Abstract

Resistance characteristics were determined for a total of 27 wood-based materials containing native soft- and hardwoods, differently modified timbers and preservative treated timbers. A functional relation between measured electrical resistance and gravimetrical wood moisture content (MC) was established in a range between 15 and 50 % MC. Most precise MC estimation was found for salt-treated timber (±2.5 %), followed by native timber (±3.5 %) and modified timber (±7 %) in the hygroscopic range. As expected, preciseness decreased above fiber saturation, but was still sufficient for native timber (±8 %) and preservative treated wood (±5 %) at approx. 50 % MC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Wood durability is the consequence of wood extractives having biocidal or inhibiting effects and the moisture performance of wood. Since fungal degradation of wood requires liquid water in the wood to allow transporting fungal enzymes, a risk of decay is given when the wood moisture content (MC) is above fiber saturation. To characterize the moisture performance of wood and to quantify the effect of moisture loads on the resulting durability it is unavoidable to measure wood MC in the field as well as on real structures in service.

Generally, there are different possibilities for measuring and recording wood MC over longer periods of time: Direct measurements can be conducted using load cells (Van den Bulcke et al. 2009), which is a precise method that allows determining the global MC of a wooden specimen, but not the particular MC at a certain position. Furthermore, the method is sensitive to wind loads and the size of test objects is limited. Hygroscopic MC measurements are based on the relationship between relative humidity RH, temperature and equilibrium wood MC. Temperature and humidity in a bore hole allow calculating the corresponding MC of the wood which is in equilibrium with the ambient air (e.g., Evans 2004). However, this method is only applicable for MCs below fiber saturation.

Finally, electrical resistance measurements provide information about wood MC and are frequently used for continuous outdoor measurements and recordings. A system for long-term data logging on timber structures and field trials has been developed by Brischke et al. (2008). A 2 k-epoxy resin was used as isolating glue and as conductive glue when mixed with graphite powder. Partly isolated stainless steel cables acted as both electrode and cable. This system was further tested in combination with mobile mini data loggers. However, since the electrical conductivity depends on wood species and wood temperature, a calibration curve describing the functional relation between electrical resistance and local moisture content is needed for every single material tested (Du 1991). Earlier results showed that measurements with sufficient accuracy were possible in a range between 15 and 50 % wood MC for different native softwoods (Brischke et al. 2008). However, cell wall modification as well as impregnation with preservatives, which are commonly applied on wood in outdoor use, is expected to have a significant impact on electrical conductivity of wood, as for instance reported by Smith et al. (2007) and Brischke et al. (2013).

Therefore, this study aimed at the determination of material-specific resistance characteristics of native soft- and hardwoods, thermally and chemically modified timber as well as timber impregnated with different types of wood preservatives.

2 Materials and methods

Resistance characteristics were determined for a wide range of materials, which were studied in terms of durability field tests and moisture monitoring of timber structures. As summarized in Table 1, native soft- and hardwoods, differently modified and preservative treated timbers were included in the tests.

Data loggers (Materialfox, Scanntronik Mugrauer) were used for resistance-based measurements. Their memory capacity comprised up to 16,000 readings. The data loggers were equipped with three ports and the effective range of measurements was between 2 × 104 and 5 × 108 Ω. A sampling interval of 30 s was chosen for the calibration experiments. The measuring principle was based on the discharge-time-measurement method. First a capacitor was charged through a small ohmic resistance and then discharged through the material to be measured. Based on the time needed for discharging, the resistance of the material was calculated.

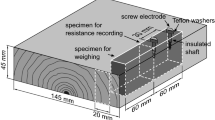

For determination of resistance characteristics, eight replicate specimens of 50 (ax.) × 20 × 30 × mm3 were used for each MC/wood species combination. Two holes of 4 mm diameter were drilled into the specimens with a distance between the centers of 30 mm parallel and 6 mm orthogonal to the grain as described in detail by Brischke et al. (2008). To determine the relationship between electrical resistance and wood moisture content (MC) gravimetric and electric MC comparative measurements were carried out at four target MCs (15, 18, 25 and 50 %) and three target temperatures (T = 4, 20, and 36 °C).

To achieve the target MCs, the specimens were stored in well ventilated miniature climate chambers filled with saturated solutions of NaCl (75 % RH; 15 % MC), KCl (85 % RH; 18 % MC), and K2SO4 (98 % RH; 25 % MC), respectively. To obtain 50 % MC the following procedure was applied: Water pressure impregnation, storing in polyethylene (PE) bags for 6 days at 4 °C, afterwards drying down to 50 % MC at room temperature, subsequent storage in PE bags for another 6 days at 4 °C. PTFE isolated stainless steel electrodes were driven into the pre-drilled holes. The MC measurements were conducted successively at the three temperatures with a Materialfox data logger, the mean values of 4–6 recordings were used for plotting the electrical resistance against the gravimetrically measured MC.

3 Results and discussion

Resistance characteristics were determined for each material as a function of electrical resistance R and wood temperature T. Therefore the exponential base function (Eq. 1) below was used for all materials:

where MC is the wood moisture content, R is the electrical resistance in 10 lgΩ, T is the wood temperature in °C, and a, b, c, d, e, f, g, h, and i are material-specific variables.

An approximation was sought for each material based on the triples of electrical resistance R, gravimetrically determined MC, and wood temperature T. Therefore the method of least squares was applied with the help of MS Excel Solver.

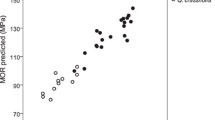

By using the specific calibration functions the accuracy of the MC estimation was acceptable for most material below fiber saturation (Fig. 1). In particular the resistance of the preservative treated timbers was surprisingly well correlated with their wood moisture content. Consequently the precision of MC estimation of the measurements was highest for preservative treated wood (±2.5 %) followed by native timbers (±5 %). Only the different modified timbers suffered from higher variation (±10–20 %), but still a moisture content range was indicated to estimate the level of wetness. Apparently conductivity of modified wood varied stronger than that of untreated wood, which might be explained by changes in the nanostructure of the cell walls coming along with changes of accessibility and transportability of ions as well as an increase in ions dissociated from acetic, formic and other acids in thermally modified or acetylated wood. Since the modification intensity can vary between processes, batches or even within one batch, one can expect significant variations in electrical conductivity too. However, generally the electrical conductivity was increased for all modification processes.

Calculated MC based on resistance measurements (MC electrical) compared with gravimetrically measured MC. Top native hardwoods and softwoods. Centre Differently modified timbers. Bottom Preservative treated timbers. Dashed lines indicate 95 % confidence intervals

Vergleich von auf Basis der Widerstandsmessungen errechneter Holzfeuchten und gravimetrisch bestimmter Holzfeuchten. Oben: Unbehandelte Nadel- und Laubhölzer. Mitte: Unterschiedlich modifizierte Hölzer. Unten: Schutzmittelbehandelte Hölzer

In contrary, the preservative treatment led to an increase in accuracy of the measurement system, whereby also here the conductivity was increased compared to native wood. This effect has been shown for some preservatives by Smith et al. (2007) and points to the need to determine not only species-specific, but also treatment and treatment-intensity specific resistance characteristics. The equilibrium MCs were slightly increased (2–3 %-points) due to the impregnation with salts.

As reported earlier by different authors (e.g., Du 1991; Brischke et al. 2008) the measuring accuracy of resistance based MC meters decreased drastically with MCs above fiber saturation, but the MC estimations still allowed fairly precise estimates for most of the native timbers (Fig. 1). Surprisingly, the preservative treated timber showed highest accuracy over the whole calibration range. Even at approximately 50 % MC, the accuracy of the investigated preservative treated timbers was ±5 %. Consequently, an increase in conductivity due to an increase in mobile ions as observed in both groups, the modified and the preservative treated timbers, does not necessarily lead to a reduction in accuracy. In summary, the immanent need for material-specific resistance characteristics to receive highest possible exactness of the measurements became obvious.

4 Conclusion

The results of the study point to the possibilities of applying electric wood MC measurements on different variations of wood durability testing including different types of wood modification and preservative treatments. A strong need to determine material-specific resistance characteristics was highlighted when precise MC estimation is required.

Considering the fact that fungal activity becomes critical at fiber saturation and above, it becomes obvious that for durability testing and monitoring of outdoor structures the relevant MC range starts shortly below fiber saturation point. The obtained characteristics clearly showed that MC measurements are applicable not only in the hygroscopic range, but also for higher MCs. Solely, the application of modified wood led to remarkable problems regarding accuracy, but were dependent on the type of modification. For estimating MC of modified wood the reduced equilibrium MC in the hygroscopic range caused by the reduced sorption of the cell wall needs to be considered.

References

Brischke C, Rapp AO, Bayerbach R (2008) Measurement system for long-term recording of wood moisture content with internal conductively glued electrodes. Build Environ 43:1566–1574

Brischke C, Sachse KA, Welzbacher CR (2013) Modelling the influence of thermal modification on the electrical conductivity of wood. Holzforschung. doi:10.1515/hf-2013-0041

Du QP (1991) Einfluss holzartenspezifischer Eigenschaften auf die elektrische Leitfähigkeit wichtiger Handelshölzer. Doctoral thesis. University Hamburg, Department Biology, Hamburg

Evans FG (2004) Monitoring a timber bridge in Norway. Int Res Group Wood Preserv, IRG Document No: IRG/WP/04-40282

Meyer L, Brischke C, Pilgård A (2012) Moisture performance based wood durability testing. Stockholm Int Res Group Wood Prot IRG/WP/12-20495

Smith WB, Yeo HM, Stark C, Morey B, Tascioglu C, Schneider P, Herdman D, Freeman M (2007) Use of moisture meters with treated wood. Int Res Group Wood Preserv IRG Document No: IRG/WP/07-40382

Van den Bulcke J, Van Acker J, De Smet J (2009) An experimental set-up for real-time continuous moisture measurements of plywood exposed to outdoor climate. Build Environ 44:2368–2377

Acknowledgments

The authors are grateful for funding in the frame of the research program ‘WoodBuild’ financed by Vinnova, Swedish Federation of Forest Industries and a number of companies in the forest and building sector.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brischke, C., Lampen, S.C. Resistance based moisture content measurements on native, modified and preservative treated wood. Eur. J. Wood Prod. 72, 289–292 (2014). https://doi.org/10.1007/s00107-013-0775-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0775-3