Abstract

A new composite of o-aminobenzene sulfonic acid self-doped polyaniline (SPAN) and multi-walled carbon nanotubes was prepared on a stainless steel wire by electrochemical method as a headspace solid-phase microextraction fiber for gas chromatography. Preparation conditions were investigated, and the resulting composite coating was characterized via scanning electron microscopy, Brunauer–Emmett–Teller (BET) analysis and thermogravimetric analysis. Introduction of MWCNTs and o-aminobenzene sulfonic acid into the composite leads to formation of plenty of microglobules and mesopores and makes BET surface area and thermal decomposition temperature of the composite increase by ~ 340% and ~ 130 ℃, respectively, compared to common polyaniline coating. Extraction conditions were optimized, and chromatographic analysis of 2,4-dichlorophenol was conducted. Extraction efficiency of the new composite coated fiber increases by 320% compared to polyaniline-coated fiber. Relative standard deviations of peak areas are 4.3%, 6.3%, 7.1% (n = 5) for identical fiber, fibers prepared in identical batch and different batches, respectively, exhibiting good repeatability and reproducibility. Detection limit is 1.30 ng L−1 (S/N = 3), and recoveries are in the ranges from 82.3 to 110.2%, from 91.5 to 109.4% and from 94.2 to 113.0% for three different water samples spiked at three levels of 500, 100 and 10 ng mL−1, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gas chromatograph (GC) is widely used in the analysis of environmental pollutants [1]. However, due to the complex nature of sample matrices reportedly containing low level of analyte concentration, preconcentration is usually required prior to their quantitation via GC [2]. Among all the preconcentration methods, solid-phase microextraction (SPME) is one of the most popular techniques owning to its simplicity, environmentally friendliness, and high enrichment coefficient [3,4,5,6].

The reported SPME techniques include fiber SPME [5, 6], in-needle SPME [7], in-tip SPME [8], in-tube SPME [9, 10] and thin-film SPME [11, 12]. Among them, the fiber SPME is commonly used, and its extraction performance depends mainly on the fiber coatings [4, 13,14,15]. Nowadays, many commercial coated fibers have been applied to SPME, such as polydimethylsiloxane, divinylbenzene, polyethylene glycol and carbowax [3, 13]. However, the availability of the commercial coated fibers is limited and cannot fully meet the needs for various pollutants and their metabolites in environment. Also, some of these fibers have some shortcomings, such as insufficient thermal or/and solvent stability and high cost [5, 14]. Therefore, varieties of in-house made fiber coatings have been reported [15,16,17,18]. Conductive polymers have been extensively used as SPME fiber coatings [19]. Among them, polyaniline (PANI) and its derivatives are attracting since they have multifunctional properties such as electroactivity, hydrophobicity, polar functional groups, and π–π interaction [15,16,17,18].

One of the drawbacks of PANI coating, however, is the poor thermal stability [20]. Using different substituted aniline monomers or dopants, the thermal stability of synthesized polymers can be, to some extent, improved under controlled electrochemical conditions [20,21,22]. Mehdinia et al. [22] prepared a aminobenzene sulfonic acid self-doped polyaniline (SPAN) fiber coating, and this coating was proved to be still stable at the high temperatures up to 350 ℃.

Another drawback of PANI coating is its insufficient extraction efficiency [16, 23,24,25]. Several published reports suggest that carbonaceous materials [5, 15, 26], inorganic materials [24, 25], metal–organic framework [17, 27], and so on contribute to improving the porosity of the PANI-based coatings and thus enhance the extraction efficiency. Among the carbonaceous materials, multi-walled carbon nanotubes (MWCNTs) are the most attractive since they can be homogeneously distributed in aniline by forming donor–acceptor complexes and increase specific surface areas of the PANI-based coatings [28, 29]. Du et al. [29] prepared a MWCNTs-doped PANI coating. This coating exhibited a higher extraction efficiency than common PANI coating.

In the present work, in order to simultaneously overcome the two drawbacks of common PANI coatings, we prepared a new composite coating of o-aminobenzene sulfonic acid self-doped polyaniline and multi-walled carbon nanotubes (MWCNTs-SPAN) by electrochemical method for headspace solid-phase microextraction GC (HS-SPME-GC). Preparation conditions were investigated, and the resulting composite coating was characterized via scanning electron microscopy (SEM), Brunauer–Emmett–Teller (BET) analysis and thermogravimetric analysis (TGA). Extraction and desorption conditions were optimized, and the performance in HS-SPME-GC was examined using 2,4-dichlorophenol (2,4-DCP) as the test analyte. 2,4-DCP was selected because it is a typical polar pollutant and has been used for evaluation of SPME fibers by some other authors [32,33,34,35,36].

Experimental

Chemicals and Materials

Methanol, 2,4-DCP, aniline, sodium chloride and sulfuric acid were from Comio Chemical Reagents Co., Ltd. (Tianjin, China). O-aminobenzene sulfonic acid was provided by Aladdin Industries (Shanghai, China). MWCNTs (10–20 nm O.D., 5–10 nm I.D., 2–8 μm length) were from Yuechuang Technology Co., Ltd. (Shenzhen, China). Stainless steel wire (0.2 mm diameter) was from local shops. Double-distilled water was prepared using a Yarong SZ-93 Water Distiller (Shanghai, China) and used throughout this work. All reagents were of analytical grade.

An aqueous standard solution of 2,4-DCP at 500 μg L−1 was prepared and used in the present work unless otherwise noted. Tap, mineral and sea water samples were collected from the city waterworks, Nongfu Spring Drinking Water Company and the sea near the coast of Xinghai Square, Dalian, China, respectively.

Apparatus

Electrochemical experiments were carried out on a CHL660A instrument (Shanghai Chenhua Instrument Co., Ltd., China). GC experiments were performed on a GC-126 instrument with a built-in flame ionization detector (FID) (Shanghai Instrument Co., Ltd., China). Chromatographic data were obtained using a FJ3000 Chromatography Workstation (Shanghai Precision Instrument Co., Ltd., China). Separations were accomplished with a PEG-20-M capillary column (30 m × 0.32 mm × 0.5 μm, Shanghai Kexiao Instrument Co., Ltd., China). SEM images were taken by a SU8010 SEM instrument (Hitachi Ltd., Japan). BET analysis and TGA were conducted on a JW-BK122W analyzer (Beijing JWGB Sci. & Tech. Co. Ltd., China) and an Setaram SETSYS thermogravimetric analyzer (TGA Setaram, France).

Preparation of MWCNTs-SPAN Coating

A section of 7-cm stainless steel wire was ultrasonically cleaned in acetone and water sequentially for 15 min. MWCNTs and self-doped polyaniline were simultaneously electrochemically deposited onto one end of the stainless steel wire for the length of 3 cm in a 20 mL solution containing MWCNTs (0.0012 g), aniline (0.1 M), o-aminobenzene sulfonic acid (0.1 M) and H2SO4 (0.5 M). Electrodeposition was achieved by potential cycling between − 0.3 and 1.0 V at a scan rate of 0.025 V s−1 for 80 cycles. After being flushed with water, the coated wire was inserted into a homemade holder and used as a SPME fiber assembly (see SI 1). Prior to use, the coating was aged for 1 h in GC injection port at 280 ℃ until the baseline was stable.

For evaluation of the new MWCNTs-SPAN composite coating by comparing with other coatings reported previously, three PANI-based coatings, including PANI, MWCNTs-PANI and SPAN coatings, were prepared referring to Bagheri's [18], Du's [29] and Mehdinia's [22] work, respectively.

Headspace Solid-Phase Microextraction

A 10-mL volume of aqueous 2,4-DCP solution was transferred into a 20 mL extraction bottle with a rubber cap. After adding appropriate amount of sodium chloride into the solution, the bottle was capped tightly. The SPME fiber was inserted into the bottle through the holder for HS-SPME. After extraction, the fiber carrying the analyte was withdrawn from the extraction bottle and inserted into GC injection port for performing thermal desorption process.

GC Calibration

Considering that the sensitivity might be different on different days, and the used GC was calibrated every day. The calibration method was as follows. A solution of 2,4-DCP (1 g L−1) was prepared and used as the reference solution. Three repeated injections (1 μL/injection) of the reference solution were performed on the first day, and the average of the peak areas was set as the permanent reference peak area. On the following each working day, the above injections were reperformed, the obtained average of peak areas was divided by the reference peak area, and the result was used as the GC calibration factor for the working day. All of the other peak areas obtained on the identical working day multiplied the calibration factor, and the results were used as the peak area values presented in the text unless otherwise noted. The calibration factor was measured at least once every day.

Results and Discussion

Preparation of the MWCNTs-SPAN Coating

As described in the earlier section, PANI is one of the most commonly used fiber coatings. Its application, however, is limited by poor thermal stability and insufficient extraction efficiency. Du et al. [29] and Mehdinia et al. [22] increased extraction efficiency of the MWCNTs-PANI coating and improved thermal stability of SPAN coating through introducing MWCNTs and − SO3− groups, respectively. In this study, in order to simultaneously resolve the above two problems of the PANI coating, a new PANI-based composite coating containing both MWCNTs and − SO3− groups was designed referring to Du’s and Mehdinia’s work, and its preparation conditions were investigated.

The molar ratio of aniline to o-aminobenzene sulfonic acid has an effect on the thermal stability. Mehdinia et al. [22] adopted a ratio of 1:1 for the preparation of SPAN coating and obtained a good improvement of the thermal stability. Therefore, the ratio of 1:1 was also used for the preparation of the MWCNTs-SPAN coating in the present study. The effect of amount of MWCNTs on extraction efficiency was investigated in the range of 0.0002–0.0022 g in 20 mL polymerization solutions containing o-aminobenzene sulfonic acid and aniline (each 0.1 M). The composite coating fibers prepared at different amounts of MWCNTs were used for the HS-SPME-GC of 2,4-DCP in the standard solution under same experimental conditions. The curve of peak area to MWCNTs amount was obtained (see SI 2). Peak area increases rapidly with the increase of MWCNTs amount until 0.0012 g and then remains almost unchanged. The amount of 0.0012 g was used in the present work.

Cyclic voltammetry (CV) is commonly chosen for the preparation of fiber coatings since the parameters, including potential scanning range, rate and cycles, can be precisely controlled, and thus, coatings of different thickness and morphology can be obtained in a reproducible manner [18, 30]. For the preparation of PANI coatings, the suitable potential scanning range is between − 0.3 and 0.9 V [25, 29, 31]. For the preparation of SPAN coatings, the upper potential limit should be increased to 1.0 V since o-aminobenzene sulfonic acid is hard to be electropolymerized due to its higher oxidation potential [22]. Therefore, in the present study, the scanning range was set between − 0.3 and 1.0 V. The scanning cycles have a significant effect on the thickness and morphology of coatings [29]. The effect was investigated from 10 to 200 cycles. The maximal peak area was obtained at the cycles of 80 (see SI 3). The cycles of 80 were used in the following experiments.

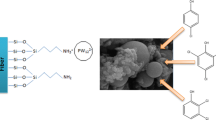

Surface Morphology and Pore Structure

The morphology of the MWCNTs-SPAN composite coating was observed using SEM (Fig. 1A). For comparison, SEM images were also taken for the PANI (Fig. 1B), MWCNTs-PANI (Fig. 1C) and SPAN (Fig. 1D) coatings. By comparison of Fig. 1A and C with Fig. 1B and D, it can be seen that when MWCNTs are present in the coatings (Fig. 1A and C), the composite firstly forms in the form of microglobules, these globules then aggregate together and form many clusters, and these clusters interconnect and finally form a porous monolithic structure. By comparison of Fig. 1A with Fig. C, it can be found that the sizes of the globules, clusters and pores of the MWCNTs-SPAN coating (Fig. 1A) are remarkably smaller and more uniform than those of the MWCNTs-PANI coating (Fig. 1C). BET analysis of the four coating powders was carried out. The BET surface areas of the PANI, SPAN, MWCNTs-PANI and MWCNTs-SPAN coatings are measured to be 23.3, 22.8, 82.5 and 102.3 m2 g−1, respectively. Compared to the PANI and SPAN coatings, the BET surface areas of the MWCNTs-PANI and MWCNTs-SPAN composites increase by ~ 340%. Du et al. [29] prepared a MWCNTs-doped PANI coating and achieved a higher extraction efficiency than common PANI coatings, but they did not measure the specific surface area of the coating. The BET cumulative absorption pore volumes are 0.11, 0.9, 0.58 and 0.28 cm3 g−1 for the PANI, SPAN, MWCNTs-PANI and MWCNTs-SPAN coatings, respectively. The pore diameter distribution curves are shown in Fig. 2. For the MWCNTs-SPAN composite, overwhelmingly majority of the pore diameters are in the range from 2 to 80 nm with the maximal dV/dlogD value being at ~ 20 nm. For the MWCNTs-PANI composite, the most of the pore diameters are above 100 nm, and no maximal dV/dlogD value can be obtained from the curve. The maximal value is estimated to be in the diameter range of macropores, or maybe even in the diameter range of megapores according to the observation from the SEM images of Fig. 1. For the PANI and SPAN coatings, it is difficult to measure their pore diameters because of their insignificant and almost unchanged dV/dlogD values in the whole test diameter range. The results of SEM and BET analysis unitedly demonstrate that MWCNTs can greatly modify the surface morphology and pore structure and thus increase the surface areas of the MWCNTs-SPAN and MWCNTs-PANI composites.

Selection of HS-SPME Conditions

Many authors had performed the HS-SPME of 2,4-DCP in aqueous samples using different fiber coatings [32,33,34,35,36]. For phenolic pollutants in aqueous samples, the presence of NaCl and low pH values can reduce their solubilities, increase the distribution ratios (gas phase/liquid phase), and thus improve extraction efficiency. Referring to their work, the NaCl concentration and the pH value were set at 0.35 g mL−1 and 2, respectively. Extraction temperature and time were investigated in the ranges of 50–90 °C and 40–60 min, respectively. The maximal peak area was obtained at 80 °C and 50 min (see SI 4). Therefore, the temperature of 80 °C and the time of 50 min were selected.

Selection of Desorption Conditions

The desorption temperature and time in GC injection port were investigated from 240 to 300 °C and from 20 to 300 s, respectively. The curves of peak area to desorption time show that when GC injection port was set at temperatures higher than 280 °C, 2,4-DCP was desorbed completely from the fiber coating after 3 min (see SI 5). Considering that higher temperatures and longer times are more harmful to coating lifetime, the desorption temperature of 280 °C and the desorption time of 3 min were adopted. No memory effect was observed in blank injections under the selected desorption conditions.

Reproducibility of the MWCNTs-SPAN Coating

The reproducibility of the MWCNTs-SPAN coating was assessed through HS-SPME-GC of 2,4-DCP in the standard solution using five coated fibers prepared in identical batch and five coated fibers from five different batches, respectively. The relative standard deviations (RSDs, %) of the peak areas are 6.3% (n = 5) and 7.1% (n = 5), respectively, and are comparable or superior to those of other fiber coatings reported previously (2.1%–13%) [29, 32,33,34,35,36] (see SI 6).

Thermal Stability and Lifetime of the MWCNTs-SPAN Coating

Thermal stabilities of the PANI, MWCNTs-PANI, SPAN and MWCNTs-SPAN coatings were tested by TGA (Fig. 3). For the four coatings, the weight loss in the range of 20–100 ℃ can be attributed to evaporation of the water moisture in the coatings [23, 29]. For the SPAN and MWCNTs-SPAN coatings, in the range of 100–350 ℃, the weights remain almost unchanged, indicating that the SPAN and MWCNTs-SPAN coatings are stable up to ~ 350 ℃. By contrast, the PANI and MWCNTs-PANI coatings start to thermally decompose at ~ 220 ℃ as reported by other authors [23, 37]. With the introduction of − SO3− groups, the thermal decomposition temperatures of SPAN and MWCNTs-SPAN coating increase by ~ 130 ℃. This is consistent with that reported by Mehdinia et al. [22].

The thermal stability was further examined through comparing chromatograms (Fig. 4). The chromatograms were obtained by leaving the coating fibers in GC injection port at 320 ℃ and simultaneously monitoring signal changes. No effluent was found for the SPAN and MWCNTs-SPAN-coated fibers within 12 min, whereas some effluents were detected after 3 min for the PANI and MWCNTs-PANI-coated fibers owing to decomposition of the coating polymers.

In order to evaluate the lifetime of the MWCNTs-SPAN coating, the dependance of relative peak area on the cumulative time for which the fiber was left in GC injection port was investigated at 280 ℃, and the plot is given in Fig. 5, together with those obtained using the MWCNTs-PANI, SPAN and PANI coatings for comparison. For the SPAN and MWCNTs-SPAN coatings, the peak areas remain almost unchanged within the time of ~ 900 min, during which 30 absorption–desorption cycles have been carried out. In contrast, for the PANI and MWCNTs-PANI coatings, the areas gradually decline by ~ 20% within 540 min, during which just 18 absorption–desorption cycles have been performed. This result implies that the SPAN and MWCNTs-SPAN-coated fibers have more longer lifetimes than the PANI and MWCNTs-PANI-coated fibers. Undoubtedly, the longer lifetimes of the SPAN and MWCNTs-SPAN coating fibers should be ascribed to their better thermal stabilities as demonstrated above.

Curves of relative peak area to cumulative time for comparison of lifetime among the PANI, SPAN, MWCNTs-PANI and MWCNTs-SPAN coatings. 2,4-DCP concentration: 500 μg L−1; extraction temperature, 80 ℃; extraction time, 50 min; salting strength: 0.35 g mL−1 NaCl; pH value: 2; desorption temperature/injection port temperature: 280 ℃; desorption time, 3 min; other conditions, as in Fig. 4

Extraction Efficiency

The extraction efficiency of the MWCNTs-SPAN coating was compared with those of the PANI, SPAN and MWCNTs-PANI coatings. In the present work, the extraction efficiencies were measured in peak areas referring to other authors' work [18, 21, 29, 31, 33]. The peak areas were obtained through HS-SPME-GC of 2,4-DCP in the standard solution using the four coating fibers at 280 ℃. The extraction efficiencies of the MWCNTs-SPAN and MWCNTs-PANI coatings are about fourfold higher than those of the PANI and SPAN coatings (Fig. 6). Undoubtedly, this is attributed to the larger specific surface areas of the coatings as demonstrated in the earlier section. Du et al. [29] had also reported that the MWCNTs-doped PANI coating provided a higher extraction efficiency than the PANI coating in their work. It also should be noted that the extraction efficiencies of the MWCNTs-SPAN and SPAN coatings are a little higher than those of the MWCNTs-PANI and PANI, respectively. This probably results from the − SO3− groups in the MWCNTs-SPAN and SPAN coatings. The presence of − SO3− groups, to some extent, modifies the surface morphology and pore structure and enlarges the specific surface areas of the coatings, just as demonstrated in the earlier section. Additionally, the intermolecular interaction between the highly polar − SO3− groups and the polar 2,4-DCP molecules may have some contribution to the extraction efficiencies of the MWCNTs-SPAN and SPAN coatings.

Bar chart for comparison of extraction efficiency among the PANI, SPAN, MWCNTs-PANI and MWCNTs-SPAN coatings. Experimental conditions, as in Fig. 5

Performance of the MWCNTs-SPAN Fiber Coating in HS-SPME-GC

The curve of peak area to concentration was plotted for 2,4-DCP in purified water in the concentration span from 10 ng L−1 to 600 μg L−1 (SI 7). Up to ~ 500 μg L−1, the peak area increases with the increase in concentration and then remains almost unchanged. Although no good linearity exists in the whole test concentration span, two calibration curves were separately made in the ranges from 50 ng L−1 to 10 μg L−1 and from 10 to 500 μg L−1. The correlation coefficients (R2) are 0.9990 and 0.9487, and the slopes are 118.1 and 4.6 cm2 L ng−1 for the two calibration curves, respectively (SI 8). There are a much better linearity and a higher sensitivity/slope in the lower concentration range. This is more beneficial for determination of the analytes at low concentration levels. The limit of detection (LOD, N/S = 3) and the precision (RSD, %) are 1.3 ng L−1 and 4.3% (n = 5), respectively. The results are summarized in Table 1, together with some data reported by other authors for comparison. Overall, the MWCNTs-SPAN coating is comparable or superior to the others in the measured indexes. In particular, it should be mentioned that LOD is dependent on not only extraction efficiency but also other factors in HS-SPME-GC. The relatively low LOD achieved by Li et al. [32], for an example, perhaps results mainly from the mass spectrometric detector used in their work. Mass spectrometers are highly sensitive to highly electronegative compounds such as 2,4-DCP, whereas the situation is just the opposite for FIDs. Therefore, if the MWCNTs-SPAN coating is combined with a mass spectrometer, a much lower LOD should be expected.

The reliability of the MWCNT-SPAN-coated fiber in practical use was assessed through determination of 2,4-DCP in three real water samples (mineral water, tap water and sea water) by HS-SPME-GC (Table 2). No the target analyte was found. Therefore, spiked samples were used as no natural matrix standard sample was available. Several typical chromatograms are given as supporting information (SI 9). The recoveries range from 82.3 to 110.2%, from 91.5 to 109.4% and from 94.2 to 113.0% with the relative standard deviations (RSD, %) between 1.5% and 9.8% (n = 3) for the samples spiked at three levels of 500, 100 and 10 ng mL−1, respectively. The accuracy and precision are acceptable for the analysis of environmental water samples.

Conclusions

A new composite of MWCNTs-SPAN has been presented for HS-SPME-GC of polar pollutants. SEM and BET analysis reveals that MWCNTs can greatly modify the surface morphology and pore structure and thus remarkably increase the surface areas of the MWCNTs-SPAN and MWCNTs-PANI coatings compared to the SPAN and PANI coatings. The result of TGA demonstrates that − SO3− groups can notably enhance the thermal stabilities of SPAN and MWCNTs-SPAN coatings compared to PANI and MWCNTs-PANI coatings. Owing to the larger specific area and higher thermal stability, MWCNTs-SPAN coating exhibits a higher extraction efficiency and a longer lifetime than PANI, SPAN and MWCNTs-PANI coatings. The performance of the MWCNTs-SPAN coating in HS-SPME-GC is assessed to be comparable or superior to those of some fiber coatings reported previously. All the merits unitedly suggest that the MWCNTs-SPAN coating has potential applications in HS-SPME-GC of a variety of polar compounds such as phenol, chlorophenols and aromatic amines in water samples.

References

Muscalu AM, Górecki T (2018) Comprehensive two-dimensional gas chromatography in environmental analysis. Trends Anal Chem 106:225–245. https://doi.org/10.1016/j.trac.2018.07.001

Wasylka JP, Szczepańska N, Guardia M, Namieśnik J (2015) Miniaturized solid-phase extraction techniques. Trends Anal Chem 73:19–38. https://doi.org/10.1016/j.trac.2015.04.026

Garces NR, Gionfriddo E, Ríos GAG, Alam MN, Boyacı E, Bojko B, Singh V, Grandy J, Pawliszyn J (2018) Advances in solid phase microextraction and perspective on future directions. Anal Chem 90:302–360. https://doi.org/10.1021/acs.analchem.7b04502

Sajid M, Nazal MK, Rutkowska M, Szczepanska N, Namiesnik J, Wasylkab JP (2019) Solid phase microextraction: apparatus, sorbent materials, and application. Crit Rev Anal Chem 49:1–18. https://doi.org/10.1080/10408347.2018.1517035

Li J, Xiao Z, Wang W, Zhang S, Wu Q, Wang C, Wang Z (2020) Rational integration of porous organic polymer and multiwall carbon nanotube for the microextraction of polycyclic aromatic hydrocarbons. Microchim Acta 187:2–8. https://doi.org/10.1007/s00604-020-04261-3

Heydari M, Saraji M, Jafari MT (2019) Electrochemically prepared three-dimensional reduced graphene oxide-polyaniline nanocomposite as a solid-phase microextraction coating for ethion determination. Talanta. https://doi.org/10.1016/j.talanta.2019.120576

Pietrzyńska M, Tomczak R, Jezierska K, Voelkel A, Jampílek J (2016) Polymer-ceramic monolithic in-needle extraction (MINE) device: preparation and examination of drug affinity. Mat Sci Eng 68:70–77. https://doi.org/10.1016/j.ejps.2017.05.040

Xie W, Mullett W, Pawliszyn J (2011) High-throughput polymer monolith in-tip SPME fiber preparation and application in drug analysis. Bioanalysis 3:2613–2625. https://doi.org/10.4155/bio.11.267

Queiroz MEC, Souza ID, Marchioni C (2018) Current advances and applications of in-tube solid-phase microextraction. Trends Anal Chem 111:261–278. https://doi.org/10.1016/j.trac.2018.12.018

Xu L, Hu Z, Duan R, Wang X, Yang Y, Dong L, Wang X (2021) Advances and applications of in-tube solid-phase microextraction for analysis of proteins. J Chromatogr A 1640:461962–461962. https://doi.org/10.1016/J.CHROMA.2021.461962

Olcer YA, Tascon M, Eroglu AE, Boyaci E (2019) Thin film microextraction: towards faster and more sensitive microextraction. Trends Anal Chem 113:93–101. https://doi.org/10.1016/j.trac.2019.01.022

Jiang R, Pawliszyn J (2012) Thin-film microextraction offers another geometry for solid-phase microextraction. Trends Anal Chem 39:245–253. https://doi.org/10.1016/j.trac.2012.07.005

Lashgari M, Yamini Y (2019) An overview of the most common lab-made coating materials in solid phase microextraction. Talanta 191:383–306. https://doi.org/10.1016/j.talanta.2018.08.077

Godage NH, Gionfriddo E (2019) A critical outlook on recent developments and applications of matrix compatible coatings for solid phase microextraction. Trends Anal Chem 111:220–228. https://doi.org/10.1016/j.trac.2018.12.019

Tafazoli Z, Azar PA, Tehrani MS, Husain SW (2018) Facile preparation of multifunctional carbon nanotube/magnetite/polyaniline nanocomposite offering a strong option for efficient solid-phase microextraction coupled with GC-MS for the analysis of phenolic compounds. J Sep Sci 41:2736–2742. https://doi.org/10.1002/jssc.201800062

Chunin N, Phooplub K, Kaewpet M, Wattanasin P, Kanatharana P, Thavarungkul P, Buranachai CT (2020) A novel 3D-printed solid phase microextraction device equipped with silver-polyaniline coated pencil lead for the extraction of phthalate esters in cosmeceutical products. Anal Chim Acta 1091:30–39. https://doi.org/10.1016/j.aca.2019.09.036

Bagheri H, Javanmardi H, Abbasi A, Banihashemi S (2016) A metal organic framework-polyaniline nanocomposite as a fiber coating for solid phase microextraction. J Chromatogr A 1431:27–35. https://doi.org/10.1016/j.chroma.2015.12.077

Bagheri H, Mir A, Babanezhad E (2005) An electropolymerized aniline-based fiber coating for solid phase microextraction of phenols from water. Anal Chim Acta 532:89–95. https://doi.org/10.1016/j.aca.2004.10.040

Mohammad OAZ, Ali M (2013) Electrochemically prepared solid-phase microextraction coatings—A review. Anal Chim Acta 781:1–13. https://doi.org/10.1016/j.aca.2013.03.012

Bekhti MA, Belardja MS, Lafjah M, Chouli F, Benyoucef A (2021) Enhanced tailored of thermal stability, optical and electrochemical properties of PANI matrix containing Al2O3 hybrid materials synthesized through in situ polymerization. Polym Composite 42:6–14. https://doi.org/10.1002/PC.25812

Wang Y, Zhang J, Zhang D, Sun C (2010) Preparation and applications of perfluorinated ion doped polyaniline based solid-phase microextraction fiber. J Chromatogr A 1217:4523–4528. https://doi.org/10.1016/j.chroma.2010.04.075

Mehdinia A, Roohi F, Jabbari A, Manafi MR (2011) Self-doped polyaniline as new polyaniline substitute for solid-phase microextraction. Anal Chim Acta 683:206–211. https://doi.org/10.1016/j.aca.2010.10.031

Ai Y, Zhao F, Zeng B (2015) Novel proton-type ionic liquid doped polyaniline for the headspace solid-phase microextraction of amines. Anal Chim Acta 880:60–66. https://doi.org/10.1016/j.aca.2015.04.028

Bagheri H, Aghakhani A, Baghernejad M, Akbarinejad A (2012) Novel polyamide-based nanofibers prepared by electrospinning technique for headspace solid-phase microextraction of phenol and chlorophenols from environmental samples. Anal Chim Acta 716:34–39. https://doi.org/10.1016/j.aca.2011.03.016

Zeng J, Zhao C, Chong F, Cao Y, Subhan F, Wang Q, Yu J, Zhang M, Luo L, Ren W, Chen X, Yan Z (2013) Oriented ZnO nanorods grown on a porous polyaniline film as a novel coating for solid-phase microextraction. J Chromatogr A 1319:21–26. https://doi.org/10.1016/j.chroma.2013.10.040

Song XY, Chen J, Shi YP (2016) Different configurations of carbon nanotubes reinforced solid-phase microextraction techniques and their applications in the environmental analysis. Trends Anal Chem 86:263–275. https://doi.org/10.1016/j.trac.2016.11.006

Hajializadeha A, Ansarib M, Foroughia MM, Kazemipour M (2020) Ultrasonic assisted synthesis of a novel ternary nanocomposite based on carbon nanotubes/zeolitic imidazolate framework-67/polyaniline for solidphase microextraction of organic pollutants. Microchem J. https://doi.org/10.1016/j.microc.2020.105008

Ghiasvand A, Dowlatshah S, Nouraei N, Heidari N, Yazdankhah F (2015) A solid-phase microextraction platinized stainless steel fiber coated with a multiwalled carbon nanotube-polyaniline nanocomposite film for the extraction of thymol and carvacrol in medicinal plants and Honey. J Chromatogr A 1406:87–93. https://doi.org/10.1016/j.chroma.2015.06.052

Du W, Zhao F, Zeng B (2009) Novel multiwalled carbon nanotubes-polyaniline composite film coated platinum wire for headspace solid-phase microextraction and gas chromatographic determination of phenolic compounds. J Chromatogr A 1216:3751–3757. https://doi.org/10.1016/j.chroma.2009.03.013

Khajeamiri AR, Kobarfard F, Moghaddam AB (2012) Application of polyaniline and polyaniline/multiwalled carbon nanotubescoated fibers for analysis of ecstasy. Chem Eng Technol 35:1515–1519. https://doi.org/10.1002/ceat.201000509

Mehdinia A, Mousavi MF (2008) Enhancing extraction rate in solid-phase microextraction by using nano-structured polyaniline coating. J Sep Sci 31:3565–3572. https://doi.org/10.1002/jssc.200800284

Li QL, Huang F, Wang XL, Wang X, Zhao RS (2017) Multiple-helix cobalt(II)-based metal-organic nanotubes on stainless steel fibers for solid-phase microextraction of chlorophenol and nitrophenols from water samples. Microchim Acta 184:1817–1825. https://doi.org/10.1007/s00604-017-2167-6

Liu Y, Huang Y, Chen G, Huang J, Zheng J, Xu J, Liu S, Qiu J, Yin L, Ruan W, Zhu F, Ouyang G (2018) A graphene oxide-based polymer composite coating for highly-efficient solid phase microextraction of phenols. Anal Chim Acta 1015:20–26. https://doi.org/10.1016/j.aca.2018.02.034

Bagheri H, Manouchehri M, Allahdadlalouni M (2017) A magnetic multifunctional dendrimeric coating on a steel fiber for solid phase microextraction of chlorophenols. Microchim Acta 184:2201–2209. https://doi.org/10.1007/s00604-017-2220-5

Bagheri H, Najarzadekan H, Roostaie A (2014) Electrospun polyamide-polyethylene glycol nanofibers for headspace solid-phase microextration. J Sep Sci 37:1880–1886. https://doi.org/10.1002/jssc.201400037

Li Y, Li W, Wang Y, Zhou H, Hu G, Zhang N, Sun C (2013) Development of a solid-phase microextraction fiber coated with poly(methacrylic acid-ethylene glycol dimethacrylate) and its application for the determination of chlorophenols in water coupled with GC. J Sep Sci 36:2121–2127. https://doi.org/10.1002/jssc.201200979

Ai Y, Wu M, Li L, Zhao F, Zeng B (2016) Highly selective and effective solid phase microextraction of benzoic acid esters using ionic liquid functionalized multiwalled carbon nanotubes-doped polyaniline coating. J Chromatogr A 1437:1–7. https://doi.org/10.1016/j.chroma.2016.01.072

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Conflict of Interest

The authors have no relevant financial or non-financial interests to disclose.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, X., Weng, Q. & Li, J. A New Composite of O-aminobenzene Sulfonic Acid Self-Doped Polyaniline and Multi-Walled Carbon Nanotubes as a Fiber Coating for Solid-Phase Microextraction Gas Chromatography. Chromatographia 85, 689–697 (2022). https://doi.org/10.1007/s10337-022-04177-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-022-04177-5