Abstract

The effect of a previous hydrostatic high-pressure (HHP) treatment on sensory and physical quality of chilled coho salmon (Oncorhynchus kisutch) was investigated. As a first stage, a 22 factorial design based on the response surface methodology was used for optimization of HHP conditions; for it, the effects on color uniformity, white spots appearance, elasticity, and hardness were analyzed. In a second stage, optimized HHP conditions (135 MPa for 30 s, 170 MPa for 30 s, and 200 MPa for 30 s; treatments T-1, T-2, and T-3, respectively) were applied as previous treatment to chilling, being sampling carried out on salmon muscle at days 0, 6, 10, 15, and 20. A marked effect on sensory and physical parameters was detected after HHP treatment and throughout the chilled storage. According to odor (rancid, putrid), texture (elasticity, gaping, firmness), and color (L* value) attributes, fish corresponding to T-1 condition was shown to have better-maintained quality throughout the chilled storage than fish belonging to T-2 and T-3 conditions; additionally, a quality enhancement (putrid odor, cohesivity, gaping) was found when compared with control samples. In agreement to the preliminary optimization study, it is concluded that T-1 condition can provide the most effective HHP pre-treatment to better maintain sensory and physical properties when salmon muscle is to be commercialized as a fresh product. Results obtained for the quality evolution of chilled fish attest the importance of establishing a judicious selection of previous HHP treatment parameters to minimize undesirable changes related to sensory and physical characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During fish chilled storage, significant losses of sensory and nutritional values have been detected as a result of different damage pathways such as endogenous enzymatic activity, microbial development, and lipid oxidation (Whittle et al. 1990). According to an increasing consumer’s demand for high-quality fresh products, fish technologists and the fish trade have developed different advanced processing systems, these including previous chemical and physical treatments (Ashie et al. 1996; Oms-Oliu et al. 2010) and employment of preservative packaging (Ozen and Floros 2001; Rodríguez et al. 2011).

One such advanced physical treatments is hydrostatic high-pressure (HHP), which has proved to enlarge the shelf-life time of marine products, while inactivating microbial development and deteriorative endogenous enzymes (Norton and Sun 2008; Yagiz et al. 2009; Erkan et al. 2011). This technology has demonstrated potential application in the seafood industry for the surimi and kamaboko production (Montero et al. 1998; Uresti et al. 2005), as assisting thawing (Rouillé et al. 2002) and thermal processing (Ramírez et al. 2009) and for the cold-smoked fish preparation (Lakshmanan et al. 2007). However, HHP has been reported to produce different kinds of detrimental effects in fish foods such as cell membrane damage, protein denaturation, lipid fraction oxidation, browning development, and constituent breakdown and aggregation (Ohshima et al. 1993; Ashie and Simpson 1996; Angsupanich and Ledward 1998). As a result, marked quality losses related to the general appearance of the product and a lowering of consumer acceptance are shown.

In recent years, the fishing sector has paid great attention to aquaculture development as a source of marine food products. Among cultivated fish, coho salmon (Oncorhynchus kisutch), also called silver salmon, has received great attention because of its increasing production in countries like Chile, Japan, and Canada (FAO 2007a) in parallel to important capture production in countries such as USA, Russian Federation, Canada, and Japan (FAO 2007b). Previous research related to the chilling storage of this species accounts for the development of different spoilage pathways and quality losses recently reviewed (Vinagre et al. 2011).

Preliminary studies account for HHP previous treatment to chilled coho salmon. In them, an inhibitory effect on microbial activity development was proved by pressure augmentation (Aubourg et al. 2010). However, pressure enhancement has also been shown to lead to a lipid oxidation development increase (Aubourg et al. 2010) and to marked protein damage in the sarcoplasmic fraction (Ortea et al. 2010). According to the great importance of sensory and physical properties on consumer acceptance of fresh fish, the present work was focused on the effect that previous HHP conditions could have on such properties in this chilled species. For it, optimized HHP conditions were tested and compared with untreated (control) fish throughout a 20-day storage period.

Materials and Methods

Raw Fish and HHP Equipment

Thirty coho salmon specimens (50–52 cm length; 2.8–3.0 kg weight) were obtained from an aquaculture facility (AquaChile, S. A., Puerto Montt, X Región, Chile) after being harvested for 30 weeks. Individuals were sacrificed in the plant by a sharp blow to the head, the gills cut, bled in a water–ice mixture, beheaded, gutted (HG type), and transported to the laboratory during 24 h under slurry ice condition (40% ice and 60% water; −1.0 °C) at a 1:1 fish-to-ice ratio. Then, the fish was filleted, cut into pieces (weight range, 125–150 g) and placed in individual flexible polyethylene bags.

HHP treatment of packaged fish pieces was performed in a cylindrical loading container at room temperature (15 ± 2 °C) in a 2-L pilot high-pressure unit (Avure Technologies Incorporated, Kent, WA, USA). In all cases, water was employed as the pressurizing medium, working at a 17 MPa/s ramp rate. Come-up times for 135, 170, and 200 MPa treatments were 8, 10, and 12 s, respectively; decompression time was less than 5 s.

Preliminary HHP Study

As a first stage, a preliminary study was undertaken to optimize the HHP condition range to be employed as previous treatment to a further chilled storage experiment. For it, a 22 factorial design of two factors in four runs plus a central point run using the response surface methodology (RSM) was performed in order to identify the significant sensory variables of the HHP process (p < 0.05). Two independent variables were considered (hydrostatic high-pressure, megapascals; holding time, minutes), being their values, respectively, in the different experiment runs as follows—100 and 0.5 (run 1), 200 and 0.5 (run 2), 100 and 0.5 (run 3), 200 and 5.0 (run 4), and 150 and 2.75 (run 5). In each experiment run, responses of salmon sensory descriptors were analyzed as expressed in “Sensory Analyses.”

HHP Processing Followed by Chilled Storage

According to the preliminary study results, three different HHP conditions (135 MPa for 30 s, 170 MPa for 30 s, and 200 MPa for 30 s; treatments T-1, T-2, and T-3, respectively) were selected and applied to fish; comparison to untreated fish (control, treatment C) was undertaken. After HHP treatment, packed fish pieces were kept at 0 °C under chilling conditions (traditional flake ice) in a refrigerated room (4 °C). Sampling was carried out on salmon white muscle at days 0, 6, 10, 15, and 20 of chilled storage. For all kinds of samples, three different batches (n = 3) were considered and analyzed separately.

Sensory Analyses

The sensory analysis was conducted according to the quantitative descriptive analysis method by a sensory panel consisting of ten experienced judges (five females and five males). Panelists were selected and trained according to international standards in sensory descriptors for raw and processed fish of different quality conditions (Howgate 1992; ISO 1993; Codex Alimentarius 1999).

The following descriptors were analyzed in salmon muscle in the preliminary HHP study: salmon color uniformity (original color maintenance), white spots appearance (formation of such spots), elasticity (recovery capacity after pressure application), and hardness (resistance of muscle fibers against compression).

Concerning the experiment where HHP treatment was followed by a chilled storage, the following descriptors were analyzed: rancid odor (presence of off-odors related to rancidity development), putrid odor (presence of off-odors related to decayed meat), amine odor (presence of off-odors related to amine formation), elasticity, and cohesivity (binding degree of myotomes in salmon muscle).

At each sampling time, fish muscle portions were presented to panelists in individual trays and were scored individually. The panel members shared samples tested. The different sensory descriptors were evaluated on non-structured linear scales with numerical scores from 0 to 10. Scores among panelists were averaged. For parameters such as salmon color uniformity, elasticity, hardness, and cohesivity, score 10 corresponds to the stage where such properties are observed in their maximum value, while score 0 represents the stage where a decrease is no more noticeable. For white spots appearance and rancid, putrid, and amine odors, score 0 represents the stage where such attributes are not noticeable, while stage 10 corresponds to the stage where no increase is possible.

Additionally, the red color appearance of the fillets was evaluated by the Roche SalmoFan™ Lineal card; for it, panelists matched the salmon muscle color with a 20–34-score card system previously established for salmonids pigmented with astaxanthin (ISO 1993; Codex Alimentarius 1999).

Finally, gaping in salmon muscle was analyzed visually by panelists after chilled storage at days 0, 6, 10, 15, and 20. The number of incisions or slits in the muscle myotomes of salmon was recorded to obtain the gaping score. Evaluation of gaping development was performed according to previous research (Andersen et al. 1994). Thus, scores were attributed as follows—0 (no gaping; 0 slits), 1 (minor gaping; 1–5 slits), 2 (moderate gaping; 6–10 slits), 3 (intense gaping; 11–15 slits), 4 (severe gaping; 16–20 slits), and 5 (extreme gaping; >20 slits).

Physical Analyses

Instrumental color analysis (CIE 1976 L*, a*, b* space) was performed by employing a tristimulus Hunter Labscan 2.0/45 colorimeter. Measurements were made directly on the salmon muscle and by employing a cuvette. For each sample analysis, color scores were obtained as mean values of four measurements obtained by rotating the measuring head 90° between duplicate measurements per position.

A shear test was used to evaluate texture in chilled salmon muscle. Firmness and deformation were determined from a stress-distance curve obtained from a universal testing machine (LR-5 K; Lloyd Instruments Limited, Hampshire, England, UK) including a load cell of 500 N connected to a computer, this including a Dapmat 40-0465 software data analysis (version 3.05, Lloyd Instruments Limited, Hampshire, England, UK). A Warner–Bratzler blade (knife edge, 60°), 1.2 mm thick, 150 mm width, and cutting at a 1 mm s−1 speed, was employed at 4 °C on a 4 × 4 × 2 cm sample. The firmness (N) was regarded as the resistance maximum of the muscle fibers against transversal shearing (maximum force) and was the height of the first peak; deformation was measured during the upward movement of the blade and was calculated as the cohesivity (millimeters) at maximum peak force (Sigurgisladóttir et al. 1999). The average value of quadruplicate replicates was considered in each sample analysis.

Statistical Analyses

Concerning the preliminary HHP study, RSM was performed to optimize both variables (hydrostatic high-pressure and holding time) by means of sensory descriptors analysis. For it, a multifactor ANOVA (panelists, specimens, and HHP treatment) was conducted on the design responses for each descriptor. The requirements for optimization were significant differences among HHP treatments but not among panelists. Multiple-regression equations were fitted for the descriptors that fulfilled this requirement to obtain the response surfaces; for it, non-significant terms were discarded. A multiple-response optimization was performed to assess the combination of experimental factors that simultaneously optimize several responses; as a result, maximization of the desirability function was obtained, this function ranging from 0 to 1 (Derringer and Suich 1980). The Statgraphics plus statistical graphics software Corporation, Manugistics Inc., Rockville, USA, was used for data analysis (Manugistics Inc. and Statistical).

Data were analyzed according to a first-order model, called main effect model. In it, equations of the fitted models for HHP variables (hydrostatic high-pressure and holding time) were obtained taking into account the interaction between both of them. The response for each sensory attribute was calculated according to the following equation (Myers and Montgomery 1995):

where Y is the estimated response for the first-order model; β 0, β 1, β 2, and β 12 are the regression coefficients for intercept, linear, and interaction terms, respectively; X 1 and X 2 are the main effects of the two independent variables; and X 1 X 2 is the interaction between both variables.

Data concerning the HHP processing followed by chilled storage were analyzed by multifactor analysis of variance ANOVA (Tukey test), taking into account possible differences among specimens, panelists, HHP treatments, and chilled storage times. Statistical program used was Statgraphics plus statistical graphics software Corporation, Manugistics Inc., Rockville, USA (Manugistics Inc. and Statistical). A confidence interval at the 95% level was used in all cases.

Results and Discussion

Preliminary HHP Study

Table 1 indicates the results of fitting a multiple linear regression model to describe the relationship between independent variables (hydrostatic high-pressure and holding time) and sensory descriptors (color uniformity, white spots appearance, elasticity, and hardness) of salmon muscle. The only response variable that presented a first-order model including interaction between both variables (hydrostatic high-pressure and holding time) was hardness (p < 0.05); its determination coefficient (R 2) indicated that the fitted model could explain 99.973% of the variability in hardness. Meantime, a good determination coefficient was also obtained in the case of elasticity (R 2 = 97.477). Regression coefficients were removed from Table 1 in cases where p values obtained from the ANOVA analysis were found higher or equal to 0.05 and were not considered statistically significant at the 95% or higher confidence level.

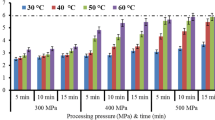

Figure 1a–d shows the response surfaces obtained for each of the sensory descriptors as a function of the processing variables. It could be observed that both the hydrostatic high-pressure (100 to 200 MPa) and the holding time (0 to 5 min) had a significant effect on the sensory properties of the salmon muscle (p < 0.05). Thus, salmon color uniformity decreased (Fig. 1a) when the pressure variable augmented, whereas holding time did not provide a significant effect, according to regression coefficients shown in Table 1. The combination of factor levels which minimizes the salmon color uniformity changes over the indicated region was 100 MPa and 30 s, with 9.354 as optimum value. Meantime, white spots appearance (Fig. 1b) indicated an increased value with holding time, the pressure effect not being significant (Table 1). One hundred megapascals and 30 s was the combination of factor levels which minimized white spots appearance (1.026 as optimum value). Both hydrostatic high-pressure and holding time variables proved a significant effect on elasticity (Fig. 1c); thus, an enlargement in both variables led to an elasticity decrease of salmon muscle, according to coefficients included in Table 1. The combination of factor levels which optimized the elasticity response was 100 MPa and 30 s, this showing 9.348 as optimum value. Finally, hardness (Fig. 1d) decreased with both pressure value and holding time but increased as a result of the interaction between both variables (Table 1).

Figure 2 provides the evaluation of the desirability function at each point of the experimental design, according to the optimization process based on the combination of the sensory descriptor responses.

Figure 2a indicates the estimated response surface of the relationship among the desirability response variable, the hydrostatic high-pressure, and the holding time by means of a three-dimensional response surface and the contour plot. Addition of the interaction term (+0.006 hydrostatic high-pressure × holding time) introduced a curvature in the response function (Myers and Montgomery 1995). For each value of pressure and holding time, a corresponding value of the desirability response was obtained, this producing a surface which lies above the pressure-holding time plane (Myers and Montgomery 1995). The optimization process indicated an optimum value for desirability of 0.75. The contour of the estimated response surface in two dimensions (hydrostatic high-pressure and holding time; Fig. 2b) indicates that the optimum values of the process variables which minimize color and elasticity changes hold hardness at a five-point score in a ten-point scale and minimize the appearance of white spots are 135.6 MPa and 30 s, respectively.

As a result, this HHP condition (135 MPa and 30 s) was chosen for being employed as a previous treatment in the present research where salmon quality changes during chilled storage were to be investigated. Two other HHP conditions where the holding time was maintained (30 s) but the pressure was intensified (170 and 200 MPa, respectively) were also selected as previous treatment. Such pressure range chosen (135–200 MPa) agrees to pressure conditions previously recommended for farmed turbot (Scophthalmus maximus) fillets as not contributing to important modifications (Chevalier et al. 2001).

HHP Treatment and Chilled Storage Study

Odor Development Assessment

Rancid odor development showed a progressive enlargement in all kinds of samples throughout the chilling time (Table 2). At time 0, very low values were detected; however, compared with control fish, an increased value was obtained as a result of the different HHP treatments, whatever the treatment employed was. Later on (6–20-day period), lower mean values were obtained for fish previously treated under T-1 condition; differences were found significant when comparison was achieved with the counterpart samples corresponding to T-2 and T-3 treatments. An increased lipid oxidation evolution in T-2- and T-3 fish samples was already observed in a previous parallel study where primary, secondary, and tertiary lipid oxidation indices were analyzed (Aubourg et al. 2010).

In general, HHP treatment has been reported to enlarge the lipid oxidation progress of fish muscle during a further refrigerated storage (Lakshmanan et al. 2007; Yagiz et al. 2007). However, isolated extracted lipids have demonstrated to be relatively stable against oxidation under HHP conditions and during further storage; additionally, the prooxidant effect of HHP treatment on muscle lipids was shown to be eliminated if a previous water washing of the muscle was applied or if a complexation compound (EDTA, for example) was added (Angsupanich and Ledward 1998; Ohshima et al. 1993). Consequently, metal-bound protein denaturation during HHP treatment has been reported to facilitate a free metal ion content increase and be responsible for an oxidation stability decrease in stored fish meat after HHP treatment.

Putrid odor assessment provided increasing values with chilling time for all kinds of samples (Table 2). At day 0, no effect could be outlined as a result of any of the previous HHP treatments tested when compared with the control batch. Later on (10–20-day period), fish corresponding to previous T-1 treatment showed lower scores than its counterpart belonging to T-2 and T-3 conditions; T-1-batch also indicated a lower putrid odor development for the 15–20-day period when compared with control fish. At the end of the experiment, the highest putrid odor was detected in the control samples.

A marked amine odor development was obtained in all kinds of samples with chilling time (Table 2). Very low scores could be observed at day 0 in all cases, so that no direct effect on amine odor development could be accorded to HHP treatment alone. At day 6, an inhibitory effect could be attributed to all kinds of previous HHP treatments when compared with untreated fish; however, no differences could be obtained among the different HHP conditions at that time. At the end of the experiment (15–20-day period), a lower score was observed in fish submitted to the strongest pressure condition. This lower value agrees to the above-mentioned previous study (Aubourg et al. 2010) where the greatest inhibitory effect of HHP treatment on microbial (psychrotrophs and aerobes) parameters was obtained in fish corresponding to the T-3 batch.

A shelf-life extension as a result of microbial activity inhibition by previous HHP treatment has been described during the chilled storage of different kinds of fish foods (Ohshima et al. 1993; Ashie et al. 1996). Thus, Atlantic salmon (Salmo salar) muscle showed a 2-day shelf-life extension during its refrigerated storage as a result of a previous HHP (150 MPa for 10 min) treatment (Amanatidou et al. 2000). Related to non-salmonid species, an HHP treatment (330 MPa for 5 min; 220 MPa for 5 min) led to a 3-day and 2-day shelf-life enlargement, respectively, in refrigerated red mullet (Mullus surmelutus) (Erkan et al. 2010). Also, refrigerated hake (Merluccius capensis) muscle subjected to a previous HHP treatment (400 MPa, three 5-min cycles) provided an important shelf-life increase (Hurtado et al. 2000).

Texture Change Analysis

Elasticity analysis provided a marked decrease with chilling time in all kinds of samples (Table 3). At day 0, mean scores indicated a progressive decrease value with increasing pressure applied; differences were found significant between fish samples corresponding to T-3 and C conditions. Up to day 15, higher mean scores were maintained in control samples; however, at the end of the experiment, fish samples corresponding to T-1 condition provided the highest elasticity values.

Cohesivity value also showed a decrease throughout the storage time for all kinds of samples (Table 3). In this parameter, fish corresponding to T-1 batch showed the highest cohesivity value at day 0. Fish belonging to such condition maintained the highest mean values throughout the whole storage period; differences with C-fish were found significant in the 15–20-day period.

In agreement to the decrease obtained for the elasticity and cohesiveness values, an increasing tendency in the gaping score was attained for all kinds of fish samples throughout the chilling storage period (Table 3). At day 0, a negative effect on fish quality could be observed as a result of the HHP treatment, greater in the case of the highest pressure applied (T-3 batch). At the end of the experiment, fish samples belonging to the two strongest HHP conditions were attributed score 5, while salmon samples related to T-1 treatment showed the lowest gaping development. Fish corresponding to T-1 treatment provided a gaping degree lower than 4 throughout the whole storage period, so that remained below the recommended border line of acceptability (Andersen et al. 1994). Contrarily, control and T-3-fish reached score 4 at day 15, while fish belonging to T-2 condition reached score 5 at the end of the experiment.

A progressive firmness enlargement with chilling time was obtained in all kinds of samples, except for those corresponding to the two highest pressure conditions at the end of the experiment (Table 3). Analysis corresponding to day 0 indicated that a firmness increase was attained in fish corresponding to C and T-3 batches when compared with its counterpart belonging to the two other groups. Samples corresponding to T-1 and T-2 conditions maintained lower mean values throughout the further chilling time.

Deformation assessment did not provide differences among the different kinds of samples throughout the entire (0–20-day period) chilling period (Table 3), so that no effect of the different HHP treatments tested could be attributed as such or subsequently during the chilled storage. Additionally, none of the four conditions tested in the present research provided a clear tendency with the storage time for the deformation value.

Texture is considered to be one of the most important quality attributes of seafoods, which determines consumer acceptance and hence, the marketability of such products. One of the biggest problems in the seafood industry, unlike other muscle foods, is the rapidity with which the flesh softens, and it is therefore required to maintain the initial firmness/tightening texture. Rapid softening of post-harvest fish tissue may be directly linked to great activity of endogenous proteases such as cathepsins, calcium-dependent proteases, collagenases, alkaline proteases, digestive enzymes, and so on. As a result, the connective tissue holding the cells together is reported to be degraded as muscle damage increases and blocks of cells become readily separated each other, so that a lower cohesivity score would be observed in muscle (Aitken and Connell 1979). A common consequence is the development of the phenomenon of gaping, resulting in tears appearing in the fillet, which further develop with storage time under refrigerated condition and leading to a lower-value appearance of the product (Fletcher et al. 2003; Espe et al. 2004).

Previous research has shown fish texture to be highly sensitive to pressure and holding time applied during the HHP treatment, so that it has been postulated that such a processing may be monitored in order to obtain the desired seafood texture (Hurtado et al. 2001; Uresti et al. 2005). HHP treatment often causes proteins to dissociate from their oligomeric structures, this affecting their subunits by means of partial unfolding and denaturation as well as protein aggregation and gelation. The observed enlargement in some texture parameters has been explained on the basis of different chemical changes such as reinforcement of hydrogen bonds of proteins and enhancement of disulphide bond formation (Heremans et al. 1997; Lanier 1998; Pérez-Won et al. 2005). If a refrigerated storage is to be applied after the HHP treatment, it has been reported that pressure-inactivated enzymes (cathepsin C, collagenase, chymotrypsin-like, trypsin-like) could be reactivated to various extents depending on the level of the pressure applied (Ashie et al. 1997).

When the HHP treatment effect is analyzed as such (chilling time 0 comparison) in the present study, it can be depicted that the highest pressure tested (200 MPa) has led to a lower texture quality, while T-1 condition has provided the most profitable texture scores (cohesivity and firmness, specially); accordingly, a negative effect of pressure on texture quality has been detected in the values range tested.

At this point, previous related research has provided varying results about the HHP effect according to the severity (pressure and holding time) of conditions applied. As a general rule, and according to the present results, stronger conditions have led to greater texture modifications. This applies to bluefish (Pomatomus saltatrix) muscle (Ashie et al. 1997), cod (Gadus morhua) muscle (Angsupanich and Ledward 1998), and Atlantic salmon (S. salar) fillets (Amanatidou et al. 2000). Contrary to such results, better texture properties were obtained by Yagiz et al. (2007) in rainbow trout (Oncorhynchus mykiss) and mahi-mahi (Coryphaena hippurus) fillets.

Related to the texture quality loss during the chilled storage, present results have demonstrated that fish previously treated under T-1 condition have retained a higher quality level, this according to gaping, elasticity, and cohesivity properties. Such a conclusion agrees to a previous and parallel research, which reported a higher protein damage during storage in fish corresponding to conditions including the two highest pressure (T-2 and T-3) values (Ortea et al. 2010); in such study, a marked sarcoplasmic protein content decrease was observed, in parallel to partial disappearance of a 29-kDa band in the electrophoretic analysis of such protein fraction.

In the case of bluefish (P. saltatrix) muscle (Ashie et al. 1997), firmness and elasticity showed higher values during refrigerated storage (4–7 °C) in individuals previously treated at 100 MPa for 30 min when compared with control; however, fish previously treated under higher (200–300 MPa) pressures provided lower values in both texture attributes throughout storage. Chéret et al. (2005) found that a higher hardness was produced in sea bass (Dicentrarchus labrax) fillets, previously treated at 400–500 MPa for 5 min after refrigerated storage (14 days at 4 °C), than in their counterpart untreated fillets; however, if a 100–200 MPa treatment was applied, no changes in hardness were obtained up to a 14-day storage. Additionally, a cohesiveness increase in HHP-treated (100–500 MPa for 5 min) sea bass fillets was obtained at the end of the storage when compared with control fish.

Color Change Analysis

According to mean values, the Roche scale analysis provided a general decrease with chilling time in all kinds of samples, especially in control and T-1-treated fish (Table 4). This decrease can be explained as partial loss of colored carotenoid compounds (namely, astaxanthin) responsible for the muscle color of salmonid species (Quevedo et al. 2010). Thus, astaxanthin content has been shown to be partially lost during chilled storage of vacuum-packaged rainbow trout (O. mykiss) (Gobantes et al. 1998) and as a result of the refrigerated storage (up to 5 days at 4 °C) of Atlantic salmon (S. salar) (Gordon Bell et al. 1998). In the present research, no differences could be observed at day 0 among the different kinds of samples, so that a definite effect of HHP treatment alone on carotenoid content could not be concluded. Comparison among samples hardly provided significant differences throughout the chilled storage; at day 15, a higher value was obtained for T-1-treated fish when compared with its counterpart belonging to the control batch.

Regarding the lightness (L*) mean values (Table 4), an increase with chilling time for all fish pre-treated under HHP conditions (T-1, T-2, and T-3 batches) could be observed, this increase being more important in fish corresponding to the two highest pressure conditions. According to day 0 results, no effect of the HPP treatment could be concluded; then, higher mean values for fish corresponding to both strongest conditions (T-2 and T-3 batches) during the 6–20-day period were observed. Differences were found significant at the end of the experiment when the following increasing score tendency was attained in fish corresponding to the different conditions: C and T-1 < T-2 < T-3. In all cases, L* values remained under score 70, which has been depicted as the permitted border line value for salmonid species (Amanatidou et al. 2000).

A marked augmentation of L* value has already been mentioned as a result of HHP treatment in different salmonid species such as salmon trout (Salmo trutta) (Matser et al. 2000), Atlantic salmon (S. salar) (Amanatidou et al. 2000), and rainbow trout (O. mykiss) (Yagiz et al. 2007); in all cases, L* value increases were greater by increasing the pressure applied. However, such previous experiments demonstrated that when considering relatively low pressures (200 MPa or less), slight L* value increases, or no increase at all, were obtained according to the present results.

As in the present study, previous research also reported L* value enlargement in stored fish, which was previously submitted to HHP treatment. Thus, an L* value increase with storage time was already observed in HHP-treated (150, 300, 450, and 600 MPa; 15 min) rainbow trout (O. mykiss) muscle during a further storage for 6 days at 4 °C (Yagiz et al. 2007).

Related to greenness/redness assessment (a* value) (Table 4), no effect of HHP treatment can be concluded at time 0. Although some significant differences are obtained among samples during the chilled storage, a clear tendency cannot be concluded so that no effect of previous HHP treatment can be implied on a* value in stored fish. According to mean values, a decreasing tendency for a* score could be outlined with chilling time in fish corresponding to T-3 condition. In all cases, a* value remained above 13, which has been recognized as the permitted border line score for salmonid species (Amanatidou et al. 2000).

Previous works on fish species have proved a general a* value decrease as a result of HHP treatment, this becoming bigger with increasing pressure and holding time applied (Ohshima et al. 1993; Ashie et al. 1996). However, when relatively low pressures (200 MPa or less) and short holding times (10 min or less) were encountered, no effect of HHP treatment has been concluded on a* value, according to the present research. Such conclusions were obtained on different salmonid species such as Atlantic salmon (S. salar) (Amanatidou et al. 2000; Yagiz et al. 2009), rainbow trout (O. mykiss) (Yagiz et al. 2007), and salmon trout (S. trutta) (Matser et al. 2000).

Concerning the b* (yellowness/blueness) value assessment (Table 4), a decreasing effect in all kinds of HHP-treated fish could be concluded at day 0 when compared with C samples; however, no differences were found as a result of the pressure (135–200 MPa) applied at that time. Later on (10–20-day storage), fish corresponding to T-2 and T-3 conditions showed lower values than its counterpart from C and T-1 batches. Additionally, a clear tendency for b* score during the chilled storage of the different batches under study could not be concluded.

Usually, this color parameter has been related to lipid oxidation development. Thus, an important relationship between b* value and the formation of polymerized Schiff bases and fluorescent compounds (tertiary lipid oxidation compounds) has been observed (Undeland et al. 2003). Previous studies on the effect of HHP treatment on b* value in fish muscle have demonstrated a great dependence on the pressure applied. For Atlantic salmon (S. salar) (Yagiz et al. 2009), it could be observed that b* value increased when applying a pressure of 300 MPa but decreased when fish was submitted to 150 MPa. In the case of carp (Cyprinus carpio) fillets (Sequeira-Munoz et al. 2006), b* score was shown to increase in all tested cases (100–200 MPa for 15–30 min) when compared with fresh fish. Finally, pressurized turbot (S. maximus) fillets at 100–200 MPa for 15–30 min provided an increasing b* value by intensifying both HHP parameters in comparison with control samples.

Regarding the evolution of b* value during refrigerated storage in HHP-treated fish, previous research has also shown no definite tendency as a result of storage time. Such conclusions are related to sea bass (D. labrax) (100 and 200 MPa for 5 min; Chéret et al. 2005) and red mullet (M. surmelutus) (220 and 330 MPa for 5 min; Erkan et al. 2010) studies.

Conclusions

A marked effect on sensory and physical attributes of salmon muscle has been detected as a result of HHP treatment as well as in case of being followed by a chilling storage. According to several odor (rancid and putrid), texture (elasticity, gaping, and firmness), and color (L* value) properties, fish corresponding to T-1 condition has proved to better maintain such properties throughout the chilled storage than its counterpart belonging to T-2 and T-3 conditions; additionally, a quality enhancement was also found when comparison was carried out with control fish (putrid odor, cohesivity, and gaping).

Previous research (Aubourg et al. 2010) had demonstrated that T-1, T-2, and T-3 HHP conditions were profitable to partially inhibit microbial activity development during coho salmon chilled storage. However, marked protein damage was also reported in fish corresponding to T-2 and T-3 batches after the HHP treatment and during the further chilled storage (Ortea et al. 2010).

Present results have demonstrated that T-1 condition can provide an effective combination of pressure and holding time in order to better maintain odor, texture, and color properties when this fish species muscle is to be commercialized under the fresh state. Results obtained in the chilled storage experiment agree to the preliminary optimization study where T-1 condition was found to be the most convenient HHP treatment to be applied. Present research attest the importance of establishing a judicious selection of treatment parameters in order to minimize undesirable changes related to sensory and physical properties.

References

Aitken, A., & Connell, J. (1979). Fish. In R. Priestley (Ed.), Effects of heating on food stuffs (pp. 219–254). London: Applied Science Publishers Ltd.

Amanatidou, A., Schlüter, O., Lemkau, K., Gorris, L., Smid, E., & Knorr, D. (2000). Effect of combined application of high pressure treatment and modified atmospheres on the shelf life of fresh Atlantic salmon. Innovative Food Science and Emerging Technologies, 1, 87–98.

Andersen, U., Stromsnes, A., Steinsholt, K., & Thomassen, M. (1994). Fillet gaping in farmed Atlantic salmon (Salmo salar). Norwegian Journal of Agricultural Science, 8, 165–179.

Angsupanich, K., & Ledward, D. (1998). High pressure treatment effects on cod (Gadus morhua) muscle. Food Chemistry, 63, 39–50.

Ashie, I., & Simpson, B. (1996). Application of high hydrostatic pressure to control enzyme related fresh seafood texture deterioration. Food Research International, 29, 569–575.

Ashie, I., Smith, J., & Simpson, B. (1996). Spoilage and shelf-life extension of fresh fish and shellfish. Critical Reviews in Food Science and Nutrition, 36, 87–121.

Ashie, I., Simpson, B., & Ramaswamy, H. (1997). Changes in texture and microstructure of pressure-treated fish muscle tissue during chilled storage. Journal of Muscle Foods, 8, 13–32.

Aubourg, S., Tabilo-Munizaga, G., Reyes, J., Rodríguez, A., & Pérez-Won, M. (2010). Effect of high-pressure treatment on microbial activity and lipid oxidation in chilled coho salmon. European Journal of Lipid Science and Technology, 112, 362–372.

Chéret, R., Chapleau, N., Delbarre-Ladrat, C., Vérrez-Bagnis, V., & De Lamballerie, M. (2005). Effects of high pressure on texture and microstructure of sea bass (Dicentrarchus labrax L.) fillets. Journal of Food Science, 70, E477–E483.

Chevalier, D., Le Bail, A., & Ghoul, M. (2001). Effects of high pressure treatment (100-200 MPa) at low temperature on turbot (Scophthalmus maximus) muscle. Food Research International, 34, 425–429.

Codex Alimentarius (1999). Directrices para la Evaluación Sensorial del Pescado y los Mariscos en Laboratorio. Norma Técnica CAC/GL 31-1999. http://www.pes.fvet.edu.uy/cursos/mail2.pdf.

Derringer, G., & Suich, R. (1980). Simultaneous optimization of several response variables. Journal of Food Quality and Technology, 12, 214–219.

Erkan, N., Üretener, G., & Alpas, H. (2010). Effect of high pressure (HP) on the quality and shelf life of red mullet (Mullus surmelutus). Innovative Food Science and Emerging Technologies, 11, 259–264.

Erkan, N., Üretener, G., Alpas, H., Selçuk, A., Özden, Ö., & Buzrul, S. (2011). Effect of high hydrostatic pressure (HHP) treatment on physicochemical properties of horse mackerel (Trachurus trachurus). Food and Bioprocess Technology, 4, 1322–1329.

Espe, M., Ruohonen, K., Bjørnevik, M., Frøyland, L., Nortvedt, R., & Kiessling, A. (2004). Interactions between ice storage time, collagen composition, gaping and textural properties in farmed salmon muscle harvested at different times of the year. Aquaculture, 240, 489–504.

FAO (2007a) Fishery statistics. Aquaculture Production. Yearbook 2005, 100/2, p. 73. Food and Agriculture Organization of the United Nations, Rome, Italy.

FAO (2007b) Fishery statistics. Capture Production. Yearbook 2005, 100/1, p. 79. Food and Agriculture Organization of the United Nations, Rome, Italy.

Fletcher, G., Corrigan, V., Summers, G., Leonard, M., Jerrett, A., & Black, S. (2003). Spoilage of rested harvested king salmon (Oncorhynchus tshawytscha). Journal of Food Science, 68, 2810–2816.

Gobantes, I., Choubert, G., & Gómez, R. (1998). Quality of pigmented (astaxanthin and canthaxanthin) rainbow trout (Oncorhynchus mykiss) fillets stored under vacuum packaging during chilled storage. Journal of Agricultural and Food Chemistry, 46, 4358–4362.

Gordon Bell, J., McEvoy, J., Webster, J., McGhee, F., Millar, R., & Sargent, J. (1998). Flesh lipid and carotenoid composition of Scottish farmed Atlantic salmon (Salmo salar). Journal of Agricultural and Food Chemistry, 46, 119–127.

Heremans, K., Van Camp, J., & Huyghabaert, A. (1997). High pressure effects on proteins. In S. Damodaran & M. Paraf (Eds.), Fundamentals of food proteins and their applications (pp. 473–502). New York: Marcel Dekker.

Howgate, P. (1992). Codex review on inspection procedures for the sensory evaluation of fish and shellfish, CX/FFP, 92/14.

Hurtado, J., Montero, P., & Borderías, A. J. (2000) Extension of shelf life of chilled hake (Merluccius capensis) by high pressure. Food Science and Technology International, 6, 243–249.

Hurtado, J., Montero, P., & Borderías, A. J. (2001). Chilled storage of pressurized octopus (Octopus vulgaris) muscle. Journal of Food Science, 66, 400–406.

ISO (1993) Sensory analysis: Methodology. General guidance for the selection, training and monitoring of assessors. Part 1: Selected assessors. In: ISO-standard 8586-1, The International Organization for Standardization, Geneva, Switzerland

Lakshmanan, R., Parkinson, J., & Piggott, J. (2007) High-pressure processing and water-holding capacity of fresh and cold-smoked salmon (Salmo salar). Food Science and Technology, 40, 544–551.

Lanier, T. (1998). High pressure processing effects of fish proteins. In F. Shahidi (Ed.), Process-induced chemical changes in food (pp. 45–55). New York: Plenum Press.

Matser, A., Stegeman, D., Kals, J., & Bartels, P. (2000). Effects of high pressure on colour and texture of fish. High Pressure Research, 19, 109–115.

Montero, P., Pérez-Mateos, M., & Borderías, A. J. (1998). Chilled storage of high pressure and heat-induced gels of blue whiting (Micromesistius poutassou) muscle. Zeitschrift für Lebensmittel-Untersuchung und -Forschung, 207, 146–153.

Myers, R. H., & Montgomery, D. C. (1995). Response surface methodology: Process and product optimization using designed experiments. New York: Wiley.

Norton, T., & Sun, D.-W. (2008). Recent advances in the use of high pressure as an effective processing technique in the food industry. Food and Bioprocess Technology, 1, 2–34.

Ohshima, T., Ushio, H., & Koizumi, C. (1993). High-pressure processing of fish and fish products. Trends in Food Science and Technology, 4, 370–375.

Oms-Oliu, G., Martín-Belloso, O., & Soliva-Fortuny, R. (2010). Pulsed light treatments for food preservation. A review. Food and Bioprocess Technology, 3, 13–23.

Ortea, I., Rodríguez, A., Tabilo-Munizaga, G., Pérez-Won, M., & Aubourg, S. (2010). Effect of hydrostatic high-pressure treatment on proteins, lipids and nucleotides in chilled farmed salmon (Oncorhynchus kisutch) muscle. European Food Research and Technology, 230, 925–934.

Ozen, B., & Floros, J. (2001). Effects of emerging food processing techniques on the packaging materials. Trends in Food Science and Technology, 12, 60–67.

Pérez-Won, M., Tabilo-Munizaga, G., & Barbosa-Cánovas, G. (2005). Effects of ultra high pressure on bay scallop (Aequipecten irradians) adductor muscles. Food Science and Technology International, 11, 477–484.

Quevedo, R., Aguilera, J. M., & Pedreschi, F. (2010). Color of salmon fillets by computer vision and sensory panel. Food and Bioprocess Technology, 3, 637–643.

Ramírez, R., Saraiva, J., Pérez Lamela, C., & Torres, J. A. (2009). Reaction kinetics analysis of chemical changes in pressure-assisted thermal processing. Food Engineering Reviews, 1, 16–30.

Rodríguez, A., Cruz, J. M., Paseiro-Losada, P., & Aubourg, S. (2011). Effect of a polyphenol-vacuum packaging on lipid deterioration during an 18-month frozen storage of coho salmon (Oncorhynchus kisutch). Food and Bioprocess Technology. doi:10.1007/s11947-011-0588-5 (in press)

Rouillé, J., Le Bail, A., Ramaswamy, H., & Leclerc, L. (2002). High pressure thawing of fish and shellfish. Journal of Food Engineering, 53, 83–88.

Sequeira-Munoz, A., Chevalier, D., Le Bail, A., Ramaswamy, H., & Simpson, J. (2006). Physicochemical changes induced in carp (Cyprinus carpio) fillets by high pressure processing at low temperature. Innovative Food Science and Emerging Technologies, 7, 13–18.

Sigurgisladóttir, S., Hafsteinsson, H., Jonsson, A., Nortvedt, R., Thomasses, M., & Torrisen, O. (1999). Textural properties of raw salmon fillets as related to sampling method. Journal of Food Science, 64, 99–104.

Undeland, I., Hultin, H., & Richards, M. (2003). Aqueous extracts from some muscles inhibit hemoglobin-mediated oxidation of cod muscle membrane lipids. Journal of Agricultural and Food Chemistry, 51, 3111–3119.

Uresti, R., Velázquez, G., Vázquez, M., Ramírez, R., & Torres, J. A. (2005). Effects of sugars and polyols on the functional and mechanical properties of pressure-treated arrowtooth flounder (Atheresthes stomias) proteins. Food Hydrocolloids, 19, 964–973.

Vinagre, J., Rodríguez, A., Larraín, M. A., & Aubourg, S. (2011). Chemical composition and quality loss during technological treatment in coho salmon (Oncorhynchus kisutch). Food Research International, 44, 1–13.

Whittle, K., Hardy, R., & Hobbs, G. (1990). Chilled fish and fishery products. In T. Gormley (Ed.), Chilled foods. The state of the art (pp. 87–116). New York: Elsevier Applied Science.

Yagiz, Y., Kristinsson, H., Balaban, M., & Marshall, M. (2007). Effect of high pressure treatment on the quality of rainbow trout (Oncorhynchus mykiss) and mahi mahi (Coryphaena hippurus). Journal of Food Science, 72, C509–C515.

Yagiz, Y., Kristinsson, H., Balaban, M., Welt, B., Ralat, M., & Marshall, M. (2009). Effect of high pressure processing and cooking treatment on the quality of Atlantic salmon. Food Chemistry, 116, 828–835.

Acknowledgments

The authors thank Mrs. Teresa Roco, Mrs. Lorena Briones, and Mr. Marcos Trigo for their excellent technical assistance and AquaChile S. A. for kindly supplying the coho salmon fish. This work was supported by the Universidad de Chile (Chile)-Consejo Superior de Investigaciones Científicas (CSIC, Spain) program (Project 2006 CL 0034) and the FONDECYT program (Chile; project number: 1080626).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aubourg, S.P., Rodríguez, A., Sierra, Y. et al. Sensory and Physical Changes in Chilled Farmed Coho Salmon (Oncorhynchus kisutch): Effect of Previous Optimized Hydrostatic High-Pressure Conditions. Food Bioprocess Technol 6, 1539–1549 (2013). https://doi.org/10.1007/s11947-012-0799-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0799-4