Abstract

Polyhedral oligomeric silsesquioxanes are 3D nanoscaled materials with large potential in solid phase microextraction (SPME). Here, as a case study, an octaglycidyldimethylsilyl modified polyhedral oligomeric silsesquioxane network is described. It was deposited on a stainless steel wire via a sol–gel method and used as a fiber coating for SPME of aromatic compounds. The uniform pore structure, high surface area, and hydrophobicity of the network make it susceptible toward isolation of non-polar and semi-polar chemical compounds. The performance of the fiber coating was tested with three classes of environmental pollutants, viz. chlorobenzenes (CBs), benzenes (benzene, toluene, ethylbenzene, xylene; known as BTEX), and polycyclic aromatic hydrocarbons. The effects of various types of sol–gel precursors on the fabrication and performance of fiber coatings were investigated. The extraction capability of the fiber coating was compared with the polydimethyl siloxane/divinylbenzene based commercial fiber. Parameters affecting headspace analysis and gas chromatographic quantitation were optimized. The method was applied to the quantification of PAHs, as model analytes, in tea, coffee and some environmental waters. Linear responses typically cover the 1–200 ng·L−1 concentration range, limits of detection are between 0.1 and 0.3 ng·L−1, intra-day relative standard deviation are <10%, and inter-day RSDs are <12%. The fiber has a long lifespan and can be used >200 times.

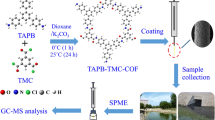

Schematic presentation of a headspace solid phase microextraction process which is implemented to the analysis of PAHs in tea and coffee samples. The SEM image of the SPME fiber coating, the 3D nanoscale polyhedral oligomeric silsesquioxane (POSS) network, and the POSS-epoxy molecular structure are shown.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid-phase microextraction (SPME) is a most useful tool for sample pretreatment and preconcentration of a wide range of compounds. This non–exhaustive strategy, in comparison to conventional extraction methods, is rapid, simple, highly efficient and solvent free [1]. The extractive–phase loaded on the SPME fibers plays a key role in the SPME efficiency, capability and selectivity [2]. Therefore, various types of fiber coatings such as carbon nanomaterials [3], conductive polymers [4],, molecular imprinted polymers (MIPs) [5] and metal organic frameworks (MOFs) [6] prepared via different methods including sol–gel [7],, chemical grafting [8], dipping [9], electrospinning [10] and hydrothermal method [11] have been extensively reported in literature. Porous hybrid materials with diverse structures are quite promising as far as induction of functionality and properties are concerned. Among these porous structures, MOFs exhibit some pronounced advantages of possessing high surface area and capable of gas uptake, although due to their poor hydrothermal stability, their applications are somehow limited [12]. Another subgroup of porous hybrid materials is polyhedral oligomeric silsesquioxanes (POSSs) with general formula of Rn(SiO1.5)n, where n is usually 6, 8, 10, or 12. These polyhedral 3D nanoscale structures are highly symmetric and stable (Fig. 1a) [13]. The amazing features of these materials, have been the major driving forces for many researches to focus on their synthesis, functionalization and polymerization [14]. The POSS–polymer nanocomposites are associated with many applications such as improving thermal and mechanical stability, drug and gene delivery with low toxicity [15, 16]. Both POSSs and MOFs have large surface area, uniform pore structure and rigidity while the hydrothermal stability of POSSs is quite considerable. All the recent surveys on POSSs properties are quite indicative that they have sufficient potential to be used as extractive phases in many ways [17]. For instance, the POSSs–based materials have been implemented as cross–linkers to fabricate SPME fiber coatings of methyl methacrylate and ionic liquid [18, 19]. These fascinating materials have shown their potential to be synthesized either in combination of other precursors or as the individual extractive phase.

Polycyclic aromatic hydrocarbons (PAHs) are a large class of environmental contaminants with fused aromatic rings which are produced during combustion of organic materials. Most of them have been proven to be carcinogenic class of chemical compounds and produced from several different sources. As industrial life grows, the human exposure to PAHs is increasing. The dietary exposure to PAHs, increase the cancer risk and causes great deals of health hazardous [20]. Many studies have been carried out to identify and quantify PAHs in various kinds of food stuffs. Among different categories of foodstuffs and beverages, tea and coffee because of their popularity and their treatment such as drying and roasting in their preparation processes are more considerable for determination of PAHs [21, 22].

In this paper, a sol–gel method was implemented to prepare a 3D nanoscale POSS–epoxy/precursors network (Fig. 1b) as a fiber coating. Some typical sol–gel precursors were applied for fabrication of POSS–epoxy–based coatings and their extraction capabilities for some selected PAHs were compared. The capability of the prominent fiber coating was also extended to the other classes of pollutants such as BTEX and CBs, while its efficiency toward PAHs remained the highest. The developed method using POSS–epoxy fiber was successfully applied to the isolation and quantitation of selected PAHs in water, tea and coffee samples.

Experimental

Chemicals and reagents

Reagents such as 3–glycidyloxypropyl–trimethoxysilane (GTMS), dibutyltin dilaurate (DBTDL), tetramethylorthosilicate (TMOS), tetraethylorthosilicate (TEOS), methyltrimethoxysilane (MTMOS), trifluoroacetic acid (TFA) 95%, ethanol, methanol, sodium hydroxide, hydrofluoric acid (40%), hydrochloric acid, naphthalene, anthracene, fluorene, acenaphthylene and acenaphthene were obtained from Merck (Darmstadt, Germany). The CB compounds including monochlorobenzene (MCB), 1,4–dichlorobenzene (14DCB), 1,2–dichlorobenzene (12DCB), 1,2,4–trichlorobenzene (124TCB) and 1,2,3,4–tetrachlorobenezne (1234TeCB), along with benzene, toluene, ethylbenzene, m–xylene and o–xylene (BTEX) were purchased from Merck. Purity of the all reagents and analytes were of analytical grade. Stock solutions of PAHs (500 mg.L−1), BTEX (1500 mg.L−1) and CBs (2000 mg.L−1) were prepared in methanol and stored at 4 °C. The diluted working solutions were prepared daily by diluting this solution with double distilled water (DDW).

Instrumentation

For optimization purposes, a gas chromatograph model Agilent 6820 (http://www.agilent.com), with a split/splitless injection port and a flame ionization detection system was used. A medium bore HP − 5 MS column (30 m, 0.32 mm i.d.) with 0.25 μm film thickness (Hewlett−Packard, Palo Alto, CA, USA) was used for chromatographic separation. The carrier gas was nitrogen (99.99%) at a flow rate of 2.5 mL.min−1. The sample introduction was performed using the splitless mode and the split valve was kept closed for 2 min. The injector and detector temperatures were set at 280 and 290 °C, respectively. For real samples analysis and the quantitative survey, a Hewlett−Packard (HP, Palo Alto, CA, USA, http://www.hpe.com) HP 6890 series GC equipped with a split/splittless injector and a HP 5973 mass − selective detection system were used. The mass spectrometer (MS) ion source was operated in the electron ionization (EI) mode (70 eV) and helium (99.999%) carrier gas, was adjusted at the flow rate of 1 mL.min−1. The temperatures of GC–MS interface, ion source and mass analyser were set at 280, 230 and 150 °C, respectively.

For separation of model compounds, initially the temperature of column was set at 75 °C and held for 1 min, after that increased to 280 °C with the rate of 40 °C min−1. The injection port was operated in the splitless mode and remained closed for 2 min at 280 °C. For quantitative analysis and achieving the highest possible signals, the time–scheduled selected ion monitoring (SIM) mode was implemented. The retention time and selected ions for each compound are tabulated in Table S1. All Samples were prepared in 9 mL clear glass vials with a PTFE faced septum and aluminum cap and all extraction processes were carried out in a home–made glass water bath placed in a circulating water system (RTG-8 NESLAB, USA) while sample solution was stirred during extraction using a Gerhardt Bonn (Germany, https://www.gerhardt.de) hot plate magnetic stirrer. The home–made SPME setup was constructed by two spinal needles with gauge numbers of 22 and 27. The field emission scanning electron microscope (FESEM) images were obtained by a Mira III TESCAN (Czech Republic, https://www.tescan.com) and thermogravimetric analysis (TGA) was performed by a Q 600 TA (USA, http://www.tainstrument.com) instrument. FTIR spectra were recorded on a Tensor 27 (Bruker, Germany, https://www.bruker.com) and 13C– and 1H– NMR spectra recoded using a Bruker 500 MHz 11.7 T (Germany). Also, an Avance 300 (Bruker, Germany) was used to record the 29Si spectra. Molecular weight of POSS–epoxy was determined by a gel permeation chromatography (GPC) Agilent 1100 series (USA). The BET analysis was performed by Belsorp mini II (Bel, Japan, https://www.groupe-bel.com) to measure the surface area of the selected sorbent.

Synthesis of POSS–epoxy

Glycidyl POSS was synthesized according to the previous report [23]. Hydrolysis and condensation of GTMS were carried out in the presence of DBTDL as a catalyst. Typically, 5 g GTMS was added to a single neck flask and then 0.5712 g water (molar ratio r = [H2O]/ [monomer] = 1.5.) and 0.05 g DBTDL were added. The mixture was stirred at 80 °C for 24 h.

FT–IR, 1H, 29Si and 13C NMR spectra were studied for the detailed structure of glycidyl POSS. The molecular weight of POSS–epoxy was determined by GPC.

Fiber preparation

Five stainless steel wires with 2 cm length were chosen as SPME fiber substrate and 1.5 cm end segment of each wire was coated by the sol–gel methodology. Firstly, the wire was immersed in hydrofluoric acid for 15 min at 40 °C. The surface of the wire gradually became black during etching process, then washed gently by double distilled water. The etched section of the fiber was cleaned with methanol, dried, and then dipped into the 1 M sodium hydroxide solution for an hour, washed with double distilled water and immersed into 0.1 M hydrochloric acid for 20 min then washed with double distilled water and dried. In order to chemically prepare the coating fiber, an amount of 200 mg of POSS–epoxy with 200 μL ethanol and different types of precursors (Table S2) were added into a micro tube and mixed for 3 min, and then 100 μL TFA (95%) was added. The end segment of fiber was then dipped vertically into the sol solution for an hour. For each fiber, this process was repeated three times. For aging and conditioning, the coated fibers were located in nitrogen atmosphere at 280 °C for 3 h.

SPME process

The headspace SPME process was performed using the synthesized POSS–epoxy fibers containing various types of precursors. During extractions, the aqueous sample was stirred by a magnetic stir bar at maximum stirring rate while the extraction temperature was controlled by the water bath. The thermal desorption process was set at 280 °C and the split valve was kept closed for 2 min. In all extractions, 5 mL of double distilled water or real water samples fortified with the selected PAHs in a 9 mL vial containing 0.5 g of sodium chloride under maximum stirring rate. Then with a PTFE septum and an aluminum cap, the vials were sealed and the extraction was performed by exposing the fiber coating to the headspace of the aqueous samples at 40 °C for 15 min. After extraction, each fiber was inserted into the GC injection port for thermal desorption.

Real samples

Different water samples, including tap and refinery plant water samples were collected and 5 mL of each sample was fortified with 10 μL of 10 μg.L−1 PAHs in methanol solution. This protocol was applied to all the fortified and non–fortified samples.

Commercial coffee and tea samples (organic and ordinary) were obtained from the local market. A volume of 2 mL methanol was added to 100 mg from the coffee or teas samples and then was sonicated for 30 min and diluted to 10 mL of double distilled water. Two extraction procedures were carried out using 5 mL of the treated sample and another 5 mL portion of the sample solution was fortified with 10 μL of 10 μg.L−1 PAHs.

Results and discussion

Most of commercial SPME fibers suffer from high cost, breakage, instability, and the possible carry–over effect. According to our initial investigation, the 3D nanoscale POSS/precursor network fibers, due to their high surface area, uniform porosity, high hydrothermal stability and mechanical strength, are suitable alternatives.

Characterization

Epoxy-modified polyhedral oligomeric silsesquioxane (POSS–epoxy)

As shown in Fig. S1, the molecular weight of the POSS–epoxy was determined by GPC and the maximum peak observed at 1300 g.mol−1, is quite correlated with the data obtained from previous researches [23]. Fig. S2a is relevant to 1H NMR spectrum of the synthesized POSS–epoxy which shows one peak at 7.3 ppm corresponding to CDCl3. There are eight peaks relevant to the protons in POSS–epoxy appearing before 7.3 ppm with proportion of 1:2:1:1:1:1:2:2 and chemical shifts of 0.6, 1.6, 2.6, 2.7, 3.2, 3.4, 3.5 and 3.7, respectively. There is no extra peak and in overall characteristic chemical shifts, peaks area and coupling constants are very similar to the reported data in literatures. In addition, the 13C (Fig. S2b) and 29Si (Fig. S2c) NMR spectra confirm the previous reported data [24]. As shown in Fig. S3a, the FT–IR data corresponding to POSS-epoxy is in agreement with previous data. The adsorption bands at 1106 and 1257 cm−1 confirm the Si–O–Si linkage and Si–CH2 band, respectively. Characteristics absorption bands for epoxy group appears at 908 and 846 cm−1 which is clearly observable. A broad peak at 3494 cm−1 is approves the presence of silanol group and incomplete dehydration [23,24,25,26,27].

The POSS–epoxy fibers

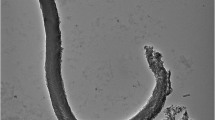

In this study, stainless steel wires were etched with HF to achieve a porous surface with higher area and consequently more sorbent loading [28]. The etched stainless steel wires were treated with sodium hydroxide to form the silanol groups on the surface and the excess hydroxyl groups were neutralized with hydrochloric acid. As far as the sol–gel process is concerned two major sets of reactions take place: (i) hydrolysis of the precursor and (ii) polycondensation of the hydrolyzed products and other sol–gel active species (Fig. S6). These reactions are catalyzed by acids or bases and lead to the formation of a polymeric network [29]. In this study, TFA as catalyst and POSS-epoxy as an active moiety along with different precursors were utilized. After preparation of POSS–epoxy fibers, it was necessary to characterize their structure. Thermal gravimetric analysis of POSS–epoxy/TMOS+MTMOS fiber coating was carried out in the range of 25–600 °C at the constant rate of 10 °C min−1 at N2 atmosphere (Fig. S4). The obtained thermogram demonstrate that the weight loss of the coating is less than 5%, which is in good agreement with the concept of high thermal stability and efficient conditioning process of fiber coating. Also the SEM micrographs show porous morphology of the coating (Fig. 2). The SEM images recorded at higher magnification scales (200 and 500 nm) are associated with the porous surface morphological structure of the POSS–epoxy/TMOS+MTMOS (Fig. 2a and b). The SEM image recorded at lower scale (5 μm) reveals uniform fabrication of fiber coating on the steel substrate (Fig. 2c). A weak absorption band at 3370 cm−1 is relevant to the elimination of the silanol groups in POSS–epoxy/TMOS+MTMOS (Fig. S3b) and high efficiency of the sol–gel process.

Fiber selection

To evaluate the extraction efficiency of the POSS fiber, four POSS–epoxy–based fiber coatings with different precursor types and amounts were prepared under similar conditions (Table S2). In addition, another fiber consisting just TMOS and MTMOS was also fabricated to clarify the role of POSS–epoxy. All the fabricated fibers were implemented in HS–SPME of some selected PAHs as model analytes. According to Fig. 3a, the POSS–epoxy/TMOS+MTMOS fiber coating exhibits higher extraction efficiency. The BET analysis results show a surface area of 491 m2.g−1 for the selected fiber coating while, the adsorption/desorption isotherm pattern (Fig. S7) verified that the synthesized coating has acceptable surface area and consequently the sufficient capability for loading and desorption of compounds.

Comparing a efficiency of the prepared 3D nanoscale fiber coatings and b extraction efficiency of POSS– epoxy/TMOS+MTMOS coating toward three classes of organic pollutants. Experimental conditions: extraction time 15 min, extraction temperature 30 °C, desorption time 2 min, desorption temperature 280 °C, stirring rate percent 100%, and salt concentration 10% (w/v)

Due to the silicate based of the POSS–epoxy coating and its natural hydrophobicity and containing numerous Van der Waals interaction sites, it can be anticipated that this coating would be an appropriate extractive phase for a wide variety of organic compounds.

The prominent fiber was quite favorable for different groups of environmental contaminants such as BTEX, CBs and PAHs while the highest efficiency was achieved for PAHs (Fig. 3b). Due to the fact that the measurement of the fiber coating volume cannot be performed precisely, the enrichment factor calculation is not a usual procedure. However, the absolute recovery (AR) values for each group of compounds were calculated and the obtained results verified the superiority of the POSS–epoxy coating toward PAHs (Table S3) [30]. The data regarding AR% were found to be in the range of 4.4–10.1, 1.7–15.1, and 8.3–41.2% for CBs, BTEX and PAHs, respectively. Among the group of compounds, PAHs were selected as model analytes to check the capability of the POSS–epoxy coating and optimize the influencing parameters.

Optimization

A mixture of PAHs including naphthalene, acenaphthylene, fluorene, and anthracene were selected as model analytes and acenaphthene was chosen as a standard for normalization of the optimization results. The extraction capability of the POSS–epoxy/TMOS+MTMOS fiber coating was evaluated by HS–SPME of PAHs in aqueous samples. Effects of different parameters such as desorption time and temperature, extraction time and temperature, ionic strength and stirring rate of the sample solution were investigated and optimized.

To warrant the complete desorption of analytes and to avoid any carry over and memory effect, optimization of desorption time and temperature is critical. This parameter was varied in the range of 1 to 4 min (Fig. 4a), and after 2 min no carry over was observable. Desorption temperature was changed in range of 220 to 280 °C. As Fig. 4b shows the highest sensitivity was obtained at 280 °C.

In HS–SPME, there is an equilibrium between vapor and the fiber coating while, the extraction temperature and time play important roles in reaching the equilibrium state. Increasing the temperature can enhance the Henry’s constant and diffusion coefficients of PAHs. As Fig. 4c shows, by increasing the temperature from 40 to 70 °C the naphthalene (the most volatile compound) signal drops, but the temperature rise is quite favorable for anthracene which is the less volatile analyte. Because of noticeable increase in anthracene signal in compared with the insignificant reduction in the peak intensity of naphthalene, the optimized extraction temperature was set at 70 °C. By adaption of this relatively high temperature, it is expected to reach the equilibrium in a shorter time. Fig. 4d shows that HS–SPME process reaches to the equilibrium state after 10 min. Also after this time the fluctuations in the signal levels decrease significantly. Within longer extraction times, due to the exothermic nature of adsorption process and based on Le Chatelier’s principle, the equilibrium process progressed in reversed direction. As expected, adsorption efficiency and signal levels are decreased with time at high temperatures. On the other hand, considering the use of metallic substrate there is a competition between adsorption and desorption of analytes on the coating surface and the latter dominates at duration times greater than 10 min. Therefore, a duration time of 10 min was selected as optimized extraction time.

Usually, enhancement in the salt content of aqueous solutions, is beneficial in HS analysis. According to the results in Fig. 4e, maximum extraction efficiency is achievable at 10% (w/v) of salt concentration. This is in agreement with the fact that an increase in the salt concentration from 0 to 10% (w/v), due to the reduction of the water solubility threshold, an increase in the concentration of PAHs in HS of sample solution and therefore enhancement in the signal levels is expected. But after 10%, the decrease in extraction efficiency and signals level may be related to the change of the surface tension and viscosity of sample solution.

The effect of stirring rate was also considered. Considering the results shown in Fig. 4f, the extraction efficiency and mass transfer of analytes from solution to headspace are directly correlated with the stirring rate. According to the results, the agitation at the maximum level of stirring rate, led to the highest extraction efficiency.

Method validation

Eventually, the developed method was validated for analysis of the selected PAHs and the analytical figures of merit including limits of detection (LODs, S/N = 3), limits of quantification (LOQs, S/N = 10), dynamic range, regression coefficient and precision (inter and intra–day) under optimized condition were investigated (Table 1). Good linear ranges with acceptable regression coefficients (0.98–0.99) were achievable and LOD and LOQ values were found in the range of 0.1–0.3 ng.L−1 and 0.3–1 ng.L−1, respectively.

Real sample analysis

In order to show the capability of the current method,an analysis of some real samples such as tap water, refinery plant water, coffee and two commercial tea samples was performed. The sample matrix effect was also investigated by analyzing the real samples fortified with standard solution of PAHs at the level of 20 ng.L−1 (Fig. S5). Relative recovery for various samples was in the range of 80–110% (Table 2), confirming the absence of any significant matrix effect. The data relevant to the level of found amounts in Table 2, are indicative of superiority of the method as far as the trace determination of these organic pollutants are concerned.

The data in Table 3 compare the current method performance with other relevant methods which have been reported for detection of PAHs. Our data show the POSS–epoxy SPME fiber is quite efficient and possess acceptable capability, precision and linearity. The noticeable LOD and LOQ values make the developed method a competitive approach toward trace determination of organic pollutants. The synthetized coating was also compared with a commercial PDMS–DVB fiber and clearly the POSS–epoxy fiber is quite prominent as long as heavier analytes are concerned. As it is shown in Fig. 5, the extraction capability of the synthesized fiber is somehow comparable with the PDMS–DVB coating. The performance of PDMS–DVB toward lighter analytes is quite favorable, while the POSS–epoxy based fiber coating shows higher extraction performance for the heavier solute such as anthracene. This phenomenon can be explained from two points of view, the commercial coating is a liquid with a rather large film thickness while the POSS–epoxy fiber is a thinner solid layer. Apparently, partition is the major interaction mechanism for the PDMS–DVB while adsorption is prominent for the prepared fiber. The thicker liquid fibers usually have more sample loadings especially in the cases of lighter analytes [30, 35]. The sorption/desorption process by the home–made fiber, due to its solid nature and low thickness, is rapid while it is thermally and mechanically more stable. Its life span exceeds more than 200 runs and is rather inexpensive to be synthesized. .

Comparing the GC–MS chromatograms obtained by the PDMS/DVB commercial fiber and the synthesized POSS– epoxy/TMOS/MTMOS fiber coating at the level of 20 ng.L−1 Experimental conditions: extraction time 10 min, extraction temperature 70 °C, desorption time 2 min, desorption temperature 280 °C, stirring rate percent 100%, and salt concentration 10% (w/v)

Conclusion

A 3D nanoscale POSS–epoxy–based SPME fiber coating was fabricated via sol–gel methodology and employed for HS–analysis of traces of aromatic compounds in water, tea and coffee samples. Among the synthesized coatings, POSS–epoxy/TMOS+MTMOS showed its superiority and an appropriate candidate for extraction of non– to semi–polar compounds. The single fiber repeatability and/or fiber–to–fiber reproducibility, are other interesting features. The nature of sol–gel based POSS–epoxy fiber coating and its high hydrothermal stability against harsh chemical and mechanical circumstances make it quite reliable with a long lifespan while it can be synthesized in a reproducible manner, as well.

References

Arthur CL, Pawliszyn J (1990) Solid phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem 62:2145–2148. https://doi.org/10.1021/ac00218a019

Aziz-Zanjani MO, Mehdinia A (2014) A review on procedures for the preparation of coatings for solid phase microextraction. Microchim Acta 181:1169–1190. https://doi.org/10.1007/s00604-014-1265-y

Saraji M, Jafari MT, Mossaddegh M (2016) Carbon nanotubes@silicon dioxide nanohybrids coating for solid-phase microextraction of organophosphorus pesticides followed by gas chromatography-corona discharge ion mobility spectrometric detection. J Chromatogr A 1429:30–39. https://doi.org/10.1016/j.chroma.2015.12.008

Mehdinia A, Khani H, Mozaffari S (2014) Fibers coated with a graphene-polyaniline nanocomposite for the headspace solid-phase microextraction of organochlorine pesticides from seawater samples. Microchim Acta 181:89–95. https://doi.org/10.1007/s00604-013-1071-y

Lan H, Gan N, Pan D, Hu F, Li T, Long N, Qiao L (2014) An automated solid-phase microextraction method based on magnetic molecularly imprinted polymer as fiber coating for detection of trace estrogens in milk powder. J Chromatogr A 1331:10–18. https://doi.org/10.1016/j.chroma.2014.01.016

Bagheri H, Javanmardi H, Abbasi A, Banihashemi S (2016) A metal organic framework-polyaniline nanocomposite as a fiber coating for solid phase microextraction. J Chromatogr A 1431:27–35. https://doi.org/10.1016/j.chroma.2015.12.077

Es-haghi A, Hosseininasab V, Bagheri H (2014) Preparation, characterization, and applications of a novel solid-phase microextraction fiber by sol-gel technology on the surface of stainless steel wire for determination of polycyclic aromatic hydrocarbons in aquatic environmental samples. Anal Chim Acta 813:48–55. https://doi.org/10.1016/j.aca.2014.01.005

Djozan D, Farajzadeh MA, Sorouraddin SM, Baheri T (2012) Determination of methamphetamine, amphetamine and ecstasy by inside-needle adsorption trap based on molecularly imprinted polymer followed by GC-FID determination. Microchim Acta 179:209–217. https://doi.org/10.1007/s00604-012-0879-1

Chen J, Zou J, Zeng J, Song X, Ji J, Wang Y, Ha J, Chen X (2010) Preparation and evaluation of graphene-coated solid-phase microextraction fiber. Anal Chim Acta 678:44–49. https://doi.org/10.1016/j.aca.2010.08.008

Bagheri H, Roostaie A (2015) Polybutylene terephthalate-nickel oxide nanocomposite as a fiber coating. Anal Chim Acta 863:20–28. https://doi.org/10.1016/j.aca.2015.01.025

Alizadeh R, Najafi NM, Kharrazi S (2011) A new solid phase micro extraction for simultaneous head space extraction of ultra traces of polar and non-polar compounds. Anal Chim Acta 689:117–121. https://doi.org/10.1016/j.aca.2011.01.013

Wang S, Tan L, Zhang C, Hussain I, Tan B (2015) Novel POSS-based organic–inorganic hybrid porous materials by low cost strategies. J Mater Chem A 3:6542–6548. https://doi.org/10.1039/C4TA06963C

Tanaka K, Chujo Y (2012) Advanced functional materials based on polyhedral oligomeric silsesquioxane (POSS). J Mater Chem 22:1733–1746. https://doi.org/10.1039/C1JM14231C

Li Z, Kong J, Wang F, He C (2017) Polyhedral oligomeric silsesquioxanes (POSSs): an important building block for organic optoelectronic materials. J Mater Chem C 5:5283–5298. https://doi.org/10.1039/C7TC01327B

Yang YY, Wang X, Hu Y, Hu H, Wu DC, Xu FJ (2014) Bioreducible POSS-cored star-shaped polycation for efficient gene delivery. ACS Appl Mater Interfaces 6:1044–1052. https://doi.org/10.1021/am404585d

Nair BP, Vaikkath D, Nair PD (2014) Polyhedral oligomeric silsesquioxane-f68 hybrid vesicles for folate receptor targeted anti-cancer drug delivery. Langmuir 30:340–347. https://doi.org/10.1021/la4036997

Zhou H, Ye Q, Xu J (2017) Polyhedral oligomeric silsesquioxane-based hybrid materials and their applications. Mater Chem Front 1:212–230. https://doi.org/10.1039/C6QM00062B

Chen C, Liang X, Wang J, Zou Y, Hu H, Cai Q, Yao S (2014) Development of a polymeric ionic liquid coating for direct-immersion solid-phase microextraction using polyhedral oligomeric silsesquioxane as cross-linker. J Chromatogr A 1348:80–86. https://doi.org/10.1016/j.chroma.2014.04.098

Chen C, Liang X, Wang J, Yang S, Yan Z, Cai Q, Yao S (2013) Development of a highly robust solid phase microextraction fiber based on crosslinked methyl methacrylate-polyhedral oligomeric silsesquioxane hybrid polymeric coating. Anal Chim Acta 792:45–51. https://doi.org/10.1016/j.aca.2013.07.018

Xia Z, Duan X, Qiu W, Liu D, Wang B, Tao S, Jiang Q, Lu B, Song Y, Hu X (2010) Health risk assessment on dietary exposure to polycyclic aromatic hydrocarbons (PAHs) in Taiyuan, China. Sci Total Environ 408:5331–5337. https://doi.org/10.1016/j.scitotenv.2010.08.008

Duedahl-Olesen L, Navaratnam MA, Jewula J, Jensen AH (2015) PAH in some Brands of tea and Coffee. Polycycl Aromat Compd 35:74–90. https://doi.org/10.1080/10406638.2014.918554

Guatemala-Morales GM, Beltrán-Medina EA, Murillo-Tovar MA, Ruiz-Palomino P, Corona-González RI, Arriola-Guevara E (2016) Validation of analytical conditions for determination of polycyclic aromatic hydrocarbons in roasted coffee by gas chromatography-mass spectrometry. Food Chem 197:747–753. https://doi.org/10.1016/j.foodchem.2015.10.135

Matějka L, Dukh O, Hlavatá D, Meissner B, Brus J (2001) Cyclization and self-organization in polymerization of trialkoxysilanes. Macromolecules 34:6904–6914. https://doi.org/10.1021/ma010136x

Gao J, Jiang C, Zhang X (2007) Kinetics of Curing and Thermal Degradation of POSS Epoxy Resin / DDS System. Int J Polym Mater 56:65–77. https://doi.org/10.1080/00914030600710620

Salaun M, Zelsmann M, Archambault S, Borah D, Kehagias N, Simao C, Lorret O, Shaw MT, Sotomayor Torres CM, Morris MA (2013) Fabrication of highly ordered sub-20 nm silicon nanopillars by block copolymer lithography combined with resist design. J Mater Chem C 2013(1):3544–3550. https://doi.org/10.1039/c3tc30300d

Hou G, Gao J, Tian C, Wu X (2014) Preparation and characterization of nanocomposite films by hybrid cationic ring opening polymerization of glycidyl-POSS. Mater Chem Phys 148:236–244. https://doi.org/10.1016/j.matchemphys.2014.07.040

Mat L, Dukh O (2000) Cage-like structure formation during sol–gel polymerization of glycidyloxypropyltrimethoxysilane. J Non-Cryst Solids 270:34–47. https://doi.org/10.1016/S0022-3093(00)00074-0

Xu H, Li Y, Jiang D, Yan X (2009) Hydrofluoric acid etched stainless steel wire for solid-phase microextraction. Anal Chem 81:4971–4977

Wang Z, Xiao C, Wu C, Han H (2000) High-performance polyethylene glycol-coated solid-phase microextraction fibers using sol-gel technology. J Chromatogr A 893:157–168. https://doi.org/10.1016/S0021-9673(00)00692-0

Pawliszyn J (2012) Handbook of solid phase microextraction. Elsevier. https://doi.org/10.1016/B978-0-12-416017-0.00015-2

Bagheri H, Ayazi Z, Aghakhani A (2011) A novel needle trap sorbent based on carbon nanotube-sol-gel for microextraction of polycyclic aromatic hydrocarbons from aquatic media. Anal Chim Acta 683:212–220. https://doi.org/10.1016/j.aca.2010.10.026

Hu X, Liu C, Li J, Luo R, Jiang H, Sun X, Shen J, Han W, Wang L (2017) Hollow mesoporous carbon spheres-based fiber coating for solid-phase microextraction of polycyclic aromatic hydrocarbons. J Chromatogr A 1520:58–64. https://doi.org/10.1016/j.chroma.2017.09.013

López-López JA, Ogalla-Chozas E, Lara-Martín PA, Pintado-Herrera MG (2017) Solvent bar micro-extraction (SBME) based determination of PAHs in seawater samples. Sci Total Environ 598:58–63. https://doi.org/10.1016/j.scitotenv.2017.04.125

Maghsoudi S, Noroozian E (2012) HP-SPME of volatile polycyclic aromatic hydrocarbons from water using multiwalled carbon nanotubes coated on a steel fiber through electrophoretic deposition. Chromatographia 75:913–921. https://doi.org/10.1007/s10337-012-2283-8

Spietelun A, Kloskowski A, Chrzanowski W, Namieśnik J (2013) Understanding solid-phase microextraction: key factors influencing the extraction process and trends in improving the technique. Chem Rev 113:1667–1685. https://doi.org/10.1021/cr300148j

Acknowledgements

The Research Council (Grant number G940603) of Sharif University of Technology (SUT) is acknowledged for supporting this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOCX 715 kb)

Rights and permissions

About this article

Cite this article

Bagheri, H., Soofi, G., Javanmardi, H. et al. A 3D nanoscale polyhedral oligomeric silsesquioxanes network for microextraction of polycyclic aromatic hydrocarbons. Microchim Acta 185, 418 (2018). https://doi.org/10.1007/s00604-018-2950-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-018-2950-z