Abstract

Issues of climate change, energy demand, and natural resources depletion are calling for circular methods to produce value-added products such as biomass, biofuel, biofertilizers, and nutraceuticals from waste. For instance, culturing photoautotrophic microalgae in wastewater and urine appears promising to recycle nutrients from waste. Here we review microalgal production with focus on wastewater treatment and urine utilization. We present photobioreactors, parameters influencing algal growth, economical aspects, and limitations from consumer acceptance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae have been cultured to produce organic matter for an extensive range of applications, involving human and animal nutrition, as biofertilizers in the agriculture sector, in cosmetics, and the health departments. Microalgae have great potential for the manufacturing of many high-value bioactive composites, including intracellular and extracellular, like lipids, amino acids, polysaccharides, phenols, antioxidants, vitamins, minerals, and pigments that can assist to compensate the cost of biofuel production in bio refinery setup (Mastropetros et al. 2022; Koutra et al. 2022). These organisms can grow well in wastewater and can be used to remove metal ions from the wastewater by combining them with biomass (Zagklis et al. 2021). In this context aquaculture, municipal and industrial wastewater are recommended as good nutrient sources for microalgal growth (Sakarika et al. 2022).

Scientists are trying to find new sustainable energy sources and hence pushing boundaries to research urine. It was reported that human urine is a good source of agriculture nutrients which can produce nitrogen (N), phosphorus (P), and potassium (K) as natural fertilizers (Sharma et al. 2021). Urine has also been reported as a good fertilizer that improves crop production and subsequently minimizes waste production (Ranasinghe et al. 2016). In addition, urine comprises less than 1% of the whole volume of domestic wastewater containing 80% of the N and 40–50% of the P, making it a promising source for the recovery of nutrients. Urine can be applied to agricultural areas in its original form for fertilization. But many legal issues are arising with this method, such as surplus to the ecosystem and vaporization of nitrogen contingent on climate situations. Additionally, high volumes of liquid are required for the storage and transportation of urine, where the continuous application becomes an overdose and adversely increases the salinity of the soil. A substitute method can be the assimilation of fertilizing nutrients into phototrophic organisms, microalgae, which are much more competent at captivating these composites.

Microalgae biomass developed on different types of wastewater can be used as a slow-release fertilizer, because of its primary configuration being alike to that of plants, though practical experiments are still limited. Instead, the economic viability of this method is high because rich-value composites like pigments could be taken out from algal biomass (Cai et al. 2013). However, these days research work is carried out for nutrient recovery through the growth of microalgae in urine (Chang et al. 2013; Jaatinen et al. 2016). Presently, domestic wastewater is considered as a reserve than waste like a nutrient reserve for the fertilization of plants, involving N and P. Large portion of the fertilizing nutrients in domestic wastewater are obtained from human urine, though it comprises only less than one percent of the total stream flow. These nutrients include 90% of K, 80% of N, and 50% of P as well as organic composites involving creatine, creatinine, and uric acid, as main components (Martin et al. 2022). Additionally, other than great concentrations of K, N, and P, many other trace elements are found in urine composition. Urine also comprises additional ions like Cu2+, Na+, Mg2+, and Cl− that are essential for plant growth (Viskari et al. 2018).

Cultivation of different types of microalgae was observed in previous studies by using existent and artificial human urine. These types are known as Chlorella sorokiniana (Tuantet et al. 2014a, 2014b), Cyanobacterium Spirulina platensis and Scenedesmus acuminatus. Some species of microalgae grow well in diluted human urine including Chlorella sorokiniana. It grew well in a continuous bioreactor with a dilution ratio of 1:2–1:3 of human urine to get a high biomass production of 9.3 g L−1 d−1 (Tuantet et al. 2014b). There is also another recent study that shows that source-separated urine can be utilized to improve the growth of microalgae photoautotrophic microorganisms that recovered nutrients by using carbon dioxide utilizing an inorganic carbon source and light by means of an energy source (Tao et al. 2022; Tuantet 2015). Microalgae cultivation needs nitrogen and phosphorus (N, P) nutrients, which are mainly present in urine with other several minor elements including (e.g., Zn, Cu, Fe, Mo, Co, and Mn) that are essential for the growth of microalgae. It was also observed that 97% of ammonium nitrogen, 96.5% of the total phosphorus and 85–98% of urea in diluted urine can be removed by the cultivation of microalgae, and this is a good strategy for waste management by using potential existing sources of urine (Behera et al. 2020).

Therefore, human urine appears as a promising medium for the growth of microalgae. This review evaluates algae growing in urine from a different perspective which includes different types of wastewater, their constituent and their treatment methods for the cultivation of microalgae. It also focused on different types of photobioreactors which are used for the combined action of wastewater treatment and cultivation of microalgae which will be helpful for future research related to the utilization of urine in algae production.

Wastewater treatment

Types of wastewaters

Wastewater that originates from home activities known as municipal sewage wastewater includes water excretions from public toilets, schools, hospitals, restaurants and hotels, which usually comprises urine and feces (Ahmed et al. 2021; Rose et al. 2015). Conservative methods of municipal sewage wastewater treatment systems contain different stages (Gandiglio et al. 2017). Firstly, they take in the sedimentation of solid ingredients known as the primary treatment stage. Secondly, the removal of suspended and liquefied organic ingredients occurs known as the secondary treatment stage. The final stage of the treatment of water, the removal of numerous liquefied inorganic composites involving nitrogen and phosphorus takes place. It is called the tertiary treatment stage (Naidoo et al. 2014) after which water is released into the surrounding environment. If these procedures are not done properly, they can contaminate shallow and groundwater supplies (Bustillo-Lecompte and Mehrvar 2017).

Wastewater that originates from different types of farm activities involving processes of animal nourishing and the handling of agricultural harvests is agricultural wastewater (Odoemena et al. 2020). Another wastewater type is industrial wastewater that originates from the processing of commercial goods such as beverages, food, clothes, paper and chemical produce that we consume. This industrial wastewater contains oils-grease, suspended solids, bacteria, pH, heavy metals and other chemical compounds. Heavy metal contaminants include chromium, cadmium, zinc, and other carbon-based chemical toxins include biocides, hydrocarbons, and surfactants (Kumar et al. 2021). Table 1 shows the types of wastewater and their effects on algae growth.

Substances in different types of wastewater and their purification

Wastewater contaminants range from steroids, antibiotics, pesticides, hydrocarbons, heavy metals, and their derivatives which eventually cause considerable environmental damage (Ahmad et al. 2020; Bhatt et al. 2021; Mishra et al. 2021). Conventional wastewater treatment methods are not entirely suitable for eradicating contaminants due to high energy consumption, high cost, large area demand, and still less ability to remove contaminants (Crini and Lichtfouse 2019; Craggs et al. 2012). Therefore, scientists are trying to find out more easy-to-maintain, cost-effective and eco-friendly technologies to eradicate contaminants from wastewater (Saravanan et al. 2021). Numerous methodologies have been established to minimalize wastewater releases and lessen the threats of pollutants, including physical methods (adsorption, coagulation/flocculation, and membrane filtration, chemical methods (oxidation, ozonation), and biological methods (enzymes, microorganisms) (Xu et al. 2018). Wastewater treatment methods are considered to have purification requirements and effluents’ characterization, overlooking their influence on the environment and general treatment performance (Khan et al. 2020).

Adsorption is reflected as one of the utmost effective methods among all the above-mentioned methods, for the treatment of wastewater because of many features, which are not so effective in other related methods (Slatni et al. 2020). Researchers have just dedicated their struggles to exploring the adsorbents with outsized surface areas, less cost, and friendliness to the surrounding environment. They found their way for effective adsorbents y using nanosized constituents, which have been noticed as an important material for confiscating dyes, organic compounds, and heavy metals from wastewater (Nassar et al. 2017). Biological treatment methods can be used to remove contaminants, which bacteria, fungi, and algae are commonly used (Rodriguez-Rangel et al. 2022). In this way, wastewater can be treated employing microbes through two types of methods, known as bioaccumulation, secondly biosorption, and biodegradation (Bilal et al. 2021; Bai and Acharya 2017; Kalra et al. 2021).

Microalgae has a significant role in the immobilized wastewater treatment system. However, some factors which can affect the immobilized microalgal wastewater treatment system and removal of nutrients, are mainly linked to environmental, biological and operational factors (Nie et al. 2020). The main structure of the microalgae immobilized system involves the accepted immobilization technique, matrix material, and essential microalgal species. For instance, alginates-based immobilized technique involves proportions of microalgae beads and the concentration of target contaminants (Emparan et al. 2021), bead size (Lee et al. 2020), volumetric fractions of diverse matrixes (Abu Sepian et al. 2019; Rushan et al. 2019), selection of alginate (Kube et al. 2019; Zamani et al. 2012), and microalgal strain (Kube et al. 2021). The bed reactor is another biological method used for the treatment of wastewater. There is limited research on the combined procedure of immobilized microalgae and bed-based reactors. There are three major types of bed reactors, which include fluidized bed reactors (Cheirsilp et al. 2017; Zheng and Ke 2017), moving bed reactors (Akizuki et al. 2021), and fixed-bed reactors (Babatsouli et al. 2015; Garbowski et al. 2020).

Over the previous few eras, the importance of the treatment of wastewater has been increased for evaluating the environmental efficiency of conventional wastewater treatment found on the activated slurry procedure (Li et al. 2022a; Soares 2020). There are various issues related to the wastewater treatment process including emission, consumption of energy, and financial gain (Dong et al. 2017). The presence of various organics and beneficial nutrients in wastewater promotes the growth of microalgae (Yadav et al. 2021). Consequently, microalgae have successfully aided in the recycling of carbon in the environment (Wang et al. 2016). Thus, neutralizing carbon in the ecosystem effectively yields 1 kWh/kg of biochemical oxygen demand (Sukla et al. 2019; Al-Jabri et al. 2020) which is essential for biological processes. Wastewater treatment methods through microalgae consume less power as compared to conventional methods (Khaldi et al. 2017). Apart from all these benefits, harvesting of microalgae is a critical factor, as normally microalgae cultivate at comparatively low cell density (Tan et al. 2020).

The main purpose of wastewater treatment is the removal of highly concentrated nutrients, particularly nitrogen and phosphorus, or else these nutrients can cause eutrophication by accumulating in lakes and rivers (Tang et al. 2018). Phosphorus is problematic to eradicate from wastewater; however, this challenge has been mitigated by the help of microbial action that helps extract and transform phosphorus into an insoluble solid element during wastewater treatment. For example, metal salts including iron (Fe) and aluminum (Al) for the congealing process consequently produce Fe–P or Al–P complexes (Kajjumba et al. 2021; Korving et al. 2019). Microalgae are effective in eradicating nitrogen, phosphorus, pesticides, toxic compounds, and heavy metals from wastewater through intracellular and extracellular mechanisms of their cell membrane and thus have the possibility to play a significant role in remediation mainly in the final treatment of wastewater (Zhao et al. 2019; Hussein et al. 2018).

Algae can cultivate in numerous aquatic environments, like fresh and oceanic water, municipal sewage wastewater (Zhou et al. 2012a), agricultural wastewater (Zhou et al. 2012b, 2012d; Hu et al. 2013, 2012) and industrial wastewaters (Ali et al. 2021). Wastewaters are distinctive in their chemical and physical characteristics depending on whether they come from fresh or oceanic waters. Modern research showed that those algal biomasses which are produced from wastewater have the excessive potential for the production of biofuel and further applications (Wang et al. 2020). More research has been done on the growth of microalgae in municipal sewage wastewater and agricultural wastewater because they are most accessible and are less unstable as compared to other types of wastewater including industrial wastewater (Zhou et al. 2012c, 2012d). Scientists examined the growth of Chlorella species on these four diverse types of wastewater to check their capabilities to remove and utilize nitrogen, phosphorus and chemical oxygen demand, and other minor elements and determined that the growth of algae and efficacy of nutrient removal were relational to the concentration of nutrient of municipal sewage wastewaters (Nirmalakhandan et al. 2019).

Agricultural wastewater, which is often derived from manure, contains high amounts of nutrients like nitrogen and phosphorus in comparison to municipal sewage wastewater. It was observed from studies that microalgae growing on agricultural waste are efficient at removing nitrogen and phosphorus from animal manure-based wastewater. For instance, the green alga (Botryococcus braunii) is well developed in piggery wastewater comprising 788 mg L−1 NO3, and 80% NO3 was removed at the initial growth stage. Scientists developed a cheap media by using deep seawater and agitated swine urine and cow dung water for increasing production of algal biomass, signifying the high possibility of the rich nutrient animal compost wastewater stimulating fast algae growth (Pittman et al. 2011). There are some studies on retrieval of nutrients by algae growth on animal manure wastewater which evaluated the probability of benthic freshwater algae despite planktonic algae because benthic freshwater algae have more ability of nutrients recovery as compared to planktonic species of algae (Pittman et al. 2011). Table 2 shows types of wastewater and their effects on algae growth.

Treatment of wastewater by using algal strains is economically effective and also completes the rigorous release and reusing principles (Whitton et al. 2015). Additionally, algal biomass can also be transformed into many valued products like biofuels, biogas, bio-fertilizers, and antibacterial and antiviral mediators, with the consequent treatment of wastewater (Raheem et al. 2015). In recent decades, the cultivation of microalgae has been studied on various types of wastewater (Fig. 1) for the removal of contaminants following nutrient recovery with biomass production (Renuka et al. 2015). The accomplishment of those studies mainly depends on the enactment of the particular strains of microalgae. Many species of microalgae including Chlorella sp., (Gouveia et al. 2016) Micractinium sp., (Santiago et al. 2013), Scenedesmus sp., (Wang et al. 2019a, 2019b) Heynigia sp., Actinastrum sp., Hindakia sp., Chlamydomonas sp., (Ghayal and Pandya 2013), Pediastrum sp., Botryococcus sp., Dictyosphaerium sp., and Coelastrum sp. and Spirulina sp., (Emparan et al. 2019) have been confirmed and were ascertained to be capable to use and remove nitrogen, phosphorus and other minor elements from the wastewater.

Application of microalgae for the treatment of wastewater can be done either by using conventional oxidation ponds or the advanced suspended algal pond schemes including high-rate algal ponds (Arashrio et al. 2018; Rao et al. 2019), which are known as shallow raceway-type oxidation ponds with automatic mixing, and these are considered as most efficient for the treatment of wastewater. Previous studies show that microalgae can be cultivated in different systems including ponds and bioreactors (Fig. 2). These bioreactors involve both open and closed systems (Liyanaarachchi et al. 2021; Rezvani et al. 2022). For treating great amounts of wastewater produced from municipal sewage, agriculture, and industry, bioreactors should be certainly clambered up and activated for effective removal of nutrients. For this purpose, a raceway pond with paddle-wheel agitation and a multi-layer bioreactor can be used which were assumed as the most reasonable and cheap culture systems for wastewater treatment (Hu et al. 2013). Some large-scale assembly of algal biofuels was produced from wastewater by using high-rate narrow, open raceway algal ponds, which were used for the treatment of municipal sewage wastewater. For instance, a 2000-L and 40.000-L pilot-scale multi-layer bioreactors were developed successfully for the cultivation of microalgae in wastewater of animal manure and centrate for efficient production of algal biomass by removing nutrients from wastewater (Min et al. 2014). In recent times, an innovative system for the cultivation of microalgae was developed known as “OMEGA” system (offshore membrane enclosures for growing algae). In this system, microalgae were grown in floating photobioreactors positioned in a safe coastal marine environment where outlets of municipal wastewater would also occur (Wiley et al. 2013; Peter et al. 2022).

Urine as wastewater

Composition of urine

Human urine is a liquid solution comprising urea, nitrogen, potassium, phosphorus and sodium chloride as main elements while calcium, magnesium, phosphate, and sulfate as minor elements. Some other trace elements also exist in urine including glucose, amino acid, vitamins and hormones. In general, source-separated urine involves the diversion or collection of urine from its point of production for treatment processes that helps in the maximum recovery of nutrients such as nitrogen and phosphorus (Jimenez et al. 2015). There were some methods devised for the recovery of nutrients from source-separated urine. Now, a new bio- electrochemical method is used for the production of energy joints with the recovery of nitrogen from urine found on microbial energy cells (Kuntke et al. 2012). More maintainable growth of microalgae can be attained if the nutrients are from reprocessed sources or wastewater supplies (Ahmad et al. 2014; Rawat et al. 2013).

Scientists successfully grew Spirulina platensis with already treated urine, and Spirulina platensis can also be grown in nitrified human urine which has a key composition close to the Zarrouk medium, which is an improved medium for culturing. Many studies proved that the growth of Spirulina platensis has the potential for the production of aquatic food. The benefit of cultivating microalgae on urine is that they clean urine by eliminating phosphorus and nitrogen from it and also harvest high production of biomass which can be used as biofuel (Chang et al. 2013). A large amount of nitrogen consists of urea [CO(NH2)2] in fresh urine, which will be converted into ammonia by hydrolyzation during storage, in the presence of microbes (Zhang et al. 2013; Kim et al. 2014). Based on this process, the microbial fuel cell has the benefit of handling ammonia (NH3) in urine besides generating electricity.

The transduction of urine to operational energy for charging smartphones and remote systems by using an integrated microbial fuel cell was done by (Walter et al. 2017). The microbial fuel cell generates electrical power through the transformation of chemical energy (Sahu 2019). This infers that sources like wastewater, urine, or any other organic matter could be used as fuels for the generation of electricity by a microbial fuel cell (Ha et al. 2012; Rengasamy and Berchmans 2012; Samsudeen et al. 2015). The notion of the microbial fuel cell was first recognized in 1911 by Potter, but only recent data are published which contains pile configuration (Ledezma et al. 2013), optimization of the constituent, and reactor design (Winfield et al. 2015; Gajda et al. 2015; Ieropoulos et al. 2013).

Cow urine also has been applied to produce electricity by means of a clayware microbial fuel cell, which was cost-effective and an easy procedure (Jadhav et al. 2016). This conversion causes an increase in pH from approximately 6 to 9 followed by bicarbonate ions and ammonia (NH3) (Larsen et al. 2021). This increase in pH activates the precipitation of magnesium and calcium in the form of phosphate and carbonate composites, which can be easily identified in stored urine with a decreased level of magnesium and calcium. Diverse sources of nitrogen like ammonium, urea, and nitrate have been considered for the growth of many diverse types of microalgae (Chang et al. 2013; Hulatt et al. 2012). It was observed that the growth of Chlorella vulgaris in a medium that contains nitrogen supply in the form of urea had a somewhat maximum level of biomass growth and harvest as compared to nitrate, whereas no growth happened in the presence of ammonium (Hulatt et al. 2012).

Annual production quantities of urine

Typically, one person produces 1.4 L of urine per day (DWA 2016). Normally each individual gives about 2.5–4.3 kg of nitrogen, 0.9–1.0 kg of potassium and 0.7–1.0 kg of phosphorus each year through urine excretion. Additionally, some substances which improve growth also exist in human urine including glucose, amino acids, and vitamins. Though human urine encompasses less than 1% of the entire municipal wastewater by capacity, it gives considerably 69% of nitrogen, 40% of phosphorus, and 60% of potassium in wastewater and, consequently, can be a reason for pollution (Chatterjee et al. 2019).

Urine disposal as source material and input in processes

Fresh urine can be toxic due to the presence of ammonia; therefore, stored urine is supposed to be fine for activities of aquaculture involving algae production because of the primary degradation of microbes, which is followed by detoxification of ammonia, deactivation of the pathogen, and stability of nutrients for its usage as nontoxic fertilizer. Human urine has great nutrients and is easily available from urine-averted desiccated eco-toilets. Human urine is considered to be one of the best fertilizers for the growth of phytoplankton in aquatic systems, which are known as important natural food for fish in pond ecologies. In recent periods, wastewater produced from human actions has instigated many harmful effects on surface water reservoirs.

Human urine is one of the contaminants, which is a waste produced by the human body in liquid form, which comes through the digestion of endogenic wastes (food and drinks) and purification of blood and then released by kidneys (Patel et al. 2020). Due to pollution problems, it needs to be considered that an ideal decentralized waste treatment system should be applied for evolving countries where the urine would be properly collected and treated for nutrient recovery purposes (Igos et al. 2017). For example, wastewater-alienated urine has been used as fluid fertilizer for plants and soil. Environmental hygiene toilets are urine departure desiccating toilets constructed on the notion that urine, feces, and water are parts of the environmental loop supplies. Human urine is confined to various types of contaminants with high absorption quantities of nitrogen (76 to 86%), phosphorus (46 to 50%), and potassium (51 to 55%). Human feces also contain 10% nitrogen, 12% potassium, and 40% phosphorus. Consumers use 80% of these sources in their fields as fertilizer. Nutrients from urine are recuperated by cost-effective techniques including urine-diverting desiccation toilets, then precipitation of struvite then nitrification, and then distillation, generating valued fertilizer for native societies (Udert et al. 2015; Krahenbühl et al. 2016; Tilley 2016). These techniques of urine separation are possible, specifically for rural areas and small towns (Xu et al. 2019).

The capabilities of human urine nutrients should not be ignored and undervalued. It is important to consider the use of urine for the growth of microalgae since in many countries fish farming is a common means of income for livelihood where culturing and production of fish are costly because of the implementation of conventional chemicals and fertilizers in aquaculture. On the other hand, the implementation of human urine in place of fertilizer would decrease the cost of production by using standard protocols. One experimental study was performed to compare the results of the primary production of phytoplankton in trial tanks nourished with fresh human urine, stored human urine, and mixed human urine. It was concluded that the prime production of phytoplankton developed in these trial tanks was impacted by the nutrient condition of the tank, specifically the nitrogen and phosphate added to the tanks that were recovered from human urine (Jana et al. 2012). Modifications in the production of phytoplankton were strongly reliant on the concentration of phosphate in each treatment. The production of phytoplankton occurred due to the increased concentration of phosphate to nitrogen. This shows that the higher concentration of phosphate in the stored human urine was the reason for the maximum values of prime production of phytoplankton in that trial tank (Jana et al. 2012).

Human urine comprised some soluble liquefied composites or drug elements with inhibitory effects (Fig. 3), which can be omitted from the fluid by stimulated carbon treatment. These pharmaceutical drugs commonly include non-steroidal anti-inflammatory drugs (NSAIDs) such as diclofenac and ibuprofen. Non-steroidal anti-inflammatory drugs (NSAIDs) have been tested for their influence on cultures of eukaryotic algae in the axenic laboratory (Bacsi et al. 2016). A stimulated carbon treatment system has been suggested as a feasible choice for decreasing the threat of the augmentation of pharmaceuticals such as antibiotics, non-steroidal anti-inflammatory drugs, and beta blockers in a decentralized system of sanitation and recycling systems (Udert et al. 2015). Some previous studies show that 60–100% of pharmaceutical drugs like ibuprofen, diclofenac, and paracetamol possibly are removed in an algae photobioreactor, through photolysis and biodegradation (de Wilt et al. 2016). High pH levels and free concentration of ammonia in urine could be the reason to constrain the growth of microalgae (Zhang et al. 2014; Chang et al. 2013). At least 100% dilution of urine should be essential for the stable growth of algae (Tuantet et al. 2014a).

The source separation of urine from gray water, brown water, and stormwater might open up several chances for the reclamation of energy, nutrients, and water from waste (Larsen et al. 2016). Even with its small volume compared to the wastewater, human urine normally gives more than two-thirds of the nitrogen and half the potassium and phosphorous present in sewage waste (Udert and Wachter 2012; Chrispim et al. 2017; Ishii and Boyer 2015). Even with its rich concentration of nutrients, urine cannot be used directly in the field as an ideal fertilizer because of its non-ideal ratio of phosphorus, nitrogen, and potassium, and its high content of ammonia and organic acids. However, if the conversion of these nutrients into valuable products is done in the right way, the possible ecological and economic benefits would be huge (Ishii and Boyer 2015; Tarpeh et al. 2017; Mehta et al. 2015).

Utilization of urine by microalgae

Microalgae growth in urine

To prevent eutrophication of surface waters and subsequent blooms of algae or cyanobacteria, nutrients must be removed from wastewater. The same microbes could thus provide a method for nutrient removal in contained treatment systems (Tuantet et al. 2019). Human urine contributes approximately 80% of nitrogen, 50% of phosphorous, and 90% of potassium to urban wastewaters despite having a volume of only 1–1.5 L/d per capita compared to 150–200 L/d of wastewater generated per capita (Chatterjee et al. 2019). Due to the high content of nutrients, urine can be used as a great source for microalgal cultivation rather than commercial fertilizer. Urine has the potential to provide nutrients for the growth of microalgal biomass, which can then be used as fertilizer and soil conditioner (Tuantet et al. 2019). Microalgae are the most promising biofuel feedstock due to their rapid growth rate, high lipid content, comparatively low land usage, and high carbon dioxide (CO2) absorption and uptake rate (Chang et al. 2013). Hence, microalgae-based biomass production can help solve the energy crisis and prevent eutrophication by growing microalgae in urine.

Various microalgae species like Chlorella sp., Scenedesmus sp., Spirulina Sp. Chlamydomonas sp. Phormidium sp., Synechocystis sp., Synechococcus sp. etc. have been grown in urine. (Piltz 2018; Abdelaziz et al. 2013). For instance, Chang et al. (2013) cultivated Spirulina platensis (Arthrospira platensis) a cyanobacteria, using synthetic and human urine in a bubble column photobioreactor under autotrophic conditions for ten (10) days. Biomass production was further increased with the addition of sodium acetate as algae could effectively remove and utilize nitrogen and phosphorus. Chlorella species like C. vulgaris, C. sorokiniana, and C. singularis are widely used in cultivation by using urine as a culture media. Jaatinen et al. (2016) cultured C. vulgaris using diluted urine and artificial media and compared their biomass yields. The results showed that diluted urine (1:100) produced the highest biomass yield, while diluted urine (1:300) was sufficient for biomass production in the pH range of 5 to 9. Ammonia production did not show an inhibitory effect on biomass yield.

C. vulgaris has also been studied by Nguyen et al. (2021) and Volpin et al. (2019). Nguyen and his team studied nutrient recovery and microalgae biomass production rate using a membrane photobioreactor. Using real urine as a draw solution, algae concentration was increased fourfold in Volpin study. C. sorokiniana is also one of the most cultivated microalgae using urine as compared to other studies. Zhang et al. (2014) cultivated C. sorokiniana with a daily supply of fresh urine; it was found that a high amount of biomass production along with nutrient recovery was achieved. Tuantet et al. (2014a, b) and Tuantet et al. (2019) optimized algae production and studied biomass production and nutrient removal capacity of C. sorokiniana using a photobioreactor. They demonstrated that increased volumetric biomass production and nutrient removal could be achieved by enriching the urine with magnesium, adjusting the nitrogen and phosphorus molar ratio, and shortening the reactor light path.

Other than that, Piltz et al. (2018) compared the growth of Chlorella sp, Chlamydomonas sp, Sphaerocystis sp, Chlamydomonas sp, Scenedesmus sp, Synechococcus sp, and Phormidium sp in urine using a Twin-Layer PSBR. They found that diluted urine provided better growth results than undiluted urine. A comparative study in terms of growth and biomass production was studied between Secendesmus sp, C. vulgaris, and Chlorococcum humicola in diluted urine in the range of 1:50 to 1:200 (Torres et al. 2014). Table 3 summarizes the relevant studies about the usage of urine as a medium to grow and the associated outcome.

Nutrient recovery by microalgae

Nutrient recovery is a long-term solution for wastewater treatment and the process recovers nutrients that should not be in waterways. These nutrients are then converted into high-quality fertilizers (Nutrient recovery from wastewater, 2022). For concentrated waste streams, nutrient recovery may be economically feasible (Fig. 4). Source-separated urine is an ideal target stream in this context because it contains most nutrients found in urban wastewater (Coppens et al. 2016). Nitrogen (N) is used in about 100 million metric tons of fertilizer each year. Phosphorus (P) reserves exist in the earth's crust, with annual use of more than 14 million metric tons in fertilizers, accounting for roughly 80% of total P production (Zhang et al. 2014). Although urine production volume is only 1–1.5 L per person per day, and total wastewater discharge can be up to 150–250 L/d, approximately 80% of N, 50% of P, and 90% of potassium (K) in domestic wastewater are originated from human urine that made up just 1% of the total wastewater. Human urine contains trace elements such as B, Cu, Zn, Mo, Fe, Co, and Mn in addition to high levels of N, P, and K (Chatterjee et al. 2019). Recycling of nutrients leads to wastewater treatment management. Also recycling carbon (C), N, and P from wastewater and excreta for algae growth is cost-effective (Miranda et al. 2015). Not only does microalgae cultivation promote nutrient recovery from wastewater, but it also promotes biomass production for value-added products such as biodiesel, bioethanol, bio-fertilizers, bioplastics, pharmaceuticals, and feed supplements. If microalgae can be grown in urine, it may be possible to extract nutrients from the urine (Luo et al. 2017; Li et al. 2019).

Various innovative techniques, such as struvite precipitation, ion exchange, and ammonia stripping, using urine diversion and treatment systems, have demonstrated the possibility of recycling, and saving water by using underlying nutrients as a source of energy (Chatterjee et al. 2019; Posadas et al. 2017).

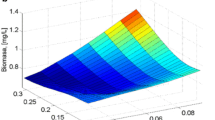

Biomass retention times have a significant effect on nutrient remediation and biomass productivity. C vulgaris shows biomass retention time-dependent nutrient recovery and biomass retention with the MBPR system (Nguyen et al. 2021). Urine concentration, source of urine and urine culture temperature also have profound effects on biomass and lipid production along with nutrient recovery. Diluted human urine has better lipid accumulation in comparison with various artificial media (Behera et al. 2020). S. platensis shows great nutrient removal capacity with human urine compared to artificial urine media (Chang et al. 2013). Nutrient recovery and biomass production increase with a reduction in the dilution of human urine. For example, C. sorokiniana biomass production improved from 1 g/L to 8 g/L with a 5-time decrease in the dilution of human urine (Tuantet et al. 2014). A decrease in culture temperature leads to lower nutrient recovery in the case of S. acuminatus (Chatterjee et al.2019). Fresh urine as a daily nutrient stock is more effective compared to concentrated used urine for better nutrient recovery (Zhang et al. 2014).

Taken together, it can be concluded that microalgae growth in urine does help in nutrient removal along with biomass production, and the dilution of human urine along with light intensity can play a vital role (Tuantet et al. 2014a, b). Table 4 shows a compilation of studies using urine as a growth media for various microalgae and their nutrient recovery and biomass production outcome.

Impact of urine application on the environment and socioeconomic sector

Considering the high nutrient content of urine, the treatment of source-separated urine appears to be very promising in terms of efficiently recovering nutrients in the form of fertilizers from the perspective of circular economy and energy limitations (Igos et al. 2017; Ishii 2015). P and N are essential nutrients in crop cultivation and the main component in urine, and their use in food production is becoming increasingly important as the world's population grows (Viskari et al. 2021). Despite the numerous advantages of urine separation and fertilizer efficiency demonstrated by research, several obstacles prevent or impede the use of urine nutrients as fertilizer. Photobioreactors are critical to producing microalgae, but they are expensive. Furthermore, urine-diverting toilets, separate pipelines, and maintenance are all required to collect urine as a source for microalgae cultivation. Building all this infrastructure will have a significant socioeconomic impact on poor and developing countries. There is still a lack of efficiency in biomass and nutrient recovery at the industrial level, as well as regulatory policies (Pathy et al. 2021; Badeti et al. 2022). Environmental effects such as soil salinization and the spread of pathogens, as well as harmful substances such as heavy metals and pharmaceuticals from urines, are also of great concern. Table 5 summarizes the impact of the use of urine in various sectors such as the environment, socioeconomic, and global markets (Giannakis et al. 2018).

Microalgae production

Design of photobioreactors

Photobioreactors (PBR) are closed systems made of glass, plastic, or other transparent materials in the form of plates, tubes, or bags. The high-power consumption and operating costs of artificial light have traditionally been major costs associated with photobioreactors, but solar-lit photobioreactors do exist (Fig. 5). The light intensity is critical for the microalgae growth in the photobioreactor; hence, the optical properties of the materials used in photobioreactor construction are vital. Materials like glass, polyvinyl chloride, polyethylene, polycarbonate, plexiglass, fiberglass, etc. are commonly used for constructing photobioreactors (Johnson et al. 2018).

The integration of capturing, transportation, distribution, and utilization of light by microalgae via photosynthesis determines the effectiveness of PBRs. In the 1940s, the first PBR systems were developed and designed (Johnson et al. 2018). PBR design can be effective if (a) the PBR utilizes the maximum light available and process it to the PBR cultivation vessel for maximum biomass production, (b) operative and pinpointed control over operational parameters, (c) mitigate capital and operational costs, as well as energy consumption during operation with maximum light energy used for biomass production (Wang et al. 2012; Fu et al. 2019).

When selecting a PBR design for a specific manufacturing process, there are numerous factors to consider. Some PBR designs are more commonly used than others; thus, a design should be chosen on a case-by-case basis to optimize the efficiency of a microalgae biofuel production process. The following sections describe some of PBR designs.

Porous membrane photobioreactors

The porous membrane of the tubular PBRs can be either vertically or horizontally supported. The growth medium circulates within the dialysis membrane tube and seeps through pores to the membrane's outer surface (Ojanen et al. 2015). A dialysis membrane tube is placed inside the PBR tube, and microalgae can be grown outside the membrane. A CO2 source is used to supply aerated CO2 gas to the culture, which, along with light, can aid biomass production. The significant interfacial area provided by the membrane is the biggest advantage of porous membrane PBRs, but high-water vapor permeability could be a pitfall (Sarbatly et al. 2013).

Bubble column photobioreactors

Bubble column reactors are multiphase contactors that use the dispersion of a gas phase in the form of bubbles inside a cylindrical vessel containing a liquid or a suspension (Leonard et al.2015). Bubble column PBRs have a higher surface area-to-volume ratio than other types of photobioreactors, making them more efficient in microalgae production with greater volumetric and areal productivity (Mubarak et al.2019). The bottom of the reactor is sparged with CO2, causing bubbles to rise uniformly across the cross-sectional area and exit through the reactor top (Gerdes et al. 2014). Compressors and gas flow meters are combined with controllers to control the speed and size of gas bubbles dispersed in the microalgae suspension (Saldarriaga et al. 2020). Microalgae cells can utilize CO2 from the bubble for biomass production. If external illumination is used, bubble column PBRs are typically made of transparent material. Plastics such as polyvinyl chloride and plexiglass are common, and glass is also used commonly. Transparent double jackets are wrapped around PBR or the PBR is placed inside an incubator for temperature control. Stainless steel tubes as heat exchangers also can be used (López-Rosales et al. 2016). Because microalgae are susceptible to mechanical shear force, the excessive mechanical shear force caused by over-aeration causes cell damage (Ding et al. 2021). PBR has several advantages, including high heat and mass transfer rates, no moving parts, compactness, ease of operation, and low maintenance and operational costs. Their main disadvantage is the significant back mixing, which can affect reaction product selectivity and conversion (Leonard et al. 2015).

Airlift photobioreactors

Airlift PBRs come under vertical tubular PBRs. Cylindrical airlift PBRs are built with distinct vertical flows known as risers and downcomers separated by a physical barrier. The barrier that separates the downcomer and riser does not extend to the airlift reactor's top or bottom. The air enters the riser via a sparger located in the PBR's riser section. The growth medium is compressed in the sparger's bubble flow and travels up the PBR to the surface, where air exits the growth medium. The growth medium cannot exit the PBR with the air, forcing it to turn laterally to the downcomer, where it turns and moves vertically down the PBR. Because the growth medium cannot exit the bottom of the PBR, it returns to the riser, from which the sparger entrains gas into the flow, and the process is repeated (Johnson et al. 2018). For adequate light availability in the center of an airlift PBR, the diameter of the column should not exceed 0.2 m. Furthermore, the cylinder's height is limited to about 4 m for structural reasons, due to the strength of the transparent materials used, and to reduce mutual shading in large commercial cultivations. High capital and cleaning costs are big disadvantages for an airlift PBR, but it does help with low power consumption, low shear stress, good mixing, and mass transfer (Huang et al. 2017).

Tubular photobioreactors

The PBR is divided into two major components: the solar receiver and the airlift system. Solar receivers are designed to maximize solar radiation interception while minimizing flow resistance and occupying as little space as possible. A bubble column, on the other hand, is used for mixing, degassing, and heat exchange culture (Fernandez et al. 2014). CO2 is also injected at the end of the airlift system and at the start of the solar receiver to increase CO2 residence time in the solar receiver section. A heat exchanger also can be included in this section to improve control over the cultivation temperature (Ojanen et al. 2015).

Vertical and horizontal tubular photobioreactors are the two most common tube orientations used in laboratories, and both can be operated continuously, semi-continuously, or discontinuously. Depending on the type of experiment, temperature, pH, and oxygen concentration can be measured at various points along the tube, while liquid and gas flow rates are measured at the CO2 injection point (Solimeno et al. 2017). The challenges associated with tubular PBRs are related to maintaining a low partial pressure of CO2 along with uniform light intensity. Due to the mixing and cooling system of PBRs, tubular PBR is relatively costly to construct and maintain. The rise in CO2 concentration at the injection point, and the maintenance of the same, can be a problem. The production of microalgae biomass is directly proportional to CO2 concentration (Giannelli et al. 2012; Moraes et al. 2020).

Flat plate photobioreactors

Flat plate PBRs are used for medium-scale cultivation of microalgae. PBR flat panels are made of two joined plates that are kept at a constant distance from each other. Flat plates can be placed vertically, horizontally, or at an angle depending on the method used. Because of the larger surface area, light consistency is very high, resulting in better microalgae cultivation (Li et al. 2014; Huang et al. 2015). For aeration and cultivation, spargers, tubes, or membranes are used to mix and deliver air and CO2 (Yan et al. 2016). CO2 can be used for the pH balance of the microalgae suspension as the pH normally rises due to the use of CO2 by the microalgae (Pfaffinger et al. 2019). Though Light-Emitting Diodes (LEDs) are commonly used as a light source, other sources like neon lamps, sodium vapor lamps, OLEDs, fluorescent, halogen lamps, etc. also have been used. The flat panel PBRs have two-sided lighting (Huang et al.2015; Benner et al. 2022). When light distribution in flat panel PBRs is compared to the light distribution in cylindrical bubble column PBRs illuminated from the outside, the light attenuation caused by microalgae in suspension is much more pronounced than in flat panel reactors (Jacobi et al. 2012). Transparent double jackets are used as heat exchangers for temperature control, or PBRs can be placed in water baths to maintain temperature. pH, dissolved oxygen, and temperature are measured online with sterilizable electrodes (Vogel et al. 2018).

Bag photobioreactors

This type of reactor is specifically important for low- and middle-income countries that require an inexpensive cultivation system, are technically simple to operate, scalable, and meet basic good manufacturing practice requirements. These requirements are fulfilled by a disposable bag PBR (Cui et al. 2022). Bag PBRs are made up of three parts: plastic bags, a frame (to hold the plastic bag), and aeration systems. The size, materials, aeration types, mixing methods, and frame structure are all important design considerations (Ting et al. 2017). Sterilization of these bags is a big disadvantage as the material used for bag production is mostly polyethylene. Although UV or gas sterilization are options, they come at a high cost. Bag PBR systems are frequently hung vertically, with growth medium pumped to the top and flowing down to the bottom. Similar to tubular PBRs, gas exchange occurs in a unit separated from the photosynthetically active area of the bag (Johnson et al. 2018). Cost-effectiveness is the main advantage of the bag type PBR but photolimitation, bad mixing, frailty to leakage, and short life span are some disadvantages associated with it (Huang et al. 2017).

Photobioreactors are closed systems used for the cultivation of microalgae. They provide precise control of environmental conditions such as temperature, light, and nutrients, which can result in higher productivity and better quality of microalgae biomass (Sun et al. 2016). Photobioreactors have higher productivity than open pond systems because they can provide optimal conditions for growth. In photobioreactors, microalgae receive a uniform amount of light, CO2, and nutrients, which promotes their growth and reproduction. Photobioreactors provide a sterile environment that minimizes contamination by unwanted microorganisms. This makes the cultivation of specific strains of microalgae easier and can result in higher purity of the final product. Photobioreactors allow for precise control of environmental conditions, which can be adjusted according to the requirements of different microalgae strains. The control of temperature, pH, and nutrient levels can optimize the growth and productivity of microalgae. Photobioreactors can be scaled up or down depending on the production needs. This makes them suitable for small-scale or large-scale production of microalgae (Chanquia et al. 2021).

However, photobioreactors also have some disadvantages that should be considered before choosing this cultivation method. Photobioreactors require a significant capital investment to build and maintain. The cost of the equipment and technology needed for photobioreactor cultivation is often higher than that of open pond systems. The use of artificial lighting and heating systems in photobioreactors requires a significant amount of energy, which can result in high operating costs. Additionally, the energy source used to power these systems may have environmental impacts. Photobioreactors require regular maintenance to ensure their proper functioning. This includes cleaning, sterilization, and monitoring of the system components. Photobioreactors require skilled personnel to operate and maintain the system. The complexity of the equipment and technology used in photobioreactors can make the cultivation process more challenging than open pond systems (Amaral et al. 2020). In conclusion, photobioreactors offer several advantages over open pond systems to produce microalgae. They provide a controlled environment that allows for higher productivity and reduced contamination. However, they also have some disadvantages that should be considered, such as high capital cost, energy consumption, maintenance requirements, and complex operation. Ultimately, the decision to use photobioreactors for microalgae cultivation should be based on the specific needs and goals of the production process.

Parameters for optimal microalgae growth

Strain, carbon and nutrient levels, light intensity, light/dark cycle, temperature, and pH have an impact on microalgae growth and carbon fixation efficiency. These factors are critical for providing optimal condition management. Understanding how these variables affect algae growth and biological carbon sequestration can aid in process optimization.

Carbon source and strain

Microalgae can absorb dissolved inorganic carbon (DIC) from the aquatic environment in the forms of CO2, H2CO3, HCO3−, and CO32− from the suspension (Zhou et al. 2017). Different microalgae have different preferences for DIC form. For instance, gaseous CO2 is the most suitable for Chlorella sp. Similarly, Nannochloropsis sp. can actively transport HCO3− (Piltz 2018; Zhou et al. 2017). A few strains of microalgae can absorb HCO3−, which is then converted to CO2 by carbonic anhydrase. The process of converting CO2 and water into organic compounds powered by ATP and NADPH generated by photosynthesis is referred to as microalgae CO2 fixation. Microalgae capture CO2 through the Calvin cycle, such as carboxylation, reduction, and regeneration. During the transfer process, the main limiting factors influencing CO2 fixation are CO2 transportation resistance and diffusion (Razzak et al. 2017; Gerotto et al. 2020). Low carbon concentrations promote unsustainable microalgae growth, and dissolving enough CO2 in the growth suspension is expensive. Below 5% (V/V) CO2 concentration is best for microalgae growth, which is less than 10–20% flue gas CO2 concentration. Microalgae cannot always use organic carbon due to the large molecular size of carbon or to being trapped in large solid particles (Chowdury et al. 2020; Zhou et al. 2017).

Light source and light intensity

Light intensity is critical in microalgae photosynthesis, and when light intensity exceeds a critical level, light saturation and photoinhibition may occur (Fig. 6). Depending on the light stress and the length of time the microalgae are exposed to the stress, photoinhibition is either reversible or irreversible (Wang et al. 2012). Natural light is the most easily available and the cheapest option as a light source for microalgae cultivation, but it has some disadvantages due to changes in weather, diurnal cycle, and season. Although sunlight has a photon flux density (PFD) of over 2000 µmol. m−2. s−1, organisms that use oxygenic photosynthesis can only achieve a theoretical maximum conversion efficiency of 8%-10% solar-to-biomass energy (Huang et al. 2017).

Photosynthetic microorganisms such as microalgae can only use the 400–700 nm range, known as photosynthetically active radiation (PAR), but PAR accounts for only 50% of sunlight (Acien et al. 2013). Non-uniform light intensity distribution inside a PBR occurs due to the absorption and scattering of light in the culture. Radiation attenuation is dependent on the light wavelength, cell concentration, PBR geometry, and light penetration distance. If the light intensity is higher than a critical value, photoinhibition will take place and extra light will be wasted as fluorescent and heat. In case of lower light intensity, photolimitation will take place and the culture will collapse.

Depending on the cell growth due to light intensity, PBR can be divided into three zones, viz. strong illumination zone, weak illumination zone, and dark zone (Huang et al. 2017). Even during the day, microalgae in a controlled cultivation system are subjected to a different type of light/dark cycle. Because of the light gradient inside a PBR, algae are cyclically exposed to different microenvironments, from the light near the PBR surface to the dark in the center of a solar tube. As a result, algae are subjected to light/dark cycles that affect biomass production (Yen et al. 2019).

Light-Emitting Diodes (LEDs), halogen lamps, fluorescent lamps, and incandescent bulbs are all examples of artificial light sources that can be used for microalgal cultivation. The energy consumption, spectrum, wavelength distribution, and cost of these light sources differ. When these factors are considered, fluorescent lamps and LEDs are the most used light sources for microalgae production. When compared to fluorescent lamps, the use of LEDs allows for better light control, and the use of different wavelengths can be beneficial for biomass production (Chowdury et al. 2020).

Temperature

It has been reported that 20-300C is the optimal temperature for microalgae cultivation. The growth rate becomes slow below 200C and when the temperature goes above 300C severe death and damage can occur. Marine microalgae are easily susceptible to slow growth rate at 280C and death at 300C. Freshwater microalgae can operate between 25 and 300C, and at even 400C also shows tolerance for a brief period (Acien et al. 2013). PBRs are optically transparent due to the need for light. Without a temperature control unit, the inside PBR temperature can rise to 10-300C from the ambient temperature in the summertime. High temperatures can lead to photocatalytic reactions and cause disturbance in the chemical equilibrium of the species, along with the solubility of supplied gas and pH (Huang et al. 2017). As a result, additional cooling mechanisms are frequently used to keep the culture within a safe range. Submerging the entire culture in a water pool, spraying with water, shading, or incorporating a heat exchanger with PBR for cooling is some of these mechanisms (Wang et al. 2012).

pH and salinity

The optimal pH range for most of the microalgae species is between 7 and 9, and it is crucial for optimal growth and target product formation (Yen et al. 2019). The solubility of CO2 and carbonates in the microalgae suspension and availability are greatly dependent on the pH. The hydroxide ion (OH) accumulates in the growing medium, causing the pH to gradually rise during photosynthetic CO2 fixation. This shifts the chemical equilibrium of the inorganic carbon in the medium toward the formation of carbonates (CO2−3−) (Chowdury et al. 2020). Thus, CO2 availability at high pH becomes a trouble for microalgae growth. Nutrient uptake by cells, intracellular metabolite production, and metal toxicity can be caused by acidic pH, whereas alkaline pH decreases the affinity of microalgae for CO2 and interferes with cell division (Chang et al. 2017). pH also can interfere with photosynthetic activity. The pH of the culture is also affected by nitrogen addition. When nitrogen is supplied in the form of ammonium, the pH of the solution rises due to a decrease in the concentration of nitrogen in microalgae. Elevated pH can also influence the concentration of phosphorus in a culture medium by causing phosphate precipitation. Microalgae, bacteria, and cyanobacteria can generally withstand salt concentrations of up to 1.7 M. (Cai et al. 2013). pH control mechanism should be employed with the PBR, with sodium bicarbonate widely used to control the pH (Huang et al. 2017). Chlorella sp. KR-1, for example, grew well in a pH range of 4–7, but its growth was significantly inhibited at a pH below 3.5 (Zhou et al. 2017).

Oxygen removal

Microalgae photosynthesis uses light energy and CO2 to produce oxygen (O2) as a byproduct. In the rubisco enzyme, microalgae have a lower binding affinity for CO2 than O2. Excessive dissolved O2 competes with CO2 for the rubisco binding site, resulting in photorespiration that reduces photosynthetic activity (Chang et al. 2017). The presence of excess oxygen and light can lead to the formation of reactive oxygen species (ROS), thus leading to cellular damage. The dissolved O2 concentration in the medium should not be higher than 400% of the air saturation level, and algae cannot tolerate elevated CO2 levels for more than 2 or 3 h. Only the degasser removes accumulated dissolved O2 via mass transfer because dissolved O2 not only oxidizes one or more enzymes but also affects the electron transmission chain and suppresses photosynthesis. Thus, dissolved O2 accumulation should be avoided, and effective mixing is an excellent way to reduce dissolved O2 (Huang et al. 2017).

Mixing

Mixing is directly related to biomass production because it is the most limiting parameter for optimal microalgae growth and biomass production (Yen et al. 2019). Microalgae density can reach 109 cells, resulting in reduced light transmission, increased rates of dissolved CO2 consumption and dissolved O2 accumulation, and a rapid increase in culture temperature (Wang et al. 2012).

Besides, mixing ensures uniform nutrient distribution to cells and efficient light utilization, as well as facilitating heat transfer, promoting gas exchange, keeping cells suspended, and preventing cell clumping and attachment to PBR walls. Furthermore, mixing is also important in PBRs because it moves cells from the photic zone to the dark zone, artificially providing light and dark cycles to boost productivity.

A mixing or agitation system is classified into two types, namely nonmechanical and mechanical. Non-mechanical mixing systems include airlift, bubble columns, and tubular PBR, while mechanical mixing systems include stirred tanks and raceway ponds (Chang et al. 2017).

Sterility and cleanability

Slow-growing microalgae species are hard to cultivate as they take a longer period for growth, biofuel production, and CO2 sequestration, thus leading to impurity formation in the PBR (Wang et al. 2012). Bag PBR has issues with sterilization as they are made up of polyethylene (Johnson et al. 2018). Cleanability is essential for a PBR to reduce the formation of biofilm on the surface and to ensure the sterility of the PBR. In this situation, PBR should be designed with a smooth internal surface that helps the prevention of biofilm formation and other sedimentation in the wall along with a large enough surface area for conventional cleaning (Wang et al. 2012).

Nutrient

For microalgae growth, major nutrient requirements are N, P, and mineral elements such as magnesium (Mg), potassium (K), iron (Fe), cobalt (Co), and vitamins. Optimal N and P levels, and C: N: P ratios, promote rapid growth and efficient CO2 fixation (Zhou et al. 2017). Urine as a microalgae growth media is highly suitable because of the high presence of N and P along with other essential nutrients. According to the molecular formula of biomass, approximately 50% of the biomass is composed of C (Chowdhury et al. 2020). C is essential as the building block for carbohydrates, proteins, nucleic acids, vitamins, and lipids. A high autotrophic production rate requires a supply of CO2 and HCO3−. N can be found in 1–14% of the dry weight of microalgae biomass and is responsible for proteins, nucleic acids, vitamins, and photosynthetic pigment formation. The percentage of P is in the range of 0.05 to 3.3% in dry mass of microalgae biomass and is essential for the formation of nucleic acid and DNA along with energy transfer (de Alva et al. 2018). Nutrients such as ammonium, ammonia, and other substances found in urine, including heavy metals, drugs, and disinfectant by-products are all very toxic to microbial growth (Collos et al. 2014). To overcome this situation, microalgae-based nutrient removal can be effective.

Nutrient content

Several nutrients in microalgae can potentially be used as the best substitute for traditional foods. Microalgae comprise many nutritional composites which can generally be considered superfoods. Spirulina is known as “the future food” as confirmed by the Food and Agriculture Organization (Ahsan et al. 2008). Microalgae have compressed nutrients that can be used in space missions; therefore, the National Aeronautics and Space Administration of the USA built some algal species into astronauts' diets as they fundamentally require a great intake of nutrients in dense volumes (Kainer 2018). Microalgae also have bioactive composites including antioxidant, anti-inflammatory, anti-carcinogenic, anti-hypertensive, anticoagulant, anti-diabetic, immunomodulatory, cardiovascular protective, antiviral, and antimicrobial (Elaya Perumal and Sundararaj 2020; Nova et al. 2020). The study on the use of algae having nutritional and nutraceutical characteristics allowed their inclusion into the “foodomics” (Dvir et al. 2021). There is a description of nutrient contents that are present in algae, and both extrinsic and intrinsic factors such as nutrients, light, and CO2 generally enhance algal biomass production (Fig. 7).

Proteins and peptides

The main concern of microalgae nutrient contents is the protein that is abundantly present in algae; for instance, Spirulina platensis have up to 70% of their dry weight as protein. It was observed that half of the customary protein will be substituted by proteins from algal or insect-based diets in the coming year 2054 (Khanra et al. 2018). Moreover, some species of microalgae like Cholera vulgaris and Arthrospira platensis have similar quality of amino acids as in soybean (Grossmann et al. 2019). Microalgae proteins can be well digested as compared to other food products like oats, wheat, and beans, and help to reduce causes of hypertension, cardiovascular diseases, and oxidative stress (Levasseur et al. 2020). Species of microalgae that provides useful peptides in food are Chlorella spp., such as C. vulgaris, C. ellipsiodea, and Spirulina platensis, Nannochloropsis oculata (Ejike et al. 2016).

Lipids and essential fatty acids

Microalgae also have essential fatty acid and polyunsaturated fatty acids including omega-3 polyunsaturated fatty acids like docosahexaenoic acid and eicosapentaenoic acid and (DHA). These bioactive composites have many benefits for human health involving the control of high blood pressure, and stroke, which decreased the risk of cardiac arrest, and helped in resolving asthma, and depression (Adarme-Vega et al. 2012). These are important factors involved in brain development, especially at the early stages of childhood (Yeiser et al. 2016; Charles et al. 2019). Microalgae are a good substitute for fish for the provision of these polyunsaturated fatty acids (Yeiser et al. 2016), and the main species with the status of Generally Recognized As Safe involve Arthrospira, Haematococcus, Chlorella, Crypthecodinium cohnii, Dunaliella, and Porphyridium cruentum (Caporgno and Mathys 2018).

Carbohydrates and polysaccharides

Carbohydrates also present a major part of microalgae contents; however, the content of carbohydrates can vary in different developmental conditions. For instance, Chlorella vulgaris can yield 9–41% carbohydrates in its dry mass and Scenedesmus obliquus provides 10 to 47% of carbohydrates. The foremost species of microalgae used to provide polysaccharides involve Chlorella sp., Porphyridium purpureum, Tetraselmis sp., Isochrysis sp., Porphyridium cruentum, and Rhodella reticulate (Levasseur et al. 2020). Polysaccharides are the most ample sort of carbohydrate in microalgae, which were used for congealing and gelling properties (Bernaerts et al. 2019). For instance, beta-glucans might control the immune response, while sulfated polysaccharides can prevent a variety of cancer cell lines by having antioxidant properties (Nazih and Bard 2018).

Carotenoids

Carotenoids are regular pigments that have many functional properties for improving human health, including antioxidants, anticancer, anti-inflammatory, and antiobesity effects, and averting ophthalmic and cardiac diseases (Cezare-Gomes et al. 2019). Many commercially significant carotenoids (containing β-carotene, astaxanthin, and zeaxanthin) can be obtained through microalgae. Some species like Chlorella spp., Dunaliella salina and Haematococcus pluvialis have carotenoids which are mostly used for the manufacturing of nutraceutical products due to their anti-aging and antioxidant characteristics (Mehariya et al. 2021). Matters of astaxanthin in Haematococcus pluvialis can range from 3% of dry weight while β-carotene in Dunaliella salina can range up to 10%, of dry weight (Cezare-Gomes et al. 2019).

Vitamins

Vitamins obtained from microalgae have an important role in the metabolism of all humans, animals, and microbes. A deficiency of vitamins causes night blindness, beriberi, and rickets. Dunaliella spp. microalgae produced pro-vitamin A (β-carotene), vitamin E (Tocopherol) which was higher than soybean oil, and vitamin C (Ascorbic acid). Though, Euglena gracilis was the greatest manufacturer of vitamin C as compared to lemon, for instance (Ismailkhodjaev et al. 2019). Arthrospira platensis and Chlorella spp. Also produced Vitamin C (Andrade et al. 2018). Dunaliella tertiolecta has the potential to produce cobalamin (vitamin B-12) and riboflavin (vitamin B-2), while Chlorella spp. produce a high amount of biotin (vitamin B-7) (Koyande et al. 2019). Recent research showed that Nannochloropsis limnetica, N. oceanica, and Dunaliella salina can produce vitamin D3 after exposure to Ultraviolet-B light (Ljubic et al. 2020).

Minerals

Minerals have important roles in many physiological functions in the human body, and their scarcity can lead to disease indications. Arthrospira species can be significant sources of minerals like potassium, magnesium, phosphorus, zinc, and chromium, calcium 180% more than milk, and iron 5100% more than spinach (Alagawany et al. 2021). Chlorella vulgaris also produce calcium, zinc, magnesium, manganese, copper, and iron (Alagawany et al. 2021). Manufacturing of food with microalgae can upsurge their mineral matters which is lower than minerals of traditional compounds (Pomport et al. 2021).

From the above discussion, it is confirmed that the use of urine as a nutrient source for microalgae cultivation can have a significant influence on the nutrient content of microalgae-based food. Urine is a rich source of nitrogen, phosphorus, and potassium, which are essential nutrients for microalgae growth. When urine is used as a fertilizer for microalgae, it can enhance the growth rate and biomass yield of the microalgae, resulting in higher nutrient content in the final product. Microalgae grown with urine as a nutrient source may contain higher levels of nitrogen, phosphorus, and potassium than microalgae grown with conventional synthetic fertilizers or other organic sources of nutrients. In addition, microalgae cultivated with urine may also contain other essential micronutrients such as calcium, magnesium, and sulfur, which are also present in urine. The nutrient content of microalgae-based food can be influenced by various factors such as the strain of microalgae used, the cultivation conditions, and the processing methods.

However, the use of urine as a nutrient source for microalgae cultivation can be an effective way to increase the nutrient content of microalgae-based food, particularly in terms of nitrogen, phosphorus, and potassium. Moreover, the use of urine as a nutrient source for microalgae production can also have environmental benefits, as it can reduce the reliance on conventional synthetic fertilizers, which can have negative impacts on soil and water quality. Urine is a readily available and renewable resource that can be collected and processed locally, reducing the carbon footprint associated with the transportation of fertilizers. In conclusion, the use of urine as a nutrient source for microalgae cultivation can significantly influence the nutrient content of microalgae-based food, particularly in terms of nitrogen, phosphorus, and potassium. However, the safety and hygiene of the final product must be ensured through appropriate treatment and processing methods (Chang et al. 2013; Lamminen et al. 2019; Tao et al. 2022).

Capital cost, operating cost, and profitability

A PBR's rational design is critical, and the capital cost (high surface area/volume ratio), operating cost (i.e., the cost of auxiliary energy demand, cleaning, and maintenance), and lifespan of the PBR should all be considered before commercial exploitation. A good PBR should have a simple structure, simple operation, and temperature control, a low capital cost, a low operating cost (i.e., low energy consumption and easy cleaning and maintenance), and a long lifespan (Huang et al. 2017).

The three storage carbon substances (i.e., protein, carbohydrate, and lipid) are the main products from microalgae that are exploited in various market scenarios, according to the economic analysis (Sun et al. 2018). Animal feed prices are calculated using a broad correlation with protein content. Protein-rich microalgae, such as Chlorella pyrenoidosa, are promising strains in animal feed, with a value of $ 750 tonne−1 (Ruiz et al. 2016). There are numerous business opportunities for microalgae products, and the interest in investing in them is growing over time. If nutrients are supplied in sufficient quantities, production can be produced, leading to a higher yield.

Algae must be sold as high-value products to attain a reasonable profit. For instance, Haematococcus pluvialis, an algae species rich in the natural source of the red pigment astaxanthin, has a high market value and demand (Kaur 2021). Biodiesel also can be obtained from microalgae biomass. If the capital cost and operational cost are maintained and along with sustainability, there will be a great market valuation for microalgae-based products.

Potential hurdles

Consumer opinion on the use of urine as an input in microalgae cultivation

Consumers are very concerned about the chemical and microbial safety of algal food products, for example, the cyanobacteria, and microalgae spirulina, are generally consumed as food or used as a nutritional supplement in many European countries such as France, Germany, and Spain (Araújo et al. 2021). Consequently, in Europe, strict legislations such as EC 2073/2005 and EC 1441/2007 are evident for both producers and consumers as vital requirements for the safety of food products. Although no standard microbial criteria have been established for microalgae, microalgae considered for food and nutritional purposes are categorized as ‘vegetable products’ under the European Food Safety Authority system of classification (Heinsoo 2014).

As urine is considered an alternative nutrition cultivation medium for alga growth, many studies have concluded the high content of contaminants such as pharmaceutical pollutants and the presence of heavy metals such as lead and copper. It has thus been confirmed that between 64 and 80% of undigested pharmaceutical products are excreted through urine which finds their way as residues or metabolites of pharmaceutical compounds into mainstream wastewater treatment plants (Ronteltap et al. 2007; Heinsoo 2014). Thus, an effective wastewater treatment process that can considerably eliminate most contaminants in urine will ensure maximum nutrient recovery and a safer and contaminant-free urine suitable for algae cultivation for food application purposes. Furthermore, the adoption of cost-effective industrial processes in wastewater treatment that can efficiently provide an effective concentration of treated urine for microalgal cultivation is very essential. Thus, nutritionally recovered and safety-assessed urine with enhanced yield performance for biomass production from algal growth will address the challenges of consumer perception of the safety of algal food products (Heinsoo 2014; Muluye et al. 2021).

One of the biggest challenges in evolving countries is the requirement for food production which should be enough to feed the increasing population (Akpan-Idiok et al. 2012). Malnutrition poses a threat to those nations which majorly rely on agricultural food production (Benoit 2012). Extensive drops in soil fertility caused due to the use of commercial chemical fertilizers in several areas have resulted in the deterioration in organic matter of the soil and hence a decreased crop yield. Conventional agriculture practices have become more problematic due to the rise in fertilizer prices for farmers in evolving countries. Human urine is a favorable product to be used in agricultural activities as it contains comparatively high amounts of nitrogen, phosphorus, and additional nutrients including potassium and micronutrients, and therefore can be used as a multi-constituent inorganic fertilizer. In fresh urine, nitrogen found as urea is useful for plants and it is also found in marketable fertilizers. Urine also comprises water and a diversity of organic and inorganic compounds in comparison to solid inorganic fertilizers (Fig. 8). Human urine is a quick and cheap source of enough liquid nitrogen. The fertilizing effects of human urine are higher than that of mineral fertilizers which were observed in many different countries as shown in Table 6.

In terms of the legal use of urine as fertilizer, legislation of the European Union does not prohibit or permit the usage of human urine as a nutrient fertilizer. Previous studies show that the application of urine as fertilizer for the cultivation of food was an ancient practice in China and was well accepted. In Southern China and Vietnam, farmers used human urine as a “valuable fertilizer.” Conventionally human urine was a good alternative to costly inorganic fertilizers to enhance production in home gardens and agriculture. In many other countries, human urine is applied as a nutrient supply for agricultural drives including Mexico, USA, Germany, Denmark, Sweden, and some African countries. There is less information on the usage of human urine as fertilizer in South Africa due to the lack of urine diversion toilets that permit the sanitary separation of urine. The new implementation of urine diversion toilets in South Africa must enhance the usage of urine as fertilizer for agricultural practices (Lamichhane et al. 2013). The application of human urine for agricultural practices is still considered a foreign concept and normally is not accepted since human urine is considered a waste product and unhealthy (Benoit 2012). Personal preconceptions and moral concerns have additional effects to cause a reduction in the approval of using human urine as a fertilizer. Perceptions and approaches concerning the health risks and peoples’ repulsion from human urine differ between different cultures and even within particular cultures universally. The common attitudes of people concerning the usage of human urine depend on many social factors linked to the use of human urine as fertilizer, such as, employment, culture, age, locality, education, religion, sex, status, class, and martial status.

In a research study, the approaches of workers and students at the Medunsa Campus of Limpopo University were questioned and discussed the implementation of human urine in the farming and production of crop plants was evaluated (Mugivhisa and Olowoyo 2015). The purpose was to assess exactly how frequently people eat cultivated fresh vegetables, fruits, and other crops, how much knowledge and awareness they had about various types of fertilizers including manure, compost, and chemical, and which kind of fertilizers they chose for cultivating their food crops. Further objectives were to evaluate how much knowledge people had about the nutritional importance of human urine and what would they like to eat, maize or spinach, enriched with animal urine or human urine. The major concern of this evaluation was to check the willingness of people to modify their approaches after they become well aware of the concerns, they had for refusing to eat those food crops which were enriched with human urine (Mugivhisa and Olowoyo 2015). In a study of Swiss farmers, 57% of farmers believed that urine can be used as an agricultural fertilizer and 42% of farmers were inclined toward purchasing products enriched by urine (Lienert et al. 2003; Lamichhane et al. 2012).

Consumer acceptance and legal barriers for use of algae as food

It was observed that the foremost challenge for the consumption of microalgae as food products is sensory acceptance, generally concerning appearance and flavor for greater concentrations. Some species of microalgae can also act as smart elements, such as smart flavor or smart color, which means that they can impart the flavor or color besides increasing nutritional value, and subsidize environmental and technological characteristics in more or fewer cases (Ashaolu and Ashaolu 2020), though they are worthy for the consumers, the manufacturer and the globe.