance sensors, fastened in the middle of the tangential surface with a distance of 32 mm between screws. The screws were insulated with a universal heat-shrinking tube except for the tip, which served as the point of measurement (Fig. 1). Sensors were located at least 20 cm from axial planes. Although the prime direction for water penetration are end-grains, the majority of the comparable tests are performed in a way that enables easier comparison. It is believed that the described approach provides average moisture performance of the tested materials. If these data are linked to the decay observations, it can be seen that the initial decay developed on the end grains as well as on the central part of the samples, close to the moisture monitoring. The electrical resistance of the wood was measured every 12 h, and these data were used for calculating the wood moisture content. Results were statistically analysed, with average and median values calculated. Besides, the percentage of the measurements exceeding 20%, 25% and 30% MC were calculated. These values are representative of the lowest limit suitable for fungal decay (Brischke and Rapp 2008).

For determination of the characteristics for electrical resistance-based MC measurements, five replicates of test samples with dimensions of 150 × 50 × 25 mm3 were used. In each sample, two stainless-steel screws were positioned the same way as described for field MC measurements. Samples were dried for 24 h at 103 ± 2 °C and weighed. They were placed in a climatic chamber (Kambič, Slovenia) with variable parameters [temperature and relative humidity (RH)] to condition samples to constant weight for 3 weeks. After conditioning, the mass and electrical resistance with Scanntronik sensors was measured. The authors are aware that there is a limited moisture gradient formed within the samples, but long conditioning times limit the gradients to a level suitable for preparation of calibration curves. Samples were measured eight times (at 25%, 40%, 60%, 80%, 90%, 100%, after impregnation with distilled water and after drying at 100% RH) and at four temperatures (30 °C, 25 °C, 20 °C, and 15 °C) except for the final drying at 100% RH (Brischke et al. 2008, 2014; Brischke and Lampen 2014; Otten et al. 2017).

To calculate the Pearson’s correlation coefficient (r), the average monthly moisture contents were used, both for the wooden model house unit (façade and decking applications) and the horizontal and vertical exposures on a nearby stand.

2.3 Laboratory trials

2.3.1 Floating test—absorption cycle

The test method for determining the water uptake and the effectiveness of the drying process described here and in the following sections (Sects. 2.3.1–2.3.4) was conducted according to draft European Standard prEN 16818 (CEN 2015b). Ten samples of each material listed in Table 1 [25 × 50 × 50 mm3, with all four edges sealed (all four sides, including axial surfaces) with epoxy resin] were used. Two semi-radial surfaces (the biggest surfaces) were submitted to an absorption and a desorption cycle. The test samples were weighed to the nearest 0.01 g, and initial mass (mi) was recorded. A container was filled with demineralised water and placed in a normal climate (20 ± 2 °C, 65 ± 2%). For the absorption cycle, test samples were placed 10 mm under the water level, ensuring that the sample surface was fully submerged. After 1 h, test samples were removed from the water, lightly blotted to remove water droplets, and weighed. Test samples were weighed again after 4, 8, 24, 48, 72 and 144 h.

2.3.2 Floating test—desorption cycle

After 144 h of absorption, the test samples were put on their side on a rack in a normal climate, with the minimum spacing between samples of 10 mm to ensure proper air circulation. Test samples were weighed after 1, 4, 8, 24, 48, 72, 96 and 168 h. After the desorption cycle, the test samples were oven-dried at 60 °C as required by the respective standard, to prevent cracking of the epoxy resin until constant mass to determine their oven-dry mass (m0).

2.3.3 Submersion test—absorption and desorption cycle

Ten samples of each material listed in Table 1 (150 × 50 × 25 mm3) with cross-sections sealed with a transparent two-component epoxy resin were submitted to an absorption and desorption cycle. The test samples were weighed to the nearest 0.01 g, and initial mass (mi) was recorded. A container was filled with demineralised water and placed in a normal climate (20 ± 2 °C, 65 ± 2%). Test samples were placed in the water, ensuring that the samples were fully submerged. After one hour, test samples were removed from the water, lightly blotted to remove water droplets and weighed. Test samples were weighed again after 4, 8, 24, 48, 72 and 168 h. The desorption cycle was carried out in the same way as the procedure described for the floating test (Sect. 2.3.2).

2.3.4 Calculation and expression of results from floating and submersion tests

Moisture content data are based on the mass of the wood without sealant. At the beginning of the process, the masses of the wood samples were determined before and after application of the sealant. At the end of the test, moisture content (MC) of each test specimen was calculated using the following equation (Eq. 1):

The amount of absorbed moisture after 144 h (a144) was calculated through Eq. 2:

where MC144 is the moisture content after 144 h of absorption and MCi is the initial moisture content.

Similarly, the amount of desorbed moisture after 168 h of desorption (d312) was calculated by Eq. 3:

where MC144 is the moisture content after 144 h of absorption and MC312 is the moisture content after 168 h of desorption.

Additionally, the residual moisture content (rm312), which represents the increase in moisture content after 144 h of desorption and is given by Eq. 4, was calculated:

Furthermore, the residue (res144) was calculated by Eq. 5:

where res144 is the residue representing the moisture content left after 168 h desorption as a percentage of the absorbed moisture after 144 h [%], MC144 is the moisture content after 144 h absorption, MCi is the initial moisture content before absorption and MC312 is the moisture content after 144 h of absorption and 168 h of desorption.

For both floating and submersion tests, average values of MC for each time step in the test were calculated, and the averages of a144, d312, rm312 and res144 were also calculated and used to calculate the Pearson’s product moment correlation coefficient (r).

2.3.5 Artificial ageing according to EN 84—the leaching procedure

Prior to the water vapour uptake, contact angle measurements and short-term capillary uptake test, a representative group of the samples was artificially aged, to remove possible extractives and other components that could act like surfactants. A similar process occurs in nature with the first extensive rain period. The European EN 84 standard (CEN 2002) describes a method for artificial ageing (leaching) of wood before testing the biological effectiveness. This standard was designed to simulate extensive leaching by natural precipitation. The first step was impregnation with demineralised water. The samples were stacked in a container, weighed down and vacuum impregnated (4 kPa) with demineralised water for 20 min and soaked for an additional 2 h. Samples were then immersed in water for 14 days, and during this period, water was replaced nine times. After the ageing process was completed, samples were dried in ambient conditions for 2 weeks prior to subsequent tests.

2.3.6 Water vapour uptake in a water-saturated atmosphere

Twenty samples of each material (ten leached and ten non-leached of dimension 50 × 15 × 25 mm3) were oven-dried at 103 °C until constant mass and weighed to the nearest 0.001 g to determine the initial oven-dry mass (m0). Particular samples were smaller than samples used for floating and immersion tests. Smaller samples were chosen, as the capacity of the climate chamber is limited and smaller samples reach the equilibrium state faster. It was presumed that the size of the samples does not have a significant effect on the final MC. The bottom of a climate chamber (glass container with stainless steel tray and ventilator) was filled with demineralised water. Samples were exposed above water with a minimal 10 mm spacing separation in the well-ventilated climate chamber and weighed again after 24 h. In addition, samples were exposed in the chamber with 100% RH until they reached equilibrium moisture content (EMC). The average EMC values in 100% RH were used for calculating the Pearson’s correlations.

2.3.7 Conditioning of the samples prior to contact angle and short-term water uptake measurements

Prior to the measurements of the contact angle of water and short-term capillary water uptake, five non-leached and five leached samples of each material with dimensions of 50 × 15 × 25 mm3 were oven-dried at 103 °C until constant mass and weighed to the nearest 0.001 g to determine the initial oven-dry mass (m0). Contact angle and short-term capillary uptake were determined on oven-dry samples. After the testing, the same samples were conditioned until they reached an equilibrium moisture content (EMC) at 20 °C in three different relative humidities (RH), i.e., 30%, 60%, and 80% in a conditioning chamber (Kambič, Slovenia). Each sample was weighed before measurements (conditioned weight) to determine the moisture content. The last conditioning was performed in a ventilated glass container in the water-saturated atmosphere at target RH of 100%. The purpose of the described preconditioning was to see whether the short-term uptake was influenced by wood moisture content. The influence of moisture on wood across the entire moisture content range (from absolutely dry to water-saturated) on the CA and short-term capillary uptake measurements was determined.

2.3.8 The contact angle of water

The change in contact angles (CA) with time of distilled water was determined by the sessile drop method. Measurements were taken on the surfaces of the six test samples (three of the test samples were leached) with the dimensions of 50 × 15 × 25 mm3 with a Theta Optical Tensiometer (Biolin Scientific Oy, Finland). For calibration of the goniometer microscope, a steel ball with a precise diameter of 4.000 mm was used. Droplets of 4 µl were applied to three different locations of each specimen, 10 mm apart from each other, on the radial surface (regardless of earlywood or latewood). Image recording was set for 125 s (7.6 frames per second, FPS) with recording started when the droplet was formed. CAs were determined by computer-aided analysis [OneAttension, Version 2.4 (r4931), Biolin Scientific, Finland, using the Young–Laplace CA analysis mode] of the shapes of the distilled water drops, as observed in an optical goniometer and recorded by a digital camera installed in the axial extension of the lens. Measurements were taken at 21 ± 1 °C. CA measurements started at the first image of a self-supporting drop on the substrate. For the analysis, all 18 CAs (left and right CA of three droplets from three samples) for each material were averaged. In addition, the amount of the change was calculated as follows by Eq. 6:

where Δ is the change of the CA from the 1 s of self-supporting drop on the surface of the sample, CAt is the CA at a chosen time, and CA1 s is the CA at 1 s of a self-supporting drop. Calculated values of the CA change (Δ) for 2, 3, 4, 5, 10, 20, 30, 40, 50, 60, 90 and 120 s of the test were used for calculating the Pearson’s correlations.

2.3.9 Short-term capillary water uptake

Short-term capillary water uptake (CWU) was measured according to the modified EN 1609 (CEN 2013b) procedure with a tensiometer device (Krüss Processor Tensiometer K100MK2, Hamburg, Germany) under normal conditions. The water uptake was measured from the axial surfaces on ten samples of each material (half of the test samples were leached) with dimensions of 50 × 15 × 25 mm3. The mass of partially immersed (0.5 mm) samples was recorded every 2 s for a period of 200 s. The results are presented as the mass of water uptake per immersed area of the specimen (g/mm2). Calculated values of water uptake in g/mm2 for 2, 4, 6, 10, 20, 30, 40, 50, 60, 90, 120, 150, 180 and 200 s of the test were used for calculating the Pearson’s correlations.

2.3.10 Data processing

The average moisture content (MC) gained in different in-service and laboratory trials was used to calculate Pearson product moment correlation coefficient (r) using Statgraphics Centurion XVII software, version 17.2.05 (Statpoint Technologies, Inc., Virginia). The multiple-variable analysis (correlations) procedure was used to calculate the correlation coefficients to measure the strength of the linear relationship between all the variables. P-values (P) below 0.05 were considered to be statistically significant.

3 Results and discussion

The original concept of this study and the respective manuscript was not to determine moisture performance of respective materials but to compare various methods for assessment of moisture performance.

3.1 Field trials

To determine the moisture content of wooden components, the electrical resistance of the wood was measured and transformed to the moisture content of wood also considering the temperature (Brischke et al. 2008, 2014; Brischke and Lampen 2014; Otten et al. 2017). As can be seen from Table 2, not all of the materials were exposed to all of the façades of the model house due to the limited space available. Scots pine heartwood (PS-HW) and the sapwood (PS-SW) were missing on the east-facing façade, and English oak (Q) was missing on the west-facing façade.

Table 2 presents the MC measurements of wood exposed on different sides of the façade and decking on the wooden model house unit and horizontal and vertical exposures on the stand. Comparing materials on each side of the model house, Norway spruce (PA 16.3%), pine sapwood (PS-SW 13.3%) and oak (Q 12.4%) had the highest median MC on the north-facing façade. European larch (LD 14.4%) and Norway spruce impregnated with the dispersion of natural wax (PA-NW 15.1%) have the highest MC on the south façade. Thermally modified Norway spruce (PA-TM 10.1%) and thermally modified Norway spruce impregnated with natural wax (PA-TM-NW 8.5%) were two materials with the highest median MC on the east-facing façade, and European beech (FS 12.5%) and heartwood of Scots pine (PS-HW 11.0%) on the west façade. However, the differences in north and south façades to east and west façades were the results of the uneven exposure. Thus, these differences should be considered with care and the influence of constructional protection (or lack of it) should also be born in mind. North and south-facing façade had a roof overhang and additionally, the upper part of the north façade has some inclination which offered protection to the samples from precipitation. On all four sides, samples mounted on the bottom part of the façade were affected by back-splashed rain. For example, European beech (FS) had the highest percentage of MC exceeding 20, 25 and 30% on south-facing façade. This could be explained with the position of the samples because they were on the bottom part in contact with the decking.

On the other hand, all of the measurements on the north-facing façade were lower than 20% MC, due to roof overhang protecting the samples from the rain. Additionally, although the façade elements are classified in the same use class as decking elements according to EN 335 (CEN 2013a), they were considerably less moist, for example, comparing the highest MC of the façade (west 12.5%) and the decking (21.7%) respectively. On the stand, horizontally mounted European beech samples had a higher median MC because the samples were on the top and not protected from rain in any way, which again showed the significance of the construction details on the final MC of outdoor exposed wood.

Monitoring of MC of wooden elements positioned in a horizontal and vertical position on a stand is presented in Table 2. If we compare the horizontal and vertical positions, the materials with the highest median MC positioned horizontally were FS (20.4%), PA (15.9%), Q (12.7%), PS-HW (11.1%) and PA-TM-NW (10.0%). On the other hand, vertically mounted samples with higher MC were PA-NW (24.9%), LD (21.5%), PS-SW (18.7%) and PA-TM (16.7%). The highest difference in MC between the positions was 12.7% for PA-NW, followed by PS-SW with 8.9% with higher MC of vertically exposed samples. However, if the micro-location is also taken into consideration along with orientation, it is possible to conclude that only PA (difference 0.3%) and Q (difference 1.6%) had a similar exposure; PA were both directly exposed to precipitation on the top of the rack and Q samples were partly sheltered by other samples. According to EN 335, the whole stand is classified as use class 3.1, though sheltering by upper positioned samples had a significant influence. The idea of the comparison of various tests is to determine the relative comparison or to determine the rank of the respective materials tested. It can be presumed that the respective test can provide this information. The test would be more valid if a roof was built above the stand, thereby avoiding the direct wetting by the rain from the top and only allow wetting from the side.

Although decking and façade applications are classified as use class 3 conditions, there is a vast difference in the overall performance. Façade is at least partially covered with a roof overhang. Thus, the recorded wood moisture content of the façade elements predominately reflects the relative humidity. On the other hand, the horizontally positioned and completely exposed terrace is considerably more exposed to the rain events and melting snow, which results in a higher median and average moisture contents. For example, the median MC of beech wood on the façade was between 10.9 and 12.5% while a median MC of 21.7% was determined on the decking. Similar ratios were determined for all of the samples. The highest median MC of the decking elements was measured on Scots pine sapwood (PS-SW 54.6%). This is expectable, as poor moisture performance of Scots pine sapwood is well known (Banks 1973; Metsä-Kortelainen et al. 2006). Rather poor water performance was determined on the thermally modified Norway spruce (PA-TM 25.3%). This phenomenon is a result of anatomical changes such as destruction of tracheid walls, ray tissues and pit deaspiration during heat treatment, and the increase in wood porosity (Metsä-Kortelainen et al. 2006; Awoyemi and Jones 2011). On the other hand, rather good water performance was determined for wax-treated thermally modified spruce (PA-TM-NW). The median moisture content of deck elements of this material was 12.2% (Table 2), which indicated excellent water performance. Good water performance of the respective material was a result of reduced hygroscopicity as a consequence of thermal modification (Wang and Cooper 2005; Esteves et al. 2008; Esteves and Pereira 2009; Willems 2014) and good water repellency of wax (Lesar et al. 2009; Lesar and Humar 2011). Expression of data for all the materials exposed on all surfaces as a percentage of days with the MC above 25% instead of median MC led to similar conclusions. For example, the percentage of days with MC above 25% for beech wood on decking is 40.9%, while ten times lower percentages were determined for exposed beech wood in façade applications (Table 2). Similar ratios were also determined for other wood-based materials.

3.2 Laboratory trials

3.2.1 Floating and submersion test

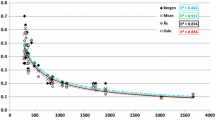

Various kinds of floating tests are frequently applied to the assessment of liquid water uptake since the risk of fungal destruction of wood depends strongly upon their moisture content and defines the moisture-induced risk index (MRI) (Rapp et al. 2000; Rapp 2004). However, there is no generally accepted method for liquid water assessment. In general, methods vary in sample size, duration time of immersion and in the sealing system applied. The data from research regarding MCs of the floating and submersion tests are illustrated in Fig. 3.

Differences became apparent between wood species and used treatments (Table 3): while Scots pine sapwood (PS-SW; 31.7% at the end of absorption cycle) showed highest and most rapid moisture content change during the absorption part of floating test, thermally modified and wax-treated Norway spruce (PA-TM-NW; 8.1% at the end of absorption cycle) showed minimal water uptake. The rest of the wood species were listed in between. However, the difference in water uptake between the Scots pine sapwood and Norway spruce (PA 19.2%) was almost the same as the difference between spruce and the best performing material (PA-TM-NW). This indicated poor water performance of Scots pine sapwood. In the submersion test, the material with the highest moisture content change was European beech (FS 53.0%). If these data are compared to those from the floating test, it is evident that the submersion test resulted in considerably higher water uptakes compared to the floating test. Beech wood samples took up three times less water during the floating test (FS 17.2%) than during the submersion (FS 53.0%). Besides, it should be considered that water uptake is expressed in percentages. Therefore, the total amount of water uptake by denser beech wood (submersion test: ST = 310.6 kg water/m3, floating test: FT = 102.9 kg water/m3) was even much higher than the water uptake by less dense wood like spruce (ST = 122.0 kg water/m3, FT = 73.5 kg water/m3). Among the materials based on Norway spruce wood, non-treated samples had highest MC after 144 h of absorption cycle during floating test (PA 19.2%), followed by wax-treated Norway spruce (PA-NW 15.0%) and thermally modified Norway spruce (PA-TM 11.6%), while the best performing was thermally modified and wax-treated Norway spruce (PA-TM-NW 8.1%). Excellent water performance of wax-treated samples reduced the risk of a fungal colonisation because the moisture content was relatively low throughout the test. A similar ranking was also observed in the submersion test. Wax-impregnated Norway spruce (PA-NW) showed a relatively slow change in MC in the first part of the absorption cycle, but in the second part, Norway spruce samples underwent a high water uptake. In addition, for both the wax-impregnated materials, the calculated residue moisture content (res144) was the highest among Norway spruce based materials (PA-TM-NW 27.5% and PA-NW 26.6%). Wax acted as a barrier and a water repellent and was active during the first period of the exposure, but at a later stage of the floating test, the wax prevented any drying of the wood. It should be considered that wax was applied in the form of an emulsion; hence, it formed only a thin film on the wood surface.

3.2.2 The contact angle of water and capillary water uptake

A key objective of this part of the study was to determine the influence of wood moisture content on short-term water uptake and contact angle. It was of interest whether wood behaved differently in rain event in hot summer (dry wood) or foggy autumnal (moist wood) weather. Hence, within this study, the influence of MC on CA of deionised water and short-term capillary water uptake (CWU) was investigated. Equilibrium moisture contents of the samples conditioned prior to the testing are presented in Table 4. These values are not discussed in particular but are essential for understanding the water performance in general.

3.2.2.1 The contact angle of water

The connection between contact angles and the moisture content of the wood substrate was investigated. Kúdela et al. (2015) reported that wood MC is an important influencing factor on the wetting process and with increased wood MC, contact angle values increased in the bound water range, resulting in a significantly reduced wetting of the wood surface. Results presented in Table 5 did not confirm these results, though in general (but with some exceptions), it was possible to say that higher CA (higher hygroscopicity and as a result lower wetting ability) was measured on the samples with higher MC. For simplicity, Table 5 contains the results for CA after one second only (although CA was measured continuously for 125 s), though, at different times, the similar trend of increasing CA with increasing MC was observed. In addition, the influence of accelerated ageing with leaching procedure according to EN 84 (CEN 2002) on CA was also tested, but based on these measurements it was possible to conclude, in some cases, that aged samples had higher CA (FS, LD and PA-TM) than other non-leached samples (PA-NW, PA-TM, PA-TM-NW, PS-HW and PS-SW). It is possible that the variability in CA values and the high standard deviation were the result of the unevenness of the wood surface and the random location of the contact angle measurements. There are two different phases (wood substrate and air) with different surface energies at the moment of the application of the water drop onto the surface, and in this case, the values of CA are results of interactions at the phase boundary between wood and liquid, chemical properties and morphology of the wood surface. This explains the differences in CA due to MC of wood, i.e. more moisture meant fewer free –OH groups, which resulted in reduced wood hydrophilicity (Kúdela 2014; Kúdela et al. 2017; Zhao and Jiang 2018).

3.2.2.2 Short-term water uptake

Short-term capillary water uptake measurements were only taken on axial planes. This orientation was selected, as the axial surface is the principal direction for water penetration, and frequently presents the weakest point for fungal degradation (Feist 1990; Kim et al. 2015). For the samples exposed outdoors, axial penetration was not the most prominent influence on the moisture content, as measurements were taken in the central part. However, water penetration in axial direction has an impact on the samples exposed on deckings through cracks, screw-holes and knots. Uptake of water determined by a tensiometer for non-aged and aged samples are presented in Table 5. It would generally be expected that with increasing MC, capillary water uptake became lower, but again, this was not observed as a rule. The positive influence of ageing according to EN 84 (capillary water uptake was lower for aged samples) was observed on FS and partly on PA-TM-NW, PS-SW and Q. On the contrary, the negative effect of ageing was determined for PA, PA-NW, PS-HW and partly PA-TM and LD. This difference was statistically significant. As expected, mostly the highest (excluding RH 100%) capillary water uptakes were measured for PS-SW, while the best performing materials were both wax-impregnated Norway spruce based materials (PA-NW and PA-TM-NW), followed by thermally modified Norway spruce and oak (PA-TM and Q).

Additionally, samples were in the chamber with a water-saturated atmosphere (RH 100%) for 24 h in order to understand the response to high relative humidity. Generally, non-aged samples had lower MC after 24 h exposure, except for PA-NW, which showed the opposite effect. Wax-impregnated and thermally modified Norway spruce (PA-TM-NW) was the best performing material (9.2% for non-aged and 9.4% for aged samples), followed by PA-TM (10.6% for non-aged and 11.2% for aged samples). After reaching an equilibrium state at 100% RH, the fibre saturation (FS, i.e. maximum moisture capacity of the cell walls) was reached (Skaar 1988), and the samples were weighed again. The best performing material at this point was PA-TM, which coincided with the literature (Esteves and Pereira 2009). Second best performing material was PA-TM-NW. Excellent water performance of this material was reported as well (Lesar and Humar 2011). All the other materials, including the wax-impregnated Norway spruce (PA-NW), responded very similarly, with an FS above 22%. In addition, it was noted that wood moisture content has a significant effect on short-term water uptake. It is presumed that not only capillary uptake but water absorption contributes to this phenomenon. Dry wood has more voids and higher affinity than wood with higher MC. This outcome has to be considered when performing this kind of tests.

3.2.2.3 Pearson’s correlations factors for moisture performance determined in in-service and laboratory testing

One of the prime objectives within this study was to determine the methods with the highest predictive power for determining moisture performance evaluated by laboratory testing and subsequently verified with in-service testing. Pearson’s correlation factors were calculated for all nine tested materials for all the performed tests as part of the multiple studies on how the in-service test correlated with the laboratory trials. Only these correlations are presented in Fig. 4. Both positive and negative correlation values higher than ± 0.7 are colour coded. Tables are colour-coded to indicate the most prominent correlations. Besides, the significance is indicated as well. The idea of the respective table is to indicate the correlation between tests where correlation is the most prominent. As can be seen from the results and Fig. 3, the correlation between moisture measurements in real applications and laboratory tests is challenging to determine. Firstly, as outdoor tests are much more comprehensive than laboratory tests, and as wood is continuously changing due to the weathering and other degradation phenomena. In general, sorption-based tests better describe vertically exposed samples that are rarely exposed to the rain, while immersion and floating tests better describe decking phenomena.

The results from fibre saturation (FS) in the water-saturated atmosphere only gave three Pearson correlations between samples exposed horizontally and vertically. The highest calculated coefficient was between FS and vertically mounted samples on the stand (S V) during the first month of exposure (r = 0.8953, P = 0.0011). EMC correlated best with the north-facing façade on the wooden model house, but not with the decking. This could be explained with the inclination of the wall and roof overhang, not allowing the rain to get directly in contact with the façade elements, so the only influencing factor was the relative humidity of the surrounding air. On the other hand, the decking was frequently exposed to rain events, with one surface being directly exposed to rain.

The floating test and all calculated values (see Eqs. 2–5) did not give any strong linear relationship with the horizontally mounted samples on the stand, but on the other hand, there were some statistically significant correlations with vertically exposed samples on the stand during the second [Jan 2016; average month temperature (T) = − 3.12 °C, average month rainfall = 0.00 mm, average month height of snow cover = 3,5 cm], third (Feb 2016; 5.00 °C, 0.25 mm, 0.5 cm) and fifth (Apr 2016; 9.26 °C, 0.04 mm, 0.4 cm) months of outdoor exposure, with the strongest correlations at the 95.0% confidence level in the second month of exposure. No statistically significant correlations with the calculated residue value (res144) can be found with all the in-service tests. At the model house, there are some strong correlations between the north façade in 41–44th month of exposure (March–July 2017), south-facing façade correlates in the fourth, fifth and sixth (February–April 2014) month with the last part of absorption cycle and with desorption part of the floating test. However, the best correlations with the floating test were found for the decking. It could be concluded that all precipitations had the most significant effect on this fact because the decking was the most exposed to rain events. The weather data from a nearby weather station (Davis, WeatherShack, USA) showed that the winds (at the test field at the Department of Wood Science and Technology in Ljubljana) during the period of the trial blew from the south most of the time. The average wind direction was 189.7°. As the deck was on the south side of the model house, this meant that it gets most of the rain on the whole surface. In addition, it was observed that with every additional year of outdoor exposure, the correlations between samples on the decking and floating test were getting stronger, with strong statistical significance of the estimated correlations.

In general, the submersion test gave similar trends when compared to the floating test, but fewer correlation coefficients between each pair of variables were higher than ± 0.7000. The trend found in the floating test that with every additional year correlations were getting stronger for decking was also found in the submersion test.

Contact angle measurements gave some Pearson correlations, but the majority of results higher than ± 0.7000 showed a significantly negative correlation. They can be found in between the horizontally mounted samples on the stand and contact angles measured on the samples conditioned at 60%, 80% and 100% RH, similarly to vertically mounted samples. No correlations were found with the samples conditioned at 100% RH. Some correlations were found on all of the façade samples, but not with the decking. It was concluded that the laboratory CA measurements did not help in predicting the behaviour of wood in in-service trials.

On the other hand, short-term capillary water uptake measurements could be used for predicting the behaviour of wood and wood-based materials. The strongest correlations were found with the decking and the samples conditioned at 60% RH, and the strength of correlations increased with every additional year of outdoor exposure. Correlations with the stand and model house were similar to the CA, but most of them showed a significantly positive correlation.

Additionally, materials were ranked for all performed laboratory and in-service trials and are presented in Tables 6 and 7. Rank one indicates the best water performance. Materials ranked with 1 in laboratory trials were only those with some additional protection, for example, thermal modification and/or wax impregnation (PA-NW, PA-TM and PA-TM-NW). Materials with the lowest ranking were FS, LD and PS-SW, predominantly beech (FS) and Scots pine sapwood (PS) with their well-known poor water performance. On the other hand, the lousy performance of LD in the laboratory opened up some questions, as larch was supposed to have a rather good water performance (Meyer-Veltrup et al. 2017). The influence of the accelerated ageing by leaching with water was not predominant for most of the materials, only for LD where the aged samples ranked better, especially in the contact angle of the water (average grade for non-aged samples was 17.1, compared to 8.0 for the aged ones). When comparing the ranks from the in-service test, materials ranked with 1 and 2 were usually PA-TM-NW and PA-TM, though in some cases Q was graded with two instead of PA-TM-NW or PA-TM. Only a slight difference in trend was observed on the decking where PA-TM-NW was ranked mostly with 1, and Q was most often rated 2. The two materials that ranked the lowest were spruce (PA), and wax-treated spruce (PA-NW) in most of the tests, while Scots pine sapwood (PS-SW) was identified as the worst-performing material on the deck.

4 Conclusion

The interaction of water with wood is highly important for the performance of wood and wood-based materials, which is why there are so many different experimental techniques for characterising water within the wood in the entire moisture domain, from absolutely dry to fully water-saturated state, and for different forms of water, such as vapour and liquid.

Differences in moisture dynamics were evident between the materials used in this research and depended on the moistening regime. Capillary water uptake was different from non-capillary water uptake, and water vapour uptake has a different mechanism.

Standard laboratory set-ups were performed in clearly defined conditions and can have a high level of reproducibility. Unfortunately, they do not fully mimic real-life conditions, so it is encouraged that the results gained in this way should be combined with those from field tests. This combination provided more realistic test conditions but often suffered from unacceptably long test durations. That is why the potential of various experimental methods performed in laboratory conditions was evaluated in order to be able to predict the outdoor moisture performance of wood.

The results showed that the decking application with every additional year of exposure gave better statistically significant correlations with most of the performed laboratory tests, except with the dynamic contact angle measurements. In addition, the first few months of outdoor exposure on the south-facing façade gave some correlations with all performed experiments. The floating test also gave some correlations with east-facing façade, which was not protected in any way to precipitation. On the other hand, the best correlations were found with the overhang-protected north-facing façade and the performed water vapour uptake in the water-saturated atmosphere test, because the roof overhang and additional inclination of the façade protected the samples from getting wet and were only exposed to water vapour from the air.

It could be further concluded that some faster laboratory trials can be used to predict the moisture performance of wood or wood-based materials in an outdoor application, but one must understand the interactions of water with wood and to what type of water uptake wood will be exposed. Based on the results obtained, if it was necessary to select a test, it would appear prudent to select the fibre saturation test, the short-term capillary water uptake test, and the absorption part of the floating test.

References

Awoyemi L, Jones IP (2011) Anatomical explanations for the changes in properties of western red cedar (Thuja plicata) wood during heat treatment. Wood Sci Technol 45:261–267. https://doi.org/10.1007/s00226-010-0315-9

Banks WB (1973) Water uptake by scots pine sapwood, and its restriction by the use of water repellents. Wood Sci Technol 7:271–284. https://doi.org/10.1007/BF00351073

Brischke C, Lampen SC (2014) Resistance based moisture content measurements on native, modified and preservative treated wood. Eur J Wood Prod 72:289–292. https://doi.org/10.1007/s00107-013-0775-3

Brischke C, Rapp AO (2008) Dose-response relationships between wood moisture content, wood temperature and fungal decay determined for 23 European field test sites. Wood Sci Technol 42:507–518. https://doi.org/10.1007/s00226-008-0191-8

Brischke C, Bayerbach R, Otto Rapp A (2006) Decay-influencing factors: a basis for service life prediction of wood and wood-based products. Wood Mater Sci Eng 1:91–107. https://doi.org/10.1080/17480270601019658

Brischke C, Rapp AO, Bayerbach R (2008) Measurement system for long-term recording of wood moisture content with internal conductively glued electrodes. Build Environ 43:1566–1574. https://doi.org/10.1016/j.buildenv.2007.10.002

Brischke C, Meyer L, Bornemann T (2013) The potential of moisture content measurements for testing the durability of timber products. Wood Sci Technol 47:869–886. https://doi.org/10.1007/s00226-013-0548-5

Brischke C, Sachse KA, Welzbacher CR (2014) Modeling the influence of thermal modification on the electrical conductivity of wood. Holzforschung 68:185–193. https://doi.org/10.1515/hf-2013-0041

CEN (2002) EN 84—wood preservatives—accelerated ageing of treated wood prior to biological testing—leaching procedure. European Committee for Standardisation, Brussels, p 7

CEN (2013a) EN 335—durability of wood and wood-based products. Use classes: definitions, application to solid wood and wood-based products. European Committee for Standardisation, Brussels, p 15

CEN (2013b) EN1609—thermal insulating products for building applications—determination of short term water absorption by partial immersion. European Committee for Standardisation, Brussels, p 12

CEN (2015a) EN 252—field test method for determining the relative protective effectiveness of a wood preservative in ground contact. European Committee for Standardisation, Brussels, p 27

CEN (2015b) EN 16818 Durability of wood and wood-based products—moisture dynamics of wood and wood-based products. European Committee for Standardisation, Brussels, p 13

Engelund ET, Thygesen LG, Svensson S, Hill CAS (2013) A critical discussion of the physics of wood-water interactions. Wood Sci Technol 47:141–161. https://doi.org/10.1007/s00226-012-0514-7

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4:370–404. https://doi.org/10.15376/biores.4.1.370-404

Esteves BM, Domingos IJ, Pereira HM (2008) Pine wood modification by heat treatment in air. BioResources 3:142–154. https://doi.org/10.15376/biores.3.1.142-154

Feist WC (1990) Outdoor Wood Weathering and Protection. In: Rowell RM, Barbour RJ (eds) Archaeological wood properties, chemistry, and preservation. American Chemical Society, Washington DC, pp 263–298

Humar M, Kržišnik D, Lesar B et al (2017) Thermal modification of wax-impregnated wood to enhance its physical, mechanical, and biological properties. Holzforschung 71:57–64. https://doi.org/10.1515/hf-2016-0063

Kim JS, Gao J, Daniel GF (2015) Ultrastructure and immunocytochemistry of degradation in spruce and ash sapwood by the brown rot fungus Postia placenta: characterization of incipient stages of decay and variation indecayprocess. Int Biodeterior Biodegrad 103:161–178. https://doi.org/10.1016/j.ibiod.2015.05.005

Kúdela J (2014) Wetting of wood surface by a liquids of a different polarity. Wood Res 59:11–24

Kúdela J, Wesserle F, Bakša J (2015) Influence of moisture content of beech wood on wetting and surface free energy. Acta Fac Xylologiae Zvolen 57:25–35

Kúdela J, Štrbová M, Jaš (2017) Influence of accelerated ageing on morphology and wetting on wood surface treated with a modified water-based coating system. Acta Fac Xylologiae Zvolen 59:27–39. https://doi.org/10.17423/afx.2017.59.1.03

Lesar B, Humar M (2011) Use of wax emulsions for improvement of wood durability and sorption properties. Eur J Wood Prod 69:231–238. https://doi.org/10.1007/s00107-010-0425-y

Lesar B, Pohleven F, Humar M (2009) Use of wax emulsions for upgrading of wood properties. In: Proceedings IRG Annual Meeting, Stockholm, Sweden, Document No.: IRG/WP 09-40451, p 8

Metsä-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170 °C, 190 °C, 210 °C and 230 °C. Holz Roh- Werkst 64:192–197. https://doi.org/10.1007/s00107-005-0063-y

Meyer L, Brischke C (2015) Interpretation of moisture monitoring data—relevance of moisture content thresholds for fungal decay relevance of moisture content thresholds for fungal decay. In: Proceedings IRG Annual Meeting, Stockholm, Sweden, Document No.: IRG/WP 15-10839, p 24

Meyer L, Brischke C, Preston A (2016) Testing the durability of timber above ground: a review on methodology. Wood Mater Sci Eng 11:283–304. https://doi.org/10.1080/17480272.2014.983163

Meyer-Veltrup L, Brischke C, Alfredsen G et al (2017) The combined effect of wetting ability and durability on outdoor performance of wood: development and verification of a new prediction approach. Wood Sci Technol 51:615–637. https://doi.org/10.1007/s00226-017-0893-x

Otten KA, Brischke C, Meyer C (2017) Material moisture content of wood and cement mortars—electrical resistance-based measurements in the high ohmic range. Constr Build Mater 153:640

Rapp AO (2004) Course of moisture content and Moisture Risk Index of coated and uncoated wood. In: Proceedings of the Final European Seminar on “High Performance Wood Coatings Exterior and Interior Performance”. Paris, France, p 19

Rapp AO, Peek R-D, Sailer M (2000) Modelling the moisture induced risk of decay for treated and untreated wood above ground. Holzforschung 54:111–118

Rémond R, Passard J, Perré P (2007) The effect of temperature and moisture content on the mechanical behaviour of wood: a comprehensive model applied to drying and bending. Eur J Mech 26:558–572. https://doi.org/10.1016/j.euromechsol.2006.09.008

Rep G, Pohleven F (2001) Wood modification—A promising method for wood preservation. Wood Constr Ind Tradit Futur 52:71–76

Rep G, Pohleven F, Bučar B (2004) Characteristics of thermally modified wood in vacuum. In: Proceedings IRG Annual Meeting, Stockholm, Sweden, Document No.: IRG/WP 04-40287, p 9

Rowell RM, Banks WB (1985) Water repellency and dimensional stability of wood. Gen. Tech. Rep. FPL-50. US Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, p 24

Skaar C (1988) Wood–water relations, 1st edn. Springer-Verlag, Berlin Heidelberg

Thybring EE, Kymäläinen M, Rautkari L (2018a) Experimental techniques for characterising water in wood covering the range from dry to fully water-saturated. Wood Sci Technol 52:297–329. https://doi.org/10.1007/s00226-017-0977-7

Thybring EE, Kymäläinen M, Rautkari L (2018b) Moisture in modified wood and its relevance for fungal decay. iForest 11:418–422. https://doi.org/10.3832/ifor2406-011

Time B (1998) Hygroscopic Moisture Transport in Wood. PhD Thesis, Norwegian University of Science and Technology

Van Den Bulcke J, Van Acker J, De Smet J (2009) An experimental set-up for real-time continuous moisture measurements of plywood exposed to outdoor climate. Build Environ 44:2368–2377. https://doi.org/10.1016/j.buildenv.2009.03.021

Wang JY, Cooper PA (2005) Effect of oil type, temperature and time on moisture properties of hot oil-treated wood. Holz Roh- Werkst 63:417–422. https://doi.org/10.1007/s00107-005-0033-4

Willems W (2014) The water vapor sorption mechanism and its hysteresis in wood: the water/void mixture postulate. Wood Sci Technol 48:499–518. https://doi.org/10.1007/s00226-014-0617-4

Winandy JE, Morrell JJ (2017) Improving the utility, performance, and durability of wood- and bio-based composites. Ann For Sci 74:25. https://doi.org/10.1007/s13595-017-0625-2

Zhao T, Jiang L (2018) Contact angle measurement of natural materials. Colloids Surf B Biointerfaces 161:324–330. https://doi.org/10.1016/j.colsurfb.2017.10.056

Acknowledgements

The authors acknowledge the support of the Slovenian Research Agency within the framework of projects L4-5517, L4-7547, program P4-0015 and the infrastructural centre (IC LES PST 0481-09). Part of the research was also supported by the project: Sustainable and innovative construction of smart buildings—TIGR4smart (C3330-16-529003). We want to acknowledge Dr Dennis Jones for language editing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors, Davor Kržišnik, Boštjan Lesar, Nejc Thaler, Jože Planinšič, Miha Humar, declares that there is no conflict of interests associated with the publication of respective manuscript entitled: a study of moisture performance of wood determined in laboratory and field trials, submitted for publication in Wood Science and Technology.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kržišnik, D., Lesar, B., Thaler, N. et al. A study on the moisture performance of wood determined in laboratory and field trials. Eur. J. Wood Prod. 78, 219–235 (2020). https://doi.org/10.1007/s00107-020-01506-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01506-z