Abstract

Baby food is made specifically for babies between the ages of 4/6 months up to 2 years, and it comes in multiple varieties and tastes. This paper proposes a protocol for a rapid and reliable determination of 19 organophosphorus pesticides (OPs) by means of a method based on ultrasound-vortex-assisted liquid–liquid microextraction coupled with a gas chromatography–ion trap mass spectrometry (UVALLME–GC-IT/MS). The method development starts from the extraction solvent evaluation, i.e., n-heptane; the solution, held for 5 min on the vortex mixer and for 6 min in an ultrasonic bath to 100 W for favoring the solvent dispersion and the determinant extraction, is centrifuged at 4000 rpm for 30 min: 1 μL of the organic extract is injected into the GC-IT/MS. All the analytical parameters investigated are deeply discussed; LODs/LOQs (0.2–1.3 and 0.5–2.9 ng/g) and recoveries (81–109%) are compared with other papers dealing the determination of OPs in baby food matrix. The whole method has been applied to real commercial freeze-dried and soft baby food samples: the results do not show any significant contaminant values.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pesticides are widely used worldwide with the main goal of improving the crop yields and the quantity of fresh fruits and vegetables in the diet (National Research Council 1993). They include more than 1000 compounds employed for checking and eradicating pests. Severe regulations guarantee the use of such substances in a safe and effective way. In fact, pesticides may simultaneously be harmful both for the environment (e.g., accumulating in ecosystems) and for the human health. In this second task, they can give adverse effects, including cancer, acute and chronic injury to the nervous system, lung damage, reproductive dysfunction, and possibly dysfunction of the endocrine and immune systems (Russo et al. 2002; Eskenazi et al. 2007). One of the main pesticide sources is the diet. Indirectly, the consumer assimilates small pesticide quantities (residues) from different foods such as meat, fruit, and vegetables. For these reasons, each nation has promoted a very strict legislation for these compounds (Codex Alimentarius Commission 2009). The U.S. Government has instituted regulatory controls on pesticide use; the European Union has harmonized and simplified the Maximum Residue Limits (MRL) for each pesticide; the Japan Food Chemical Research Foundation has made available a database of MRLs, searchable by pesticide and crop, also providing links to legislation on the Positive List system. MRLs of pesticides in foods have been set up by many international bodies (European Commission 2005). This issue is important for adults, but it is even more important for infants and children. These two categories (not considered as “little adults”) show a rapid metabolic rate compared with that of mature with the consequence of dissimilarities in the skill of making activation, detoxification, and excretion of xenobiotic species (Fenske et al. 2002; D’Souza 2011; Meeker 2012). Furthermore, the newborns are even more different, anatomically and physiologically, than adults. This sub-population exhibits highest sensitivity to pesticides: “emerging data suggest that neurologic and behavioral effects may result from low-level chronic exposure to some organophosphate and organochlorine pesticides” as well as “exposure to neurotoxic compounds at levels believed to be safe for adults could result in permanent loss of brain function if it occurred during the prenatal or early childhood period of brain development” (National Research Council 1993).

Starting from these human health considerations, and despite their worldwide use, some papers reporting protocols or data on organophosphorous pesticides (OPs) in milk-based infant formulas or in baby food are present in literature as confirmed by D’Souza (2011). A multi-residue pesticide determination basically covers a wide range of residues; the first step is to make a homogenized sample followed by extraction of pesticides from sample matrix, removal of co-extracted water from the sample matrix, cleanup by solid phase extraction (SPE), and finally determination by GC or LC. Then most common organic solvents used for pesticide extraction are acetone, acetonitrile, and ethyl acetate. Erney (1995) investigated 29 OPs in whole/chocolate/skim milk and infant formula by solid phase extraction (SPE) with gas chromatography and flame photometric detection (GC–FPD) whereas Mezcua et al. (2007) published an automated analytical method for determining 12 organochlorine and OPs in milk-based infant formulas. On the other hand, interesting discussions on the sample preparation steps and matrix interference removal have been reported by Georgakopoulos et al. (2009, 2011).

The protocol, based on extraction with pressurized liquid extraction (PLE) and determination by GC tandem mass spectrometry (GC-MS/MS), allows to reach limits of detection (LODs) ranging between 0.01 and 2.6 μg/kg with recoveries between 70 and 110%. Another interesting approach was performed by Melgar et al. (2010) for analyzing seven OPs by means of a SPE into acetone and GC with a nitrogen–phosphorus detector (NPD), reaching LODs of 8–65 μg/kg. This topic is really interesting, so different international organizations recommend the evaluation of residues in baby foods (European Commission 2013).

This paper aims to set up a simple, cost-effective, sensitive, and reproducible analytical methodology for determining OPs at trace levels in commercial freeze-dried and soft baby food samples. All the steps of this novel method were evaluated and largely discussed in order to achieve high levels of sensitivity, reproducibility, and selectivity.

Materials and Methods

Chemicals

Pesticide standards (methacrifos, pirofos, phorate, seraphos, diazinon, etrimphos, dichlofenthion, chlorpyrifos-methyl, pirimiphos-methyl, malathion, chlorpyriphos, parathion-ethyl, pirimiphos-ethyl, bromophos, chlorfenvinphos, bromophos-ethyl, stiriphos, diethion, coumaphos) were obtained from Società Italiana Chimici S.p.A. (Rome, Italy): the standard solutions (1 g/L) were prepared by dissolving the pesticides in acetone. These solutions were further diluted with n-hexane to prepare final solutions for spiking. Isoctane, heptane, benzene, toluene, cyclohexane, ethyl ether, and sodium chloride (ACS reagent grade) were obtained from Carlo Erba (Milan, Italy). Bromopropylate (Società Italiana Chimici S.p.A.) in acetone has been used as Internal Standard (IS): 5 ng/μL is added to each sample before starting the analytical procedure with the aim of following each analytical step and minimizing the possible errors. The IS was added to each soft baby food sample prior to freeze drying.

Ultrasound-Vortex-Assisted Dispersive Liquid–Liquid Microextraction (USVADLLME) Procedure

The extraction method is based on a variant of the DLLME extraction method. About 5 g of soft baby food sample, with the addition of 5 μL of IS, was freeze-dried for 4 h at temperatures of − 53 °C and at a pressure of 0.017 mbar in a freeze-drier LIO5P (5Pascal, Trezzano sul Naviglio, Italy); the loss weight was about 85% for the fruit samples (pear and plum) and about 80% for the meat/fish samples (chicken, rabbit, sea bream, and plaice). After, 0.1 g of each freeze-dried sample (i.e., each soft baby food subjected to lyophilization process and each commercial freeze-dried product) was transferred into a 10-mL screw cap glass tube with a conical bottom and 10 mL of buffer solution at pH 4.0 was added (buffer solutions at different pH were tested—different experiments were performing by means of the addition of the buffer solution to the freeze-dried sample): this solution is required for 1 min on the vortex. Then 250 μL of heptane (extraction solvent) was added.

The dispersion was performed by means of 5 min of vortex by mechanical rotation followed by means of 6 min of ultrasound bath. The solution becomes cloudy. For promoting the separation of this solution, 0.1 g of NaCl (10 g/L) was added. Finally, the solution was centrifugated at 4000 rpm for 30 min: the obtained micro-drop is transferred into a vial. The vortex and ultrasound parameters (e.g., vortex/ultrasound time) were deeply investigated in a previous paper (Russo et al. 2015): these steps were tested and confirmed in this study (data are not reported for not weighting the manuscript). After sodium sulfate addition for eliminating water residual, 1 μL of the final solution was injected in GC-IT/MS for determining the 19 OPs.

GC-IT/MS Determination and Quantification

A gas chromatograph model Trace GC Ultra Finnigan (ThermFinnigan, Bremen, Germany) equipped with a programmed temperature vaporizer (PTV) injector and connected to an ion trap mass spectrometer model PolarisQ (ThermFinnigan), and data system “Xcalibur” (ThermoFisher Scientific, Waltham. MA) were used for GC-MS determination in the total ion current (TIC) and selected ion monitoring (SIM) modes.

A fused-silica capillary column with chemically bonded phase (SE-54, 5% phenyl–95% dimethylpolysiloxane) was prepared in our laboratory with the following characteristics: 30 m × 250 μm i.d.; N (theoretical plate number) 125,000 for n-dodecane at 90 °C; K′ (capacity factor) 6.9; df (film thickness) 0.24 μm; uopt (optimum linear velocity of carrier gas, hydrogen) 38.0 cm/s; UTE% (utilization of theoretical efficiency) 92% (Cartoni et al. 1986, 1991; Russo et al. 1996, 2014a). The fused-silica capillary column used is very similar to commercial ones showing very good chromatographic efficiency and being more convenient from an economic point of view.

Helium was used as carrier gas at constant flow rate of 1 mL min−1 and as dumping gas in the ion trap at 0.3 mL/min. The PTV injector was performed in splitless mode, 10 s after injection the vaporizer was heated from 100 to 280 °C at 800 °C/min and cooled after 5.00 min; the splitless valve was opened after 120 s from the injection. The column was kept at 90 °C for 60 s and then the temperature was programmed from 90 to 290 °C at 10 °C/min. The transfer line and the ion source were held at 270 and 250 °C, respectively. The chromatogram was captured in positive electronic impact (70 eV) in a range between 55 and 380 amu.

The compound concentrations were obtained by calibration graphs of the ratio Area(OP)/Area(IS,bromopropylate) plotted versus each OP concentration (pg/μL). All the samples were quantified in triplicate.

Results and Discussion

Role of the Matrix

In the analytical protocol development for investigating OPs, the two matrices investigated, i.e., baby and freeze-dried foods, play a very important role. The first is soft, almost gelatinous; the second, i.e., freeze-dried product, popular baby foodstuff in Italy, looks like a powder. Processing this last sample, the emulsion is easily obtained: the extraction analytical protocol can be directly applied to freeze-dried food. Instead, for the baby foods, the situation is more complicated. The considerable difference between the two matrices (gelatinous and powder) does not allow obtaining a clear emulsion when baby foods are analyzed: the solution appears as an extremely gelatinous emulsion and this occurrence inhibits the procedure. For this reason, the baby foods were subjected to a lyophilization step before the extraction procedure: in this way, a clear solution is obtained. The authors consider that the surfactants added for stabilizing the food could be responsible for it. The lyophilization step was performed at − 52 °C and 0.080 mbar for 4 h in a freeze-drier system. Each solution was further processed according to the analytical methodology developed.

Analytical Methodology Evaluation

An important issue has been devoted to finding the best analytical conditions for the OP extraction and the GC-IT/MS determination. For evaluating the reliability of the whole analytical method, freeze-dried samples were spiked with a standard solution of five OPs (i.e., phorate, malathion, chlorpyrifos, parathion, coumaphos, 40 ng/g each). These five OPs were chosen because they were considered representative of the different analyzed compounds. By this solution, all the analytical experimental variables have been investigated, such as the extraction solvent, the pH influence on the extraction process, the salt effect, the method reproducibility, and the recoveries at different concentrations.

First, the best extraction solvent, an important step in the development of novel extraction procedures, was studied. The extraction solvent should be immiscible with water, should have high extraction efficiency for the target determinant, and should be distinguished with a high signal-to-noise ratio. Six different solvents such as n-heptane, iso-octane, cyclohexane, benzene, toluene, and diethyl ether were used for evaluating the extraction process. Table 1 shows the results: the two aromatic solvents, benzene and toluene, allow poor recoveries with very high RSD, ranging between 49 and 86% and 34–71%, respectively, as well as the cycloalkane (recoveries between 35 and 68%), whereas the ether does not recover any OP.

n-Heptane and iso-octane are solvents able to give good OP recoveries, 92–102% and 72–89%, respectively: n-heptane was chosen as extraction solvent. The main consequence is that the method provides efficient extractions if a linear, or branched at least, apolar hydrocarbon is used as a solvent, whereas it does not give any significant result with aromatic hydrocarbons, cyclic hydrocarbons, and solvents with a certain polarity.

After, the pH of the buffer solution, which is added to the freeze-dried sample for obtaining the dispersion, has been deeply studied (European Commission 2013). This step is really important because it represents the starting point of the procedure: a poor sample solubilization affects the procedure, e.g., it does not allow achieving good recoveries. Preliminarily, different pH levels of such solution, from acid to alkaline range, were studied for identifying the optimal zone where the extraction process could occur (Table 2).

The best recoveries are obtained at pH 4.1, whereas very high percentage recoveries are achieved at alkaline pH (probably, it is due to low IS extraction, and, consequently, the ratio is very high). Further experiments were performed for the identification of the best pH. Different extractions were performed at five different pH levels ranging between 3.8 and 4.5 (Table 2): the method shows good recoveries for pH ranging between 4.0 and 4.2.

Another investigated parameter was the salt effect and, particularly, the effect of the salting-out, i.e., the addition of sodium chloride to the solution for reducing the solubility of the electrolyte. The recoveries of OPs obtained by adding both 10 and 15 g/L of NaCl are comparable (Table 3), whereas the recoveries were very bad with higher amounts (with 20 g/L, recoveries are over 129%, due both to a co-extraction of matrix interference and to a poor IS extraction). It is advisable to use a concentration of 10 g/L for avoiding the addition of much salt. On the other hand, adding a lower NaCl amount (5 g/L), the emulsion is not well broken and the determinants are not totally extracted; an excessive NaCl amount will negatively affect the IS extraction and consequently alter the percentage recovery values.

It is well known that the efficiency of microextraction methods can be affected by the composition of the sample matrix (Yiantzi et al., 2010). For this aim, the entire procedure has been applied for investigating the recoveries of the five OPs in the different matrices analyzed in this study: two commercial freeze-dried products (turkey and rabbit) and six soft baby foods (chicken, rabbit, sea bream, plaice, pear, plum). In both cases, the recoveries were studied at two different concentrations of spiking, i.e., 10 and 50 ng/g, with the instruction of freeze-drying the soft baby foods before processing. The spiking occurred before the freeze-drying: the results, reported in Table 4, are good, meaning that the whole analytical procedure could be applied to all 19 OPs.

GC-IT/MS Performance

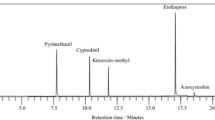

Figure 1a shows the chromatogram of the mix standard solution of 19 OPs (10 ng/mL of each OP): the peaks are well separated and with good efficiency. Figure 1b and c shows the chromatograms obtained analyzing a freeze-dried (rabbit) sample (a) and the same sample spiked with the mix standard OP solution (10 ng mL−1 of each OP) (b).

GC-IT/MS chromatograms of a standard OP solution (10 ng mL−1 of each OP), b freeze-dried sample (rabbit), and c the same sample spiked with standard OP solution (analytical condition—250 μL of n-heptane as extraction solvent; pH 4.1; NaCl 10 g L−1). Peak legend: 1, methacrifos; 2, pirofos; 3, phorate; 4, seraphos; 5, diazinon; 6, etrimfhos; 7, dichlofenthion; 8, chlorpyrifos-methyl; 9, pirimiphos-methyl; 10, malathion; 11, chlorpyrifos; 12, parathion-ethyl; 13, pirimiphos-ethyl; 14, bromophos; 15, chlorfenvinphos; 16, bromophos-ethyl; 17, stirophos; 18, diethion; IS, internal standard (bromopropylate); 19, coumaphos. For the experimental conditions, see the text

Table 5 shows the retention times, the molecular weights, the typical fragment ions (abundance 100%), the limits of detection (LOD), and the limits of quantification (LOQ) of the 19 OPs (and IS as well) studied.

The typical fragment ions depend on the type of molecule. No compound shows ions with the same m/z value (a deep discussion on the SIM ion selection could be found in a previous paper, Russo et al. 2002). Table 5 also reports the calibration data: the relationship between signal and concentration is quite good for almost all the compounds, the correlation coefficients range between 0.9822 and 0.9997 in the range 5–1000 ng/g. For the linearity, a seven-point calibration curve was plotted in the concentration range above reported, i.e., 5, 10, 50, 100, 200, 500, and 1000 ng/g. The LODs are included between 0.2 and 1.3 ng/g with a RSD ≤ 8.7% whereas the LOQs were between 0.5 and 2.9 ng/g with a RSD ≤ 9.2%. These values were determining according to Knoll’s definition (Knoll 1985), i.e., the smallest measured quantities of the target determinants that produce chromatographic peaks equal to three (LOD) or seven (LOQ) times the standard deviation of the baseline noise (using three or seven times the standard deviation to assess S/N required to make a measurement defined as “different from zero”). These LODs and LOQs are meaningful for determining OPs in such matrices.

The entire analytical procedure has been applied to the determination of 19 OPs in soft and freeze-dried baby foods for evaluating the matrix effect: Table 6 shows the percentage OP recoveries at different spiking concentrations (10 and 50 ng/g) in two different matrices (rabbit and pear).

The recoveries range between 85 and 109% for the freeze-dried matrix and 81–106% for the soft baby with the relative standard deviations (RSDs) below 10 and 12, respectively. It should be underlined that these values take in account the whole analytical procedure (i.e., lyophilization, OP extraction, and GC-IT/MS determination steps) avoiding any further physical–chemical treatment of the sample. The recoveries seem to be independent of the matrix, even if those obtained from processing the soft sample are lower than those obtained from freeze-dried ones. In this last case, the reason could be due to the further process (freeze-drying process) to which soft food is the subject before applying the entire analytical procedure.

Comparison with Similar Studies

An important issue of this paper was to develop a rapid, easy, and sensitive methodology for analyzing OPs in such matrices. For this aim, the authors compared the results obtained with those reported in literature for similar papers. Actually, as just reported, there are few papers dealing with such determination in baby food, so the literature was extended to papers reporting such determinations in foods for newborns or, at least, for (primary) school children. Table 7 shows a comparison among the main analytical parameters, i.e., recoveries, LODs, and LOQs, determined in this study and those found by other authors in similar baby food matrices. The comparison between different analytical methods including the detection apparatus confirms the goodness of this approach previously used with other compounds in same matrices (Russo et al. 2012, 2014b, 2014c, 2016; Cinelli et al. 2014a, 2014b). In particular, the analytical methodology used by other authors should be considered.

Many studies are performed by QuEchERS followed by high technology detection systems (e.g., MS/MS(QqQ), LC-MS, QT-OFMS). In few cases, LODs/LOQs are better than those found in this paper, but the instrumental implications are very expensive (PLE-GC-MS/MS in Erney 1995, with very poor recoveries, 50–83%, and QuEchERS-nano-LC-MS in Mirabelli et al. 2016), whereas this determination is based on the application of a very easy and inexpensive analytical protocol. This issue should be considered in a laboratory where routine analyses are performed. Finally, it should be considered that, although the LOQs obtained from this study are not better than those from other studies, the improvement of sensitivity resulted from the lyophilization step.

Application to Real Samples

As part of this study, 16 samples (2 commercial freeze-dried and 6 soft baby foods as above described; 2 different Italian brands for each type) have been analyzed by means of the UVALLME–GC-IT/MS procedure: no OP has been detected or quantified in any sample.

Conclusions

The determination of hazard compounds in very sensitive matrices is a really important task, particularly in matrices like baby foods where even a small contamination could be very harmful for the relative sub-population (i.e., newborns and infants). The protocol set up in this paper would likely help in a rapid and effective determination of organophosphorous compounds in commercial freeze-dried and soft baby foods. Using a modified LLME extraction followed by a GC-IT/MS determination, LODs/LOQs between 0.2–1.3 and 0.5–2.9 ng/g, respectively, and recoveries ranging between 81 and 109% were achieved. If these data are compared with similar studies in literature, this protocol could be almost considered a very interesting method for detecting OPs in baby foods worldwide, also taking into account the very low physical–chemical sample manipulation and the inexpensive costs of the entire procedure. The application of this analytical procedure to baby foods available in the Italian market (two brands) has evidenced no presence of OPs at such levels. In any case, for avoiding misunderstanding or considering the topic ended, it should be important to note some considerations: (a) pesticide traces are worldwide found in baby food in very small amounts, (b) very few studies have been performed on the “synergistic effects” of exposure to several pesticides in small amounts, and (c) OPs may act differently in combination than they do alone. The authors’ question is: what does it mean to eat a celery stalk with traces of some pesticides (Ault et al. 1979), or to feed baby food to an infant laced at low levels with five? In authors’ opinion, this is an interesting question to be deciphered and could be a future target in this field: a systematic analytical approach for determining different classes of pesticides by means of an easy and effective analytical protocol (for instance, this proposed protocol applied to other pesticides) will help to solve it.

References

Amendola G, Pelosi P, Barbini DA (2015) Determination of pesticide residues in animal origin baby foods by gas chromatography coupled with triple quadrupole mass spectrometry. J Environ Sci Health B 50:109–120

Anagnostopoulos CJ, Aplada Sarli P, Miliadis GE, Haroutounian CA (2010) Validation of the QuEChERS method for the determination of 25 priority pesticide residues in cereal-based baby foods by gas chromatography with electron capture and nitrogen phosphorous detection. Hell Plant Protect J 3:71–80

Ault JA, Schofield CM, Johnson LD, Waltz RH (1979) Automated gel permeation chromatographic preparation of vegetables, fruits, and crops for organophosphate residue determination utilizing flame photometric detection. J Agric Food Chem 27:825–828

Authority of Ireland (2004) Report on surveillance of infant food for pesticide residues. Available online: https://www.fsai.ie/uploadedFiles/pesticide_residues_infant.pdf (accessed on November 2017)

Cartoni GP, Goretti G, Monticelli B, Russo MV (1986) Evaluation of capillary gas chromatographic columns in series: analytical application to lemon oil. J Chromatogr A 370:93–101

Cartoni GP, Castellani L, Goretti G, Russo MV, Zacchei P (1991) Gas–liquid microcapillary columns precoated with graphitized carbon black. J Chromatogr A 552:197–204

Cinelli G, Avino P, Notardonato I, Russo MV (2014a) Ultrasound-vortex-assisted dispersive liquid–liquid microextraction coupled with gas chromatography with a nitrogen–phosphorus detector for simultaneous and rapid determination of organophosphorus pesticides and triazines in wine. Anal Methods 6:782–790

Cinelli G, Avino P, Notardonato I, Centola A, Russo MV (2014b) Study of XAD-2 adsorbent for the enrichment of trace levels of phthalate esters in hydroalcoholic food beverages and analysis by gas chromatography coupled with flame ionization and ion-trap mass spectrometry detectors. Food Chem 146:181–187

Codex Alimentarius Commission (2009) Pesticide maximum residue limit (MRL) legislation around the world. Ministry of Primary Industries, New Zealand. Available online: http://www.foodsafety.govt.nz/industry/sectors/plant-products/pesticide-mrl/worldwide.htm (accessed on January 2018)

Cojocariu C, Hetmanski MT, Silcock P, Fussell RJ (2015) Three-fold increase in productivity for pesticide residue analysis in baby food using fast triple quadrupole GC-MS/MS. application note 10432, Thermo Scientific. Available online: https://tools.thermofisher.com/content/sfs/brochures/AN-10432-GC-MS-Pesticides-Baby-Food-AN10432-EN.pdf (accessed on November 2017)

D’Souza PE (2011) Concentrations of pesticide residues in baby foods: understanding a common pathway of exposure for infants. Master’s thesis, Emory University, 22 April 2011. Available online http://pid.emory.edu/ark:/25593/948f6 (accessed on 10 October 2017)

Erney DR (1995) Determination of organophosphorus pesticides in whole/chocolate/skim-milk and infant formula using solid-phase extraction with capillary gas chromatography/flame photometric detection. J Sep Sci 18:59–62

Eskenazi B, Rosas LG, Marks AR, Bradman A, Harley K, Holland N, Johnson C, Fenster L, Barr DB (2007) Pesticide toxicity and the developing brain. Basic Clin Pharmacol Toxicol 102:228–236

European Commission (2005) Commission Regulation (EU) No 396/2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending Council Directive 91/414/EC, 16/03/2005

European Commission (2013) Method validation and quality control procedures for pesticide residues analysis in food and feed. SANCO/12571/2013. 2013, pp. 42. Available online http://www.accredia.it/UploadDocs/4584_AqcGuidance_Sanco_2013_12571.pdf (accessed on June 2017)

Fenske RA, Kedan G, Lu C, Fisker-Andersen JA, Curl CL (2002) Assessment of organophosphorous pesticide exposures in the diets of preschool children in Washington state. J Expo Anal Environ Epidemiol 22:21–28

Gelardi RC, Mountford MK (1993) Infant formulas: evidence of the absence of pesticide residues. Regul Toxicol Pharmacol 17:181–192

Georgakopoulos P, Mylona A, Athanasopoulos P, Drosinos EH, Skandamis PN (2009) Evaluation of cost-effective methods in the pesticide residue analysis of non-fatty baby foods. Food Chem 115:1164–1169

Georgakopoulos P, Zachari R, Mataragas M, Athanasopoulos P, Drosinos EH, Skandamis PN (2011) Optimisation of octadecyl (C18) sorbent amount in QuEChERS analytical method for the accurate organophosphorus pesticide residues determination in low-fatty baby foods with response surface methodology. Food Chem 128:536–542

González-Curbelo MÁ, Hernández-Borges J, Borges-Miquel TM, Rodríguez-Delgado MÁ (2013) Determination of organophosphorus pesticides and metabolites in cereal-based baby foods and wheat flour by means of ultrasound-assisted extraction and hollow-fiber liquid-phase microextraction prior to gas chromatography with nitrogen phosphorus detection. J Chromatogr A 1313:166–174

Hercegová A, Dömötörová M, Matisová E, Kirchnera M, Otrekala R, Stefuca V (2005) Fast gas chromatography with solid phase extraction clean-up for ultratrace analysis of pesticide residues in baby food. J Chromatogr A 1084:46–53

Hercegová A, Dömötörová M, Kruzlicová D, Matisová E (2006) Comparison of sample preparation methods combined with fast gas chromatography-mass spectrometry for ultratrace analysis of pesticide residues in baby food. J Sep Sci 29:1102–1109

Knoll JE (1985) Estimation of the limit of detection in chromatography. J Chromatogr Sci 23:422–425

Meeker JD (2012) Exposure to environmental endocrine disruptors and child development. Arch Pediatr Adolesc Med 166:E1–E7

Melgar MJ, Santaeufemia M, García MA (2010) Organophosphorus pesticide residues in raw milk and infant formulas from Spanish northwest. J Env Sci Health B 45:595–600

Mezcua M, Repetti MR, Agüera A, Ferrer C, García-Reyes JF, Fernández-Alba AR (2007) Determination of pesticides in milk-based infant formulas by pressurized liquid extraction followed by gas chromatography tandem mass spectrometry. Anal Bioanal Chem 389:1833–1840

Mirabelli MF, Wolf J-C, Zenobi R (2016) Pesticide analysis at ppt concentration levels: coupling nano-liquid chromatography with dielectric barrier discharge ionization-mass spectrometry. Anal Bioanal Chem 408:3425–3434

Mukherjee I, Gopal M (1996) Insecticide residues in baby food, animal feed, and vegetables by gas liquid chromatography. Bull Environ Contam Toxicol 56:381–388

National Research Council (1993) Committee on Pesticides in the Diets of Infants and Children. Pesticides in the diets of infants and children. ISBN: 0-309-58535-X. Available online: http://www.nap.edu/catalog/2126.html (accessed on January 2018)

Pérez-Ortega P, Lara-Ortega FJ, Gilbert-López B, Moreno-González D, García-Reyes JF, Molina-Díaz A (2017) Screening of over 600 pesticides, veterinary drugs, food-packaging contaminants, mycotoxins, and other chemicals in food by ultra-high performance liquid chromatography quadrupole time-of-flight mass spectrometry (UHPLC-QTOFMS). Food Anal Methods 10:1216–1244

Petrarca MH, Fernandes JO, Godoy HT, Cunha SC (2016) Multiclass pesticide analysis in fruit-based baby food: a comparative study of sample preparation techniques previous to gas chromatography-mass spectrometry. Food Chem 212:528–536

Russo MV, Goretti G, Soriero A (1996) Preparation and application of fused-silica capillary microcolumns (25–50 μm ID) in gas chromatography. Ann Chim 86:115–124

Russo MV, Campanella L, Avino P (2002) Determination of organophosphorus pesticide residues in human tissues by capillary gas chromatography-negative chemical ionization mass spectrometry analysis. J Chromatogr B 780:431–441

Russo MV, Avino P, Cinelli G, Notardonato I (2012) Sampling of organophosphorus pesticides at trace levels in the atmosphere using XAD-2 adsorbent and analysis by gas chromatography coupled with nitrogen-phosphorus and ion-trap mass spectrometry detectors. Anal Bioanal Chem 404:1517–1527

Russo MV, Avino P, Centola A, Notardonato I, Cinelli G (2014a) Rapid and simple determination of acrylamide in conventional cereal-based foods and potato chips through conversion to 3-[bis(trifluoroethanoyl)amino]-3-oxopropyl trifluoroacetate by gas chromatography coupled with electron capture and ion trap mass spectrometry detectors. Food Chem 146:204–211

Russo MV, Notardonato I, Avino P, Cinelli G (2014b) Fast determination of phthalate ester residues in soft drinks and light alcoholic beverages by ultrasound/vortex assisted dispersive liquid–liquid microextraction followed by gas chromatography–ion trap mass spectrometry. RSC Adv 4:59655–59663

Russo MV, Notardonato I, Avino P, Cinelli G (2014c) Determination of phthalate esters at trace levels in light alcoholic drinks and soft drinks by XAD-2 adsorbent and gas chromatography coupled with ion trap-mass spectrometry detection. Anal Methods 6:7030–7037

Russo MV, Avino P, Perugini L, Notardonato I (2015) Extraction and GC-MS analysis of phthalate esters in food matrices: a review. RSC Adv 5:37023–37043

Russo MV, Avino P, Notardonato I (2016) Fast analysis of phthalates in freeze-dried baby foods by ultrasound-vortex-assisted liquid–liquid microextraction coupled with gas chromatography–ion trap/mass spectrometry. J Chromatogr A 1474:1–7

Shimadzu (2013) Analysis of organophosphorus pesticides in baby foods using a triple-quadrupole GC/MS/MS system. Appl. Note No. GCMS-1304. Available online: http://www.ssi.shimadzu.com/products/literature/gcms/gcms-1304.pdf (accessed on 10 December 2017)

Vukovic G, Shtereva D, Bursic V, Mladenova R, Lazic R (2012) Application of GC-MSD and LC-MS/MS for the determination of priority pesticides in baby foods in Serbian market. LWT- Food Sci Technol. 49:312–319

Yang A, El-Atya AMA, Park J-H, Goudah A, Rahman MM, Do J-A, Choi O-J, Shim J-H (2014) Analysis of 10 systemic pesticide residues in various baby foods using liquid chromatography-tandem mass spectrometry. Biomed Chromatogr 28:735–741

Yiantzi E, Psillakis E, Tyrovola K, Kalogerakis N (2010) Vortex-assisted liquid–liquid microextraction of octylphenol, nonylphenol and bisphenol-a. Talanta 80:2057–2062

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Ivan Notardonato declares that he has no conflict of interest. Mario Vincenzo Russo declares that he has no conflict of interest. Matteo Vitali declares that he has no conflict of interest. Carmela Protano declares that he has no conflict of interest. Pasquale Avino declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human or animal subjects and so the ethical approval is not necessary and not required.

Informed Consent

Not applicable. This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Notardonato, I., Russo, M.V., Vitali, M. et al. Analytical Method Validation for Determining Organophosphorus Pesticides in Baby Foods by a Modified Liquid–Liquid Microextraction Method and Gas Chromatography–Ion Trap/Mass Spectrometry Analysis. Food Anal. Methods 12, 41–50 (2019). https://doi.org/10.1007/s12161-018-1335-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-018-1335-6