Abstract

A robust electrochemical sensing platform based on graphene oxide-copper terephthalate (GO/Cu-tpa) composite has been fabricated. The prepared composite was characterized through FTIR, XRD, SEM, and EDS techniques. The electrochemical characterization of the composite was studied after immobilizing the composite material as a thin film on the glassy carbon electrode through voltammetry techniques. The fabricated electrode exhibited an excellent electrocatalytic activity in the oxidation of nitrite. The sensor showed a linear response in the concentration range 5 – 625 μM with a detection limit of 0.3 μM and sensitivity of 0.86 ± 0.06 μA μM−1 cm−2. The electrochemical sensor was validated by measuring the trace level nitrite from water samples, and the results are in good agreement with the standard protocol.

Schematic representation of GO/Cu-terepthalate composite preparation and fabrication of nitrite sensor

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metal organic frameworks (MOFs) are the new emerging class of highly porous crystalline materials fabricated using metal salt sources and organic linker molecules. These materials have the advantageous properties of high specific surface area, high porosity, and good stability [1, 2]. These properties have opened the new pathway for many applications concerned with gas storage and separation, catalysis, energy storage and conversion, biological applications, and electrochemical sensors [3, 4].

Among various MOFs reported, very few have been utilized in the electroanalysis [5, 6]. The electrochemistry of MOFs is primarily based on the electroactive properties of metal ions in the framework and also the polyfunctional organic linker molecules [7]. However, the applications are still limited because of weaker properties of MOFs to suit in sensing mechanism. In order to overcome these limitations, MOFs based composite modified electrodes have been explored in studying the various electrochemical reactions at the interface [8, 9]. Among the various substrates used, carbon has been used as a versatile substrate material in the preparation of MOF composites with diversified applications. The facile charge transfer inside the framework can be accelerated by combining it with carbon substrates like carbon paste, CNTs, and graphene. This combination has the advantages of π-π interaction and also hydrogen bonding between carbon substrate, metal ions, and organic linker molecules present in MOFs. This property facilitates the increased conductivity of the composite material to suit its utility as an electrocatalyst in various electrochemical applications [10].

Nitrite species being considered as a carcinogenic in nature are added as preservatives by food industries to store food products and to keep microbial growth at bay [11, 12]. These added nitrites can expend toxic effects on human health [13]. Hence, it is quit essential to develop a simple strategy for its quantification from environment for monitoring purpose.

Existing conventional methods for nitrite determination, like spectrophotometric method, chromatographic method, flow-injection analysis, chemiluminescence, and electrophoretic methods are time consuming, require skilled personnel to operate the instrument as well as use of expensive reagents [14]. However the electrochemical methods have the advantages of rapid, simple, easy, and cost effective means over existing conventional methods [15]. In electrochemical analysis, the development of chemically modified electrodes is an important criterion to achieve selectivity and sensitivity in target analyte measurement [16]. A range of protocols have been published in recent years for nitrite measurement [17,18,19,20,21,22,23,24,25,26,27,28]. Various MOFs and its composites have been used as modifier molecules in fabricating chemically modified electrodes in the sensing of lead [29], ascorbic acid [30], hydrazine [31], nitrobenzene [32], acetaminophen, and dopamine [20].

Various MOF based composites [33,34,35,36], such as Au-ZnMOF [32], MOF-525/GNR [37], Au/CuMOF/CPE [38], Cu MOF/rgo [39], and Ag@MOF-5 [40] have been reported for nitrite measurement. Although very few reports are available for the Cu-MOF-based composite materials for nitrite detection [25], it is still necessary to explore new electrocatalyst based on MOFs because the above reported sensor materials require time consuming synthetic procedures, high temperatures, and expensive reagent–containing noble metals. To overcome these limitations, we have reported a simple protocol to prepare a Graphene oxide/Cu-terephthalate hybrid composite (GO/Cu-tpa) and its utility as an electrocatalyst in the quantification of nitrite at trace level.

Experimental section

Chemicals and reagents

Analar grade chemicals were used throughout the experiment without any further purification. Terephthalic acid was purchased from s.d. fine-chem limited, Mumbai, India. Cupric nitrate, dimethyl formamide (DMF), triethyl amine, and graphite power were procured from Sigma-Aldrich, India. Sodium nitrite, disodium hydrogen phosphate, sodium hydroxide, hydrochloric acid, chloroform, and ethyl alcohol were purchased from Merck specialties Pvt. Ltd., India. All the solutions were prepared using double distilled water.

Instrumentation

All pH measurements were carried out using control dynamics pH meter (model: APX 175). Infrared spectroscopic measurements were recorded using FTIR-8400S Shimadzu. X-Ray diffraction patterns were recorded using PXRD Bruker D8 advance diffractometer with Cu-Kα radiation source. The energy dispersive spectroscopic (EDS) study for chemical composition and surface morphology through FESEM images were recorded using scanning electron microscope FEI ESEM QUANTA 200. All the electrochemical measurements were made by using CHI6194B series electrochemical analyzer (CH Instruments, Texas, USA) with a computer controlled potentiostat at room temperature (27 ± 2 °C). An electrochemical cell of 10 mL capacity with standard three electrode assembly was used throughout the experiment. The three electrode system consists of Ag/AgCl (3 M KCl) electrode as reference electrode, Platinum wire (99.9%) as counter electrode and composite modified glassy carbon electrode as working electrode throughout the experiment.

Synthesis of GO

Graphitic powder was oxidized to graphene oxide by following Hummer’s method with slight modification [41]. In brief, graphitic powder (1 g) was added to 23.5 mL of pre-cooled concentrated sulfuric acid. KMnO4 (3 g) was added slowly with constant stirring and cooling. The temperature was maintained less than 20 °C, and later the temperature was raised to 35 °C and maintained for 30 min followed by addition of 46 mL of distilled water and kept undisturbed for 15 min. The reaction was completed by adding 140 mL of distilled water and 10 mL of hydrogen peroxide. Finally the black residue obtained was centrifuged and washed repeatedly with 5% HCl followed by acetone. The prepared graphene oxide was dried overnight in an oven at 65 °C.

Preparation of Cu-tpa and its composite

Cupric nitrate (180 mg) was dissolved in 50 mL of DMF solvent. Terephthalic acid (100 mg) was added as an organic ligand and stirred at room temperature into DMF solution. Tri-ethyl amine was added drop wisely, and the system was sealed and stirred continuously for 4 h. The resulting precipitate was centrifuged and washed with DMF, chloroform, and ethanol. Finally, the obtained Cu-terephthalate crystals were dried overnight at 60 °C in a vacuum oven [42]. Similarly for the preparation of GO/Cu-tpa composite, along with metal precursor, previously prepared graphene oxide (100 mg) was added, and the same procedure was followed as mentioned above.

Fabrication of GO/Cu-tpa composite modified electrode

Prior to the modification, the bare glassy carbon electrode was polished using alumina powder of decreasing sizes 1, 0.3, and 0.05 μm. The polished electrodes were washed repeatedly with double distilled water and ultrasonicated in ethanol and water to remove adsorbed impurities. The composite modified electrode was fabricated by drop coating 10 μL of GO/Cu-tpa dispersed solution on the surface of clean and polished bare glassy carbon electrode and dried at room temperature. This composite modified electrode was further used as a working electrode throughout the experiment.

Results and discussion

Characterization of the composite

The prepared Cu-tpa crystals and GO/Cu-tpa composite were characterized using FTIR, XRD, SEM, and EDS techniques to ascertain the bond formation between Cu-tpa and graphene oxide, its morphology, and the elemental composition.

FTIR study

The evidence for the nature of interaction between graphene oxide sheets and Cu-tpa in the composite was studied through FTIR study. The IR spectra of GO (Fig. 1a) showed a broad peak at 3086 cm−1 is due to the characteristic of –OH stretching vibrations, and the IR spectrum of terephthalic acid is given in ESI 1. A strong band at 1397 cm−1 is due to C-O stretching of terephthalic acid (Fig. 1b). The band at 1570 cm−1 is due to asymmetric stretching of carboxylic group. The IR spectrum of the Cu-tpa shows less intense peak at 1611 cm−1 and is shifted to 1626 cm−1 and peak at 1719 cm−1 due to –C=O stretching is shifted to 1665 cm−1 after interaction. This shows that the bonding interactions have occurred between GO sheets and Cu-tpa crystals. The prominent peaks observed at 1379 cm−1, 1496 cm−1, 1580 cm−1, and 1625 cm−1 for Cu-tpa, and the peaks obtained between 1040 and 1650 cm−1 typical for GO are retained in the GO/Cu-tpa composite (Fig. 1c). Thus, FTIR study of the composite revealed that the necessary π-π interaction and hydrogen bonding between graphene oxide sheets and Cu-tpa has resulted in increasing the surface defects in GO sheets. Hence, the facile electron transfer within the composite is enhanced, and these results are in good agreement with the reported literature [42].

X-ray diffraction study

The powder XRD pattern of GO/Cu-tpa composite (Fig. 2b) displayed the predominant diffraction peaks of Cu-tpa crystals (Fig. 2a) at 2θ degree values 8.2°, 10.2°, 12°, 13°, 15°,17.2°, and 19.5° and are present in the GO/Cu-tpa composite suggesting that the crystalline structure of Cu-tpa is well maintained even after its intercalation into the graphene oxide sheets [43].

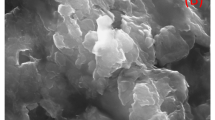

Scanning electron microscopic study

The surface morphology of the synthesized Cu-tpa crystals and GO/Cu-tpa composite were studied by recording the scanning electron microscopy images (Fig. 3). Figure 3a shows the layered structure of graphene oxide sheets. Figure 4b clearly indicates the formation of Cu-tpa crystals (inset: enlarged view) in cubic shape. The morphology of the prepared composite clearly shows the immobilized cubic Cu-tpa crystals on layered GO sheets and is uniformly distributed without any agglomeration. This confirms that the Cu-tpa crystals are very well dispersed between graphene oxide sheets, and also, the crystalline nature is well maintained even after the addition of graphene oxide during the preparation of composite. The elemental composition analysis was carried out by recording the energy dispersive spectrum (Fig. 4) in conjunction with SEM. The EDS spectrum showed the presence of Cu, C, and O as major elements. The Cu content has been found to be 18.97% which is in close agreement with the theoretically calculated value of 17.97% in the prepared composite, and the atomic percentage of elements has been tabulated in Table 1, and the EDS spectrum of Cu-tpa is given in ESI 2.

Electrochemical characterization of modified electrode

The electrochemical behavior of GO/Cu-tpa modified glassy carbon electrode was studied by cyclic voltammetry. The voltammograms were recorded in the potential window − 0.8 to 1.2 V in a phosphate buffer solution of pH 7 at a scan rate of 50 mV S−1. The resulting voltammograms showed significant redox peaks at − 0.02 V (a), − 0.17 V (b), and − 0.25 V (c) representing the oxidation of Cu to Cu (II) as well as topotactic reduction of Cu (II) to Cu (I) and Cu (I) to Cu metal respectively (Fig. 5 peaks a, b, c). This reduction process is electrolyte dependent which is coupled with the ingress of cations from the electrolyte into the GO/Cu-tpa coated on the electrode along with electron transfer.

Hence the modified electrode displayed a set of redox peaks of Cu metal centers, i.e., of copper, which are in good agreement with the reported literature [7].

Electrocatalytic oxidation of nitrite at GO/Cu-tpa modified electrode

The initial cyclic voltammetric study revealed the redox nature of the composite. Hence the electrocatalytic behavior of the composite modified electrode in the electro oxidation of nitrite has been thoroughly examined through the electrochemical behavior of bare, Cu-tpa and GO/Cu-tpa modified electrodes. The Cu-tpa modified electrode in presence of nitrite did not show any considerable analytical signal. The current response for bare electrode showed a sluggish behavior. Whereas, the GO/Cu-tpa composite modified electrode showed a significant enhancement in the peak current response (fourfold rise) for the electro oxidation of nitrite at 0.9 V compared with Cu-tpa modified and bare glassy carbon electrodes (Fig. 6). Generally, EC mechanism occurs when an anodic peak current increases and cathodic peak current decreases during analyte addition to the supporting electrolyte solution. In the present investigation, GO/Cu-tpa modified electrode showed a single anodic peak at − 0.023 V in absence of nitrite and two cathodic peaks at − 0.171 and − 0.25 V which could be assigned to the reduction of Cu (II) to Cu (I) and Cu (I) to Cu-metal. The composite showed a significant enhancement in the current response in presence of nitrite species along with a shift in Cu oxidative peak potential at − 0.028 V and reductive peak potentials at − 0.17 V and − 0.34 V. This behavior might be due to the interaction of GO/Cu-tpa with nitrite in forming an adduct which is also favored by the accessibility of the MOF framework to charge transfer. Hence the reduction potential of Cu (II) centers becomes significantly shifted from − 0.25 to − 0.35 V due to its interaction. The electrocatalytic process is also modulated by electrolyte counter ions. The catalytic effect is associated with Cu (II) to Cu (I) and Cu metal conversions. In the presence of size allowed cations, the electrochemical pathway changes significantly and reduction occurs in two steps. Here the charge conservation involves the entry of electrolyte cations coupled with electron transfer by means of series of faradaic reactions which involves electron mobility between adjacent immobilized redox centers, and redox conductivity can be easily achieved between GO/Cu-tpa/GCE and electrolyte interface. The GO/Cu-MOF composite accelerated the electron transfer rate in the oxidation of nitrite. Hence the enhanced current response has been attributed to the increased electron conductivity of GO/Cu-tpa composite with the mediation of Cu redox centers on the glassy carbon electrode surface [44].

The catalytic activity of Cu-tpa might be attributed to their immediate reduction to Cu(I) and Cu metallic species. The plausible mechanism in the oxidation of nitrite at the modified interface might be shown as given below.

The Cu-tpa MOF with large surface area suffers from low conductivity and limits their application in electrochemical studies. The introduction of conductive bridges like graphene oxide sheets boosts up the electron transfer rate within the composite causes the enhancement of analytical response. In the present study, the anodic peak current response for the oxidation of nitrite in comparison with other modified electrodes demonstrates the positive synergism between Cu-tpa crystals and conductive GO sheets leading to the improved charge transfer ability to the composite. These results are in good agreement with the reported literature [32].

In order to study the species responsible for electrocatalysis in the present study, cyclic voltammetric scans initiated at different starting potentials, i.e., − 0.8 V and 0.4 V were recorded. From these experimental results, we have observed that the peak currents are absolutely different at different potential window ranges. In absence of nitrite (Fig. 7), the scan initiated at − 0.8 V, the modified interface showed higher current compared with the scan initiated at 0.4 V. This is due to the pronounced charge transfer ability within the GO/Cu-tpa composite between graphene oxide and Cu redox centers of Cu-tpa. Similarly in presence of nitrite (Fig. 8), higher oxidative current intensities were observed for nitrite oxidation for the scans initiated at − 0.8 V and lower peak current responses for the scans initiated at 0.4 V. Therefore we can conclude that at more negative potentials, the formation of metallic copper with the ingress of charge balancing electrolyte cations and the oxidative redissolution of electrochemically generated metal within the MOF matrix might be taking place. The above electrocatalytic phenomenon is operating at the electrode interface which is mainly responsible for the electrolyte dependent nitrite oxidation process.

Further, the enhanced current response is also attributed to the increased conductivity of the composite which is confirmed through electrochemical impedance measurements. From the Nyquist plot (ESI 3), it has been found that the charge transfer resistance (Rct) value for the bare glassy carbon electrode is 3.40 × 107 Ω whereas the GO/Cu-tpa composite modified electrode showed the Rct value of 1.40 × 105 Ω. This indicates that the composite modified electrode has lower impedance value which greatly improves the conductivity and hence increases the electron transfer rate at the modified interface. The influence of scan rate on the electrochemical behavior of modified electrode was studied. The overlaid cyclic voltammograms of GO/Cu-tpa modified electrode measured at different scan rates in presence of nitrite are shown in ESI 4. It was observed that the anodic peak current increased linearly with the scan rate towards more positive values with R2 = 0.98. This indicates that the electrocatalytic oxidation of nitrite at GO/Cu-tpa modified electrode surface is adsorption controlled process [45].

Optimization study

Square wave voltammetry (SWV) as a sensitive technique was further utilized in the trace level measurement of nitrite [45]. The experimental conditions responsible in the quantitative measurement of nitrite with increased selectivity were optimized by varying the conditions like pH, pulse frequency, pulse amplitude (Figs. ESI 5–7), and analyte concentration. The optimized conditions are used in the nitrite measurement. Medium pH 4, pulse frequency—10 Hz and pulse amplitude—70 mV [46,47,48].

Electrochemical measurement of nitrite

The quantification of nitrite was performed using square wave voltammetric technique under optimized conditions at GO/Cu-tpa composite modified electrode. The resulting overlaid voltammograms showed a substantial increment in the anodic peak current responses at composite modified electrode with successive additions of known concentrations of nitrite. Hence the calibration plot was constructed by considering the anodic peak current against nitrite concentration and is given in ESI 8 under supplementary information. The current response was proportional to the increasing nitrite concentration over the range from 5 to 625 μM with a correlation coefficient of 0.985. Further, the limit of detection (LOD) was found to be 0.3 μM. The sensitivity of the modified electrode was found to be 0.86 ± 0.06 μA μM−1 cm−2. Conversely, the peak potentials were found to shift towards negative values showing the EC mechanism in electrocatalytic oxidation of nitrite. This might be accounted to the synergistic effect of Cu-tpa and GO sheets, which facilitates the conducting pathway through the transfer of electrons.

For completeness, the comparison of analytical sensing parameters such as type of modified electrode, linear range, LOD, and sensitivity of the existing nitrite sensors along with the proposed nitrite sensor has been summarized in Table 2. Although the sensitivity of GO/Cu-tpa composite modified electrode is not so superior than some of the existing nitrite sensors, but still, it is higher than few mentioned in the comparison table. Hence these results depicts that the composite can be used as an alternate electrode material for the measurement of nitrite at low level concentration.

Selectivity of the composite modified electrode towards nitrite

The presence of common interfering ions may seriously influence the overall performance of the modified electrode. Hence the effect of some cations such as Na+, K+, Cu2+, Ca2+, Zn2+, Mg2+, \( {\mathrm{NH}}_4^{+} \), and anions like \( {\mathrm{NO}}_3^{-},{\mathrm{ClO}}_4^{-},{\mathrm{SO}}_4^{2-},{\mathrm{SO}}_3^{2-},{\mathrm{CO}}_3^{2-} \), CH3COO−, ascorbic acid, acetaminophen, dopamine, and citric acid on the analytical response at GO/Cu-tpa modified electrode towards electro oxidation of 250 μM nitrite has been studied. The variations in the current response in presence of 100 mM concentration of the interfering species have been studied. No significant change in the peak current response was observed in presence of these anions and cations. However the current responses were found to be varied slightly at 5 fold increase in the concentration of interfering species. The graphical representation of interference study has been shown in ESI 9 under supplementary information.

Stability and reproducibility

The stability of the modified electrode is an important aspect in assessing the superiority of the developed sensor. Hence the composite modified electrode surface was checked by measuring the voltammograms up to 5 continuous repeated cycles in presence of 1.5 mM of nitrite. A decrease of 7% in current response was observed after the second cycle (Fig. 9). As the cycling continues, the peak intensity for Cu oxidation/reduction was also found to increase. This might be due to the slow and partial disintegration of Cu-MOF lattice upon consecutive cyclic scans which may block the active sites present in the substrate [7]. However considerable analytical signal was obtained for the electro oxidation of nitrite even after 5 cycles showing the greater stability of the modified electrode interface. These results demonstrate that the modified interface is stable towards nitrite detection which can be used for prolonged study.

Additionally, the reproducibility of the proposed sensor has been checked at different time intervals from the day of experiment to 15 days and 30 days. The modified interface displayed a significant response within ± 5% variation of the anodic peak current in the oxidation of nitrite after 30 days (ESI 10).

Application study

The utility of the GO/Cu-tpa prepared composite modified electrode as a sensor was evaluated by the measurement of nitrite in real water samples such as tap, bore well, and sewage water samples. The tap and bore well water samples were used as it is whereas the sewage water was treated with activated charcoal and filtered to remove the suspended particulate matter and odor. Each 5 mL of sample was taken in an electrochemical cell containing 4 mL of buffer solution. The pH of the samples was pre-adjusted to pH 7. The nitrite concentration was measured in both original and spiked samples. The results obtained were found to be in good agreement with the standard Griess–Ilosvay method [55]. The recovery studies were carried out for three successive measurements (n = 3) and were found to be satisfactory with RSD between 97.5 and 103.2% (Table 3). These results demonstrated that the GO/Cu-tpa composite modified electrode serves as a suitable electrochemical platform in the trace level measurement of nitrite for routine analysis.

Conclusions

A simple and sensitive electrochemical sensing platform comprising GO/Cu-tpa composite has been fabricated. The composite has been characterized using FTIR, XRD, SEM, and electrochemical techniques. The fabricated electrode showed an excellent electrocatalytic activity towards the electro oxidation of nitrite with wide linearity in the concentration range 5–625 μM with a very low detection limit of 0.3 μM. The proposed method has been successfully applied to measure trace level nitrite from various water samples. The results showed a quantitative recovery of spiked samples in comparison with the standard protocol. Hence GO/Cu-tpa composite can be used as a novel sensing material in the electrochemical nitrite quantification study.

References

Rosi NL, Eddaoudi M, Kim J, Keeffe OM, Yaghi OM (2002) Advances in the chemistry of metal organic frameworks. CrystEngComm 4(68):401–404

Zhou HC, Long JR, Yaghi OM (2012) Introduction to metal organic frameworks. Chem Rev 112(2):673–674

Meek ST, Greathouse JA, Allendorf MD (2011) Metal organic frameworks: a rapidly growing class of versatile Nanoporous materials. Adv Mater 23(2):249–267

Yi FY, Chen D, Wu MK, Han L, Jiang HL (2016) Chemical sensors based on metal organic frameworks. ChemPlusChem 81(8):675–690

Liu W, Yin XB (2016) Metal organic frameworks for electrochemical applications. TrAC Trends Anal Chem 75:86–96

Kempahanumakkagari S, Vellingiri K, Deep A, Kwon EE, Bolan N, Kim KH (2018) Metal organic framework composites as electrocatalysts for electrochemical sensing applications. Coord Chem Rev 357:105–129

Domenech A, García H, Domenech Carbo MT, Llabres i Xamena F (2007) Electrochemistry of metal organic frameworks: a description from the voltammetry of microparticles approach. J Phys Chem C 111(37):13701–13711

Jiao S, Jin J, Wang L (2015) One-pot preparation of Au-RGO/PDDA nanocomposites and their application for nitrite sensing. Sens Actuators B Chem 208:36–42

Wang Z, Li M, Ye Y, Yang Y, Lu Y, Ma X, Zhang Z, Xiang S (2019) MOF-derived binary mixed carbon/metal oxide porous materials for constructing simultaneous determination of hydroquinone and catechol sensor. J Solid State Electrochem 23(1):81–89

Liu XW, Sun TJ, Hu JL, Wang SD (2016) Composites of metal organic frameworks and carbon based materials: preparations, functionalities and applications. J Mater Chem A 4(10):3584–3616

Jakszyn P, Gonzalez CA (2006) Nitrosamine and related food intake and gastric and oesophageal cancer risk: a systematic review of the epidemiological evidence. World J Gastroenterol 12(27):4296–4303

Rahman MS Handbook of food preservation, 2nd edn. CRC Press. Taylor and Francis Group, Boca Raton

Vittozzi L (1992) Toxicology of nitrates and nitrites. Food Addit Contam 9(5):579–585

Moorcroft MJ, Davis J, Compton RG (2001) Detection and determination of nitrate and nitrite: a review. Talanta 54(5):785–803

Wang QH, Yu LJ, Liu Y, Lin L, Lu RG, Zhu JP, He L, Lu ZL (2017) Methods for the detection and determination of nitrite and nitrate: a review. Talanta 165:709–720

Redepenning JG (1987) Chemically modified electrodes: a general overview. TrAC Trends Anal Chem 6(1):18–22

Raoof JB, Ojani R, Ramine M (2009) Voltammetric sensor for nitrite determination based on its electrocatalytic reduction at the surface of p-duroquinone modified carbon paste electrode. J Solid State Electrochem 13(9):1311–1319

Mani V, Wu TY, Chen SM (2014) Iron nanoparticles decorated graphene multiwalled carbon nanotubes nanocomposite modified glassy carbon electrode for the sensitive determination of nitrite. J Solid State Electrochem 18(4):1015–1023

Shahbakhsh M, Noroozifar M (2018) Copper polydopamine complex/multiwalled carbon nanotubes as novel modifier for simultaneous electrochemical determination of ascorbic acid, dopamine, acetaminophen, nitrite and xanthine. J Solid State Electrochem 22(10):3049–3057

Chen Q, Ai S, Fan H, Cai J, Ma Q, Zhu X, Yin H (2010) The immobilization of cytochrome c on MWNT PAMAM Chit nanocomposite incorporated with DNA biocomposite film modified glassy carbon electrode for the determination of nitrite. J Solid State Electrochem 14(9):1681–1688

Sonkar PK, Ganesan V (2015) Synthesis and characterization of silver nanoparticle-anchored amine-functionalized mesoporous silica for electrocatalytic determination of nitrite. J Solid State Electrochem 19(7):2107–2115

Zhang L, Wang L (2013) Poly(2-amino-5-(4-pyridinyl)-1, 3, 4-thiadiazole) film modified electrode for the simultaneous determinations of dopamine, uric acid and nitrite. J Solid State Electrochem 17(3):691–700

He Q, Gan T, Zheng D, Hu S (2010) Direct electrochemistry and electrocatalysis of nitrite based on nano-alumina-modified electrode. J Solid State Electrochem 14(6):1057–1064

Gligor D, Walcarius A (2014) Glassy carbon electrode modified with a film of poly(toluidine blue O) and carbon nanotubes for nitrite detection. J Solid State Electrochem 18(6):1519–1528

Gligor D, Cuibus F, Peipmann R, Bund A (2017) Novel amperometric sensors for nitrite detection using electrodes modified with PEDOT prepared in ionic liquids. J Solid State Electrochem 21(1):281–290

De Menezes EW, Nunes MR, Arenas LT, Dias SLP, Garcia ITS, Gushikem Y, Costa TMH, Benvenutti EV (2012) Gold nanoparticle/charged silsesquioxane films immobilized onto Al/SiO2 surface applied on the electrooxidation of nitrite. J Solid State Electrochem 16(12):3703–3713

Kamyabi MA, Asgari Z, Monfared HH (2010) Electrocatalytic oxidation of nitrite at a terpyridine manganese(II) complex modified carbon past electrode. J Solid State Electrochem 14(9):1547–1553

Yang C, Xu J, Hu S (2007) Development of a novel nitrite amperometric sensor based on poly(toluidine blue) film electrode. J Solid State Electrochem 11(4):514–520

Wang Y, Wu Y, Xie J, Hu X (2013) Metal organic framework modified carbon paste electrode for lead sensor. Sens Actuators B Chem 177:1161–1166

Song Y, Gong C, Su D, Shen Y, Song Y, Wang L (2016) A novel ascorbic acid electrochemical sensor based on spherical MOF-5 arrayed on a three-dimensional porous carbon electrode. Anal Methods 8(10):2290–2296

Hosseini H, Ahmar H, Dehghani A, Bagheri A, Fakhari AR, Amini MM (2013) Au-SH-SiO2 nanoparticles supported on metal-organic framework (Au-SH-SiO2@Cu-MOF) as a sensor for electrocatalytic oxidation and determination of hydrazine. Electrochim Acta 88:301–309

Yadav DK, Ganesan V, Sonkar PK, Gupta R, Rastogi PK (2016) Electrochemical investigation of gold nanoparticles incorporated zinc based metal-organic framework for selective recognition of nitrite and nitrobenzene. Electrochim Acta 200:276–282

Chen Q, Li X, Min X, Cheng D, Zhou J, Li Y, Xie Z, Liu P, Cai W, Zhang C (2017) Determination of catechol and hydroquinone with high sensitivity using MOF graphene composites modified electrode. J Electroanal Chem 789:114–122

Arul P, John SA (2018) Size controlled synthesis of Ni-MOF using polyvinylpyrrolidone: new electrode material for the trace level determination of nitrobenzene. J Electroanal Chem 829:168–176

Chen H, Wu X, Lao C, Li Y, Yuan Q, Gan W (2019) MOF derived porous carbon modified rGO for simultaneous determination of hydroquinone and catechol. J Electroanal Chem 835:254–261

Sun D, Deng Q, Long J (2018) Highly sensitive electrochemical sensor for estradiol based on the signal amplification strategy of cu-BDC frameworks. J Solid State Electrochem 22(2):487–493

Yuan B, Zhang J, Zhang R, Shi H, Wang N, Li J, Ma F, Zhang D (2016) Cu-based metal organic framework as a novel sensing platform for the enhanced electro oxidation of nitrite. Sensors Actuators B Chem 222:632–637

Saraf M, Rajak R, Mobin SM (2016) A fascinating multitasking cu-MOF/rGO hybrid for high performance supercapacitors and highly sensitive and selective electrochemical nitrite sensors. J Mater Chem A 4(42):16432–16445

Yadav DK, Ganesan V, Marken F, Gupta R, Sonkar PK (2016) Metal@MOF materials in electroanalysis: silver-enhanced oxidation reactivity towards nitrophenols adsorbed into a zinc metal organic framework Ag@MOF-5(Zn). Electrochim Acta 219:482–491

Li J, Xia J, Zhang F, Wang Z, Liu Q (2018) An electrochemical sensor based on copper-based metal-organic frameworks-graphene composites for determination of dihydroxybenzene isomers in water. Talanta 181:80–86

Hummers WS Jr, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339–1339

Wang X, Wang Q, Wang Q, Gao F, Gao F, Yang Y, Guo H (2014) Highly dispersible and stable copper terephthalate metal organic framework graphene oxide nanocomposite for an electrochemical sensing application. ACS Appl Mater Interfaces 6(14):11573–11580

Zhang Y, Bo X, Luhana C, Wang H, Li M, Guo L (2013) Facile synthesis of a Cu-based MOF confined in macroporous carbon hybrid material with enhanced electrocatalytic ability. Chem Commun 49(61):6885–6887

Domenech-Carbo A (2009) Electrochemistry of porous materials. CRC press

Wang Y, Laborda E, Compton RG (2012) Electrochemical oxidation of nitrite: kinetic, mechanistic and analytical study by square wave voltammetry. J Electroanal Chem 670:56–61

Piela B, Wrona PK (2002) Oxidation of nitrites on solid electrodes: I. determination of the reaction mechanism on the pure electrode surface. J Electrochem Soc 149(2):E55–E63

Lovric M, Komorsky-Lovric S (1988) Square-wave voltammetry of an adsorbed reactant. J Electroanal Chem Interfacial Electrochem 248(2):239–253

O’Dea JJ, Ribes A, Osteryoung JG (1993) Square-wave voltammetry applied to the totally irreversible reduction of adsorbate. J Electroanal Chem 345(1):287–301

Kung CW, Li YS, Lee MH, Wang SY, Chiang WH, Ho KC (2016) In situ growth of porphyrinic metal–organic framework nanocrystals on graphene nanoribbons for the electrocatalytic oxidation of nitrite. J Mater Chem A 4(7):10673–10682

Chen D, Jiang J, Du X (2016) Electrocatalytic oxidation of nitrite using metal-free nitrogen-doped reduced graphene oxide nanosheets for sensitive detection. Talanta 155:329–335

Kung CW, Chang TH, Chou LY, Hupp JT, Farha OK, Ho KC (2015) Porphyrin-based metal–organic framework thin films for electrochemical nitrite detection. Electrochem Commun 58:51–56

Zhang S, Li B, Sheng Q, Zheng J (2016) Electrochemical sensor for sensitive determination of nitrite based on the CuS MWCNT nanocomposites. J Electroanal Chem 769:118–123

Suma BP, Adarakatti PS, Kempahanumakkagari SK, Malingappa P (2019) A new polyoxometalate/rGO/Pani composite modified electrode for electrochemical sensing of nitrite and its application to food and environmental samples. Mater Chem Phys 229:269–278

Patri SB, Adarakatti PS, Malingappa P (2019) Silver nanoparticles-chitosan composite embedded graphite screen-printed electrodes as a novel electrochemical platform in the measurement of trace level nitrite: application to milk powder samples. Curr Anal Chem 15(1):56–65

Baird RB, Rice EW, Eaton AD, Clesceri LS (2012) Standard methods for the examination of, water and waste water APHA, 22nd edn. American Water Works, Association WEF, Denver

Funding

The authors acknowledge DST-SERB, New Delhi, India for the financial support and award of research fellowship to Mrs. Suma B P (Award No: EMR/2016/002466).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The graphene oxide/ copper terepthalate composite has been synthesized by a simple solvothermal route.

• The composite has been characterized by spectroscopic and electrochemical techniques.

• It has been used as a novel electrochemical sensing platform in the measurement of nitrite.

• The composite modified electrode showed a good linearity in the concentration range 5- 625 μM with a detection limit of 0.3 μM.

• The sensor has been successfully applied to real sample analysis and the results are in good agreement with the standard protocol results.

Electronic supplementary material

ESM 1

(DOCS 993 kb)

Rights and permissions

About this article

Cite this article

Suma B P, Pandurangappa M Graphene oxide/copper terephthalate composite as a sensing platform for nitrite quantification and its application to environmental samples. J Solid State Electrochem 24, 69–79 (2020). https://doi.org/10.1007/s10008-019-04454-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-019-04454-8