Abstract

A phosphorus dendrimer with multiple amino groups was synthesized via a two-step reaction with phosphonitrilic chloride trimer and 4-acetamidophenol. The trinuclear nickel complex was subsequently prepared with the phosphorus dendrimer and nickel chloride hexahydrate as starting materials. The structures of the phosphorus dendrimer and the trinuclear nickel complex were characterized by physicochemical and spectroscopic methods. The trinuclear nickel complex based on the phosphorus dendrimer was evaluated as catalyst precursor for ethylene oligomerization using methylaluminoxane (MAO) as an activator. Under the conditions of 0.5 h, 0.9 MPa, 25 °C and Al/Ni molar ratio of 700, the catalytic activity of the trinuclear nickel complex showed a maximum value of 2.31 × 105 g/(mol Ni h), and the oligomerization products were mainly low-carbon olefins (C4 and C6). The ligand structure and the coordination mode showed notable variations in the catalytic activities and the product distribution due to the influence of electronic and steric effects. The catalytic activity of the nickel complex based on the ligand with an aryl backbone was superior to the nickel complex based on the ligand with an alkyl backbone.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As an important industrial raw material, α-olefin is widely used in the synthesis of detergents, plasticizers, lubricating oils, fine chemicals, linear low-density polyethylene (LLDPE) and monomers of copolymerization [1,2,3,4]. The main technologies of producing α-olefin are wax cracking method, gas method and ethylene oligomerization method. However, ethylene oligomerization is one of the most advanced production routes for the production of α-olefins [3,4,5]. Currently, many catalysts have been used for the production of linear α-olefins through the oligomerization of ethylene. And the late-transition metal complexes containing bi- and tri-dentate ligands are widely used in the ethylene oligomerization process [6]. The extremely electron-deficient early metal catalysts tend to be poisoned by polar functional groups [7]. In contrast, the novel late transition metal catalysts have advantages not only in catalytic activity and selectivity but also in their potential for tolerating heteroatom functionalities [8]. In 1995, Brookhart and co-workers [9, 10] demonstrated that late transition metal complexes of α-diimines, specifically that of Pd and Ni, could be used as highly active catalysts for ethylene oligomerization [11]. The unique and versatile reactivity of nickel enables the oligomerization of ethylene, propylene, and butenes into a wide range of oligomers that are highly sought-after in numerous fields to be controlled [12]. In the past decades, nickel complexes, especially mononuclear nickel and binuclear nickel complexes, have emerged as the catalysts for ethylene oligomerization and have attracted wide attention in both academic and industrial research due to their lower oxophilcity [13,14,15,16,17]. Schumann and co-workers designed and synthesized a series of binuclear methylene bridged α-diimine nickel complexes and the catalytic activity was up to 3.22 × 105 g/(mol Ni·h) for the binuclear methylene bridged α-diimine nickel complexes in ethylene polymerization, which showed higher activities than their mononuclear analogs in ethylene polymerization [18]. Xiao and co-workers developed bis-chelate and binuclear nickel complexes based on 2-alkoxyimidate-1,10-phenanthroline derivatives, and the results showed that the catalytic activity (3.23 × 105 g/ (mol Nih)) of the binuclear complex was far higher than the bis-chelate complex. In addition, the nickel complex exhibited high selectivity toward butene with 83.4% and the selectivity of 19.1% for 1-butene [19]. Chen and co-workers synthesized a series of binuclear nickel catalysts based on dinucleating α-diimine ligands and investigated the catalytic properties in ethylene polymerization, and the results indicated that the naphthalene-bridged α-diimine binuclear nickel complex showed higher catalytic activity of 4.64 × 106 g/(mol Ni h) in ethylene polymerization comparing with the mononuclear analog [20]. Many reports showed that binuclear transition metal catalysts could improve the polymerization activity and reduce molecular weight distribution [16,17,18,19,20]. Transition metal catalysts with multiple active centers have attracted much attention in ethylene olig-/polymerization.

However, few multi-metal center catalysts have been reported as catalyst precursors in ethylene oligo-/polymerization. Tansir Ahamad and co-workers reported nickel complexes with aromatic amine-terminated first generation (G1) and second-generation (G2) polyamide dendrimers as catalysts for ethylene oligomerization. The effect of dendrimer generation on activity showed that the second-generation catalyst was more active than the first generation catalyst [21]. In addition, the multiple active centers of the trinuclear metal complex make it have a more suitable reaction rate in homogeneous system and have extremely high local catalyst and ligand concentrations [22]. At present, most of the multi-nuclear nickel catalysts used for ethylene oligomerization were based on polyamidoamine (PAMAM) and polypropylene (PPI) dendrimers backbone with flexible structure, and moreover, these dendrimers mainly coordinated with transition metal through the Schiff-base reaction.

In this work, we aimed to design and synthesize a trinuclear nickel complex with a phosphorus dendrimer containing a rigid group [23, 24] through the complexation of primary amines (-NH2). The ethylene oligomerization behavior of the trinuclear nickel complex and the effect of the oligomerization parameters on the ethylene oligomerization behavior were investigated to obtain the optimum oligomerization process. The effect of the dendrimer structure on the ethylene oligomerization behavior and the dendritic effect of the trinuclear nickel complex in ethylene oligomerization were also investigated.

Experimental section

Materials and general instrumentations

Manipulations of air and moisture-sensitive compounds were performed under a nitrogen atmosphere using standard Schlenk techniques. Methylaluminoxane (MAO, 10 wt% in toluene) was purchased from Sigma-Aldrich (China). Phosphonitrilic chloride trimer, 4-acetamidophenol and potassium carbonate were provided by Shanghai Aladdin Biochemical Technology Co. Ltd. (China). Acetonitrile, n-hexane and ethanol were purchased from Tianjin kemio Chemical Reagent Co., Ltd. Methanol was obtained from DAMAO chemical reagent factory. Sodium hydroxide was purchased from Liaoning Quanrui Reagent Co., Ltd. Tetrahydrofuran was purchased from Tianjin Ruijinte Chemicals Co., Ltd.

IR spectra were recorded on a Nicolet FTIR 750 infrared spectrometer using the KBr pellets method. Thermal gravimetric analysis was carried out on SDT Q600 by heating the samples from 30 to 900 °C under nitrogen atmosphere at a heating rate of 10 °C /min. 1H NMR, 13C NMR and 31P NMR spectra were obtained on a Varian 400 MHz in deuterated dimethyl sulfoxide (DMSO-d6) as the solvent and tetramethylsilane (TMS) as the internal standard. The absorbency of the ligand and its complex were determined using a TU-1901 solid diffuse UV–vis spectra photometer. Mass spectra (MS) were collected on a Bruker Apex Ultra 70 FTMS using electrospray ionization (ESI) as ion-source. The nickel element analysis of the synthesized PD-complex was calculated using ICPS-7510 spectrometer. The sample was prepared by treating 10 mg of PD-complex with 2 mL of HCl, 6 mL of HNO3 and 5 mL of HF, respectively, and the solution was diluted with deionized water at room temperature. Gas chromatography (GC) analyses were conducted on Fuli GC 9720 equipped with a flame ionization detector (FID) and a 50 m (0.2 mm i.d., 0.5 μm film thickness) HP-PONA column.

Synthesis of trinuclear nickel complex with phosphorus dendrimer

Phosphorus dendrimer (PD-(NH2)6) and the corresponding nickel complex (PD-complex) were synthesized as previously described by Jiang [25]. In brief, a mixture of phosphonitrilic chloride trimer (1.046 g, 0.003 mol), 4-acetamidophenol (3.713 g, 0.021 mol), and K2CO3 (3.141 g, 0.023 mol) in acetonitrile (100 mL) was heated at 80 °C under vigorous stirring for 24 h. The resulting mixture was washed with water (3 × 50 mL). The resulting solid was dried in a vacuum at 50 °C for 12 h to yield the white solid (PD-(NHOC)6). Yield: 78%. Mp: 249.8–252.5 °C.

PD-(NHOC)6 (1.007 g, 0.002 mol) was dissolved in 50 mL methanol, and the above PD-(NHOC)6 solution was added to the NaOH solution (20 wt%). The mixture was heated to 90 °C and was stirred for 24 h. The solvent was filtered off, and the remaining solid was washed with ethanol (3 × 20 mL), n-hexane (3 × 20 mL) and water (3 × 50 mL), respectively. The resulting solid was dried in a vacuum at 60 °C for 48 h to yield the light-yellow solid (PD-(NH2)6). Yield: 74%. Mp: 169.9–170.5 °C.

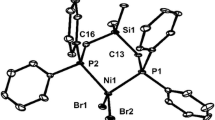

PD-(NH2)6 (1.31 g, 5 mmol) was dissolved in 25 mL ethanol. Nickel chloride hexahydrate (4.27 g, 18 mmol) was added into the PD-(NH2)6 solution, and the reaction mixture was allowed to stir under reflux for 24 h to form a green precipitate. The precipitate was filtered and washed with plenty of ethanol to afford the PD-complex as a green solid in the yield of 87%. ESI–MS (m/z): 1137.2 [M–Cl]+, 878.1 [M–2NiCl2–Cl]+, 784.2 [M–3NiCl2]+, 326.9 [M–3NiCl2–6O–C6H6N] +, 157.0 [M–3NiCl2–5O–6C6H6N] +. Anal. by ICP (atomic %): Ni 14.79. (Calcd. 15.01).

Oligomerization reaction

Ethylene oligomerization was carried out in a 100 ml stainless steel autoclave equipped with a magnetic stirrer and ethylene pressure control system. The reactor was charged with ethylene three times after the reactor temperature reached to the desired value, and the ethylene was maintained at the constant pressure. Under ethylene atmosphere, the appropriate amounts of solvent, co-catalyst and precatalyst precursor were injected into the reactor with a syringe, respectively. Ethylene must be supplied continuously to hold the desired stable pressure. The mixture was vigorously stirred for the desired time under the appropriate pressure of ethylene throughout the experiment. After the reaction, the reaction mixture was cooled in an ice-water bath and the gas mixture was collected with gasbags. The liquid mixture was quenched by 10% hydrochloric acid in ethanol. The qualitative analysis of gas mixture and the liquid mixture was identified by GC. The chromatographic analyses were performed on a Fuli GC9720 instrument equipped with HP-PONA capillary column (60 m long, 0.25 mm ID, 0.5 μm film thickness). The analysis conditions were 50 °C for 5 min, heated at 10 °C/min until the temperature reached 140 °C, then heated at 5 °C/min until the temperature reached 240 °C and maintained at the temperature for 5 min. The oligomers were identified by co-injecting n-hexane as the internal standard for quantification.

Results and discussion

Synthesis and characterization

PD-(NH2)6 was synthesized by reacting phosphonitrilic chloride trimer with 4-acetamidopheno via the substitution reaction and the hydrolysis reaction (Scheme1). In order to obtain the PD-(NH2)6 and its corresponding nickel complex with the high yield and the high purity, potassium carbonate (K2CO3) as catalyst and acid binding agent and the excessive amount of 4-acetamidophenol were used in the synthesis of PD-(NHOC)6. The compound (KCl) obtained by the reaction of K2CO3 and HCl formed in the synthesis of PD-(NHOC)6, the unreacted K2CO3 and the excess 4-acetamidophenol were removed by washing the product with 60 °C hot water. Nickel chloride hexahydrate was used in excess and the reaction was carried out at the reflux of ethanol, which was higher than the reaction temperature of the nickel complexes in our previous works [26]. The yields and the values of the melting point for PD–(NHOC)6 and PD–(NH2)6 were listed in the experimental section, and the Ni content and the ESI–MS value for the PD-complex were also listed in the experimental section. The structure of the PD-(NH2)6 was characterized by a combination of FTIR, 1H NMR, 13C NMR, 31P NMR and UV, while the structure of the PD-complex was established by a combination of FTIR, UV and MS.

The absorption bands at 3436 cm−1 and 1625 cm−1 in the FTIR spectrum of the PD-(NH2)6 ligand were attributed to symmetric and asymmetric stretching vibrations of -NH2 group, and which confirmed that the acylamino group of PD-(NHOC)6 was completely hydrolyzed to form amine groups [21]. The disappearance of the -CONH- group at around 1651 cm−1 and 1530 cm−1 further confirmed that the hydrolysis reaction was carried out successfully for PD-(NHOC)6. Moreover, the spectrum of PD-(NH2)6 indicated the skeleton vibrational mode of the benzene ring at about 1505 cm−1. The band at 1266 cm−1 was assigned to the stretching vibration of Ph-O in the FTIR spectra of PD-(NHOC)6 and PD-(NH2)6 (Fig. 1). The band that appeared at 1161 cm−1 was assigned to the P=N bond of cyclotriphosphazene [27, 28]. The band observed at 965 cm−1 was attributed to the P-O stretching vibration. The band at 883 cm−1 was assigned to the P-N bond of cyclotriphosphazene [29]. Compared with the spectrum of PD-(NH2)6, the shift in the υ(N–H) stretching frequency from around 3436–3322 cm−1 was observed in the spectrum of the PD-complex (Fig. 1), and the absorption peak of –NH2 at 1625 cm−1 was broadened, which indicated the coordination interaction between the amino nitrogen atoms and the metal ions.

The solid-state diffuse UV–vis spectra of the PD-(NH2)6 ligand and PD-complex are shown in Fig. 2. The solid-state diffuse UV–vis spectrum of the PD-(NH2)6 ligand showed five absorption bands at 208, 224, 266, 298 and 382 nm, respectively. The bands at 208 and 224 nm were assigned to the K band of the benzene ring, and the bands at 266 and 298 nm to the B band of the benzene ring [30]. The band at 382 nm corresponded to the R band of n → π* transition for P=N. Comparing with the spectrum of PD-(NH2)6, the intensity of absorption for the R band of the n → π* transition for P=N, K band and B band of benzene ring disappeared in the spectrum of PD-complex. In addition, the peak at 720 nm located in the near-infrared region was observed, which was assigned to a d-d transition of Ni2+. The results further indicated an effective coordination interaction between the amino nitrogen atoms and the metal centers.

The 1H NMR, 13C NMR and 31P NMR spectra of the PD-(NH2)6 are shown in Fig. 3. The 1H NMR spectrum (Fig. 3a) showed the amino proton (-NH2) as a sharp singlet at 4.9 ppm, and the hydrogen protons on the benzene ring were observed over the range of 6.38–6.48 ppm. The 13C NMR spectrum (Fig. 3b) showed aromatic carbon resonances at 114.81, 121.56, 141.35, and 146.08 ppm, respectively. The 31P NMR spectrum (Fig. 3c) exhibited a singlet at 10.64 ppm, which indicated the chemical equivalence of all the phosphorus atoms in PD-(NH2)6. This result indicated that the phosphazene heterocyclic ring structure was stable in the substitution reaction and the hydrolysis reaction. The results of the NMR experiments indicated that the PD-(NH2)6 was synthesized successfully.

The ESI mass spectrum for the PD-complex is shown in Fig. 4. The ESI mass spectrum of the PD-complex showed that the molecular ion peak was at m/z 1153 . Fragmentation peaks due to the elimination of Ni and Cl were observed at m/z 784 in the ESI mass spectrum of PD-complex. The other spectroscopic analysis of the PD-complex was summarized in the synthesis section. These values were in good agreement with the proposed composition for the PD-complex, which demonstrated that the PD-complex was synthesized successfully.

TGA /DTG curves for PD-(NH2)6 and PD-complex under the N2 atmosphere at the heating rate of 10 °C/min are shown in Fig. 5. For PD–(NH2)6, the thermal degradation process could be subdivided into three stages based on the DTG curve. The first weight loss in the first region (30–345 °C) was 1.1 wt%, which corresponded to the moisture loss. Approximately 32 wt% of weight loss observed in the second region (345–667 °C) was attributed to the cleavage of the P–O bond, which caused the phenoxy group to break away from the phosphazene ring to form small molecules, such as benzene. The aromatic structure began to be carbonized and the molecular structure was further destroyed and decomposed after 400 °C [31]. The third weight loss (33.6 wt%) observed in the temperature range 667–1091 °C corresponded to cyclotriphosphazene from the ligand [32]. The residual mass (33.3 wt%) of the ligand corresponded to carbon and phosphorus produced in the decomposition of PD-(NH2)6.

For the PD-complex, approximately 8.7 wt% of weight loss observed in the first region (30–308 °C) corresponded to scission of trace water, intermolecular cross-linking, and some defects in the cyclophospazene network structure. The second weight loss (9.63 wt%) observed in the temperature range of 308–710 °C was attributed to the collapse of the complex skeleton, which caused the degradation of the phenoxyl and decomposition of benzene ring [31]. The third weight loss (16.56 wt%) observed in the temperature range of 710–900 °C corresponded to decomposition of cyclotriphosphazene [32]. The residual mass (38.4 wt%) of PD-complex corresponded to carbon, phosphorus and nickel reduced in the decomposition of the complex. Comparing the thermogravimetric spectrum of PD–(NH2)6 with the thermogravimetric spectrum of PD-complex, the difference between them was mainly in the first weight loss and residual mass. The result of the thermal analysis revealed that the synthesized PD-complex was stable up to 308 °C, slightly worse than the PD-(NH2)6, which was stable up to 345 °C.

Influence of reaction conditions on ethylene oligomerization

The influence of Al/Ni ratio on the catalytic performance was first investigated using methylaluminoxane (MAO) as an activator with 2 μmol PD-complex under the conditions of 0.5 h, 0.5 MPa, 25 °C. Variation of the Al/Ni ratio in the range of 300–900 showed a significant effect on the oligomerization activity and the oligomer distribution (Fig. 6). As the molar ratio of Al/Ni increased, the catalytic activity improved significantly. The highest catalytic activity of 1.85 × 105 g/(mol Ni·h) was obtained at the Al/Ni ratio of 900. A possible reason was that a higher co-catalyst mole ratio might lead to the activation of the nickel sites to create adequate activated state, and promoted the catalytic activity. In terms of the product distributions, we found that the complex showed good selectivity toward 1-butene. A possible explanation for this phenomenon was because increasing the Al/Ni molar ratio might make the rate of chain growth decrease and the β-hydride elimination correspondingly increase [26].

The effects of reaction temperature on the catalytic performance of the PD-complex in ethylene oligomerization under the conditions of 0.5 h, 0.5 MPa and Al/Ni molar ratio of 700 are shown in Fig. 7. It was clear that the catalytic activities exhibited a decreasing trend when the temperature increased from 25 to 55 °C, and the catalytic activity reached a minimum value at approximately 55 °C. The selectivity toward C6 first increased and then decreased with increasing reaction temperature, which could be explained by the chain growth rate increasing more than the chain transfer rate below 45 °C and the chain growth rate was more dominating at 45 °C [33].

As shown in Fig. 8, the effects of ethylene pressure on catalytic activity and the selectivity for PD-complex were studied by varying reaction pressure from 0.1 to 0.9 MPa under the conditions of 0.5 h, 25 °C and Al/Ni mole ratio of 700. The results showed that the ethylene oligomerization activities for PD-complex increased with increasing the ethylene pressure when the reaction pressure increased from 0.1 to 0.9 MPa, ultimately achieving 2.3 × 105 g/(mol Ni h). This was understandable that the catalytic activity increased by increasing the olefin pressure due to ethylene solubility dependence on pressure. In addition, the selectivity toward lower chain oligomers of PD-complex was inclined to a higher ethylene concentration (Fig. 9).

Influence of the ligand structure on catalytic performance

In order to study the effect of the dendrimer backbone and the coordination mode on the catalytic performance, the catalytic properties of 1.0G dendritic nickel complex (Cat.1) with aromatic amine-terminated [21] and star iminopyridyl nickel complex (Cat.2) based on 1.0G dendrimer with amine as the core [34] were compared in this work (Entry 2 and 3 in Table 1). It was clear that the dendrimer backbone and the coordination had a significant effect on catalytic performance. As can be seen from Table 1, Cat.1 showed higher activity than PD-complex, and Cat.2 displayed the lowest activity, which had been attributed to the electronic effects. Specifically, raising the electrophilicity of the central metal is an effective strategy to increase catalytic activities [35]. For Cat.1 and PD-complex, the orbital occupied by the lone pair electrons of N in the amine group was conjugated with the benzene ring, which reduced the electron density around the nitrogen and increased the electrophilicity of nickel. Compared with PD-complex, the activation center of Cat.1 was more stable and had higher activity, because Cat.1 was coordinated with the metal through the two amino groups of the same aromatic ring. However, the large electronegativity of the N atom on the pyridine ring in Cat.2 led to the decrease of electrophilicity of Ni, which resulted in the low activity. PD-complex had a higher selectivity on short-chain oligomers, comparing with Cat.2. The reason for the phenomenon might be attributed to that the larger steric hindrance tend to be more prone to forming low-carbon oligomers. However, Cat.1 had a higher selectivity on high carbon olefins (C8+) in toluene (Table 1), especially for C12 olefin. The reason for this difference in selectivity was that the GC analysis was done on the residues after evaporation of the solvent for 1.0G dendritic complex, thus no low-carbon oligomers (C4–C8).

The result for ethylene oligomerization at the Ni-sites was explained by the mechanism (Scheme 2), which consisted of chain initiation, chain propagation and β-H elimination of α-olefin (chain transfer) [36, 37]. An increasing steric hindrance of the ligand led to an increase in β-hydrogen elimination and thus to light olefin [38]. For PD-complex, considerable steric hindrance owing to the distortion of the P-O bond led to an increase in the β-hydrogen elimination and the formation of C4–C6 olefins.

Conclusions

PD-complex based PD-(NH2)6 was successfully synthesized and the analytical methods of FTIR, 1H NMR, 13C NMR, TGA, and MS confirmed the structures of PD-(NH2)6 and the PD-complex. With MAO as co-catalyst and cyclohexane as the solvent, the PD-complex showed good catalytic activity in ethylene oligomerization and the major products were C4–C6 oligomers. The selectivity of oligomers was quite sensitive to the reaction temperature for PD-complex, and the higher reaction temperature tended to be more prone to forming high-carbon oligomers. The ligand structure and the coordination mode played an important role in the catalytic activities and the product distribution. Increasing the electrophilicity of nickel was shown to favor the catalytic activities, and a higher steric hindrance of the ligand was observed to favor an increase in β-hydrogen elimination and thus to light olefin.

References

Bahuleyan BK, Ahn IY, Appukuttan V, Lee SH, Ha CS, Kim I, Suh H (2010) Macromol Res 18(7):701–704

Forestière A, Olivier-Bourbigou H, Saussine L (2009) Oil Gas Sci Technol 64(6):649–667

Belov GP, Matkovsky PE (2010) Petrol Chem+ 50(4):283–289

Van Leeuwen PW, Clément ND, Tschan MJL (2011) Coordin Chem Rev 255(13–14):1499–1517

Huang YW, Wei W, Meng XJ, Zhang L, Chen YH, Jiang T (2018) Appl Organomet Chem 32(2):e4014

Meng XJ, Zhang L, Chen YH, Jiang T (2016) React Kinet Mech Cat 119(2):481–490

Mu HL, Pan L, Song DP, Li YS (2015) Chem Rev 115(22):12091–12137

Wang H, Yan W, Jiang T, Liu BB, Xu WQ, Ma JJ, Hu YL (2002) Chin Sci Bull 47(19):1616–1618

Johnson LK, Killian CM, Brookhart M (1995) J Am Chem Soc 117(23):6414–6415

Ittel SD, Johnson LK, Brookhart M (2000) Chem Rev 100(4):1169–1204

Luk YYG, Foucher DA, Gossage RA (2013) CR Chim 16(6):73–579

Olivier-Bourbigou H, Breuil PAR, Magna L, Michel T, Espada Pastor MF, Delcroix D (2020) Chem Rev 120(15):7919–7983

Wei W, Yu BW, Alam F, Huang YW, Cheng SL, Jiang T (2019) Transit Metal Chem 44(2):125–133

Ainooson MK, Ojwach SO, Guzei IA, Spencer LC, Darkwa J (2011) J Organomet Chem 696(8):1528–1535

Gibson VC, Spitzmesser SK (2003) Chem Rev 103(1):283–316

Britovsek GJ, Bruce M, Gibson VC, Kimberley BS, Maddox PJ, Mastroianni S, McTavish SJ, Redshaw C, Solan GA, Strömberg S, White AJP, Williams DJ (1999) J Am Chem Soc 121(38):8728–8740

Delferro M, Marks TJ (2011) Chem Rev 111(3):2450–2485

Luo HK, Schumann H (2005) J Mol Catal A-Chem 227(1–2):153–161

Xiao LW, Jie SY, Song YG, Cao XP, Sun WH (2008) J Organomet Chem 693(26):3858–3866

Na YN, Wang XB, Lian KB, Zhu Y, Li WM, Luo Y, Chen CL (2017) ChemCatChem 9(6):1062–1066

Ahamad T, Alshehri SM, Mapolie SF (2010) Catal Lett 138(3):171–179

Smith G, Chen R, Mapolie S (2010) J Organomet Chem 673(1–2):111–115

Wang D, Astruc D (2013) Coordin Chem Rev 257(15–16):2317–2334

Ouali A, Laurent R, Caminade AM, Majoral JP, Taillefer M (2006) J Am Chem Soc 128(50):15990–15991

Jiang P, Gu XY, Zhang S, Wu SD, Zhao Q, Hu ZW (2015) Ind Eng Chem Res 54(11):2974–2982

Li CQ, Wang FF, Lin ZY, Zhang N, Wang J (2016) Inorg Chim Acta 453:430–438

Qiu SL, Ma C, Wang X, Zhou X, Feng XM, Yuen RK, Hu Y (2018) J Hazard Mate 344:839–848

Zhou X, Mu XW, Cai W, Wang JL, Chu FK, Xu ZM, Song L, Xing WY, Hu Y (2019) Acs Appl Mater Inter 11(44):41736–41749

Zhou X, Qiu SL, He LX, Wang X, Zhu YL, Chu FK, Wang BB, Song L, Hu Y (2021) Chem Eng J 6:130655

Wang J, Zhang N, Li CQ, Shi WG, Lin ZY (2016) J Organomet Chem 822:104–111

Xue R, Guo H, Wang T, Wang X, Ai JB, Yue LG, Wei YL, Yang W (2017) Mater Lett 209:171–174

Bai YW, Wang XD, Wu DZ (2012) Ind Eng Chem Res 51(46):15064–15074

Chen LD, Jiang Y, Huo HL, Liu JY, Li YY, Li CQ, Zhang N, Wang J (2020) Appl Catal A-Gen 594:117457

Zhang N, Wu YS, Li YY, Chen LD, Zhang MS, Wang J (2021) Polym Bull 1–13

Yang WH, Yi J, Ma ZF, Sun WH (2017) Catal Commun 101:40–43

Bekmukhaedov GE, Sukhov AV, Kuchkaev AM, Yakhvarov DG (2020) Catalysts 10(5):498

Skupinska J (1991) Chem Rev 91(4):613–648

Helldörfer M, Milius W, Alt HG (2003) J Mol Catal A-Chem 197(1–2):1–13

Acknowledgements

This work was supported by Heilongjiang Scientific Research Foundation for Postdoctoral Settlement of China (16190023) for the financial support. We are grateful to State Key Lab of Inorganic Synthesis and Preparative Chemistry of Jilin University and Analysis and Test Center of Northeast Petroleum University for the characterization work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, L., Huang, J., Chen, N. et al. Synthesis and ethylene oligomerization behavior of trinuclear nickel complex with phosphorus dendrimer. Transit Met Chem 47, 1–9 (2022). https://doi.org/10.1007/s11243-021-00483-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11243-021-00483-3