Abstract

The utilization of a bifunctional amine and H3PW12O40 (PW12) as a direct solid-phase microextraction (D-SPME) coating was investigated for the first time. The fiber was synthesized using positively charged 3-aminopropyltriethoxysilane as the crosslinking agent, and provided sites for the immobilization of PW12. Fourier transform infrared spectroscopy and field emission scanning electron microscopy were used to characterize the synthetic compound. This new fiber was developed to determine some chlorophenols [4-chlorophenol (4-CPh), 2,3-dichlorophenol (2,3-DCPh), and 2,4,6-trichlorophenol (2,4,6-TCPh)] via SPME-HPLC. Using the experimental design method, the adsorption and desorption factors of the fiber—including ionic strength and adsorption and desorption times—for the three chlorophenols were systematically investigated by SPME-HPLC-UV. In the concentration range 50–5000 µg L−1, the calibration curves were linear for the analytes and the limits of detection varied from 0.3 to 2.5 µg L−1. The single-fiber repeatability and fiber-to-fiber reproducibility were in the ranges 4.8–6.4 and 10.2–12.1%, respectively. The application of the fiber to environmental water samples spiked at 70 µg L−1 with the chlorophenols yielded recoveries in the range 88.80–92.88%. Advantages of this novel bifunctional-coated SPME fiber include its increased extraction efficiency for chlorophenols and its long lifetime (it was used for >70 cycles of D-SPME-HPLC operation without showing any appreciable reduction in extraction performance).

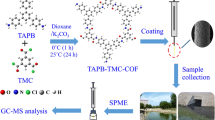

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chlorophenols (CPs) have been applied as antiseptics, insecticides, herbicides, fungicides, wood preservatives, and intermediates in the synthesis of dyes and pharmaceuticals. They are also by-products of the chlorination of drinking water and the chlorine bleaching of wood pulp [1]. As a consequence, these semivolatile organic chlorine compounds are now found throughout the world in surface and ground waters, waste waters, bottom sediments, atmospheric air, and soils. However, the toxicity and persistence of CPs in environmental matrices make them environmentally hazardous compounds: they are classified as US Environmental Protection Agency Priority Pollutants and European Union Priority Substances [1, 2]. Indeed, several phenols have been classified as priority contaminants by the European Union (EU), and the maximum concentration of total phenols in drinking water is defined as 0.5 mg L−1 in the European Council directive 80/778/EC [1]. Gas chromatography (GC) and high-performance liquid chromatography (HPLC) are commonly employed for the analysis of phenol compounds. GC and HPLC analyses are usually performed following the extraction and concentration of the compounds using liquid–liquid extraction (LLE), solid-phase extraction (SPE), or solid-phase microextraction (SPME). Developed in the early 1990s [3], solid-phase microextraction (SPME) is a simple sample preparation method that integrates sampling, extraction, and sample introduction into one step while consuming less solvent [4, 5].

However, commercial SPME fibers do have drawbacks; among the most important are their low thermal and chemical stabilities due to the direct physical deposition of the coating materials onto the fused silica fibers [6]. In general, the pores and surface area of a coating are important factors to consider in the characterization of the coating, as they affect the trapping of analytes. A number of experimental SPME coatings have been prepared and investigated for their potential application to the extraction and preconcentration of compounds [7, 8].

Soluble metal oxide clusters (polyoxometallates) such as phosphotungstic acid (H3PW12O40, PW12) have recently received increasing interest in the field of chemically modified electrodes [9] and high-activity catalysts for various reactions [10] due to their excellent thermal and redox stabilities, special electrocatalytic properties, commercial availability, ease of handling, remarkably low toxicity, environmentally friendly nature, cost-effectiveness, high Brønsted acidity, mobile ionic structure, and easy absorption of polar molecules in the bulk, leading to a pseudo-liquid phase [9]. However, the high solubility of PW12 in water and polar organic solvents and its low surface area limit its practical applications. A feasible method of overcoming these constraints is to heterogenize the heteropoly acid [10]. In addition, the specific surface area of PW12 increases markedly when it is supported on a solid surface such as that provided by a fused silica fiber [11]. Moreover, the fused silica fiber surface is easily modified with different functional groups. The grafting of (3‐aminopropyl)triethoxysilane (APTES) onto a silica surface has recently been reported as a method for introducing functional amino groups onto a silica surface [10, 12]. Acidic species, for example iso- and heteropoly acids such as PW12, can be firmly anchored on an aminosilylated silica surface through acid–base interactions using surface-bonded amino groups as a base [13, 14]. Immobilized heteropoly acid/fused silica composite materials are expected to show satisfactory phenol adsorption capacities and antileaching properties due to the strong interactions between amino groups and polyacid species.

Chlorophenols have high polarities due to the presence of chlorine and are thus strongly adsorbed by synthetic fibers via dipole–dipole interactions resulting from the high polarity of the phosphotungstic acid adsorbed on the fiber. Figure 1 shows the structures of the chlorophenols used in this work.

In the work reported in the present paper, PW12 was immobilized on an aminosilylated fused silica fiber, thus creating a novel bifunctional acid–base solid. We coated the fused silica fiber with amine base and heteropolyacid functions in order to create a candidate fiber for use in the solid-phase microextraction (SPME) of chlorophenols. Various techniques, including transmission electron microscopy (TEM) and infrared (IR) spectroscopy, were used to characterize the coated fiber. In addition, we attempted to develop a fast, dependable, and sensitive SPME-HPLC method for the analysis of three chlorophenols in environmental water samples.

Experimental

Reagents and Solutions

4-Chlorophenol (4-CPh), 2,3-dichlorophenol (2,3-DCPh), and 2,4,6-trichlorophenol (2,4,6-TCPh) were purchased from Sigma (St. Louis, MO, USA); phosphotungstic acid hydrate (H3[P(W3O10)4]·xH2O) and 3-aminopropyltriethoxysilane (APTES) were from Merck (Darmstadt, Germany). Stock solutions of the selected compounds were prepared by diluting each chlorophenol with methanol to a concentration of 1000 mg L−1. The solutions were stored in a refrigerator at 4 °C. They were then diluted with deionized water to the desired concentration to optimize the extraction parameters of the subsequently coated SPME fiber. Commercial PDMS (coating thickness = 100 µm) and PDMS/DVB-coated (coating thickness = 65 µm) SPME fibers were purchased from Sigma–Aldrich and Polymicro Technologies, Inc. (Phoenix, AZ, USA), respectively. Fused silica fibers (o.d. = 140 mm × 0.25 mm) were obtained from the Xinnuo Photoconductive Fiber Corporation (Handan, China).

Apparatus

An Agilent (Palo Alto, CA, USA) 1260 Infinity HPLC instrument equipped with an Agilent G1312B pump (1100 series), a G4218AUV detector (1100 series), and a Rheodyne 7725 injector valve (Cotati, CA, USA) was used to carry out separations. The method was optimized at a flow rate of 0.8 mL min−1 and a UV detection wavelength of 230 nm. A C18 column with a diameter of 4.6 mm and a length of 250 mm was used to perform isocratic separations using a mixture of acidic water (hydrochloric acid) and methanol (pH 5.5, 30:70) as the mobile phase. A TESCAN (Brno, Czech Republic) MIRA3 instrument operating at 15 kV was used to obtain field emission scanning electron microscopy (FE-SEM) micrographs. A Varian (Palo Alto, CA, USA) model 640 spectrophotometer was used to record Fourier transform infrared (FT-IR) spectra using pressed KBr pellets.

Silanization of the Fiber Surface and Immobilization of a Phosphotungstic Acid (PW12) Layer on the Fiber

The silanization procedure for the fiber surface was similar to that used for a fused silica capillary in a previous work [15]. The primary steps were as follows. One end of the fused silica fiber (2 cm) was immersed in acetone to remove the protective polyimide layer. It was then dipped in a 1.0 M NaOH solution and heated in a hot water bath (70 °C) for 30 min. Next, the fiber was placed in a dry tube and kept at 120 °C for another 30 min in an oven, after which it was rinsed with ultrapure water to achieve a pH of 7 and dried at ambient temperature. The hydroxylated part of the fiber was dipped in an APTES solution for 5 min, removed, and immediately immersed in PW12 powder. Afterwards, the fiber was taken out and placed in an oven at 70 °C for 1 h to encourage the silanization reaction of APTES with the silanol on the silica fiber surface (forming Si–O–Si bonds) as well as the acid–base interaction of the APTES amino groups with PW12 acidic groups. This coating procedure was repeated several times to achieve the desired coating thickness [5]. Ultimately, the fiber was rinsed with toluene and ethanol and dried at ambient temperature.

Extraction Using the PW12-Coated SPME Fiber

The PW12-coated SPME fiber was used to directly extract 4-CPh, 2,3-DCPh, and 2,4,6-TCPh from a mixed solution at pH 6.5. The parameters optimized by the experimental design method included extraction time, desorption time, and ionic strength. The Statgraphics Plus 5.1 software package was applied in the design of 21 experiments via the Box–Behnken method in order to obtain maximum efficiency in the extraction process.

Analytes were extracted from 10-mL solutions containing 50 mg L−1 of chlorophenols and NaCl (13–27% w/v) in 15-mL sample vials at pH 6.5. The sample vials were tightly sealed with aluminum caps. The solution was magnetically stirred at 500 rpm. The PW12-coated SPME fiber was immersed in the sample solution for 20–40 min at ambient temperature. Following the extraction, the PW12-coated SPME fiber was kept in methanol (the desorption solvent; 20 µl) for 15–35 min on a shaker working at a rate of 250 rpm. Finally, methanol (20 μl) was injected into the HPLC loop for final analysis.

Environmental Water Analysis

Agricultural ground water was obtained from Kordestan Province, Iran. All samples were filtered prior to analysis and analyzed according to the procedure described in the section “Extraction Using the PW12-Coated SPME Fiber.”

Results and Discussion

Preparation of the PW12-Coated SPME Fiber

Silica fibers were first hydroxylated using a NaOH solution to break the Si–O–Si bonds and form Si–OH groups, which were then transformed to –NH2 groups by reacting them with APTES, as shown in Fig. 2. Strong interactions between the amino groups and the polyacid species lead to the formation of the PW12-coated SPME fiber [10]. The linker APTES is a strong base that undergoes a strong acid–base interaction with PW12, although some of the amino groups of APTES molecules do not interact with PW12. Therefore, bifunctional amine base and heteropolyacid functions form on the fused silica fiber surface.

FTIR spectra of the uncoated fused silica fiber, APTES, PW12, and the PW12-APTES@fiber (i.e., the removed fiber coating) in the 4000–400 cm−1 range are shown in Fig. 3. The band observed for all samples in the range 1624–1641 cm−1 is associated with the –OH vibration of physisorbed H2O. Bands due to the Si–O–Si moiety in silica were observed at around 1000–1250, 805–820, and 461–475 cm−1.

The presence of characteristic stretching peaks from –NH2 and Si–O in the 2000–700 cm−1 range confirmed the successful hybridization of APTES onto the fused silica fiber. Absorption peaks at 3275, 1574, and 774 cm−1 are associated with the –NH2 functional group [16], while peaks due to Si–O–C and Si–O–Si occur at 1045 and 1119 cm−1, respectively; these two peaks overlap to form a broad peak.

Four IR bands that appear at 1080 cm−1 (P–O band), 990 cm−1 (W=O band), and 890 and 810 cm−1 (W–O–W bands) are characteristic of the primary structure of unsupported PW12 [17]. Peaks for the PW12-APTES@fiber were redshifted compared with those for pure PW12. This may be attributed to the strong interactions between the amino groups on the fiber and PW12 due to strong adsorption through acid–base interactions.

FE-SEM images of an uncoated and a PW12-coated fused silica fiber are shown in Fig. 4. Since the PW12 coating can be observed, it is clear that the synthetic strategy was successful. The coated fiber surface is very rough and porous. The fiber has its own special surface microstructure that leads to a high extraction capacity, as illustrated by the images. Figure 4 shows bifunctional solids, amine base functions (APTES), and heteropolyacid functions (PW12) on the fused silica fiber, which together yeield an efficient and robust bifunctional acid–base solid-coated fiber.

The elemental composition of the PW12-APTES@fiber was also analyzed by examining its EDS spectrum (Fig. 4c). This further confirmed the presence of the elements Si, W, O, P, and C in the PW12-APTES@fiber.

Extraction Ability of the PW12-coated SPME Fiber

The extraction ability of PW12-APTES@fiber was compared with those of silica fibers treated with NaOH and the APTES@fiber under the same extraction conditions. One might expect chlorophenol anions to be able to ion exchange into the amine phase without the addition of PW12. However, given that the pK a of 4-chlorophenol is about 8.4 and that of 2,4,6-trichlorophenol is 6.5 (and that of dichlorophenol is somewhere in between those two values), it seems likely that the trichlorophenol is the only one of these compounds that is likely to participate in anion exchange. Given that adding chloride ions enhances the recovery (rather than decreasing the capture), this supports the hypothesis that the PW12 phase plays the most important role in the bifunctional coating. More support for the important role played by the PW12 is obtained by comparing the PW12-APTES@fiber to a SPME fiber coated only with the amine (no PW12). As observed in Fig. 5, the fused silica fiber and the APTES@fiber exhibit lower chlorophenol extraction efficiencies—possibly as a result of their only weakly polar functional groups—than the PW12-APTES@fiber. This can be attributed to the hydrophilic and electrostatic interactions between PW12 and chlorophenols.

Comparison of the PW12-APTES@fiber with Commercial Fibers

To further estimate the extraction ability of the PW12-coated fiber, we compared its extraction efficiency to those of two commercial SPME fibers. Since there are a wide variety of commercially available SPME fibers, it was not possible to compare the PW12-APTES@fiber with all of them, so we chose two of the most widely used fibers: PDMS-coated and PDMS/DVB-coated fibers. The chlorophenol extraction efficiency of the PW12-APTES@fiber was found to be higher than that of the fiber coated with 100 µm of PDMS or that of the fiber coated with 65 mm of PDMS/DVB; see Fig. 6 [4]. In addition, the LODs of the commercial PDMS/DVB-coated SPME fiber in the extraction of chlorophenols were studied. As observed in Table 1, the PDMS/DVB-coated fiber had lower LODs than the PDMS-coated SPME fiber. However, in spite of the relatively thin layer of PW12 on the fiber compared to the PDMS and PDMS/DVB coatings, the PW12-coated fiber presented the lowest LODs for the extracted chlorophenols.

Comparison of the chlorophenol extraction efficiencies of the PW12-APTES@fiber and the two commercial fibers tested. Experimental conditions were as described for Fig. 5

Optimization of SPME

A literature survey shows that one of the most important parameters to optimize when extracting chlorophenols is pH [18, 19]. Phenols and PW12 are both protonated at acidic pH and charge repulsion prevents phenol molecules from approaching the surface of a fiber coated with PW12. At alkaline pH, phenols are deprotonated and form phenolate anions. PW12 is also negatively charged. Thus, repulsion between these two negatively charged species reduces extraction efficiency.

A pH value of 6.5 was therefore selected for extraction. Experimental design was used to investigate the factors that affect analyte extraction and the significant interactions between these factors prior to the analysis of chlorophenols. The Box–Behnken method was employed to optimize these parameters, which included the extraction time (A), ionic strength (B), and desorption time (C). Table 2 shows these factors and their levels. The normalized experimental design results were evaluated at the 95% confidence level. A standardized Pareto chart was used to explore all of the parameters that affect the extraction efficiency (data not shown). A main effects plot was used to identify the parameter values that yield high extraction efficiency (Fig. 7). Table 2 shows the factors considered and their levels. Increasing the extraction time up to 38 min was found to increase the extraction efficiency for all the analytes, whereas the efficiency plateaued for extraction times of greater than 38 min. Thus, the optimal extraction time was 38 min. The addition of NaCl salt allowed the ionic strength of the solution to be controlled. On the whole, the addition of salt to the solution, which is referred to as the “salting out” process, increased the partition coefficients of the organic compounds to the fiber coating. Addition of NaCl to the solution increased the maximum amount of chlorophenol extracted, as shown by the results in Fig. 7. Therefore, 27% (w/v) was chosen as the optimal % NaCl. Desorption time, which was studied in the range 15–35 min. was the last parameter to be studied. Increasing the desorption time increased the chlorophenol desorption efficiency (Fig. 7). The redistribution of chlorophenols from the PW12-APTES@fiber to methanol increased up to 30 min, after which there was no further increase. Therefore, 30 min was chosen as the optimal desorption time.

Compared with the one-at-a-time method for optimizing the extraction parameters, one of the most important benefits of experimental design is that the interactions between the parameters are considered. The interaction between the salt percentage (B) and the desorption time (C) in the parameter ranges selected is shown in Fig. 8. We can see that these parameters are completely dependent on each other, so they cannot be investigated separately.

Method Performance

The performance of the proposed PW12/SPME HPLC method was studied under the optimized conditions. Standard solutions were used to calculate the linear dynamic ranges (LDRs) of the method for 4-CPh, 2,3-DCPh, and 2,4,6-TCPh. The LDRs for all the analytes are shown in Table 1. The correlation coefficients (R 2) for the calibration curves varied from 0.983 (2,4,6-TCPh) to 0.993 (4-CPh) within a wide concentration range.

Five replicates of standard solutions containing 50 mg L−1 of each analyte were used to determine the precision of the PW12/SPME-HPLC method. The relative standard deviation (RSD) values ranged from 4.8 for 2,5-DCPh to 6.4% for 4-CPh, whereas the fiber-to-fiber RSDs, as shown in Table 1, varied from 10.2% for 2,3-DCPh to 12.1% for 4-CPh. Moreover, the calculated interday RSDs, calculated based on the results obtained on three days, were in the range 9.5–10.2%. The limits of detection (LODs) were 0.3, 0.4, and 2.5 µg L−1 for 2,4,6-TCPh, 2,3-DCPh, and 4-CPh, respectively. Upon comparing the figures of merit for the PW12-coated SPME fiber to those of a commercial PDMS-SPME fiber, the LOD of the PW12-coated SPME fiber was found to be 1.8-fold and 27-fold lower for 4-CPh and 2,3-DCPh, respectively, and 7-fold lower for 2,4,6-TCPh (Table 1). Similarly, the PW12-coated fiber gave LODs that were 1.1–10 times lower than those afforded by the PDMS/DVB fiber.

In addition, we found that the PW12-coated SPME fiber could be used over 70 times with no appreciable reduction in extraction performance.

Application of the Method to Real Samples

The PW12-coated SPME was used to extract chlorophenols from agricultural ground waters in the Kordestan Province of Iran. Chlorophenol concentrations were below the detection limit of the method generally employed for agricultural ground water sample analysis, according to the data. A recovery test was carried out by adding 70 µg L−1 of each analyte to the sample to evaluate the reliability of the developed method (Fig. 9). Recoveries in the 89–92% range were observed; Table 1. Figure 9 shows that all three chlorophenols were measurable in the agricultural ground water sample. The 2,4,6-TCPh concentration was 6.2 mg L−1, as shown in Table 1. The applicability of the PW12/SPME-HPLC method for the trace analysis of chlorophenol derivatives in environmental water samples is therefore demonstrated by the results.

Comparison of the PW12-SPME-HPLC Method with Other Methods

The developed method was compared with other previously reported approaches for determining CPs (Table 3). The LODs of the method developed here were generally found to be comparable to those of previously reported methods, although the LODs of the DLLME-GC-ECD method were at least 30 times lower than those for the PW12-SPME-HPLC method. One of the reasons for the low LODs of the DLLME-GC-ECD method is the high sensitivity of the ECD detector. The low LODs of the PW12-APTES@fiber relative to other methods are due to its appropriately tailored fiber coating. However, the advantages of using SPME are also very evident when compared with conventional extraction techniques such as LLE, especially when a large number of samples need to be prepared [20]. The SPME procedure is simple and organic solvent consumption is far lower than for LLE. The evaporation and reconstitution steps required in LLE prior to injection into the chromatographic system are not needed in SPME, making it particularly desirable for the quantification of highly volatile analytes that could evaporate during the pre-injection steps in LLE. Therefore, it is important to develop a consistent SPME/HPLC-UV method for the quantification of phenolic compounds in complex sample matrices and the isolation of phenolic fractions from different matrices [20]. In addition, there is great potential for the sample preparation time to be significantly reduced using SPME, as well as disposal costs, and SPME can be applied to very small sample volumes.

On the other hand, the disadvantages of SPME should not be overlooked. There are only a few commercially available SPME fibers. In comparison with LLE, SPME is a relatively nonselective extraction method, and great effort is needed to increase its relative extraction recovery and efficiency. In addition, extra clean-up procedures are necessary before repeating analyses using the same fiber. Quantitation is more prone to errors due to changes in the matrix in SPME than in other conventional extraction methods, and matrix effects need to be thoroughly investigated during method validation [21].

Extraction of the desired components was also carried out using the PDMS/DVB-coated fiber under optimal conditions according to the experimental design. The LODs for the extraction of CPs using the PW12-coated fiber were found to be lower than those obtained with the PDMS/DVB-coated SPME fiber due to the larger number of oxygen atoms (from PW12) on the PW12-coated SPME fiber surface compared with the PDMS/DVB-coated SPME fiber surface. Thus, PW12-SPME-HPLC was shown to be an effective technique for the preconcentration and determination of CPs in different environmental water samples.

Conclusion

In the present study, a SPME sorbent based on PW12 was prepared to optimize a procedure for the preconcentration and determination of trace amounts of some chlorophenols in environmental water samples.

Experimental design was applied to study the effects of three different factors on the SPME performance of the PW12-APTES@fiber developed here. According to the results, adding NaCl to the water samples, increasing the extraction time, and increasing the desorption time considerably increase the extraction efficiency. Applying experimental design meant that fewer experiments were required to determine the optimal SPME conditions, and it allowed the interactions among factors and curvature effects to be considered. Thus, the optimal conditions found by experimental design are more reliable than those obtained by investigating the influence of each factor one at a time.

The need for hazardous organic solvents in the synthetic method was avoided, and over 100 fused silica substrates could be covered simultaneously with the new coating. As a result, this method can be considered an efficient synthetic method that is suitable for commercial use. The benefits of the prepared PW12-APTES@fiber for the preconcentration of phenol compounds in water samples included the enhanced extraction capacity due to strong interactions between the analytes and the sorbent, its simplicity, its low cost, and its ease of handling in comparison with other traditional SPME fibers. Satisfactory accuracy, linearity, precision, and detection limits for the extraction of chlorophenols from water were also shown by the method.

References

Holopainen S, Luukkonen V, Nousiainen M, Sillanpää M (2013) Talanta 114:176–182

Vayssieres L (2003) Adv Mater 15:464–466

Arthur CL, Pawliszyn J (1990) Anal Chem 62:2145–2148

Alizadeh R (2016) Talanta 146:831–838

Zhang S, Du Z, Li G (2013) Talanta 115:32–39

Li X, Zhong M, Xu S, Sun C (2006) J Chromatogr A 1135:101–108

Lord H, Pawliszyn J (2000) J Chromatogr A 885:153–193

Dietz C, Sanz J, Cámara C (2006) J Chromatogr A 1103:183–192

Li W, Li L, Wang Z, Cui A, Sun C, Zhao J (2001) Mater Lett 49:228–234

Cai W, Zhou Y, Bao R, Yue B, He H (2013) Chin J Catal 34:193–199

Anandan S, Yoon M, Park S-E (2003) J Photosci 10:231–236

Zhou Y, Bao R, Yue B, Gu M, Pei S, He H (2007) J Mol Catal A Chem 270:50–55

Zhou Y, Yue B, Bao R-L, Liu S-X, He H-Y (2006) Chin J Chem 24:1001–1005

Shiju NR, Alberts AH, Khalid S, Brown DR, Rothenberg G (2011) Angew Chem 123:9789–9793

Liu H, Li J, Liu X, Jiang S (2009) Talanta 78:929–935

Kim Y, Ketpang K, Jaritphun S, Park JS, Shanmugam S (2015) J Mater Chem A 3:8148–8155

Fazaeli R, Aliyan H, Tangestaninejad S, Foroushani SP (2014) J Iran Chem Soc 11:1687–1701

Păcurariu C, Mihoc G, Popa A, Muntean SG, Ianoş R (2013) Chem Eng J 222:218–227

Mousavi M, Noroozian E, Jalali-Heravi M, Mollahosseini A (2007) Anal Chim Acta 581:71–77

Pinto PCR, da Silva EAB, Rodrigues ArEd (2010) Ind Eng Chem Res 49:12311–12318

Xie W, Pawliszyn J, Mullett W, Matuszewski B (2007) J Pharm Biomed Anal 45:599–608

Li Q, Wang X, Yuan D (2009) J Chromatogr 1216:1305–1311

Bagheri H, Mir A, Babanezhad E (2005) Anal Chim Acta 532:89–95

Liu X, Ji Y, Zhang Y, Zhang H, Liu M (2007) J Chromatogr 1165:10–17

López-Jiménez FJ, Rubio S, Pérez-Bendito D (2008) J Chromatogr 1195:25–33

Llorca-Pórcel J, Martínez-Parreño M, Martínez-Soriano E, Valor I (2009) J Chromatogr A 1216:5955–5961

Fattahi N, Assadi Y, Hosseini MRM, Jahromi EZ (2007) J Chromatogr A 1157:23–29

Villar-Navarro M, Ramos-Payán M, Luis Pérez-Bernal J, Fernández-Torres R, Callejón-Mochón M, Ángel Bello-López M (2012) Talanta 99:55–61

Li X-S, Xu L-D, Shan Y-B, Yuan B-F, Feng Y-Q (2012) J Chromatogr A 1265:24–30

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

This article does not contain any studies with human participants, so no informed consent was necessary for this study.

Rights and permissions

About this article

Cite this article

Bordbar, M., Noori-Ahmadabadi, J., Yeganeh-Faal, A. et al. Application of Amine and Phosphotungstic Acid Groups as a Novel Bifunctional Fiber Coating in SPME-HPLC of Volatile Phenols in Water. Chromatographia 80, 1605–1613 (2017). https://doi.org/10.1007/s10337-017-3402-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-017-3402-3