Abstract

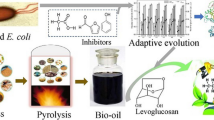

Robustness of fermenting strains to lignocellulose derived inhibitors is critical for efficient biofuel and biochemical productions. In this study, the industrial fermenting strain Corynebacterium glutamicum S9114 was evolved for improved inhibitor tolerance using long-term adaptive evolution by continuously transferring into the inhibitors containing corn stover hydrolysate every 24 h, and finally a stably evolved C. glutamicum was obtained after 128 days of serial transfers. The evolved strain exhibited the highly increased conversion rate to the typical lignocellulose derived inhibitors including furfural, 5-hydroxymethylfurfural, vanillin, syringaldehyde, 4-hydroxybenzaldehyde, and acetic acid. Glucose consumption was obviously accelerated, and 22.4 g/L of glutamic acid was achieved in the corn stover hydrolysate, approximately 68.4% greater than that by the original strain. Whole genome re-sequencing revealed various mutations with the potential connection to the improved performance of the evolved strain. Transcriptional analysis further demonstrated that the glucose-PTS transport and the pentose phosphate pathway were significantly upregulated in the evolved strain, which very likely contributed to the accelerated glucose consumption, as well as sufficient NAD(P)H supply for aldehyde inhibitors reduction conversion and thus enhanced the inhibitor tolerance. This study provided important experimental evidences and valuable genetic information for robust strain construction and modification in lignocellulose biorefining processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biorecalcitrance of lignocellulose requires pretreatment step to break its complex rigid structure and to release fermentable sugars for subsequent microbial fermentation. During the harsh pretreatment process, various small inhibitory compounds are inevitably generated from partial overdegradation of lignocellulose, and they are usually classified into three categories, furan aldehydes such as furfural and 5-hydroxymethylfurfural (HMF) from dehydration of pentose and hexose, respectively; weak organic acids such as formic acid, acetic acid, and levulinic acid from acetyl group hydrolysis or furans oxidation; as well as phenolic compounds such as vanillin, syringaldehyde, and 4-hydroxybenzaldehyde from partial breakdown of lignin components (Jönsson et al. 2013). These undesirable inhibitors are known to severely impair the fermentation process by inhibiting microbial cell growth and metabolism (Mills et al. 2009; Taylor et al. 2012). Therefore, it is essential to circumvent or alleviate the inhibitor toxicity on microorganisms for efficient microbial fermentation of biofuels and biochemicals from lignocellulose feedstocks.

Application of robust fermenting strains with improved inhibitor tolerance is an effective approach to overcome the inhibitory effects, and different strategies have been developed for this kind of strain construction. Among them, adaptive evolution is a classical and powerful method based on the selection of advantageous cellular properties through iterative genetic diversification (spontaneous or induced mutation) and selective pressure by mimicking the natural selection (Sauer 2001). In contrast to the rational design and metabolic engineering, the main strategy for strain development, adaptive evolution only requires a well-designed selection procedure but does not need the detailed understanding about the inhibitor action and responsible genes; it is therefore able to optimize the process and more suitable for industrial application (Almeida et al. 2007; Qin et al. 2016). Currently, many different microorganisms with increased stress tolerance have been obtained by employing such adaptive strategy, including Escherichia coli (Arense et al. 2010; Mundhada et al. 2017; Rajaraman et al. 2016), Saccharomyces cerevisiae (Koppram et al. 2012; Wallace-Salinas and Gorwa-Grauslund 2013), Zymomonas mobilis (Mohagheghi et al. 2015; Shui et al. 2015), and Crypthecodinium cohnii (Li et al. 2017). These results provide evidences that the adaptive evolution can be a faster and more convenient way to develop inhibitor-tolerance strains. In addition, the advance of next-generation sequencing technique which makes the correlation between genotypic change and phenotypic change feasible also promotes the strategy application (Mohagheghi et al. 2015).

As a fast-growing and aerobic gram-positive microorganism, Corynebacterium glutamicum is widely used for industrial production of various amino acids, such as glutamate and lysine (Kinoshita et al. 2004; Nakayama et al. 1961). Currently, C. glutamicum has also been used for producing biofuels and other biochemicals, including ethanol, isobutanol, lactate, and succinate (Becker and Wittmann 2012). The feedstocks traditionally used for the industrial fermentation by C. glutamicum are sugars from cane and starch hydrolysate from corn. Recent studies have suggested that renewable lignocellulosic biomass could be used as the promising alternative feedstocks (Gopinath et al. 2011). However, the problem of fermentation inhibitors in lignocellulosic hydrolysate remains urgent to be solved (Rumbold et al. 2009; Wang et al. 2014). Previous studies showed that C. glutamicum converts furfural to furfuryl alcohol under anaerobic condition and further to furoic acid under aerobic condition (Tsuge et al. 2014). Different from the conversion pattern of furan aldehyde inhibitors, C. glutamicum is able to utilize a large variety of phenolic compounds (Shen et al. 2012), as well as acetic acid (Gerstmeir et al. 2003) as the sole carbon and energy source for cell growth. Nevertheless, these typical inhibitors still displayed strong growth inhibition to C. glutamicum even at lower concentrations. More importantly, the inhibitor mixtures in hydrolysate had much more toxic effects for the additive or synergistic manner in combination (Sakai et al. 2007; Xu et al. 2015). Therefore, it is crucial to acquire the complete tolerance to fermentation inhibitors for C. glutamicum to increase its utilization efficiency of the practical lignocellulose feedstocks.

In the present study, a long-term adaptive evolution strategy was used to develop a robust C. glutamicum strain with high tolerance to various lignocellulose derived inhibitors by continuously transferring into fresh non-detoxified corn stover hydrolysate. The underlying molecular mechanism contributing to the improved inhibitor tolerance and accelerated sugar utilization of the evolved strain was further elucidated by genome re-sequencing and transcriptional analysis. This study provided the valuable guidance for the future metabolic engineering of more robust fermenting strains.

Materials and methods

Raw materials and reagents

Corn stover was harvested in fall 2013 from Dancheng, Henan, China. After collection, the corn stover was milled and screened through a mesh with the circle diameter of 10 mm, then washed to remove field dirt, stones and metals, finally dried at 105 °C until constant weight, and stored in sealed plastic bags for use.

The cellulase enzyme Youtell no. 6 was purchased from Hunan Youtell Biochemical Co., Yueyang, Hunan, China. The filter paper activity was 135 FPU/g determined using the National Renewable Energy Laboratory (NREL) Laboratory Analytical Procedure (LAP) LAP-006 (Adney and Baker 1996), and the cellobiase activity was 344 CBU/g according to the method described by Ghose (1987). The protein concentration was 90 mg/g measured by Bradford method.

Inhibitor chemicals furfural and HMF were purchased from Shanghai DEMO Medical Tech Co., Shanghai, China. Vanillin, syringaldehyde, and 4-hydroxybenzaldehyde were purchased from Sangon Biotech Co., Shanghai, China. Acetic acid was from Lingfeng Chemical Reagent Co., Shanghai, China. Yeast extract was from Oxoid, Hampshire, UK. Corn steep liquor was purchased from Xiwang Sugar Co., Zouping, Shandong, China. Penicillin was purchased from New Probe Biochem Co., Beijing, China, and the labeled titer was 1650 U/mg which finally diluted into the 50 mg/mL penicillin solution used for induction experiment. All other chemical reagents were of analytical reagent grade and from Lingfeng Chemical Reagents Co., Shanghai, China.

Pretreatment and hydrolysate preparation

The dry dilute acid pretreatment of corn stover was carried out in a helical ribbon impeller-driven reactor by co-currently feeding of dilute sulfuric acid solution and dry corn stover (He et al. 2014). The pretreatment condition was maintained at 175 °C for 5 min at a solid to liquid ratio of 2:1 (w/w) with 2.5 g of sulfuric acid per 100 g of dry corn stover (2.5% acid usage). The raw corn stover contained 37.2% of cellulose and 19.9% of hemicellulose, and the pretreated corn stover contained 39.9% of cellulose and 3.0% of hemicellulose determined according to the two-step acid hydrolysis method described in NREL LAP protocol (Sluiter et al. 2012).

The pretreated corn stover was enzymatically hydrolyzed at 15% (w/w) solids loading in a 5-L bioreactor using 15 FPU/g dry corn stover matter of cellulase at 50 °C, pH 4.8 for 48 h. The hydrolysate slurry was centrifuged at 10,000 rpm for 10 min, autoclaved at 115 °C for 20 min, and filtered by filter paper before use (Zhang et al. 2016). The non-detoxified hydrolysate prepared contained 33.69 g/L glucose, 19.51 g/L xylose, 2.54 g/L acetic acid, 0.38 g/L furfural, 0.21 g/L HMF, 0.29 g/L vanillin, 0.13 g/L syringaldehyde, and 0.03 g/L 4-hydroxybenzaldehyde. Before fermentation, additional glucose was added into corn stover hydrolysate to maintain the glucose concentration to 60 g/L, and the nutrient compositions including 1 g/L KH2PO4, 0.6 g/L MgSO4, 3 g/L urea, 2 mg/L FeSO4, 2 mg/L MnSO4, and 0.5 g/L corn steep liquor were added as well.

Strains, media, and culture conditions

The industrial fermenting strain, C. glutamicum S9114, was obtained from Shanghai Industrial Institute of Microorganisms (SIIM), Shanghai, China with the storage number as SIIM B460, which has the same origin to C. glutamicum CICC 20935 accessible in China Center of Industrial Culture Collection (CICC) with the registration number of CICC 20935. The strain was transferred from − 80 °C and maintained on LB-agar plates containing 5 g/L yeast extract, 10 g/L peptone, 10 g/L NaCl, and 15 g/L agar.

The media used for C. glutamicum culture included the following: (1) Preculture medium: 25 g/L glucose, 1.5 g/L KH2PO4, 0.6 g/L MgSO4, 2.5 g/L urea, 2 mg/L FeSO4, 2 mg/L MnSO4, and 25 g/L corn steep liquor; (2) seed culture medium: 25 g/L glucose, 1.5 g/L KH2PO4, 0.6 g/L MgSO4, 2.5 g/L urea, 2 mg/L FeSO4, 2 mg/L MnSO4, and 5 g/L corn steep liquor; (3) fermentation medium: 60 g/L glucose, 1 g/L KH2PO4, 0.6 g/L MgSO4, 3 g/L urea, 2 mg/L FeSO4, 2 mg/L MnSO4, and 0.5 g/L corn steep liquor. All media were at pH 7 and sterilized at 115 °C for 20 min. FeSO4 and MnSO4 solutions were separately filtrated for sterilization and then added to the media.

One fresh colony was transferred into 30 mL of preculture medium in the 250-mL Erlenmeyer flask and incubated at 30 °C, 200 rpm. After 12 h, 5% (v/v) of the culture was transferred into 30 mL of seed culture medium and incubated for 8 h at 30 °C, 200 rpm. The seed culture was used then as the inoculum for all fermentation experiments.

Adaptive evolution

Adaptive evolution of C. glutamicum S9114 was carried out in the 250-mL Erlenmeyer flask containing 30 mL of 15% (w/w) corn stover hydrolysate at 30 °C, 200 rpm. Firstly, 5% (v/v) of the seed culture was transferred into the hydrolysate and pH was adjusted at 7.0 using 20% urea throughout the cultivation. After 24 h, 5% (v/v) of the sub-culture was transferred into fresh hydrolysate and incubated under the same conditions. Serial transfer was repeated for 128 days until the fermentation performance tended to be constant. Samples were taken prior to each transfer for the cell growth, the glutamic acid, and the residual sugar analysis.

Inhibitor tolerance evaluation and glutamic acid fermentation

Inhibitor tolerance of C. glutamicum was evaluated in 30 mL of the fermentation medium in the 250-mL Erlenmeyer flask adding different inhibitors of furfural, HMF, vanillin, syringaldehyde, 4-hydroxybenzaldehyde, and acetic acid, respectively. Five percent (v/v) of the seed culture was inoculated and incubated at 30 °C in the shaker at 200 rpm. The pH was adjusted at 7.0 using 20% urea throughout the fermentation. Samples were taken periodically to detect the inhibitor concentrations.

Glutamic acid fermentation was performed in 30 mL of the fermentation medium or corn stover hydrolysate with 5% (v/v) or 20% (v/v) of seed culture inoculation. The culture was incubated at 30 °C, 200 rpm, and the pH was adjusted at 7.0 with 20% urea. To induce glutamic acid production in the hydrolysate, 60 μL of 50 mg/mL penicillin solution was added at 8 and 16 h, respectively. Samples were collected periodically to detect the cell growth and the concentration of glucose and glutamic acid.

Analytical methods

Cell growth was determined by measuring optical density (OD) at 600 nm. Samples taken during fermentation were centrifuged at 12,000 rpm for 5 min, and then the supernatants were filtered through a 0.22 μm filter before analysis. Glucose and glutamic acid were monitored with a SBA-40D biosensor (Shandong Academy of Sciences, Jinan, China). Furfural, HMF, vanillin, syringaldehyde, and 4-hydroxybenzaldehyde were analyzed using reverse-phase HPLC (LC-20AT, Japan), equipped with a YMC-Pack ODS-A column (YMC, Tokyo, Japan) and an SPD-20A UV detector (Shimadzu, Kyoto, Japan). Furfural was analyzed using 50% acetonitrile solution as the mobile phase at 35 °C with the flow rate of 1.0 mL/min under the detection wavelength of 220 nm. HMF was analyzed using the following gradient: the initial flow phase was composed of pure water (pump A) and acetonitrile (pump B) at a ratio of 95% to 5%; acetonitrile was first increased from 5 to 100% over 0 to 15 min then decreased from 100 to 5% over 15 to 20 min, and finally, used at 5% over 20 to 30 min. The flow rate was 0.6 mL/min, the column temperature was 35 °C, and the detector wavelength was 230 nm. Vanillin, syringaldehyde, and 4-hydroxybenzaldehyde were analyzed using 100% acetonitrile solution (pump A) and 0.1% formic acid (pump B) at a ratio of 90 to 10% as the mobile phase at 1.0 mL/min with the column temperature of 35 °C and the detection wavelength of 270 nm. Acetic acid was determined by HPLC (LC-20AD, Japan) equipped with an Aminex HPX-87H column (Bio-Rad, Hercules, CA, USA) and a RI detector RID-10A (Shimadzu, Kyoto, Japan), operated at 65 °C at the flow rate of 0.6 mL/min using 5 mM H2SO4 as the mobile phase.

Whole genome re-sequencing through NGS

Genomic DNA from the original and evolved C. glutamicum strains were extracted using TIANamp Bacterial DNA Kit (Tiangen Biotech Co., Beijing, China) according to the manufacturer’s instruction. Genomic library construction and whole-genome resequencing were performed at the Genome Center at Wuxi AppTec Co., Shanghai, China using Illumina Hiseq 2500 (Illumina, Inc. San Diego, CA, USA). The paired-end reads from the two strains were mapped to the reference genome sequence of C. glutamicum S9114 (Lv et al. 2011) separately using the BWA software (Li 2013). The potential mutations including point mutations and insertions/deletions were identified using the Snippy software (Reumerman et al. 2013) and Breseq software (Barrick et al. 2014). The objective mutations in the evolved strain were obtained after removing the same mutations both in the two kinds of strains. All the intragenic mutations considered causing amino acid substitutions and the intergenic mutations were confirmed by PCR amplification and followed by Sanger sequencing. The primers used for this validation are listed in Table S1.

qRT-PCR analysis

Both the original and evolved C. glutamicum strains were cultured in the fermentation medium at 30 °C, 200 rpm for 8 h. Cells were collected and centrifuged at 8000 rpm for 5 min at 4 °C and then stored at − 80 °C for subsequent RNA extraction and qRT-PCR analysis.

The total RNA was extracted using RNAiso Plus reagent (TAKARA, Otsu, Japan) after the cell mass were grinded. Integrity and quantity of the RNA samples were detected by a ratio of OD260/OD280 readings using a DU 800 spectrophotometer (Beckman Coulter, Fullerton, CA, USA). Reverse transcription reactions were carried out using ReverTra Ace qPCR RT Master Mix with gDNA Remover kit (TOYOBO, Osaka, Japan) according to the manufacturer’s protocol. For each qRT-PCR reaction, a SYBR Green Real-Time PCR Master Mix kit (TOYOBO, Osaka, Japan) was used and the PCR reaction was run on a Bio-Rad CFX 96 System (Bio-Rad, Hercules, CA). Primers for qRT-PCR analysis are listed in Table S1. PCR conditions were as follows: 95 °C for 1 min; 40 cycles of 95 °C for 15 s, 55 °C for 15 s, and 72 °C for 30 s; and a final melting curve step by heating from 65 to 95 °C with a speed of 0.5 °C per 5 s. The original C. glutamicum was used as the control strain. 16S rDNA gene (CGS9114_RS11955) was served as an internal control to normalize for the difference in total RNA quantity. Transcription levels of selected genes were quantified using the formula 2−ΔΔCt.

Results

Inhibitor conversion of C. glutamicum after the adaptive evolution

Adaptive evolution of C. glutamicum S9114 was carried out in 15% (w/w) solids loading corn stover hydrolysate by consecutively transferring into fresh hydrolysate every 24 h. As shown in Fig. 1, the cell growth and glucose consumption fluctuated up to 70 transfers and then maintained stable with only random shift. After 128 days (equivalent to 3072 h) of serial transfers, the cell growth tended to be constant with OD600 nm of 16.4 from the initial 8.7, and residual glucose concentration was decreased and kept with 28.2 g/L from the initial 36.6 g/L. Since biotin in the hydrolysate was excessive and no additional penicillin or surfactant was added, almost no glutamic acid was observed during the whole adaptation process (Nara et al. 1964; Takinami et al. 1965).

The inhibitor tolerance of the evolved C. glutamicum was compared with the original strain in the synthetic fermentation medium under the stress of six typical inhibitor compounds commonly derived from lignocellulose pretreatment, including furfural, HMF, vanillin, syringaldehyde, 4-hydroxybenzaldehyde, and acetic acid. Just similar to other C. glutamicum strains, the evolved and original strains both exhibited inhibitor degradation capacity, including converting furfural, HMF, and syringaldehyde into corresponding alcohols and acids, degrading 4-hydroxybenzaldehyde and vanillin finally into the tricarboxylic acid (TCA) cycle through the corresponding alcohols and acids and completely utilizing acetic acid as the sole carbon and energy source (unpublished data). The evolved strain showed a slight increase for the cell growth (data not shown), but more importantly, it presented an obviously accelerated conversion rate to each inhibitor. As shown in Fig. 2, when 1 g/L of furfural was added, about 0.9 g/L was converted at 2 h by the evolved strain, half-time shorter than that for the original strain; when 0.7 g/L of HMF was added, 0.44 g/L of HMF was reduced at 2 h by the evolved strain, while 0.45 g/L of HMF was still left by the original strain at the same time. For the phenolic compounds, 0.17 g/L of vanillin, 0.14 g/L of syringaldehyde, and 0.21 g/L of 4-hydroxybenzaldehyde were reduced at 4 h by the evolved strain, leading to an apparently conversion increase compared to the original strain at 26.3, 27.2, and 30.9%, respectively. For 6 g/L of acetic acid added initially, it was completely reduced at 48 h, 16 h shorter than the time for complete conversion by the original strain. These results indicated that the inhibitor tolerance and conversion rate of C. glutamicum S9114 were improved significantly after the adaptive evolution in corn stover hydrolysate.

Comparison of the inhibitor conversion of the original and evolved C. glutamicum. a Furfural 1.0 g/L. b HMF 0.7 g/L. c Vanillin 0.2 g/L. d Syringaldehyde 0.2 g/L. e 4-Hydroxybenzaldehyde 0.3 g/L. f Acetic acid 6 g/L. Conditions: 30 °C, 200 rpm, pH 7.0. Mean values were presented with error bars representing at least two standard deviations

Glutamic acid fermentation by the evolved C. glutamicum

Glutamic acid fermentation performance of the evolved C. glutamicum was conducted in liquid synthetic medium and corn stover hydrolysate, respectively. Figure 3 compares the fermentation profiles of the evolved strain to original strain in the simplified fermentation medium. Although the growth rate of the evolved strain in the synthetic medium was lower than that of the original strain (0.54 vs 0.68 for OD600 nm/h), the specific growth rates of the two strains were practically similar (0.43/h), and both strains reached the stationary growth phase after approximately 12 h (Fig. 3a; Table 1). Figure 3a also shows that the maximal cell mass of the evolved strain was slightly lower than that of the original strain (7.4 vs 8.6 for OD600 nm). The glucose consumption rate was significantly increased for the evolved strain with only 5.5 g/L of residual glucose left at the end of the fermentation, in contrast with 17.0 g/L left by the original strain (Fig. 3b). Glutamic acid was accumulated with the decrease of glucose. Unexpectedly, the faster glucose metabolism in the evolved strain did not bring about a higher glutamic acid generation. As shown in Fig. 3b, only 15.6 g/L of glutamic acid was observed by the evolved strain, 25.7% less than that by the original strain.

Figure 4 shows the glutamic acid fermentability of the evolved strain in 15% solids loading corn stover hydrolysate. As the inhibitors existence, cell growth of the evolved strain was obviously improved in the hydrolysate, and the maximum cell mass (OD600 nm) reached 15.0, compared to the original strain of 12.4. Glucose consumption rate of the evolved strain was accelerated distinctly as well in the hydrolysate, and completely consumed at 48 h, in contrast with 27.3% of residual glucose left even after 72-h culture by the original strain. After penicillin was added at 8 and 16 h for induction, glutamic acid production was finally accumulated to 22.4 g/L, 68.4% higher than that for the original strain and also significantly higher than that in synthetic medium by the two kinds of strains, and glutamic acid yield increased to 0.48 g/g glucose, 35.3% higher than that for the original strain and very close to that for the original strain in synthetic medium (0.53 g/g glucose) (Fig. 4b; Table 1). These results indicated that the adaptive evolution strongly improved inhibitor tolerance and fermentation of C. glutamicum strain, making the evolved C. glutamicum very suitable for glutamic acid production using the lignocellulose hydrolysate. Previous studies on ethanol production (Gu et al. 2014; Qureshi et al. 2015) also proved that the ethanol fermentation performance was improved using the inhibitor-containing hydrolysate adaptation process, and similar results were obtained in the present study.

Glutamic acid fermentation of the original and evolved C. glutamicum in 15% (w/w) corn stover hydrolysate. a Cell growth. b Glucose consumption and glutamic acid production. Conditions: 30 °C, 200 rpm, pH 7.0. Sixty microliters of 50 mg/mL penicillin was added at 8 and 16 h, respectively, for glutamic acid production. Mean values were presented with error bars representing at least two standard deviations

Genome re-sequencing and mutation mining of C. glutamicum

After the adaptive evolution, the evolved C. glutamicum exhibited enhanced inhibitor conversion rate (Fig. 2) and improved cell growth and glutamic acid fermentation performance in corn stover hydrolysate (Fig. 4). In particular, we observed the accelerated glucose consumption and an unexpected lower glutamic acid production in synthetic medium (Fig. 3). To identify the underlying genetic changes responsible for the altered phenotypes, the whole genome of the original and the evolved strains were re-sequenced. After both alignment to the published genome sequence of C. glutamicum S9114 (Lv et al. 2011) and excluding the same mutations, a total of seven mutations including two intragenic deletions and five single-nucleotide polymorphisms (SNPs) were found in the evolved strain (Table 2). Of the five SNPs, one was located in intergenic region, while four occurred in intragenic regions with only one of non-synonymous mutation.

As shown in Table 2, one intragenic deletion mutation was located within the encoding sequence of CGS9114_RS08730, deleting seven amino acids at the position 228 by inserting another serine. CGS9114_RS08730 encodes the ATP-binding subunit ClpX of the ATP-dependent Clp protease, which is involved in responses to environmental and cellular stresses by degrading abnormal and damaged proteins to further prevent the build-up of protein aggregates in cells (Ambro et al. 2012; Hou et al. 2014). The mutated CGS9114_RS08730 was supposed to enhance its ATP-binding activity and strengthen the degradation ability of the Clp protease on damaged proteins impaired by the inhibitors. The non-synonymous SNP in the evolved strain occurred in CGS9114_RS14945, which encodes TetR family transcriptional regulator McbR, leading to a change of aspartate to alanine at the position 47. McbR negatively regulates the expression of at least 45 genes, and these genes play a variety of functions for (S-adenosyl) methionine and cysteine biosynthesis, sulfate reduction, sulfur-containing compounds uptake and utilization, as well as transcriptional regulation (Rey et al. 2005; Rey et al. 2003). Previous studies reported that the expression of sulfur amino acid biosynthesis genes was increased in response to furfural and the supplementation of cysteine and methionine was effective in increasing inhibitor tolerance (Kanna and Matsumura 2015; Miller et al. 2009). Accordingly, the evolved CGS9114_RS14945 might release the repression on sulfur amino acid biosynthesis and then heighten the inhibitor tolerance to furan aldehydes.

The intergenic SNP located within the promoter region between the divergently expressed CGS9114_RS11050 and CGS9114_RS11055. CGS9114_RS11050 encodes phosphoenolpyruvate-protein phosphotransferase, and CGS9114_RS11055 encodes DeoR family transcriptional regulator FruR. Both the two genes are involved in the sugar transport system, the phosphoenolpyruvate (PEP)-dependent sugar phosphotransferase system (PTS) in C. glutamicum (Ikeda 2012; Tanaka et al. 2008). The C. glutamicum strain has been reported to have its specific PTS for glucose, which consists of glucose-specific EII component (EIIGlc) encoded by ptsG (CGS9114_RS14440) and the two general components EI and HPr encoded by ptsI (CGS9114_RS11050) and ptsH (CGS9114_RS11070), respectively. Except for ptsG, ptsI and ptsH are both under the negative regulation of FruR regulator. Considering the clearly increased glucose consumption in the evolved strain (Figs. 3 and 4), the intergenic SNP might influence the glucose transport by regulating the transcriptional activities of the glucose-PTS system.

Table 2 also shows that one intragenic deletion was within CGS9114_RS03450 which encodes E1 subunit of the 2-oxoglutarate dehydrogenase complex (ODHC). ODHC is a key enzyme associated with glutamic acid production, which located at the branch point between the TCA cycle and the glutamate biosynthesis pathway (Asakura et al. 2007; Kim et al. 2009). In the original strain, CGS9114_RS03450 is a pseudogene with total length of 3667 bp, which partly blocks the TCA cycle and is beneficial for carbon source flowing into glutamic acid production. Nevertheless, in the evolved strain, the single nucleotide deletion at the position 140 of CGS9114_RS03450 led it to be a normal gene. It might result in the 2-oxoglutarate competition by the functional ODHC with glutamate dehydrogenase at this branch point, making less carbon source direction toward glutamate biosynthesis, which is consistent with the result of the lower accumulation of glutamic acid in the evolved strain in synthetic medium (Fig. 3).

Transcriptional analysis by qRT-PCR

To determine whether the glucose specific PTS transport was affected by the intergenic SNP, the quantitative real-time PCR (qRT-PCR) was performed on the glucose-PTS related genes. As shown in Fig. 5, the transcriptional regulator gene fruR (CGS9114_RS11055) which probably directly regulated by the intergenic SNP was highly repressed (close to zero expression). Among the three key glucose-PTS genes, ptsG (CGS9114_RS14440) and ptsH (CGS9114_RS11070) were not significantly changed at the transcriptional level; however, for the ptsI (CGS9114_RS11050), it showed obviously upregulated expression with 2.24-fold change. This data suggested that the intergenic mutation in the promoter region might function via two patterns: firstly, depressing the expression of gene fruR and then releasing the negative regulation on genes ptsH and ptsI, and secondly, directly affecting the promoter of gene ptsI and then regulating its transcriptional level.

Metabolic pathway of the central carbon metabolism in the evolved C. glutamicum S9114. Black dash arrowed line indicates the negative regulation of FruR regulator on the glucose-PTS transport. The value in parentheses indicates the fold change of the gene expression for the evolved strain compared to the original strain. Red and green indicate upregulation and downregulation respectively with a fold change between 1.5-fold and 2-fold; bold colored with red and green indicates the levels changed significantly with a fold change greater than 2-fold. Blue triangle indicates key reactions for NAD(P)H regeneration (color figure online)

Since the glucose-PTS gene ptsI was highly upregulated in the evolved strain which might affect the glucose transport and further cause accelerated glucose consumption, the expression of the central carbon metabolism was also investigated at the transcriptional level. Figure 5 shows that most of the glycolytic genes were not differentially expressed compared to the original strain, except for the glyceraldehyde-3-phosphate dehydrogenase gene (CGS9114_RS09335) which was upregulated by 2.23-fold. Pentose phosphate pathway (PPP)-related genes, including glucose-6-phosphate dehydrogenase gene (CGS9114_RS06460), 6-phosphogluconate dehydrogenase gene (CGS9114_RS07055), transketolase gene (CGS9114_RS06470), and transaldolase gene (CGS9114_RS06465), all showed upregulated expression with 2.02-, 1.50-, 1.48-, and 1.79-fold changes, respectively. Figure 5 also indicates that the TCA cycle was slightly enhanced and the glyoxylate cycle was inhibited, such that isocitrate dehydrogenase gene (CGS9114_RS02730), 2-oxoglutarate dehydrogenase E1 component gene (CGS9114_RS03450), and succinate dehydrogenase genes (CGS9114_RS04935, CGS9114_RS04940) were upregulated, while isocitrate lyase gene (CGS9114_RS09005) and malate synthase gene (CGS9114_RS09010) were both downregulated. Consistent with the fermentation observation of the lower glutamic acid accumulation for the evolved strain in the synthetic medium (Fig. 3), glutamate dehydrogenase genes CGS9114_RS07420 and CGS9114_RS12025 were all highly downregulated.

Discussion

In the present study, the adaptive evolution strategy was developed by successively culturing the industrial strain C. glutamicum S9114 in fresh corn stover hydrolysate (15%, w/w). After approximately 4 months of serial transferring, the evolved strain presented obvious improvement in glucose metabolism and inhibitor conversion rate to the six model inhibitor compounds, including furfural, HMF, vanillin, syringaldehyde, 4-hydroxybenzaldehyde, and acetic acid. As a result of the enhanced inhibitor tolerance, glutamic acid production of the evolved strain in the non-detoxified hydrolysate was significantly increased as well, with the concentration of 22.4 g/L under penicillin-trigger condition, and this is the very meaningful result of cellulosic glutamic acid production using the practical lignocellulose feedstock. This study demonstrated that adaptive evolution is a powerful tool for robust C. glutamicum strain development, especially for multiple inhibitor-stress tolerance improvement.

Genome re-sequencing analysis revealed that the intergenic SNP within CGS9114_RS11050 and CGS9114_RS11055 might be responsible for the accelerated glucose consumption in the evolved strain. As illustrated in Fig. 5, transcriptional analysis confirmed that the intergenic SNP promoted the glucose transport in C. glutamicum through upregulating ptsI (CGS9114_RS11050). The upregulation of the glucose transport in the evolved strain could further reprogram the transcription profile and alter metabolic pathways. The earlier steps of glycolysis for catalyzing glucose to glyceraldehyde-3-phosphate maintained constant, while the PPP pathway was highly upregulated, suggesting that more glucose was probably metabolized via the PPP pathway in the evolved strain which is consistent with the accelerated glucose consumption as shown in Figs. 3 and 4. On the other hand, the upregulation of ptsI which catalyzes phosphoenolpyruvate to pyruvate would inevitably lead to the accumulation of pyruvate. The enhanced intracellular pyruvate pool possibly resulted in increased activities of lactate dehydrogenase and drove more carbon flux toward lactic acid (Mei et al. 2016), leading to a reduced glutamic acid production (Fig. 3b). In fact, we had observed that the lactate dehydrogenase gene (CGS9114_RS02700) was upregulated (2.21-fold) in the evolved strain (data not shown). Considering the lower cell mass on the evolved strain even with the faster glucose consumption (Fig. 3), one reason might be highly related to the by-product production of lactic acid. In addition, we also supposed that the evolved strain might be much more suitable under the inhibitor condition than the synthetic medium condition after the long-term adaptation in the hydrolysate.

In addition, the deletion mutation within CGS9114_RS03450 with encoding the E1 component of ODHC made this original pseudogene to be a normal gene, which could compete for 2-oxoglutarate with glutamate biosynthesis and redistribute metabolic pathways as well. Transcriptional analysis (Fig. 5) further revealed that the mutated CGS9114_RS03450 and other TCA cycle-related genes in the evolved strain were upregulated, and the glutamate dehydrogenase genes were repressed, indicating that more glucose was shifted to the TCA cycle while glutamic acid biosynthesis was partly blocked. Therefore, when cultured in the simplified synthetic medium without inhibitor addition, the evolved strain showed accelerated glucose consumption and lower glutamic acid production compared to the original strain (Fig. 3). However, when cultured in the liquid corn stover hydrolysate with penicillin induction, much more glutamic acid was accumulated (Fig. 4). It is probably because the activity of the normal ODHC in the evolved strain was severely reduced by the oxoglutarate dehydrogenase inhibitor protein OdhI (CGS9114_RS07110) which was significantly increased upon penicillin treatment as reported in previous studies (Kim et al. 2010; Schultz et al. 2007), and then the carbon metabolic flux more likely directed to glutamic acid biosynthesis again. This phenomenon makes the evolved strain very suitable for glutamic acid production using the non-detoxified lignocellulose hydrolysate.

Gene expression analysis indicated that the accelerated glucose consumption strengthened the PPP pathway in the evolved strain. The key gene responsible for NAD(P)H regeneration in this process, glucose-6-phosphate dehydrogenase gene (CGS9114_RS06460), as well as glyceraldehyde-3-phosphate dehydrogenase gene (CGS9114_RS09335) in glycolysis were both obviously upregulated by more than 2-fold, and therefore, it could supply sufficient cofactors needed for the reduction conversion of furan aldehyde and phenolic aldehyde inhibitors (Gorsich et al. 2006; Liu 2011; Nguyen et al. 2014; Wang et al. 2017). Other than the NAD(P)H regeneration, the CGS9114_RS02660, being directly regulated by McbR and encoding homoserine O-acetyltransferase in the methionine biosynthesis, was upregulated by 5.48-fold in the evolved strain (data not shown), indicating that the mutant regulator McbR probably promotes the S-adenosylmethionine biosynthesis and further improves the inhibitor tolerance individually or synergistically with the accelerated NAD(P)H production (Miller et al. 2009). Another mutated gene CGS9114_RS08730 (Table 2) which probably protect the cell against environmental stress might also play important roles in inhibitor tolerance improvement in the evolved strain, as the stress tolerance of strain is always the results of multi-gene regulation.

In conclusion, a robust industrial strain C. glutamicum for glutamic acid production was successfully developed by adaptive evolution approach with high tolerance to different inhibitors from pretreated lignocellulosic feedstocks. Genome re-sequencing and transcriptional analysis were performed to determine the underlying genetic changes responsible for the improvement inhibitor tolerance and fermentation performance in the evolved strain. Further works such as overexpression or co-overexpression of different mutant relevant genes, as well as directly introducing the mutations in the original strain or reverting to the wild-type allele in the evolved strain, should be performed to fully understand the mechanisms involved in the phenotypes alteration. However, the mutated genes identified in the present study can be considered as the candidate genes for robust strains modification in the future. The present study also provided a practical method for improving fermentability of microorganisms used in industrial lignocellulose biorefinery.

References

Adney B, Baker J (1996) Measurement of cellulase activities: laboratory analytical procedure (LAP). LAP-006. National Renewable Energy Laboratory, Golden

Almeida JRM, Modig T, Petersson A, Hahn-Hagerdal B, Liden G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82(4):340–349. https://doi.org/10.1002/jctb.1676

Ambro L, Pevala V, Bauer J, Kutejova E (2012) The influence of ATP-dependent proteases on a variety of nucleoid-associated processes. J Struct Biol 179(2):181–192. https://doi.org/10.1016/j.jsb.2012.05.018

Arense P, Bernal V, Iborra JL, Cánovas M (2010) Metabolic adaptation of Escherichia coli to long-term exposure to salt stress. Process Biochem 45(9):1459–1467. https://doi.org/10.1016/j.procbio.2010.05.022

Asakura Y, Kimura E, Usuda Y, Kawahara Y, Matsui K, Osumi T, Nakamatsu T (2007) Altered metabolic flux due to deletion of odhA causes L-glutamate overproduction in Corynebacterium glutamicum. Appl Environ Microbiol 73(4):1308–1319. https://doi.org/10.1128/AEM.01867-06

Barrick JE, Colburn G, Deatherage DE, Traverse CC, Strand MD, Borges JJ, Knoester DB, Reba A, Meyer AG (2014) Identifying structural variation in haploid microbial genomes from short-read resequencing data using breseq. BMC Genomics 15(1):1039. https://doi.org/10.1186/1471-2164-15-1039

Becker J, Wittmann C (2012) Bio-based production of chemicals, materials and fuels—Corynebacterium glutamicum as versatile cell factory. Curr Opin Biotechnol 23(4):631–640. https://doi.org/10.1016/j.copbio.2011.11.012

Gerstmeir R, Wendisch VF, Schnicke S, Ruan H, Farwick M, Reinscheid D, Eikmanns BJ (2003) Acetate metabolism and its regulation in Corynebacterium glutamicum. J Biotechnol 104(1–3):99–122. https://doi.org/10.1016/S0168-1656(03)00167-6

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59(2):257–268. https://doi.org/10.1351/pac198759020257

Gopinath V, Meiswinkel TM, Wendisch VF, Nampoothiri KM (2011) Amino acid production from rice straw and wheat bran hydrolysates by recombinant pentose-utilizing Corynebacterium glutamicum. Appl Microbiol Biotechnol 92(5):985–996. https://doi.org/10.1007/s00253-011-3478-x

Gorsich SW, Dien BS, Nichols NN, Slininger PJ, Liu ZL, Skory CD (2006) Tolerance to furfural-induced stress is associated with pentose phosphate pathway genes ZWF1, GND1, RPE1, and TKL1 in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 71(3):339–349. https://doi.org/10.1007/s00253-005-0142-3

Gu H, Zhang J, Bao J (2014) Inhibitor analysis and adaptive evolution of Saccharomyces cerevisiae for simultaneous saccharification and ethanol fermentation from industrial waste corncob residues. Bioresour Technol 157:6–13. https://doi.org/10.1016/j.biortech.2014.01.060

He YQ, Zhang J, Bao J (2014) Dry dilute acid pretreatment by co-currently feeding of corn stover feedstock and dilute acid solution without impregnation. Bioresour Technol 158:360–364. https://doi.org/10.1016/j.biortech.2014.02.074

Hou XH, Zhang JQ, Song XY, Ma XB, Zhang SY (2014) Contribution of ClpP to stress tolerance and virulence properties of Streptococcus mutans. J Basic Microbiol 54(11):1222–1232. https://doi.org/10.1002/jobm.201300747

Ikeda M (2012) Sugar transport systems in Corynebacterium glutamicum: features and applications to strain development. Appl Microbiol Biotechnol 96(5):1191–1200. https://doi.org/10.1007/s00253-012-4488-z

Jönsson LJ, Alriksson B, Nilvebrant NO (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6(1):16. https://doi.org/10.1186/1754-6834-6-16

Kanna M, Matsumura Y (2015) Effect of low-concentration furfural on sulfur amino acid biosynthesis in Saccharomyces cerevisiae. J Jpn Petrol Inst 58(3):165–168. https://doi.org/10.1627/jpi.58.165

Kim J, Fukuda H, Hirasawa T, Nagahisa K, Nagai K, Wachi M, Shimizu H (2010) Requirement of de novo synthesis of the OdhI protein in penicillin-induced glutamate production by Corynebacterium glutamicum. Appl Microbiol Biotechnol 86(3):911–920. https://doi.org/10.1007/s00253-009-2360-6

Kim J, Hirasawa T, Sato Y, Nagahisa K, Furusawa C, Shimizu H (2009) Effect of odhA overexpression and odhA antisense RNA expression on Tween-40-triggered glutamate production by Corynebacterium glutamicum. Appl Microbiol Biotechnol 81(6):1097–1106. https://doi.org/10.1007/s00253-008-1743-4

Kinoshita S, Udaka S, Shimono M (2004) Studies on the amino acid fermentation. Part 1. Production of L-glutamic acid by various microorganisms. J Gen Appl Microbiol 50(6):331–343 PMID: 15965888

Koppram R, Albers E, Olsson L (2012) Evolutionary engineering strategies to enhance tolerance of xylose utilizing recombinant yeast to inhibitors derived from spruce biomass. Biotechnol Biofuels 5(1):32. https://doi.org/10.1186/1754-6834-5-32

Li H (2013) Aligning sequence reads, clone sequences and assembly contigs with BWA-MEM. ArXiv preprint. arXiv:1303.3997v2 [q-bio.GN]

Li X, Pei G, Liu L, Chen L, Zhang W (2017) Metabolomic analysis and lipid accumulation in a glucose tolerant Crypthecodinium cohnii strain obtained by adaptive laboratory evolution. Bioresour Technol 235:87–95. https://doi.org/10.1016/j.biortech.2017.03.049

Liu ZL (2011) Molecular mechanisms of yeast tolerance and in situ detoxification of lignocellulose hydrolysates. Appl Microbiol Biotechnol 90(3):809–825. https://doi.org/10.1007/s00253-011-3167-9

Lv Y, Wu Z, Han S, Lin Y, Zheng S (2011) Genome sequence of Corynebacterium glutamicum S9114, a strain for industrial production of glutamate. J Bacteriol 193(21):6096–6097. https://doi.org/10.1128/JB.06074-11

Mei J, Xu N, Ye C, Liu L, Wu J (2016) Reconstruction and analysis of a genome-scale metabolic network of Corynebacterium glutamicum S9114. Gene 575(2(2):615–622. https://doi.org/10.1016/j.gene.2015.09.038

Miller EN, Jarboe LR, Turner PC, Pharkya P, Yomano LP, York SW, Nunn D, Shanmugam KT, Ingram LO (2009) Furfural inhibits growth by limiting sulfur assimilation in ethanologenic Escherichia coli strain LY180. Appl Environ Microbiol 75(19):6132–6141. https://doi.org/10.1128/AEM.01187-09

Mills TY, Sandoval NR, Gill RT (2009) Cellulosic hydrolysate toxicity and tolerance mechanisms in Escherichia coli. Biotechnol Biofuels 2(1):26. https://doi.org/10.1186/1754-6834-2-26

Mohagheghi A, Linger JG, Yang SH, Smith H, Dowe N, Zhang M, Pienkos PT (2015) Improving a recombinant Zymomonas mobilis strain 8b through continuous adaptation on dilute acid pretreated corn stover hydrolysate. Biotechnol Biofuels 8(1):55. https://doi.org/10.1186/s13068-015-0233-z

Mundhada H, Miguel JS, Schneider K, Koza A, Christensen HB, Klein T, Phaneuf PV, Herrgard M, Feist AM, Nielsen AT (2017) Increased production of L-serine in Escherichia coli through adaptive laboratory evolution. Metab Eng 37:141–150. https://doi.org/10.1016/j.ymben.2016.11.008

Nakayama K, Kitada S, Kinoshita S (1961) Studies on lysine fermentation I. The control mechanism on lysine accumulation by homoserine and threonine. J Gen Appl Microbiol 7(3):145–154. https://doi.org/10.2323/jgam.7.145

Nara T, Samejima H, Kinoshita S (1964) Effect of penicillin on amino acid fermentation. Agric Biol Chem 28(2):120–124. https://doi.org/10.1080/00021369.1964.10858215

Nguyen TT, Kitajima S, Izawa S (2014) Importance of glucose-6-phosphate dehydrogenase (G6PDH) for vanillin tolerance in Saccharomyces cerevisiae. J Biosci Bioeng 118(3):263–269. https://doi.org/10.1016/j.jbiosc.2014.02.025

Qin D, Hu Y, Cheng J, Wang N, Li S, Wang D (2016) An auto-inducible Escherichia coli strain obtained by adaptive laboratory evolution for fatty acid synthesis from ionic liquid-treated bamboo hydrolysate. Bioresour Technol 221:375–384. https://doi.org/10.1016/j.biortech.2016.09.024

Qureshi AS, Zhang J, Bao J (2015) High ethanol fermentation performance of the dry dilute acid pretreated corn stover by an evolutionarily adapted Saccharomyces cerevisiae strain. Bioresour Technol 189:399–404. https://doi.org/10.1016/j.biortech.2015.04.025

Rajaraman E, Agarwal A, Crigler J, Seipelt-Thiemann R, Altman E, Eiteman MA (2016) Transcriptional analysis and adaptive evolution of Escherichia coli strains growing on acetate. Appl Microbiol Biotechnol 100(17):7777–7785. https://doi.org/10.1007/s00253-016-7724-0

Reumerman RA, Tucker NP, Herron PR, Hoskisson PA, Sangal V (2013) Tool for rapid annotation of microbial SNPs (TRAMS): a simple program for rapid annotation of genomic variation in prokaryotes. Antonie Van Leeuwenhoek 104(3):431–434. https://doi.org/10.1007/s10482-013-9953-x

Rey DA, Nentwich SS, Koch DJ, Ruckert C, Puhler A, Tauch A, Kalinowski J (2005) The McbR repressor modulated by the effector substance S-adenosylhomocysteine controls directly the transcription of a regulon involved in sulphur metabolism of Corynebacterium glutamicum ATCC 13032. Mol Microbiol 56(4):871–887. https://doi.org/10.1111/j.1365-2958.2005.04586.x

Rey DA, Pühler A, Kalinowski J (2003) The putative transcriptional repressor McbR, member of the TetR-family, is involved in the regulation of the metabolic network directing the synthesis of sulfur containing amino acids in Corynebacterium glutamicum. J Biotechnol 103(1):51–65. https://doi.org/10.1016/S0168-1656(03)00073-7

Rumbold K, van Buijsen HJ, Overkamp KM, van Groenestijn JW, Punt PJ, van der Werf MJ (2009) Microbial production host selection for converting second-generation feedstocks into bioproducts. Microb Cell Factories 8(1):64. https://doi.org/10.1186/1475-2859-8-64

Sakai S, Tsuchida Y, Nakamoto H, Okino S, Ichihashi O, Kawaguchi H, Watanabe T, Inui M, Yukawa H (2007) Effect of lignocellulose-derived inhibitors on growth of and ethanol production by growth-arrested Corynebacterium glutamicum R. Appl Environ Microbiol 73(7):2349–2453. https://doi.org/10.1128/AEM.02880-06

Sauer U (2001) Evolutionary engineering of industrially important microbial phenotypes. Adv Biochem Eng Biotechnol 73:129–169 11816810

Schultz C, Niebisch A, Gebel L, Bott M (2007) Glutamate production by Corynebacterium glutamicum: dependence on the oxoglutarate dehydrogenase inhibitor protein OdhI and protein kinase PknG. Appl Microbiol Biotechnol 76(3):691–700. https://doi.org/10.1007/s00253-007-0933-9

Shen XH, Zhou NY, Liu SJ (2012) Degradation and assimilation of aromatic compounds by Corynebacterium glutamicum: another potential for applications for this bacterium? Appl Microbiol Biotechnol 95(1):77–89. https://doi.org/10.1007/s00253-012-4139-4

Shui ZX, Qin H, Wu B, Ruan ZY, Wang LS, Tan FR, Wang JL, Tang XY, Dai LC, GQ H, He MX (2015) Adaptive laboratory evolution of ethanologenic Zymomonas mobilis strain tolerant to furfural and acetic acid inhibitors. Appl Microbiol Biotechnol 99(13):5739–5748. https://doi.org/10.1007/s00253-015-6616-z

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2012) Determination of structural carbohydrates and lignin in biomass. LAP NREL/TP510-42618. National Renewable Energy Laboratory, Golden

Takinami K, Yoshii H, Tsuri H, Okada H (1965) Biochemical effects of fatty acid and its derivatives on L-glutamic acid fermentation. Part III. Biotin-Tween 60 relationship in the accumulation of L-glutamic acid and the growth of Brevibacterium lactofermentum. Agric Biol Chem 29:351–359

Tanaka Y, Okai N, Teramoto H, Inui M, Yukawa H (2008) Regulation of the expression of phosphoenolpyruvate: carbohydrate phosphotransferase system (PTS) genes in Corynebacterium glutamicum R. Microbiology 154(1):264–274. https://doi.org/10.1099/mic.0.2007/008862-0

Taylor MP, Mulako I, Tuffin M, Cowan D (2012) Understanding physiological responses to pre-treatment inhibitors in ethanologenic fermentations. Biotechnol J 7(9):1169–1181. https://doi.org/10.1002/biot.201100335

Tsuge Y, Hori Y, Kudou M, Ishii J, Hasunuma T, Kondo A (2014) Detoxification of furfural in Corynebacterium glutamicum under aerobic and anaerobic conditions. Appl Microbiol Biotechnol 98(20):8675–8683. https://doi.org/10.1007/s00253-014-5924-z

Wallace-Salinas V, Gorwa-Grauslund MF (2013) Adaptive evolution of an industrial strain of Saccharomyces cerevisiae for combined tolerance to inhibitors and temperature. Biotechnol Biofuels 6(1):151. https://doi.org/10.1186/1754-6834-6-151

Wang C, Zhang H, Cai H, Zhou Z, Chen Y, Chen Y, Ouyang P (2014) Succinic acid production from corn cob hydrolysates by genetically engineered Corynebacterium glutamicum. Appl Biochem Biotechnol 172(1):340–350. https://doi.org/10.1007/s12010-013-0539-x

Wang X, Gao Q, Bao J (2017) Enhancement of furan aldehydes conversion in Zymomonas mobilis by elevating dehydrogenase activity and cofactor regeneration. Biotechnol Biofuels 10(1):24. https://doi.org/10.1186/s13068-017-0714-3

Xu H, Wang C, Zhou Z, Chen Z, Cai H (2015) Effects of lignocellulose-derived inhibitors on growth and succinic acid accumulation by Corynebacterium glutamicum. Biotechnol Bioprocess Eng 20(4):744–752. https://doi.org/10.1007/s12257-015-0201-2

Zhang HS, Zhang J, Bao J (2016) High titer gluconic acid fermentation by Aspergillus niger from dry dilute acid pretreated corn stover without detoxification. Bioresour Technol 203:211–219. https://doi.org/10.1016/j.biortech.2015.12.042

Funding

This research was supported by the Natural Science Foundation of China (31300070).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

This study does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 231 kb)

Rights and permissions

About this article

Cite this article

Wang, X., Khushk, I., Xiao, Y. et al. Tolerance improvement of Corynebacterium glutamicum on lignocellulose derived inhibitors by adaptive evolution. Appl Microbiol Biotechnol 102, 377–388 (2018). https://doi.org/10.1007/s00253-017-8627-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8627-4