Abstract

Deteriorating the quality of different parts of the ecosystem due to toxic metals is a serious global issue. Hexavalent chromium is a metal that can cause adverse effects on all living beings, including plants, animals, and microorganisms, on exposure to high concentrations for prolonged periods. Removing hexavalent chromium from various types of wastes is challenging; hence the present study investigated the use of bacteria incorporated with selected natural substrates in removing hexavalent chromium from water. Isolated Staphylococcus edaphicus KCB02A11 has shown higher removal efficiency with a wide hexavalent chromium range (0.025-8.5 mg/L) within 96 h. Incorporating the isolated strain with natural substrates commonly found in the environment (hay and wood husk) showed high removal potential [100% removal with 8.5 mg/L of Cr(VI)], even within less than 72 h, with the formation of biofilms on the used substrates applied for metal removal on a large scale for prolonged periods. This study is the first report investigating hexavalent chromium tolerance and removal by Staphylococcus edaphicus KCB02A11.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals are essential raw materials in many industrial applications and inevitably generate a significant amount of metal-contaminated wastes. Environmental pollution caused by heavy metal accumulation in the ecosystem has become a global concern, where adverse effects are rendered on flora and fauna due to toxicity and subsequent bioaccumulation, persistency, and least potential of biodegradability (Mehmood et al. 2019; Ravindra and Mor 2019; Ukah et al. 2019; Kaur and Roy 2021).

Chromium (Cr) compounds are widely used in leather tanning, pigment and dye production, electroplating, wood preserving, and refractory materials (Almeida et al. 2019; Coetzee et al. 2020). Of two of the common forms of Cr, trivalent chromium [Cr(III)] is known as naturally occurring in nature, while hexavalent chromium [Cr(VI)] is produced by the industrial process (Owlad et al. 2009). Furthermore, it is a known fact that Cr(VI) is highly toxic than Cr(III) to living beings as it is highly soluble and mobile (Megharaj et al. 2003; Pan et al. 2014; Ertani et al. 2017).

Prolonged exposure to Cr(VI) may cause kidney and liver dysfunctions, nasal irritations, nasal perforations, skin irritations, skin ulcerations, skin allergies and lung cancers in animals, including humans (Kotaś and Stasicka 2000; Owlad et al. 2009). Based on this sufficient evidence, International Agency for Research on Cancer (IARC) announced that Cr(VI) as a carcinogenic agent in 1990 (Saha et al. 2011). Furthermore, exposure to Cr compounds can cause toxic effects on higher plants at the level of 100 µM Kg−1 on a dry weight basis (Davies et al. 2002). Besides, chromium toxicity can reduce germination, growth pattern changes, reduction of yield, and increase seed deforming, etc. in plants while leading to growth inhibitions, lag phase elongations, inhibition of oxygen uptake, denaturing enzymes and mutagenesis on microorganisms (Cervantes et al. 2001; Shanker et al. 2005; Igiri et al. 2018).

Due to the toxicity, international and national legislation authorities have regulated Cr(VI) disposal. World Health Organization (WHO) and the United States Environmental Protection Agency (US EPA) have mainly concerned with drinking water quality and recommend a maximum permissible level for Cr(VI) of 0.05 mg/L (Altun et al. 2016; Cherdchoo et al. 2019). Concerning the higher exposure probability, Occupational Safety and Health Administration (OSHA) has legislated the maximum exposure limit for Cr(VI) compounds for 8-hour work shifts and 40-hour workweeks as 0.052 mg/L to the occupational community (Mishra and Bharagava 2016). However, these discharge limits change according to national and regional standards, the type of industry, and the nature of the discharge environment (Vaiopoulou et al., 2020).

Therefore, Cr(VI) contaminated effluents need to be remediated into less toxic and less soluble forms to minimize harmful effects on the ecosystem, and is possible to achieve physical, chemical and/or biological methods. The Physical remediation can be done with techniques such as adsorption, electrolysis, membrane filtration, soil washing and capping (Jobby et al. 2018; Shahnaz et al. 2020).

Chemical remediation is mainly based on the reduction of Cr(VI) into Cr(III) using a variety of chemicals such as SO2, CaS5, Na2S2O5, Na2SO3, FeSO4, BaSO3, TiO2, N2H4, H2O2, and Ca(OH)2 (Ma et al. 2016; Dong et al. 2018; Jobby et al. 2018). On the contrary, bioremediation is functioned with bacteria, fungi, algae and plants with low energy consumption, low operational costs, fewer environmental health hazards, and with high efficiency compared to physical and chemical methods (Fernández et al. 2013; Narayanasamy et al. 2022).

Several bacterial species such as Staphylococcus sp., Pseudomonas sp., Enterobacter sp., Deinococcus sp., Shewanella sp., Agrobacterium sp., Escherichia sp., Thermus sp., Microbacterium sp., Desulfovibrio sp., Deinococcus sp., Brucella sp., and Bacillus sp. were identified as Cr(VI) removers from contaminated sources through “directly” with enzymes or “indirectly” with metabolic end products (Vatsouria et al. 2005; Mistry et al. 2010; Mythili and Karthikeyan 2011; Sharma and Adholeya 2012; Thatoi et al. 2014; Suresh et al. 2021). Furthermore, Narayani & Shetty (2013) and Igiri et al. (2018) report that microbial bioremediation of Cr(VI) can be stimulated or inhibited by physical and chemical factors, including pH value, cell density, initial Cr(VI) concentration, temperature, aerobic/anaerobic environment, electron donors, oxyanions, salt concentration, presence of heavy metals, metabolic inhibitors and oxidation-reduction potential etc.

Representatives of the Staphylococcus genus, such as S. epidermidis, S. sciuri, S.cohini, S. aureus, and S. xylocus, etc., have shown Cr(VI) removal potential with different efficiencies (Table 1). However, the Cr(VI) tolerance and removal potential of Staphylococcus edaphicus has not previously been reported. The current study reports the potential of isolated Staphylococcus edaphicus and its biofilms incorporated with natural adsorbents in Cr(VI) removal.

Methods

Identification of bacteria

The bacterial strain isolated previously from a study carried out by Seneviratne & Rathnayake (2019) was used in this study. The DNA extraction, 16 S rRNA gene amplification and PCR product sequencing were done at Genetech Molecular Diagnostics and School of Gene Technology, Sri Lanka. Bacterial 16 S rRNA gene sequence was amplified by Polymerase chain reaction (PCR) using forward and reverse universal primers [785 F (5’-GGATTAGATACCCTGGTA-3’) and 907R (5’-CCGTCAATTCMTTTRAGTTT-3’)] while post molecular analysis was followed with NCBI GenBank database and relevant open-source software. The tasks of the chromatogram sequence edition process, forward and reverse sequence aligning process, and consensus sequence preparations were completed using BioEdit Sequence Alignment Editor (Version 7.2.5). The obtained bacterial DNA sequence was deposited in the NCBI GenBank with all relevant data. The phylogenetic relationship of the bacterial isolate was determined through phylogenetic tree construction using Mega 10.2.6.

Preparation of metal stock solutions and chemical analysis

Cr(VI) stock solution (100 mg/L) and working Cr(VI) solutions were prepared by dissolving appropriate amounts of K2Cr2O7 (AnalaR NORMAPUR, Belgium) in deionized water. Analytical verification of metal solutions were assured using inductively coupled plasma mass spectrometry (ICP-MS) according to the method APHA 3120 B: 2017. Furthermore, metal binding in glassware was avoided by acid washing them (with HNO3) before use.

Tolerance and removal of Cr(VI) by bacteria

Bacterial culture (approximately 107 CFU/mL, overnight grown in nutrient broth) was inoculated into Tris minimal (modified) medium (at pH 7) supplemented with a range of concentrations (0.025-16.0 mg/L) of Cr(VI) in the presence and absence of the selected natural adsorbents. Controls were set as media without Cr(VI) but inoculated with the bacterial inoculum. The inoculated bioassay samples were incubated for 96 h., at 100 rpm at room temperature in a shaking incubator (JSSI-202 C Series). Optical density measurements were taken at 600 nm at 24 h. intervals to monitor the growth response of the bacteria during the study period using Thermo Scientific™ Multiskant™ FC Microplate Photometer. The viability of the bacterial isolate was determined during the study period by streaking on nutrient agar solid media at every 24 h. interval. Experiments were carried out in triplicate for a precise study.

Bioassay samples withdrawn at 24 h. intervals were centrifuged at 6000 rpm for 10 min to separate cell-free supernatant and bacterial cells. The pellets were resuspended in a solution (pH 7.0) containing 1 × 10− 4 M EDTA with 6 × 10− 4 M CaCl2 to adjust the ionic strength and remove absorbed ions from cell surfaces. The resuspended samples were incubated in the dark for 10 min and centrifuged. The supernatants were removed using suction, and cell pellets were washed twice in deionized water to remove further bound ions to cell walls (Miranda and Rojas 2006). Collected cell pellets were acid digested with 2 mL of concentrated HNO3 acid for 48 h. and reconstituted to 20 mL with deionised water (Madhaiyan et al. 2007).

Initial Cr(VI) amount added to the test solution, including the remaining Cr(VI) amount in cell-free supernatant and acid-digested bacterial cells were quantified using US EPA Method 7196 A with 1,5-diphenyl carbazide (DPC) (Megharaj et al. 2003; Lee et al. 2003), and analytically verified using ICP-MS as per the APHA 3120 B: 2017 protocol.

Analysis of Cr(VI) removal potential by selected adsorbents

Dried hay and wood husk (10.0 g/L) were cut into irregular lengths between 5 and 10 cm and sterilized by autoclaving. Assays were conducted in the presence of Cr(VI) but without the bacterial culture as described earlier. Initial Cr(VI) and remaining Cr(VI) content after 96 h. were measured using the DPC method every 24 h. during the experiment.

Detection of bacterial biofilm formation

Bacterial culture was inoculated into Tris minimal (modified) medium and incubated at 37 °C for 18 h. Incubated culture (1 mL) was added into the freshly prepared same medium with a 1:100 ratio. Aliquots of 0.2 mL were transferred into 96 well, flat-bottomed polystyrene sterile microtiter plate and incubated at 37 °C for 24 h. After the incubation period, contents in the microplate wells were gently removed by an aspirator and washed four times using phosphate-buffered saline (PBS pH 7.2) (0.20 mL). Wells were filled with sodium acetate (2%, 0.20 mL) and stained with crystal violet (0.1% w/v) for 5 min. Excess stains were removed and rinsed off using deionized water. Plates were air-dried, and the optical density of stained cell adhered wells were measured at 570 nm (Christensen et al. 1985; Mathur et al. 2006).

Bacterial biofilm formation on the adsorbents and their Cr(VI) removal potential

Pre-sterilized adsorbents and the bacterial culture were added (approximately 107 CFU/mL, grown overnight in nutrient broth) to Tris minimal (modified) medium and allowed to form biofilms on adsorbents for 48 h., at 100 rpm at room temperature in the shaking incubator. The bioassay samples were supplemented with Cr(VI) (8.5 mg/L) and incubated for another 96 h. at the same growth conditions. The concentration of Cr(VI) at 8.5 mg/L was selected based on the removal performance of the selected bacterial strain during the experimental period. Cr(VI) content of the bioassay samples was measured by the DPC method at every 24 h. interval up to 96 h. using the cell-free supernatant prepared by centrifugation. The bacterial biofilm formation was also visualized by ZEISS Scanning Electron Microscope (AT 10.00 KV).

Estimation of Cr(VI) removal

Cr(VI) removal of the bacterial strain, adsorbent, and strain incorporated adsorbents (biofilms) were calculated as a percentage using mathematical expression based on data collected by DPC colorimetric method as described in Krishna and Sree (2013).

Statistical analysis

The medium effective concentrations (EC50) of bacterial isolate and Cr(VI) removal potential of natural adsorbents, bacterial isolate and their biofilms were calculated by probit analysis and independent samples Kruskal – Wallis test respectively with 95% confidence using IBM SPSS Statistics, version 25.

Results

Molecular identification of the bacterial isolate.

The aligned 16 S rRNA consensus sequence of the bacterial isolate was identified with NCBI’s BLAST algorithm (https://blast.ncbi.nlm.nih.gov/Blast.cgi) (Kabir et al. 2018; Pradhan et al. 2020). According to the blasting suite, the isolated strain exhibited higher similarity to Staphylococcus edaphicus CCM 8730 (Accession No. NR156818.1) with 100% query cover, 0.0 of E-value and 99.88% of percentage identity. Moreover, the phylogeny of the isolate revealed a higher phylogenetic relationship with Staphylococcus edaphicus strains that were aligned using the MUSCLE algorithm and the constructed phylogenetic tree using MEGA 10.2.6 (Fig. 1). The bacterial DNA sequences obtained in this study were deposited in the GenBank database under the accession number OL881276. The identified bacterium was named S. edaphicus KCB02A11 here in.

A neighbour-joining phylogenic tree based on 16 S rRNA gene sequences showing the phylogenetic relationship among isolated strain S. edaphicus KCB02A11 and other selected species constructed using Mega 10.2.6. The bootstrap numbers indicate the value of 1000 replicate trees. The NCBI accession numbers are given in parenthesis

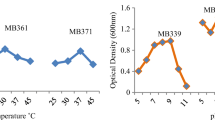

Growth response of S. edaphicus KCB02A11 in Cr(VI) supplemented media

According to dose-response bioassays, S. edaphicus KCB02A11 has shown higher tolerance up to 16.0 mg/L of Cr(VI). The growth response curves of S. edaphicus KCB02A11 exhibited a gradual growth in all tested Cr(VI) contents except the highest tested concentration of 16.0 mg/L which showed a slight growth compared to others. However, none of the concentrations has surpassed the bacterial growth in non-metal added control (Fig. 2). This change of patterns may be due to the toxicity of Cr(VI) towards bacteria. According to the dose-response analysis at 600 nm high bacterial growth was observed under low Cr(VI) contests while lower growth was in high Cr(VI) concentrations.

The 50% effective concentration (EC50) estimations (Table 2) of the bacterial strain resulted in different values for every 24 h. time interval, decreasing with exposure time up to 96 h. in considerable amounts from 78.686 mg/L (in 24 h.) to 0.084 mg/L (in 96 h.) This may be due to the toxicity of Cr(VI) towards bacterial cells with time.

Total chromium removal by S. edaphicus KCB02A11

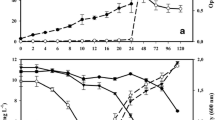

Cr(VI) removal studies showed that it was evident that the S. edaphicus KCB02A11 could achieve a complete Cr(VI) removal up to the concentration of 8.5 mg/L within the study period of 96 h. following a gradual decrease of Cr(VI) removal in higher concentrations (Fig. 3A and B).

The graphical interpretations further revealed a complete Cr(VI) removal by bacterial cells in suspension within 24 h. at lower concentrations (0.025–0.5 mg/L) while complete removal of 8.5 mg/L within 96 h. required a gradual increase in time. Removal potential of the tested concentrations higher than 8.5 mg/L showed the same pattern but around 50% maximum removal at the end of the experimental period (96 h). This analysis also revealed a negative correlation between the Cr(VI) removal potential of the bacterial isolate and the metal concentration as it exhibited a decrease of Cr(VI) removal at 8.5 mg/L of Cr(VI) and afterwards (Fig. 3A, and Fig. 3B). Moreover, the results of the Cr(VI) analysis of acid digested cell pellets also indicate the absence of Cr(VI) inside and cell walls of bacterial cells.

Meanwhile, ICP-MS analysis in cell-free supernatant exhibited 42.30% of total chromium removal at 6.5 mg/L Cr(VI) which was the highest among other tested concentrations [7.5, 8.5, and 9.5 mg/L Cr(VI)]. Hence, the total chromium removal ability of the S. edaphicus KCB02A11 was inversely proportional to the Cr(VI) in the medium (Fig. 4). Considering this total chromium removal pattern of the tested strain, it can be assumed that the total chromium removal potential of the S. edaphicus KCB02A11 is curtailed with increasing Cr(VI) concentration.

Biofilm formation and detection

Quantitative biofilm detection results describe that the selected strain can produce “moderately adherent” biofilms according to the standard biofilm detection method proposed by Christensen et al., (1985). This biofilm formation was also screened by scanning electron microscope after they were immobilized on straw. Figure 5 shows the SEM images of the S. edaphicus KCB02A11 biofilm on hay (Mag. 2.50 K X) cocci-shaped cells representing S. edaphicus KCB02A11 cells (Mag. 10.00 K X) in Tris minimal (modified) medium.

Comparison of removal ability of natural adsorbents, bacterial strain and its biofilms

Comparison of the Cr(VI) removal by selected natural adsorbents; straw and wood husk, S. edaphicus KCB02A11 cells in suspension and S. edaphicus KCB02A11 biofilm on adsorbents were tested upon exposure to the 8.5 mg L− 1 Cr(VI), which was the highest concentration of Cr(VI) in which the S. edaphicus KCB02A11 biofilms on hay was able to remove completely within 72 h where as S. edaphicus KCB02A11 in solution required 96 h to remove the said concentration completely. Straw and wood husk adsorbents reached their maximum removal capacities of 62.25% and 31.39%, respectively, within 72 h. and 48 h. Biofilms of S. edaphicus KCB02A11 on wood husk exhibited 45.99% Cr(VI) removal within 96 h. (Fig. 6). However, it was further found that after reaching maximum removal by hay and wood husk adsorbents, a portion of adsorbed Cr(VI) is released back to the medium. Furthermore, the independent samples Kruskal – Wallis test also revealed that, Cr(VI) removal capabilities among adsorbents, bacterial strain and biofilms were significantly different from each other (p = 0.008, α = 0.05).

Discussion

Owing to the chemical and physical properties of chromium, such as inert nature, hardness, strength, high-temperature resistance, and corrosion resistance, Cr in its oxidation states of Cr(III) and Cr(VI) are mostly used in metallurgical (67%), followed by refractories (18%), while the rest of the fraction is applied in Cr-induced chemical production, including textile, leather tanning, wood preserving, and pigment production, etc. (Shanker et al. 2005; Saha et al. 2011). Further, it is reported that the above industrial activities are responsible for discharging more than 170,000 tons of waste contaminated with chromium to the ecosystem annually (Kamaludeen et al. 2003).

Humans and other biota like animals, plants, and microorganisms are exposed to these inappropriately discharged chromium through ingestion, inhalation, direct contact with skin, roots, shoots, cell membranes, etc. (Joutey et al. 2015; Coetzee et al. 2020; Kumar et al. 2020; Xu et al. 2021).

Moreover, it is reported that Cr(VI) can cause inhibition of cell growth and cell division, oxidative DNA damage, and morphological changes in the microorganisms (Mishra and Bharagava 2016). Owing to the above hazardous impacts of Cr(VI), local and international authorities responsible for the health and protection of the public and environment have legislated maximum permissible limits for Cr(VI) discharge to the environment.

The theory behind the bioremediation of Cr(VI) contaminated wastes is to use biological agents that have both Cr(VI) tolerance and removal capabilities with the help of their defence mechanisms such as biotransformation, bioreduction, and biosorption (Joutey et al. 2015). The usage of Cr(VI) tolerant and removal bacteria for Cr(VI) bioremediation has emerged as one of the most preponderant remediation techniques over the last few decades due to cost-effectiveness and environmental friendliness (Malaviya and Singh 2016; Bhattacharya et al. 2019).

According to dose-response bioassays, S. edaphicus KCB02A11 has shown higher tolerance up to 16.0 mg/L of Cr(VI). This bacterium was initially tested for Cr(VI) tolerance in the range of 0.025 mg/L– 0.20 mg/L of Cr(VI), keeping 0.10 mg/L as the middle reference point, which is the maximum regulated Cr(VI) tolerance level legislated by the National Environmental Act of Sri Lanka (National Environmental Act Sri Lanka 2008), followed by gradually increasing the exposure concentration of Cr(VI) up to 16.0 mg/L. Further, it was observed that the isolated strain was viable in all tested Cr(VI) concentrations during the study period of 96 h. The growth response curves of S. edaphicus KCB02A11 showed a gradual increase in all tested Cr(VI) concentrations except the highest tested concentration of 16.0 mg/L, which showed a slight growth compared to others. However, none of the Cr concentrations has surpassed the bacterial growth in non-metal added control (Fig. 2). This change of patterns may be due to the toxicity of Cr(VI) towards bacteria.

Previous reports on Staphylococcus sp. showed different tolerance limits for Cr(VI), which varied depending on the strain. With providing the high weight of evidence, studies by Zahoor et al., (2009) and Ilias et al., (2011) have reported that wastewater-isolated S. capitis and S. aureus have higher Cr(VI) tolerance, such as 2800 mg/L and 2000 mg/L, while another comparative study of Pereira et al., (2017) has reported that, S. saprophyticus and S. arlettae were able to tolerate 300 mg/L of Cr(VI). Furthermore, some strains belonging to the genus Staphylococcus were shown to be tolerant up to 500 mg/L (Rajbanshi, 2009) and 25 mg/L of Cr(VI) (Mistry et al. 2010) in their growth medium. Most of the above-tested Staphylococcus strains have been isolated from different contaminated sites such as tannery waste, contaminated landfills, and wastewater effluents. Therefore, it can be assumed that the tolerance capabilities of the isolated bacteria may have been influenced by their habitat characteristics. In contrast, it is also believed that some components in conventional growth media could reduce metal toxicity by metal binding, such as glucose and phosphate buffers (Rathnayake et al. 2013). Therefore, the present study used Tris minimal (modified) medium, which consisted of the least amount of glucose (0.20%) and Tris HCl buffer to optimize the Cr(VI) availability.

Quantitative biofilm detection (Christenson et al., 1985) reveals that the selected strain can produce “moderately adherent” biofilms. This biofilm formation could be another reason for Cr(VI) tolerance of the strain as self-producing extracellular polymeric substances (EPS) confer tolerance to heavy metals (Chien et al. 2013; Yin et al. 2019).

The 50% effective concentration (EC50) estimates (Table 2) of the bacterial strain yielded different values for every 24 h. time interval, decreasing with exposure time up to 96 h. This may be due to the toxicity of Cr(VI) towards bacterial cells. As a common observation, most of the calculated EC50 values were below 1 mg/L during the study period. This may be due to effective concentrations strictly depending on the nature of the growth medium (Rathnayake et al. 2013). Therefore, it can be assumed that the lower metal-binding capability of the tris minimal (modified) medium may have influenced EC50 values of the tested strain by increasing the Cr(VI) availability. According to the effective concentration analysis, the viability of S. edaphicus KCB02A11 can be drastically influenced by Cr(VI) at 96 h. On the contrary, Cr(VI) removal experiments of S. edaphicus KCB02A11 exhibit complete Cr(VI) removal reached at 96 h. of exposure. Therefore, it can be assumed that isolated strain may have the ability to remove Cr(VI) even after losing viability, which has been demonstrated by many toxicological studies using different heavy metals, including Cr(VI), and bacterial strains, including Staphylococcus sp. (Mukherjee et al. 2018), Bacillus sp. (Srinath et al. 2002; Huang et al. 2013; Dadrasnia et al. 2015; Mohapatra et al. 2019), Kocuria sp. (Akbarpour Nesheli et al. 2018), Arthrobacter sp. (Hlihor et al. 2017), Variovorax paradoxus, Arthrobacter viscosus (Malkoc et al. 2016), and Pseudomonas sp. (Gabr et al. 2008).

Bacterial bioremediation of Cr(VI) can be achieved by biosorption and biotransformation. During the biotransformation, Cr(VI) is reduced to Cr(III). Bacterial strains that can reduce hexavalent chromium are usually known as Chromium Reducing Bacteria (CRB). The Gram-positive CRB is believed to have a significantly high tolerance to higher Cr(VI) concentrations than Gram-negative CRB (Thatoi et al. 2014). Additionally, it has also been reported that chromium tolerance and reduction are independent properties of bacteria (Elangovan et al. 2006; Narayani and Shetty 2013; Thatoi et al. 2014). According to the Cr(VI) removal studies, it was evident that the S. edaphicus KCB02A11 could achieve a complete Cr(VI) removal up to the concentration of 8.5 mg/L within the study period of 96 h. followed by a gradual decrease of Cr(VI) removal at higher concentrations (Fig. 3). The results of the Cr(VI) analysis of acid digested cell pellets also indicate the absence of Cr(VI) inside bacterial cells. Further, ICP-MS analysis of cell-free supernatant revealed a 42.30% of total chromium removal from the 6.5 mg/L Cr(VI) incorporated sample, which was the highest among other tested concentrations (7.5, 8.5, and 9.5 mg/L Cr(VI)). Hence, the total chromium removal ability of the S. edaphicus KCB02A11 is inversely proportional to the Cr(VI) in the medium (Fig. 5). Considering this total chromium removal pattern of the tested strain, it can be assumed that the total chromium removal potential of the S. edaphicus KCB02A11 is curtailed with increasing Cr(VI) concentrations.

With regard to bacterial Cr resistance, previous studies show that heavy metal tolerance could be accomplished through periplasmic biosorption, intercellular bioaccumulation, and biotransformation (Cervantes and Campos-García 2007; Ramírez-Díaz et al. 2008; Pei et al. 2009; Joutey et al. 2015). Among these mechanisms, biotransformation is considered the best method to tolerate Cr(VI) via reduction to Cr(III), as it extracellularly reacts with functional groups in the bacterial cell wall (Ramírez-Díaz et al. 2008; Joutey et al. 2015). It has also been reported that bacterial EPS contributes to removing Cr(VI) from the medium via negatively charged hydroxyl, carboxyl, phenolic, and sulfhydryl functional groups through reduction, adsorption, and both (Chen et al. 2016; Kang et al. 2017; Tyagi et al. 2020) discloses that bacterial EPS production may also be enhanced with increasing Cr(VI) in the growth medium. No color development was observed in the DPC bioassay conducted with acid-digested biofilm cells, confirming no Cr(VI) inside the cells. Hence, it is assumed that the S. edaphicus KCB02A11 biofilm and EPS may have contributed to Cr(VI) reduction and chelation of resulting Cr(III) ions to the cells surface and EPS while the rest of Cr(III) was released back into the medium.

Natural adsorbents such as wood husk, green coconut shells, orange peel, citrus pectin, hazelnut shells, Terminally arjuna nuts, almond shells and wool, etc., are eco-friendly, low-cost materials reported in the literature which can remove Cr(VI) from contaminated sites (Zakaria et al. 2007; Owlad et al. 2009; Kumar and Meikap 2014; Ramirez Losada et al. 2018). Based on the above evidence, Hay and Wood husk were used in the present study. It was revealed that both hay and wood husk provided a matrix for biofilm formation and acted as adsorbents for Cr(VI) removal.

A comparison of the Cr(VI) removal of S. edaphicus KCB02A11 in solution and S. edaphicus KCB02A11 biofilm on adsorbents were done with respect to the 8.5 mg L− 1 Cr(VI), which was the maximum removal concentration of the isolate during the study period of 96 h. The study discovered that S. edaphicus KCB02A11 could potentially remove Cr(VI) completely within 96 h. while hay and wood husk adsorbents reached their maximum removal capacities of 62.25% and 31.39%, respectively, within 72 h. and 48 h. Biofilms of S. edaphicus KCB02A11on wood husk exhibited 45.99% Cr(VI) removal within 96 h., whereas 100% removal on hay within 72 h. (Fig. 4).

However, it was further noticed that after reaching the maximum removal by hay and wood husk adsorbents, a portion of adsorbed Cr(VI) is released back into the medium. This can be minimized by modifying adsorbents either by chemical treatment or physical treatment. Few researchers (Argun et al., 2008; Sciban et al. 2006; Wan Ngah et al., 2008) reported that the efficiency of heavy metal adsorption to natural adsorbents such as rice husk, sawdust, fruit/vegetable waste could be optimized by treating with acids (sulfuric acid, nitric acid, hydrochloric acid, citric acid, tartaric acid), bases (sodium hydroxide, calcium hydroxide, sodium carbonate) and salts (sodium chloride, calcium chloride, zinc chloride). With respect to physical changes, adsorbent capacity can be enhanced by increasing surface area, pore size, pore distribution and adsorbent sites (Gautam et al. 2014). However, this study was mainly focused on bacterial remediation rather than physical or chemical remediation. Therefore, hay and wood husk were mainly used to facilitate biofilm formation, curtailing the operational cost required in consecutive remediation cycles. The present study proved this assumption by providing a high weight of evidence as the S. edaphicus KCB02A11 biofilm on hay achieved Cr(VI) remediation in a new batch of contaminants even after 30 days of initial remediation cycle retaining the viability of the aggregated community. The biofilm analysis revealed that S. edaphicus KCB02A11 biofilm on hay could be regenerated and reused up to five continuous cycles.

Conclusion

The isolated Staphylococcus edaphicus KCB02A11 is a Cr(VI) tolerant bacterial strain having Cr(VI) removal capability with Cr(VI) bioreduction potential. Further, this removal could be optimized with the biofilms formed on the hay, which has excellent potential for its application in the remediation of Cr-contaminated waters.

Data Availability

All data generated or analysed during this study are included in this published article.

References

Akbarpour Nesheli M, Asgarani E, Dabbagh R (2018) Biosorption potential of Cr(VI) by Kocuria sp. ASB107, a radio-resistant bacterium isolated from Ramsar, Iran. Chem Ecol 34:163–176. https://doi.org/10.1080/02757540.2017.1399126

Almeida JC, Cardoso CED, Tavares DS et al (2019) Chromium removal from contaminated waters using nanomaterials – A review. TRAC Trends Anal Chem 118:277–291. https://doi.org/10.1016/j.trac.2019.05.005

Altun T, Parlayıcı Ş, Pehlivan E (2016) Hexavalent chromium removal using agricultural waste “rye husk. Desalination Water Treat 57:17748–17756. https://doi.org/10.1080/19443994.2015.1085914

Argun ME, Dursun S (2008) A new approach to modification of natural adsorbent for heavy metal adsorption. Bioresour Technol 99:2516–2527. https://doi.org/10.1016/j.biortech.2007.04.037

Aryal M, Ziagova M, Liakopoulou-Kyriakides M (2011) Comparison of cr(VI) and as(V) removal in single and binary mixtures with Fe(III)-treated Staphylococcus xylosus biomass: thermodynamic studies. Chem Eng J 169:100–106. https://doi.org/10.1016/j.cej.2011.02.059

Bhattacharya A, Gupta A, Kaur A, Malik D (2019) Alleviation of hexavalent chromium by using microorganisms: insight into the strategies and complications. Water Sci Technol 79:411–424. https://doi.org/10.2166/wst.2019.060

Cervantes C, Campos-García J (2007) Reduction and efflux of chromate by bacteria. In: Nies DH, Silver S (eds) Molecular Microbiology of Heavy Metals. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 407–419

Cervantes C, Campos-García J, Devars S et al (2001) Interactions of chromium with microorganisms and plants. FEMS Microbiol Rev 25:335–347. https://doi.org/10.1111/j.1574-6976.2001.tb00581.x

Chen C-Y, Cheng C-Y, Chen C-K et al (2016) Hexavalent chromium removal and bioelectricity generation by Ochrobactrum sp. YC211 under different oxygen conditions. J Environ Sci Health Part A 51:502–508. https://doi.org/10.1080/10934529.2015.1128731

Cherdchoo W, Nithettham S, Charoenpanich J (2019) Removal of cr(VI) from synthetic wastewater by adsorption onto coffee ground and mixed waste tea. Chemosphere 221:758–767. https://doi.org/10.1016/j.chemosphere.2019.01.100

Chien C-C, Lin B-C, Wu C-H (2013) Biofilm formation and heavy metal resistance by an environmental Pseudomonas sp. Biochem Eng J 78:132–137. https://doi.org/10.1016/j.bej.2013.01.014

Christensen GD, Simpson WA, Younger JJ et al (1985) Adherence of coagulase-negative staphylococci to plastic tissue culture plates: a quantitative model for the adherence of staphylococci to medical devices. J Clin Microbiol 22:996–1006. https://doi.org/10.1128/JCM.22.6.996-1006.1985

Coetzee JJ, Bansal N, Chirwa EMN (2020) Chromium in Environment, its toxic effect from Chromite-Mining and Ferrochrome Industries, and its possible bioremediation. Expo Health 12:51–62. https://doi.org/10.1007/s12403-018-0284-z

Dadrasnia A, Chuan Wei K, Shahsavari N et al (2015) Biosorption potential of Bacillus salmalaya strain 139SI for removal of cr(VI) from aqueous solution. IJERPH 12:15321–15338. https://doi.org/10.3390/ijerph121214985

Davies FT, Puryear JD, Newton RJ et al (2002) Mycorrhizal fungi increase chromium uptake by sunflower plants: influence on tissue mineral concentration, growth, and gas exchange. J Plant Nutr 25:2389–2407. https://doi.org/10.1081/PLN-120014702

Dong C, Ji J, Shen B et al (2018) Enhancement of H2O2 decomposition by the co-catalytic effect of WS2 on the Fenton reaction for the synchronous reduction of Cr(VI) and remediation of Phenol. Environ Sci Technol 52:11297–11308. https://doi.org/10.1021/acs.est.8b02403

Dutta A, Ghosh S, Choudhury JD et al (2017) Isolation of indigenous Staphylococcus sciuri from chromium-contaminated paddy field and its application for reduction of Cr(VI) in rice plants cultivated in pots. Bioremediat J 0:1–8. https://doi.org/10.1080/10889868.2017.1282935

Elahi A, Rehman A (2019) Multiple metal resistance and Cr6+ reduction by bacterium, Staphylococcus sciuri A-HS1, isolated from untreated tannery effluent. J King Saud Univ - Sci 31:1005–1013. https://doi.org/10.1016/j.jksus.2018.07.016

Elangovan R, Abhipsa S, Rohit B et al (2006) Reduction of Cr(VI) by a Bacillus sp. Biotechnol Lett 28:247–252. https://doi.org/10.1007/s10529-005-5526-z

Ertani A, Mietto A, Borin M, Nardi S (2017) Chromium in agricultural soils and crops: a review. Water Air Soil Pollut 228:190. https://doi.org/10.1007/s11270-017-3356-y

Fernández PM, Cabral ME, Delgado OD et al (2013) Textile-dye polluted waters as a source for selecting chromate-reducing yeasts through Cr(VI)-enriched microcosms. Int Biodeterior Biodegrad 79:28–35. https://doi.org/10.1016/j.ibiod.2013.01.009

Gabr RM, Hassan SHA, Shoreit AAM (2008) Biosorption of lead and nickel by living and non-living cells of Pseudomonas aeruginosa ASU 6a. Int Biodeterior Biodegrad 62:195–203. https://doi.org/10.1016/j.ibiod.2008.01.008

Gautam RK, Mudhoo A, Lofrano G, Chattopadhyaya MC (2014) Biomass-derived biosorbents for metal ions sequestration: adsorbent modification and activation methods and adsorbent regeneration. J Environ Chem Eng 2:239–259. https://doi.org/10.1016/j.jece.2013.12.019

He J, Chen X, Zhang Q, Achal V (2019) More effective immobilization of divalent lead than hexavalent chromium through carbonate mineralization by Staphylococcus epidermidis HJ2. Int Biodeterior Biodegrad 140:67–71. https://doi.org/10.1016/j.ibiod.2019.03.012

Hlihor RM, Figueiredo H, Tavares T, Gavrilescu M (2017) Biosorption potential of dead and living Arthrobacter viscosus biomass in the removal of Cr(VI): batch and column studies. Process Saf Environ Prot 108:44–56. https://doi.org/10.1016/j.psep.2016.06.016

Huang F, Dang Z, Guo C-L et al (2013) Biosorption of Cd(II) by live and dead cells of Bacillus cereus RC-1 isolated from cadmium-contaminated soil. Colloids Surf B 107:11–18. https://doi.org/10.1016/j.colsurfb.2013.01.062

Igiri BE, Okoduwa SIR, Idoko GO et al (2018) Toxicity and bioremediation of heavy metals contaminated ecosystem from Tannery Wastewater: a review. J Toxicol 2018:1–16. https://doi.org/10.1155/2018/2568038

Ilias M, Rafiqullah IMd, Debnath BC et al (2011) Isolation and characterization of chromium(VI)-Reducing Bacteria from Tannery Effluents. Indian J Microbiol 51:76–81. https://doi.org/10.1007/s12088-011-0095-4

Jobby R, Jha P, Yadav AK, Desai N (2018) Biosorption and biotransformation of hexavalent chromium [Cr(VI)]: a comprehensive review. Chemosphere 207:255–266. https://doi.org/10.1016/j.chemosphere.2018.05.050

Joutey NT, Sayel H, Bahafid W, El Ghachtouli N (2015) Mechanisms of hexavalent chromium resistance and removal by microorganisms. In: Whitacre DM (ed) Reviews of environmental contamination and toxicology volume 233. Springer International Publishing, Cham, pp 45–69

Kabir MM, Fakhruddin ANM, Chowdhury MAZ et al (2018) Isolation and characterization of chromium(VI)-reducing bacteria from tannery effluents and solid wastes. World J Microbiol Biotechnol 34:126. https://doi.org/10.1007/s11274-018-2510-z

Kamaludeen SPB, Megharaj M, Juhasz AL et al (2003) Chromium-microorganism interactions in soils: remediation implications. In: Ware GW (ed) Reviews of Environmental Contamination and Toxicology. Springer New York, New York, NY, pp 93–164

Kang C, Wu P, Li L et al (2017) Cr(VI) reduction and Cr(III) immobilization by resting cells of Pseudomonas aeruginosa CCTCC AB93066: spectroscopic, microscopic, and mass balance analysis. Environ Sci Pollut Res 24:5949–5963. https://doi.org/10.1007/s11356-016-8356-8

Kaur S, Roy A (2021) Bioremediation of heavy metals from wastewater using nanomaterials. Environ Dev Sustain 23:9617–9640. https://doi.org/10.1007/s10668-020-01078-1

Kotaś J, Stasicka Z (2000) Chromium occurrence in the environment and methods of its speciation. Environ Pollut 107:263–283. https://doi.org/10.1016/S0269-7491(99)00168-2

Krishna D, Sree RP (2013) Artificial neural network and response Surface Methodology Approach for modeling and optimization of chromium (VI) adsorption from Waste Water using Ragi Husk Powder. Indian Chem Eng 55:200–222. https://doi.org/10.1080/00194506.2013.829257

Kumar S, Meikap BC (2014) Removal of chromium(VI) from waste water by using adsorbent prepared from green coconut shell. Desalination Water Treat 52:3122–3132. https://doi.org/10.1080/19443994.2013.801796

Kumar A, Gahoi P, Verma N (2020) Simultaneous scavenging of Cr(VI) from soil and facilitation of nutrient uptake in plant using a mixture of carbon microfibers and nanofibers. Chemosphere 239:124760. https://doi.org/10.1016/j.chemosphere.2019.124760

Lee T, Lim H, Lee Y, Park J-W (2003) Use of waste iron metal for removal of Cr(VI) from water. Chemosphere 53:479–485. https://doi.org/10.1016/S0045-6535(03)00548-4

Ma Y, Li F, Jiang Y et al (2016) Remediation of Cr(VI)-Contaminated soil using the acidified hydrazine hydrate. Bull Environ Contam Toxicol 97:392–394. https://doi.org/10.1007/s00128-016-1862-z

Madhaiyan M, Poonguzhali S, Sa T (2007) Metal tolerating methylotrophic bacteria reduces nickel and cadmium toxicity and promotes plant growth of tomato (Lycopersicon esculentum L). Chemosphere 69:220–228. https://doi.org/10.1016/j.chemosphere.2007.04.017

Malaviya P, Singh A (2016) Bioremediation of chromium solutions and chromium containing wastewaters. Crit Rev Microbiol 42:607–633. https://doi.org/10.3109/1040841X.2014.974501

Malkoc S, Kaynak E, Guven K (2016) Biosorption of zinc(II) on dead and living biomass of Variovorax paradoxus and Arthrobacter viscosus. Desalination Water Treat 57:15445–15454. https://doi.org/10.1080/19443994.2015.1073181

Mathur T, Singhal S, Khan S et al (2006) Detection of biofilm formation among the clinical isolates of Staphylococci: an evaluation of three different screening methods. Indian J Med Microbiol 24:25. https://doi.org/10.4103/0255-0857.19890

Megharaj M, Avudainayagam S, Naidu R (2003) Toxicity of Hexavalent Chromium and its reduction by bacteria isolated from soil contaminated with tannery waste. Curr Microbiol 47:51–54. https://doi.org/10.1007/s00284-002-3889-0

Mehmood A, Aslam Mirza M, Aziz Choudhary M et al (2019) Spatial distribution of heavy metals in crops in a wastewater irrigated zone and health risk assessment. Environ Res 168:382–388. https://doi.org/10.1016/j.envres.2018.09.020

Miranda CD, Rojas R (2006) Copper accumulation by bacteria and transfer to scallop larvae. Mar Pollut Bull 52:293–300. https://doi.org/10.1016/j.marpolbul.2005.08.022

Mishra S, Bharagava RN (2016) Toxic and genotoxic effects of hexavalent chromium in environment and its bioremediation strategies. J Environ Sci Health Part C 34:1–32. https://doi.org/10.1080/10590501.2015.1096883

Mistry K, Desai C, Lal S et al (2010) Hexavalent chromium reduction by Staphylococcus sp. isolated from Cr(Vi) contaminated landfill. Int. j. biotechnol. biochem. 2010;6(1):117–29.

Mohapatra RK, Parhi PK, Pandey S et al (2019) Active and passive biosorption of Pb(II) using live and dead biomass of marine bacterium Bacillus xiamenensis PbRPSD202: kinetics and isotherm studies. J Environ Manage 247:121–134. https://doi.org/10.1016/j.jenvman.2019.06.073

Mukherjee S, Sahu P, Halder G (2018) Comparative assessment of the fluoride removal capability of immobilized and dead cells of Staphylococcus lentus (KX941098) isolated from contaminated groundwater. Environ Prog Sustainable Energy 37:1573–1586. https://doi.org/10.1002/ep.12853

Mythili K, Karthikeyan B (2011) Bioremediation of Cr(VI) from tannery effluent using Bacillus spp and Staphylococcus spp. Int J Pharm Biol Arch, 2(5), pp.1460–1463.

Narayanasamy S, Sundaram V, Sundaram T, Vo DVN (2022) Biosorptive ascendency of plant based biosorbents in removing hexavalent chromium from aqueous solutions?Insights into isotherm and kinetic studies. Environ Res 210:112902

Narayani M, Shetty KV (2013) Chromium-resistant Bacteria and their Environmental Condition for Hexavalent Chromium removal: a review. Crit Rev Environ Sci Technol 43:955–1009. https://doi.org/10.1080/10643389.2011.627022

National Environmental Act Sri Lanka (2008) National Environmental Act, No. 47 OF 1980. 31

Owlad M, Aroua MK, Daud WAW, Baroutian S (2009) Removal of Hexavalent Chromium-Contaminated Water and Wastewater: a review. Water Air Soil Pollut 200:59–77. https://doi.org/10.1007/s11270-008-9893-7

Pan X, Liu Z, Chen Z et al (2014) Investigation of Cr(VI) reduction and Cr(III) immobilization mechanism by planktonic cells and biofilms of Bacillus subtilis ATCC-6633. Water Res 55:21–29. https://doi.org/10.1016/j.watres.2014.01.066

Pei QH, Shahir S, Santhana Raj AS et al (2009) Chromium(VI) resistance and removal by Acinetobacter haemolyticus. World J Microbiol Biotechnol 25:1085–1093. https://doi.org/10.1007/s11274-009-9989-2

Pereira EJ, Ramaiah N (2019) Chromate detoxification potential of Staphylococcus sp. isolates from an estuary. Ecotoxicology 28:457–466. https://doi.org/10.1007/s10646-019-02038-w

Pereira EJ, Fonseca S, Meena RM, Ramaiah N (2017) Improved sprouting and growth of mung plants in Chromate contaminated Soils treated with Marine strains of Staphylococcus Species. Indian J Microbiol 57:400–408. https://doi.org/10.1007/s12088-017-0668-y

Pradhan SK, Singh NR, Das S, Thatoi H (2020) Molecular identification and phylogenetic analysis of chromium-resistant bacteria isolated from chromite mine area soil, Sukinda, India using 16S rRNA sequencing. Soil and Sediment Contamination: An International Journal 29:805–822. https://doi.org/10.1080/15320383.2020.1771272

Rajbanshi A (2009) Study on Heavy Metal resistant Bacteria in Guheswori Sewage Treatment Plant. Our Nat 6:52–57. https://doi.org/10.3126/on.v6i1.1655

Ramirez Losada VA, Bonilla EP, Carvajal Pinilla LA, Serrezuela RR (2018) Removal of chromium in wastewater from tanneries applying bioremediation with algae, orange peels and citrus pectin. ces 11:433–449. https://doi.org/10.12988/ces.2018.8235

Ramírez-Díaz MI, Díaz-Pérez C, Vargas E et al (2008) Mechanisms of bacterial resistance to chromium compounds. Biometals 21:321–332. https://doi.org/10.1007/s10534-007-9121-8

Rathnayake IVN, Megharaj M, Krishnamurti GSR et al (2013) Heavy metal toxicity to bacteria – are the existing growth media accurate enough to determine heavy metal toxicity? Chemosphere 90:1195–1200. https://doi.org/10.1016/j.chemosphere.2012.09.036

Ravindra K, Mor S (2019) Distribution and health risk assessment of arsenic and selected heavy metals in groundwater of Chandigarh, India. Environ Pollut 250:820–830. https://doi.org/10.1016/j.envpol.2019.03.080

Saha R, Nandi R, Saha B (2011) Sources and toxicity of hexavalent chromium. J Coord Chem 64:1782–1806. https://doi.org/10.1080/00958972.2011.583646

Saxena D, Levin R, Firer MA (2000) Removal of chromate from industrial effluent by a new isolate of Staphylococcus cohnii. Water Sci Technol 42:93–98. https://doi.org/10.2166/wst.2000.0297

Sciban M, Klasnja M, Skrbic B (2006) Modified softwood sawdust as adsorbent of heavy metal ions from water. J Hazard Mater 136:266–271. https://doi.org/10.1016/j.jhazmat.2005.12.009

Seneviratne DGNS, Rathnayake IVN (2019) Tolerance of Cr(VI) and Cd(II) by three bacterial genera isolated from a waterbody receiving industrial effluent. In: Proceedings of the Postgraduate Institute of Science Research Congress, University of Peradeniya, Sri Lanka, October 2019, p 6

Shahnaz T, Sharma V, Subbiah S, Narayanasamy S (2020) Multivariate optimisation of Cr(VI), Co(III) and Cu(II) adsorption onto nanobentonite incorporated nanocellulose/chitosan aerogel using response surface methodology. J Water Process Eng 36:101283

Shanker A, Cervantes C, Lozatavera H, Avudainayagam S (2005) Chromium toxicity in plants. Environ Int 31:739–753. https://doi.org/10.1016/j.envint.2005.02.003

Sharma S, Adholeya A (2012) Hexavalent Chromium reduction in Tannery Effluent by Bacterial Species isolated from Tannery Effluent contaminated soil. J of Environmental Science and Technology 5:142–154. https://doi.org/10.3923/jest.2012.142.154

Srinath T, Verma T, Ramteke PW, Garg SK (2002) Chromium (VI) biosorption and bioaccumulation by chromate resistant bacteria. Chemosphere 48:427–435. https://doi.org/10.1016/S0045-6535(02)00089-9

Suresh G, Balasubramanian B, Ravichandran N et al (2021) Bioremediation of hexavalent chromium-contaminated wastewater by Bacillus thuringiensis and Staphylococcus capitis isolated from tannery sediment. Biomass Conv Bioref 11:383–391. https://doi.org/10.1007/s13399-020-01259-y

Thatoi H, Das S, Mishra J et al (2014) Bacterial chromate reductase, a potential enzyme for bioremediation of hexavalent chromium: a review. J Environ Manage 146:383–399. https://doi.org/10.1016/j.jenvman.2014.07.014

Tyagi B, Gupta B, Thakur IS (2020) Biosorption of Cr(VI) from aqueous solution by extracellular polymeric substances (EPS) produced by Parapedobacter sp. ISTM3 strain isolated from Mawsmai cave, Meghalaya, India. Environ Res 191:110064. https://doi.org/10.1016/j.envres.2020.110064

Ukah BU, Egbueri JC, Unigwe CO, Ubido OE (2019) Extent of heavy metals pollution and health risk assessment of groundwater in a densely populated industrial area, Lagos, Nigeria. Int J Energ Water Res 3:291–303. https://doi.org/10.1007/s42108-019-00039-3

Vaiopoulou E, Gikas P (2020) Regulations for chromium emissions to the aquatic environment in Europe and elsewhere. Chemosphere 254:126876. https://doi.org/10.1016/j.chemosphere.2020.126876

Vatsouria A, Vainshtein M, Kuschk P et al (2005) Anaerobic co-reduction of chromate and nitrate by bacterial cultures of Staphylococcus epidermidis L-02. J ind microbiol biotechnol 32:409–414. https://doi.org/10.1007/s10295-005-0020-0

Wan Ngah WS, Hanafiah MAKM (2008) Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Bioresour Technol 99:3935–3948. https://doi.org/10.1016/j.biortech.2007.06.011

Wang XS, Li Y, Huang LP, Chen J (2020) Adsorption of Cr(VI) from Aqueous Solutions by Staphylococcus aureus Biomass. 38:500–505. https://doi.org/10.1002/clen.201000128

Xu Z-R, Cai M-L, Chen S-H et al (2021) High-Affinity Sulfate Transporter Sultr1;2 is a major transporter for Cr(VI) uptake in plants. Environ Sci Technol 55. https://doi.org/10.1021/acs.est.0c04384

Yin K, Wang Q, Lv M, Chen L (2019) Microorganism remediation strategies towards heavy metals. Chem Eng J 360:1553–1563. https://doi.org/10.1016/j.cej.2018.10.226

Zahoor A, Rehman A (2009) Isolation of Cr(VI) reducing bacteria from industrial effluents and their potential use in bioremediation of chromium containing wastewater. J Environ Sci 21:814–820. https://doi.org/10.1016/S1001-0742(08)62346-3

Zakaria ZA, Zakaria Z, Surif S, Ahmad WA (2007) Hexavalent chromium reduction by Acinetobacter haemolyticus isolated from heavy-metal contaminated wastewater. J Hazard Mater 146:30–38. https://doi.org/10.1016/j.jhazmat.2006.11.052

Zhang X, Wu W, Virgo N, Zou L, Liu P, Li X (2014) Global transcriptome analysis of hexavalent chromium stress responses in Staphylococcus aureus LZ-01. Ecotoxicology 23:1534–1545

Ziagova M, Dimitriadis G, Aslanidou D, Papaioannou X (2007) Comparative study of Cd(II) and Cr(VI) biosorption on Staphylococcus xylosus and Pseudomonas sp. in single and binary mixtures. 98:2859–2865. https://doi.org/10.1016/j.biortech.2006.09.043

Funding

This research was funded by National Research Council, Sri Lanka, Investigator Driven Research Grant-18-083.

Author information

Authors and Affiliations

Contributions

AMKCBA designed the experiments, conducted the experiments and analyzed the results, contributed to the interpretation of results, and prepared the first draft. IVNR conceptualized the research, secured funding, designed experiments, supervised the study, contributed to the interpretation of results, commented on the first draft, and contributed to the revision of the manuscript. MPD supervised the study and contributed to the revision of the manuscript. MM contributed to the conceptualization of the research, contributed to the interpretation of results, commented on the first draft and contributed to the revision of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no financial or non-financial interests to disclose

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aththanayake, A.M.K.C.B., Rathnayake, I.V.N., Deeyamulla, M.P. et al. Staphylococcus edaphicus KCB02A11 incorporated with natural adsorbents: first report on its tolerance and removal of hexavalent chromium [Cr(VI)]. World J Microbiol Biotechnol 39, 173 (2023). https://doi.org/10.1007/s11274-023-03614-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-023-03614-3