Abstract

Nickel complexes with aromatic amine terminated first generation (G1) and second generation (G2) polyamide dendrimers {POA-(NH2)n (n = 6 or 12, POM = Polyamide)} were synthesized. All the synthesized dendrimers and metallodendrimers were characterized by elemental and spectral analysis. These novel dendritic complexes were evaluated as catalyst precursors in the oligomerization of ethylene, using methylaluminoxane (MAO) as an activator at two different pressure and different Al/M (M = Zn) ratio. In the case of 1 atm pressure of ethylene, and 500:1 and 1,000:1 Al/Ni molar ratio, for C 1 and C 2 respectively display higher catalytic activity towards ethylene polymerization. Oligomerization using the generation 1 dendrimer complex, C 1 yields short chain oligomers whereas those obtained from the generation 2 dendrimer catalyst, C 2 resulted in longer chain products with molecular weights up to 9.54 × 104 and 9.86 × 104 g/mol at 1 and 5 atm respectively.

Graphical Abstract

Two new Nickel metallodendrimers C 1 and C 2 were evaluated as catalysts precursor in the polymerization of ethylene using methylaluminooxane (MOA) as co-catalyst at two different pressure and different Al/M (M = Zn) ratio. Both catalysts evaluated were found to be active for ethylene oligomerization giving polymers and higher molecular weight products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Metallodendrimers are well-defined, highly branched, there dimensional macromolecules with characteristic globular structures for the larger systems [1]. These novel macromolecules functionalized with transition metals have inspired many researchers to develop new materials and several applications have been explored, catalysis being one of them [2]. The recent impressive strides in synthetic procedures increased the accessibility of functionalized metallodendrimers, resulting in a rapid development of dendrimer chemistry. The potential interest of metallodendrimers as catalyst, arise mainly from their ability to combine the advantage of homogenous and heterogeneous catalyses in one system, more ever their shape and sized make them more suitable for recycling than soluble polymer supported catalyst [3–5]. The multiple sites located at their surfaces may afford reaction rates comparable to those shown in homogenous systems due to the accessibility for the substrate [6]. Recently there have been several reports detailing the application of metallodendrimers as catalysts. In a number of instances, some sort of dendritic effect has been observed, Mapolie et al. [7] report nickel complexes based on Periphery-functionalized dendrimers salicylaldime ligand as catalysts for the vinyl polymerization of norbornene. When comparing the effect of dendrimer generation on activity, the second generation catalysts were found to be more active than the first generation catalysts. De la Mata et al. reported the use of titanium-containing carbosilane dendrimers as catalysts for the polymerization of ethylene. Using these metallodendrimers as catalyst precursors, polyethylene with high molecular weight and low polydispersity was produced [8]. The dendritic nature of the catalyst also resulted in a higher degree of crystallinity in the polymers obtained. The Periphery-functionalized dendrimers have their ligand systems, and thus the metal complexes, at the surface of the dendrimer. The transition metals will be directly available for the substrate, in contrast to core-functionalized systems, for example, in which the substrate has to penetrate the dendrimer prior to reaction [9]. This accessibility allows reaction rates that are comparable with homogeneous systems. On the other hand, the periphery-functionalized systems contain multiple reaction sites and ligands, which results in extremely high local catalyst and ligand concentrations [10]. This inspireed us to synthesize periphery-functionalized metallodendrimer precatalysts for the polymerization of olefin. Herein we selected amino functionalized dendrimers as a ligand support these dendrimers were modified into metallodendrimes with transition metal ions. This article describes the preparation and characterization of the Ni metallodendrimers, as precatalyst using [PDA-(NH)2]6 [PDA-(NH)2]12 and abbreviated as C1 (nickel complex of first generation) and C2 (nickel complex of second generation) respectively. The comparison study of the metallodendrimers for ethylene polymerization upon activation with MAO at different pressure.

2 Results and Discussion

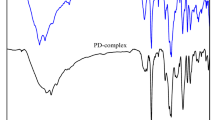

A general synthetic route for the first and second generation dendrimeric ligands PAD-(NH2)6 and PAD-(NH2)12 is shown in Scheme 1. The PAD-(NH2)6 and PAD-(NH2)12 were prepared using ammonium formate and commercial Zinc Powder as a reducing agent from their corresponding PAD-(NO2)6 and PAD-(NO2)12 according to the literature [11]. The yellow powder of 1,3,5 tris(3,5 dinitrophenyl) benzamide [PAD-(NO2)6] was prepared by the reaction of 1,3,5-benzene tricarboxylchloride with 3,5 dinitroaniline in acetone in 1:3 molar ratio in good yield. PAD-(NO2)6 can be purified simply by precipitation in NaHCO3 aqueous in quantitative yield. The formation and isolation of PAD-(NO2)6 were confirmed by IR, elemental analysis, 1H NMR, and 13C NMR spectroscopy as shown Figs. 1 and 2. The IR spectrum of PAD-(NO2)6 showed strong absorption at 1,650 cm−1 characteristic to C=O stretching of amide group and terminal nitro groups at 1,588 and 1,290 cm−1. The reduction of PAD-(NO2)6 by employing SnCl2 and concentrated hydrochloric acid successfully afforded the desired 1,3,5 tris(3,5 diaminophenyl) benzamide {PAD-(NH2)6} as a first generated dendrimers. The FTIR spectrum of {PAD-(NH2)6} show a strong peak at 3,410 cm−1 due to terminal amino groups [12]. The proton signals at δ 4.36 indicate the presence of NH2 group hydrogen. The 12-amine-terminated second generation polyamide was synthesized when PAD-(NH2)6 react with 3,5-dinitrobenzolyl chloride in acetone under nitrogen atmosphere in 75% yield, then the similar reduction of (5) as used in the synthesis of first generation dendrimers. The structures of PAD-(NH2)12 was also characterized by elemental analysis, IR, 1H NMR, and 13C NMR. The 1H NMR spectra of PAD-(NO2)12 show proton signals for the internal branches amide and outer branch amide at 10.20 and 10.01 ppm respectively [13]. The terminal amino protons show resonance signals at 4.82 ppm. Scheme 2 shows the synthetic route for metallodendrimers of Ni with PAD-(NH2)6 and PAD-(NH2)12. The metal complexes were synthesized via simple complexation reaction of metal salts with first and second generation dendrimers in ethanol (Scheme 3).

The Nickel complexes were isolated as green colour powder in good yields. The formation of metal complexes was supported by UV–Vis, FTIR, and elemental analysis. The results of elemental analysis revealed that the metal ions attached to the aromatic amine groups via coordination-covalent bonds and containing two chloride ions with each metal ions. In IR spectra of the complexes the NH stretching at 3,405–3,410 cm−1 shifted to the lower frequency when compare with their parental dendrimeric ligands [14]. In the metallodendrimers C1 and C2, the new strong peak at 530 cm−1 is due to the M-N stretch of the bond formed during coordination of Ni via terminal amino group. Although the MALDI-TOF MS measurement of C1 and C2 provide a clear spectrum and indicated its formation and isolation as shown in Fig. 3.

Polymerizations of ethylene were conducted at 1 and 5 atmospheric pressure of ethylene in toluene using first generation and second generation metallodendrimers, and methylaluminoxane (MAO) as co-catalyst. We investigated the effect of Al/Ni ratios which ranged from 50:1 to 2,000:1 molar ratios on the activities of precatalyst first generation C 1 and second generation C 2 for ethylene polymerization at room temperature. The activities of the C 1 and C 2 expressed as turn over frequencies (TOF) and given in Table 1 with 1 atm pressure of ethylene. The oligomeric products were weighed after evaporation of the solvent. C 1 showed optimum catalyst activity at an Al:Ni ratio of 500:1 while C 2 showed optimum activity at an Al:Ni ratio of 1,000:1 when the reaction were carried out with 1 atm pressure of ethylene. As shown in Table 2. the higher polymerization activity was observed at an Al:Ni ratio of 1,000:1 for both catalysts. It is also observed that the ethylene concentration significantly affect the catalytic behaviour of the metallodendrimers. In comparison with the result obtained with 1 atm pressure of ethylene, the distribution of oligomers formed at 5 atm of ethylene pressure shift to higher carbon number of olefins. The oligomers obtained from our C 1 catalyst and C 2 catalyst, were analyzed using gas chromatography (GC). The GC analysis was done on the residues after evaporation of the solvent. This was done after we confirmed that no low boiling point oligomers were present in the reaction medium. From the results it would appear that at low levels of Al, the chain transfer process from the active Ni centre to the Al is much more rapid than chain growth. This results in relatively shorter oligomer chains being formed. At these low Al concentrations, largely C10 and C12 oligomers were obtained, with C10 being more dominant. At very high levels of Al longer chain oligomers were obtained. From our results we observe that our two dendrimer systems give very different types of oligomeric products. Oligomerization using the generation 1 dendrimer complex, C 1 yields short chain oligomers whereas those obtained from the generation 2 dendrimer catalyst, C 2 resulted in longer chain products with molecular weights up to 9.54 × 104 and 9.86 × 104 g/mol at 1 and 5 atm respectively. The overall activity of the generation 2 catalyst is significantly higher than that of the generation 1 catalyst. It should however be noted that the optimum activity for the generation 2 catalyst is obtained at Al concentrations that are twice as high than those used in reactions of the generation 1 catalyst. A possible reason for this difference in behaviour of the two catalysts in respect of the amount of co-catalyst used could be due to differences in the architecture of the two dendrimeric catalysts [15]. The generation 1 catalyst, C 1 has three amide units within its internal structure, while the generation 2 catalyst, C 2 has six amide units. In both cases these amide, being Lewis base sites, are potential positions for the binding of the Lewis acidic organoaluminium co-catalyst. It is thus thought that the co-catalyst as shown Scheme 2 MAO, first binds to these Lewis basic sites before it becomes involved in the activation of the metal centre. It is well known that N-donor molecules form adducts with Lewis acidic Aluminium complexes [16–18]. Since the C 2 has more N-donor sites it will react with a larger amount of the aluminum alkyl than the C 1 . It therefore requires larger amounts of co-catalyst before the optimum activity is reached for the C 2 system.

3 Conclusion

In this study, we have successfully synthesized two new metallodendrimers and used as a catalysts for ethylene oligomerization in the presence of MAO (co-catalyst). The catalytic activities were found to be sensitive to the pressure, co-catalyst to catalyst ratio. The best co-catalyst to catalyst ratio is 1,000:1, at this ratio C2 exhibit higher activity then C1, but at 500:1, Al:Ni ratio C2 show slightly lower catalytic activity than C1. The type of molecular oligomers formed is also dependent on the nature of the catalyst generation. The C 1 support the formation of short chain oligomers within the C10–C20 (50–60%) diesel range, while C 2 produces higher molecular weight products which were waxy in nature (100%). This behaviour of catalyst C1 and C2 can be used in petrochemical industries.

4 Experimental Section

4.1 Materials and Methods

Manipulations of air and moisture sensitive compounds were performed under a nitrogen atmosphere using standard Schlenk techniques. Toluene was refluxed over sodium-benzophenone and distilled under argon prior to use. Methylaluminoxane (MAO, a 1.46 M solution in toluene) and other chemicals were purchased from Sigma-Aldrich. Infrared spectra were recorded on a Perkin Elmer Paragon 1000 PC FT-IR spectrophotometer, using KBr plates. 1H NMR (400 MHz) and 13C NMR (100 MHz) spectra were recorded on a Varian XR200 spectrometer, using tetramethylsilane as an internal standard. MALDI-TOF Mass spectra were recorded using a KMPACT MALDI mass spectrometer (Shimadzu Kratos) in positive mode. Gas chromatography analysis was carried out on a Varian CP-3800 using a HP PONA column. The yield of oligomers was calculated by referencing to the mass of the solvent on the basis of the prerequisite that the mass of each fraction was approximately proportional to its integrated area in the GC trace Dodecane was used as an internal standard. Gel permeation chromatography was performed on a Polymer Laboratories GPC220 instrument using polystyrene standards.

4.2 Synthesis

4.2.1 Synthesis of 1,3,5-Tris(3,5-Dinitrophenyl) Benzamide (1)

1,3,5-Benzene tricarboxylchloride (2.65 g, 0.1 mol) and 3,5-dinitroaniline (2.74 g, 0.3 mol) were mixed in a 250 mL round bottom flask in 100 mL of ethanol. The resulting yellow colour solution was allowed to reflux for 6 h under nitrogen. After the mixture was cooled to room temperature was distilled off under reduced pressure, and the residue was dissolved in hexane resulting precipitate was filtrated and washed off several time. The desired compound [1,3,5-tris(3,5-dinitrophenyl) benzamide)] was obtained as a yellow solid powder in 70% yield after purification by column chromatography (silica gel, 3/1 (v/v) petroleum ether/ethyl acetate). Mp: 190 °C. FTIR (KBr, cm−1): 1110, 1340, 1560, 1588, 1615, 1710, 3265; 1H NMR (400 MHz, DMSO, TMS, δ): 10.46 (s, 3H, NHCO), 7.12 (s, 3H, ArH), 6.96 (s, 3H, ArH), 6.42 (s, 6H, ArH). Anal. Calcd for C27H15N9O15 (705.46): C, 45.97; H, 2.14; N, 17.87. Found: C, 45.95; H, 2.13; N, 17.89.

4.2.2 Synthesis of First-Generation Dendritic Ligand (2)

To a solution of 1 (3.52 g, 50 mmol in 30 mL of acetone) and Sn (7.64 g), conc. HCl (60 mL) was drop wised added and refluxed for 30 min. Cool the flask and add a solution of sodium hydroxide in 100 cm3 of water to re-dissolve the initial precipitate. Add 3 g of powdered sodium chloride to the mixture, shake to dissolve, and then transfer the liquid to a separating funnel and 10 mL of chloroform. The separated organic mixture was washed off several times with water. The solvent was evaporated at reduced pressure, and the desired compound 2 was obtained as a brown colours powder in 54% yield after purification by column chromatography (silica gel, 3/1 petroleum ether/ethyl acetate). Mp: 245 °C, FTIR (KBr, cm−1): 1511, 1556, 1596, 1622, 1680, 3409. 1H NMR (400 MHz, DMSO, TMS, δ): 9.84(s, 3H, NH–CO), 6.81 (s, 3H, ArH), 6.52 (s, 6H, ArH), 6.21 (s, 3H, ArH) and 4.83 (s, 12H, Ar–NH 2); 13C NMR (100 MHz, DMSO, TMS): 102.3, 128.4, 134.9, 136.8, and 174.8 ppm. ESI-MS (m/z): 526.23 (M + H+). Anal. Calcd for C27H27N9O3 (525.56): C, 61.70; H, 5.18; N, 23.99. Found: C, 61.71; H, 5.17; N, 23.98.

4.2.3 Synthesis of Second Generation Nitro Group Terminated Dendrimers (3)

To a solution of 2 (5.26 g, 10 mmol) in chloroform (100 mL) was added 1,3-dinitrobenzoyl chloride (13.99 g, 60 mmol) and the mixture was refluxed under nitrogen, with stirring at 70 °C for 5 h resulting yellow colour mixture found. The process of reaction was monitored by TLC using CH2Cl2 and hexane as eluent. After completion of the reaction the solvent was removed under reduced pressure and washed off several time using water, and obtained as a yellow brown powder in 60% yield. Mp: 275 °C. FTIR (KBr, cm−1): 1115, 1342, 1560, 1558, 1588, 1650, 1720, 3245; 1H NMR (400 MHz, DMSO, TMS, δ): 9.81 (s, 3H, NH–CO), 9.76 (s, 6H, NH–CO), 7.27 (s, 9H, ArH), 6.84 (s, 3H, ArH), 6.62 (s, 6H, ArH), and 6.25 (s, 12H, ArH). 13C NMR (100 MHz, DMSO, TMS): 104.2, 112.5, 114.2, 129.8, 133.3, 135.4, 137.2, 145.2, 171.8 and 174.1 ppm. Anal. Calcd for C69H39N21O33 (1690.17): C, 62.29; H, 4.77; N, 22.11. Found: C, 62.30; H, 4.78; N, 22.10.

4.2.4 Synthesis of Second Generation Dendritic Ligand (4)

Using the same procedure as for the synthesis of 3 was obtained as a yellow powder in 52% yield as a brown powder. Mp: 348 °C. FTIR (KBr, cm−1): 1114, 1340, 1562, 1560, 1586, 1652, 1721, 3265; 1H NMR (400 MHz, DMSO, TMS, δ): 4.82 (s, 48H, NH 2), 10.10 (s, 3H, NH–CO), 9.82 (s, 6H, NH–CO), 7.18 (s, 9H, ArH), 6.82 (s, 3H, ArH), 6.48 (s, 6H, ArH), and 6.21 (s, 12H, ArH). 13C NMR (100 MHz, DMSO, TMS): 103.2, 110.8, 115.4, 123.8, 134.2, 136.0, 138.4, 147.0, 170.6 and 173.2 ppm. Anal. Calcd for C69H39N21O9 (1330.51): C, 49.03; H, 2.33; N, 17.40. Found: C, 49.01; H, 2.24; N, 17.42.

4.2.5 Synthesis of Generation 1 Dendritic Nickel Complex (C1)

To the 1,3,5-tris(3,5-diaminophenyl) benzamide (1.31 g, 5 mmol) in ethanol (25 mL) in a round bottom flask was added Nickel chloride hexahydrate (3.80 g, 15 mmol) and the reaction mixture was allowed to stir under reflux for 24 h forming a green precipitate. The precipitate was filtered off by vacuum filtration and washed extensively with ethanol to afford C 1 as a green solid in 80% yield. Mp: 245 °C, FTIR (KBr, cm−1): 1515, 1550, 1584, 1620, 1680, 3374. Anal. Calcd for C27H27N9O3Ni3Cl6 (914.35): C, 35.47; H, 2.98; N, 13.79; Cl, 23.26; Ni, 19.26. Found: C, 35.47; H, 2.98; N, 13.79, Cl, 23.26, Ni, 19.26.

4.2.6 Synthesis of Generation 2 Dendritic Nickel Complex (C2)

To a solution of the PAD-(NH2)12 dendrimeric ligand (6.65 g, 5 mmol) in ethanol (10 mL) was added nickel chloride hexahydrate (7.60 g, 30 mmol) and the mixture stirred under reflux for 24 h. The solvent was evaporated via rotary evaporation to give a green residue. The residue was then dissolved in dichloromethane (15 mL) and the solution was filtered by gravity and dried to afford complex C 2 as a green solid in 76% yield. Mp: 348 °C. FTIR (KBr, cm−1): 1110, 1342, 1560, 1556, 1582, 1648, 1712, 3260; C69H39N21O9Ni6Cl12 (2083.77): C, 39.77; H, 1.89; N, 14.12; Cl, 20.42; Ni, 16.90. Found: C, 39.78; H, 1.88; N, 14.14, Cl, 20.43, Ni, 16.91.

References

Martinovic J, Paquim A-MC, Diculescu VC, Van Wyk J, Iwuoha E, Baker P, Mapolie S, Brett AMO (2008) Electrochem Acta 53(14):4907–4919

Newkome GR, Yao Z, Baker GR, Gupta VK, Russo PS, Saunders MJ (1986) J Am Chem Soc 108:849

Astruc D, Chardac F (2001) Chem Rev 101:2991

van Koten G, Jastrzebski JTBH (1999) J Mol Catal A Chem 146:317

Ooestrom GE, Reek JNH, Kramer PCJ, Van Leeuwen PWNM (2001) Angew Chem Int Ed 40:1828

de Souza RF, Bernardo-Gusmao K, Cunha GA, Loup C, Leca F, Reau R (2004) J Catal 226:235

Malgas R, Mapolie SF, Ojwach SO, Smith GS, Darkwa J (2008) Catal Commun 9:1612

Arévalo S, de Jesús E, de la Mata FJ, Flores JC, Gómez R, Rodrigo M-M, Vigo S (2005) J Organomet Chem 690:4620

Smith G, Chen R, Mapolie S (2003) J Organomet Chem 673(1–2):111

Müller C, Ackerman LJ, Reek JNH, Kamer PCJ, Van Leeuwen PWNM (2004) J Am Chem Soc 124:14960

Zhou Y, Li J, Liu H, Zhao L, Jiang H (2006) Tetrahedron Lett 47(48):8511–8514

Ueda M, Kameyama A, Hashimoto K (1988) Macromolecules 12:19

Okazaki M, Washio I, Shibasaki Y, Ueda M (2003) J Am Chem Soc 125:8120

Okazaki M, Hyakawa T, Ueda M, Takeuchi K, Asai M (2001) J Polym Sci Polym A Polym Chem 38:78

Kim I, Kwak CH, Kim JS, Ha C-S (2005) Appl Catal A Gen 287:98

Eisch J (1995) In: Abel EW, Stone FGA, Wilkinson G (eds) Comprehensive organometallic chemistry II. Pergamon, New York, p 431

Cotton FA, Wilkinson G, Murillo CA, Bochmann M (1999) Advanced inorganic chemistry, 6th edn. Wiley, New York, p 196

Robinson GH (1993) In: Robinson GH (ed) Coordination chemistry of aluminum. VCH, New York

Acknowledgments

We would like to thanks the College of Science Research centre, King Saud University, for financial support under Grant No. CHEM/2010/10 and vice reactor of King Saud University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahamad, T., Alshehri, S.M. & Mapolie, S.F. Synthesis Characterization of Polyamide Metallodendrimers and their Catalytic Activities in Ethylene Oligomerization. Catal Lett 138, 171–179 (2010). https://doi.org/10.1007/s10562-010-0393-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-010-0393-1