Abstract

This research is focused on optimizing high-pressure processing (HPP) for decreasing weight loss of albacore steaks (Thunnus alalunga) while retaining as much as possible the quality of fresh fish. After HPP treatments (0.1–500 MPa, 2 min), samples were stored (24 h, 4°C) and then analyzed (weight loss, color, texture, appearance, water holding capacity, salt-soluble protein content, and lipid oxidation). Weight loss increased from 50 to 150 MPa, without other substantial modification. Above 200 MPa, HPP treatment caused a progressive weight loss reduction. 200 MPa decreased weight loss by 41.6% with respect to 150 MPa, without noticeable changes in color, texture, appearance, or lipid oxidation. 250 MPa decreased weight loss by 50.1% compared to the controls but produced minor changes in color. 500 MPa provoked the maximum reduction of weight loss with respect to the controls (59%), although it caused marked differences in all quality parameters, which would affect consumer acceptance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Albacore (Thunnus alalunga) is a highly appreciated fish because of its excellent organoleptic properties (white color, firm texture, flavorful flesh) and nutritional characteristics (high content of polyunsaturated fatty acids and high biological value proteins) (Ben-Gigirey et al. 1999). At summer, juvenile specimens perform seasonal feeding migrations to the Bay of Biscay, where the target of albacore fisheries is, having a great economic and social impact in the area (Pusineri et al. 2005). Albacore is seasonal and a highly perishable food due to its high water activity, neutral pH, presence of autolytic enzymes, and lower content of connective tissue (Alves de Oliveira et al. 2017; Chouhan et al. 2015). Lipid and myoglobin oxidation are the main factors which lead to fish spoilage (Kaewprachu et al. 2017), resulting in the development of rancidity and color changes. Moreover, weight loss is a very important issue during processing due to economic losses as well as loss of water-soluble nutrients and its negative impact on appearance (Christensen et al. 2017). Thus, research on the development of innovative technologies which enable to decrease weight loss minimizing quality losses during storage is of growing interest.

High-pressure processing (HPP) is an alternative non-thermal food preservation technology which has been proposed to decrease weight loss of some food products (Souza et al. 2011; Xuan et al. 2018). Souza et al. (2011) found that HPP at 215 MPa for 15 s at 33.3°C decreased weight loss of HPP-treated longissimus dorsi and semimembranosus pork muscles in comparison with control samples. Xuan et al. (2018) observed in HPP-treated razor clam (200–400 MPa for 1–10 min at room temperature) a decrease in weight loss in all HPP-treated samples compared to untreated samples. Decrease in weight loss as a result of HPP treatment has been attributed to denaturation of myofibrillar and/or sarcoplasmic proteins, which leads to protein gelation, implying better water retention (Chéret et al. 2005; Christensen et al. 2017). However, undesirable changes in color, texture, or structure have been reported in several species after HPP treatment (Suemitsu and Cristianini 2019; Yagiz et al. 2009). Moreover, these changes are more pronounced as pressure increases (Chouhan et al. 2015; Christensen et al. 2017; Ramirez-Suarez and Morrissey 2006; Yagiz et al. 2009).

Although research on HPP has been carried out in several seafood products, literature about the use and optimization of HPP treatment for reducing weight loss in this kind of products is scarce. Most published works normally involved two or three pressure levels, studying their impact on relevant quality aspects other than weight loss, such as color, texture or lipid oxidation (Aubourg et al. 2013; Gómez-Estaca et al. 2009; Ramirez-Suarez and Morrissey 2006; Teixeira et al. 2014; Truong et al. 2016).

Furthermore, it is well known that the effects of HPP on seafood are strongly dependent on pressure conditions and the species (Barba et al. 2015). Despite its great value and industrial interest, research about the effects of HPP in albacore is scarce, and it has been mainly done in minced product instead of whole tissue (Ramirez-Suarez and Morrissey 2006).

The aim of this work was to find the optimal HPP treatment for fresh albacore (T. alalunga), which could decrease weight loss while retaining as much as possible the inherent color and texture of fresh fish. To achieve this objective, a comprehensive study was done, applying HPP treatments ranging from 50 to 500 MPa (50, 100, 150, 200, 250, 300, 350, 400, 450, and 500 MPa) for 2 min in albacore steaks and analyzing their impact on weight loss, color, appearance, texture, water holding capacity, salt-soluble protein content, and thiobarbituric acid reactive substances (TBARS).

Material and Methods

Fish Sample

Albacore was caught in the Bay of Biscay (subarea 28.8) in August 2017. On the same day the fish was landed at the port, it was purchased from a local supplier (Pescados Marisa, Portugalete, Spain), transported to the pilot plant, and finally, processed. Albacore steaks were individually vacuum-packed using polyethylene bags at 80 mbar and then HPP treated.

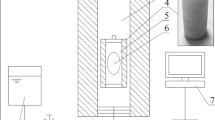

HPP Treatments

Samples were processed using a 55-L high-pressure unit (WAVE 6000/55HT; Hiperbaric, Burgos, Spain). Water was employed as the pressuring medium. Inlet water temperature was 6°C, and chamber temperature reached a maximum temperature of 16.4°C during HPP treatments. Pressure levels applied (50, 100, 150, 200, 250, 300, 350, 400, 450, and 500 MPa) were reached after 36, 62, 84, 102, 118, 146, 162, 160, 174, and 190 s, respectively. Treatment time at the selected pressure was 2 min (Alves de Oliveira et al. 2017; Christensen et al. 2017). Decompression time was less than 4 s for all HPP treatments applied. For each repetition, four albacore steaks were treated for each HPP treatment (50–500 MPa for 2 min). Four non-pressurized samples were used as control (0.1 MPa). After the treatments, samples were refrigerated (4°C) for 24 h and then immediately analyzed.

Weight Loss

Weight loss was determined using the method described by Otero et al. (2019). Steaks were weighted before and after HPP treatment. Excess drip from the steak surface was removed using filter paper. Weight loss was calculated as the difference in weight before and after HPP treatment divided by the weight before HPP treatment.

Water Holding Capacity

Water holding capacity (WHC) was determined as described Gómez-Estaca et al. (2009) with some modifications. Albacore muscle, 1 ± 0.01 g, was placed in a centrifuge tube above two filter papers (filter paper Whatman 1, diameter of 90 mm). The tubes were centrifuged at 2000 × g for 10 min at 10°C (Sorvall Legend XTR Centrifuge, Thermo Scientific, Waltham, MA, USA). The sample was removed from the filter papers, and then the wet filter papers were weighed. Filter papers were then dried in an oven (UFE 500, Memmert GmbH + Co. KG, Schwabach, Germany) at 105°C for 48 h, and once dried, they were weighed again. WHC was calculated using the following equation (Otero et al. 2019) and was expressed as percent (%):

where M is the moisture content of the sample expressed as a decimal ratio, Ws is the weight of the sample, and Wp1 and Wp2 are the weight of the filter paper before and after drying, respectively.

Moisture content was determined by oven drying (UFE 500, Memmert GmbH + Co. KG, Schwabach, Germany) at 105°C until constant weight (Ben-Gigirey et al. 1999).

Color

CIELAB parameters were measured in albacore steaks after pressure treatment using a colorimeter (Konica Minolta C-400, Tokyo, Japan). Lightness (L*), red-green value (a* value: +a* for redness, −a* for greenness), and yellow-blue value (b* value: +b* for yellowness, −b* for blueness) were measured. Total color difference was also determined using the following equation:

ΔL*, Δa*, and Δb* correspond to the differences between L*, a*, and b* values of HPP-treated samples and control (untreated) samples.

Color was measured in both white and red muscle of albacore steaks. For each repetition, four steaks were analyzed for treatment conditions, and each steak was measured in three different locations for both white and red muscle.

Texture Profile Analysis (TPA)

Texture parameters were measured at room temperature using TA.HDplus (Stable Micro Systems Ltd., Goldaming, UK) equipped with 5 kg load cell capacity. Samples were cut into cubes of 2 × 2 × 2 cm. Twelve cubes were analyzed for each treatment conditions. TPA was performed with a 75-mm diameter stainless steel flat probe (P/75). The samples were compressed to 30% of their original height at 5 mm s−1 for two consecutive cycles separated by a 5-s interval, obtaining the corresponding force (N)-time (s) curves. The following texture parameters were calculated using Texture Exponent 32 Software (Stable Micro Systems Ltd., Goldaming, UK) based on the force-time curves:

Hardness (N): maximum force needed to compress the sample (maximum peak at the first compression) (Chéret et al. 2005)

Adhesiveness (N·s): work necessary to pull the compressing plunger away from the sample (negative area under the baseline between the compression cycles) (Kruk et al. 2011)

Springiness: ability of the sample to recover its original form after removing the deforming force (Chéret et al. 2005)

Chewiness: work needed to chew a solid sample for swallowing (hardness × cohesiveness × springiness) (Chéret et al. 2005)

Salt-Soluble Protein Content

Two grams of albacore muscle were immersed in 20 mL buffer solution (0.6 M KCl, 0.05 M sodium phosphate, pH = 7.4) and homogenized at 10,000 rpm for 30 s. The homogenate was centrifuged at 10,000 rpm for 10 min at 4°C (Sorvall Legend XTR Centrifuge, Thermo Scientific, Waltham, MA, USA). The resulting supernatant contained the myofibrillar proteins. Salt-soluble protein content was determined by the Bradford method (Bradford 1976) with bovine serum albumin as standard. Results were expressed as milligrams of salt-soluble protein per gram of sample.

Lipid Oxidation

Thiobarbituric acid index (TBARS value) was employed to measure the extent of lipid oxidation (Chouhan et al. 2015), following the method described by Vyncke (1970) with some modifications. TBARS was defined as the increase in the absorbance due to the formation of pink-colored compounds after the reaction between secondary compounds of lipid oxidation presents in the trichloroacetic acid (TCA) extract of fish muscle and 2-thiobarbituric acid (Méndez et al. 2017). Five grams of muscle were homogenized with 10 mL of TCA extracting solution (7.5% trichloroacetic acid in water, 0.1% propyl gallate, and 0.1% EDTA). The homogenate was centrifuged at 10,000 rpm for 10 min at 4°C (Sorvall Legend XTR Centrifuge, Thermo Scientific, Waltham, MA, USA). Then, the supernatant was mixed (1:1, v/v) with TBA (0.02 M) in Eppendorf tubes and heated in boiling water (95°C for 40 min). After heating, the tubes were immediately cooled with running water. Absorbance was measured at 532 nm in a Varioskan Flash 40053 (Thermo Scientific, Singapore, Singapore). TBARS value was determined using a standard curve prepared with 1,1,3,3-tetraethoxypropane (TEP) (Truong et al. 2016). Results were expressed as milligrams of malonaldehyde (MDA) per kilogram of muscle (Truong et al. 2016).

Statistical Analysis

Experiments were conducted in duplicate. Results were expressed as mean values ± 95% confidence interval (IC 95). Results were analyzed using one-way analysis of variance (ANOVA), and differences between pairs of means were evaluated by Tukey’s test with 5% significance level. SPSS software (SPSS Statistical Software, Inc., Chicago, IL, USA) was used to carry out statistical analysis.

Results and Discussion

Weight Loss

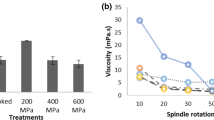

In the control albacore, there was a weight loss of 1.38 ± 0.19%. Similar weight loss values were obtained in bluefin tuna after 2 days of refrigerated storage (Jiang et al. 2019). Weight loss of albacore steaks increased at pressures from 50 to 150 MPa compared to the control (Fig. 1a), reaching a value of 2.24 ± 0.36% at 150 MPa. However, a progressive decreasing trend in weight loss was observed above 200 MPa. Treated samples at 200 MPa showed a 41.6% decrease in weight loss in comparison with treated samples at 150 MPa. At 250 MPa, weight loss decreased by 50.1% compared with the control samples. Treated Albacore at 500 MPa showed the highest decrease in weight loss, reaching a value of 0.56 ± 0.11% (59.4% decrease in comparison with the control samples).These results were in accordance with the results reported by Souza et al. (2011) in treated samples of longissimus dorsi and semimembranosus pork muscles at 215 MPa for 15 s at 33.3°C, in which drip loss was decreased from 2.16 and 2.13% to 0.30 and 0.33%, respectively, as a result of the HPP treatment. However, no effect on weight loss of HPP treatment was observed in sea bass and cod (Chéret et al. 2005; Christensen et al. 2017), and a higher weight loss was found in mackerel after HPP treatment (200 and 500 MPa for 2 min at 8–9°C) (Christensen et al. 2017). These different behaviors would be related to the significant effect of fish species on the impact of HPP (Barba et al. 2015), highlighting the necessity of individual studies for optimizing HPP treatments. In this regard, the muscle structure of albacore is more similar to white meat than to white fish species, being more stable to protein denaturation and degradation (Venugopal 2005).

The progressive increase of weight loss at low pressure levels (50–150 MPa) found in the present work could be related to the changes in tissue architecture, the increase of cell permeabilization, and the consequent output of intracellular liquid (Rastogi et al. 2007). At pressure levels between 150 and 250 MPa, a progressive reduction of weight loss was obtained. This can be attributable to the HPP-mediated changes in protein, such as denaturation, aggregation, and gelatinization (Alves de Oliveira et al. 2017; Rastogi et al. 2007). Above 250 MPa, weight loss reduction was maintained constant. This could be due to protein changes induced by HPP treatment around 250 MPa become irreversible, and hence, weight loss does not decrease much more as the pressure increased (Chéret et al. 2005). Similar pressures to those which decreased weight loss in this work (200 MPa) led to extend shelf life of yellowfin tuna in chilled storage up to 10 days with respect to the untreated samples (Kamalakanth et al. 2011). A longer shelf life was also found in HPP-treated minced albacore (275–310 MPa for 2–6 min) in comparison with the control albacore (Ramirez-Suarez and Morrissey 2006).

Water Holding Capacity

HPP treatment had no effect on the WHC of albacore steaks since only HPP-treated albacore at 400 MPa showed significantly lower values (p ≤ 0.05) than the control albacore (Fig. 1b). These results are in agreement with those reported by Christensen et al. (2017). These authors did not observe significant changes in WHC compared with control samples after 0 days of refrigerated storage in HPP-treated cod, mackerel and salmon at 200 and 500 MPa for 2 min at 8–9°C. Gómez-Estaca et al. (2007) reported that treated dolphinfish at 400 Ma for 15 min at 20°C showed significantly lower WHC (p ≤ 0.05) than control samples, while there were no significant changes at lower pressures. Other authors reported that WHC significantly decreased as a result of HPP treatment (Gómez-Estaca et al. 2009; Jiranuntakul et al. 2018). The WHC of control samples was slightly lower than the values determined by Gómez-Estaca et al. (2009) in untreated tuna carpaccio. However, WHC of treated albacore at 200 and 250 MPa for 2 min was similar to that determined in treated tuna carpaccio at 200 MPa and 250 MPa for 15 min at 7°C (Gómez-Estaca et al. 2009), while WHC of treated samples at 150 MPa for 2 min was similar to that determined by Jiranuntakul et al. (2018) in treated skipjack tuna at 150 MPa for 3 min at room temperature. Decrease in WHC could be attributed to muscle protein denaturation, which would reduce water-protein interactions (Gómez-Estaca et al. 2009).

Color

Figure 2 shows L* (a), a* value (b), b* value (c), and total color difference (ΔE, d) of white and red muscle of albacore steaks after HPP treatment (50–500 MPa for 2 min). HPP treatment increased the L* value of the white muscle of albacore with increasing pressure, leading to significant changes (p ≤ 0.05) above 200 MPa when compared to control samples (Fig. 2a). Other authors also found an increasing trend in L* value due to the HPP treatment in hilsa, cod, salmon, albacore, hake, salmon, and tilapia (Chouhan et al. 2015; Christensen et al. 2017; Ramirez-Suarez and Morrissey 2006; Suemitsu and Cristianini 2019; Yagiz et al. 2009). Actin and myosin denaturation due to HPP treatment could lead to an increased light reflectance of muscle, resulting in an increment of L* value (Chouhan et al. 2015).

L* (a), a* value (b), b* value (c), and total color difference (d) of white (light gray bars) and red muscle (dark gray bars) of fresh albacore steaks after HPP treatment (50–500 MPa). Results of control samples (0.1 MPa) are also shown. Errors bars indicate 95 CI. Different letters indicate significant differences (p ≤ 0.05) as a result of the pressure applied for white (lowercase letters) and red (capital letters) muscle

The red muscle of albacore steaks, which is rich in myoglobin, showed an increase in L* value due to HPP treatment. However, significant differences with respect to control samples were only observed in HPP-treated samples above 350 MPa. Similar results were observed in beef, a food product with high myoglobin content (Jung et al. 2003; Kim et al. 2014; Marcos et al. 2010). The increase in L* value of red muscle as a result of HPP treatment could be attributed to globin denaturation and heme group displacement or release (Marcos et al. 2010).

No effect of HPP treatment on the a* value of the white muscle of albacore steaks was observed (Fig. 2b). There were some significant differences depending on the pressure applied, although a clear tendency cannot be concluded. Similar results were obtained by other authors (Aubourg et al. 2013; Gómez-Estaca et al. 2009; Hughes et al. 2016). Gómez-Estaca et al. (2009) reported that a* value is highly dependent on the species and the HPP treatment conditions. The white muscle of albacore does not have a high content of myoglobin, which is responsible for the redness of meat and, consequently, determines the a* value. This could justify the lack of a clear effect of pressure in the a* value of white muscle.

Related to the a* value of red muscle, there was an initial increase in the HPP-treated samples, although significant differences (p ≤ 0.05) were only detected in treated samples at 100 MPa in comparison with control samples (Fig. 2b). Above 150 MPa, the a* value started to decrease, reaching similar values than the control samples at 150 and 200 MPa. The a* value of HPP-treated samples at 250, 350, 450, and 500 MPa was significantly lower than those of the control samples. Similar changes were reported by Jung et al. (2003), who observed an initial increase in a* value in HPP-treated beef muscle up to 350 MPa for 4 min at 10°C and then a decrease between 350 and 600 MPa for 4 min at 10°C. A decrease in a* value due to HPP treatment was also reported by other authors in beef (Kim et al. 2014; Marcos et al. 2010). It has been suggested that the enzymatic system involved in metmyoglobin reduction could be activated at lower pressures leading to a decrease of metmyoglobin content and, consequently, to an increase in a* value (Jung et al. 2003). However, at higher pressures, ferrous myoglobin oxidation to ferric metmyoglobin due to HPP treatment could involve a decrease in a* value (Carlez et al. 1995; Marcos et al. 2010).

The b* value of white muscle of albacore steaks increased with increasing pressure, although significant changes (p ≤ 0.05) were detected above 150 MPa in comparison with control samples, according to the pressure from which weight loss started to decrease in comparison with control samples (Fig. 2c). There were no significant changes (p > 0.05) in b*value between 250 and 500 MPa. In tilapia, b* value significantly increased at HPP treatments above 300 MPa for 1 min at 5°C (Suemitsu and Cristianini 2019). An increase in b* value was also reported in turbot and hilsa as a result of HPP treatment of up to 200 MPa for 30 min at 4°C and 350 MPa for 10 min at room temperature, respectively (Chevalier et al. 2001; Chouhan et al. 2015). However, b* value decreased in salmon and after HPP treatment, independently of the applied pressure (135 to 200 MPa for 30 s at 15°C) (Aubourg et al. 2013). Changes in b* value could be related to lipid oxidation development (Aubourg et al. 2013).

The b* value of red muscle was significantly higher (p ≤ 0.05) in HPP-treated samples at 100, 150, 450, and 500 MPa when compared to control samples. A significant increase in b* value was also reported in treated beef above 400 MPa for 20 min at 10, 20, and 30°C (Marcos et al. 2010).

The total color difference (ΔE) of white muscle of albacore steaks gradually increased with pressure (Fig. 2d). A rise of 10 units of ΔE, which is considered to modify significantly the appearance of meat (Jung et al. 2003), was reached above 250 MPa. Similar results were obtained in turbot and hilsa (Chevalier et al. 2001; Chouhan et al. 2015). Since noticeable changes in color parameters took place around 150–250 MPa and weight loss started to decrease at 200 MPa, the most adequate treatment could be ranged between 200 and 250 MPa.

In red muscle, ΔE also increased with the pressure increment, although this was not as remarkable as in the white muscle. Albacore red muscle pressurized at 450 MPa and 500 MPa showed the highest increase in ΔE, reaching values above 10 units. Similar results were obtained in treated beef above 400 MPa for 20 min (Marcos et al. 2010).

Appearance

Albacore steaks still retained its characteristic appearance after HPP treatment up to 200 MPa (Fig. 3). Above 250 MPa, the white muscle of albacore steaks became lighter and more opaque, while inappreciable changes were detected in the red muscle. Above 350 MPa, albacore steaks had a cooked-like appearance. Similar results were observed in barramundi, cod, tilapia, and sea bass (Angsupanich and Ledward 1998; Suemitsu and Cristianini 2019; Teixeira et al. 2014; Truong et al. 2016). Chouhan et al. (2015) observed that treated hilsa at 250 MPa for 10 min at room temperature was similar to the control samples, while HPP-treated samples at 350 MPa for 10 min at room temperature became lighter and more opaque, being similar to cooked samples. Suemitsu and Cristianini (2019) carried out a sensorial analysis to evaluate the appearance of HPP-treated tilapia steaks from 100 to 400 MPa for 3 min at 5°C. These authors observed that liking scores of treated samples at 200 MPa were similar to those of the controls.

Changes in appearance were in accordance with the results observed in color measurements, where L* and b* values of white muscle were significantly higher than those of controls in HPP-treated samples above 200 MPa and 150 MPa for 2 min, whereas a* value of red muscle significantly decreased above 250 MPa for 2 min. Furthermore, remarkable changes in appearance of albacore steaks started to occur above 250 MPa, concurrently with the significant decrease in weight loss compared to untreated samples.

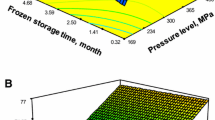

Texture (TPA)

Figure 4 shows hardness (a), adhesiveness (b), springiness (c), and chewiness (d) of albacore steaks after HPP treatment (50–500 MPa for 2 min). After HPP treatment, hardness reached 4.4 ± 0.6 and 8.2 ± 1.3 N in treated samples at 250 and 300 MPa, respectively, while control samples resulted in a hardness of 3.4 ± 0.5 N (Fig. 4a). Similar values were obtained in treated minced albacore under similar conditions of pressure and time (around 4 N at 275 MPa and around 7 N at 310 min for 2 min) immediately after treatment (Ramirez-Suarez and Morrissey 2006). No effect of HPP treatment was observed at lower pressures (≤ 200 MPa). However, at higher pressures (≥ 250 MPa), hardness increased with increasing pressure, showing significantly higher values (p ≤ 0.05) than control samples. Moreover, significant differences (p ≤ 0.05) were observed among treatments. Treated samples at 500 MPa showed a remarkable increase (p ≤ 0.05) in hardness compared to treated samples at 450 MPa. Jiranuntakul et al. (2018) observed that HPP treatment up to 600 MPa for 1, 3, and 5 min at room temperature resulted in a significant increase in hardness of skipjack tuna compared to raw samples. Chouhan et al. (2015) also reported in hilsa steaks an increasing trend with increasing pressure immediately after HPP treatment up to 350 MPa for 10 min at room temperature. By contrast, no significant changes in hardness due to HPP treatment were reported in tilapia and abalone (Hughes et al. 2016; Suemitsu and Cristianini 2019). The increase in hardness could be justified by the protein denaturation which would take place around 200–250 MPa and which would also be related to the decrease in weight loss and color changes (Alves de Oliveira et al. 2017).

Hardness (a), adhesiveness (b), springiness (c), and chewiness (d) of fresh albacore steaks after HPP treatment (50–500 MPa for 2 min). Texture parameters of control samples (0.1 MPa) are also shown. Error bars indicate 95 CI. Different letters indicate significant differences (p ≤ 0.05) as a result of the pressure applied

Adhesiveness of albacore steaks started to increase at 200 MPa and then decreased at 300 MPa (Fig. 4b). Processed samples between 250 and 350 MPa showed a significantly higher adhesiveness (p 0≤ .05) than control samples. These results are in agreement with Yagiz et al. (2009) who observed in HPP-treated salmon at 300 MPa for 15 min at room temperature an increase in adhesiveness with respect to control samples. Torres et al. (2014) observed at time 0 of frozen storage that adhesiveness of horse mackerel increased due to the HPP pretreatment applied before freezing (up to 450 MPa for 5 min at room temperature). The increase in adhesiveness between 250 and 350 MPa could be caused by the unfolding of actin and sarcoplasmic proteins and the formation of hydrogen bonded networks (Angsupanich and Ledward 1998). Angsupanich and Ledward (1998) observed by differential scanning calorimetry (DSC) that the peak corresponding to myosin had disappeared after HPP treatment at 200 MPa for 20 min at room temperature, coinciding with a decrease in adhesiveness with respect to the control, whereas the peaks corresponding to actin and sarcoplasmic proteins had disappeared after HPP treatment at 300 MPa for 20 min at room temperature, coinciding with an increase in adhesiveness. Christensen et al. (2017) also observed that the peak corresponding to myosin disappeared after HPP treatment at 200 MPa for 2 min at 8–9°C in cod and mackerel, while further pressure was required for actin denaturation.

All treated albacore samples, excluding those treated at 50 and 150 MPa, showed significantly higher springiness (p ≤ 0.05) than the controls (Fig. 4c). These results are in accordance with Chouhan et al. (2015) who observed that the springiness of treated hilsa steaks at 300 MPa for 10 min at room temperature was significantly higher than that of the control samples at day 0 of refrigerated storage, while no differences were found at 150 MPa for 10 min at room temperature. Springiness of skipjack tuna decreased at low pressures (150–300 MPa, up to 3 min), while it increased at higher pressures (400–600 MPa, up to 3 min) compared to control samples (Jiranuntakul et al. 2018).

Chewiness gradually increased with the pressure (Fig. 4d). However, there were no significant differences (p > 0.05) between HPP-treated samples below 200 MPa and the control samples. A similar trend was reported in several fish species (Angsupanich and Ledward 1998; Chouhan et al. 2015; Yagiz et al. 2009).

The hardness, springiness, and chewiness of HPP-treated albacore changed in the same manner with the pressure. Thus, the unfolding of actin and sarcoplasmic proteins and the formation of hydrogen-bonded networks due to HPP treatment could be involved in these changes (Angsupanich and Ledward 1998; Chouhan et al. 2015).

Concluding, noticeable changes in texture parameters of albacore took place above 200–250 MPa, while weight loss started to decrease above 200 MPa. This could be explained by the protein denaturation due to HPP treatment, which affects both weight loss and texture of albacore steaks.

Salt-Soluble Protein Content

Figure 5 shows the salt-soluble protein content of albacore steaks after HPP treatment (50–500 MPa for 2 min). Salt-soluble protein index indicates denaturation and aggregation of muscle proteins extracted in a high ionic strength solution (0.6 M), which is predominated by myofibrillar proteins but may also contain sarcoplasmic proteins (Venugopal 2005). Salt-soluble protein decreased as the pressure level increased. Treated samples above 150 MPa showed a significantly lower (p ≤ 0.05) level than the control samples. There were no significant differences (p > 0.05) in treated samples between 150 MPa and 350 MPa. Treated albacore at 500 MPa showed the lowest salt-soluble protein content. Ko et al. (2006) also observed in HPP-treated tilapia that salt-soluble protein decreased with increasing pressure above 200 MPa for 1 h at 25°C, whereas there was no effect of HPP treatment on water-soluble protein (mainly sarcoplasmic proteins). Decrease in salt-soluble protein above 200 MPa could be related to actomyosin coagulation due to pressure treatment (Ko et al. 2006). A progressive decrease in sarcoplasmic protein with increasing pressure was observed in treated salmon from 135 to 200 MPa for 30 s at 15°C (Ortea et al. 2010). Méndez et al. (2017) did not observe significant changes in sarcoplasmic and myofibrillar protein content in sardine at time 0 of frozen storage as a result of HPP pretreatment (125–200 MPa for 0 min at 20°C) before freezing, although they reported an inverse correlation among myofibrillar protein content and the pressure applied. Thus, higher pressures could result in significant changes in salt-soluble protein content.

Lipid Oxidation

TBARS values after HPP treatment (50–500 MPa for 2 min) are shown in Fig. 6. Control samples presented a TBARS value of 1.62 ± 0.27 mg MDA kg−1. Similar values were detected at day 0 of refrigerated storage in non-pressurized minced albacore samples (Ramirez-Suarez and Morrissey 2006). This content was markedly higher than values detected in other fish species, such as hilsa or sardine (Chouhan et al. 2015; Méndez et al. 2017), although it was below the acceptability limit referenced by Silbande et al. (2016) in yellowfin tuna (5–8 mg MDA kg−1). Moreover, albacore presents a high amount of red muscle, which has a high pro-oxidant substance content, such as iron, hemoglobin, or myoglobin (Alves de Oliveira et al. 2017). Thus, albacore could be highly susceptible to lipid oxidation.

In accordance with Chouhan et al. (2015) and Yagiz et al. (2009), a clear effect of HPP treatment on lipid oxidation could not be concluded. Only albacore treated samples treated at 400 MPa for 2 min showed lower (p ≤ 0.05) TBARS values than the controls. Other authors observed an increase in TBARS value due to HPP treatment (Angsupanich and Ledward 1998; Chevalier et al. 2001; Gómez-Estaca et al. 2009) that could be attributed to the release of heme proteins and the disruption of lipid membranes (Barba et al. 2015). By contrast, Ramirez-Suarez and Morrissey (2006) did not find differences in TBARS value between HPP-treated minced albacore (up to 310 MPa for 2–6 min at 10°C) and the control samples at day 0 of refrigerated storage. Thus, it could be concluded that TBARS value is highly dependent on fish species, HPP treatment conditions (pressure, temperature, and time), and sample handling (catching and transport conditions and presentation mode) (Barba et al. 2015; Otero et al. 2019; Ramirez-Suarez and Morrissey 2006).

According to bibliography, HPP has no relevant effects on total lipid content and fatty acid profile in oily fish species like albacore. For example, no differences in total lipid content between the control and HPP-treated samples at similar conditions to those employed in the present work (135–200 MPa for 30 s) were found in salmon (Ortea et al. 2010). Regarding the fatty acid profile, other authors reported no differences between HPP-treated salmon (150 and 300 MPa for 15 min) and the control in total saturated, monoenes, n−3PUFA, and n−6PUFA fatty acid compositions (Yagiz et al. 2009). Similarly, no differences were found in the fatty acid profile of beef as a consequence of intense HPP treatments (200–400 MPa for 20 min) (McArdle et al. 2010).

Conclusions

A pressure of 500 MPa for 2 min would lead to the maximum reduction of weight loss (59.4% decrease in comparison with control samples) and, consequently, decrease economic losses during processing of albacore. However, this HPP treatment caused marked differences in color (significantly higher L* and b* values in both white and red muscle and lower a* value in red muscle than the control samples, respectively, and ΔE higher than 10 units in both white and red muscle) and texture (significantly higher hardness, springiness, and chewiness than the control samples) which could affect consumer acceptance. Weight loss of albacore steaks started to decrease around 200 MPa (5.2% decrease in comparison with control samples). At 250 MPa, there was a reduction of 50.1% compared with untreated samples. Pressures ranging from 200 to 250 MPa for 2 min were suitable to decrease weight loss in albacore without great impact in color and texture and, therefore, better retain the fresh quality. Further research is necessary to determine if the promising results obtained in this work at 200–250 MPa remains during cool storage. Furthermore, it is necessary to determine the impact of HPP pretreatments on weight loss when albacore is subjected to long-term preservation technologies like freezing or heat treatments.

References

Alves de Oliveira, F., Cabral Neto, O., Marcondes Rodrigues dos Santos, L., Rocha Ferreira, E. H., & Rosenthal, A. (2017). Effect of high pressure on fish meat quality—a review. Trends in Food Science and Technology, 66, 1–19. doi:https://doi.org/10.1016/j.tifs.2017.04.014

Angsupanich, K., & Ledward, D. A. (1998). High pressure treatment effects on cod (Gadus morhua) muscle. Food Chemistry, 63(1), 39–50. https://doi.org/10.1016/S0308-8146(97)00234-3.

Aubourg, S. P., Rodríguez, A., Sierra, Y., Tabilo-Munizaga, G., & Pérez-Won, M. (2013). Sensory and physical changes in chilled farmed coho salmon (Oncorhynchus kisutch): effect of previous optimized hydrostatic high-pressure conditions. Food and Bioprocess Technology, 6(6), 1539–1549. https://doi.org/10.1007/s11947-012-0799-4.

Barba, F. J., Terefe, N. S., Buckow, R., Knorr, D., & Orlien, V. (2015). New opportunities and perspectives of high pressure treatment to improve health and safety attributes of foods. A review. Food Research International, 77, 725–742. https://doi.org/10.1016/j.foodres.2015.05.015.

Ben-Gigirey, B., Sousa, J. M., Villa, T. G., & Barros-Velazquez, J. (1999). Chemical changes and visual appearance of albacore tuna as related to frozen storage. Journal of Food Science, 64, 20–24. https://doi.org/10.1111/j.1365-2621.1999.tb09853.x.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72(1–2), 248–254. https://doi.org/10.1016/0003-2697(76)90527-3.

Carlez, A., Veciana-Nogues, T., & Cheftel, J.-C. (1995). Changes in colour and myoglobin of minced beef meat due to high pressure processing. LWT - Food Science and Technology, 28(5), 528–538. https://doi.org/10.1006/fstl.1995.0088.

Chéret, R., Chapleau, N., Delbarre-Ladrat, C., Verrez-Bagnis, V., & de Lamballerie, M. (2005). Effects of high pressure on texture and microstructure of sea bass (Dicentrarchus labrax L.) fillets. Journal of Food Science, 70(8), e477–e483. https://doi.org/10.1111/j.1365-2621.2005.tb11518.x.

Chevalier, D., Le Bail, A., & Ghoul, M. (2001). Effects of high pressure treatment (100–200 MPa) at low temperature on turbot (Scophthalmus maximus) muscle. Food Research International, 34(5), 425–429. https://doi.org/10.1016/S0963-9969(00)00187-3.

Chouhan, A., Kaur, B. P., & Rao, P. S. (2015). Effect of high pressure processing and thermal treatment on quality of hilsa (Tenualosa ilisha) fillets during refrigerated storage. Innovative Food Science and Emerging Technologies, 29, 151–160. https://doi.org/10.1016/j.ifset.2015.03.016.

Christensen, L. B., Hovda, M. B., & Rode, T. M. (2017). Quality changes in high pressure processed cod, salmon and mackerel during storage. Food Control, 72, 90–96. https://doi.org/10.1016/j.foodcont.2016.07.037.

Gómez-Estaca, J., Gómez-Guillén, M. C., & Montero, P. (2007). High pressure effects on the quality and preservation of cold-smoked dolphinfish (Coryphaena hippurus) fillets. Food Chemistry, 102(4), 1250–1259. https://doi.org/10.1016/j.foodchem.2006.07.014.

Gómez-Estaca, J., López-Caballero, M. E., Gómez-Guillén, M. C., López de Lacey, A., & Montero, P. (2009). High pressure technology as a tool to obtain high quality carpaccio and carpaccio-like products from fish. Innovative Food Science and Emerging Technologies, 10(2), 148–154. https://doi.org/10.1016/j.ifset.2008.10.006.

Hughes, B. H., Perkins, L. B., Yang, T. C., & Skonberg, D. I. (2016). Impact of post-rigor high pressure processing on the physicochemical and microbial shelf-life of cultured red abalone (Haliotis rufescens). Food Chemistry, 194, 487–494. https://doi.org/10.1016/j.foodchem.2015.07.144.

Jiang, W., Hu, S., Li, S., & Liu, Y. (2019). Evaluation of the preservation effect of gelatin-water soluble chitosan film incorporated with Maillard peptides on bluefin tuna (Thunnus thynnus) slices packaging. LWT, 113, 108294. https://doi.org/10.1016/j.lwt.2019.108294.

Jiranuntakul, W., Nakwiang, N., Berends, P., Kasemsuwan, T., Saetung, T., & Devahastin, S. (2018). Physicochemical, microstructural, and microbiological properties of skipjack tuna (Katsuwonus pelamis) after high-pressure processing. Journal of Food Science, 83(9), 2324–2336. https://doi.org/10.1111/1750-3841.14318.

Jung, S., Ghoul, M., & De Lamballerie-Anton, M. (2003). Influence of high pressure on the color and microbial quality of beef meat. LWT - Food Science and Technology, 36(6), 625–631. https://doi.org/10.1016/S0023-6438(03)00082-3.

Kaewprachu, P., Osako, K., Benjakul, S., Suthiluk, P., & Rawdkuen, S. (2017). Shelf life extension for bluefin tuna slices (Thunnus thynnus) wrapped with myofibrillar protein film incorporated with catechin-Kradon extract. Food Control, 79, 333–343. https://doi.org/10.1016/j.foodcont.2017.04.014.

Kamalakanth, C. K., Ginson, J., Bindu, J., Venkateswarlu, R., Das, S., Chauhan, O. P., & Gopal, T. K. S. (2011). Effect of high pressure on K-value, microbial and sensory characteristics of yellowfin tuna (Thunnus albacares) chunks in EVOH films during chill storage. Innovative Food Science and Emerging Technologies, 12, 451–455. https://doi.org/10.1016/j.ifset.2011.06.001.

Kim, H. J., Kruk, Z. A., Jung, Y., Jung, S., Lee, H. J., & Jo, C. (2014). Effects of high hydrostatic pressure on the quality and safety of beef after the addition of conjugated linoleic acid. Innovative Food Science and Emerging Technologies, 26, 86–92. https://doi.org/10.1016/j.ifset.2014.06.001.

Ko, W. C., Jao, C. L., Hwang, J. S., & Hsu, K. C. (2006). Effect of high-pressure treatment on processing quality of tilapia meat fillets. Journal of Food Engineering, 77, 1007–1011. https://doi.org/10.1016/j.jfoodeng.2005.08.029.

Kruk, Z. A., Yun, H., Rutley, D. L., Lee, E. J., Kim, Y. J., & Jo, C. (2011). The effect of high pressure on microbial population, meat quality and sensory characteristics of chicken breast fillet. Food Control, 22(1), 6–12. https://doi.org/10.1016/j.foodcont.2010.06.003.

Marcos, B., Kerry, J. P., & Mullen, A. M. (2010). High pressure induced changes on sarcoplasmic protein fraction and quality indicators. Meat Science, 85(1), 115–120. https://doi.org/10.1016/j.meatsci.2009.12.014.

McArdle, R., Marcos, B., Kerry, J. P., & Mullen, A. (2010). Monitoring the effects of high pressure processing and temperature on selected beef quality attributes. Meat Science, 86(3), 629–634. https://doi.org/10.1016/j.meatsci.2010.05.001.

Méndez, L., Fidalgo, L. G., Pazos, M., Lavilla, M., Torres, J. A., Saraiva, J. A., Vázquez, M., & Aubourg, S. P. (2017). Lipid and protein changes related to quality loss in frozen sardine (Sardina pilchardus) previously processed under high-pressure conditions. Food and Bioprocess Technology, 10(2), 296–306. https://doi.org/10.1007/s11947-016-1815-x.

Ortea, I., Rodríguez, A., Tabilo-Munizaga, G., Pérez-Won, M., & Aubourg, S. P. (2010). Effect of hydrostatic high-pressure treatment on proteins, lipids and nucleotides in chilled farmed salmon (Oncorhynchus kisutch) muscle. European Food Research and Technology, 230(6), 925–934. https://doi.org/10.1007/s00217-010-1239-1.

Otero, L., Pérez-Mateos, M., Holgado, F., Márquez-Ruiz, G., & López-Caballero, M. E. (2019). Hyperbaric cold storage: pressure as an effective tool for extending the shelf-life of refrigerated mackerel (Scomber scombrus, L.). Innovative Food Science and Emerging Technologies, 51, 41–50. https://doi.org/10.1016/j.ifset.2018.05.003.

Pusineri, C., Vasseur, Y., Hassani, S., Meynier, L., Spitz, J., & Ridoux, V. (2005). Food and feeding ecology of juvenile albacore, Thunnus alalunga, off the Bay of Biscay: a case study. ICES Journal of Marine Science, 62(1), 116–122. https://doi.org/10.1016/j.icesjms.2004.09.004.

Ramirez-Suarez, J. C., & Morrissey, M. T. (2006). Effect of high pressure processing (HPP) on shelf life of albacore tuna (Thunnus alalunga) minced muscle. Innovative Food Science and Emerging Technologies, 7(1–2), 19–27. https://doi.org/10.1016/j.ifset.2005.08.004.

Rastogi, N. K., Raghavarao, K. S. M. S., Balasubramaniam, V. M., Niranjan, K., & Knorr, D. (2007). Opportunities and challenges in high pressure processing of foods. Critical Reviews in Food Science and Nutrition, 47(1), 69–112. https://doi.org/10.1080/10408390600626420.

Silbande, A., Adenet, S., Smith-Ravin, J., Joffraud, J. J., Rochefort, K., & Leroi, F. (2016). Quality assessment of ice-stored tropical yellowfin tuna (Thunnus albacares) and influence of vacuum and modified atmosphere packaging. Food Microbiology, 60, 62–72. https://doi.org/10.1016/j.fm.2016.06.016.

Souza, C. M., Boler, D. D., Clark, D. L., Kutzler, L. W., Holmer, S. F., Summerfield, J. W., Cannon, J. E., Smit, N. R., McKeith, F., & Killefer, J. (2011). The effects of high pressure processing on pork quality, palatability, and further processed products. Meat Science, 87(4), 419–427. https://doi.org/10.1016/j.meatsci.2010.11.023.

Suemitsu, L., & Cristianini, M. (2019). Effects of high pressure processing (HPP) on quality attributes of tilapia (Oreochromis niloticus) fillets during refrigerated storage. LWT, 101, 92–99. https://doi.org/10.1016/j.lwt.2018.11.028.

Teixeira, B., Marques, A., Mendes, R., Gonçalves, A., Fidalgo, L., Oliveira, M., Saraiva, J. A., & Nunes, M. L. (2014). Effects of high-pressure processing on the quality of sea bass (Dicentrarchus labrax) fillets during refrigerated storage. Food and Bioprocess Technology, 7(5), 1333–1343. https://doi.org/10.1007/s11947-013-1170-0.

Torres, J. A., Saraiva, J. A., Guerra-Rodríguez, E., Aubourg, S. P., & Vázquez, M. (2014). Effect of combining high-pressure processing and frozen storage on the functional and sensory properties of horse mackerel (Trachurus trachurus). Innovative Food Science and Emerging Technologies, 21, 2–11. https://doi.org/10.1016/j.ifset.2013.12.001.

Truong, B. Q., Buckow, R., Nguyen, M. H., & Stathopoulos, C. E. (2016). High pressure processing of barramundi (Lates calcarifer) muscle before freezing: the effects on selected physicochemical properties during frozen storage. Journal of Food Engineering, 169, 72–78. https://doi.org/10.1016/j.jfoodeng.2015.08.020.

Venugopal, V. (2005). Nutritional value and processing effects. In V. Venugopal (Ed.), Seafood processing: adding value through quick freezing, retortable packaging, and cook-chilling (pp. 425–446). Boca Raton: CRC Press.

Vyncke, W. (1970). Direct determination of the thiobarbituric acid value in trichloroacetic acid extracts of fish as a measure of oxidative rancidity. Fette, Seifen, Anstrichmittel, 72(12), 1084–1087. https://doi.org/10.1002/lipi.19700721218.

Xuan, X. T., Cui, Y., Lin, X. D., Yu, J. F., Liao, X. J., Ling, J. G., & Shang, H. T. (2018). Impact of high hydrostatic pressure on the shelling efficacy, physicochemical properties, and microstructure of fresh razor clam (Sinonovacula constricta). Journal of Food Science, 83(2), 284–293. https://doi.org/10.1111/1750-3841.14032.

Yagiz, Y., Kristinsson, H. G., Balaban, M. O., Welt, B. A., Ralat, M., & Marshall, M. R. (2009). Effect of high pressure processing and cooking treatment on the quality of Atlantic salmon. Food Chemistry, 116(4), 828–835. https://doi.org/10.1016/j.foodchem.2009.03.029.

Acknowledgements

The authors thank Mary Flour for revising the manuscript for English spelling and grammar.

Funding

The authors thank the Basque Country Government for the financial support to carry out this research work. LC gratefully acknowledges the financial support for her doctoral studies from the Basque Country Government through a research scholarship for young researchers and technologists from the Department of Agriculture, Fisheries and Food.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cartagena, L., Puértolas, E. & Martínez de Marañón, I. High-Pressure Processing (HPP) for Decreasing Weight Loss of Fresh Albacore (Thunnus alalunga) Steaks. Food Bioprocess Technol 12, 2074–2084 (2019). https://doi.org/10.1007/s11947-019-02369-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-02369-w