Abstract

Nitrite is widely used due to its personal properties. It not only exists in the food processing and chemical industry but also in every corner of the natural world. Nevertheless, excessive use of nitrite can cause serious environmental and human health hazards. Therefore, the efficient and sensitive detection of nitrite content has become a problem that must be faced. Among numerous methods, the electrochemical method has been widely studied for its advantages, such as fast reaction speed, high sensitivity, and miniaturization. The principle of operation of the nitrite electrochemical sensor is as follows. A modified layer located on the electrode surface oxidizes nitrite to nitrate. The sensing signal generated during oxidation can be converted into a measurable electrochemical signal. The electrochemical signal is proportional to nitrite concentration within a certain range, so that nitrite can be quantitatively detected. However, the sensor’s performance is affected by the high oxidation potential of the bare electrode in electrochemistry. Therefore, the electrode is often modified to improve the sensor’s performance in the study. In this review, the research progress of materials other than precious metals is discussed in the electrochemical detection of nitrite in recent years (2023–2013). The properties of carbon materials, non-noble metals, metal-organic framework compounds, conductive polymers, and their composites in electrochemical sensors are discussed in detail. Besides, it also looks forward to the challenges and prospects of nanomaterials in electrochemical sensor applications.

Graphical Abstract

Article overall summary diagram

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nitrite is a nitrogenous compound that is ubiquitous in nature. It is mainly derived from the nitrogen cycle in nature. It is not only present in the environment but also widely used in the food processing and chemical industries [1]. It can be used in dye production in the chemical industry and certain organic synthesis, while it can be used as a food colorant and preservative in food production. However, when nitrite levels are too high, there is a greater risk to human health and aquatic plants. On the one hand, when the nitrite concentration exceeds 0.02 mg/L, it will directly affect the growth and development of aquatic organisms, will induce disease outbreaks, and may even lead to the death of many aquatic organisms [2]. On the other hand, nitrite can form nitrosamines in the human body. Nitrosamines are precursors of carcinogenic compounds, and long-term ingestion can induce the development of cancer [3, 4]. The International Agency for Research on Cancer has classified nitrite as a possible carcinogen to humans (class 2a) [5]. At present, most countries have enacted corresponding laws and regulations to control the content of nitrite, which can reduce the harm of nitrite to humans and the environment to some extent. However, we still need to establish a complete testing program. A complete detection procedure is established when a systematic understanding of the mechanism of action nitrite is available [6].

At present, a variety of methods have been developed for the detection of nitrite content to control the excessive intake of nitrite content. Studies have been reported in the literature, and it has been found that the methods used include spectrophotometry [7, 8], chemiluminescence [9, 10], chromatography [11, 12], capillary electrophoresis [13,14,15], fluorescent probes [16], and electrochemistry [17]. Among the known methods, the electrochemical method has attracted wide attention because of its advantages of high sensitivity, simplicity, and accuracy.

In electrochemical detection, the electrochemical sensor is the most important component. The principle is that nitrite interacts with the material and thus undergoes a specific redox reaction at the electrode surface. The electrochemical active substances are produced during the reaction. And the substances can be converted into a detectable electrochemical signal by the sensor, thus being used for qualitative and quantitative analysis [18, 19]. The electrochemical method can realize direct electrocatalytic oxidation of nitrite on the electrode surface. However, the sensor’s performance is hindered by the high oxidation potential of nitrite at the bare electrode [20]. Therefore, the electrode needs to be modified to improve the detection performance of the sensor.

With the development of science and technology, various materials have been developed for modifying electrodes. The modified sensor for nitrite detection not only increases the electrochemical reaction of NO2− redox but also plays a great role in expanding the detection range of nitrite and reducing the detection limit [21]. In recent years, nanomaterial sensors have become a powerful analytical tool due to the development and use of various functional nanomaterials [4]. At present, the nanomaterials commonly used to modify electrodes include graphene (GR), carbon nanotubes (CNTs), carbon nanofibers, carbon nanodots, and other carbon materials; metals, metal oxides, and other metal materials; metal-organic framework compounds [22]; conducting polymers [23]; and enzymes [24]. Carbon materials have become the most widely used materials among the above-mentioned nanomaterials due to their large specific surface area and wide range of raw materials. The metal-organic framework is a material that emerged in the later period and has attracted extensive research because of its unique and fascinating structure. Modified electrodes exhibit higher reactivity and faster electron transfer rates for nitrite detection. Although there are many electrodes modified by precious metals in metal oxides, they show good electrocatalytic properties when used for nitrate detection. For example, Salagare et al. doped palladium oxide (PdO) with RGO using an in situ chemical solution technique for nitrite sensing. The peak oxidation current of nitrite showed a linear relationship with its concentration ranging from 10 to 1500 μM, and the LOD was 10.14 μM [25]. Salagare et al. prepared silver nanoparticle-modified zinc oxide nanocomposites by ethylene glycol reduction method for nitrite sensing. The detection range of nitrite was 30~1400 μM, and the detection limit was 14 μM [26]. The application of electrodes modified by precious metals is limited in practical work due to the scarcity of precious metals and the difficulty of polymerization. Therefore, this article does not take precious metal materials as the object of study.

This article reviews the application of nanomaterial-modified electrochemical sensors in nitrite detection in the past decade (2023–2013). Research on nitrate sensors is on the rise overall, and composites tend to outperform single materials. In addition, when summarizing the various detection limits and linear ranges for nitrite, it was found that the sensor has a wide linear range and the detection limits have been down to the micromolar level. In research, nitrite sensors have been used to detect a variety of actual samples, including water, soil, beverages, sausages, and pickles. The purpose of this article is to provide the reader with a systematic understanding of the current state of research on sensors modified with non-precious materials so that more convenient and feasible sensors can be developed.

Nitrite sensor based on carbon

In the electrochemical method, it is not efficient when used directly to detect nitrite due to the high oxidation potential of the bare electrode. Therefore, some functional nanomaterials are commonly used to modify the electrode. Among the functional nanomaterials developed, carbon materials have attracted extensive research because of their large specific surface area and high electrical conductivity [27]. In recent years, researchers have developed a variety of electrochemical sensors modified with carbon materials of different properties. The sensors can be used for the detection of nitrite. These carbon materials include carbon nanotubes [28], graphene [29], and nanoporous carbon (NC) [30]. In this section, the application of carbon nanotubes and graphene materials in electrochemistry is mainly introduced. The properties of these nanocomposites are then summarized in Table 1.

Nitrite sensor based on carbon nanotubes

Since CNTs have been studied, scholars have continuously used them for modifying electrochemical sensors. Carbon nanotubes are rolling graphene sheets with axis symmetry. Based on the different layers of graphene, it can be divided into single-walled nanotubes (SWCNTS) and multi-walled nanotubes (MWCNTS) [87]. Single-walled nanotubes have attracted extensive research because they can be compatible with other substances. For example, Xian et al. applied a covalent modification approach to immobilize single-walled carbon nanotubes with single-stranded deoxyribonucleic acid composites on the surface of glassy carbon electrodes (GCEs) [31]. The modified electrodes not only have a large specific surface area and good electrical conductivity, but the presence of single-walled nanotubes can enhance the electron transfer rate so that the sensor has high catalytic performance. Under the optimal experimental conditions, the linear range of the sensor can be gained from 0.6 to 540 μM, and the minimum detection limit is as low as 0.15 μM by differential pulse voltammetry (DPV). In addition, the sensor has good stability and strong anti-interference ability. The good stability of the sensor is mainly attributed to the fact that the nanocomposites are immobilized on the electrode surface by covalent bonds rather than simply physically adsorbed on the electrode surface. Based on this research, the composite material was further optimized. For example, Yang et al. used a one-step electrodeposition method to immobilize DNA-CNTs/Cu2+ on the surface of a glassy carbon electrode [32]. Through cyclic voltammetry (CV), it can be found that adding CNTs/Cu2+ can enhance charge transfer and reduce the hindrance of DNA film to charge. After optimization of the experimental conditions, the sensor was measured using amperometry (Amp). The results showed that the DNA-CNTs/Cu2+-modified sensor had a linear range of 3 × 10−8~2.6 × 10−3 M and a detection limit of 3 × 10−8 M (S/N = 3). The reproducibility of the sensor was studied using five identically modified electrodes, and the RSD was measured to be 4.4%. These results indicated that the reproducibility of the sensor was good. In addition, the current response of nitrite was measured every day. It was found that the current response value was maintained at more than 88% of the initial reaction after 30 days. This result indicated that the sensor had strong stability and could be detected in real samples.

Compared with other materials, multi-walled carbon nanotubes have remarkable electrocatalytic activity and a strong current response. However, there is almost no interaction of available ions to detect a particular analyte at low concentrations, and multi-walled nanotubes are less hydrophobic in aqueous solutions. To overcome these problems, multi-walled nanotubes can be modified by adding appropriate functional groups to improve the hydrophobicity and electrocatalytic stability of the nanotubes [21, 88, 89]. For example, Sudha et al. constructed COOH-functionalized multi-walled nanotubes for modifying glassy carbon electrodes [41]. COOH-functionalized multi-walled nanotubes had more graphitic properties than the original MWCNT, so more active sites (C=C and COOH groups of HOOC-MWCNT) can interact with the analyte. The feature can achieve the purpose of low-concentration sensing. In addition, the detection range of the sensor was determined to be 100 μM~0.7 mM, and the detection limit was 565 nM by differential pulse voltammetry. To demonstrate the practicability of the sensor, the samples of ground pond water were tested. The results showed a recovery of 102% for nitrite. To further improve the performance of this composite, it can be compounded with a metal material. For example, Zhu et al. compounded COOH-functionalized multi-walled nanotubes with Bi2Se3 [44]. Bi2Se3@MWNTs-COOH nanocomposites were synthesized to modify GCE/carbon electrodes (CE) by a one-step hydrothermal method. Five samples were prepared by adding different concentrations of reagents. Among them, Bi2Se3@MWNTs-COOH-50% had the lowest charge transfer resistance. The result indicated that the composite has the highest electron transfer rate. By measuring the CV curves of different electrodes, it can be obtained that Bi2Se3@MWNTs-COOH had the largest current response value (Fig. 1). The result indicated that Bi2Se3@MWNTs-COOH has a larger surface area, which is favorable for nitrite adsorption. The disposable electrochemical sensor has a detection range of 0.01 μM~7.0 mM, and the minimum detection limit is 0.002 μM for the detection of nitrite. In short, the sensor has great potential for the detection of nitrite.

a EIS of Bi2Se3@MWNTs-COOH-x electrodes. b CV curves of the different electrodes to detect 1.0-mM nitrite in 0.1-M PBS (pH 7.0) at 100 mV s−1. c Schematic diagram of the synthesis method of Bi2Se3@MWCNTs-COOH/CEs and the preparation process d [44]. Copyright 2021, Elsevier

Nitrite sensor based on graphene

Graphene is a two-dimensional carbon nanomaterial composed of sp2 hybrid orbital carbon atoms. Its structure is a honeycomb hexagonal lattice network and can be extended indefinitely [90]. Graphene has become the most promising material for nitrite detection because of its cheap raw material and good electrical conductivity [60, 91]. Graphene can be divided into graphene oxide (GO) and reduced graphene oxide (rGO). Reduced graphene oxide includes chemically reduced graphene oxide (CrGO) and electrochemically reduced graphene oxide (ErGO). rGO has higher electrical conductivity compared to GO. So rGO is more widely used than graphene [6, 21]. However, pure graphene has serious aggregation and homogeneity problems. So electrochemical properties are usually reduced [92].

Doping graphene with various heteroatoms is an effective method to improve the structural and electrochemical properties of graphene. Yuan et al. used a simple laser engraving method to prepare N and O co-doped porous graphene under UV irradiation (Fig. 2) [47]. LIG was detected by DPV. The results showed a good linear relationship between the peak current and the analyte concentration. And the sensor had a detection range of 5~450 μM, and the minimum detection limit was 0.8 μM, which was 55 times lower than the detection limit of 3 mg/L set by the World Health Organization. Surprisingly, the electrode had good reproducibility and strong anti-interference ability. In short, the sensor has broad application prospects in detecting nitrite. Cheng et al. prepared graphene-based nanocomposites sb-ZnO (stir bar-shaped ZnO)/N-rGO for modifying glassy carbon electrodes by combining a novel stir bar-shaped ZnO with N-doped reduced graphene oxide using a hydrothermal method [22]. There is a large active surface area due to extra valence bonds between π-electron and lone pairs of N atoms in graphene oxide. The large active surface can accelerate the electron transfer rate. In addition, ZnO enhances the electron transfer capability and provides a large surface area due to a wide direct band gap and extended excitation binding energy. With the synergistic effect of N-rGO and sb-ZnO, the nanocomposite-modified electrode has a low detection limit of 0.13 μM and a linear range of 0.2 μM~1.2 mM and 1.5~7.8 mM. In addition, the recovery rate of nitrite by this sensor is between 96.0 and 103.0% in practical applications of ham sausage, sauerkraut, and tap water.

Fabrication scheme of LIG and electrochemical sensing electrodes [47]. Copyright 2022, Elsevier

Another way to improve the sensitivity is to incorporate various nanomaterials, such as metal oxides and conducting polymers. In recent years, transition metal hydroxides have been confirmed to have high electrocatalytic activity and are promising for various applications in electrochemical sensors. For example, Salagare et al. successfully prepared cobalt-nickel-reduced graphene oxide nanoparticles by complexing transition metal mixed oxides NiCo2O4 with RGO using urea nitrate complexing agent auto-ignition method [75]. The nanocomposite has a unique porous structure and layered connections. CV and DPV method was used to study the electrocatalytic behavior of the material towards nitrite. The results showed that the composite-modified graphite electrode (NiCo-RGO) had a larger peak anodic current than the bare graphite electrode. The linear range was found to be 60~860 μM with a detection limit of 18.0 μM about the NiCo-RGO/GCE-based sensor for nitrite detection by the DPV method. In addition, the material showed good reproducibility, repeatability, and stability for electrochemical sensing of nitrite. Good recoveries were obtained in real samples of water, cucumber juice, and milk. The sensor has good prospects for commercialization. Yılmaz-Alhan et al. prepared a two-dimensional carbon-metal oxide composite electrode to modify the glassy carbon electrode [68]. Transition metal manganese oxide was doped with reduced graphene oxide and then combined with a glassy carbon electrode to form MnO2-rGO/GC electrode. The MnO2-rGO-based composites have good electrochemical properties due to the high electrical conductivity of the MnO2-rGO/GC electrode, which enables rapid electron transfer between the redox couple and the electrode surface. The sensor has a detection limit as low as 0.02 μM and a detection range of 0.1~5.5 μM. The MnO2-reduced graphene oxide composite was used to test fruit juice and tap water with good recovery and high interference resistance. Wang et al. prepared nanocomposites (Ni(OH)2/sr-GO) of nickel hydroxide and reduced graphene oxide by a one-step solvothermal method without reducing agents and bases. They constructed an electrochemical sensor for nitrite detection [62]. In electrochemical tests, the Ni(OH)2/sr-GO nanocomposites showed high electrocatalytic activity. The detection range of the sensor is 0.1~663.6 mM, and the detection limit is 0.07 mM (S/N = 3) by amperometry. In addition, the sensor has good selectivity and stability, and low relative deviation with good recovery can be obtained to detect nitrite in water samples. Cheng et al. prepared perovskite oxides La0.8Sr0.2MnO3 (LSM) and reduced graphene oxide by sol-gel method and Hummer method [93]. Then, the LSM/rGOx composites were successfully prepared by mixing the two in different proportions by probe ultrasound. At 15 wt% rGO content, LSM particles have the best dispersion on rGO. In addition to this, composites have the largest peak current and the smallest transfer resistance in CV and electrochemical impedance tests. This shows that LSM/rGO1.5 composites have the strongest oxidation ability to nitrite and the fastest electron transfer rate. The catalytic mechanism of LSM/rGOx for nitrite oxidation can be inferred from electrochemical tests. Firstly, Mn(II) or Mn(III) is electrochemically oxidized to Mn(III) and Mn(IV), and secondly, Mn(III) and Mn(IV) chemically oxidize NO2− to NO3− (Fig. 3). The three-electrode sensor based on LSM/rGOx has an ultra-low detection limit (0.016 μM), good stability, and accuracy for NO2− detection in water. And it is expected to be used for the detection of nitrite in real environments. Among the conductive polymers, polyaniline has been widely studied for its good conductivity and stability. For example, Sivakumar et al. prepared polyaniline-@graphene oxide (PANI@GO) nanocomposites and used them to modify GCE [74]. The electrochemical performance of PANI@GO/GCE for nitrite oxidation was evaluated by comparing PANI@GO/GCE with GO/GCE, PANI/GCE, and bare GCE electrodes by CV technique. The results showed that the electrode had the highest oxidation current (about 45.7 μA) and the lowest overpotential (0.83 V). The electrode had a wide linear range (2–44,000 μM), high sensitivity (117.23 μA mM−1 cm−2), and low detection limit (0.5 μM). In addition, PANI@GO/GCE electrode had good selectivity, stability, repeatability, and reproducibility in nitrite detection. A good recovery rate (98.07~106.11%) was obtained when the electrode was used in real-time applications of rain water and tap water samples, indicating that the sensor is suitable for real-time applications. Li et al. successfully prepared polyaniline/reduced graphene oxide composites by combining polyaniline with reduced graphene oxide by in situ electrochemical reduction and cyclic voltammetry electrochemical polymerization, which was used to modify the interdigital electrode (IDE) [58]. The electrochemical test on the composite showed that the π-π superposition force between aniline and rGO made electron transfer easier and contributed to the conductivity of IDE compared to bare electrodes. At the same time, the increase in conductivity and the transfer of electrons are conducive to the polymerization of aniline, which can increase the current and reduce the oxidation potential. The property gives the sensor good electrochemical performance. The detection range of the sensor is 0.4~183.7 mM, and the detection limit is 0.1 μM. Reduced graphene oxide is a derivative of graphene, different graphene materials can be obtained depending on the reduction method. Among them, ErGO is widely used because of its easy control and safety in synthesis. For example, Yue et al. prepared CuOx/ErGO nanohybrids by electrodeposition method [64]. Depending on the pH, CuOx/ErGO nanohybrids with different morphologies can be synthesized. With the gradual increase of pH, CuOx/ErGO can take on peony-shaped, honeycomb-shaped, rose-shaped, and purple myrtle-shaped. Among them, the electrochemical sensor prepared from honeycomb CuOx/ErGO showed the highest electrocatalytic activity for nitrite oxidation. The sensor has a detection limit as low as 0.072 mM and a detection range of 0.1–100 mM. In addition, the recovery rate of the sensor was between 94.29 and 106.21% when detecting drinking water. The method is highly accurate in detecting nitrite and has good prospects for development and application.

a CV curve of the sensor at a scanning rate of 30 mV s−1 in 5-mM NaNO2. b Nyquist diagram of the sensor in 0.1-M KCl solution containing 5-mM [Fe(CN)6]3−/4−. c Description of making electrochemical sensor based on LSM/rGOx sensor electrode. d Schematic diagram of nitrite oxidation reaction mechanism and XPS results of Mn before and after electrochemistry tests [93]. Copyright 2022, Elsevier

Nitrite sensor based on metal-organic frameworks

Among functional nanomaterials, metal-organic frameworks are the later emerging porous materials. Metal-organic frameworks are important porous crystalline coordination polymers that are self-assembled by various metal ions or metal clusters and organic ligands through coordination bonds. It has the advantages of a large specific surface area, high porosity, and adjustable pore size [94,95,96]. At present, it has been widely used in electrochemical sensing (Fig. 4) [97]. However, the original MOF is chemically less stable because of weak coordination bonds and active groups in the MOF [98]. In addition to this, the original MOF conductivity is lower. This is due to less skeletal overlap between the p-orbital of the ligand and the d-orbital of the metal ions. Performance is not ideal when used for inspection [99]. In order to overcome these disadvantages, they are generally modified. One approach is to combine metal-organic frameworks with other functional materials to form composites, and the other is to pyrolyze MOFs to obtain their derivatives [100]. This section mainly introduces the application of MOF composites and their derivatives in electrochemical sensors. The performance of MOFs in electrochemical sensors is shown in Table 2.

Application of MOF composites in electrochemical sensors [97]. Copyright 2023, RSC Advances

Nitrite sensor based on MOF composite

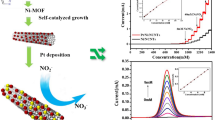

In MOF-based composites, electroactive materials are often used to prepare continuous composites. These materials include metal oxides, carbon-based materials, and conductive polymers. Carbonaceous materials such as graphene, carbon nanofibers, and graphite dots are the preferred substrate materials for the preparation of composite materials. Among many kinds of MOFs, Cu-MOF materials have good electrocatalytic performance due to the REDOX properties of Cu+/Cu2+. For example, Sivakumar et al. prepared copper nanoporous carbon (Cu@NPC) nanoporous structures using a solvothermal method based on a two-step method (Fig. 5d) [119]. However, its poor electrical conductivity has limited the further development of electrochemical sensing. Adding carbon material to Cu-MOF material can overcome this problem. Due to the characteristics of π-π interaction and hydrogen bond interaction between carbon-based materials and MOFs, the conductivity and electron transfer rate can be accelerated in MOFs. For example, copper-functionalized MOF materials were synthesized by compounding copper ions with UiO-67-BPY and subsequently combined copper-chelated UiO-67-BPY MOF with graphene oxide for modification of electrodes [104]. In electrochemical tests, the current of Cu@MOF/ERG (electrochemically reduced graphene)/GCE is large compared to Cu@MOF/GCE, indicating faster electron transfer. The possible reason is that the π-electron conjugation effect of MOFs is amplified due to the chelation of bipyridyl ligands with copper, thereby enhancing the charge conductivity. In addition, the synergistic effect between ERG and MOFs makes the electrode surface more stable, which is beneficial to increase the specific surface area of the electrode and improve its sensitivity in electrochemical detection. The sensor was investigated through the DPV, and its detection range was 10–6000 μM with the detection limit of 1.2 μM for nitrite. In addition, the electrode had excellent reproducibility and stability and had great potential for future sensor platforms. Ambaye et al. synthesized carbon black (CB)/Cu-MOF nanocomposites via ultrasound and used them to modify SPCE (Fig. 5c) [117]. CB/Cu-MOF/SPCE electrodes were compared with SPCE, Cu-MOF/SPCE, and CB/SPCE electrodes by CV method and LSV in order to study the electrochemical response of electrodes to nitrite detection. The results showed that the CB/Cu-MOF/SPCE electrode had the highest current response and was 5 times higher than that of bare SPCE (Fig. 5a, b). The electrode material had a wide detection range (1.0–200.0 μM) and low detection limit (0.084 μM) when used for nitrite sensing. The electrochemical sensing of nitrite showed good reproducibility, repeatability, and stability. In addition, CB/Cu-MOF/SPCE obtained a satisfactory recovery rate (100.90~103.40%) in the detection of nitrite in wastewater samples. The results showed that the sensor has great potential in the detection of nitrite in aquatic substrates. Salagare et al. successfully synthesized a composite material based on carboxyl-functionalized MWCNTs/Co-MOFs by solvothermal method and successfully built a sensor for nitrite determination [118]. Under optimal experimental conditions, the sensor based on this composite exhibits excellent electrocatalytic performance. It has a wide linear range (80–1160 μM) and a low detection limit (18.8 μM). In addition, the sensor obtained satisfactory recoveries for the determination of nitrite in beverage and water samples, which is promising for application.

a CV and b LSV responses of 100-μmol L−1 nitrite at (a) bare-SPCE, (b) Cu-MOF/SPCE, (c) CB/SPCE, and (d) CB-Cu-/SPCE. c Schematic description of the preparation procedures of the CB/Cu-MOF [117]. Copyright 2023, Elsevier. d Schematic representation of Cu-BTC and Cu@NPC [119]. Copyright 2023, Elsevier

In the construction of heterostructures, the hybridization of MOFs and iron-based oxides is more widely used. Compounding MOFs with iron oxides can significantly improve the electrical conductivity and catalytic activity of the materials. For example, Amali et al. constructed an electrochemical sensor platform for nitrite detection using Fe2O3 NPs/Cu-BDC (copper(II)-benzene-1,4-dicarboxylate) MOF-modified screen-printed carbon electrode [103]. The composites were characterized, and the results proved to be successfully synthesized. The Rct of the material was significantly reduced due to the addition of Fe2O3 NPs. The reason is that the synergistic effect of both reduces the interface electron transfer resistance of the composite, which is conducive to improving the electrocatalytic activity of nitrite oxidation. Under the best experimental conditions, the electrode was studied using amperometry, and the results demonstrated that the sensor has a wide detection range and low detection limit, the detection range is 1~2000 μM, and the detection limit is 0.074 μM (S/N = 3). Among the conductive polymers, polypyrrole is widely used because of its good electrical conductivity, ease of polymerization, and low cost [120, 121]. In recent years, conductive polypyrrole and metal-organic skeleton composites have made great progress in the field of electrochemistry. For example, Xu et al. successfully prepared a new PPy/UiO-66 nanocomposite by compounding PPy with UiO-66 by in situ polymerization [122]. In the electrochemical test, the sensors prepared from PPy/UiO-66 composite not only increased the activity of catalytic nitrite but also increased the conductivity. The enhanced performance of the sensor may be due to the good electrical conductivity of the conductive polypyrrole that promotes electron transfer in the nanocomposite and provides a large specific surface area for the adsorption and reaction of NO2−. The large surface area facilitates the catalytic oxidation of analytes. The sensor based on PPy/UiO-6 composite has a detection range of 0.05~1055.5 μM and a detection limit of 0.037 μM. It can be used as a potential nitrite sensing material.

Nitrite sensor based on MOF derivatives

The preparation of MOF derivatives can not only retain the structural properties of parent MOFs but also enhance the electrical conductivity and catalytic activity of the parent body. There is great potential for electrochemical analysis [88]. In recent years, two-dimensional (2D) ZIF derivatives have attracted much attention due to their low diffusion resistance and easily available active centers and have been successfully applied to energy storage and antibiotic removal. Yang et al. first synthesized Co-ZIF-L in rod form and then carbonized it under an Ar atmosphere to obtain CoN-CRs (Fig. 6g) [109]. CoN-CSs were obtained by pyrolysis of the flakes of Co-ZIF-L. The prepared materials were analyzed by a series of techniques, and the results showed that CoN-CRs had stronger nitrite detection performance than CoN-CSs. The possible reason is that CoN-CRs have better surface area and more accessible active sites. Under optimal experimental conditions, the CoN-CRs-based sensors have a wider linear range of 0.5–8000 μM and a detection limit of 0.17 μM. The sensor has been successfully applied to the detection of nitrite in sausage and tap water with satisfactory recoveries. In conclusion, CoN-CRs are a promising sensing material for nitrite detection. Most of the current studies have focused on two-dimensional compounds of MOFs, and fewer studies have been conducted on three-dimensional compounds. Therefore, it is of great significance to study the MOFs of ternary composite systems. Gao et al. prepared the core-shell heterostructures of Cu@C@ZIF-8 composites by lysing Cu-MOFs@ZIF-8 under an Ar atmosphere as an electrochemical sensing platform for nitrite detection [108]. Due to the large specific surface area and high catalytic activity of the Cu@C, ZIF-8 had excellent electrocatalytic activity for nitrite detection. In the electrochemical test, the sensor has a linear response range of 0.1~300.0 μM and a lower detection limit of 0.033 μM. Besides, the sensor has good stability and reproducibility. In addition, the sensor’s good selectivity is mainly attributed to the ZIF-8’s narrow penetration channel. The sensor has been applied to the detection of nitrite in sausages with satisfactory results. In addition, Zhe et al. successfully constructed crystalline-amorphous zinc/cobalt iron porous nanosheets (C-A Zn/Co-Fe PNSs) on carbon cloth (CC) using a multi-step heterogeneous synthesis strategy [115]. By characterizing the composites, the results show that it is composed of interlaced carbon fibers and uniformly distributed hybrid nanosheet. And the special hybrid structure of the nanosheets is conducive to local enrichment of nitrite. Among the prepared materials, C-A Zn/Co-Fe PNSs@CC have the largest oxidation peak current and the lowest charge transfer resistance (Fig. 6a, b, d, e). These advantages show that C-A Zn/Co-Fe PNSs@CC has fast electron transfer ability and more significant conductivity. In addition, sensors based on C-A Zn/Co-Fe PNSs@CC have the advantages of wide linear range (1.25~4001.25 μM), low detection limit (0.44 μM), and high sensitivity (1297.13 μA/(mM cm2)). This study provides a new way for the development of catalysts with excellent electrocatalytic activity and has great application prospects in nitrite detection. Dong et al. prepared Ni-MOF by microwave radiation and converted Cu2+ and Ni2+ ions into Cu/Ni organic skeletons to form Cu-Ni-BTC (1,3,5-benzenetricarboxylic acid, H3BTC) [112]. Then, the Cu-Ni-BTC is calcined to obtain a derivative CuO@NiO. Finally, myoglobin (Mb) is fixed on a sensing interface based on a CuO@NiO and ionic liquid (IL) composite membrane (Fig. 6f). Electrochemical tests showed that Mb maintained biological activity on the surface of CuO@NiO/IL composite membrane. Mb/CuO@NiO/IL has good electrocatalytic activity for nitrite. The nitrite sensing mechanism is shown in (Fig. 6c). Mb/CuO@NiO/IL-CPE (carbon paste electrode)-based sensors have linear ranges of 1.0~1536 μM and 1536~3636 μM for NO2−, with detection limits as low as 0.4 μM.

a CV results of 0.1-M KCl at different electrodes in 5.0-mM [Fe(CN)6]3−/4− solution [115]. Copyright 2023, Elsevier. b EIS results at different electrodes in 5.0-mM [Fe(CN)6]3−/4− solution and 0.1-M KCl [115]. c The mechanism of nitrite sensing [112]. Copyright 2020, Elsevier. d Schematic diagram of C-A Zn/Co-Fe synthesis PNSs@CC [115]. e Schematic diagram of synthesis mechanism [115]. f Schematic diagram of the synthesis method of Mb/CuO@NiO/IL-CPE and the preparation process [112]. g Description of the construction of CoN-CSs and CoN-CRs for nitrite detection [109]. Copyright 2022, Elsevier

Nitrite sensor based on metal materials (excludes non-precious metals)

In recent years, electrochemical sensors based on different chemically modified electrodes have been manufactured. Among them, metal material is a commonly used electrode-modified material. Its surface size is adjustable, and it has good electrocatalytic activity and can be used as a sensor for long-term stability and selectivity at relatively low temperatures [123, 124]. This section focuses on the application of non-precious metal materials as well as composite materials in nitrite sensors. The properties of such nanomaterials are summarized in Table 3.

Nitrite sensor based on metal oxides (excludes non-precious metals)

In recent years, metal oxides prepared by suitable methods have the advantages of a larger specific area, good electrical conductivity, low price, and better stability. Due to these advantages, metal oxides are widely used in the research of nitrite sensors [8, 125]. Puspalak et al. successfully synthesized cobalt oxide nanoparticles for modification of CPE electrodes by precipitation and calcination method using green synthesis method with sugarcane juice as capping agent [154]. The CV method shows that the electrode has a certain response value for different concentrations of nitrite. In Amp detection, sensors based on this electrode have a wide detection range (50–800 μM) and a low detection limit (0.3 μM) in the detection of nitrite. What is more, the sensor can be used to detect nitrite in farmland soil samples, which can alleviate soil pollution to a certain extent and has a greater application prospect. As a kind of multi-purpose metal oxide, TiO2 has been applied in the field of electrochemical sensing because of its advantages of good biocompatibility, high conductivity, and low cost. Salagare et al. successfully prepared TiO2-RGO nanocomposites by compositing TiO2 with RGO and used them to modify a glassy carbon electrode to construct a nitrite sensing platform [155]. The composite material has larger surface area, higher electrical conductivity, and excellent nitrite electrocatalytic activity. By CV and LSV methods, it was found that the oxidation peak of the TiO2-RGO electrode to nitrite was higher than that of other electrodes, and the electrode based on the composite material had a high sensitivity (4.853 μA/μM cm2), a wide linear range (10~2000 μM), and a low detection limit (0.006 μM). In addition, the sensor has obtained a good recovery rate in the determination of NO2− in water and buttermilk samples and has a good application prospect. Among many metal oxide-based nanomaterials, ZnO is recognized as the best nanostructure due to its wide band gap and strong binding energy [159, 160]. However, most of the ZnO-based nanomaterials prepared have the disadvantages of high detection limit and low sensitivity at present. It is well known that the topography of nanomaterials has a great influence on the performance of the sensor, and the large specific surface area can accelerate the electron transfer during the sensing process [161]. Therefore, it is possible to start by changing the morphology of ZnO. For example, Cheng et al. synthesized a unique approximately nearly spherical ZnO nanostructure by solvothermal method [127]. The mixed solvents were synthesized by using polyethylene glycol 400 with water in a volume ratio of 12:1. Unlike other reported transition metal oxide nanoparticles, this approximately spherical ZnO nanostructure had higher uniformity and better dispersion, and no self-aggregation occurs when the particles are small (Fig. 7a, b, c). Comparison of sensing performance of bare GCE and near-spherical ZnO/GCE by CV and CA techniques. The results showed that the current response values of the modified electrodes were significantly higher than those of the bare electrodes. In addition, ZnO-based sensors had a wide linear range, low detection limits, and strong immunity to interference. Moreover, they showed a satisfactory recovery rate in the detection of actual samples. In conclusion, nearly spherical ZnO nanomaterials have a wide range of promising applications for detection and analysis. Besides, nanostructured CeO2 is also widely used in various fields due to its good chemical and physical properties, superior reusability, and stability [162, 163]. However, the nanostructure CeO2 has a wide band gap and relatively low conductivity. Therefore, it needs to be modified when used as a sensing material [164]. For example, Manibalan et al. successfully doped Sn with CeO2 using a simple precipitation synthesis method (Fig. 7d) [125]. The doping of Sn improves charge transfer as well as exposes the CeO2 metal oxide active region, which can improve the electrical conductivity of CeO2 and make CeO2 nanoparticles have better surface properties. Characterized by XRD, FTIR, and TEM techniques, the results showed that the morphology of the catalyst was spherical nanoparticle clumps with a particle size of 8.5 nm. The catalytic performance of Sn-CeO2/GCE was studied by the amperometry method for nitrite. The results showed that the sensor had a detection range of 10 × 10−6~6 × 10−3 M and a detection limit of 16 nM. In short, the sensors have good prospects for application and development.

Nitrite sensor based on metal oxide composite (excludes non-precious metals)

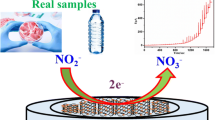

The performance of single metal oxides is inferior to that of metal oxide composites when used as catalysts. Metal oxides can be compounded with carbon materials, conductive polymers, metal-organic frameworks, and other substances. The composite nanomaterials of reduced graphene oxide and Fe3O4 have excellent catalytic and electrical properties and exhibit excellent electrocatalytic activity in electrochemical sensors. Bharath et al. used mechanochemical ball milling to prepare high-quality graphene nanosheets from graphite in the presence of KMnO4 and aspartic acid [149]. After that, Fe3O4/RGO composites were successfully prepared by loading Fe3O4 nanoparticles onto graphene using a simple hydrothermal method. The Fe3O4-RGO nanocomposites were characterized using HRTEM images, and the results demonstrated that good Fe3O4 nanoparticles were distributed on the surface of reduced graphene oxide sheets, with an average particle size of 90 nm. The Fe3O4-RGO nanocomposites were loaded into GCE, and the prepared sensor exhibited good electrocatalytic activity, wide detection range, and low detection limit for nitrite. Radhakrishnan et al. prepared Fe2O3/rGO composites by one-step hydrothermal method [165], since Fe2O3 nanoparticles are well dispersed on the rGO surface and Fe2O3 nanoparticles on both sides of rGO can limit the aggregation of rGO. Therefore, the composite has high specific surface area, good electrical conductivity, and good catalytic performance for the oxidation of nitrite (Fig. 8a–f). Sensor based on Fe2O3/rGO composites has a wide detection range (0.05–780 μM) and a low detection limit (0.015 μM). The sensor can be applied to the environment, food, and other fields. In addition, conductive polymers have excellent electrical conductivity and tunable organic functional groups for intermolecular interactions with different target analytes. To improve the long-term stability of the conductive polymer, inorganic materials can be added and compounded with the conductive polymer. For example, the synergistic effect of conductive polymers and metal oxides can also show greater electrochemical sensing capabilities. Qiu and Qu combined polyaniline with MnO2 (Fig. 8g) [128]. The transition metal oxide manganese dioxide has a unique oxidation behavior at different electrochemical potentials when used as an electrochemical sensing material. And the amine and imine groups in polyaniline contribute to the adsorption of nitrite on the nanocomposites. The morphology of MnCO3, MnO2, polyaniline, and polyaniline-MnO2 nanocomposites was characterized by scanning electron microscopy. The results showed that manganese carbonate was slightly spherical and manganese dioxide was also spherical and larger in size. And in the image of the composite material, block polyaniline can be seen and spherical manganese dioxide was wrapped around the polyaniline. Composite materials were used to modify GCEs to prepare nitrite sensors. The sensor has a low detection limit (CV of 4.38 μM, CA of 1.08 μM) and a wide linear range (CV of 0.1~10 mM, CA of 19.98~732.17 μM). In addition, the organic-inorganic nanocomposite exhibited excellent sensing performance in actual sample analysis.

FE-SEM micrographs of a GO, b rGO, c Fe2O3/rGO, and d Fe2O3. e Nitrite detection scheme using Fe2O3/rGO-modified glassy carbon electrode. f CV behavior of the modified GC electrode in the presence of 1-mM [Fe(CN)6]3−/4− in 0.1-M KCl with a scan rate of 50 mV s−1 and EIS behavior of the modified GC electrode by impedance measurement in the frequency range 100 KHz to 0.1 Hz at a DC potential of 200 mV and an AC potential of ±10 mV in the presence of 1-mM [Fe(CN)6]3−/4− in 0.1-M KCl (curve a, bare GC; curve b, rGO; curve c, Fe2O3/rGO; curve d, Fe2O3-modified electrode) [165]. Copyright 2014, Elsevier. g Preparation of polyaniline-manganese dioxide organic-inorganic nanocomposites for nitrite electrochemical sensing [128]. Copyright 2022, Elsevier

Nitrite sensor based on conductive polymer composite

Conductive polymers have been widely used since their inception in 1977 and are of particular importance in materials science [166, 167]. Conducting polymers are increasingly used in the detection of analytes by voltammetry or amperometry due to their selectivity, sensitivity, and strong adhesion to electrode surfaces [168]. They are an excellent choice for developing and modifying highly sensitive electrochemical sensors. A review of the literature from 2015 to 2020 (Science Direct and Wiley websites) shows that the number of papers on conductive polymer-based sensors has been increasing over the past few years [166]. This section focuses on the application of conductive polymer composites in nitrite sensors, and some of the properties exhibited by the material in modified electrodes are summarized in Table 4.

Among the conducting polymers, polyaniline, polypyrrole, polyacetylene, and their derivatives have received great attention. Li et al. prepared a polythiophene derivative membrane-modified GCE by a one-step electropolymerization method to establish a nitrite sensor [177]. DTT is a molten bicyclic heterocyclic compound with a rigid planar frame and an extended π-conjugated electronic structure. The effect of PolyDTTF on the electrochemical oxidation of nitrite was studied. The results showed that PolyDTTF had good electrical conductivity and enhanced electrocatalytic activity, which can greatly improve the electron transfer kinetics and facilitate the oxidation of nitrite. In addition to this, sensors based on this material had significant detection limits and good detection ranges. The reason may be that PolyDTTF has high electron affinity and synergistic effect, which enables rapid adsorption of analytes to the electrode surface. In conclusion, the preparation method is simple, the film thickness can be controlled, and the sensor can be used for detection in real samples. The sensor offers the possibility of application in the food industry and environmental analysis. Since it is challenging to synthesize a single polymer to meet multiple requirements in the practical application of nitrite detection. Therefore, composites are often used to modify the electrodes. Generally, conducting polymers are often compounded with metal nanoparticles, carbon-based nanomaterials, metal-organic framework chemicals, and other substances. For example, Lu et al. successfully synthesized Co/PPy nanocone composites by compounding metallic cobalt with conductive polymer PPy by electrodeposition technique [23]. Polypyrrole has excellent electrochemical stability and high electrical conductivity compared to other conductive polymers. It can be used as an attachment substrate for various metal nanomaterials. Due to the synergistic effect of nanocomposite components, the composite material has the advantages of high sensitivity, high capacitance, and controllable conductivity. Because its three-dimensional structure provides more active sites for nitrite detection, the composite exhibits good nitrite determination performance in electrochemical studies. Carboxyl graphene is a two-dimensional crystalline carbon material that has received great attention in practice due to its excellent properties. Xiao et al. prepared composites of CG (carboxyl graphene), PPy, and CS (chitosan) nanocomposites [173]. For CS is rich in amino groups, it can attract negatively charged nitrite. The recombination of PPy and CG provides a large specific surface area and numerous active sites. In conclusion, the composite material can improve the selectivity and sensitivity of nitrite determination. In addition, DPV is used for electrochemical performance testing. The results showed that the detection range of the composite-modified sensor was 0.2~1000 μM, and the detection limit was 0.02 μM. The sensor has a promising application in the practical detection of nitrite. Saho et al. synthesized fibrous nanocomposites of reduced graphene oxide, manganese ferrite, and polyaniline (RGO/MnFe2O4/polyaniline) in a two-step process [63]. The introduction of RGO not only prevents the agglomeration of MnFe2O4 nanoparticles and increases the specific surface area but also helps to accelerate the electron transfer process from reduced graphene oxide flakes to MnFe2O4 nanoparticles. In addition, the strong interaction between graphene and polyaniline allows for uninterrupted charge flow during nitrite oxidation (Fig. 9). The electrode modified based on this composite has a wide linear range (0.05~12,000 μM) and a low detection limit (0.015 μM), which can be used for the detection of nitrite in rain water samples.

a Ferrocyanide cyclic voltammetry of electrodes modified with different modifiers in a 0.1-M phosphate buffer at pH 7. b Nyquist diagram recorded by modifying the electrode with different modifiers at an excitation potential of 0.3 V in a 0.1-M phosphate buffer at pH 7. c Equivalent circuit used for the fitting of the impedance plot. d The synthesis procedure adopted to synthesize the nanocomposite material [63]. Copyright 2020, Elsevier

Conclusion and outlook

This paper reviews the research progress and application status of nitrite electrochemical sensors based on four nanomaterials. The characteristics and advantages of carbon nanomaterials (graphene, carbon nanotubes), metal-organic frameworks, non-precious metals, and conducting polymers are systematically introduced in nitrite electrochemical sensors. These materials have been extensively studied for their unique and fascinating properties (e.g., graphene has large specific surface area and inexpensive and readily available raw materials, metal-organic frameworks with high porosity and tunable pore size). However, individual materials also have some disadvantages, which leads to the performance in nitrite detection often inferior to that of composite materials. Many studies have shown that the synergistic effect of composites not only improves stability and accelerates the electron transfer rate but also provides more active sites in the detection of nitrite. Although the field has achieved great results over the course of decades of development. However, further research on electrochemical nitrite sensors still faces many challenges. The morphology, purity, and dispersion of carbon nanomaterials have great influence on the electrocatalytic performance. It is necessary to seek new synthesis methods or consider three-dimensional structures. In addition, the carbon nanomaterials will peel off the electrode surface, which will affect the stability of the sensor and limit its further development in the long-term detection of nitrite. Therefore, it is necessary to study more robust fixing methods. Due to the poor structural stability and conductivity of MOF materials, the sensor is not ideal for nitrite detection. Developing functional MOF composites remains a challenge. In addition, the synthesis process of MOF composites that has been studied is too complex to achieve large-scale production, so it is still necessary to explore new synthesis paths. As far as metal materials are concerned, the electrocatalytic performance of precious metals is better than that of non-precious metals, so it is still a difficult problem to find non-precious metals that can replace precious metals. At present, there are few electrochemical methods on the combination of conductive polymers with carbon nanomaterials and metal materials. So it can be considered to combine conductive polymers with other materials to further improve the electrocatalytic performance. In general, the first is the preparation method; the preparation of nanomaterials involves precise and targeted control of the shape and size of the nanomaterials in most cases. Different preparation methods often affect the performance of the catalyst size. In addition to this, most sensors are manufactured on rigid substrates, resulting in a lack of flexibility in the sensors. Second, when designing a catalyst with excellent performance, it is necessary to explain the reaction process and mechanism on the catalyst. In principle, the catalytic performance of a catalyst is determined by its electronic structure, while the true catalytic active site and the exact reaction mechanism of some materials are still unclear. Finally, in most cases, nitrite electrochemical sensors have the disadvantages of high cost of large-scale preparation, time-consuming synthesis process, and threats to humans and the environment of nanomaterials. These disadvantages limit the practical application of the sensor.

For future research on nitrite electrochemical sensors, the following aspects can be considered. First, research should focus on new synthetic methods to change the structure and composition of catalysts in order to adjust their electronic structure. And new nanomaterials can be combined with good conductive polymers. In addition to this, low-cost, biocompatible materials and more environmentally friendly synthesis methods and equipment should be used. Second, the reaction mechanism of nitrite sensors is further explored, and the true catalytic active sites of various materials are clarified. This results in higher sensitivity and better selectivity of nitrite electrochemical sensors. Finally, technologies such as screen printing, ARM microcontrollers, and mobile intelligence can be combined to build portable NO2− electrochemical sensors to achieve remote real-time measurement of nitrite content. And existing nitrite sensors can be integrated into nutrient management programs in agroecosystems to facilitate rapid and accurate detection of spatial and temporal changes in nitrite levels in soil.

References

Dai L, Chang DW, Baek JB et al (2012) Carbon nanomaterials for advanced energy conversion and storage. Small 8(8):1130–1166. https://doi.org/10.1002/smll.201101594

Li D, Wang T, Li Z et al (2019) Application of graphene-based materials for detection of nitrate and nitrite in water-a review. Sensors (Basel) 20(1):54. https://doi.org/10.3390/s20010054

Zhang J, Zhang T, Yang J-H (2022) Precious metal nanomaterial-modified electrochemical sensors for nitrite detection. Ionics 28(5):2041–2064. https://doi.org/10.1007/s11581-022-04509-3

Amali RKA, Lim HN, Ibrahim I et al (2021) Significance of nanomaterials in electrochemical sensors for nitrate detection: a review. Trends Environ Anal Chem 31:e00135. https://doi.org/10.1016/j.teac.2021.e00135

Donnelly-Greenan EL, Nevins HM, Harvey JT (2019) Entangled seabird and marine mammal reports from citizen science surveys from coastal California (1997-2017). Mar Pollut Bull 149:110557. https://doi.org/10.1016/j.marpolbul.2019.110557

Li X, Ping J, Ying Y (2019) Recent developments in carbon nanomaterial-enabled electrochemical sensors for nitrite detection. TrAC Trends Anal Chem 113:1–12. https://doi.org/10.1016/j.trac.2019.01.008

Hatta M, Ruzicka JJ, Measures CI (2020) The performance of a new linear light path flow cell is compared with a liquid core waveguide and the linear cell is used for spectrophotometric determination of nitrite in sea water at nanomolar concentrations. Talanta 219:121240. https://doi.org/10.1016/j.talanta.2020.121240

Mao Y, Bao Y, Han D-X et al (2018) Research progress on nitrite electrochemical sensor. Chin J Anal Chem 46(2):147–155. https://doi.org/10.1016/s1872-2040(17)61066-1

Wu J, Wang X, Lin Y et al (2016) Peroxynitrous-acid-induced chemiluminescence detection of nitrite based on microfluidic chip. Talanta 154:73–79. https://doi.org/10.1016/j.talanta.2016.03.062

Kodamatani H, Yamazaki S, Saito K et al (2009) Selective determination method for measurement of nitrite and nitrate in water samples using high-performance liquid chromatography with post-column photochemical reaction and chemiluminescence detection. J Chromatogr A 1216(15):3163–3167. https://doi.org/10.1016/j.chroma.2009.01.096

Chamandust S, Mehrasebi MR, Kamali K et al (2016) Simultaneous determination of nitrite and nitrate in milk samples by ion chromatography method and estimation of dietary intake. Int J Food Prop 19(9):1983–1993. https://doi.org/10.1080/10942912.2015.1091007

Fu Y, Bian C, Kuang J et al (2015) A palladium-tin modified microband electrode array for nitrate determination. Sensors (Basel) 15(9):23249–23261. https://doi.org/10.3390/s150923249

Kalaycıoğlu Z, Erim FB (2015) Simultaneous determination of nitrate and nitrite in fish products with improved sensitivity by sample stacking-capillary electrophoresis. Food Anal Methods 9(3):706–711. https://doi.org/10.1007/s12161-015-0241-4

Xu Z, Shi W, Yang C et al (2020) A colorimetric fluorescent probe for rapid and specific detection of nitrite. Luminescence 35(2):299–304. https://doi.org/10.1002/bio.3727

Bagheri H, Hajian A, Rezaei M et al (2017) Composite of Cu metal nanoparticles-multiwall carbon nanotubes-reduced graphene oxide as a novel and high performance platform of the electrochemical sensor for simultaneous determination of nitrite and nitrate. J Hazard Mater 324(Pt B):762–772. https://doi.org/10.1016/j.jhazmat.2016.11.055

Yang J-H, Yang H, Liu S et al (2015) Microwave-assisted synthesis graphite-supported Pd nanoparticles for detection of nitrite. Sensors Actuators B Chem 220:652–658. https://doi.org/10.1016/j.snb.2015.05.118

Kanoun O, Lazarevic-Pasti T, Pasti I et al (2021) A review of nanocomposite-modified electrochemical sensors for water quality monitoring. Sensors (Basel) 21(12):4131. https://doi.org/10.3390/s21124131

Rassaei L, Marken F, Sillanpää M et al (2011) Nanoparticles in electrochemical sensors for environmental monitoring. TrAC Trends Anal Chem 30(11):1704–1715. https://doi.org/10.1016/j.trac.2011.05.009

Li T, Shang D, Gao S et al (2022) Two-dimensional material-based electrochemical sensors/biosensors for food safety and biomolecular detection. Biosensors (Basel) 12(5):314. https://doi.org/10.3390/bios12050314

Dou B, Yan J, Chen Q et al (2021) Development of an innovative nitrite sensing platform based on the construction of carbon-layer-coated In2O3 porous tubes. Sensors Actuators B Chem 328:129082. https://doi.org/10.1016/j.snb.2020.129082

Li G, Xia Y, Tian Y et al (2019) Review—recent developments on graphene-based electrochemical sensors toward nitrite. J Electrochem Soc 166(12):B881–B895. https://doi.org/10.1149/2.0171912jes

Cheng Z, Song H, Zhang X et al (2022) Enhanced non-enzyme nitrite electrochemical sensing property based on stir bar-shaped ZnO nanorods decorated with nitrogen-doped reduced graphene oxide. Sensors Actuators B Chem 355:131313. https://doi.org/10.1016/j.snb.2021.131313

Lu H, Wang H, Yang L et al (2021) A sensitive electrochemical sensor based on metal cobalt wrapped conducting polymer polypyrrole nanocone arrays for the assay of nitrite. Mikrochim Acta 189(1):26. https://doi.org/10.1007/s00604-021-05131-2

Madasamy T, Pandiaraj M, Balamurugan M et al (2014) Copper, zinc superoxide dismutase and nitrate reductase coimmobilized bienzymatic biosensor for the simultaneous determination of nitrite and nitrate. Biosens Bioelectron 52:209–215. https://doi.org/10.1016/j.bios.2013.08.036

Salagare S, Adarakatti PS, Venkataramanappa Y et al (2021) Electrochemical nitrite sensing employing palladium oxide–reduced graphene oxide (PdO-RGO) nanocomposites: application to food and environmental samples. Ionics 28(2):927–938. https://doi.org/10.1007/s11581-021-04355-9

Salagare S, Adarakatti PS, Yarradoddappa V (2021) Facile synthesis of silver nanoparticle-decorated zinc oxide nanocomposite-based pencil graphite electrode for selective electrochemical determination of nitrite. Carbon Letters 31(6):1273–1286. https://doi.org/10.1007/s42823-021-00251-4

Umapathi R, Venkateswara Raju C, Majid Ghoreishian S et al (2022) Recent advances in the use of graphitic carbon nitride-based composites for the electrochemical detection of hazardous contaminants. Coord Chem Rev 470:214708. https://doi.org/10.1016/j.ccr.2022.214708

Moyo M, Mudarikwa P, Shumba M et al (2017) Voltammetric sensing of nitrite in aqueous solution using titanium dioxide anchored multiwalled carbon nanotubes. Ionics 24(8):2489–2498. https://doi.org/10.1007/s11581-017-2358-5

Liu H-Y, Wen J-J, Huang Z-H et al (2019) Prussian blue analogue of copper-cobalt decorated with multi-walled carbon nanotubes based electrochemical sensor for sensitive determination of nitrite in food samples. Chin J Anal Chem 47(6):e19066–e19072. https://doi.org/10.1016/s1872-2040(19)61168-0

Zhu D, Zhen Q, Xin J et al (2020) A free-standing and flexible phosphorus/nitrogen dual-doped three-dimensional reticular porous carbon frameworks encapsulated cobalt phosphide with superior performance for nitrite detection in drinking water and sausage samples. Sensors Actuators B Chem 321:128541. https://doi.org/10.1016/j.snb.2020.128541

Xian H, Wang P, Zhou Y et al (2010) Electrochemical determination of nitrite via covalent immobilization of a single-walled carbon nanotubes and single stranded deoxyribonucleic acid nanocomposite on a glassy carbon electrode. Microchim Acta 171(1-2):63–69. https://doi.org/10.1007/s00604-010-0404-3

Yang S, Xia B, Zeng X et al (2010) Fabrication of DNA functionalized carbon nanotubes/Cu2+ complex by one-step electrodeposition and its sensitive determination of nitrite. Anal Chim Acta 667(1-2):57–62. https://doi.org/10.1016/j.aca.2010.03.063

Salhi O, Ez-Zine T, Oularbi L et al (2022) Electrochemical sensing of nitrite ions using modified electrode by poly 1,8-diaminonaphthalene/functionalized multi-walled carbon nanotubes. Front Chem 10:870393. https://doi.org/10.3389/fchem.2022.870393

Atta NF, Galal A, Ahmed YM et al (2021) Development of an innovative nitrite sensing platform based on the construction of an electrochemical composite sensor of polymer coated CNTs and decorated with magnetite nanoparticles. Electroanalysis 33(6):1510–1519. https://doi.org/10.1002/elan.202060598

Rashed MA, Faisal M, Alsaiari M et al (2021) MWCNT-doped polypyrrole-carbon black modified glassy carbon electrode for efficient electrochemical sensing of nitrite ions. Electrocatalysis 12(6):650–666. https://doi.org/10.1007/s12678-021-00675-6

Chen Y, Waterhouse GIN, Qiao X et al (2022) Sensitive analytical detection of nitrite using an electrochemical sensor with STAB-functionalized Nb2C@MWCNTs for signal amplification. Food Chem 372:131356. https://doi.org/10.1016/j.foodchem.2021.131356

Lu S, Hummel M, Kang S et al (2020) Selective voltammetric determination of nitrite using cobalt phthalocyanine modified on multiwalled carbon nanotubes. J Electrochem Soc 167(4):046515. https://doi.org/10.1149/1945-7111/ab7982

Mounesh and K. R. Venugopala Reddy (2020) Sensitive and reliable electrochemical detection of nitrite and H2O2 embellish-CoPc coupled with appliance of composite MWCNTs. Anal Chim Acta 1108:98–107. https://doi.org/10.1016/j.aca.2020.02.057

Annalakshmi M, Balasubramanian P, Chen SM et al (2018) Amperometric sensing of nitrite at nanomolar concentrations by using carboxylated multiwalled carbon nanotubes modified with titanium nitride nanoparticles. Mikrochim Acta 186(1):8. https://doi.org/10.1007/s00604-018-3136-4

Rębiś T, Falkowski M, Kryjewski M et al (2019) Single-walled carbon nanotube/sulfanyl porphyrazine hybrids deposited on glassy carbon electrode for sensitive determination of nitrites. Dyes Pigm 171:107660. https://doi.org/10.1016/j.dyepig.2019.107660

Sudha V, Senthil Kumar SM, Thangamuthu R (2018) Simultaneous electrochemical sensing of sulphite and nitrite on acid-functionalized multi-walled carbon nanotubes modified electrodes. J Alloys Compd 749:990–999. https://doi.org/10.1016/j.jallcom.2018.03.287

Arulraj AD, Sundaram E, Vasantha VS et al (2018) Polypyrrole with a functionalized multi-walled carbon nanotube hybrid nanocomposite: a new and efficient nitrite sensor. New J Chem 42(5):3748–3757. https://doi.org/10.1039/c7nj04130f

Lin XR, Zheng YF, Song XC (2018) Fe2O3/MWCNTs nanocomposite decorated glassy carbon electrode for the determination of nitrite. Bull Mater Sci 41(2):35. https://doi.org/10.1007/s12034-018-1553-y

Zhu F, Shi H, Wang C et al (2021) Disposable carbon electrodes modified by a bismuth selenide/carboxylic multiwalled carbon nanotubes composite for the effective electrocatalytic analysis of nitrite. Sensors Actuators B Chem 332:129454. https://doi.org/10.1016/j.snb.2021.129454

Brahem A, Al-Hamry A, Gross MA et al (2022) Stability enhancement of laser-scribed reduced graphene oxide electrodes functionalized by iron oxide/reduced graphene oxide nanocomposites for nitrite sensors. J Compos Sci 6(8):221. https://doi.org/10.3390/jcs6080221

Paisanpisuttisin A, Poonwattanapong P, Rakthabut P et al (2022) Sensitive electrochemical sensor based on nickel/PDDA/reduced graphene oxide modified screen-printed carbon electrode for nitrite detection. RSC Adv 12(45):29491–29502. https://doi.org/10.1039/d2ra03918d

Yuan X, Chen J, Ling Y et al (2022) A facile and efficient nitrite electrochemical sensor based on N, O co-doped porous graphene film. Microchem J 178:107361. https://doi.org/10.1016/j.microc.2022.107361

Sookhakian M, Mat Teridi MA, Tong GB et al (2021) Reduced graphene oxide/copper nanoparticle composites as electrochemical sensor materials for nitrate detection. ACS Appl Nano Mater 4(11):12737–12744. https://doi.org/10.1021/acsanm.1c03351

Suma BP, Pandurangappa M (2019) Graphene oxide/copper terephthalate composite as a sensing platform for nitrite quantification and its application to environmental samples. J Solid State Electrochem 24(1):69–79. https://doi.org/10.1007/s10008-019-04454-8

Tajiki A, Abdouss M, Sadjadi S et al (2020) Voltammetric detection of nitrite anions employing imidazole functionalized reduced graphene oxide as an electrocatalyst. Electroanalysis 32(10):2290–2298. https://doi.org/10.1002/elan.202060187

Madhuvilakku R, Alagar S, Mariappan R et al (2020) Glassy carbon electrodes modified with reduced graphene oxide-MoS2-poly (3, 4-ethylene dioxythiophene) nanocomposites for the non-enzymatic detection of nitrite in water and milk. Anal Chim Acta 1093:93–105. https://doi.org/10.1016/j.aca.2019.09.043

Saranya S, Deepa PN (2020) Evolution of novel rGO/ZrHCF composite and utility in electrocatalysis towards nanomolar detection of sodium nitrite and ferulic acid. J Mater Sci Mater Electron 31(21):18923–18936. https://doi.org/10.1007/s10854-020-04430-3

Rashed MA, Faisal M, Harraz FA et al (2020) rGO/ZnO/Nafion nanocomposite as highly sensitive and selective amperometric sensor for detecting nitrite ions (NO2−). J Taiwan Inst Chem Eng 112:345–356. https://doi.org/10.1016/j.jtice.2020.05.015

Ahammad AJS, Alam MK, Islam T et al (2020) Poly (brilliant cresyl blue)-reduced graphene oxide modified activated GCE for nitrite detection: analyzing the synergistic interactions through experimental and computational study. Electrochim Acta 349:136375. https://doi.org/10.1016/j.electacta.2020.136375

Zhao Z, Zhang J, Wang W et al (2019) Synthesis and electrochemical properties of Co3O4-rGO/CNTs composites towards highly sensitive nitrite detection. Appl Surf Sci 485:274–282. https://doi.org/10.1016/j.apsusc.2019.04.202

Li Y, Cheng C, Yang Y et al (2019) A novel electrochemical sensor based on CuO/H-C3N4/rGO nanocomposite for efficient electrochemical sensing nitrite. J Alloys Compd 798:764–772. https://doi.org/10.1016/j.jallcom.2019.05.137

Rostami M, Abdi G, Kazemi SH et al (2019) Nanocomposite of magnetic nanoparticles/graphene oxide decorated with acetic acid moieties on glassy carbon electrode: a facile method to detect nitrite concentration. J Electroanal Chem 847:113239. https://doi.org/10.1016/j.jelechem.2019.113239

Li L, Liu H, Li B et al (2019) Design and construction of polyaniline/reduced graphene oxide three-dimensional dendritic architecture on interdigital electrode for sensitive detection nitrite. Macromol Res 28(5):455–464. https://doi.org/10.1007/s13233-020-8062-8

Suma BP, Adarakatti PS, Kempahanumakkagari SK et al (2019) A new polyoxometalate/rGO/Pani composite modified electrode for electrochemical sensing of nitrite and its application to food and environmental samples. Mater Chem Phys 229:269–278. https://doi.org/10.1016/j.matchemphys.2019.02.087

Zhang J, Zhang Y, Zhou J et al (2018) Construction of a highly sensitive non-enzymatic nitrite sensor using electrochemically reduced holey graphene. Anal Chim Acta 1043:28–34. https://doi.org/10.1016/j.aca.2018.08.045

Hu J, Zhang J, Zhao Z et al (2017) Synthesis and electrochemical properties of rGO-MoS2 heterostructures for highly sensitive nitrite detection. Ionics 24(2):577–587. https://doi.org/10.1007/s11581-017-2202-y

Wang Y, Cao W, Yin C et al (2018) Nonenzymatic amperometric sensor for nitrite detection based on a nanocomposite consisting of nickel hydroxide and reduced graphene oxide. Electroanalysis 30(12):2916–2924. https://doi.org/10.1002/elan.201800627

Sahoo S, Sahoo PK, Sharma A et al (2020) Interfacial polymerized RGO/MnFe2O4/polyaniline fibrous nanocomposite supported glassy carbon electrode for selective and ultrasensitive detection of nitrite. Sensors Actuators B Chem 309:127763. https://doi.org/10.1016/j.snb.2020.127763

Yue X, Luo X, Zhou Z et al (2019) pH-regulated synthesis of CuOx/ERGO nanohybrids with tunable electrocatalytic oxidation activity towards nitrite sensing. New J Chem 43(12):4947–4958. https://doi.org/10.1039/c9nj00474b

Wang S, Liu M, He S et al (2018) Protonated carbon nitride induced hierarchically ordered Fe2O3/H C3N4/rGO architecture with enhanced electrochemical sensing of nitrite. Sensors Actuators B Chem 260:490–498. https://doi.org/10.1016/j.snb.2018.01.073

Zhang G, Pan P, Yang Z et al (2020) Rapid synthesis of cypress-like CuO nanomaterials and CuO/MWCNTs composites for ultra-high sensitivity electrochemical sensing of nitrite. Microchem J 159:105439. https://doi.org/10.1016/j.microc.2020.105439

Govindasamy M, Wang SF, Huang CH et al (2022) Colloidal synthesis of perovskite-type lanthanum aluminate incorporated graphene oxide composites: electrochemical detection of nitrite in meat extract and drinking water. Microchim Acta 189(5):210. https://doi.org/10.1007/s00604-022-05296-4

Yılmaz-Alhan B, Çelik G, Oguzhan Caglayan M et al (2022) Determination of nitrite on manganese dioxide doped reduced graphene oxide modified glassy carbon by differential pulse voltammetry. Chem Pap 76(8):4919–4925. https://doi.org/10.1007/s11696-022-02218-9

Yue X, Li Y, Li M et al (2021) Three-dimensional porous carbon derived from different organic acid salts for application in electrochemical sensing. RSC Adv 11(50):31834–31844. https://doi.org/10.1039/d1ra05105a

Liu Q, Zhang B, Du S et al (2020) Porous hollow carbon nanospheres as a novel sensing platform for sensitive detection of nitrite in pickle directly. J Appl Electrochem 51(2):295–306. https://doi.org/10.1007/s10800-020-01501-5

Alsaiari M, Saleem A, Alsaiari R et al (2022) SiO2/Al2O3/C grafted 3-n propylpyridinium silsesquioxane chloride-based non-enzymatic electrochemical sensor for determination of carcinogenic nitrite in food products. Food Chem 369:130970. https://doi.org/10.1016/j.foodchem.2021.130970

Dong X, Xie S, Zhu J et al (2021) Mesoporous CoOx/C nanocomposites functionalized electrochemical sensor for rapid and continuous detection of nitrite. Coatings 11(5):596. https://doi.org/10.3390/coatings11050596

Zhang Y, Zhu W, Wang Y et al (2019) High-performance electrochemical nitrite sensing enabled using commercial carbon fiber cloth. Inorg Chem Front 6(6):1501–1506. https://doi.org/10.1039/c9qi00255c

Sivakumar M, Sakthivel M, Chen S-M et al (2017) An electrochemical selective detection of nitrite sensor for polyaniline doped graphene oxide modified electrode. Int J Electrochem Sci 12(6):4835–4846. https://doi.org/10.20964/2017.06.24

Salagare S, Adarakatti PS, Almalki ASA et al (2022) An efficient electrochemical sensor for nitrite based on a mesoporous nickel cobaltite-reduced graphene oxide (NiCo-RGO) nanocomposite. Mater Res Innov 27(4):212–222. https://doi.org/10.1080/14328917.2022.2113678

Gligor D, Walcarius A (2014) Glassy carbon electrode modified with a film of poly(toluidine blue O) and carbon nanotubes for nitrite detection. J Solid State Electrochem 18(6):1519–1528. https://doi.org/10.1007/s10008-013-2365-z

Zhang D, Ma H, Chen Y et al (2013) Amperometric detection of nitrite based on Dawson-type vanodotungstophosphate and carbon nanotubes. Anal Chim Acta 792:35–44. https://doi.org/10.1016/j.aca.2013.07.010

Zhou L, Wang J-P, Gai L et al (2013) An amperometric sensor based on ionic liquid and carbon nanotube modified composite electrode for the determination of nitrite in milk. Sensors Actuators B Chem 181:65–70. https://doi.org/10.1016/j.snb.2013.02.041

Moheimanian N, Raoof JB, Safavi A et al (2013) Nitrite electrochemical sensor for food analysis based on direct immobilization of hemoglobin on multi-walled carbon nanotube ionic liquid electrode. J Iran Chem Soc 11(4):1217–1222. https://doi.org/10.1007/s13738-013-0391-5

Majidi MR, Naseri A, Panahian S et al (2013) Electrocatalytic oxidation and determination of nitrite at multi-walled carbon nanotubes modified carbon ceramic electrode. J Chin Chem Soc 60(3):314–320. https://doi.org/10.1002/jccs.201200365

Mani V, Wu T-Y, Chen S-M (2013) Iron nanoparticles decorated graphene-multiwalled carbon nanotubes nanocomposite-modified glassy carbon electrode for the sensitive determination of nitrite. J Solid State Electrochem 18(4):1015–1023. https://doi.org/10.1007/s10008-013-2349-z

Xu F, Deng M, Liu Y et al (2014) Facile preparation of poly (diallyldimethylammonium chloride) modified reduced graphene oxide for sensitive detection of nitrite. Electrochem Commun 47:33–36. https://doi.org/10.1016/j.elecom.2014.07.016

Liu M, Wang L, Meng Y et al (2014) (4-Ferrocenylethyne) phenylamine functionalized graphene oxide modified electrode for sensitive nitrite sensing. Electrochim Acta 116:504–511. https://doi.org/10.1016/j.electacta.2013.11.060

Gholivand MB, Jalalvand AR, Goicoechea HC (2014) Computer-assisted electrochemical fabrication of a highly selective and sensitive amperometric nitrite sensor based on surface decoration of electrochemically reduced graphene oxide nanosheets with CoNi bimetallic alloy nanoparticles. Mater Sci Eng C 40:109–120. https://doi.org/10.1016/j.msec.2014.03.044

Zhang D, Fang Y, Miao Z et al (2013) Direct electrodeposion of reduced graphene oxide and dendritic copper nanoclusters on glassy carbon electrode for electrochemical detection of nitrite. Electrochim Acta 107:656–663. https://doi.org/10.1016/j.electacta.2013.06.015

Yang YJ, Li W (2014) CTAB functionalized graphene oxide/multiwalled carbon nanotube composite modified electrode for the simultaneous determination of ascorbic acid, dopamine, uric acid and nitrite. Biosens Bioelectron 56:300–306. https://doi.org/10.1016/j.bios.2014.01.037

Wang J, Yin G, Shao Y et al (2008) Electrochemical durability investigation of single-walled and multi-walled carbon nanotubes under potentiostatic conditions. J Power Sources 176(1):128–131. https://doi.org/10.1016/j.jpowsour.2007.10.057

Yang Z, Zhong Y, Zhou X et al (2022) Metal-organic framework-based sensors for nitrite detection: a short review. J Food Meas Charact 16(2):1572–1582. https://doi.org/10.1007/s11694-021-01270-5

Saraf M, Rajak R, Mobin SM (2016) A fascinating multitasking Cu-MOF/rGO hybrid for high performance supercapacitors and highly sensitive and selective electrochemical nitrite sensors. J Mater Chem A 4(42):16432–16445. https://doi.org/10.1039/c6ta06470a

Ping J, Zhou Y, Wu Y et al (2015) Recent advances in aptasensors based on graphene and graphene-like nanomaterials. Biosens Bioelectron 64:373–385. https://doi.org/10.1016/j.bios.2014.08.090

Mehmeti E, Stankovic DM, Hajrizi A et al (2016) The use of graphene nanoribbons as efficient electrochemical sensing material for nitrite determination. Talanta 159:34–39. https://doi.org/10.1016/j.talanta.2016.05.079

Liu Z, Manikandan VS, Chen A (2019) Recent advances in nanomaterial-based electrochemical sensing of nitric oxide and nitrite for biomedical and food research. Curr Opin Electrochem 16:127–133. https://doi.org/10.1016/j.coelec.2019.05.013

Cheng C, Zhang Y, Chen H et al (2023) Reduced graphene oxide-wrapped La(0.8)Sr(0.2)MnO(3) microspheres sensing electrode for highly sensitive nitrite detection. Talanta 260:124644. https://doi.org/10.1016/j.talanta.2023.124644

Magri A, Petriccione M, Gutierrez TJ (2021) Metal-organic frameworks for food applications: a review. Food Chem 354:129533. https://doi.org/10.1016/j.foodchem.2021.129533

Wang C, Liu D, Xie Z et al (2014) Functional metal-organic frameworks via ligand doping: influences of ligand charge and steric demand. Inorg Chem 53(3):1331–1338. https://doi.org/10.1021/ic402015q

Lu W, Wei Z, Gu ZY et al (2014) Tuning the structure and function of metal-organic frameworks via linker design. Chem Soc Rev 43(16):5561–5593. https://doi.org/10.1039/c4cs00003j

Zhang W, Li X, Ding X et al (2023) Progress and opportunities for metal-organic framework composites in electrochemical sensors. RSC Adv 13(16):10800–10817. https://doi.org/10.1039/d3ra00966a

Zou D, Liu D (2019) Understanding the modifications and applications of highly stable porous frameworks via UiO-66. Mater Today Chem 12:139–165. https://doi.org/10.1016/j.mtchem.2018.12.004

Feng L, Hou HB, Zhou H (2020) UiO-66 derivatives and their composite membranes for effective proton conduction. Dalton Trans 49(47):17130–17139. https://doi.org/10.1039/d0dt03051a

Yao M-S, Li W-H, Xu G (2021) Metal–organic frameworks and their derivatives for electrically-transduced gas sensors. Coord Chem Rev 426:213479. https://doi.org/10.1016/j.ccr.2020.213479

Cheng D, Li X, Qiu Y et al (2017) A simple modified electrode based on MIL-53(Fe) for the highly sensitive detection of hydrogen peroxide and nitrite. Anal Methods 9(13):2082–2088. https://doi.org/10.1039/c6ay03164a

Zhao Y, Jiang L, Shangguan L et al (2018) Synthesis of porphyrin-based two-dimensional metal–organic framework nanodisk with small size and few layers. J Mater Chem A 6(6):2828–2833. https://doi.org/10.1039/c7ta07911g

Amali RKA, Lim HN, Ibrahim I et al (2022) A copper-based metal-organic framework decorated with electrodeposited Fe(2)O(3) nanoparticles for electrochemical nitrite sensing. Mikrochim Acta 189(9):356. https://doi.org/10.1007/s00604-022-05450-y

Zhang H-J, Chen W-Y, Zou X et al (2022) A novel copper-functionalized MOF modified composite electrode for high-efficiency detection of nitrite and histamine. J Electrochem Soc 169(7):077511. https://doi.org/10.1149/1945-7111/ac8078