Abstract

The use of fruits, legumes, and ancient grains for bread-making applications is receiving particular attention, since they involve nutrient dense grains with proven health-promoting attributes. Dilution by 34% of the basic wheat flour matrix by accumulative ternary addition of heat-moisture-treated teff, chestnut, and chickpea flours did significantly impact both the extractability and the distribution of lipid subfractions in composite flours, doughs, and breads, and induced dynamics in lipid binding over mixing, fermentation, and baking steps. A preferential covalent lipid binding to the inside part of the starch granules takes place sequentially during bread-making steps at the expenses of both accessible free lipids and lipids initially bound non-covalently to the gluten/non-gluten proteins and to the outside part of the starch granules. Larger accumulation of starch lipids over mixing encompassed smaller extent of starch hydrolysis in fresh breads and smaller slowly digestible starch formation, while higher increase of starch lipids after fermentation and baking led to a bigger extent of starch digestibility and to a more prominent formation of slowly digestible starch fraction but to lower volume in fresh breads. Extensive binding of either protein bounded lipids or free lipids over fermentation and baking provided breads with promoted specific volume and anti-radical activity and slower retrogradation kinetics on ageing, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Grain lipids constitute a complex family of compounds, present both as free and bound to protein and starch biopolymers and other constituents in the grain matrix. In bread-making applications, lipids play a key role from both technological and nutritional points of view, affecting storage stability because of their ability to associate with proteins, due to their amphipathic nature, and with starch, forming inclusion complexes [1]. Amylose–lipid complexation can prevent the co-crystallization of amylose with amylopectin, and lipids can also complex with the outer branches of amylopectin, so that inhibiting starch retrogradation directly [2].

In conventional wheat flour breadmaking, protein and starch lipid binding in both wheat flour and additive-bread systems have been reported to significantly correlate with loaf volume, crumb structure, and texture of bread [3]. At dough level and in presence of surfactants, free and bound lipids preferentially bind to gluten (monoglycerides) and to the outside part of the starch granules (cationic surfactants). Hydrocolloids preferentially bound to the gluten and to the outside part of the starch granules depending on their polarity [4]. In wheat bread, a preferential binding of the added anionic surfactant to the starch with a concomitant displacement of endogenous polar lipids from starch to gluten was observed [5].

The endogenous lipids and gluten proteins act synergistically to stabilize the gas cells during fermentation [6]. In diluted wheat flour systems by the addition of non-gluten forming grain flours, lipid binding takes place to both gluten and non-gluten proteins and to mixed starches during bread-making stages. In single and blended oat, rye, buckwheat, and wheat flour matrices, lipids bound to proteins during dough mixing are translocated and bound to starch during baking. Starch lipids showed the most significant correlations with parameters related to dough and bread performance during breadmaking, especially over the mixing step [3]. In complex grain flour matrices, during baking, lipids bind to the gluten/non-gluten proteins at the expenses of both a free lipid displacement and a lipid migration from the inside part of the starch granules to the protein active sites [7, 8].

Heat-moisture treatment (HMT) of associated nutrient dense non-wheat flours appears as a clean label simple strategy to create added value to breads from highly diluted wheat flour matrices, provided that single and interactive effects of the thermal treatment of blended flours on the structural features of breads are known [9]. Non-wheat flours submitted to HMT exhibited structural changes in protein and starch biopolymers [10] that are expected to impact on the lipid redistribution in doughs and breads thereof. The significance of the thermal treatment on lipid binding has not been explored yet.

This research is aimed at characterizing the lipid fractions at flour, dough, and bread stages of blended teff, chestnut, and chickpea added to a wheat flour matrix, prior to analyze the impact of the pool of free lipids and the starch- and protein–lipid binding along the bread-making steps on the physico-chemical, nutritional, and thermal properties of composite matrices.

Materials and methods

Materials

Commercial flours from refined common wheat Triticum aestivum (WT), teff Eragrostis tef (TF), chestnut Castanea sativa (CN), and whole chickpea Cicer arietinum (CP) were obtained from the Spanish market. Refined WT (70% extraction rate) of 195 × 10−4 J energy of deformation W, 0.57 curve configuration ratio P/L, and 58.8% water absorption in Brabender Farinograph was used. Carboxymethylcellulose Aquasorb® A-500 (CMC) was bought from Copenhagen Pectin (Denmark), and commercial wheat sour dough pie was kindly supplied by Ireks (Spain).

Methods

Heat-moisture treatment (HMT) of flours

HMT conditions (15% moisture content, 1 h and 120 °C) were selected based on the previous experiments [9], in which maximization of visco-metric profile and minimization of loss of hydration properties of flour samples were applied as criteria. Single TF, CN, and CP flour samples were thermally treated. Untreated (−) and HMT (+) single flours were used in quaternary blends (T:CN:CP:WT) in the presence of WT—for dough-making.

Chemical and nutritional characteristics of native and HMT flours

Moisture, protein, dietary fibre, and fat contents (% flour, dry basis) of native (untreated) and HMT single WT, T, CN, and CP flours (Table 1) were determined following the ICC methods [11]. Two replicates were made for each analysis. Starch content of flours was determined using total Starch Assay Kit (Megazyme kit AA/AMG).

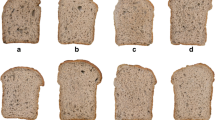

Breadmaking of wheat and wheat-based blended flours

Doughs and breads were prepared from wheat-based blended flours (T, CN, CP) by WT replacement at 34%, and incorporation of ternary blends of T (20%, flour basis), CN (7%, flour basis) and CP (7%, flour basis) flours according to a multilevel factorial design with the following attributes: three experimental factors (TF, CN, and CP flours) at two levels, coded 0 (untreated) and 1 (HMT), and 5 error degrees of freedom. The model resulted in eight randomized runs in one block. A three-digit bread sample code was set referring to no HMT (0) and HMT (1) TF (first digit), CN (second digit), and CP (third digit) flours in sample formulation, as it follows: 110, 101,100, 000, 001, 111, 010, and 011. Blended flours (100 g), water (100%, flour basis), commercial compressed yeast (3%, flour basis), salt (2%, flour basis), commercial sour dough pie (5%, flour basis), and CMC (3%, flour basis) were mixed in a 10 kg mixer at 60 rev/min for 10 min up to optimum dough development. 6 kg of blended flours were used per trial. Fermented doughs were obtained after bulk fermentation (10 min at 28 °C), dividing (300 g), rounding, moulding, panning, and proofing up to maximum volume increment (50 min at 28 °C), and were baked at 225 °C for 25 min to make blended breads. 40 bread loaves were obtained per trial, and stored for 0, 1, 3, 6, and 8 days to study kinetics of thermal transitions on ageing. Two trials were made per formulation.

Bread volume

Loaf volume was determined by the rapeseed displacement method as used and data compiled previously [12]. Specific loaf volume was calculated dividing the loaf volume by the corresponding loaf weight.

Starch digestibility and anti-radical activity

In vitro starch hydrolysis kinetics and relevant starch fractions in freeze-dried and ground fresh blended breads was determined previously adapted and described [13]. Rapidly Digestible Starch (RDS) and Slowly Digestible Starch (SDS) were measured after incubation for 20 min and 120 min, respectively. Digestible starch (DS) was calculated by the sum of RDS and SDS. Total starch (TS) was calculated by the sum of DS and RS. A first-order kinetic equation [C = C∞ (1 − e−kt)] was applied to describe the kinetics of starch hydrolysis, where C, C∞, and k were the hydrolysis degree at each time, the maximum hydrolysis extent, and the kinetic constant, respectively. Resistant starch (RS) determination was performed according to AACC Method 32–40. Three replicates were made per analysis.

The stable 2,2-diphenyl-1-picrylhydrazyl (DPPH•) radical was used to measure the radical scavenging capacity of the bioaccessible polyphenol enzymatic extracts of bread samples according to the DPPH• method adapted and described previously [12]. Readings were taken from two replicates per sample. Plots of μmol DPPH vs time (min) were drawn, and calculations were made to know the anti-radical activity (ARA), ARA = [([DPPH]INITIAL − [DPPH]PLATEAU) × 100]/[DPPH]INITIAL.

Thermal measurements and retrogradation kinetics

Thermal properties regarding starch retrogradation of control and blended samples were assessed in a Differential Scanning Calorimeter Perkin-Elmer DSC-7 (Norwalk, USA) as previously reported [14]. Stored gelatinized dough samples were submitted to a second DSC scan to analyze starch retrogradation at the different storage periods. Scanning conditions included keeping sample pans at 25 °C for 1 min, and then heating from 25 to 130 °C at a rate of 10 °C/min. The enthalpy of amylopectin retrogradation (ΔHr) was calculated, and To, Tp, and Te for the thermal transitions, identified. All samples were analyzed in duplicate. Modelling of crystallization data was carried out using the Avrami equation, and model factors were estimated by fitting experimental data for melting enthalpies to the nonlinear regression equation:

where Θ is crystallinity, H∞, is the levelling-off value of melting enthalpy at which the extent of crystallization in starch stoped, Ht is the melting enthalpy at time t, and Ho is the melting enthalpy at initial time, t is time of crystallization, k is a rate constant, and n is the Avrami exponent.

Lipid determinations

Flour, dough, and bread free lipids (FL)

Flour (10 g), ground freeze-dried dough (10 g), and ground freeze-dried bread (20 g) samples were extracted with light petroleum ether under reflux conditions for 90 min in a soxhlet [15]. The solvent was removed under vacuum and the extracts were determined gravimetrically. Determinations were made per duplicate.

Flour and dough bound lipids (BL)

Residues of the FL extraction were extracted with chloroform under reflux conditions [15] to obtain total bound lipids (non-covalent forces) to both starch and proteins (BL). Determinations were made per duplicate.

Bread protein-bound lipids (PBL)

Residues of FL extraction (10 g) were treated with 100 mL 1% pepsin in 50 mM sulphuric acid, (pH 1.6) and gently stirred for 4 h at 40 °C [5]. This fraction specifically refers to lipids easily or strongly bound to proteins. Determinations were made per duplicate.

Starchy lipids (SL)

Flour and dough starchy lipids were obtained by acid hydrolysis of the non-starchy lipid-free residue (ICC 136) [11]. This fraction specifically refers to lipids covalently bound to starch. Determinations were made per duplicate.

Bread starch-bound lipids (SBL)

Residues of FL extraction (10 g) were reacted with 100 mL 0.5% α-amylase in 10 mM NaH2PO4, (pH 6.5) and gently stirred for 4 h at 70°C. When the reaction was completed, 100 mL of Cl3CH were added, and the mixture stirred for 1 h at room temperature and centrifuged. Supernatants were washed with 5% NaCl, the solvent removed, weighed (SBL), and stored under nitrogen until analysis [5]. This fraction specifically refers to lipids easily or strongly bound to starch granules either by non-covalent (outside) or by covalent forces (inside). Determinations were made per duplicate.

Total lipids were indirectly determined by the addition of FL+BL+SL amounts retrieved in flours and doughs, and by the addition of FL+PBL+SBL levels determined in breads. All lipid fractions and subfractions’ contents were expressed in g/100 g flour basis, as is.

Statistical analysis

Multivariate analysis of variance and correlation matrix of data were performed using Statgraphics V.7.1 program (Bitstream, Cambridge, MN). Multiple range test (Fisher’s least significant differences, LSD) for analytical variables was applied to know the difference between each pair of means.

Results and discussion

Plural physico-chemical and biochemical approaches have been performed (a) to know the qualitative and quantitative profiles of endogenous lipid fractions of single and multigrain flour, dough, and bread matrices and (b) to link lipid binding along bread-making steps to physical, nutritional, and starch retrogradation kinetics parameters in fresh and aged composite bread matrices.

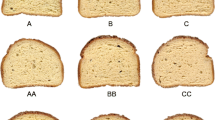

Lipid extractability and distribution in single and multigrain flour, dough, and bread samples

Data for extractability (g/100 g flour) and distribution (% of total lipids) of lipid fractions and subfractions from untreated and HMT single and blended flour, dough, and bread samples are reported in Figs. 1 and 2. Total lipids (g/100 g flour basis) in single flours ranged from 2.263 g (WT) to 6.902 g (CP) in untreated samples, and from 2.078 g (WT+) to 7.260 g (CP+) in HMT samples, with no significant changes on thermal treatment for TF and CN flours with intermediate total lipid contents at about 3.506 g and 4.620 g, respectively (Fig. 1). Main lipid subfractions were FL (> 53%), while BL and SL were lower (< 26%) in all cases, particularly for CP− (8% SL) and TF+ (9% BL). Results are in accordance with those previously found for untreated wheat [4, 5], for chestnut [16], for chickpea [17], and for teff flours [18].

Content (g/100 g flour, d. b.) (left) and percentage distribution (right) of free lipid (FL), bound lipid (BL), starch lipid (SL), protein-bound lipid (PBL), and starch-bound lipid (SBL) of flours (a), doughs (b), and breads (c) from blended wheat-based matrices formulated with teff (TF), chestnut (CN), and chickpea (CP) flours. Three-digit code refers to untreated (0) and heat-moisture-treated (1) TF:CN:CP flours replacing wheat flour in sample formulation

Total lipids of blended HMT materials accounted for 2.894 g (110) to 3.037 g (101) in flours, from 2.562 g (101) to 2.772 g (111) in doughs, and from 2.385 g (001) to 2.766 g (110) in breads, expliciting discreet variation with respect to untreated samples 000 − 2.549 g flour, 2.730 g dough, 2.997 g bread (Fig. 2). FL was the most prominent fraction in terms of absolute content and as a percentage of total lipids in flour and dough samples, whereas starch-bound lipids (SBL) predominated in breads with no exception (Fig. 2). Bound lipids (BL) constituted intermediate lipid fraction in all blended flour matrices and minor fraction in all blended dough matrices, while starchy lipids (SL) accounted for intermediate quantitative lipid fractions in blended doughs and minor in blended flours. FL varied little in blended flours (from 1.819—110 to 1.984—111 g/100 g flour basis), doughs (from 0.997—101 to 1.285—010 g/100 g flour basis, accounting from 39 to 65% of total lipids), and breads (from 0.359—000 to 0.492—101 g/100 g flour basis, accounting from 14 to 18% of total lipids). PBL in breads varied from 12 (000) to 15% (010) of total lipids, while SBL accounted from 67 (001) to 74% (000) of total lipids (Fig. 2).

Incorporation of any HMT non-wheat grain flour significantly changed the quantitative lipid profile of blended flours, doughs, and breads, especially for T+ and CN+ (Table 2). At flour level, blending WT− with either T+ or CN+ promoted the amount of SL by 5–8%, and induced a decline of BL by 5–10%, while CP+ led to a discreet fall in SL by 6% and a promotion of FL by 5% in blended flours. At dough level, a significant (p < 0.05) increase of SL (+11%) and a decrease in BL (− 9%) was provided by blending CP+ or TF+ flours, respectively, in composite doughs. At bread stage, TF+ incorporation favoured accumulation of FL (12%), PBL (9%), and SBL (7%) (Table 2). Simultaneous presence of untreated and HMT non-wheat flours induced significant interactions on major free and bound lipid subfractions of bread-making matrices, particularly for TF/CP and CN/CP (Table 3). Thermally treated T+ (1) in the presence of native CP (0) provided minimum extractability (g/100 g flour) for BL (0.581 g), and maximum for SL in blended flours (0.500 g), Fl (0.454 g), and PBL (0.387 g) in breads (Table 3). In addition, in the presence of native CN (0), thermally treated CP+ (1) maximized extraction of FL in blended flours (1.962 g) and composite breads (0.465 g), while simultaneous presence of CN+/CP-maximized extractability of SL in flours (0.507 g) and PBL in breads (0.383 g).

Lipid binding during mixing, fermentation, and baking of composite matrices

Along bread-making steps—mixing, fermentation and baking-, lipid subfractions of composite matrices underwent significant quantitative changes as a result of a balance between (a) release of protein- and/or starch-bound lipids to the pool of free lipids, (b) binding of free lipids to protein and/or starch, and (c) translocation of protein-bound lipids to starch-bound lipids and/or vice versa.

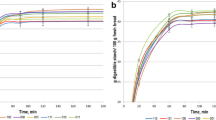

During mixing, a variable depletion of the pool of FL—from − 31% (010) to − 50% (101)—was denoted in composite HMT matrices, in accordance with a discreet variation in BL—from − 2% (110) to − 21% (101)—and a variable notable promotion of SL—from + 60% (110) to + 147% (101)—(Fig. 3). Incorporation of CP+ to blended flours notably enhanced the extent of the changes, encompassing an accumulation 55% higher of SL in doughs at the expenses of a fall by 5% and 17% bigger in the extractability of FL and BL in composite doughs, respectively (Table 2). On the contrary, CN+ mitigated the changes during mixing leading to decreases in the amount of FL and BL, 80% and 45% of the extent that CN− provided, respectively. Simultaneous presence of TF+/CN− or CN+/CP− maximized the depletion in FL (− 50%/− 33%) and BL (− 22%/− 6%) after mixing, while TF+/CP− led to a notable fall in FL (− 45%) and to the greatest accumulation in SL (+ 133%). In wheat flour systems, dough development redistributes almost all polar and part of the non-polar lipids originally present in the flour free lipid extract, probably from lipids interacting with or becoming physically entrapped within the gluten network [19]. It has been reported that when hydrating flour to produce dough, the majority of the lipid classes endogenously present in wheat flour redistribute and lose their extractability with a non-polar solvent within the first 0.5 min. During further mixing, by applying mechanical action on the developing dough, new interactions occur with the gluten fraction, and lipids become entrapped within or interact with the developed gluten network [20]. Around 80% of FL migrated to the active sites of both gluten and starch leading to a notable accumulation of BL and SL in doughs, respectively [8]. In composite matrices, mixing impacted the lipid distribution inducing binding from flour to dough of both FL and BL through a respective sharp decrease up to − 50% in the pool of free lipids and a slight decrease in BL up to − 21%. Concomitantly, a prominent accumulation of SL up to 150% took place in blended doughs (Fig. 3), so that a preferential covalent lipid binding to the inside part of the starch granules takes place during mixing at the expenses of both accessible free lipids and lipids initially bound non-covalently to the gluten/non-gluten proteins and to the outside part of the starch granules. It has been alluded that the binding of free lipids with gluten proteins may provide them with the ability to align at the interface of gas cells during the initial phases of dough mixing and increase gas cell stability throughout the bread-making process [19]. When non-gluten forming flours are added to the bread-making system, interferences in the binding of lipids to main biopolymers—protein, starch—can occur, since original wheat flour system is diluted with other fat, protein, starch, and dietary fibre entities that compete for water and active sites of biomolecules. This is the case of the present flours used, whose chemical composition is particularly rich in fat (T, CP), protein (CP), and dietary fibre (T, CP) (Table 1). In addition, thermal treatment HMT of flours adds complexity to the composite matrices through protein insolubilisation ascribed either to their denaturation/aggregation or covalent crosslinking.

Changes (%) in lipid subfractions free lipids (FL), bound lipids (BL), starch lipids (SL) during mixing (FD) and during fermentation and baking (DB) of blended wheat-based matrices formulated with teff (TF), chestnut (CN), and chickpea (CP) flours. Three-digit code refers to untreated (0) and heat-moisture-treated (1) TF:CN:CP flours replacing wheat flour in sample formulation

After consecutive fermentation and baking steps of composite matrices, a decrease of FL contents from − 51% (101) to − 71% (010), a well as of BL from − 23% (110) to − 46% (000) took place, with a concomitant increase of SL from 71% (111) to 125% (100) (Fig. 3). The presence of TF+ flour moderated the changes in FL and BL, but enhanced those of SBL, while CP+ mitigated SL changes (Table 2). Cooperative presence of either TF+/CN− or TF+/CP− provided minimum depletion in BL (− 25%), and maximum accumulation of SL (+ 99%–+ 119%) (Table 3).

Transformation of dough into bread after successive fermentation and baking steps induced binding of FL and also of BL from dough to bread through a sharp decrease in the pool of FL and BL and a concomitant increase in SBL of mixed breads (Fig. 3). This means that a preferential lipid binding to the outside and inside starch granules takes place during fermentation and later baking at the expenses of both an FL displacement and a BL translocation to new starch active sites. Nature of teff prolamins lower polymerization, hydrophobicity, and denaturation temperature [21] can stimulate lipid binding, particularly for the most accessible fraction (FL). In fact, in WT systems, FL migration takes place mainly to the gluten protein active sites and very little to the starch leading to a discreet accumulation of PBL and a poor increase of SBL from dough to bread [8].

Relationships between lipid dynamics along breadmaking of composite matrices and physico-chemical, nutritional, and thermal properties of fresh and aged breads

It has been demonstrated that surface-active components such as polar lipids stabilize liquid lamellae surrounding gas cells, thus enabling a larger loaf volume [22]. In this work, content (g/100 g flour), and dynamics (%) during mixing, and fermentation/baking of lipid subfractions from HMT flours, doughs, and breads significantly (p < 0.01, < 0.05) correlated (coefficient of correlation, r) with some physical (− 0.8768 < r < 0.5523), nutritional (− 0.8339 < r < 0.8167), and thermal (− 0.7468 < r < 0.7069) features of fresh and aged HMT-blended breads previously obtained [12,13,14] (Table 4). Higher levels of BL determined in doughs corresponded to larger specific volume (r = 0.5523) and anti-radical activity in fresh breads (r = 0.6439), higher maximum enthalpy of retrogradation (r = 0.6667), and slower rate of starch retrogradation (r = − 0.762) on ageing. Concomitantly, increased contents of SL in doughs were consistent with lower extent of starch hydrolysis: C∞ (r = − 0.509), HI (r = − 0.5049), SDS (r = − 0.6816), eGI (r = − 0.5212), AUC (r = − 0.5062), but higher starch retrogradation kinetics n (r= 0.5471).

Dynamics on starch lipids along bread-making steps significantly (p < 0.01) correlated with main nutritional features, while dynamics of free and protein-bonded lipids correlated with specific volume, anti-radical activity of fresh breads, and retrogradation kinetics on ageing (Table 4, Fig. 4). It can be noticed that larger accumulation of SL over mixing encompassed smaller extent of starch hydrolysis in fresh breads (r = − 0.6415) and smaller SDS formation (r = − 0.7655), while higher increase of SL after fermentation and baking led to a bigger extent of starch digestibility (r = 0.8167) and to a more prominent formation of SDS fraction (r = 0.8167), but to lower volume (r = − 0.8768) in fresh breads (Table 4, Fig. 4a, b). The amylose–inclusion complexes that are formed are variably degraded by enzymes. The structural characteristics of the complexes strongly influence their degradability, with more highly crystalline amylose–inclusion complexes having lower digestibilities [23]. Extensive binding of either PBL or FL over fermentation and baking provided breads with promoted specific volume (r = − 0.7319, − 0.5717) and anti-radical activity (r = − 0.6823, − 0.8339) and slower retrogradation kinetics on ageing (r = 0.6459, 0.7069), respectively (Fig. 4). Amylose–lipid complex formation restricts the solubility and mobility of amylose. This, in combination with steric hindrance brought about by complexation, prevents (a) amylose double helix formation and crystallization [24], (b) can prevent the co-crystallization with amylopectin, and (c) lipids can also complex with the outer branches of amylopectin and, as such, inhibit retrogradation in a more direct way [25].

Dependence of specific volume (a), slowly digestible starch SDS (b), anti-radical activity ARA (c), and Avrami exponent of retrogradation nr (d) on the dynamics of free lipids (FL), bound lipids (BL), starch lipids (SL) during mixing (FD) and during fermentation, and baking (DB) of blended wheat-based matrices formulated with teff (TF), chestnut (CN), and chickpea (CP) flours

Conclusions

Dilution by 34% of the basic wheat flour matrix by accumulative ternary addition of heat-moisture-treated teff, chestnut, and chickpea flours did significantly (p < 0.01) impact both the extractability and the distribution of lipid subfractions in composite flours, doughs, and breads, and induced dynamics in lipid binding over mixing, fermentation, and baking steps, in variable extent.

A preferential covalent lipid binding to the inside part of the starch granules takes place during mixing at the expenses of both accessible free lipids and lipids initially bound non-covalently to the gluten/non-gluten proteins and to the outside part of the starch granules. Successive fermentation and baking steps induced binding of FL and also of BL from dough to bread through a sharp decrease in the pool of FL and BL, and a concomitant increase in SBL of mixed breads. This means that a preferential lipid binding to the outside and inside starch granules takes place during fermentation and later baking at the expenses of both an FL displacement and a BL translocation to starch active sites. Larger accumulation of SL over mixing encompassed smaller extent of starch hydrolysis in fresh breads and smaller SDS formation, while higher increase of SL after fermentation and baking led to a bigger extent of starch digestibility and to a more prominent formation of SDS fraction, but to lower volume in fresh breads. Extensive binding of either PBL or FL over fermentation and baking provided breads with promoted specific volume and anti-radical activity and slower retrogradation kinetics on ageing, respectively.

References

Goesaert H, Brijs K, Veraverbeke WS, Courtin CM, Gebruers K, Delcour JA (2005) Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends Food Sci Technol 16:12–30

Putseys JA, Lamberts L, Delcour JA (2010) Amylose-inclusion complexes: formation, identity and physico-chemical properties. J Cereal Sci 51:238–247

Angioloni A, Collar C (2011) Significance of lipid binding on the functional and nutritional profiles of single and multigrain matrices. Eur Food Res Technol 233:141–150

Collar C, Armero E, Martínez J (1998) Lipid binding of formula bread doughs Relationships with dough and bread technological performance. Z Lebensm Unters Forsch A 207:110–121

Collar C, Martínez JC, Rosell CM (2001) Lipid binding of fresh and stored formulated wheat breads. Relationships with dough and bread technological performance. Food Sci Technol Int 7/6:501–510

Gan Z, Ellis PR, Schofield JD (1995) Gas cell stabilization and gas retention in wheat bread dough. J Cereal Sci 21:215–230

Collar C, Angioloni A (2014) Pseudocereals and teff in complex breadmaking matrices: impact of lipid dynamics on the bread functional and nutritional profiles. J Cereal Sci 59:145–154

Collar C, Conte P (2016) Lipid dynamics in blended wheat and non-wheat flours breadmaking matrices: impact on fresh and aged composite breads. Food Sci Technol Int 23:24–35

Collar C, Armero E (2018) Impact of heat moisture treatment and hydration level on physico-chemical and viscoelastic properties of doughs from wheat-barley composite flours. Eur Food Res Technol 244(2):355–366

Chen X, He X, Fu X, Huang Q (2015) In vitro digestion and physicochemical properties of wheat starch/flour modified by heat moisture treatment. J Cereal Sci 63:109–115

ICC (1976–1996) ICC standard methods of the international association for cereal chemistry. 104/1, 105/2, 110/1, 115/1, 136, 162, 166. The Association, Vienna

Collar C, Armero E (2018) Value-added value-added of heat moisture treated mixed flours in wheat-based matrices: a functional and nutritional approach. Food Bioprocess Technol 11:1536–1551

Collar C, Armero E (2018) Kinetics of in vitro starch hydrolysis and relevant starch nutritional fractions in heat-moisture treated blended wheat-based bread matrices: impact of treatment of non-wheat flours. Eur Food Res Technol 244:1977–1984

Collar C, Armero E (2019) Functional and thermal behaviours of heat-moisture-treated starch-rich wheat-based blended matrices: impact of treatment of non-wheat flours. Food Bioprocess Technol 12:599–612

McCormack G, Panozzo J, Bekes F, MacRitchie F (1991) Contributions to breadmaking of inherent variations in lipid content and composition of wheat cultivars. I. Results of survey. J Cereal Sci 13:255–261

Paciulli M, Rinaldi M, Cirlini M, Scazzina F, Chiavaro E (2016) Chestnut flour addition in commercial gluten-free bread: a shelf-life study. LWT Food Sci Technol 70:88–95

Alajaji SA, El-Adawy TA (2006) Nutritional composition of chickpea (Cicer arietinum L.) as affected by microwave cooking and other traditional cooking methods. J Food Compos Anal 19(8):806–812

Hager AS, Wolter A, Jacob F, Zannini E, Arendt EK (2012) Nutritional properties and ultra-structure of commercial gluten free flours from different botanical sources compared to wheat flours. J Cereal Sci 56:239–247

Pareyt B, Finnie SM, Putseys JA, Delcour JA (2011) Lipids in bread making: sources, interactions, and impact on bread quality. J Cereal Sci 54:266–279

Gerits LR, Pareyt B, Delcour JA (2013) Single run HPLC separation coupled to evaporative light scattering detection unravels wheat flour endogenous lipid redistribution during bread dough making. LWT Food Sci Technol 53:426–433

Adebowale AA, Emmambux MN, Beukes M, Taylor JRN (2011) Fractionation and characterization of teff proteins. J Cereal Sci 54:380–386

Sroan B, MacRitchie F (2009) Mechanism of gas cell stabilization in breadmaking. II. The secondary liquid lamellae. J Cereal Sci 49:41–46

Kwasniewska-Karolak I, Nebesny E, Rosicka-Kaczmarek J (2008) Characterization of amyloseelipid complexes derived from different wheat varieties and their susceptibility to enzymatic hydrolysis. Food Sci Technol Int 14:29–37

Zhou Z, Robards K, Helliwell S, Blanchard C (2007) Effect of the addition of fatty acids on rice starch properties. Food Res Int 40:209–214

Nakazawa Y, Wang YJ (2004) Effect of annealing on starch-palmitic acid interaction. Carbohyd Polym 57:327–335

Acknowledgements

The authors acknowledge the Institutions Ministerio de Economía y Competitividad (MINECO) and Federación Europea de Desarrollo Regional (FEDER) for funding the Project AGL2015-63849-C2-1-R.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with ethic requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Collar, C., Armero, E. Lipid composition and dynamics during breadmaking in heat-moisture-treated associated matrices. Eur Food Res Technol 245, 2413–2424 (2019). https://doi.org/10.1007/s00217-019-03365-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03365-2