Abstract

A large number of studies on the decay performance of wood in outdoor exposure have been conducted in the past. However, no test methodology for wooden components exposed above ground reflecting the variety of different loads has been established so far. Many test protocols were modified in different ways throughout the years and results were often published only in an encoded or incomplete way. This makes it difficult to obtain comparable results to work on a comprehensive above-ground test methodology. Therefore, a comparative study on moisture performance and the resulting decay response was conducted. Five different wood species were exposed according to 24 different test methods representing a wide range of different exposure situations including in- and on-ground exposure. After three years of exposure the moisture load as well as decay development differed between the test methods and tested materials. Different parameters were identified influencing the moisture performance of wood in the respective test set-ups and finally an attempt was made to set up a test methodology providing sets of test methods for differently severe applications within use class 3.1 and 3.2 as defined in the European standard EN 335 (2013).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The complexity of testing the biological durability of wood results from the different areas and exposure situations wood is used in. Wood was always used for constructions in the building sector where the areas of application are ranging from simple structures like range land fences to more complex ones like balconies, studwork, bridges or nowadays also roller coasters (Seidel and Wiegand 2001). All these different constructions and their specific details are exposed to a wide range of different agents and combinations and intensities of their actions. With respect to the service life of wooden components exposed outdoors the decisive loads responsible for the risk of damage can mainly be reduced to moisture, temperature and the presence of wood destroying organisms. The first step to classify a wooden component with respect to an expected load is to distinguish between in-ground (use class 4) and above-ground exposure (use class 3.1 and 3.2 according to EN 335 (2013)). In the past numerous test methods were conducted all over the world and have been described in literature referring to both of these exposure conditions (e.g. Fougerousse 1976; De Groot 1992; Francis and Norton 2005; Fredriksson 2010; Brischke et al. 2012).

Among these tests the ones reflecting above-ground exposure are not regularly used to determine durability and only eight methods are standardized: two European standards (EN 330 2014; CEN/TS 12037 2003), five US standards (AWPA E9 2013; AWPA E16 2013; AWPA E18 2013; AWPA E25, 2013; AWPA E27 2013) and one Australian standard (AWPC 2007). The reason for this can be found in the long testing periods needed for above-ground tests compared to testing in ground contact. While tests in ground contact can lead to final results after one to five years, depending on wood species, modification or treatment (Larsson Brelid et al. 2011), failure due to decay in above-ground tests can take many more years or even decades (Wang et al. 2008; Augusta 2007). However, testing wood durability exclusively in ground stands in contrast to the fact that the majority of timber products in outdoor use with different requirements according to dimensional accuracy as well as load bearing capacity are exposed above ground, for example façades, terrace decking, windows, balconies or carports (Blom and Bergström 2006; Friese et al. 2009). Furthermore, results from in-ground tests cannot be transferred to the performance of timber products used in above-ground situations (Kutnik et al. 2014).

For most of the test protocols decay progress is determined regularly every 6–12 months, but since the moisture and temperature load is usually not recorded, reliable information about their ability to reflect different exposure situations is lacking. Furthermore, the influence of different acceleration measures (i.e. methods to intensify decay) like defect coatings, feeder boards or artificial shading is not fully understood. The high variation of test methods which are conducted under varying conditions including different evaluators, different test sites and different accelerations or modifications makes it difficult to get comparable results which are strongly needed for service life prediction of timber structures (Brischke et al. 2011, 2013b).

To overcome this drawback a comparative study on moisture performance and the resulting decay response was conducted. Five different wood species were exposed according to 24 different test methods representing a wide range of different exposure situations. The test set-up covered established and standardized test methods (e.g. L-joint test, decking test, ground proximity test) as well as some new alternative test methods.

2 Materials and methods

2.1 Wood materials

In this study, the moisture performance and natural durability of five wood species (Table 1) were tested using 24 different field test methods. All specimens were free of cracks, decay and other obvious defects.

2.2 Test set-up

Ten replicates of each test material were exposed to a field test site in Hannover, Germany, in 2012 (Fig. 1) (coordinates: 52.395067°N, 9.701913°E, elevation: 54 m, mean temperature: 9.2 °C, precipitation sum: 642 mm, climate: temperate zone). The ground of the test site was covered with gravel.

In Table 2, schematic drawings of all tests including dimensions and details of exposure and specimen composition are shown. All tests were carried out according to the named references. A detailed analysis of design details and acceleration measures is given by Meyer et al. (2016). In addition to decay assessment, moisture content and temperature were determined once a day.

2.3 Decay assessment

Decay was assessed every six months and evaluated according to EN 252 (2015). A pick-test was used, where a pointed knife is pricked into the specimens and backed out again. The fracture characteristics of the splinters as well as depth and appearance of decay were assessed visually, and referred to the evaluation scheme according to EN 252 (2015). For test set-ups with cross sections deviating from the cross section given in the standard (50 × 25 mm2) the rating scheme was adapted to the respective dimensions (Table 3). Therefore, the maximum decay depth [mm] was approximated in 0.5 mm steps to reach the minimum intact cross section [%] given for the ratings according to EN 252 (2015) specimen dimensions.

2.4 Durability classification

Since the mean lifetime of the specimens was not yet obtained for all materials tested after three years of exposure, the mean decay rate v mean was calculated (Eq. 1) as previously reported by Brischke et al. (2013a).

Equation 1: Mean decay rate v mean after certain time:

where v mean is mean decay rate of specimens [a−1], v i is decay rate of single specimen [a−1], R is decay rating, e.g. according to EN 252 (2015), t is exposure time [a], n is number of replicate specimens

2.5 Moisture content and temperature measurements

MC and wood temperature were recorded on three of ten replicates per material in all tests once a day. The moisture and temperature recording was performed with data logging devices “Materialfox Mini” and “Thermofox Mini” (Scanntronik Mugrauer GmbH, Zorneding, Germany). The memory capacity was 16,000. The data loggers were equipped with three ports. The measuring ranged from 2 × 104 to 5 × 108 Ω. The measuring principle was based on the discharge–time–measurement method. First, a capacitor was charged through a very small ohmic resistance and then discharged through the material to be measured. Based on the time needed for discharging, the resistance of the material can be calculated.

Resistance characteristic curves were established for every single material under test by determining the relationship between the gravimetric MC and the electric MC at different temperatures (Brischke and Lampen 2014). Gravimetric and electric MC measurements were carried out in comparison at four target MCs (MC = 15, 18, 25 and 50%) and three target temperatures (T = 4, 20, and 36 °C).

The measuring points were installed from the bottom side of the specimens and located in their center. The electrodes were installed at half of the depth of each specimen. The distance between the centers of the two measuring points was 30 mm parallel and 6 mm orthogonal to the grain. The electrodes were made from polyamide coated stainless steel cables with a core diameter of 1 mm. The electrodes were glued into predrilled holes of 4 mm diameter with an epoxy resin. The bottom part of the holes was filled with 0.1 ml of an epoxy-graphite mixture to provide conductivity. The first 5 mm of the plastic coating of the electrode was removed before putting it into the glue. After 24 h hardening the remaining volume of the hole was filled up with an isolating epoxy resin. After hardening the electrodes were connected to the data logger.

3 Results and discussion

3.1 Moisture performance and durability

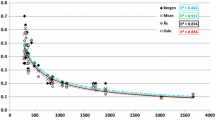

Both MC and decay development differed significantly between wood species as well as between the different test methods. In Fig. 2a and b, moisture courses and the corresponding decay development are exemplary shown for beech and Norway spruce heartwood for six different test set-ups. For all tests, high MC over longer periods led to fast decay development (e.g. horizontal double layer, Fig. 2a-3). However, some tests with similarly high MC showed differences in decay development, such as sandwich tests exposed close to the ground under a shade-box (Fig. 2a-2) and the in-ground test (Fig. 2a-1). In contrast to the in-ground test, the sandwich test seems to cause a time lag of one year between exposure and onset of decay. This might on the one hand be explained by the fungal flora in soil, which is able to immediately infest the wood in ground contact, whereas the elevated set-up needed longer intervals prior to air-borne infestation. Furthermore, the negative peaks in the moisture courses especially for beech show a higher potential to re-dry for the elevated sandwich test samples right after heavy rain events. Time lags were also observed for Norway spruce exposed to the Bundle II test (Fig. 2b-4), the Decking test (Fig. 2b-5) and the Façade element test (Fig. 2b-6).

3.2 Time of wetness

For quantifying the differences in moisture loads between the different test methods the time of wetness (ToW) was calculated and expressed as the number of days with MC ≥25% (Table 4). After an exposure period of three years, ToW differed significantly between test methods as well as between tested materials. The ToW for all wood species was summed up for every test and finally the percentage was calculated to give an indication of differences in moisture loads between all 24 tests. Therefore, different test set-ups were ranked with respect to their ToW and grouped accordingly (cf. Table 5).

It became clear that high moisture loads were caused by shade boxes, exposure close to the ground and defect coatings. Medium moisture loads occurred in tests that consisted of segmented specimens but were exposed far above ground (>1 m) or single layer specimens. Low moisture loads were found in test set-ups that were exposed vertically or enabled a fast re-drying like the façade element or the Johansson test.

As expected, the highest number of wet days was determined for the in-ground test specimens that were wet at 91% of the exposure time. This can of course be explained by the fact that the specimens had been in contact with wet soil almost all the time. The second highest ToW was determined for those methods providing a defect of the coating. Here, the effect of high capillary water uptake through cracks and a hindered re-drying due to areas with still intact coating became obvious. Similar observations were made by Francis and Norton (2005) who compared coated and uncoated Lap-joint specimens at several climatically different locations in Australia.

Segmented specimens creating a water trapping joint like in the horizontal double layer test or the sandwich test also showed high MC on 75 and 82% of the days of exposure. A further detail which showed the effect on the moisture load was artificial shading. The sandwich test exposed close to ground as well as the ground proximity test, both exposed under a shade box, showed higher ToW compared to exposure without shading.

The test set-ups that caused the lowest ToW were either composed of two to three members exposed vertically or consisted of single members. Vertical exposure (e.g. cross brace test or Johansson test) allowed fast water draining, whereby single members re-dried faster after rain events compared to segmented specimens with joints.

3.3 Decay resistance

Although moisture, more specifically the time of wetness, is considered to be the key factor for decay, other parameters such as temperature and the presence of decay causing organisms have an effect on decay progress. To identify the decay potential of the 24 different test set-ups the decay rate v of the material exposed to the different test set-ups was calculated and summed up for all materials under test (Table 6).

A correlation between the two test factors (1) number of days with MC ≥25% and (2) decay rate is given in Fig. 3. Here, the mean of all wood species was used to minimize the influence of outliers as observed for example for Scots pine exposed to the sandwich test, close to ground (cf. Table 4). The three ToW-groups marked by three different shades of grey and defined in Table 5 were added to the graph.

Except for a few outliers, the two measures correlated fairly well. In some cases deviations might be caused by (1) the distance to ground, (2) the position of the MC measuring points or (3) the decay assessment procedure. All outliers which showed a high decay rate with comparably low number of days above 25% MC (Decking test, Rod test, On-ground test, Horizontal double layer test, in-ground test) were either exposed in or on the ground or extremely close to the ground (10 cm or less). Therefore, bacteria and other microorganisms which accelerate decay development have to be taken into account additionally (Clausen 1996).

In the Johansson test (Fig. 4a) decay developed almost exclusively close to the end grains (Fig. 4b). In contrast, the measuring points were installed at the bottom part of the upper members (Fig. 4c). Such influence of the measuring position was previously indicated by Meyer et al. (2014). Similar difficulties to detect decay occurred in the L-joint (Fig. 5a) and Lap-joint tests (Fig. 5c). Here, decay often developed either behind the coating or the end-grain sealing and was therefore not detected over a long period (Fig. 5b, d). The end-grain sealant of Lap-joint specimens is intended to protect them from water uptake to simulate a long timber member typical for construction purposes. At the same time it serves as moisture barrier, hinders re-drying, and promotes decay inside the specimen, where it is most difficult to be detected. In contrast to the end grain area, in the joint area the wood has, to some extent, the possibility to re-dry after wetting.

3.4 Evaluation

Besides the moisture induced risk and the development of decay further aspects have to be taken into account to identify suitable test methods. Therefore, all test methods have been evaluated previously with respect to practicability, time and effort required for preparing and conducting the test as well as material and component costs (Meyer et al. 2013). The three crucial factors (1) moisture induced risk, (2) decay rate and (3) practicability issues have been assessed as summarized in Table 7.

Within the group of methods with high moisture load, the horizontal double layer provided a combination of high moisture loads, fast and severe decay, and a low rating for costs and efforts. Methods where specimens are in direct contact with the ground need to be considered separately and were not regarded as potential test methods for above ground situations.

Within the group of test methods resulting in a medium moisture induced risk the Bundle test type II turned out to be one of the most promising tests with very inexpensive sample preparation but high moisture load within this group. Specimens in the rod test, which showed a high decay development, decayed almost exclusively on the bottom which was in direct contact with the ground. In addition, this method turned out to be very time consuming with respect to sample preparation as well as evaluation, because all ten specimens serve as one replicate and need to be disassembled.

All tests within the group providing low moisture induced risk showed, as expected, low decay rates except the Johansson method, where specimens decayed mainly at the steel screws, not in the overlap area where MC measurements were performed and decay was intended to occur first. Consequently, all tests within this group require long exposure periods before first signs of decay can be detected. To allow achieving test results within this group in an acceptable long time span, moisture monitoring appears to be the only feasible alternative to usual decay assessments. The potential of such alternative measurements was previously reported by Brischke et al. (2013a). Façade elements can consequently serve as relevant test set-ups within this group representing the lowest moisture-induced decay risk.

4 Conclusion

The evaluation of the 24 test methods with respect to moisture performance and decay development resulted in considerable differences between test methods as well as between the response of different wood species to the method-specific moisture induced risk. In most of the cases the time of wetness coincided well with the resulting decay response. However, especially if the wooden component is exposed close to, on, or in the ground additional factors influencing the degradation need to be considered, for example the fungal flora which is permanently present in soil. Further influencing factors are the position of measuring and the detection of decay progress. In addition, one has to keep in mind that due to the huge range of different exposure situations of wooden components in real life, one test method cannot sufficiently reflect the decay behaviour of a wooden material in all these different exposures. Therefore, a set of test methods for different applications is needed rather than one universal method. Based on this study, the suitability of the various in and above ground test methods to serve as elements of a comprehensive test methodology was investigated. The methods were ranked according to different criteria and the most feasible methods were identified in a quantitative manner to represent at least three groups of differently severe moisture induced risk. With respect to the time of wetness, the different test set-ups were classified into three groups (high, medium, and low). Within these groups they were evaluated by the following factors (1) moisture induced risk, (2) decay rate and (3) practicability. The following test methods turned out to be the most promising: horizontal double layer, bundle test and the Façade-decking element.

References

Augusta U (2007) Untersuchung der natürlichen Dauerhaftigkeit wirtschaftlich bedeutender Holzarten bei verschiedener Beanspruchung im Außenbereich. (Natural durability of European wood species in different use classes) (In German): Doctoral thesis, University Hamburg, Faculty of Mathematics, Informatics and Natural Sciences, Department Biology, Germany

AWPA E9 (2013) Standard field test for the evaluation of wood preservatives to be used above ground (UC3A and UC3B): L-joint test. American Wood Protection Association. Birmingham, USA

AWPA E16 (2013) Standard field test for evaluation of wood preservatives to be used above ground (UC3B): horizontal lap-joint test. American Wood Protection Association. Birmingham, USA

AWPA E18 (2013) Standard field test for evaluation of wood preservatives to be used above ground (UC3B), ground proximity decay test. American Wood Protection Association. Birmingham, USA

AWPA E25 (2013) Standard field test for evaluation of wood preservatives to be used above ground (UC3B): decking test. American Wood Protection Association. Birmingham, USA

AWPA E27 (2013) Standard field test for evaluation of wood preservatives to be used above ground (UC3B): accelerated horizontal lap joint test. American Wood Protection Association. Birmingham, USA

AWPC (2007) Protocols for assessment of wood preservatives. Australian Wood Preservation Committee, Ensis

Blom Å, Bergström M (2006) Untreated Scots pine (Pinus sylvestris) and Norway spruce (Picea abies) wood-panels exposed out of ground contact in Sweden for two years. Holz Roh Werkst 64:53–61

Bornemann T, Brischke C, Lück JM (2012) Comparative studies on the moisture performance and durability of wooden facades. The International Research Group on Wood Protection, IRG/WP 12-20492

Brischke C, Lampen SC (2014) Resistance based moisture content measurements on native, modified and preservative treated wood. Eur J Wood Prod 72:289–292

Brischke C, Welzbacher CR, Meyer L, Bornemann T, Larsson-Brelid P, Pilgård A, Frühwald Hansson E, Westin M, Rapp AO, Thelandersson S, Jermer J (2011) Service life prediction of wooden components—Part 3: approaching a comprehensive test methodology. The International Research Group on Wood Protection, IRG/WP 11-20464

Brischke C, Meyer L, Alfredsen G, Humar M, Francis LP, Flæte PO, Larsson Brelid P (2012) Durability of timber products—Part 1: inventory and evaluation of above ground literature data on natural durability of timbers. The International Research Group on Wood Protection, IRG/WP 12-20498

Brischke C, Meyer L, Bornemann T (2013a) The potential of moisture content measurements for testing the durability of timber products. Wood Sci Technol 47:869–886

Brischke C, Meyer L, Alfredsen G, Humar M, Francis L, Flæte PO, Larsson Brelid P (2013b) Natural durability of timber exposed above ground—a survey. Drvna Industrija 64:113–129

CEN TS 12037 (2003) Wood preservatives—Field test method for determining the relative protective effectiveness of a wood preservative exposed out of ground contact—horizontal Lap-joint method. Beuth, Berlin

Clausen CA (1996) Bacterial associations with decaying wood: a review. Int Biodeterior Biodegrad 37:101–107

Cookson LJ, Carr J (2009) Accelerated H3 above ground decay trials in Australia. The International Research Group on Wood Protection, IRG/WP 09-20411

De Groot RC (1992) Test assemblies for monitoring decay in wood exposed above ground. Int Biodeterior Biodegrad 29:151–175

EN 335 (2013) Durability of wood and wood-based products—use classes: definitions, application to solid wood and wood-based products. Beuth, Berlin

EN 330 (2014) Wood preservatives—Determination of the relative protective effectiveness of a wood preservative for use under a coating and exposed out-of-ground contact—field test: L-joint method. Beuth, Berlin

EN 252 (2015) Field test method for determining the relative protective effectiveness of a wood preservative in ground contact. Beuth, Berlin

Fougerousse M (1976) Wood preservatives: field tests out of ground contact—Brief survey of principles and methodology. The International Research Group on Wood Protection, IRG/WP 76-269

Francis LP, Norton J (2005) Above-ground durability estimation in Australia. Results after 16 years exposure. The International Research Group on Wood Protection, IRG/WP 05-20314

Fredriksson M (2010) Methods for determination of moisture conditions in wood exposed to high moisture levels. Licentiate thesis, Lund University, Lund Institute of Technology, Division of Building Materials, Lund

Friese F, Larnøy E, Alfredsen G, Pfeffer A, Militz H (2009) Comparison between different decay assessment methods. In: Proceedings of the 5th Meeting of the Nordic-Baltic Network in Wood Science and Engineering (WSE), Copenhagen, Denmark, pp 85–91

Highley TL (1995) Comparative durability of untreated wood in use above ground. Int Biodeterior Biodegrad 35:409–419

Johansson P, Jermer J, Johansson I (2001) Field trial with wood preservatives for class AB. SP Swedish national testing and research institute, Boras

Kutnik M, Suttie E, Brischke C (2014) European standards on durability and performance of wood and wood-based products–Trends and challenges. Wood Mat Sci Eng 9(3):122–133

Laks PE, Mirros PI, Larkin GM, Ingram JK (2008) Field tests of naturally durable north american wood species. The International Research Group on Wood Protection, IRG/WP 08-10675

Larsson Brelid P, Brischke C, Pilgård A, Hansson M, Westin M, Rapp AO, Jermer J (2011) Methods of field data evaluation—time versus reliability. The International Research Group on Wood Protection, IRG/WP 11-20466

Meyer L, Brischke C, Rieken J (2013) Testing the performance of timber using 27 different field test methods. The International Research Group on Wood Protection, IRG/WP 13-20517

Meyer L, Brischke C, Kasselmann M, Rösmann C (2014) Moisture performance testing of wood—practical experiences. The International Research Group on Wood Protection, IRG/WP 14-20546

Meyer L, Brischke C, Preston A (2016) Testing the durability of timber above ground: a review on methodology. Wood Mater Sci Eng 11(5):283–304

Seidel A, Wiegand T (2001) Die Holzachterbahn “Colossos” in Soltau. (The wooden rollercoaster “Collossos” in Soltau) (in German). Bautechnik 78(10):747–749

Van Acker J, Stevens M (2003) Biological durability of wood in relation to end-use—Part 2: the use of an accelerated outdoor L-joint performance test. Holz Roh-Werkst 61:125–132

Wang CH, Leicester RH, Ngyen MN (2008) Decay above ground. Manual No.4. CSIRO Sustainable Ecosystems, Urban Systems Program, Highett, Victoria

Westin M, Rapp AO, Nilsson T (2004) Durability of pine modified by 9 different methods. The International Research Group on Wood Protection, IRG/WP 04-40288

Zahora A (2008) Above ground field testing—Influence of test method and location on the relative performance of various preservative systems. The International Research Group on Wood Protection, IRG/WP 08-20393

Acknowledgements

Scientific exchange and parts of the experimental work have been financed by Stora Enso Timber, who is deeply acknowledged. Weather data was kindly provided by the Institute of Meteorology and Climatology, Leibniz University Hannover. Holger Schilke is acknowledged for processing and providing the data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meyer-Veltrup, L., Brischke, C. & Källander, B. Testing the durability of timber above ground: evaluation of different test methods. Eur. J. Wood Prod. 75, 291–304 (2017). https://doi.org/10.1007/s00107-016-1137-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1137-8