Abstract

An efficient and selective automated analytical method for the determination and quantification of a selected group of 12 organochlorine and organophosphorous pesticides in milk-based infant formulas has been developed. The samples were extracted by pressurized liquid extraction (PLE) and analysed using GC-MS/MS. The use of alumina as the fat retainer in the PLE extraction cell, together with the application of an injector temperature program during the GC injection process, avoided typical matrix interferences without the application of additional cleanup steps. Mean recoveries of between 70 and 110% were achieved for most of the compounds, except for chlorpyrifos methyl (50%), vinclozoline (48%), fenitrothion (56%) and procymidone (53%), with relative standard deviations ranging from 9 to 17%. Low limits of quantification were obtained for the studied compounds, from 0.01 to 2.6 μg kg−1, thus guaranteeing their accurate determination within the rigorous requirements established for baby food. The validated method was applied to a pilot monitoring study in Spain. Twenty five samples of different brands of powdered infant formulas were obtained from supermarkets. Positive findings of endosulfan I, endosulfan II, fenitrothion, chlorpyrifos ethyl and bifenthrin were detected at concentrations ranging from 0.03 to 5.03 μg kg−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The presence of pesticide residues in food can negatively affect human health. This stimulates the establishment of legal directives to control their levels through the maximum residue limits (MRLs). Special attention is paid to the safety of children and infants, as they represent a vulnerable risk group within the population. Therefore, the European Commission (EC) has specified an MRL of 10 μg kg−1 for any individual pesticide in processed cereal-based food and baby food (on the basis of the opinions of the Scientific Committee of Food, Directive 2003/13/EC) [1] and has established the prohibition of use of highly toxic pesticides (which have acceptable daily intake values lower than 0.5 μg kg−1 body weight) in the production of agricultural products intended for baby foods.

Among the most common foods included in infants’ diet are dried milk-based formulas, which very often constitute the only food consumed during their first months of life. Since infant formulas are manufactured from dried hydrolysed cow’s milk, special attention must be paid to their possible contamination from pesticide residues that could be present in the raw material [2–5]. Pesticides can appear in milk due to several possible causes: (a) the use of insecticides directly on dairy cattle for ectoparasitic control; (b) pasture, forage (fodder), or animal feed manufactured from plant material that has been treated with insecticides; and (c) the use of insecticides in stables or dairy factories. The amount of pesticides in milk depends on various factors, such as the stability of the pesticide, its metabolic fate in animals and its mode of application or intake. Evidence of their presence has been extensively reported [6–9]. Because of this, the control of infant formulas for pesticide residues appears to be an important issue. However, to date, only a few studies have been published concerning this topic [10–13].

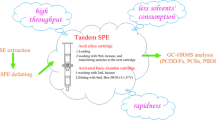

Several extraction methods have been proposed for the analysis of pesticides in milk (natural and powdered), such as extraction with non-polar solvents [14,15], solid-matrix phase dispersion [7,9,16,17], liquid–liquid extraction [8,18–20], solid-phase microextraction (SPME) [4,21] or SPE [6]. However, one of the main problems associated with the analysis of infant formulas is their high lipids content, which are often co-extracted along with the analytes of interest. It is well known that, in gas chromatography, large amounts of injected fat may cause problems in the injector and at the top of the column [22,23]. Different strategies have been developed to remove these interferences in fat-containing food samples, which in most cases include the application of complex and labourious cleanup procedures [24–29]. To avoid some of the main disadvantages associated with the application of cleanup steps, such as reduced sample treatment time and minimizing the organic solvents consumed, modern extraction techniques are being applied: such is the case with the pressurized liquid extraction (PLE) technique, which allows the combination of selective extraction with integrated cleanup strategies, by using fat-retainer compounds placed in the PLE extraction cell [30]. Some methods have been successfully applied to the analysis of different contaminants in fat-containing matrices, such as PCBs in lard fat, fish meal, cod liver oil or feed [31, 32]. However, to the best of our knowledge, no references have been published on the analysis of pesticides in infant formulas.

The aim of this work was to develop a multiresidue method useful for the determination of 12 organophosphorus and organochlorine pesticides in infant formulas, combining PLE with on-line cleanup followed by gas chromatography tandem mass spectrometry analysis.

Experimental

Reagents

Pesticide standards were obtained from Riedel-de Häen (Seelze, Germany). Neutral alumina (99.9% purity), C18 and Hydromatrix were supplied by Sigma–Aldrich (Steinheim, Germany). HPLC-grade methanol and acetonitrile were from Merck (Darmstadt, Germany). Ethyl acetate and cyclohexane were from Panreac (Barcelona, Spain). Stock solutions containing 5 mg mL−1 of the analytes were prepared in methanol and stored in the dark at −20 °C. Spiking standard solutions were prepared by a series of tenfold dilution of the stock solutions in methanol, and stored at −20 °C for a maximum period of 1 month.

Apparatus and methods

PLE extraction

The powdered infant formulas used in the validation study corresponded to different brands purchased from local supermarkets. The extractions were performed using an ASE200 pressurized liquid extractor (Dionex, Idstein, Germany). In the experiments, 0.5-g sample aliquots were placed into 11-mL extraction cells. Before loading the sample, a cellulose filter was placed in the outlet of the cell followed by 0.5 g of alumina, used with the aim of reducing the fat contents of the extracts. Finally Hydromatrix was used to fill up the dead volume of the cell. One cycle of extraction with acetonitrile was carried out under the following conditions: oven temperature, 100 °C; extraction pressure, 1,500 psi; static time, 5 min and a flush volume of 60%. The extracts were collected in pre-cleaned 30-mL glass vials and evaporated until dry under a gentle nitrogen stream by using a Turbo Vap (Zymark, Hopkinton, MA). After that, samples were recomposed in 1 mL of MeOH. An aliquot (500 μL) of supernatant was separated to obtain the reduced quantity of fat, evaporated again until dry and finally recomposed in 500 μL of ethyl acetate/hexane (1:1, v/v).

GC-MS/MS analysis

Analyses were performed using a Varian 4000 GC-MS/MS system (Varian, Walnut Creek, CA, USA) equipped with a CP-8400 autosampler. Data acquisition and processing were performed using the Varian Star Workstation software 6.42 version. The system worked under internal configuration, using electron ionization (EI). A fused silica tubing 2 m × 0.25-mm i.d. from Supelco (Bellefonte, PA, USA) was used as a guard column connected to a J&W Scientific capillary column HP-5MS (5% diphenyl 95% dimethylsiloxane), 30 m × 0.25-mm i.d., 0.25-μm film thickness. Sample injections were performed in a 1079 PTV injector, through an empty liner, filled with 0.5 cm Carbofrit (Restek, Bellefonte, USA) placed at 3.6 cm from the upper part of the liner. Injector operating conditions were as follows: injection volume, 8 μL; vent time, 50 s; split ratio, 50 and injection speed, 5 μL s−1. The injector temperature was held at 70 °C during the solvent evaporation stage and then ramped to 180 °C at 80 °C min−1. This temperature was held for 10 min. Helium carrier gas flow was maintained at 1 mL min−1.

The GC temperature program was 70 °C for 3.50 min, programmed to 180 °C at 15 °C min−1 (8 min), then to 280 °C at 8 °C min−1 (6 min) and finally to 300 °C (10 min) at 20 °C min−1.

Results and discussion

Optimization of extraction procedure

Two objectives came into question during the optimization of the PLE extraction method: (i) to obtain good recoveries for the analytes of interest and (ii) to minimize the fat content present in the final extracts. Because of the complexity of the matrix and the different range of polarities of the target compounds, a compromise between both objectives had to be reached. Since the extraction efficiency on PLE depends on the extraction solvent employed, two solvents with different polarities, acetonitrile (polarity index 6.2) and ethyl acetate (polarity index 4.3), were assayed. The portion of fat extracted in each case was estimated by weighing. When ethyl acetate was used as the extraction solvent, 90% of fat content was extracted from the samples, in contrast with 40% extracted when acetonitrile was the selected solvent. Although this result was not surprising, because of the higher polarity of acetonitrile, better recoveries (57–140%) were also obtained for most of the compounds in this case and this extraction solvent was therefore the selected candidate.

Additional tests were performed with the aim of further reducing the fat contained in the milk extracts. As a first approach, portions of different sorbent materials, usually used as fat retainers, were placed at the bottom of the extraction cells in order to perform sample extraction and cleanup in just one step. Assays using C18, Florisil and alumina were also performed. Blank samples of powdered infant formulas were fortified and extracted to estimate possible losses by adsorption of the target compounds in the sorbent materials. A reduction in the fat content was achieved in all cases, going from 40%, extracted with only acetonitrile, to values between 19 and 27% by using the selected sorbents. Considering the recovery values, alumina was the sorbent that afforded better results and was therefore the final choice. Figure 1 shows a scheme of the PLE extraction cell.

Once the extraction method was established with a sample size of 0.5 g, a bigger sample size was investigated (1 g). When 1 g was taken, a greater quantity of fat retainer was necessary to achieve the same fat reduction and no improvements in the limits of quantification were observed.

Optimization of injection conditions

To improve the limits of detection for the target compounds in the analysis, a large-volume injection procedure, based on programmable temperature vaporizing (PTV) injection, was employed [33, 34]. A sample volume of 8 μL was used. Under these conditions, even the presence of small quantities of fatty components of the matrix in the extracts drastically affected the analytical determinations. With the aim of avoiding this problem, temperature conditions during the sample injection were optimized to achieve a selective desorption of analytes, thereby avoiding the introduction of matrix interferences into the analytical column. The initial injector temperature and the gradient rate were set at 70 °C and 80 °C min−1, respectively, in all the experiments, but different final temperatures (300 °C, 200 °C and 180 °C) were tested. Milk extracts containing the studied analytes at 0.5 mg L−1 were analysed in the GC-(IT)-MS. Figure 2 shows the full scan chromatograms obtained at the different temperatures.

It can be observed that at 180 °C, the presence of matrix co-extracts is highly reduced. Furthermore, the signal to noise ratios obtained for most of the compounds increase as is shown in Fig. 3.

At this low temperature, the analytes are efficiently desorbed from the Carbofrit, a sorbent material that fills the insert liner, while the fatty components present in the extracts are retained. After successive injections the retention capability of the sorbent is overloaded and a cleaning step has to be introduced to lengthen the lifetime of the Carbofrit. After sequences of six injections, a cleaning injection is introduced in which the final temperature of the Carbofrit is set at 300 °C. Because of this, the split ratio is increased to 100 to save the analytical column from matrix interferences. In this way, fat interferences are reduced and no additional cleanup steps were necessary after the extraction procedure.

Optimization of MS/MS parameters

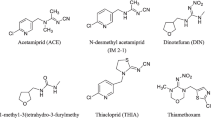

Typical MS/MS parameters were optimized for each compound as follows. The precursor ion chosen to be isolated in the trap was the base peak of the full scan mass spectrum for each compound, which corresponds to the molecular ion in some cases like simazine m/z 201 [M]+, fenitrothion m/z 277 [M]+ and procymidone m/z 283 [M]+, typical losses like methyl chlorine atoms or the methyl group e.g. with chlorpyriphos methyl m/z 286 [M−Cl]+, chlorpyriphos ethyl m/z 314 [M−Cl]+, lindane m/z 219 [M−2Cl]+, vinclozoline m/z 212 [M−2Cl]+, endosulfan I, II m/z 170 [M−4Cl]+, endosulfan sulfate [M−4Cl]+ and atrazina m/z 200 [M−CH3]+, or larger groups like in bifenthrin m/z 181 [M−C9O2F3ClH8]. A narrow isolation window of 3 (±1.5 mass units wide) was selected. Fragmentation of the precursor ions was performed by collision-induced dissociation (CID) in the non-resonant (intermolecular) excitation mode for all the pesticides. The excitation storage level, which is the lowest mass stored during CID, was calculated by using the “q calculator” tool included in the software, which sets limits to the excitation storage level—the precursor mass set by the operator. The parameter q was set to an optimum value of 0.4. The excitation amplitude was determined experimentally by running several analyses with different values of this parameter using the automated method development (AMD) tool. The value at which the precursor ion remained with a relative abundance of around 30% and at which at least two fragment ions were achieved with appreciable abundance was chosen. The final values optimized in this study are shown in Table 1. Once the MS/MS conditions were optimized, the base peak in the product ion spectrum of each compound was selected as the quantification mass. The product ions selected for quantification and identification purposes are shown in Table 1, these ions are well established and they correspond to typical losses like ethyl or methyl groups, for example, simazine m/z 186 [M−CH3]+, m/z 173 [M−CH2CH3]+, procymidone m/z 255 [M−CH2CH3]+, hydroxyl groups, fenitrothion m/z 260 [M−OH]+, or chlorine atoms like in vinclozoline m/z 145 [M−2Cl]+, endosulfan I, II m/z 170 [M−6Cl]+ or endosulfan sulfate [M−5Cl]+. The analyte confirmation was guaranteed by their retention times and presence of two fragment ions for each compound. Both the retention time and the relative abundance of the diagnostic ions must be within the established range.

Figure 4 shows the selected ions chromatogram of an infant formula extract spiked with the target compounds at 5 μg kg−1 and obtained using the developed MS/MS method.

Analytical performance

Results of the validation are summarized in Table 2. All the validation studies were performed by using extracts of infant formulas previously analysed to confirm the absence of the studied compounds. Precision was assessed by the repeated injection of a spiked PLE extract at a concentration level close to the limit of detection (LOD) of the pesticides (1.0 μg kg−1), during the same day (intraday precision, n = 10) and on different days (interday precision, n = 6). Relative standard deviations were 3–9% for intraday analysis and 7–17% for the long-term study. Calibration curves were constructed for each individual pesticide to determine their linearity range and limit of detection. The curves, in the form of straight lines, were obtained by injecting infant formula extracts containing the pesticides at six concentration levels in the initial range from 0.1 to 50 μg kg−1. Each point in the curves was obtained as the average of three injections. Integrated peak area data of the selected quantification masses (see Table 1) were used to construct the curves. Correlation coefficients (R 2) obtained were better than 0.99 for most of the pesticides, except for procymidone. LODs and LOQs were estimated based on the response observed at the lowest detected point of the calibration curve for each pesticide. Calculations were performed considering an extrapolation at S/N = 3 for LODs and S/N = 10 for LOQs. LODs were empirically verified by analysing matrix extracts spiked at these concentration levels to check the presence of all the diagnostic ions at their correct relative abundances. Values obtained ranged from 0.005 to 0.800 μg kg−1 of powdered formula for the LOD and from 0.01 to 2.60 μg kg−1 for the LOQ. These limits were compatible with the tolerances in baby food.

Pesticide recoveries were studied by analysing infant formulas spiked at 5 μg kg−1. The recovery values for the target compounds were calculated by comparison of analyte signal responses obtained from the samples spiked before and after the extraction at this concentration level. Triplicate analyses of each recovery test were carried out. The mean recoveries were generally 70–110%, with relative standard deviations (RSDs) between 9 and 17% (Table 2), except for chlorpyrifos methyl, vinclozoline, fenitrothion and procymidone, which exhibited recovery values of 48–56%. These values could be very low but the good precision of the method and the sensitivity of the GC-MS/MS system used allow for an accurately calculated concentration despite the low levels of recuperation.

Application to a monitoring study

The developed method was applied in a pilot monitoring study in Spain. Twenty five samples of different commercial brands were collected in different supermarkets. The products chosen were specially recommended for infant diets as a substitute to breast milk or as a complement in their diet. The results found are detailed in Table 3. Positive findings of 20% were detected in the samples. Endosulfan I and endosulfan II were found in five of the samples analysed, at concentration levels that were from 1.18 to 5.03 μg kg−1. Fenitrothion, chlorpyrifos ethyl and bifenthrin were also found in four of the analysed brands at maximum concentrations of 0.23, 1.30 and 0.68 μg kg−1, respectively. The LMR established for these compounds, according to European legislation, is 10 μg kg−1, as a general limit. The concentrations found in the analyses performed were lower than this limit in all cases. Figure 5 shows an infant milk formula extract analysed by GC-MS/MS, in which fenitrothion, chlorpyrifos ethyl, endosulfan I and endosulfan II were found.

Conclusions

The PLE-GC-MS/MS multiresidue method developed is a selective, simple, rapid and suitable procedure for the accurate identification and quantification of the 12 studied pesticides in milk infant formulas. The use of an on-line cleanup utilising alumina in the extraction cell during the PLE process and the optimization of the desorption temperature during the GC injection allows the avoidance of typical interferences caused by co-extraction of lipids present in the samples. The method offers adequate identification criteria since at least two product ions for each compound can be obtained. The very good limits of detection achieved by GC-MS/MS guarantee the accurate quantification of the pesticides at levels lower than those required by the legislation. Application to real samples permitted the confirmation of the method’s suitability in routine analysis and proved the presence of some of the target pesticides in commercial products, thus enforcing the necessity for control of these pesticides in infant food.

References

Commission directive 2003/13/EC of 10 February 2003 amending Directive 96/5/EC on processed cereal-based foods and baby foods for infants and young children

Yess NJ, Houston MG, Gunderson EL (1991) Food and Drug Administration pesticide-residue monitoring of foods - 1978–1982. J Assoc of Anal Chem 74:265–272

Kituyi EN, Wandiga SO, Jumba IO (1997) Occurrence of chlorfenvinphos residues in cow’s milk sampled at a range of sites in western Kenya. Bull Environ Cont Toxicol 58:969–975

Röbrig L, Meish HU (2000) Application of solid phase microextraction for the rapid analysis of chlorinated organics in breast milk. Fresenius J Anal Chem 366:106–111

Covaci A, Hura C, Shepens P (2001) Determination of selected persistent organochlorine pollutants in human milk using solid phase disk extraction and narrow bore capillary GC-MS. Chromatographia 54:247–252

Martínez MP, Angulo R, Pozo R, Jodral M (1997) Organochlorine pesticides in pasteurized milk and associated health risks. Food Chem Toxicol 35:621–624

Yague C, Bayarri S, Lazaro R, Conchello P, Arino A, Herrera A (2001) Multiresidue determination of organochlorine pesticides and polychlorinated biphenyls in milk by gas chromatography with electron-capture detection after extraction by matrix solid-phase dispersion. JAOAC Int 84:1561–1568

Pagliuca G, Serraino A, Gazzotti T, Zironi E, Borsari A, Rosmini R (2006) Organophosphorus pesticides residues in Italian raw milk. J Dairy Res 73:340–344

Cardeal de Lourdes Z, Dias CD (2006) Analysis of organophosphorus pesticides in whole milk by solid phase microextraction method. J Environ Sci Health 41:369–375

Picó Y, Viana E, Font G, Mañes J (1995) Determination of organochlorine pesticide content in human-milk and infant formulas using solid-phase extraction and capillary gas-chromatography. J Agricult Food Chem 43:1610–1615

Barkatina EN, Murokh VI, Kolomietz ND, Pertsovskii AL, Shulyakovskaya OV (1998) Determination of residual chlorinated organic pesticides in foodstuff by gas chromatography. J Anal Chem 53:861–864

Izquierdo P, Allara M, Torres G, García A, Pinero M (2004) Organochlorine pesticide residues in infant formulas. Revista científica-Facultad Ciencias Veterinarias 14:147–152

Cressey PJ, Vannort RW (2003) Pesticide content of infant formulae and weaning foods available in New Zealand. Food Add Contam 20:57–64

Campoy C, Jiménez M, Olea-Serrano MF, Moreno Frías M, Cañabate F, Olea N, Bayés R, Molina Font JA (2001) Analysis of organochlorine pesticides in human milk: preliminary results. Early Hum Dev 65:S183–S190

Focant JF, Sjodin A, Turner WE, Patterson DG Jr (2004) Measurement of selected polybrominated diphenyl ethers, polybrominated and polychlorinated biphenyls, and organochlorine pesticides in human serum and milk using comprehensive two-dimensional gas chromatography isotope dilution time-of-flight mass spectrometry. Anal Chem 76:6313–6320

Di Muccio A, Pelos P, Camoni I, Barbini DA, Dommarco R, Genrah T, Ausili A (1996) Selective, solid-matrix dispersion extraction of organophosphate pesticide residues from milk. J Chromatogr A 754:497–507

Di Muccio A, Pelosi P, Barbini DA, Generali T, Ausili A, Fergori F (1997) Selective extraction of pyrethroid pesticide residues from milk by solid-matrix dispersion. J Chromatogr A 765:51–60

Zhu L, Fe KH, Zhao L, Lee HK (2002) Analysis of phenoxy herbicides in bovine milk by means of liquid-liquid-liquid microextraction with a hollow-fiber membrane. J Chromatogr A 963:335–343

Lake IR, Foxall CD, Lovett AA, Fernandes A, Dowding A, White S, Rose M (2005) Effects of river flooding on PCDD/F and PCB levels in cow’s milk, soil, and grass. Environ Sci Technol 39:9033–9038

Bennett DA, Chung AC, Lee SM (1997) Multiresidue method for analysis of pesticides in liquid whole milk. J AOAC Int 80:1065–1077

González-Rodríguez MJ, Arrebola Liébanas FJ, Garrido Frénich A, Martínez Vidal JL, Sánchez López FJ (2005) Anal Bioanal Chem 382:164–172

Grob KJr (1984) Effect of dirt injected on-column in capillary gas-chromatography - analysis of the sterol fraction of oils as an example. J Chromatogr 287:1–14

Grob KJr, Bossard M (1984) Effect of dirt on quantitative-analyses by capillary gas-chromatography with splitless injection. J Chromatogr 294:65–75

Ferrer C, Ramos MJ, García-Reyes JF, Ferrer I, Thurman EM, Fernández-Alba AR (2005) Determination of pesticide residues in olives and olive oil by matrix solid-phase dispersion followed by gas chromatography/mass spectrometry and liquid chromatography/tandem mass spectrometry. J Chromatogr A 1069:183–194

García-Reyes JF, Ferrer C, Ramos MJ, Fernández-Alba AR, Molina-Díaz A (2007) Determination of pesticide residues in olive oil and olives. Trends Anal Chem 26:239–251

Hsu JF, Leon Guo Y, Liu CH, Hu SC, Wang JN, Liao PC (2007) A comparison of PCDD/PCDFs exposure in infants via formula milk or breast milk feeding. Chemosphere 66:311–319

Loran S, Bayarri S, Concello P, Herrera A (2007) Evaluation of GC-ion trap-MS/MS methodology for monitoring PCDD/Fs in infant formulas. Chemosphere 67:513–520

Ramos L, Torre M, Laborda F, Marina ML (1998) Determination of polychlorinated biphenyls in soybean infant formulas by gas chromatography. J Chromatogr A 823:365–372

Hercegova A, Domotorova M, Matisova E (2007) Sample preparation methods in the analysis of pesticides in baby food with subsequent chromatographic determination. J of Chromatogr A 1153:54

Björklund E, Sporring S, Wiberg K, Haglund P, Von Holst C (2006) New strategies for extraction and clean-up of persistent organic pollutants from food and feed samples using selective pressurized liquid extraction. Trends Anal Chem 25:318–325

Sporring S, Björklund E (2004) Selective pressurized liquid extraction from fat-containing food and feed samples. Influence of cell dimensions, solvent type, temperature and flush volume. J Chromatogr A 1040:155–161

Björklund E, Müller A, Von Holst C (2001) Comparison of fat retainers in accelerated solvent extraction for the selective extraction of PCBs from fat-containing samples. Anal Chem 73:4050–4053

Stan HJ, Linkerhägner M (1996) Large-volume injection in residue analysis with capillary gas chromatography using a conventional autosampler and injection by programmed-temperature vaporization with solvent venting. J Chromatogr A 727:275–289

Korenková E, Matisová E, Slobodnik J (2003) Study on the feasibility of coupling large-volume injection to fast gas chromatography with mass spectrometric detection for analysis of organochlorine pesticides. J Sep Sci 26:1193–1197

Acknowledgements

This work has been supported by the European Commission (Alfa project No: AML/B7-311/97/0666/II-0461-FA-FCD-FI). M. Mezcua acknowledges the “Juan de la Cierva” research contract from Spanish Ministry of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mezcua, M., Repetti, M.R., Agüera, A. et al. Determination of pesticides in milk-based infant formulas by pressurized liquid extraction followed by gas chromatography tandem mass spectrometry. Anal Bioanal Chem 389, 1833–1840 (2007). https://doi.org/10.1007/s00216-007-1501-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-007-1501-y