Abstract

The impact of heat moisture treatment (HMT) on the thermoviscous, viscoelastic and mechanical properties of binary flour matrices (wheat:barley, 60:40, wt:wt) was investigated in untreated and HMT (15% moisture content, 1 h heating time at 120 °C) hydrated samples to assess the potential of HMT to modify dough viscoelasticity and doughmaking functionality in diluted breadmaking wheat matrices. HMT significance was tackled (a) in excess of water, by applying successive cooking and cooling cycles to hydrated samples (14%, w:w), determination of viscometric parameters, and subsequent determination of textural (compression test) and viscoelastic parameters (stress relaxation test) in pasted and gelled hydrated flours, and (b) under water restrictions by assessing the consistency (forward extrusion test), the primary and secondary mechanical properties (Texture Profile Analysis), and the viscoelastic behaviour (stress relaxation test) of untreated and HMT mixed doughs made at different flour hydration levels (63 and 70%). In highly hydrated blends, HMT barley flour provided enhanced viscosity patterns regardless of the presence of native or HMT wheat flour, and harder gels with larger initial stress to reach a defined deformation, particularly in the presence of HMT wheat flour. Under restricted water availability, doughs made at 70% hydration level when compared to their counterparts made at 63% explicited lower stress relaxation curves with higher values for both initial decay rate and extent of the decay, shorter relaxation times and higher percent of stress relaxation, giving softer and more cohesive doughs. The most elastic-like dough blends were those prepared with HMT wheat and barley flours at 63% hydration, while the most viscous-like doughs were those from native flours made at 70% hydration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Barley is increasingly incorporated to baked goods either as a whole grain or as a food ingredient mainly due to its superior nutritional profile and associated health promoting effects. The presence of β-glucan and phenolic compounds in barley flour has shown to lower cholesterol and blood glucose levels [1], and barley proteins have been recognized as a rich source of some essential amino acids [2].

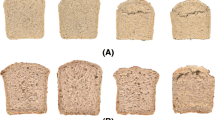

Mixed breads obtained by 40% replacement of wheat flour by commercial barley flour are more nutritious in terms of elevated intake of important nutrients, such as dietary fibre fractions (soluble, insoluble, resistant starch and β-glucans), slowly digestible starch subfraction and bioaccessible polyphenols providing higher antiradical activity with health-promoting effects, compared to their wheat flour counterparts [3]. Concomitantly to nutritional and health-related benefits, an impairment of bread quality of high-barley breads, particularly loaf volume and texture of composite breads, was observed, ascribed to both the dilution of wheat dough biopolymers—gluten and starch—and the mechanical interference with gluten network formation by insoluble dietary fibre [3]. In breadmaking applications, replacement of wheat flour by significant amounts of non-gluten forming flours, such as barley, can seriously constrain both dough viscoelasticity and gas retention capability of blended dough matrices that limits final bread performance.

Heat moisture treatment (HMT) constitutes an environmentally friendly technique, of interest to make low glycaemic index foods without any chemical residue, and a clean label alternative to chemical modification for altering the gelatinization and retrogradation properties of starches [4] and flours [5], and the aggregation/disaggregation equilibrium of proteins [6]. HMT is a physical modification that allows control of molecular mobility at high temperatures by limiting the amount of water. HMT causes the rearrangement of starch polymers chains, and may modify its X-ray pattern, crystallinity, swelling power, amylose leaching, pasting, and gelatinization properties, as well as its susceptibility to enzymatic or acidic hydrolysis, which affect the starch rheological properties [7]. HMT can render granule’s surface hydrophobic [8], and can confer to starch granules more rigidity and resistance to the quick heating by altering the swelling behaviour [9]. Gluten proteins are responsible for the unique viscoelastic properties of wheat dough. Upon water addition and mixing, they unfold and build a transient network comprising mainly disulphide bonds, the most favourable arrangement of hydrogen bonds, hydrophobic interactions and entanglements. If the conformation of those proteins is altered by thermal treatments, their ability to take part in these processes is also changed and, therefore, the dough formation process is greatly modified. During HMT, protein solubility decreases associated with gluten proteins denaturation together with aggregation in wheat systems. Protein bodies were deformed and denatured, and interactions between denatured proteins, and between proteins and starch granules, caused the association of the protein networks with the surfaces of starch granules. Protein layers, in cooperation with the increased hydrophobicity, retarded the swelling of HMT starch granules in wheat flour [10]. Microscopic observations by confocal laser scanning microscopy and light microscopy revealed that HMT caused the clumping of starch granules and the aggregation of denatured protein [10]. In wheat dough, observed rheological changes for small and large deformations can be described assuming protein aggregation (leading to a weakened protein network and possibly acting as additional filler particles) and starch surface modifications (leading to changed starch–protein and starch–starch) interactions [6].

The main bulk of research has been devoted to the significance of hydrothermal treatment on starches, being information about the effect of HMT on cereal and grain flours very limited, and the impact of the treatment on dough performance restricted to hydrated wheat flours of different baking quality [11]. Significance of HMT on functional performance of blended doughs—hydrated wheat/non-wheat flours—has not been addressed so far.

This paper is aimed at exploring the potential of HMT to restore/improve dough viscoelasticty in diluted wheat matrices with incorporation of non-gluten forming flours with added nutritional value (barley) by (a) investigating the viscosity changes induced by HMT that occur during starch gelatinization, pasting and gelling in single (wheat, barley) and blended flours (wheat/barley) matrices with surplus water, (b) at knowing the impact of HMT on the viscoelastic and textural/mechanical behaviour of blended doughs under water restrictions.

Materials and methods

Materials

Commercial flours from refined common wheat Triticum aestivum (WT), and whole barley Hordeum vulgare L. (CB), were purchased from the Spanish market. Refined WT (70% extraction rate) of 200 × 10−4 J energy of deformation W, 0.6 curve configuration ratio P/L, and 57% water absorption in Brabender Farinograph, was used.

Methods

Chemical and nutritional composition of flours

Moisture, protein, ash and fat contents of native commercial flours were determined following the ICC methods [12].Total, soluble and insoluble dietary fibre contents were determined according to the AOAC method 991.43 [13]. Resistant starch determination was performed according to AOAC Official Method 2002.02 [14] using Megazyme kit K-RSTAR 08/11. β-glucan content (Megazyme kit K-BGLU 07/11) was determined following the ICC Standard Method No. 166. Amylose/amylopectin ratio (Megazyme kit K-AMYL 07/11) was estimated using a modification of a Con A method with lipid removal prior to analysis. Three replicates were made for each analysis. Digestible carbohydrates were calculated by indirect determination as 100 − [Moisture + Protein + Fat + Ash + Dietary Fibre] [15].

Heat-moisture treatment (HMT)

Single BL and WT flour samples were weighed and placed into screw-capped glass containers. Small amount of distilled water was added slowly with frequent stirring until moisture levels (w/w) of the total mixture reached 15 and 25%, respectively, and equilibrated for 24 h at room temperature. Hydrated samples were kept for 1 h at 120 °C in a convection oven (P-Selecta, Barcelona, Spain). After cooling to room temperature, the samples were passed through 100-mesh sieve for further analysis. The moisture content was measured before and after HMT using a moisture analyzer (DBS60-3, Kern, Balingen, Germany). Untreated native flours were used as controls. Untreated (−) and HMT (+) flours were used singly (WT, CB) and in binary blends (WT:CB, 60:40, w:w) for analysis. Blends were hydrated with 63 and 70% of water (flour basis) to make doughs of 163 and 170 of dough yield (DY), respectively. Four different blended doughs were obtained per DY: WT− CB−, WT− CB+, WT+ CB−, WT+ CB+.

HMT conditions (15% moisture content, 1 h and 120 °C) were selected on the basis of previous experiments in which maximization of viscometric profile and minimization of loss of hydration properties of hydrated flour samples were applied as criteria.

Functional properties of single and blended wheat—barley flours

Functional characteristics of untreated and HMT single WT and CB, and blended WT/CB flours, were assessed as it follows. Solvent Retention Capacity (SRC) was determined according to the AACC method 56-11 [16] to quantify potential contributions to water holding capacity by other flour components having water-uptake capabilities [17]. The solvents used were water, sucrose (50% w/v), sodium bicarbonate (5% w/v), and lactic acid (5% v/v). 25 mL of prepared solvent was added to 5 g of flour in 30 mL centrifuge bottles. Centrifugation at 1239g (3000 rpm) was performed for 15 min. After decanting, a gel remained. Gels were weighed and the SRC value (%) calculated as % SRC = [[((gel wt/flour wt) × (86/(100 − % flour moisture)) − 1)] × 100] for each solvent.

Bulk density was calculated as weight of sample per unit volume of sample (g/ml). The flour samples were gently filled into 10 ml graduated cylinders, previously tared. The bottom of the cylinder was gently tapped on a laboratory bench several times until there was no further diminution of the sample level after filling to the 10 ml mark. Measurements were made in triplicate [18].

Water absorption index (WAI) and water solubility index (WSI) were determined as described by Singh et al. [19] with modifications of the heating conditions as follows. The ground flour samples (2.5 g) were mixed with 30 ml distilled water, using a glass rod, and heated at 30 and 60 °C for 15 min in a water bath. The cooked paste was cooled to room temperature and transferred to centrifuge tubes and centrifuged at 3000g for 10 min. WAI and WSI were calculated using the expressions:

Colour measurements were determined on flours using a Photoshop system following the method previously described by Angioloni and Collar [20], and the results were expressed in accordance with the Hunter Lab colour space. The Photoshop (Adobe Photoshop CS5 extended) system (L, a, b colour coordinates) was calibrated using colour sheets from Pantone Formula Guide (Pantone, Inc., USA). Images were acquired at 300 pixel resolution with a ScanJet II cx flatbed scanner (Hewlett-Packard, USA). Parameters determined were L [L = 0 (black) and L = 100(white)], a (−a = greenness and +a = redness), b (−b = blueness and +b = yellowness), as described earlier [20]. Hunter Lab colour space parameters from Minolta colorimeter were calculated from the calibration linear equation Colorimeter vs Photoshop.

Rheological assessment of hydrated flours, gels and doughs

Hydrated flours

Thermoviscous test Viscometric profiles (gelatinization, pasting, and setback properties) of 14% (w/v) hydrated single (WT, CB) and blended (WT/CB, 60/40, w/w) untreated (−) and HMT (+) flours were obtained with a Rapid Visco Analyser (RVA-4, Newport Scientific, Warriewood, Australia) using ICC Standard 162. Samples (3.5 g, 14% moisture basis) were transferred into canisters and ≈25 ± 0.1 mL of distilled water were added (corrected to compensate for 14% moisture basis). The slurry was heated to 50 °C and stirred at 160 rpm for 10 s for thorough dispersion. The slurry was held at 50 °C for up to 1 min, and then heated to 95 °C over 3 min 42 s and held at 95 °C for 2 min 30 s, and finally cooled to 50 °C over 3 min 48 s, and held at 50 °C for 2 min. The pasting temperature (when viscosity first increases by at least 25 cP over a 20 s period), peak time (when peak viscosity occurred), peak viscosity (maximum hot paste viscosity), holding strength or trough viscosity (minimum hot paste viscosity), breakdown (peak viscosity minus holding strength or trough viscosity), viscosity at 95 °C, viscosity at the end of the 95 °C holding period, viscosity at 50 °C, final viscosity (end of test after cooling to 50 °C and holding at this temperature), setback (final viscosity minus peak viscosity), and total setback (final viscosity minus holding strength) were calculated from the pasting curve [21] using Thermocline v. 2.2 software. For each viscometric measurement, 3 samples were used.

Gels

Gel texture After RVA testing, canisters containing flour pastes were covered with paraffin film and kept at 4 °C for 24 h. Texture of gels in canisters (with a dimension of 20 mm in height and 38 mm in diameter) were determined in a TA-XT2 Texture Analyzer by compression to a distance of 15 mm at a speed of 2.0 mm/s using a cylindrical Perspex probe of 25 mm in diameter. The peak force measured in duplicate was reported as gel hardness.

Stress relaxation test The stress relaxation data were collected by applying an instantaneous strain to the sample and the force required to maintain the formed deformation was observed as a function of time [23]. Stress relaxation tests were applied on the gels obtained from RVA experiments after storage at 4 °C for 24 h. The stress–relaxation tests were conducted using a texture analyzer mentioned in the previous paragraph fitted with a load cell of 30 kg and a P/25 cylindrical probe and the relaxation data were obtained under this configuration. The gel samples in the canisters were directly placed under a cylindrical plate and compressed to 30% a crosshead speed of 0.5 mm/s for 300 s at room temperature (25 °C). To minimize the frictional effects, samples, base and probe were lubricated with liquid paraffin [24]. Stress relaxation tests were replicated two times. The obtained stress relaxation curves were normalized and linearized according to the Peleg [25], and Peleg and Pollak [26] model, as. F 0 t/(F 0 − F( t )) = k 1 + k 2t, where F 0 is the initial force, F(t) is the momentary force at time (t) and k 1(s), k 2 are constants related to stress decay rate and to residual stress at the end of the experiment, respectively. In addition, percent stress relaxation (% SR = (F 0 − F 300)0.100/F 0), 1/k 1 (initial rate of relaxation), 1/k 2 (extent of relaxation) and relaxation time (RT as the time required for F 0 to drop to 36.8% of its values, respectively), representing viscoelastic behaviour, were compared for the different samples.

Forward extrusion test Forward extrusion assays of untreated and HMT binary WT/CB doughs made at DY of 160 and 170 were performed in a TA-XT2 texture analyser (Stable Micro Systems, Surrey, UK) equipped with a 30 kg-load cell and operating at 10 mm/s head speed. The test measures the compression force required for a piston disc to extrude the dough through a specific size outlet (10 mm) in the base of the sample container. The extrusion cell and the compression plunger were 5 and 4.9 cm in diameter, respectively. Samples (35 cm3 volume) were carefully scooped into acrylic cylindrical containers with help of spatula. The complete sample container was located into a centralizing insert fitted into the Heavy Duty Platform, and the plunger was attached to the load cell using a probe adaptor. 14 cm3 of samples were extruded by compressing a fixed distance of 7 mm. Compression force–time curve allowed evaluating maximum force, determined as the force at which the slope changed. The change of slope was visually detected, and the force at this point was calculated using the Texture Analyser software. The curve plateau representing the force necessary to continue with the extrusion process and the area under the curve were both used to define the sample consistency. All measurements were performed in triplicate.

Doughs

Texture profile analysis (TPA) TPA of untreated and HMT binary WT/CB doughs made at DY of 160 and 170 was performed by applying a double compression cycle in a TA-XT2 texture analyser using a 1 cm diameter probe, 75 s waiting period, and 60% compression, as described previously [22]. The primary textural properties were measured in the absence of dough adhesiveness using a plastic film on the dough surface to avoid the distortion induced by the negative peak of adhesiveness, while dough adhesiveness was measured separately by running a second TPA without the plastic film and disregarding the other parameters.

Stress relaxation test Doughs were submitted to uniaxial compression using an acrylic probe (37-mm diameter) to a 10% strain and the change in force with time was measured for 300 s. A pretest speed of 5 mm/s and test speed of 0.5 mm/s were used. The obtained stress relaxation curves were normalized and linearized according to the Peleg [25], and Peleg and Pollak [26] model, as for the gels as previously described. Relaxation time (RT) as the time required for F 0 to drop to 50% of its values, respectively, were compared for the different samples.

Statistical analysis

Multivariate analysis of variance of data and non-linear regression analysis were performed using Statgraphics V.7.1 program (Bitstream, Cambridge, MN). Multiple range test (Fisher’s least significant differences, LSD) for analytical variables was applied to know the difference between each pair of means.

Results and discussion

Functional properties of untreated and HMT single and blended flours

Grain flours constitute natural and practical food systems for studying multiple food component interactions [27], since besides starch, proteins, fat and dietary fibre are included in the chemical and nutritional composition of composite food matrices (Table 1).

Colour parameters, bulk density, and hydration properties—WAI, WSI, SP, and SRC—of untreated and HMT single WT, CB and blended WT/CB flours are compiled in Table 2. The colour of any food product generally changes during heat treatment and thus influences the acceptability [28]. L, a and b values for WT flour samples did not change with HMT, while they showed variable trends for CB flours: a significant decrease in lightness L but an increase in both a (greenness/redness) and b (blueness/yellowness) values, which extent rises with the moisture of CB flour samples. Similar changes previously observed in HMT pearl millet flour [28] were ascribed to polymerization of phenolics and pigments [29] and to conversion of flavonols in colour pigment intermediate compounds [30], in good accordance with the 30% higher amount of polyphenols in CB flour vs WT flour [3].

HMT of flours at 15% of moisture content had significant rising effect on bulk density of both WT (7%) and CB (4%) samples (Table 2), in agreement with data reported for maize flour [31] and pearl millet flour [28] after hydrothermal treatments. However, decrease in bulk density was observed as moisture of flours increased from 15 to 25%, particularly for HMTCB flour (−13%). Similar results were associated with wheat corn extruded flour to gelatinization of starch [32].

The WSI, WAI and SP power of all samples exhibited a continuous increase as temperature rose from 30 to 60 °C, particularly for WF flours. Conversely, hydration indexes of flours at 60 °C decreased significantly after HMT, the decrease being larger with increasing flour moisture. Compared to native flours, WSI of HMT15 and HMT25 flours decreased up to 50% (WT25) and up to 38% (CB15, CB25); WAI declined from 15% (WT15) to 18% (WT25) and by 7% (CB25) at 60 °C. Consistently, SP depleted gradually with moisture content in both HMT flours, from 13 to 6% (WT) and from 6 to 4.5% (CB) at 60 °C (Table 2). Waduge et al. [33] proposed the reduction in solubility and swelling power of barley starch [34]. The formation of amylose–lipid complexes within the starch granule was stressed as responsible for the reduction in the swelling capacity and starch solubility in white sorghum starch submitted to HMT [35]. Their results showed that amylose inhibited granule swelling under conditions where amylose–lipid complexes were likely to be formed, as it is the case of flours (Table 1). So that, the decrease in solubility and swelling power was ascribed to the structural rearrangement and/or re-associations of starch chains caused by HMT. In particular, HMT promotes the formation of ordered double helices, and consequently, limits starch swelling and solubility, as suggested by Lawal [36].

The SRC test is a solvation assay for flours based on the enhanced swelling behaviour of individual polymer networks in selected single diagnostic solvents—water, 5% w/w lactic acid (LA) in water (for glutenin), 5% w/w sodium carbonate (Na2CO3) in water (for damaged starch), and 50% w/w sucrose in water (for pentosans)—which are used to predict the functional contribution of each individual flour component. SRC method is based on a classical thermodynamic determination of the solubility parameter of network-forming polymers. For flour typically used to produce bread by the sponge–dough method, optimal SRC profile values would be ≥100% in 5% w/w lactic acid, ≤96% in 50% w/w sucrose in water, ≤72% in 5% w/w sodium carbonate extracts [37]. In this work, a straight dough breadmaking system was used instead, and some mean values for water retention components of WT and blended wheat–barley flours (WT/CB) were outside the typical range for a sponge–dough bread system in mixed and thermally treated flours, but especially for HMT binary WT/CB samples and water retention of pentosans (124%) and damaged starch (106%). Results are consistent with an additional deleterious effect of HMT to the replacement of WT flour by CB, on the optimal SRC profile of mixed flours.

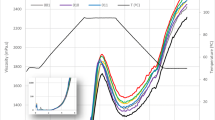

Impact of HMT on the pasting and gelling of single and blended flours

Pasting properties provide information on intermolecular bonding between densely packed starch granules and the rigidity of swollen starch granules during the heating process derived parameters being strongly affected by HMT [5]. The mean results pertaining to pasting properties of single (WT, CB) and blended (WT:CB, 60:40, w:w) flours as affected by HMT (15% moisture, 1 h, 120 °C) are given in Table 3, and qualitative and quantitative RVA profiles are displayed comparatively in Fig. 1. HMT flours reached much higher viscosity values during earlier pasting and subsequent gelling than the corresponding native counterparts (Fig. 1). Values for peak viscosity and total setback (mPa.s), respectively, account for 2683 and 3257 (BL+) vs 224 and 200 (BL−), and 2908 and 1500 (WT+) vs 2240 and 1156 (WT−), confirming trends previously found [5]. Similar patterns were reported for wheat flour submitted to dry heat and/or mild hydrothermal treatments [11, 38]. Authors related the decrease in onset pasting time and increase in peak viscosity in the Amylograph profile to the increased hydrophobicity of gluten proteins and to the occurrence of lipophilization of starch granules due to the change of the properties of the proteins on the starch granule surface from hydrophilic to hydrophobic [38]. In addition, changes in the gluten protein structure encompassed a minor swelling of the starch granules that occurred in the presence of the moisture content in the flour, and observed increased retrogradation values compared to the untreated flours indicated a tendency of higher re-association ability of amylose [11]. Analogous increased hydrophobicity of prolamins and glutelins in CB+ could explain the prominent enhanced viscosity profile observed. Both additive and non-additive pasting behaviour have been already found for starch [39], additive-wheat flour [21], and flour blends [40, 41]. In this work, viscosity patterns during both pasting and gelling cycles of blended untreated and HMT flours were much lower than could be expected from its compositional flours (Table 3). Decrease was particularly relevant for blends with untreated CB (WT− CB−, WT+ CB−) with viscosity values as low as 27% (peak viscosity), 7% (holding strength), 13% (final viscosity) and 19% (total setback) the expected values for an additive viscometric behaviour of single flours in blends, vs 55, 30, 39, and 46%, respectively, in blends with treated CB (WT− CB+, WT+ CB+). In blended flours, HMT provided enhanced viscometric profiles during both pasting and gelling (Fig. 1). Particular higher values of viscosity features were observed for the sample WT+ CB+, followed by the sample WT− CB+, while on the contrary, lower profiles were reached by WT− CB− followed by WT+ CB− (Fig. 1; Table 3) in good agreement with the significant single effect of HMT on the enhancement of CB flour viscometer parameters compared to those of WT counterparts. This is particularly true for peak viscosity (+194 vs +31%), holding strength (710 vs 38%), and viscosity at end of 95 °C (+612 vs 37%) during pasting, and total setback (+483 vs +24%), viscosity at 50 °C (+489 vs +28%) and final viscosity (+546 vs 29%) during gelling, respectively (Table 3).

Impact of HMT on viscoelastic and textural/mechanical behaviour of gels and doughs from single and blended flours

Physical parameters from stress relaxation, compression, forward extrusion and texture profile analysis tests of untreated and HMT blended gel and dough matrices at different DY are compiled in Table 4. Significant single and interactive effects (p < 0.05) of flour and HMT on viscoelastic and mechanical parameters are shown in Table 5. In excess of water (14% flour concentration), gelatinised and gelled mixed flours in RVA canisters exhibited increased strength to compression with HMT, effect being larger for CB+ (190%) than for WT+ (21%), but lower than the increase provided by the simultaneous presence of WT+/CB+ (230%) in the binary mixture (Table 4). The increase in the final viscosity and the setback (Fig. 1) is a sign of the increase of starch paste stability and gel hardness. The starch components have been solubilized during the starch collapse at the breakdown phase, but they were capable of re-association during the cooling process. This phenomenon led to increased retrogradation. During HMT, increase in gel hardness has been attributed to the increased cross-linking between starch chains in the particular amylose portion. These allowed the formation of more junction zone in the continuous phase of the gel, resulting in the increased gel hardness [42]. Results are consistent with those found for early indica rice [43].

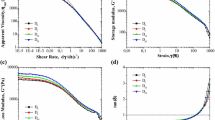

Viscoelastic materials exhibit stress relaxation phenomena. In stress relaxation tests, a constant strain is applied and the stress required to maintain the deformation is measured as a function of time. The measured relaxation time shows how fast the material dissipates stress after receiving a sudden deformation. It was reported that relaxation time is the time when the viscoelastic material dissipates its force to about 36.8% of the originally applied force [44]. The relaxation constants are related to viscoelastic characteristics of samples. The constant 1/k 2 is related to the asymptotic level of stress not relaxed at long times, since the constant 1/k 1 is related to the initial stress decay rate [45]. At gel level, small variations were observed with HMT in the relaxation parameters, except for the initial force F 0 that followed the same trend as the gel strength after compression. The lower k 1 values were noticed in both untreated WT− CB− and treated WT+ CB+ gels (Table 4). No differences with HMT were gained regarding either the relaxation time or the % of stress relaxation (Table 4). Under restricted water availability, samples such as doughs showed differentiated viscoelastic and textural parameters with DY first, and with HMT of flours, secondly (Table 4). In blends, HMT of WT decreased dough consistency, % SR, cohesiveness and resilience, and increased k 2 regardless of DY, while HMT of CB increased dough consistency (Table 5). At DY 170, HMT decreased the relaxation time by 12% for CB+ and increased by 35% for WT+, while at DY 163, sharp increases by 93% (WT+) and 73% (CB+) were denoted (Table 5). HMT changed dough hardness, adhesiveness, and cohesiveness in variable extent only for WT+ (32, −72, −26%, respectively) when flour is incorporated to doughs of DY 170, and specifically for CB+ (62, −30, −17%, respectively) when flour is mixed in doughs of DY 163. HMT of flours decreased dough resilience only for WT, being extent of depletion greater in softer than in harder doughs (−43 vs −31%).

In general, doughs made at DY 170 compared to their counterparts made at DY 163 explicited lower relaxation curves with small values for both k 1 (8.3–9.4 vs 11.8–14.0) and k 2 (1.4–1.5 vs 1.4–1.8), shorter relaxation times (13–19 s vs 20–78 s) and higher percent of stress relaxation (65–72% vs 54–69%), giving softer (70–117 N vs 161–232 N), more cohesive (0.51–0.73 vs 0.38–0.63), and adhesive (141–558 vs 72–122 g s) doughs (Table 4).

Obtained results for untreated WT− CB− and WT− CB+ doughs at DY 170 showed lowest values for k 1 and k 2. This indicates a steeper descent in the relaxation curves toward a lower residual value, which is related to a more viscous-like character of the doughs in agreement with concomitant lower values for F 0, RT TPA hardness and higher values for cohesiveness and adhesiveness (Table 4). On the contrary, WT+ CB+ at DY 163 exhibited the most elastic dough with the smallest depletion in initial rate of stress (1/k 1), as well as in the value asymptotically approached by normalized stress (1/k 2). It reflects the change in structure of dough, which under water restrictions becomes more elastic.

Conclusions

HMT of flours modified dough viscoelasticity and doughmaking functionality of diluted breadmaking wheat matrices made with 40% of wheat flour replacement by barley flour. The trend and extent of the changes closely depend on water availability. In excess of water, HMT provided enhanced viscometric profiles during both pasting and gelling in blended flours, particularly for samples with HMT-treated barley, while on the contrary, lower profiles were reached by sample blends with native barley flour. The gelling ability of HMT-treated barley provided harder gels, and may confer a suitable thickening effect to blended doughs that may improve gas retention in the presence of a diluted gluten network. Under water restrictions, flour hydration governs viscoelasticity and mechanical properties of blended doughs, while HMT only modulates dough performance. In general, doughs made at 70% of hydration level compared to their counterparts made at 63% explicited lower relaxation curves with smaller values for both k 1 and k 2, shorter relaxation times and higher percent of stress relaxation, giving softer and more cohesive doughs. Obtained results for untreated doughs and barley-treated blended doughs at 70% hydration showed steeper descent in the relaxation curves toward a lower residual value, related to a more viscous-like character of the doughs in agreement with concomitant lower values for initial stress, relaxation time, and dough hardness and higher values for cohesiveness and adhesiveness. On the contrary, blends with both wheat and barley-treated flours at 63% of hydration exhibited the most elastic dough with the smallest depletion in initial rate of stress, as well as in the value asymptotically approached by normalized stress. It reflects the change in dough structure, which under water restrictions becomes more elastic.

Abbreviations

- a :

-

Greenness/redness

- b :

-

Blueness/yellowness

- CB−:

-

Native commercial barley flour

- CB:

-

Commercial barley

- CB+:

-

Commercial barley flour treated at 15% moisture for 1 h at 120 °C

- DY:

-

Dough yield

- F 0 :

-

Initial stress (g force, N)

- HMT:

-

Heat moisture treatment

- k 1 :

-

Constant related to stress decay rate (s)

- k 2 :

-

Constant related to residual stress at the end of the experiment

- L :

-

Lightness

- %SR:

-

Percent of stress relaxation

- RT:

-

Relaxation time (min)

- RVA:

-

Rapid visco analyser

- SP:

-

Swelling power (g/g)

- SRC:

-

Solvent retention capacity (%)

- WAI:

-

Water solubility index (% solids, flour, d. b.)

- WT−:

-

Native wheat flour

- WT:

-

Wheat

- WT+:

-

Wheat flour treated at 15% moisture for 1 h at 120 °C

- WT+ CB−:

-

Blend of wheat flour treated at 15% moisture for 1 h at 120 °C and native commercial barley flour, mixed at 60:40, wt:wt

- WT+ CB+:

-

Blend of wheat and commercial barley flours individually treated at 15% moisture for 1 h at 120 °C and mixed at 60:40, wt:wt

- WT− CB−:

-

Native wheat and commercial barley flours mixed at 60:40, wt:wt

- WT− CB+:

-

Blend of native wheat flour and commercial barley flour treated at 15% moisture for 1 h at 120 °C, mixed at 60:40, wt:wt

References

Cavallero A, Empilli S, Brighenti F, Stanca AM (2002) High-β-glucan barley fractions in bread making and their effects on human glycemic response. J Cereal Sci 36:59–66

Newman CW, El-Negoumy AM, Eslick RF (1978) Replacing soy protein in swine diets with high-protein barley and amino acids. J Anim Sci 46:161–166

Collar C, Angioloni A (2014) Nutritional and functional performance of barley flours in breadmaking: mixed breads vs wheat breads. Eur Food Res Technol 238:459–469

Gunaratne A, Hoover R (2002) Effect of heat-moisture on the structure and physicochemical properties of tuber and root starches. Carbohyd Polym 49:425–437

Collar C (2017) Significance of heat moisture treatment conditions on the pasting and gelling behaviour of various starch-rich cereal and pseudocereal flours. Food Sci Technol Int (accepted for publication May 2017)

Mann J, Schiedt B, Baumann A, Conde-Petit B, Vilgis TA (2013) Effect of heat treatment on wheat dough rheology and wheat protein solubility. Food Sci Technol Int 20(5):341–351

Zavareze ER, Dias ARG (2011) Impact of heat-moisture treatment and annealing in starches: a review. Carbohyd Polym 83:317–328

Seguchi M (1984) Oil-binding ability of heat-treated wheat starch. Cereal Chem 61:248–250

McCann TH, Leder A, Buckow R, Day L (2013) Modification of structure and mixing properties of wheat flour through high-pressure processing. Food Res Int 53(1):352–361

Chen X, He X, Fu X, Huang Q (2015) In vitro digestion and physicochemical properties of wheat starch/flour modified by heat-moisture treatment. J Cereal Sci 63:109–115

Bucsella B, Takács A, Vizer V, Schwendener U, Tömösközi S (2016) Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chem 190(2016):990–996

ICC (2014) ICC standard methods of the international association for cereal science and technology 104/1, 105/2, 110/1, 115/1, 136, 162, 166. The Association, Vienna

AOAC (1991) Total, soluble, and insoluble dietary fiber in foods. In: Association of Official Analytical Chemists

AOAC (2000) Official methods of analysis, 17th edn. AOAC International, Gaithersburg

FAO/WHO (2003) Food energy-methods of analysis and conversion factors. In: FAO Food and Nutrition Paper 77, Rome

AACC (2005) Approved methods of the American Association of Cereal Chemists, 10th edn. AACC St. Paul, MN: The Association

Traynham TL, Myers DJ, Carriquiry AL, Johnson LA (2007) Evaluation of water-holding capacity for wheat-soy flour blends. J Am Oil Chem Soc 84:151–155

Kaur M, Singh N (2005) Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem 91:403–411

Singh J, Singh N, Sharma TR, Saxena SK (2003) Physicochemical, rheological and cookie making properties of corn and potato flours. Food Chem 83:387–393

Angioloni A, Collar C (2009) Bread crumb quality assessment: a plural physical approach. Eur Food Res Technol 229:21–30

Collar C (2003) Significance of viscosity profile of pasted and gelled formulated wheat doughs on bread staling. Eur Food Res Technol 216:505–513

Armero E, Collar C (1997) Texture properties of formulated wheat doughs. Relationships with dough and bread technological quality. Zeitschrift für Lebensmittel-Untersuchung und Forschung A 204:136–145

Sozer N, Dalgic AC (2007) Modelling of rheological characteristics of various spaghetti types. Eur Food Res Technol 225:183–190

Yildiz O, Yurt B, Baştürk A, Toker OS, Yilmaz MT, Karaman S, Dağlıoğlu O (2013) Pasting properties, texture profile and stress–relaxation behavior of wheat starch/dietary fiber systems. Food Res Int 53(2013):278–290

Peleg M (1979) Characterisation of the stress relaxation curves of solid food. J Food Sci 44:277–281

Peleg M, Pollak NT (1982) The problem of equilibrium conditions in stress relaxation curves of solids foods. J Texture Stud 13:1–11

Zhang G, Hamaker BR (2005) Sorghum (Sorghum bicolor L. Moench) flour pasting properties influenced by free fatty acids and protein. Cereal Chem 82:534–540

Yadav DN, Kaur J, Anand T, Singh AK (2012) Storage stability and pasting properties of hydrothermally treated pearl millet flour. Int J Food Sci Technol 47:2532–2537

Hrazdina G (1971) Reaction of anthocyanin 3,5 glucosides, formation of 3,5-di(O-b-d-glucosyl)-7-hydroxy coumarin. Phytochemistry 10:1125–1130

Akingbala JO (1991) Effect of processing on flavonoids in millet (Pennisetum americum) flour. Cereal Chem 68:180–183

Bolade MK, Usman MA, Rasheed AA, Benson EL, Salifou I (2002) Influence of hydrothermal treatment of maize grains on the quality and acceptability of tuwon masara (traditional maize gel). Food Chem 79:479–483

Case SE, Hamann DD, Schwartz SJ (1992) Effect of starch gelatinization on physical properties of extruded wheat- and corn-based products. Cereal Chem 69:401–404

Waduge RN, Hoover R, Vasanthan T, Gao J, Li J (2006) Effect of annealing on the structure and physicochemical properties of barley starches of varying amylose content. Food Res Int 39:59–77

Jyothi AN, Sajeev MS, Sreekumar JN (2010) Hydrothermal modifications of tropical tuber starches. 1. Effect of heat-moisture treatment on the physicochemical, rheological and gelatinization characteristics. Starch/Stärke 62:28–40

Olayinka OO, Adebowale KO, Olu-Owolabi BI (2008) Effect of heat moisture treatment on physicochemical properties of white sorghum starch. Food Hydrocoll 22:225–230

Lawal OS (2005) Studies on the hydrothermal modifications of new cocoyam (Xanthosoma sagittifolium) starch. Int J Biol Macromol 37:268–277

Heywood AA, Myers DJ, Bailey TB, Johnson LA (2002) Functional properties of low-fat soy flour produced by an extrusion expelling system. J Am Oil Chem Soc 79:1249–1253

Ozawa M, Kato Y, Seguchi M (2009) Investigation of dry-heated hard and soft wheat flour. Starch/Stärke 61(7):398–406

Waterschoot J, Gomand SV, Fierens E, Delcour JA (2015) Starch blends and their physicochemical properties. Starch/Stärke 67:1–13

Collar C (2016) Impact of visco-metric profile of composite dough matrices on starch digestibility and firming and retrogradation kinetics of breads thereof: additive and interactive effects of non-wheat flours. J Cereal Sci 69:32–39

Collar C, Balestra F, Ancarani D (2014) Value added of resistant starch maize based matrices in breadmaking: nutritional and functional assessment. Food Bioprocess Technol 7:3579–3590

Liu H, Corke H, Ramsden L (2000) The effect of autoclaving on the acetylation of ae, wx and normal maize starches. Starch 52:353–360

Sun Q, Wang T, Xiong L, Zhao Y (2013) The effect of heat moisture treatment on physicochemical properties of early indica rice. Food Chem 141:853–857

Mohsenin NN (1986) Physical properties of plant and animal materials. Structure, physical characteristics and mechanical properties, 2nd edn. Gordon and Breach Science Publisher Inc, New York

Gamero M, Fiszman SM, Duran L (1993) Stress relaxation of fruit gels. Evaluation of models and effects of concentration. J Food Sci 58(1125–1128):1134

Acknowledgements

The authors acknowledge the institutions Ministerio de Economía y Competitividad (MINECO) and Federación Europea de Desarrollo Regional (FEDER) for funding the Project AGL2015-63849-C2-1-R.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Collar, C., Armero, E. Impact of heat moisture treatment and hydration level on physico-chemical and viscoelastic properties of doughs from wheat-barley composite flours. Eur Food Res Technol 244, 355–366 (2018). https://doi.org/10.1007/s00217-017-2961-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2961-8